The Effect of Wet-grinding on the Properties of Glass Powder and Its Application in Cement Based Materials

2024-01-03WANGYingbinYANGJieSUYingHEXingyangSTRNADELBohum

WANG Yingbin, YANG Jie, SU Ying, HE Xingyang*, STRNADEL Bohumír,2

(1. School of Civil Engineering, Architecture and Environment, Hubei University of Technology, Wuhan 430068, China; 2. Center for Advanced and Innovative Technologies, VŠB-Technical University of Ostrava, Ostrava-Poruba 70833, Czech Republic)

Abstract: To improve the pozzolanic reactivity, waste glass (WG) needs to be micronized to fine particles so as to expedite the leaching of active constituent.The key feature of this work is to examine the effect of wet-grinded WG on the mechanical and structural properties of cement based materials.The experimental results show that wet-grinding can improve the ions leaching behavior of WGP and decrease the stability of silicon oxide bond.The pozzolanic reactivity of WGP was dramatically enhanced after wet-grinding, as high as 144.1% at 1 d and 110.9% at 28 d when the mean grain size of WGP reached 0.90 μm.The ground WGP can promote the transformation of capillary pores to gel pores to improve the compactness of microstructure regardless of the reaction time.

Key words: supplementary cementitious materials; pozzolanic reactivity; wet-grinding; compressive strength

1 Introduction

In China, the amount of construction waste accounted for approximately 40% of the total urban waste.According to statistics, the construction waste produced in China was more than 2 billion tons, 2%of which is made up of WG, in 2018[1].Currently,about 87% of WG was directly landfilled rather than collected for recycling[2].Due to the non-biodegradable characteristics of WG, the existing disposal method not only occupies considerable land resources, but also causes various environmental problems.Consequently,there is an environmental incentive to reuse WG.

Cement is one of the most important and widely used construction materials.The global cement industry produces over four billion tonnes annually[3,4].It is stated that cement industry is one of the most attractive ways of dealing with WG (either as aggregate or substitution of cement).

Previously, many scholars have attempted to evaluate the feasibility of using WG as an alternative fine aggregate in mortars and concretes[5-8].The advantages of WG aggregate (WGA) have been certified such as reducing dry shrinkage, enhancing workability, improving high-temperature resistance and reinforcing abrasion performance of concrete.However,the main issue is the potential reaction (alkali-aggregate reaction, AAR) between amorphous silica in WGA and alkalis in cement or WG.Lyeet al[9]and Topcuet al[10]proved that the WG type had a significant effect on the AAR of mortar, and the ASR was aggravated by using high volume WGA.Bazant[11]revealed that the AAR can be accelerated when WGA particle size larger than 1.18 mm.The results also showed that WG pieces smaller than 300 μm could reduce the negative effects caused by ASR to some extent.Shiet al[12]pointed out that the replacement of cement with ground WGP reduced the AAR-induced expansion.Recently,many literatures have also proved that the use of finely WGP (< 74 μm) as an alternative cementitious material significantly enhanced the durability of concrete[13,14].

Considering the risk of AAR, attempts have been made to refine WGP to improve pozzolanic activity[15-18].In order to obtain fine WGP grains, Shaoet al[13]used different sieve size to classify WGP (75-150, 38-75, and 0-38 μm) and evaluated the reactivity of WGP.They indicated that the finer the WGP is,the higher its pozzolanic activity is.Mirzahosseinietal[19]adopted wet-sieving method to obtain WGP with different Blaine surface area ranging from 53 to 476 m2/kg and found that the fine WGP is considered to have good application values.Luet al[20]showed that the average particle size of WGP was only decreased to 28.3 μm after 4 h of grinding.The above-mentioned studies proved the difficult-to-grind characteristics of WG.This will certainly affect the activity of WGP and the mechanical properties of cementitious materials.

According to the previous studies, the compressive strength can be improved for specimens with low WGP dosage.Aliabdoet al[21]evaluated the effect of WGP dosage on the compressive strength of concrete and concluded that the concrete strength was enhanced when the dosage of WGP was less than 10%.Patelet al[22]noticed the significant reduction of compressive strength with the increase amount of WGP in concrete.Khatibet al[23]observed that the strength increment of concrete is optimal when 10% WGP was blended and Chikhalikar[24]concluded that the increment in strength could be observed as 20% WGP was applied.The variation of the test results might be due to the fact that the selected WGP have different fineness and morphologies.Further studies[25]agreed that mortars and concretes with 20% WGP exhibit lower strength compared to the control sample.

Wet milling has been widely used in mineral processing engineering.The authors have also systematically studied the properties variation of lithium slag[26], fly ash[27]and granulated blast furnace slag[28]treated by wet milling, and proved its practicability.Despite all the aforementioned results,existing research rarely focus on the preparation of superfine WGP and their effect on the properties of cement pastes.Extensive research has been performed to study the behavior of wet grinded solid waste and proved that wet milling is an effective method to treat solid waste.However, the efficiency of wet mechanoactivation of WG is still unclear.Therefore,the aim of this work is to evaluate the feasibility of wet milling for WG treatment and the effect of superfine WGP on the mechanical property and microstructure development of WGP-cement composite pastes.

Fig.1 Particle size distribution of (a) ordinary portland cement and (b) WGP0

2 Experimental

2.1 Materials

Ordinary portland cement of grade 42.5 supplied by Huaxin cement Co., Ltd.confirming to GB/T 4131-2014 was used in this work as notified in Fig.1 and Table 1 with Blaine surface area of 348 m2/kg and average particle size of 14.6 μm.

