Effect of Curing Age on Tensile Properties of Fly Ash Based Engineered Geopolymer Composites (FA-EGC) by Uniaxial Tensile Test and Ultrasonic Pulse Velocity Method

2024-01-03GUOXiaoluLIShuyue

GUO Xiaolu, LI Shuyue

(1. Key Laboratory of Advanced Civil Engineering Materials of Ministry of Education, Tongji University, Shanghai 201804, China; 2. School of Materials Science and Engineering, Tongji University, Shanghai 201804, China))

Abstract: Tensile properties of fly ash based engineered geopolymer composites (FA-EGC) at different curing ages were studied by uniaxial tensile test and ultrasonic pulse velocity (UPV) methods, which included uniaxial tensile properties, the correlation between ultrasonic pulse velocity and tensile properties, and characteristic parameters of microcracks.The experimental results show that obvious strain hardening behavior can be found in FA-EGC at different curing ages.With the increase of curing age, the tensile strength increases,the tensile strain decreases and the toughness becomes worse.The UPV of FA-EGC increases with curing age,and a strong correlation can be found between tensile strength and UPV.With the increase of curing age, the average crack width of FA-EGC decreases and the total number of cracks increases.This is because the strength of geopolymer increases fast at early age, thus the later strength development of FA-EGC tend to be stable.At the same time, the bond strength between fiber and matrix, and the friction of fiber / matrix interface continue to increase with curing age, thus the bridging effect of fiber is gradually strengthened.In conclusion, the increase of curing age is beneficial to the development of tensile properties of FA-EGC.

Key words: engineered geopolymer composites (EGC); tensile properties; ultrasonic pulse velocity(UPV); characteristic parameters of microcracks

1 Introduction

The low tensile strength and fracture toughness of ordinary concrete make its cracking problem more and more prominent under load and environmental effects, which leads to the hidden dangers of durability and safety of many concrete structures[1].In order to overcome the shortcomings of easy cracking and poor toughness of concrete, L MDet al[2]proposed a performance driven method based on micromechanics to adjust the microstructure of engineered cementitious composites(ECC).The designed ECC has the characteristics of high toughness and strain hardening,which has been used in some civil engineering projects.The strain capacity of ECC is between 3%-7%[3], which is 500-600 times higher than that of ordinary concrete.However, the higher cement content using in ECC usually leads to the problems of high shrinkage, high hydration heat and high cost[4].In addition, the energy consumed and the greenhouse gases emitted in the production of cement have negative impacts on global resources, environment and climate[5].Geopolymer with fly ash as the main raw material has the characteristics of ceramics, cement, and polymer materials.It is a green and economical cementitious material that can partially replace cement, for the CO2produced in the production of raw materials and the consumption of resources are far less than that of cement[6].Therefore,combining the respective advantages of geopolymer and ECC, developing engineered geopolymer composites (EGC) with geopolymer as the cementitious material instead of cement in ECC can provide a way to reasonably solve the above problems.

Geopolymer is a chemically activated material with high early strength[7], thus the curing age has a great impact on the tensile properties of EGC.Kan LLet al[8]studied the tensile properties of EGC at 1,3, 7, 28, 56, and 120 d, and the results show that the tensile strength of the EGC first increases and then tends to be stable with the increase of curing age,reaching the maximum at 56 d, and the tensile strain and initial crack strength also show the same trend.However, another research done by Kan LLet al[9]obtained results inconsistent.It was found that the tensile strength and tensile strain of EGC increase and decrease with the increase of curing age, respectively.Other scholars[10,11]studied the relationship between ultrasonic pulse velocity and strength of concrete materials at different curing ages (5, 7, 28, 56 d, and 14,28, and 60 d, respectively), and found that there is a strong correlation between them.In recent studies,there is no general agreement on the effect of curing age on the tensile strength and tensile strain, and few studies focus on the correlation between UPV and tensile properties.

