Pumpability of Manufactured Sand Self-compacting Concrete

2024-01-03LIHuajianHUANGFaliTUHaifengSUNDeyiWANGZhenYIZhonglaiYANGZhiqiangXIEYongjiang

LI Huajian, HUANG Fali, TU Haifeng, SUN Deyi, WANG Zhen, YI Zhonglai,YANG Zhiqiang*, XIE Yongjiang

(1. Railway Engineering Research Institute, China Academy of Railway Science Corporation Limited, Beijing 100081, China; 2. School of Civil Engineering, Beijing Jiaotong University, Beijing 100044, China;3. China Railway Engineering Design and Consulting Group Co., Ltd,Beijing 100055, China)

Abstract: By the addition of superplasticizer and air entraining agent, manufactured sand selfcompacting concrete (MS SCC) with slump flow varying from 500 to 700 mm and air content varying from 2.0% to 9.0% were prepared and the pumpability of MS SCC was studied by a sliding pipe rheometer (Sliper).According to the Kaplan’s model, the initial pump pressure and the pump resistance of MS SCC were obtained.Meanwhile, rheological properties including the yield stress and the plastic viscosity of MS SCC were measured by a rheometer.The experimental results show that the increase of slump flow contributes to a higher pumpability and a proper air content, i e, 6% is beneficial for the pumpability of MS SCC.Due to the existence of stone powder and stronger angularity of MS, the initial pump pressure of MS SCC is only about 60%-88%that of river sand (RS) SCC with the same slump flow and air content, indicating that MS SCC possesses a higher pumpability than RS SCC.

Key words: manufactured sand; self-compacting concrete; pumpability; sliding pipe rheometer;rheology

1 Introduction

The development of modern concrete structure requires higher performance concrete material, for which the workability and durability are the two important and key parameters[1].As a special type of concrete that can fill the formwork without external vibration,self-compacting concrete (SCC) has been studied and applied to more and more engineering constructions[2-4].Take China Railway Track System III (CRTS III), for example.SCC is used as the filling layer between concrete slab track and support layer[5].It is reported that exceeds 5,400 km (double line) CRTS III ballastless track has been built in China, and more than 2,500 km CRTS III ballastless track are under construction including the Jakarta-Bandung High-Speed Railway in Indonesia.In total, 5,000,000 m3SCC has been or will be used in CRTS III track system[6].

In the last decades, river sand (RS) is the first choice for the production of SCC.However, with the growing demand of fine aggregate and environmental restrictions for the exploitation of RS, MS was selected and used in cement-based materials as an alternative for RS[7-10].Compared with RS, MS is quite different in shape, grade as well as composition.Since MS is manufactured by mechanical crushing from the parent rock, a certain content of stone powder is unavoidable.Up to date a series of studies have been carried out to MS SCC.Prakash[11]compared the flowability of fresh MS SCC with RS SCC and claimed that a higher volume of paste is needed for the required flowability for MS SCC.Qu[12]proposed that a proper content of stone powder of MS is beneficial for the flowability of the fresh MS SCC.Houet al[13]prepared SCC with MS containing stone powder content of 9wt%, and no slump loss was found even in 4 hours.All these studies indicate that MS could be used in the production SCC with high performances, but the influence of MS on the workability of SCC is still unclear.

The “pumpability”, also known as “pressure workability”, is defined as the degree of mobility and stability of fresh concrete delivered through a pumping pipe under pressure[14].The pumpability of conventional vibrated concrete (CVC) has been explored for several decades[15-17].However, the study on the pumpability of SCC is limited.Since the low yield stress and the appropriate plastic viscosity determine the complexity of the SCC during the pumping process[18], and accordingly the research results of CVC pumpability may not be applicable for SCC[19].Feys[20]confirmed that the plastic viscosity of RS SCC would be decreased after pumping because the shear stress leads to the redispersion of cementitious materials during the process of pumping.Jianget al[21]claimed that the pump pressure of MS SCC was increased, decreased or unchanged after pumping, depending on different application cases.Nevertheless, more works on the pumpability of MS SCC are urgently needed.