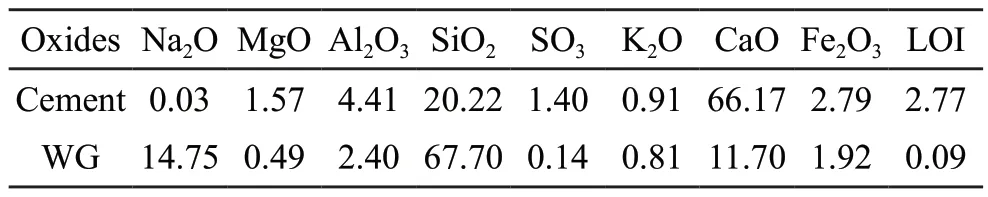

Table 1 Chemical compositions of cement and WG

Brown waste glass bottles used as a raw material were obtained from disposal area of civil engineering materials Labs.The selected bottles were rinsed with water to get rid of the residual organic compound and the packaging.Then, the washed bottles were dried in an oven at 60 ℃ for 24 h and crushed in a jaw crusher to produce glass cullet (GC) with grain size smaller than 1.5 mm.Then the GC was grinded in a ball mill for 10 min to obtain WGP which was named as WGP0(in Fig.1).

2.2 Experiments

2.2.1 Preparation of wet grinded WGP

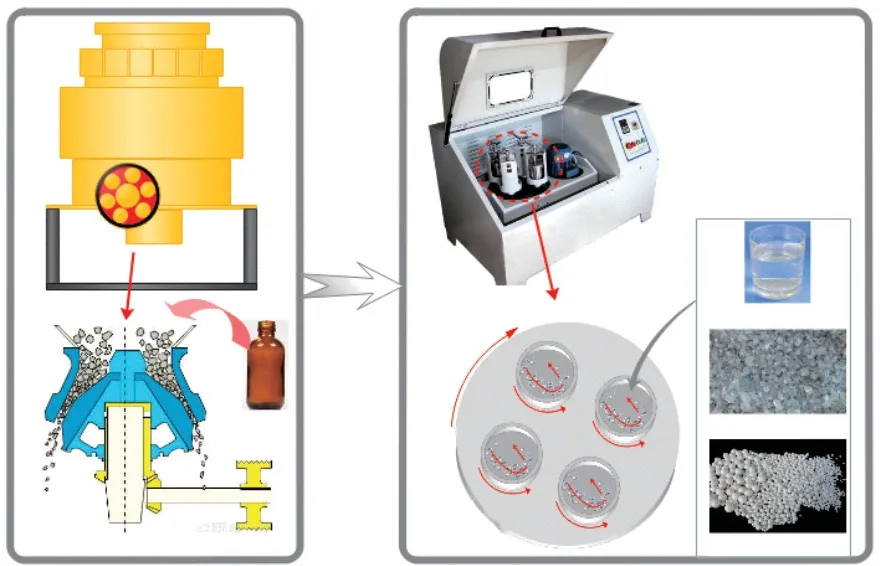

To realize the superfine-grinding of WG,vertical planetary mill (VPM) with zirconia balls as milling medium was applied to treat GC in aqueous environment.The calculated water, WGP0 and milling medium were separately weighted and were loaded into mill system.Thereafter, the WGP0 was grinded for specific durations (20 min for WGP2, 60 min for WGP6, and 120 min for WGP12) in the VPM with spindle speed of 400 rpm.The schematic illustration for preparation of WGP is depicted in Fig.2.Four types of zirconia balls (1 mm: 3 mm: 5 mm: 8 mm: 10 mm=2: 2: 3: 2: 1) were selected.In addition, the milling medium to GC weight ratio and water to GC weight ratio were fixed to be 3:1 and 2:1, respectively.

2.2.2 Preparation of specimens

Fig.2 Schematic illustration for preparation of WGP

After grinding, the WGP paste was pre-mixed with water to guarantee monodispersity of final WGP particles.Subsequently, cement and sand were added to mixing vessel in the desired proportions and stirred for the required time (according to the GB/T 17671-1999).Table 2 shows the mix proportion of specimens.The binder to sand weight ratio and water to binder weight ratio were 1:3 and 1:2, respectively.The dosage of WGP was set to 20%.Mixtures were cast in steel molds with a dimension of 40 mm × 40 mm × 40 mm.Mortars were demoulded after 1d and then cured in the standard condition (20 ± 1 ℃, 90% RH).

Table 2 Mix proportions of WGP-cement specimens

WGP-cement pastes were also prepared for the measurement of reaction products and microstructures.After 1 and 28 days of curing, the hardened pastes were crushed into pieces and immersed in acetone for 48 h to hinder the further hydration of cement, and then dried at 80 ℃ for 24 h.The sample was divided into two parts; one part is used for microstructure analysis,while the second part of the sample is grinded to fine powder for reaction products analysis.

2.2.3 Methods

Compressive strength measurement of mortars was performed by using a TYE-300F tester with loading speed of 2.4 kN/s.Three specimens were tested and the average value was calculated as compressive strength.

Matersizer 3000 laser particle analyzer was used to analyze the particle size distribution of wet grinded WGP.

The leaching behaviour of WGP with different milling duration was evaluated by using the ICPAES.It should be noted that the prepared WGP slurry must be filtered immediately after grinding in order to minimize the experimental error.