In order to further study the effect of different curing ages on the tensile properties of fly ash based engineered geopolymer composites (FA-EGC).Stressstrain curve of FA-EGC cured to different curing ages(3, 7, 14, and 28 d) was obtained through uniaxial tensile test.Based on that, initial cracking strength,ultimate strength and ultimate strain at different curing ages were obtained.In addition, the correlation between ultrasonic pulse velocity (UPV), and tensile strength of FA-EGC at different curing ages was explored.Meanwhile, different functions (linear function,quadratic function, and exponential function) were used for fitting.And the distribution of cracks (including the number of cracks, average crack width, and maximum crack width,etc.) was counted and compared.

2 Experimental

2.1 Raw materials

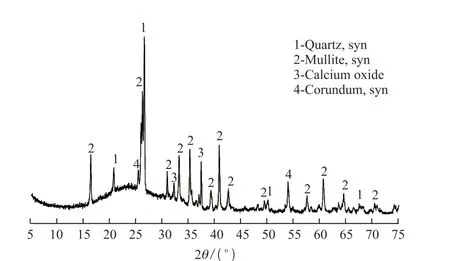

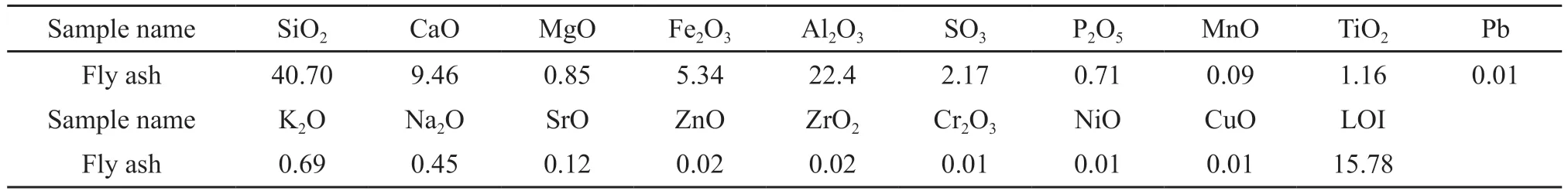

The main chemical compositions of fly ash measured by X-ray fluorescence spectrometry(XRF)are SiO2, CaO, Fe2O3and Al2O3(shown in Table 1),and the main phase components measured by X-ray diffraction(XRD) are quartz (SiO2), mullite (Al6Si2O13),calcium oxide (CaO) and corundum (Al2O3) (shown in Fig.1).Japanese kololi PVA fiber was adopted, and the main technical parameters are shown in Table 2.The solid content of sodium silicate used to prepare compound alkali activator is 42.7wt% and the initial modulus is 2.25.The purity of NaOH is 96.0%.And NaOH is used to adjust sodium silicate, and configure compound alkali activator with modulus of 1.5.

Fig.1 XRD pattern of fly ash

2.2 Mix proportion design

This research was carried out based on the mix proportion design of fly ash based engineered geopolymer composites (FA-EGC) by our previous studies[12], in which the content of sodium silicate is 6% (calculated based on the content of Na2O in sodium silicate), the water to solid ratio is 0.35 and the content(volume fraction) of fiber is 1%.

2.3 Preparation and curing of samples

The preparation process of FA-EGC samples refers to the cement mortar.In order to make the fiber have good dispersion, the fiber and fly ash were poured into the mixing pot for pre mixing for 60 s.After mixing evenly, water and compound alkali activatorwere added and fully mixed in the cement mortar mixer.The mixed slurry were poured into the mold(as shown in Fig.2(a)), and vibrated on the vibrating table, then the mold was removed after the “dog bone” sample (as shown in Fig.2(b)[12,13]was cured in the standard environment for 24 h, and then kept somples in the standard environment for curing to the corresponding age.

