Experimental Behavior of Recycled Aggregate Concrete Filled Steel Tubular Columns

2024-01-03ThirumalaiSureshBabu

Thirumalai R, Suresh Babu S

(1.Research Scholar-Full Time, Dept. of Civil Engineering, Kongu Engineering College Perundurai, Erode 638060, Tamilnadu, India; 2.Dept.of Civil Engineering, Kongu Engineering College Perundurai, Erode 638060, Tamilnadu, India)

Abstract: During the modernization or rehabilitation activity, the demolished structural waste causes large soil pollution and unavailability of natural aggregate is the big concern for the construction industry.Therefore, this manuscript deals with the Composite Steel Circular Column (CSCC) with Recycled Aggregate concrete (RAC) as infill is partly used, with the replacement of 25% and 50% in M30 grade of Concrete.And internal reinforcement steel is fully replaced by rolled steel tubes (circular and square) with varied thickness,ISA-unequal angle.Around 14 specimens are cast and examined under axial load for analysis of the deflection characteristics, the load-bearing capacity along with its buckling behavior.The experimental values are estimated through LVDT (linear variable differential transducer) at 3-phase.The curve of load-deflection is drawn with the load pattern.From the date interpretation, it is found column made of 50%-RAC has more than 25%-RAC.

Key words: composite steel circular column (CSCC); recycled aggregate concrete (RAC); ISAinternational standard angle; LVDT (linear variable differential transducer)