Conventionally, the pumpability of fresh concrete is assessed by the slump and slump flow test[22].However, this method has many limitations, as it cannot simulate some vital parameters of the actual pumping process,i e, very high spreads and pump pipe lengths.Besides, some crucial mixture proportion parameters including paste volume and aggregates grading cannot be taken into consideration when testing the pumpability of concrete[23,24].Thus, for fresh concrete of a same slump flow, the pumpability may vary significantly.In 2004, Djela[25]reported a rectilinear movement tribometer that could be used to test the pumpability of concrete directly.Nevertheless, the poor sealing performance of the rectilinear movement tribometer during the test process may lead to an inaccurate results, and it couldn’t reliably simulate the actually flow rate of concrete[26].In 2014, the sliding pipe rheometer (Sliper)that can be used to evaluate the pumpability of concrete was invented by a German engineer[27].The principle of Sliper is close to actual pumping, and the correlation between Sliper’s test results and the actual data is pretty high.In the Ref.[28], Viktoret alclaimed that the concrete prepared with natural quartz aggregate presented higher pumpability than prepared with crushed basalt aggregate based on the Sliper test.Rounded aggregate and crushed aggregate are both used for fine and coarse aggregate, the influence of fine aggregate type on the pumpability of concrete may however be different.

This study is designed to bring the understanding of the pumpability of MS SCC a step further by using a Sliper, which is beneficial for guiding the mix proportion of pumping MS SCC.The influences of slump flow (500 - 700 mm) and air content (2.0% - 9.0%)on the pumpability of MS SCC was analyzed.Then,a comparative study on the pumpability of MS SCC and RS SCC was conducted.After that, the rheological properties of MS SCC were studied by a rheometer.Based on these investigations, the correlations between the initial pump pressure and the yield stress, the pumping resistance and the plastic viscosity of MS SCC and RS SCC were discussed.

2 Experimental

2.1 Materials

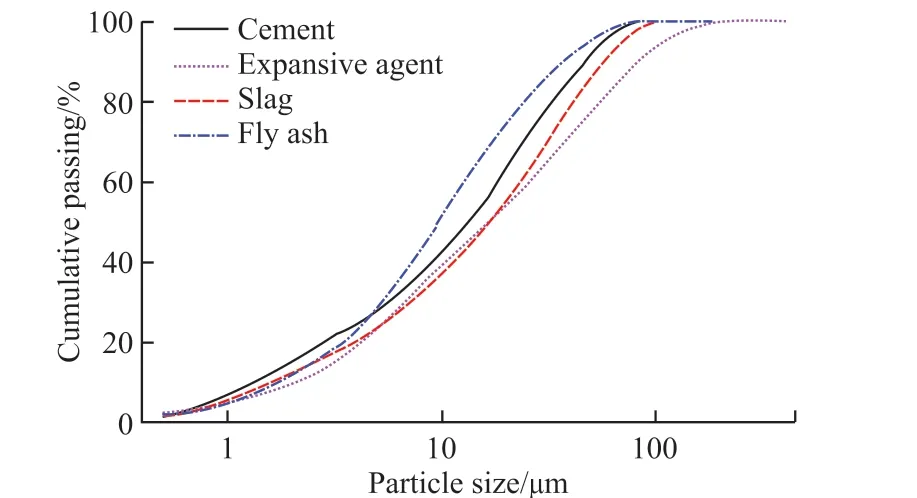

Fig.1 The particle size distributions of the used cement, expansive agent, slag, and fly ash

Portland cement PO 42.5 complying to the Chinese standard GB 175-2007[29], type II calcium sulphoaluminate-calcium oxide expansive agent complying to GB 23439-2017[30], grade-S95 blast furnace slag complying to the GB/T 18046-2017[31]and class-I fly ash complying to the GB/T 1596-2017[32]were used.The chemical compositions of these materials are listed in Table 1, which were tested by X-ray fluorescence (XRF).The specific surface and density were measured, and the results are also listed in Table 1.Theparticle size distributions of the used cement, expansive agent, slag, and fly ash were determined by means of laser, and the results are shown in Fig.1.

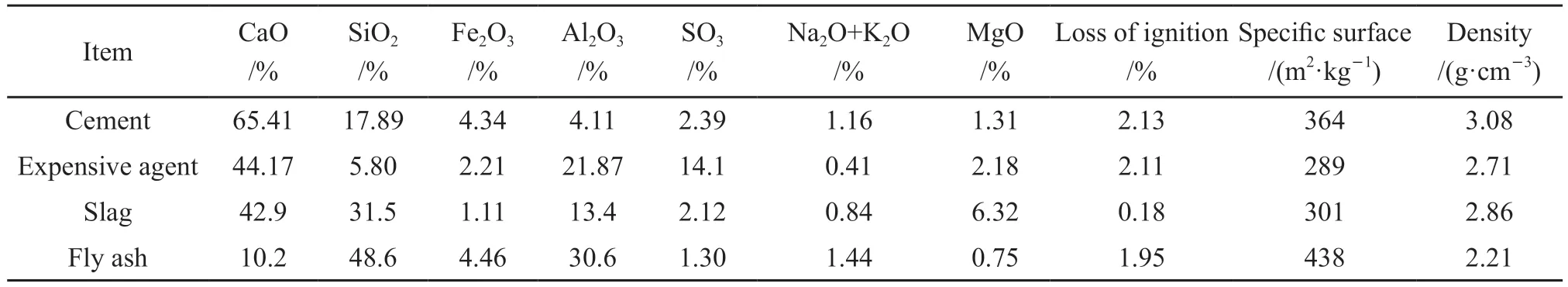

Table 1 Chemical compositions and physical properties of the used cement, expansive agent, slag, and fly ash