Table 1 Chemical compositions of fly ash/%

Table 2 Main technical parameters of polyvinyl alcohol(PVA) fiber

Fig.2 Mold object and sample specification of “dog bone” sample

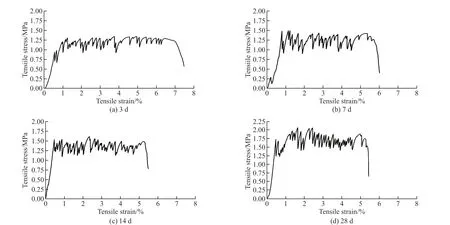

Fig.3 Stress-strain curves of FA-EGC at different curing ages

2.4 Test method and process

The CMT (model 4204) universal testing machine was used to conduct uniaxial tensile test on the sample according to the Tensile Test Method for Metallic Materials at room temperature (GB/T 228-2002) to obtain force-displacement curve, and the tensile rate was controlled to 0.4 mm/min.

The ultrasonic pulse velocity of the sample was measured by ZBL-U520 non-metallic ultrasonic detector.

The basic characteristics of cracks (including total number of cracks, width of each crack, and maximum crack width) on each sample were observed and counted by digital microscope, and the measurement gauge distance is 80 mm.

3 Results and discussion

3.1 Stress-strain curves

After FA-EGC samples were cured to 3, 7, 14, and 28 d, respectively, uniaxial tensile test was carried out to obtain the force displacement curve the full stressstrain curve of each group of samples was calculated,as shown in Fig.3.

According to Fig.3, the uniaxial tensile process of FA-EGC samples at different curing ages conforms to the initial cracking stress criterion[14], which is composed of three stages: linear elastic stage, strain hardening and multi cracking development stage, and crack local propagation stage.And with the extension of curing age, tensile strength shows an increasing trend from 3 to 28 d, while tensile strain decreases with the increase of curing age from 3 d to 14 d and tensile strain of 28 d shows little change compared with that of 14 d.

3.2 Tensile properties

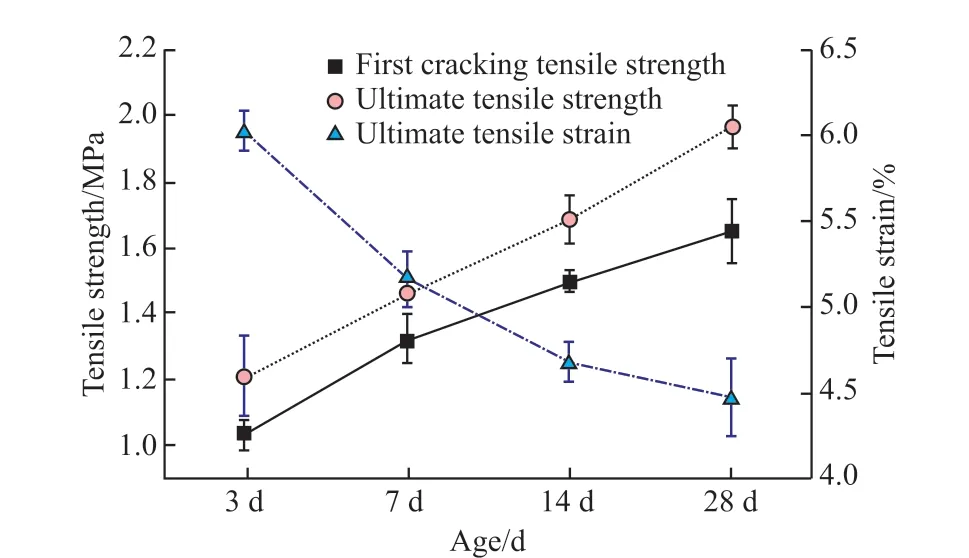

Based on the full stress-strain curve of FA-EGC samples at different curing ages, the changes of first cracking tensile strength, ultimate tensile strength and ultimate tensile strain with curing age were obtained, as shown in Fig.4.

Fig.4 Tensile properties of FA-EGC at different ages

It can be seen from Fig.4 that the ultimate strain of 3, 7, 14, and 28 d samples can reach more than 4%,meeting the ultimate strain standard of high ductility materials(strain > 3.0%)[3], and even the ultimate strain of 3 and 7 d is more than 5.0%.The specimen with the largest strain is 3 d sample, and its average extreme strain is even higher than 6.0%, which is 6.03%.Results above indicate that all samples show good tensile properties and high toughness.Compared to the tensile properties of ECC studied by Wu HLet al[15],tensile strain of FA-EGC is higher than that of ECC,and first cracking tensile strength and ultimate tensile strength are lower than that of ECC at 28 d, but are still at good levels, which illustrates the potential of partial replacing ECC with FA-EGC.