1 Introduction

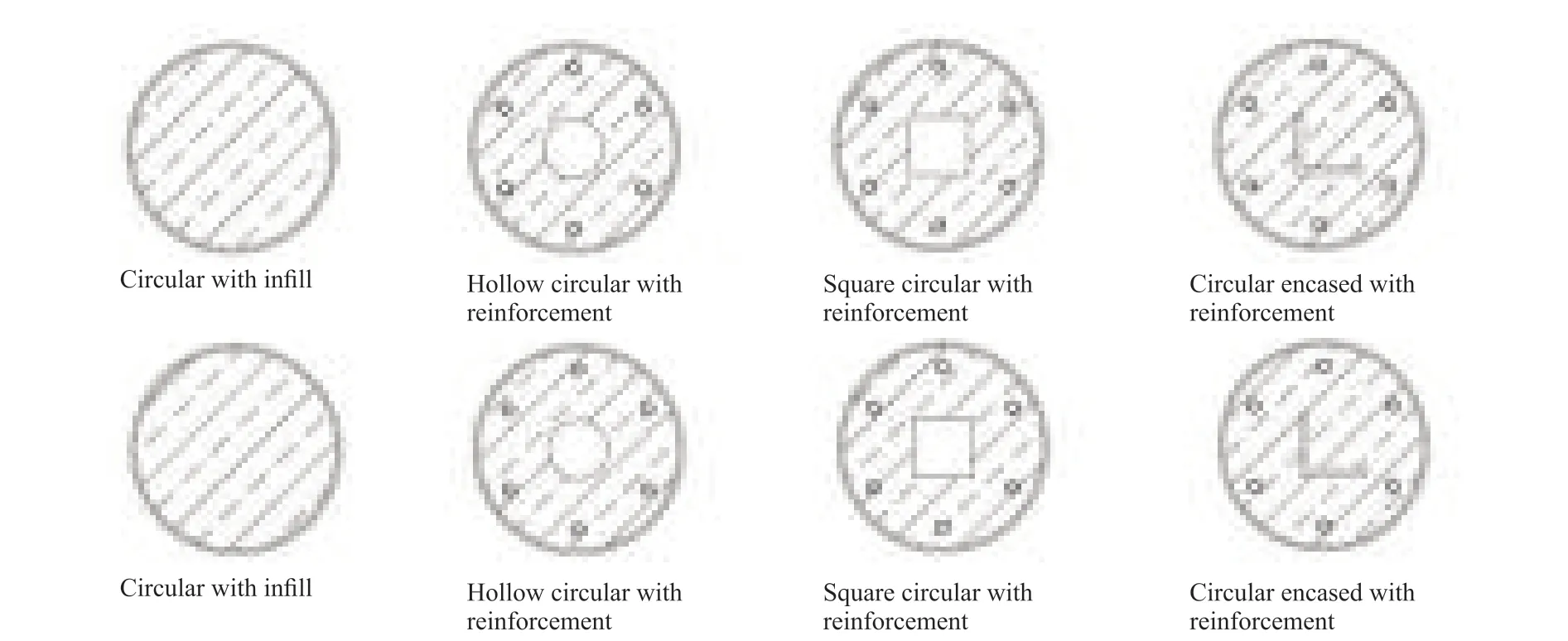

A compositecolumn of steel-concrete is the wellknown compression member that are developed with rolled section of steel encased in the concrete or hot rolled steel enclosing the concrete mixture in it.The main function of the steel-concrete column is to bear the load exerted on it.In general, there are different steel concrete composite column based on cross section and are broadly classified as either partialorfullsections as in Fig.1.The developed steel-concrete column does not require any additional reinforcement other than any fire retarding material and it can be used for suitable application.The friction and the bond that exist between steel and the concrete provide the essential support for resisting the external load.As mentioned before, the excessing spalling of concreteunder the fire conditions can be evaded with the secondary or supplementary reinforcement.The steel in the column the early construction loads and the concrete is either filled into its tubular column or casted around it.Both the steel and concrete present in the composite column provide many benefits like high ratio among strength to weight of steel.For effectively limiting the deflections the subsequent addition ofconcrete allows theconstruction frame.

2 Recycled concrete aggregate(RCA)

Recycling of concrete aggregates isprocess of reusing the existing concrete and limit the natural resource exploitation that might acts as a new source of concrete.The report on usage of RCA in new concrete specify that the performance of the RCA is equivalent to typical natural aggregates concrete and supported its direct usage in reconstructions.Recycling of concrete involves crushing, breaking, and removal of existing concrete into a high-quality specified size material through a simple process.The recycling of concrete involves the removal of reinforcing steel and other items and make it freefrom any material contamination.Some commonly availablerecycling materials are balls of clay, wood, asphalt, chlorides, glass, gypsum board,sealants, plaster, paper, and many more.