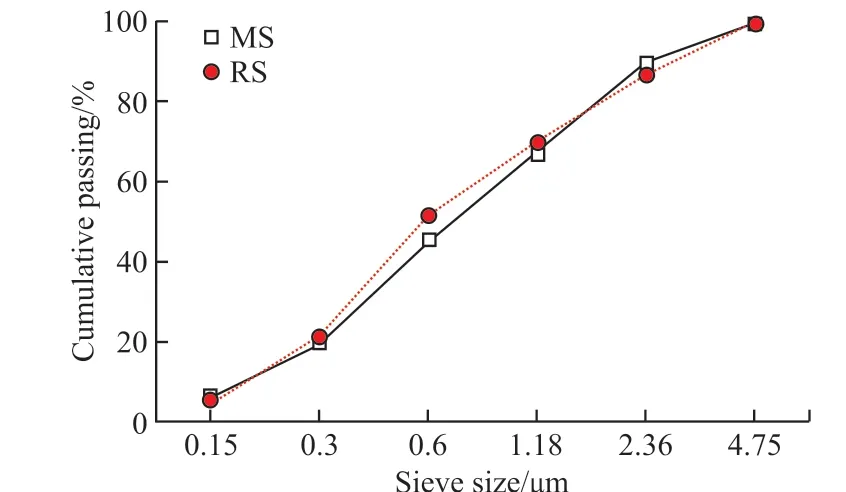

Fig.2 Gradation curves of MS and RS

MS, crushed from limestone, with a fineness modulus of 2.6 and stone powder of 6% was employed in this study.Meanwhile, RS with a same fineness modulus was used.The gradation curves of MS and RS are presented in Fig.2, and whose apparent density is 2.62 and 2.69 g/cm3for MS and RS, respectively.The contour images of frontal projection of MS and RS are shown in Fig.3.It is obvious that MS possesses more rough surfaces, edges, and corners than RS.Meanwhile, 5- 16 mm continuous-grading crushed limestone coarse aggregate was used.

In order to obtain the expected slump flow, the polycarboxylate superplasticizer (SP) with a water reducing rate of 27% was used.The rosin resin type air entraining agent (AE), purchased from SOBUTE New Materials Co., Ltd, was employed for the expected air content.The viscosity-enhancing admixtures (VMA)which was composed of mineral admixture and cellulose ether was also added to avoid segregation and bleeding of SCC.

2.2 Mixture proportions

Fig.3 Contour images of frontal projection of fine aggregate

Table 2 Mix proportion, slump flow, air content, and VSI of fresh SCC

The mix proportion and the corresponding slump flow (SF), air content (AC) as well as visual stability index (VSI) of fresh SCC are provided in Table 2.The slump flow and air content of SCC were measured according to GB/T 50080-2016[33].VSI was used to evaluate the segregation degree of fresh SCC, and class 1 indicates that only very slight bleeding could be observed on the SCC surface according to AASHTO-T-351[34].It is seen that the air content of the first group of MS SCC (A1 - A5) was fixed at 4.0±0.5%, while the slump flows of fresh SCC are 490, 550, 600, 650, and 690 mm by changing the dosage of SP.In order to improve the stability of SCC, VMA, a quite common admixture,was added into the mixture.The slump flow of the second group of MS SCC (B1-B4) was fixed at 650 mm,while the air contents are 2.3%, 4.3%, 6.0%, and 8.8%.The fine aggregates of sample C1-C5 and sample D1-D4 were RS.The other raw materials, slump flow as well as air content were the same as the first and second group of MS SCC.