With the extension of curing age, the first cracking strength and ultimate strength show an increasing trend.The average first cracking strength of 28 d samples is 58.7%, 25.0% and 10.7% higher than that of 3, 7, and 14 d samples, respectively.And the average ultimate strength is 63.3%, 34.2%, and 16.0% higher than that of 3, 7, and 14 d samples, respectively.While the ultimate strain decreases, as the average ultimate strain of samples for 7, 14, and 28 d is 14.3%, 22.4%, and 25.9% lower than that of 3 d specimens respectively.This change trend above is similar to that of Kan LLet al[9].The reason why the ultimate strength of the sample increases with the extension of curing age is speculated as follows: the ultimate strength of FA-EGC is jointly determined by the interaction among matrix, fiber and fiber / matrix interface.With the increase of curing age,the matrix strength increases, the grip degree between fiber and matrix will also increase, so that the bond strength and the interfacial friction between fiber and matrix increases as well.It means the bridging effect of fiber also increases gradually, thus the ultimate strength increases.

In addition, the slope of the ultimate strain curve of the sample is the smallest from 3 to 7 d and the largest from 14 to 28 d, indicating that the decrease of the ultimate strain is the most obvious in the early 3-7 d and the decreasing range is the smallest in the later 14-28 d.And the decreasing range decreases with the increase of curing age.The first cracking strength and ultimate strength show a similar trend, which increase gradually with the increase of curing age.From 3 d to 7 d, the increase of the first cracking strength of the samples is greater than that of the samples from 7d to 28 d.This is because geopolymer has high early strength[7], Wang SL[16]found that the compressive strength of fly ash based geopolymer samples curing under room temperature can reach nearly 40.0 MPa in 1 d and 71.3 MPa in 5 d, and its early strength increases rapidly, but the strength increases very slowly after 5 d.Rahimahet al[17]tested the compressive strength of fly ash based geopolymers curing at room temperature and high temperature respectively.It was found that the compressive strength of samples curing at room temperature for 7 d can reach 70%-80% of that of 28 d, while the early strength of samples curing at high temperature increases more significantly, for the compressive strength of 1 d could reach 80% of that of 28 d.Due to the high early strength of geopolymer, the earlier the age, the greater the increase of first cracking strength.This phenomenon reflects the strain hardening rule of EGC material, that is, with the increase of curing age, the samples continuously harden, the strength increases and the toughness decreases.

3.3 Ultrasonic pulse velocity (UPV)

The UPV of FA-EGC at different curing ages (3, 7,14, and 28 d) is shown in Fig.5.

According to Fig.5, the UPV of FA-EGC increases with the increase of curing age.The UPV of samples at 7, 14, and 28 d increased by 4.4%, 14.4%,and 24.3% respectively compared with that at 3 d.This trend is similar to that of the change of ultimate tensile strength with curing age, both positively correlated with age.This is because with the increase of curing age, FA-EGC samples continue to geopolymerize, and the generated geopolymerization products continue to fill the pores in the matrix.As a result, the porosity continues to decrease and the matrix structure is gradually dense[8,9].And the propagation speed of ultrasonic wave in air is significantly lower than that in solid, thus, the time of ultrasonic transmission gradually shortens and the UPV gradually increases.Moreover, when the curing age increases, the bond strength and the interfacial friction between the fiber and the matrix as well as the compactness of the matrix continue to increase, thus the tensile strength of the sample also increases.This synergistic growth effect provides a good prerequisite for the fitting of UPV and tensile strength.

Fig.5 UPV of EGC at different curing ages

Fig.6 Function fitting curves of FA-EGC tensile strength and UPV

On this basis, 3 different functions (linear function, quadratic function and exponential function)were used to fit the tensile strength and UPV of samples at different curing ages.The results are shown in Fig.6.