X-ray diffractometer (D/MAX-IIIA) was adopted to characterize the reaction products of hardened pastes.The selected parameters were: Cu (Kα) radiation (40 kV, 40 mA); 2θrange from 5° to 60°; scanning speed of 4°/min with step-size of 0.02°.

Reaction products were also analyzed by using a quantitative differential thermal analyzer (DTA,STA449F3).The parameters were set as 30-1 000 ℃with 10 ℃/min under N2atmosphere.

As for microstructure analysis, the samples were coated with a thin carbon layer to improve the conductivity, and the images were collected using an field emission scanning electron microscope(QUANTAFEG 450).

Pore structure characteristics of specimens were estimated by mercury intrusion porosimetry(Poremaster GT-60) test.

3 Results and discussion

3.1 Physicochemical characteristics of WGP

The WGP0 shows an average particle size of 10.50 μm, which reduces to 4.96, 2.71, and 0.90 μm when the grinding duration increased to 20, 60,and 120 min.In this study two parameters, namely surface area mean diameter D[3,2] and volume mean diameter D[4,3], were applied to investigate the effect of wet-grinding on WGP particles.For active mineral admixture, D[3,2] is usually used to evaluate the activity of particles.The smaller value of the D[3,2]denotes the higher pozzolanic activity of mineral admixture.Besides, parameter D[4,3] can be used to investigate the filling and stacking characteristics of particles.The difference between D[4,3] and D[3,2]means the degree of irregularity of the particles.The smaller the value of D[4,3]-D[3,2], the more regular the particles shape.Variations of particle parameters versus grinding time for WGP are depicted in Table.3.It was noticed that with the increase in grinding duration,there was a decrease in D[3,2] value, implying that the activity of WGP can be improved due to the increment of surface area.The value of D[4,3] was also decreased dramatically, proving that the filling effect of WGP in cementitious material was enhanced after wetgrinding.Moreover, The difference between D[4,3]and D[3,2] was 17.77 μm for WGP0, which decreased to 0.37 μm when the grinding duration increased to 120 min.The decrease of D[4,3]-D[3,2] in favor of the reduction of friction between particles on account of the particle shaping of WGP during wet-grinding.The aforementioned results indicate that wet-grinding is an effective method to improve the mechanical property and compactness of microstructure of hardened paste,which will be proved in section 3.2 and 3.4.

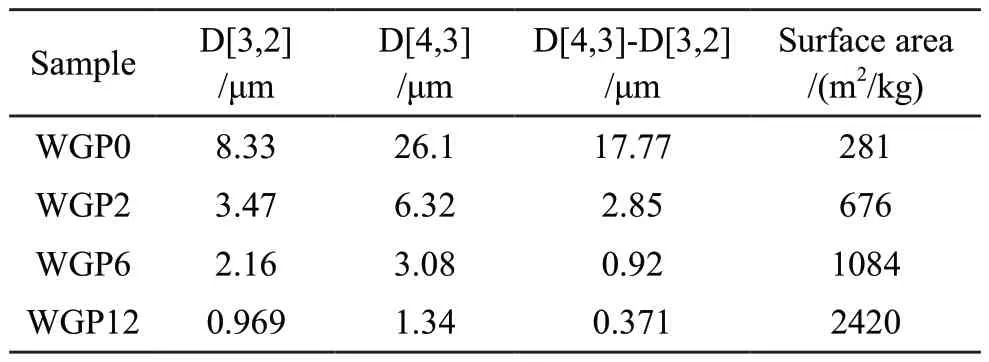

Table 3 Parameters of WGP particles under different wetgrinding durations

Fig.3 Ions dissolution behavior of WGP slurry under different wetgrinding times

The leaching characteristics of WGP after different wet-grinding durations are shown in Fig.3.As can be seen, the concentrations of Si, Ca, and Al increased with the wet-grinding duration.The Si concentration is the highest of all measured ions because of the chemical composition of WG.It is worth noting that high alkali environment could be realized by the wet-grinding treatment due to the significant increment in Na+and K+concentrations as the wetgrinding duration was prolonged.According to our previous research, the dissolved Si phase could set prehydration environment and promote the precipitation of C-S-H gel.Furthermore, the higher alkalinity of WGP slurry caused by dissolution of Na+and K+will promote Si-O bond fracture to accelerate the dissolution of C3S and C2S[29,30].In terms of reaction dynamics, OH-caused by wet-grinding is beneficial to the nucleation of calcium hydroxide which leads to the reduction of Ca2+concentration, and thus promotes the precipitation of C-S-H[31].Based on the aforementioned understanding,the ions dissolution behavior attributed to wet-grinding not only provides an ions rich environment to form hydration products, but creates an alkali environment to accelerate the hydration rate of cementious materials.