2.3 Pumpability test

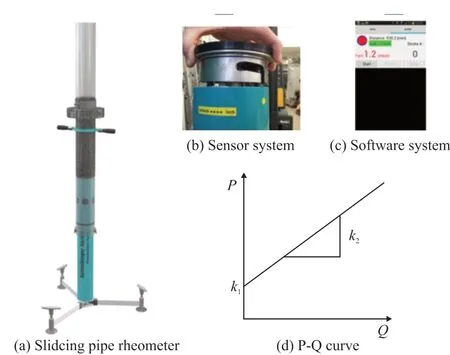

Fig.4 Test principle of Sliper

The pumpability of SCC was determined by the sliding pipe rheometer, as shown in Fig.4.During the testing process, the pumping pressure (P) and the flow rate (Q) under different weights were firstly measured.Afterwards, the test data was collected and analyzed by the software system.It is known that concrete flow may be as slip flow or slip-plus-shear flow, which are expressed as Eq.(1) and Eq.(2), respectively.However,only slip flow was observed in the Sliper test according to the study of Viktor[27]and Kong[35].The slurry in concrete transfers by the effect of friction and then enriches on the inner wall of the pipe to form lubrication layer or sometimes called slippage layer[36].Therefore,the appropriate thickness, stable and continuous lubrication layer are the prerequisite for the concrete mixture to pump successfully.In the Sliper test, the crossover point of theP-Qcurve andYaxis is expressed ask1, and the slope ofP-Qcurve is expressed ask2.From Eq.(3) and Eq.(4), it is seen that there are linear correlations betweenk1and the yield stress of lubrication layer,k2and the plastic viscosity of lubrication layer,respectively.k1andk2are defined as the initial pump pressure and the pump resistance of fresh concrete[27].Accordingly, the decreasedk1andk2mean that the yield stress and plastic viscosity of lubrication layer are decreased, indicating a higher pumpability of mixture.

where,Pis the pumping pressure in Pa;Lis the length of pipe in m;Ris the radius of pipe in m;Qis the flow rate in m3/h;kris the filling coefficient;ηLLis the viscosity coefficient of lubrication layer in Pa·s/m;ηis the plastic viscosity of concrete in Pa·s/m;τ0andτ0,LLare the yield stress of concrete and lubrication layer in Pa.

2.4 Rheological test

The rheological properties of SCC were measured using a rheometer (RHM-3000 ICAR) and the experimental details are shown in Table 3.In this experiment,a preshearing was conducted before testing to control the adverse effect of thixotropy of SCC.The speed was reduced from 0.50 to 0.05 rps step by step,i e, every sample were tested at 10 different speeds.Since the test is finished in about 70 s, the influence of aggregate settling and slump flow loss during the test period on the rheological testing results could be ignored[37].

2.5 Fine aggregate morphology

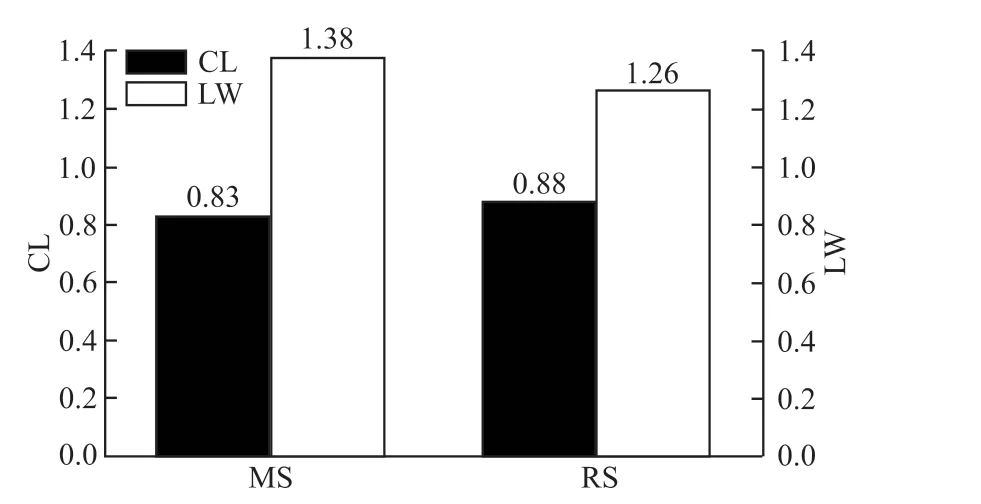

The morphology of MS and RS were determined by a BT-2900 morphology analysis instrument.The images of free-falling fine aggregate were taken by a HD digital camera and then two morphology parameters,ie, circularity (CL) and length diameter ratio (LW) were analyzed[38].CLmeans the circular degree of fine aggregate and a smallerCLvalue indicates a stronger angularity.LWpresents the flaky degree of fine aggregate and a higherLWvalue indicates a stronger angularity.The calculation formulas of circularity and length diameter ratio are expressed as Eq.(5) and Eq.(6), respectively.

where,Ais the projected area of fine aggregate in mm2;Dthe perimeter of fine aggregate in mm;LandWthe length and the diameter of projection particle’s minimum bounding rectangle in mm, respetively.