Fig.1 Cross-sections concrete steel column

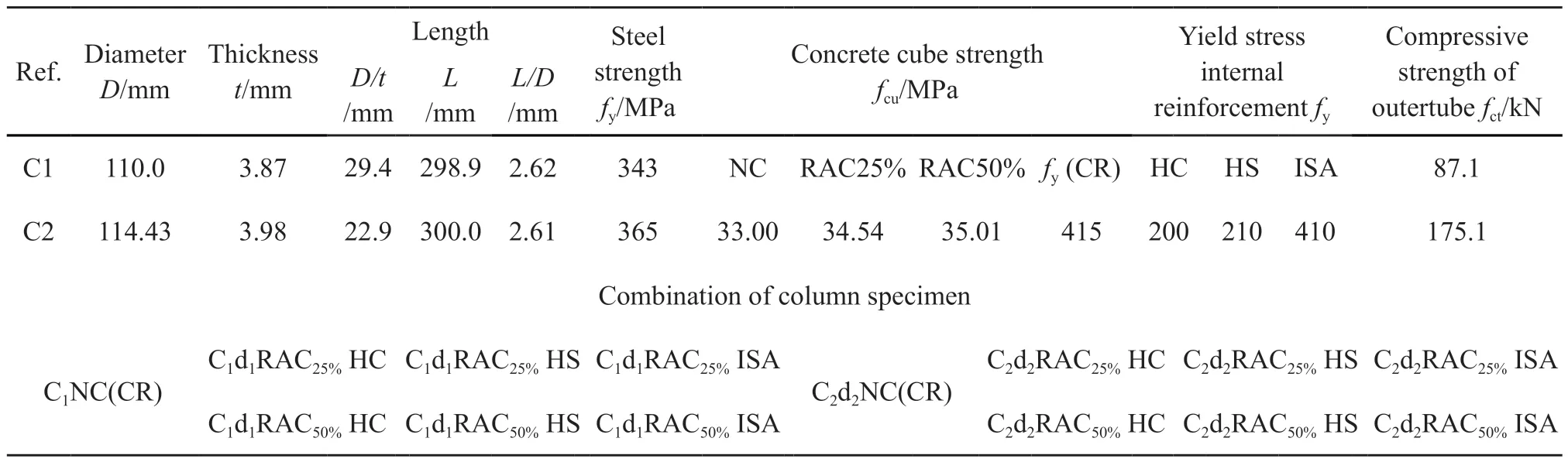

Table 1 Column specimen and properties

3 Experimental setup for column under axial load

Each specimen was tested under axial compression loading in a loading frame at the structural laboratory.The assembly of the test column was placed accurately by employing a plumb bob at the center of the loading frame.This avoids eccentricity at both ends of the column mild steel plate support condition was provided.The axial load is achieved by using spherical steel ball having 55 mm in diameter and 0.6 kg of mass was used in between the two mild steel plates to ensure proper verticality of support mild steel plates are welded and are aligned using 6 mm diameter mild steel smooth bar which is used in on the fur sides of the plate.The column is lifted by 100 on the capacity hydraulic jack which is kept at the bottom of the testing platform above which the steel plate bottom support was placed.Then the test specimen is placed bottom support and the top support is placed over the top column head and finally, it touches the load cell which is pivoted in the horizontal element of the loading frame.The column vertical alignment was checked before start testing.The column was loaded under axial compressive load (25 kN) by hydraulic jack which is placed at the column top as in Fig.2.The column is loaded gradually for failure and buckling of the column.