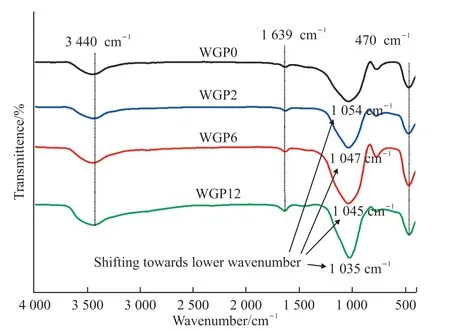

Fig.4 FTIR spectra of WGP under different wet-grinding time

FTIR spectra corresponding to WGP with different grinding durations are shown in Fig.4.The peaks located at 3 440 and 1 639 cm-1are attributed to the stretching vibration of O-H and bending vibration of H-O-H, respectively[32].It is interesting to note that the intensities of these bands increased as a function of wet-grinding duration.This variation was mainly because of the breaking of Si-O bonds in WGP structure and the formation of Si-OH group during wetgrinding process.Similar results were found in our previous work about the effect of wet-grinding on the structure of silicate solid waste[33].The absorption peaks around 470 cm-1is assigned to the symmetric bending vibrations of Si-O-Si.The strong band between 800 and 1 250 cm-1is related to the SiOnstructural units.A shifting of Si-O band towards lower wave number with the increasing wet-grinding duration was observed.The variation in Si-O band energy (△E) was calculated as follows[34]:

where,his the Plank’s constant,cthe velocity of light,v1andv2the wave numbers of the silicon oxide bond of WGP before and after wet-grinding, respectively.

The results presented that the Si-O bond energy of WGP2, WGP6, and WGP12 was decreased by 0.86× 10-3, 1.16 × 10-3, and 2.35 × 10-3eV compared to WGP0.It implies that wet-grinding treatment dramatically decreased the stability of Si-O bond, and contributed to the further hydration of WGP in alkali condition.

3.2 Mechanical property of cement-based materials

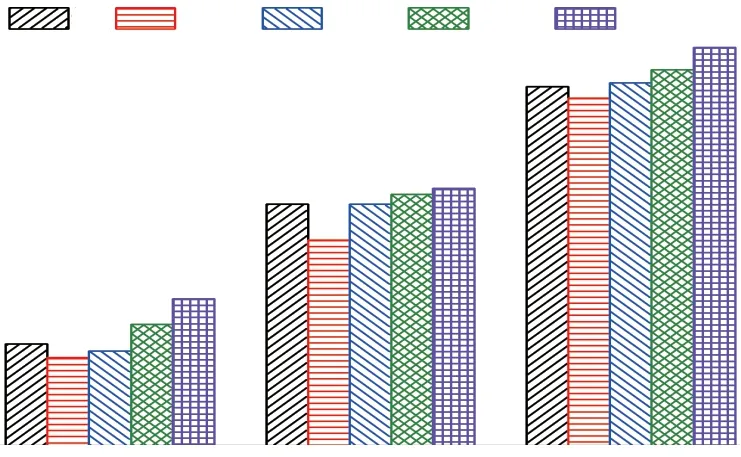

The effect of WGP particle size on the compressive strength of cement mortars was investigated and the results are shown in Fig.5.It can be seen that the compressive strength of specimens increased with a reduction of WGP fineness.The specimen WGP0 presented the lowest compressive strength at all ages.For instance, the strength of reference specimen PC at 1 d was 13.6 MPa, which decreased to 11.8 MPa when WGP0 was incorporated,and the compressive strength at 28 d decreased from 47.7 to 46.2 MPa.This is mainly due to the low activity of WGP in alkali condition and poor filling effect of WGP particles in the matrix.Our previous work[1]proved that WGP could promote the hydration of cement when its particle size is lower than 5 μm.

Fig.5 Compressive strengths of cement mortars

The compressive strength of specimens containing WGP2, WGP6, and WGP12 at 1 d was 12.7, 16.2,and 19.6 MPa, respectively, which shows an uptrend with the reduction of WGP particle size.It was found that the compressive strength of WGP6 and WGP12 was higher than that of reference ones.Elaqraet al[35]investigated the effect of water immersion of activity of WGP and found that the compressive strength of concrete was enhanced to a certain extent.The reason is that Ca2+and Na+dissolved in water, and improved the alkalinity of pore solution to accelerate the hydration of cement.Meanwhile, finer WGP could be considered as nucleation site in the early stage, and the silicate ions on the surface of WGP particles react with OHto form Si(OH)4.In addition, Na+and Ca2+can react with H3SiO4-and H2SiO4-to form hydrated sodium silicate and calcium silicate gels, which can promote the formation of gel.

At the age of 28 d, the compressive strength of mortars with wet grinded WGP was higher than that of specimen PC, implying that the pozzolanic reaction of WGP seems to play an important role in the mechanical property.The finer particles tend to have higher specific surface area, which could provide more dissolved SiO-4to react with Ca2+in the pore solution of cement paste[36].Moreover, the small particles can play a seeding effect of heterogeneous nucleation for hydration products.

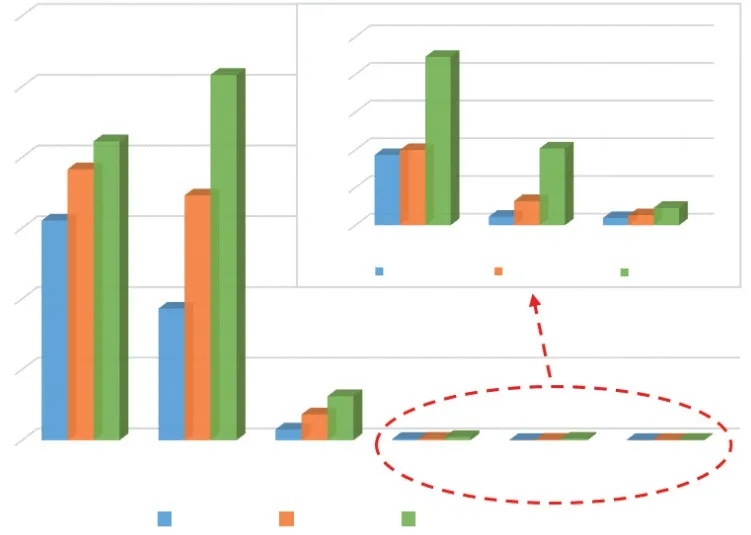

Fig.6 Comparison of activity index of WGP prepared with those of WGP in literatures