3 Results and discussion

3.1 Effect of slump flow on the pumpability of MS SCC

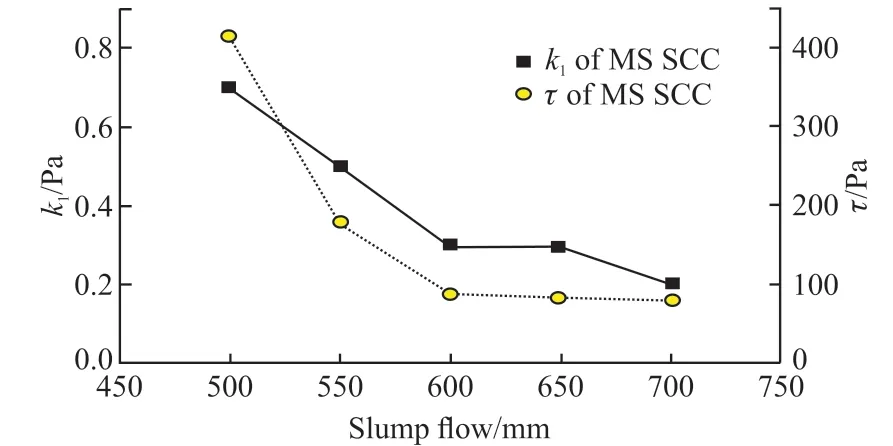

Fig.5 presents the effects of slump flow on the initial pump pressure of MS SCC.It is clear that the initial pump pressure decreases with the increase of slump flow, which is in consistency with the well-known influence of slump flow on the pumpability of concrete.In this experiment, the slump flow of MS SCC mixture is improved by increasing the dosage of SP, which contributes to the even dispersion of cement particles.With the effect of electrostatic repulsion and steric hindrance,the free water was released and leads to the decrease of the yield stress of lubrication layer[39].

Fig.5 Effect of slump flow on the initial pump pressure and yield stress of MS SCC

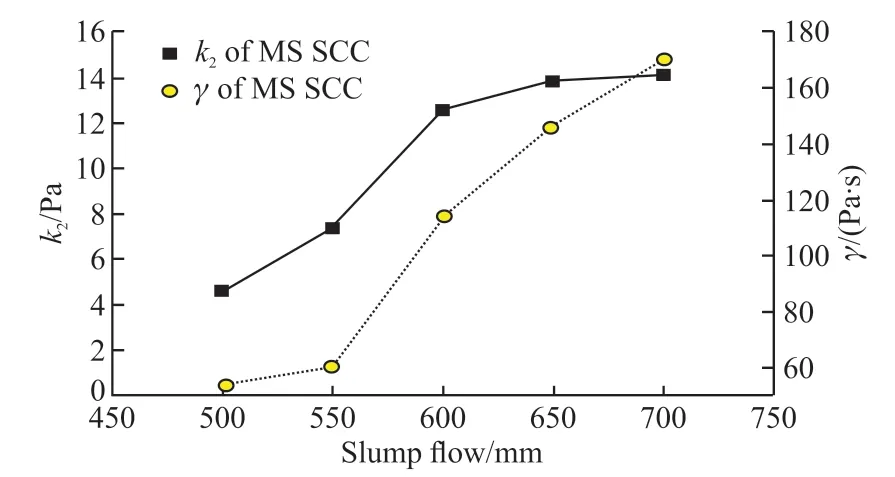

As shown in Fig.6, the pump resistance of MS SCC increases with the increasing slump flow.When the slump flow of MS SCC is increased, the segregation and bleeding tendency of MS SCC mixtures are more obvious.According to Saucier[40], the increase of friction resistance between pumping pipe and aggregate particles may be triggered by the segregation and bleeding, which may get the pumping pipe clogged.Therefore, in order to obtain a similar VSI of different MS SCC mixture, 1.0wt% - 5.0wt% cementitious materials VMA was added, which is water-soluble polymer that can increase the viscosity and the cohesion of concrete mixture by adsorbing and fixing free water[41,42].Hence, the apparent volume is increased by swelling,resulting in the increase of plastic viscosity of mixture and further to ensure the segregation resistance of MS SCC[43].Therefore, when VMA was added to MS SCC,the plastic viscosity of mixture and lubrication layer is increased, thus the pump resistance of MS SCC is increased with the increasing slump flow.