Fig.2 Experiment setup for column for applying axial load

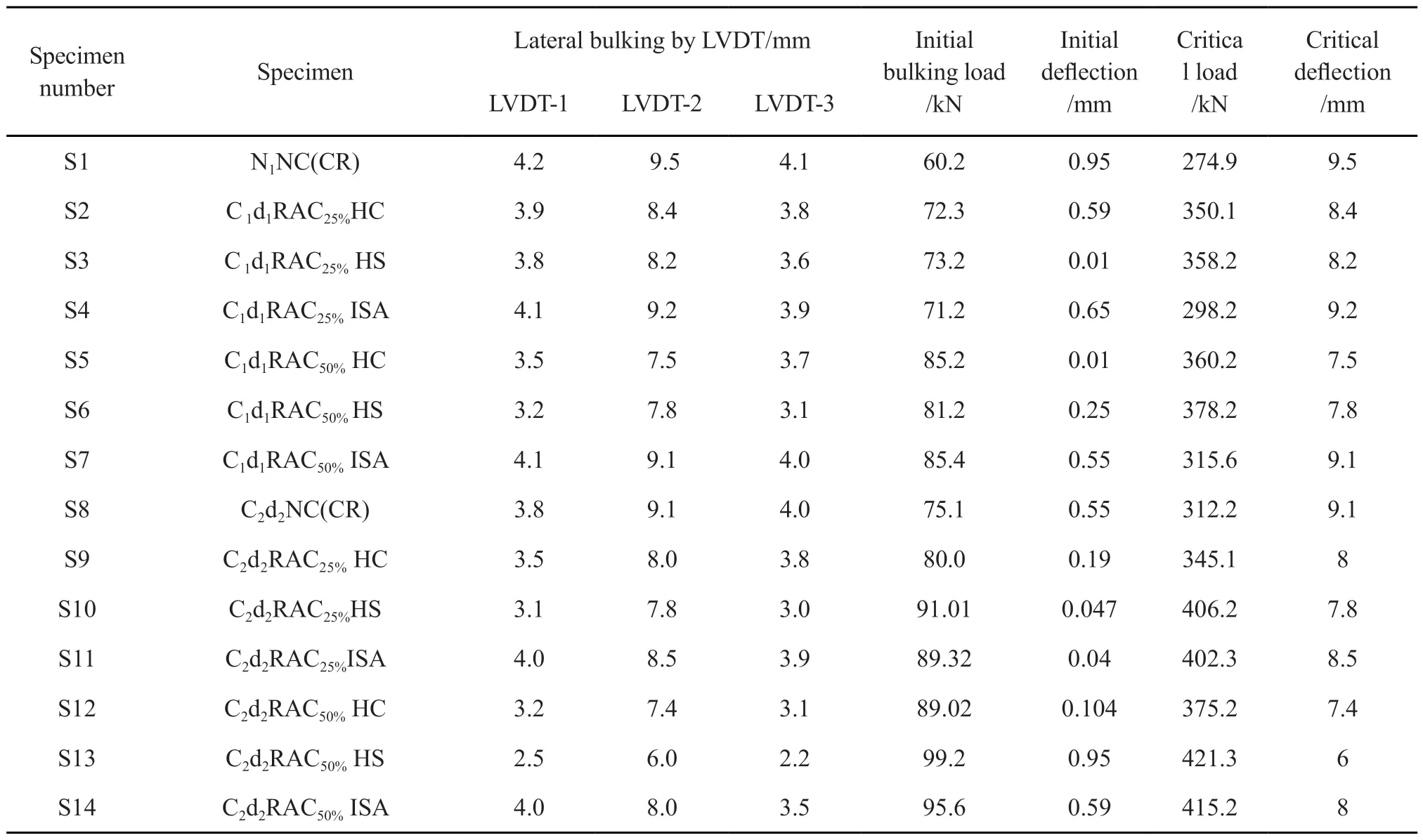

Table 2 Result obtained from testing

4 Results and decision

4.1 Decsion between three phace of LVDT-1, 2, and 3

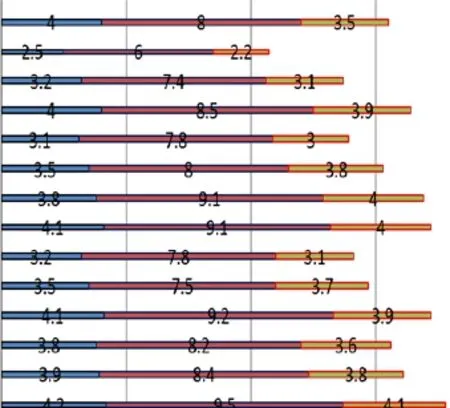

Fig.3 shows that LVDT is placed at three-phase alongside of the columns.Minimum deflection of 2.5,6, and 2.1 mm is observed in S13 {C2d2RAC50% HS}specimen at LVDT- 1, 2, and 3, respectively.And maximum Deflection of 4.2, 9.5, and 4.1 mm is found in S1{C1NC(CR)}.