The strength activity index was calculated to evaluate the pozzolanic reaction of WGP.The comparison with previous literatures was also performed (as shown in Fig.6[13,20,22,37-39]).The activity indexes at 1 d were calculated as 86.8% for WGP0 and 93.4% for WGP2.It is interesting to find that the activity indexes of WGP6 and WGP12 are as high as 119.1% and 144.1%.The comparison of the values in this study with those of WGP in literatures indicate that wet grinded WGP at 28 d has higher activity index(101.0%, 104.6%, and 110.9%).It can be conducted that the prepared WGP has good pozzolanic activity and could be potentially applied as supplementary cementitious materials in construction and building materials.

3.3 Hydration products of cement-based materials

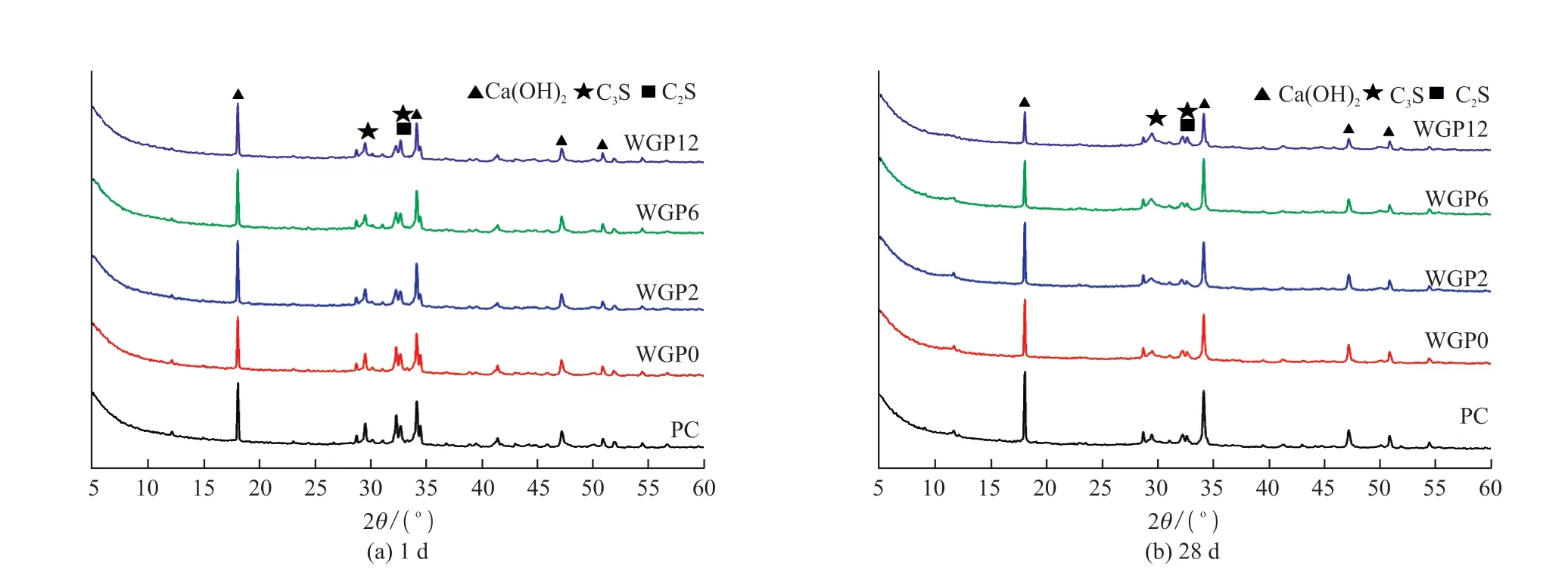

The XRD patterns of samples at curing age of 1 and 28 d are presented Fig.7.As can be noticed,the main crystalline phases in hardened pastes were identified as portlandite and C-S-H gel originated from cement hydration.The unhydrated C3S and C2S were also detected in all specimens.

In the early hydration period, the variation of C3S and C2S can indirectly reflect the stimulation effect of WGP on cement hydration process.The important observation was that the intensity of unhydrated minerals peaks decreased obviously with the increase of WGP grinding duration, indicating that wet grinded WGP can significantly promote the hydration of cement.The increase of peak intensity of portlandite can also be observed simultaneously.It was apparent that finer WGP treated by wet-grinding leads to more reaction products.

After 28 d of reaction, the peak intensity of portlandite greatly decreased with the reduction of WGP fineness, proving that the pozzolanic reaction of WGP was dramatically improved by wet-grinding to form more reaction products which was in accordance with the mechanical property analysis.