Fig.6 Effect of slump flow on the pump resistance and plastic viscosity of MS SCC

3.2 Effect of air content on the pumpability of MS SCC

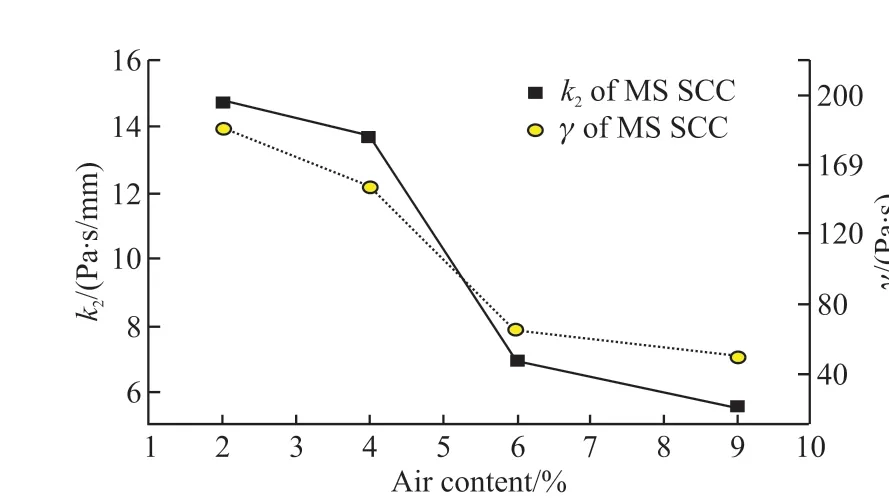

Fig.7 presents the effects of air content on the initial pump pressure and yield stress of MS SCC.It is seen that the initial pump pressurek1decreases first and then increases with the increasing air content.Since a higher air content of SCC is beneficial for lubricating,which consequently decreases the yield stress of lubrication layer.The initial pump pressure was decreased with the increase of air content.However, when the air content is higher than 6%, the compressibility of the SCC mixture increases obviously during the process of pumping, leading to the hammering action to the pump pipe of MS SCC mixture.Therefore, the initial pump pressure of MS SCC was increased dramatically when the air content exceeds 6%.

The effects of air content on the pump resistance and plastic viscosity of MS SCC are displayed in Fig.8.It is observed that that pump resistance of the MS SCC decreases with the increasing air content.As a higher air content means a lower actual content of cementitious material in unit volume, the increase of air content leads to the decrease of the cohesive strength and the plastic viscosity of MS SCC, which is beneficial for decreasing the pump resistance[44].Therefore, considering the coupling effect of air content on the initial pump pressure and the pump resistance, MS SCC presents the best pumpability when the air content is about 6.0% in this experiment.

Fig.8 Effect of air content on the pump resistance and plastic viscosity of MS SCC

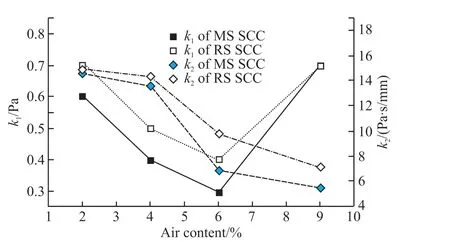

3.3 Comparison of pumpability of MS SCC and RS SCC

The pumpabilities of MS SCC and RS SCC are compared and the results are shown in Fig.9 and Fig.10.It is found that the pumpability of MS SCC is clearly higher than that of RS SCC.For instance,k1andk2of MS SCC with a slump flow of 600 mm and air content of 4% is only about 60% and 90% of RS SCC with the same slump flow and air content.

Fig.9 Effect of fine aggregate type on pumpability of SCC with different slump flows

Fig.10 Effect of fine aggregate type on pumpability of SCC with different air contents