Fig.3 Deflection over 14 column specimen measured on LVDT

4.2 Decsion onload and deflection between verious column specimens

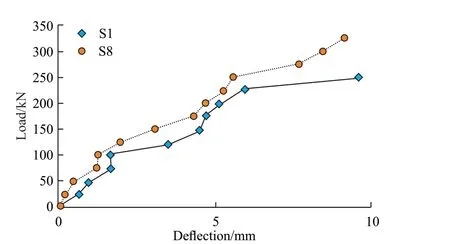

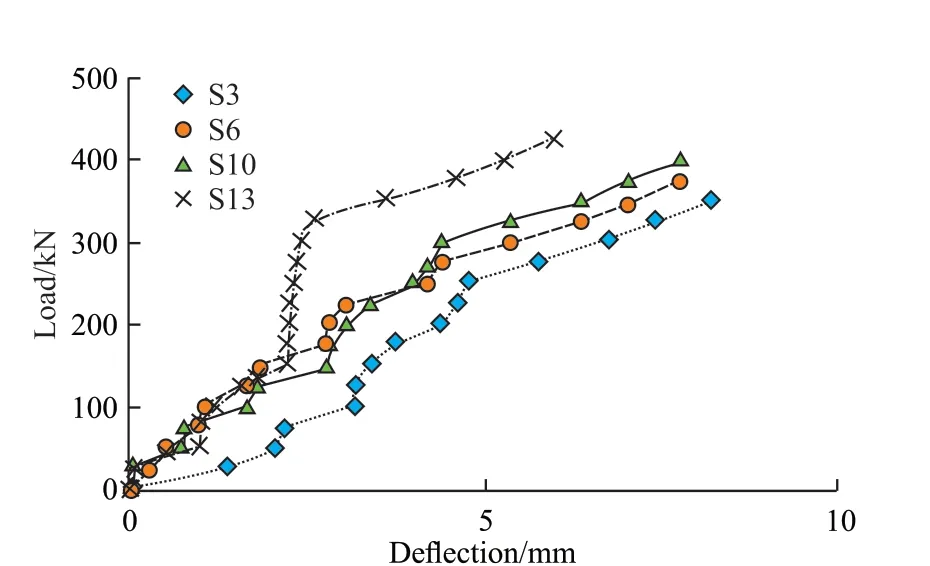

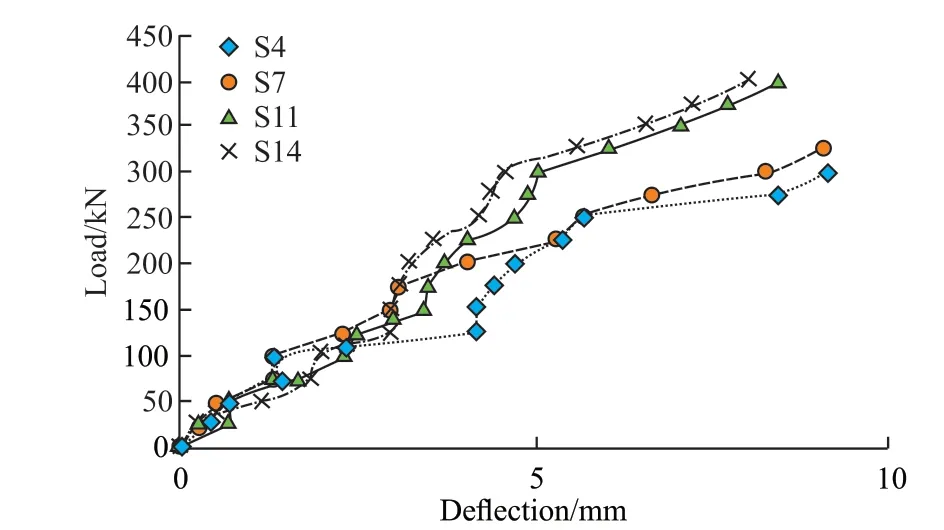

Figs.4-6 shows the respective graphs for the 14 different combinations of composite columns tested.It can be concluded from the graphs that the rate of deflection decreases with the increase of RAC percentage(25% and 50%).The load-lateral deflectionresponses of all 14 composite columns are given in Fig.3, where the lateral deflection is observed at the column mid height and it was evident that the variation in the in-fills of concrete had no impact on the load-lateral deflection curve as all specimen have similar shape.

Fig.4 Load and deflection of C1NC(CR) vs C2d2NC(CR)

Fig.5 Load and deflection of C1d1RAC25% HC, C1d1RAC50% HC,C2d21RAC25% HC, and C2d21RAC50% HC

Fig.6 Load and deflection of C1d1RAC25% ISA, C1d1RAC50% ISA,C2d2RAC25% ISA, and C2d2RAC50% ISA

5 Conclusions

In this study a challenge to revise the prospect of the composite column that is fabricated by filling RAC over hollow structural steel in real-time practice.From the obtained results, the following conclusions are drawn:

a) The local buckling does not occur in the steel tube compression zone until the ultimate strength is achieved.

b) The strain observed with respect to ultimate strength increases proportionally with the ratio of load eccentricity.In circularspecimens, the observed compressivestrain over the ultimate strength is more than the yieldingstrain of steel.

c) The characteristic C1NC(CR)columns failure modes are similar tothoseo ftheother composite columns combination and it is due to buckling failure.The increase in RAC% increased the ultimate capacities of composite columns.

d) The in-fill columns with RAC showed increased ultimate strength than the normal concretefilled specimens.The normal concrete showed ultimate strength which is 1.9%-10.1% lesser than the RAC based composite columns with 25% and 50% recycledcoarse aggregate.

e) It was found that C2d2RAC50%HS composite column has high ultimatecapacitiescompared with other columns combination, and also possesses less lateral deflection.

f) The unique factor of all combinations of the composite column is at elastic in nature, even after the ultimate load is applied to the columns.It is observed that the composite columns regain its original state and shape, during the period of deload.

Conflict of interest

All authors declare that there are no competing interests.

杂志排行

Journal of Wuhan University of Technology(Materials Science Edition)的其它文章

- Enhanced Electrochemical Performances of Ni Doped Cr8O21 Cathode Materials for Lithium-ion Batteries

- Design on the Prestressed Concrete Frame Beam-column

- Synthesis and Flocculation of Polyacrylamide with Low Water Absorption for Non-dispersible Underwater Concrete

- Impact-abrasive Wear Behavior of ZTA and NbC Reinforced Fe60 Matrix Composites

- Synthesis and Characterization of Hollow Strontium Carbonate Pompons by Composite Soft Template Method

- Preparation of Co/CoOx Derived from a Lowtemperature Etching of ZIF-67 for Oxygen Reduction and Oxygen Evolution Catalytic Reaction