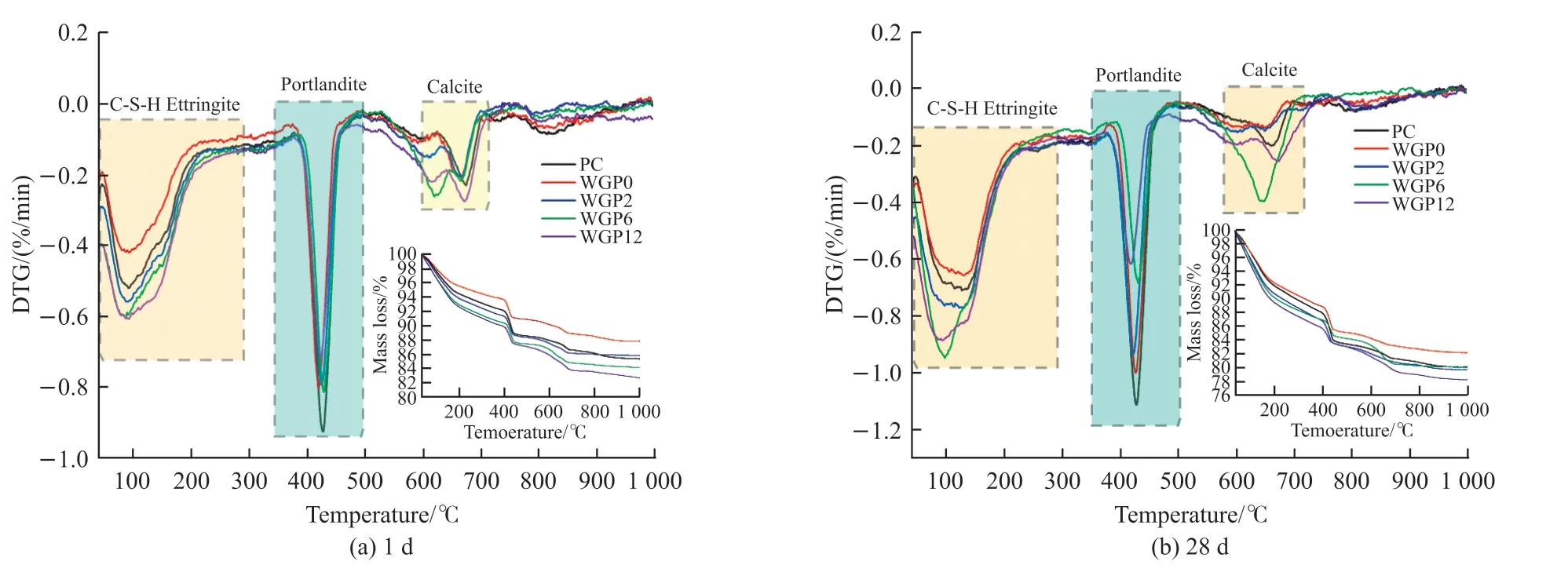

The TG-DTG curves of specimens with diff-erent WGP are given in Fig.8.Evidently, all specimens exhibit three significant mass loss ranges in DTG curves.The mass loss between 40 and 200℃ is attributed to the evaporation of free water and decomposition of reaction products,eg, ettringite,calcium silicate hydrate gel[40].The mass loss in the range of 400 - 500 ℃ is mainly due to the dehydration of calcium hydroxide.Besides, the mass loss caused by decomposition of calcite at 550 - 750 ℃ can be seen clearly.

Fig.7 XRD patterns of hardened specimens containing WGP

The quantitative analysis was carried out on the hardened pastes with and without WGP.The hydration degree of cement can be reflected by quantification of chemically bound water (Wn) and calcium hydroxide(CH).The mass loss at 400-500 ℃ is dehydration of calcium hydroxide (CH1).Therefore, this content could be calculated as follows:

where,Wis the weight (%) at corresponding temperature, andmH2OandmCHthe molecular weights of water and CH, respectively.Because CH in the samples can react with CO2in the air to generate CaCO3which is decomposed at 550-750 ℃, the total production of CH can be adjusted as follows:

According to the Ref.[41], the initial temperature of was selected to be 130 ℃ to calculate the chemically bound water:

where,Wnis the chemically bound water (%);LOIthe loss on ignition for received cement.

Fig.8 TG-DTG curves of hardened specimens containing WGP

When the cement is completely hydrated, the chemically bound water isWn,∞(0.23Ccem),Ccemis the cement content (%) in the paste.The reaction degree (α)of cement can be calculated as follows:

Quantitative analysis results are depicted in Table 4.The weight loss between 40 - 200 ℃ was decreased after the incorporation of WGP0 due to the dilution effect and low reactivity of WGP particles.However,the weight loss increased dramatically when wetgrinded WGP was employed.This result corresponds very well with the findings of XRD and compressive strength.Chemically, the reaction of WGP in alkali environment is a process in which the siliceous components is first dissolved and then precipitated.In this regard, the reduction of Si-O bond energy proved by FTIR, is beneficial for the pozzolanic reaction of WGP particles.The effect of wet-grinded WGP particles on the heterogeneous nucleation of reaction products would be another reason for the increase of mass loss.

Table 4 Quantitative analysis of WGP-cement composite cement-based materials

The CH content of samples containing wetgrinded WGP after 1d reaction is notably higher than that of samples with WGP0.This can be attributed to the fact that the dissolved alkali-metal ions in wetgrinded WGP paste promoted the reaction of C3S and the nucleation of CH.But the CH content of sample WGP12 was slightly decreased compared with the WGP6 sample.This indicates that WGP12 has a rather high pozzolanic activity in the very early period.After 28 d of reaction, CH content decreased with the reduction of WGP fineness, which indicated an enhancement in WGP reactivity caused by wetgrinding.