Fig.11 Circularity and length-diameter ratio of MS and RS

When RS is substituted by MS in SCC, two main changes may occur: an increase of total binder content as a certain content of stone powder exists in MS; a stronger angularity of fine aggregate.In this study, MS including 6.0wt% of stone powder which is less than 75 μm was used, meaning that 48 kg stone powder in per m3SCC.It is believed that the stone powder can supplement the particle size distribution of cementitious materials in concrete and further increase the slurry content of concrete mixture, which not only ensures the stability of SCC but also increases the thickness of lubrication layer during the process of pumping[45-47].Meanwhile, as shown in Fig.3, the morphology of MS and RS are different.The circularity and the length diameter ratio of MS and RS from the morphology analysis instrument are displayed in Fig.11.It is seen that the circularity of MS is smaller than RS while the length diameter ratio of MS is higher than RS, indicating that MS shows a stronger angularity.Therefore, MS exhibits a greater biting force in concrete which is beneficial for the overall slide.As shown in Fig.12(a), the shear stress is linearly decreased from the maximum to 0 with the inner wall surface to the center of pipe during the process of pumping[48].The difference of shear stress promotes the fine sand mortar moving to the inner wall surface of the pipe to form lubrication layer (Figs.12(b)and 12(c)).Simultaneously, the coarse aggregate shifts to the central region of pipe with a lower shear rate.It is reported that only the fine aggregate less than 0.25 mm can stay in the lubrication layer[49].Therefore, MS moves to the pipe center under the shear stress more easily compared with relatively scattered RS in SCC.

Fig.12 Formation model of lubrication layer of MS SCC and RS SCC

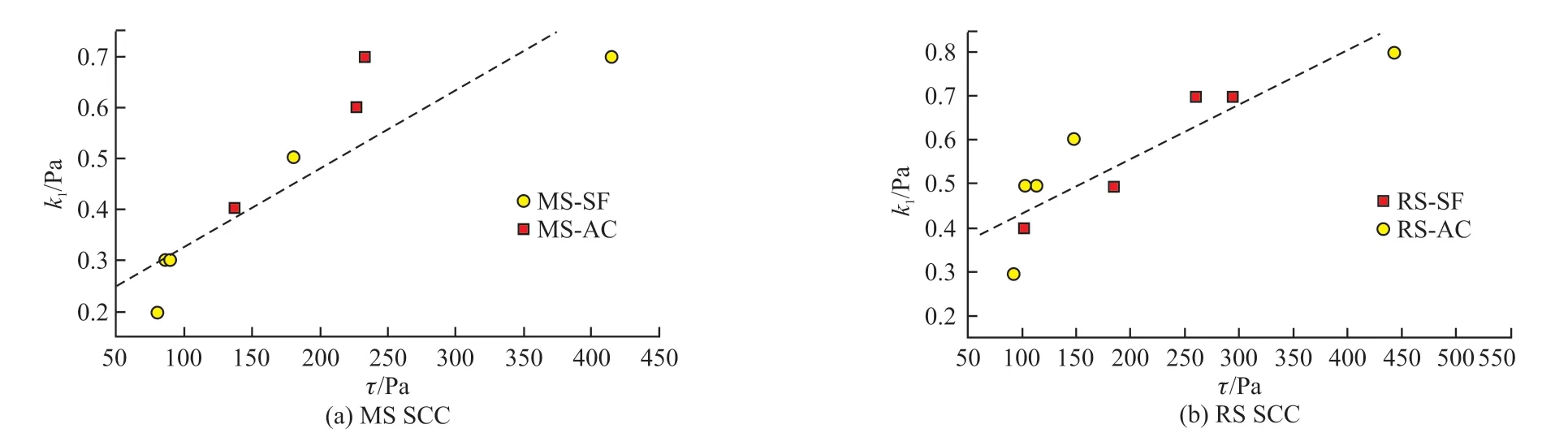

Fig.13 The relationship between k1 tested by sliper and yield stress τ tested by rheometer

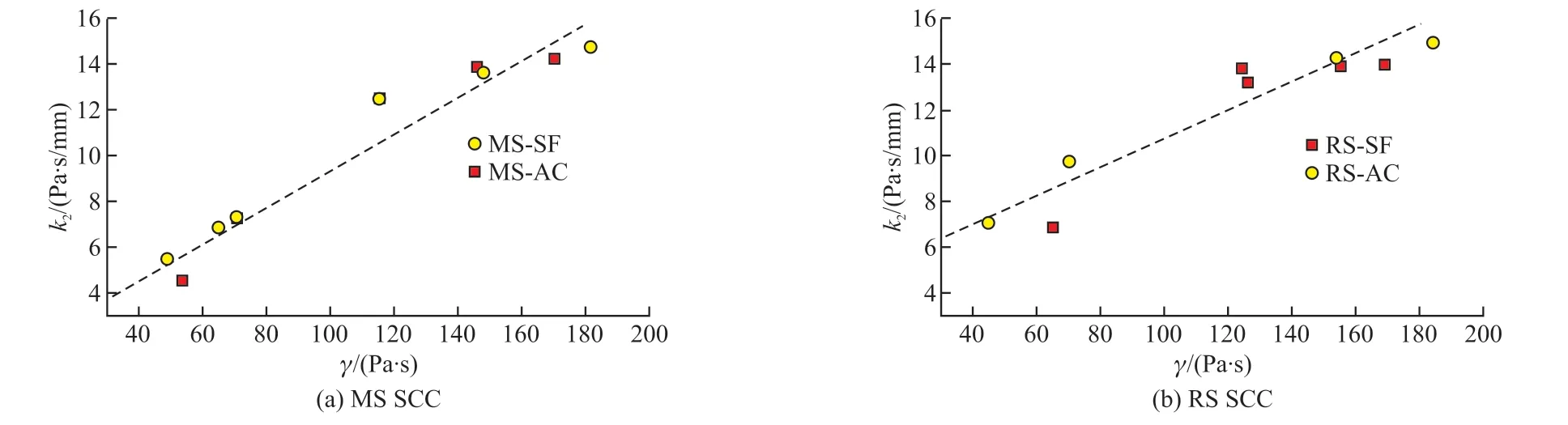

Fig.14 The relationship between k2 tested by sliper and plastic viscosity γ tested by rheometer

3.4 Relationship between the pumpability and rheology of SCC

Compared with the traditional workability testing method of SCC, such as slump flow,T500, and J-ring,etc[50], the rheological parameters including the yield stressτand the plastic viscosityγwith clear physical meaning can better describe the workability.Nevertheless, a higher rheology of SCC never means a better pumpability.Therefore, the study on the relationship between rheological parameters and pumpability parameters is of great significance to evaluate the pumpability and design the pumping SCC mix proportion.Herein, the relationship between the yield stress and the initial pump pressure, the plastic viscosity and the pump resistance were fitted and presented as follows.

Fig.13 shows the relationship betweenk1tested by sliper and yield stressτtested by rheometer.It is seen thatk1increases withτfor both MS SCC and RS SCC.Furthermore, as shown in Eqs.(7) and (8), a linear correlation betweenk1andτare found, whose coefficients of determination are 0.76 and 0.74, respectively:

In the Ref.[27], a nearly perfect linear correlation (coefficients of determinationR2of 0.99) between pump resistancek2and plastic viscosity from viscometerγwas found.In this study, comparisons betweenk2andγof MS SCC and RS SCC are illustrated in Fig.14.As shown in Eqs.(9) and (10), it is obvious that a better linear correlation exists betweenk2andγthan that betweenk1andτas the coefficients of determination are 0.94 and 0.88 for MS SCC and RS SCC, respectively.The results point to a close that the correlation between pumpability and rheology of MS SCC and RS SCC,and the rheological properties can be a favorable indicator for the pumpability of SCC.

4 Conclusions

In the present study, MS SCC and RS SCC with different slump flow and air content were prepared and the pumpability of MS SCC was explored by a Sliper.From the results of this study, the following conclusions can be drawn:

a) The initial pump pressure of MS SCC decreases with the increase of slump flow.The pump resistance of MS SCC increases with the increasing slump flow,a finding different from the CVC.The increase of the pump resistance of MS SCC is attributable to the addition of VMA, which adjusts the workability and, which increases the plastic viscosity of lubrication layer.

b) An appropriate air content contributes to the pumpability of MS SCC.As the increase of air content,the initial pump pressure of MS SCC decreases first and then increases.However, the pump resistance is gradually decreased with the increasing air content.In this study, MS SCC with an air content of 6.0% shows the best pumpability.

c) The pumpability of MS SCC is better than that of RS SCC with a same slump and air content.Stone powder in MS can not only help improve the segregation resistance of SCC, but also increase the thickness of lubrication layer.As apposed to river sand, more manufactured sand moves to the pipe center because of the strong angularity that contributes to the formation of lubrication layer.

d) There is a linear correlation between the results of Sliper test and rheological test.However, it is found that using yield stress from rheological test to evaluate the pump resistance of SCC is more reliable than using plastic viscosity to evaluate the initial pump pressure.

Conflict of interest

All authors declare that there are no competing interests.

杂志排行

Journal of Wuhan University of Technology(Materials Science Edition)的其它文章

- Enhanced Electrochemical Performances of Ni Doped Cr8O21 Cathode Materials for Lithium-ion Batteries

- Design on the Prestressed Concrete Frame Beam-column

- Synthesis and Flocculation of Polyacrylamide with Low Water Absorption for Non-dispersible Underwater Concrete

- Experimental Behavior of Recycled Aggregate Concrete Filled Steel Tubular Columns

- Impact-abrasive Wear Behavior of ZTA and NbC Reinforced Fe60 Matrix Composites

- Synthesis and Characterization of Hollow Strontium Carbonate Pompons by Composite Soft Template Method