In terms of hydration degree (α), an obvious increase in the α value can be observed.Take α at 28 days for example, the α of specimens with WGP2(65.36%), WGP6 (66.39%), and WGP12 (67.32%)is greatly higher than specimen containing WGP0(54.40%).The increase of α of cement is favorable for WGP efficient utilization in cement-based materials.

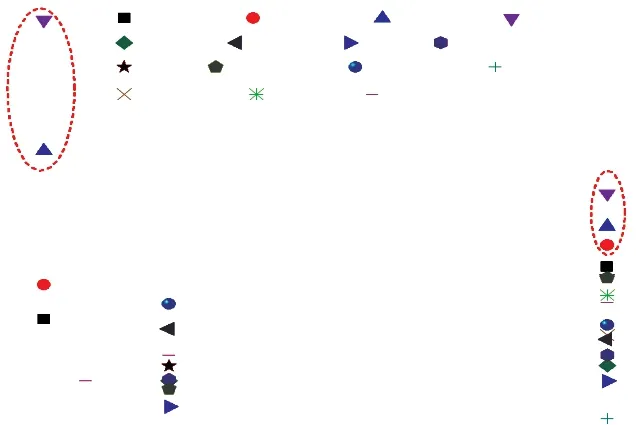

3.4 Microstructure of cement-based materials

The microstructure development of hardened pastes with WGP as function of grinding duration is shown in Fig.9.It can be seen that the compactness of specimens was improved as the decrease of WGP particle size.The loose and porous structure of reference specimen PC was clearly visible (Fig.9(a)).From Fig.9(b), specimen WGP0 presented more compact structure with large quantity of unreacted WGP embedded in the hydration products.It is obvious that WGP particles still have smooth surface and only corner / edge was eroded by CH.In Figs.9(c)-9(d), the wet-grinded WGP particles were uniformly distributed in the hardened matrix.Furthermore, the WGP particles were seriously eroded by alkali to form C-S-H gel which can be observed on the WGP surface, confirming the high pozzolanic activity of wet-grinded WGP.Compared to specimen WGP6,sample WGP12 presented more hydration products and denser structure, as shown in Fig.9(e).The influence of WGP12 on the microstructure of specimen at 1d was also monitored to verify its reaction characteristic in the early stage (Fig.9(f)).It can be found that the WGP particles surface was surrounded by hydration products due to the reaction of WGP.

The above results indicate that the amount of unreacted WGP decreased with prolongation of grinding time, proving that WGP dissolution rate is also improved to generate more hydration products as the wet-grinding duration increased.

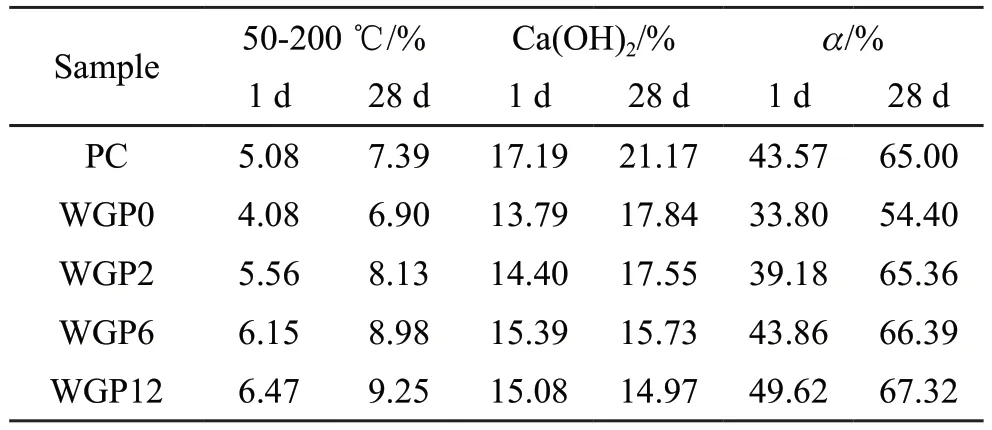

In this work, the pores are divided into gel pore(<10 nm), fine capillary pores (10-50 nm), middle capillary pores (50-100 nm) and large capillary pores(>100 nm).The pore size distribution of mixtures with WGP as function of wet-grinding duration is presented in Fig.10.Specimen PC at 1 d shows a most probable pore size of 76.74 nm, which increased to 677.71 nm when WGP0 was added.Evidently, wet grinded WGP can dramatically reduce the pore size of WGP-cement pastes.The most probable pore size at 1 d decreased from 96.65 to 13.40 nm as the wet-grinding duration increased from 20 to 120 min.Similarly, the most probable pore size at 28 d reduced from 70.18 to 6.85 nm if the grinding time reached 60 min.

The above results prove that wet-grinding treatment can dramatically improve the compactness of hardened pastes containing WGP to the benefit of mechanical development.

Fig.9 SEM images: (a) PC 28 d; (b) WGP0 28 d; (c) WGP2 28 d; (d) WGP6 28 d; (e) WGP12 28 d; (f) WGP12 1 d

Fig.10 Pore size distribution of pastes with WGP as function of grinding duration

The pore volume fraction of specimens with and without WGP was calculated, as shown in Fig.11.At the age of 1 d, fine capillary pores (10-50 nm), middle capillary pores (50-100 nm), and large capillary pores(>100 nm) are the dominant pore type.The proportion of large capillary pores for specimen with WGP2 is 50.29% which is over twice that of PC.The proportion of large capillary pores for specimens WGP6 and WGP12, however, is 33.02% and 26.21% that are similar to cement.Meanwhile, the gel pores volume fraction of WGP6 and WGP12 is 13.78% and 15.05%,which are almost twice that of PC (7%).

At the age of 28 d, the gel pores and small capillary pores volume fraction of WGP2, WGP6, and WGP12 are all higher than that of PC, especially the gel pores.The trend of pore volume fraction variation shows that the addition of WGP significantly reduced the capillary pores and increased the gel pores of specimens.Not only the WGP particles could improve the generation of hydration products, but the pozzolanic reaction of WGP at later age could produce secondary C-S-H gel to fill the pores.The result has also explained the higher compressive strength of specimens containing WGP2, WGP6, and WGP12 at 28 d.

Fig.11 Pore volume fraction of WGP-Cement specimens

Fig.12 Illustration for operational principle of wet-grinded WGP

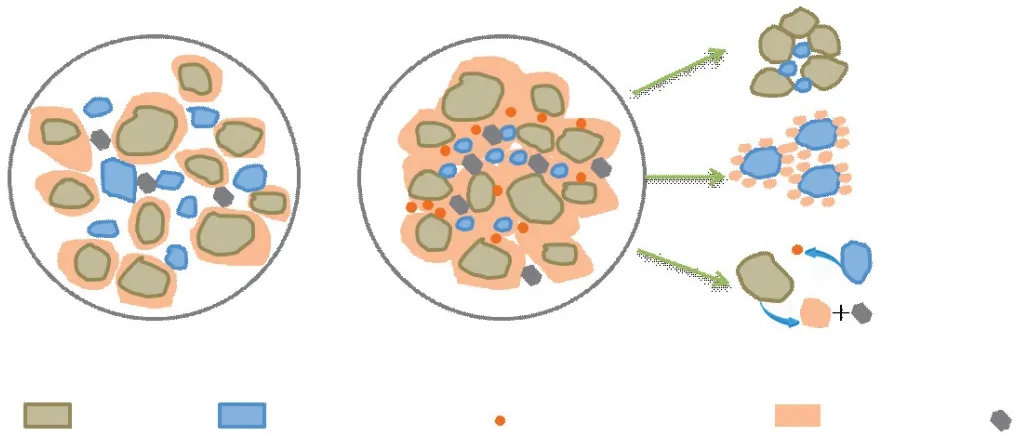

3.5 Discussion

WGP particle without wet-grinding has dense structure, which is an adverse factor for the pozzolanic reaction of WGP in the alkali environment.In addition,the non-hydrophilic and smooth characteristics of WGP surface are liable to cause water seepage during the hardening process of fresh pastes.Thus the mechanical property and microstructure of cementitious materials containing WGP cannot hold a candle to reference sample PC.

For wet-grinded WGP, the operational principle can be understood from the chemical and physical evolutions.The operational principle is illustrated in Fig.12.Physically, fine WGP particle is beneficial to densify the microstructure of hardened paste by pore filling effect (Figs.10 and 11).The fine particles also can act as crystallization nucleus which would be helpful for the heterogeneous nucleation of hydration products.In addition, the leached alkali metal ions decreased the solubility of CH and promoted the precipitation of CH crystal, and then accelerated the hydration speed of cement.Chemically, high alkali environment caused by the leaching of Na+and K+can promote the breaking of Si-O bond in C3S and C2S, hydroxylate the clinker surface and accelerate the dissolution rate of cement particles.The reduction of Si-O bond energy after wet-grinding (Fig.4) is helpful for the bond breaking of Si-O-Si in WGP during the reaction to form more hydration products.As mentioned above, the mechanical property and microstructure of cementitious materials with WGP can be improved due to the physic-chemistry effect of wetgrinding.

4 Couclusions

a) Wet-grinding can refine WGP particles,improve the leaching of effective ions and decrease the stability of Si-O bond.The compressive strength of mortars containing wet-grinded WGP was higher than that of reference ones.Pozzolanic reactivity of WGP was dramatically improved after wet-grinding.The WGP after 120 min grinding showed an activity index of 144.1% at 1 d and 110.9% at 28 d.

b) The wet-grinded WGP greatly accelerated the hydration process of cement and presented high pozzolanic reactivity in the early hydration stage when grinding time reached 120 min.

c) Through SEM and MIP analysis, the compactness of specimens was improved with the decrease of WGP particle size.Wet-grinding can greatly promote the transformation of capillary pores to gel pores in cement system regardless of the reaction time, which are helpful for the development of mechanical property.The wet-grinded WGP has good pozzolanic activity and could be potentially applied as supplementary cementitious materials in construction and building materials.

Conflict of interest

All authors declare that there are no competing interests.

杂志排行

Journal of Wuhan University of Technology(Materials Science Edition)的其它文章

- Enhanced Electrochemical Performances of Ni Doped Cr8O21 Cathode Materials for Lithium-ion Batteries

- Design on the Prestressed Concrete Frame Beam-column

- Synthesis and Flocculation of Polyacrylamide with Low Water Absorption for Non-dispersible Underwater Concrete

- Experimental Behavior of Recycled Aggregate Concrete Filled Steel Tubular Columns

- Impact-abrasive Wear Behavior of ZTA and NbC Reinforced Fe60 Matrix Composites

- Synthesis and Characterization of Hollow Strontium Carbonate Pompons by Composite Soft Template Method