It can be seen from Fig.6 that the tensile strength and UPV of FA-EGC have a strong correlation.With the increase of curing age, the tensile strength and UPV of the sample continue to increase, and each data point is densely distributed around the 3 function curves.The correlation coefficientsR2of the 3 functional relations are 0.963, 0.954 and 0.959, respectively, which are very close to 1.Among them, the fitting degree of linear function is higher.

3.4 Cracks characteristics

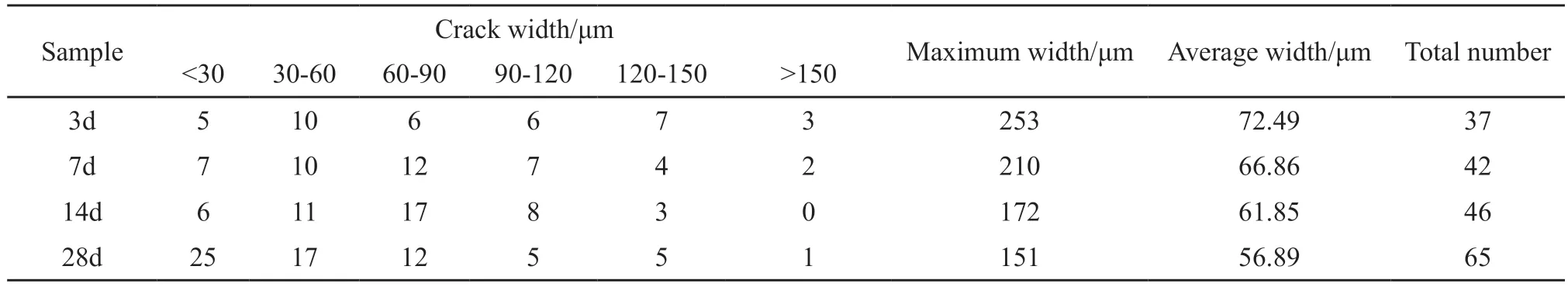

The number and width of cracks after uniaxial ten-sile test failure of FA-EGC materials can indirectly reflect the tensile properties of the material.The crack characteristics of FA-EGC samples curing to different curing ages and completing uniaxial tensile test were counted, including the number of cracks in different width ranges, maximum crack width, average crack width and total crack number, as shown in Table 3.

According to Table 3, the crack width of the sample curing for 28 d is concentrated below 60 μm,and the number of cracks in this range accounts for 64.6% of the total.The crack width of 14 and 7 d samples is mostly concentrated between 30 and 90 μm, accounting for 60.9% and 52.4% of the total,and especially in the range of 60-90 μm it is more distributed, which is more than 1/3 of the total.The crack width of 3 d sample is more widely distributed,even in the range of 120-150 μm the proportion is still as high as 18.9%.In conclusion, with the increase of curing age, the crack width gradually moves towards a smaller width, and the later age sample contains more cracks with the width below 30μm, the early age samples contain more large cracks with the width above 120 μm.

At the same time, with the increase of curing age,the maximum crack width and average crack width of the sample show a decreasing trend.The maximum crack width and average crack width of 28 d samples are 40.3%, 28.1%, 12.2% and 21.5%, 14.9%, 8.0%lower than those of 3, 7, and 14 d samples, respectively.The total number of cracks shows the opposite trend and increases with curing age.The total number ofcracks of 28 d samples increases by 73.0%, 52.4%, and 39.1% compared with 3, 7, and 14 d samples.

Table 3 Crack characteristics of FA-EGC samples at different curing ages

In conclusion, the longer the curing age, the more the number of cracks and the smaller the crack width of FA-EGC sample.The reason may be that the growth of curing age leads to further geopolymerization of FA-EGC samples, making the microstructure of the material more compact.Moreover, because geopolymer has high early strength[16], the strength of the material develops to a stable period at 7 d or earlier, and the matrix strength increases slowly, meanwhile the bond strength between fiber and matrix and the friction of fiber / matrix interface increase with curing age, so that the bridging effect of fiber is gradually strengthened.Therefore, it is more conducive to the generation of microcracks and the development of tensile properties.

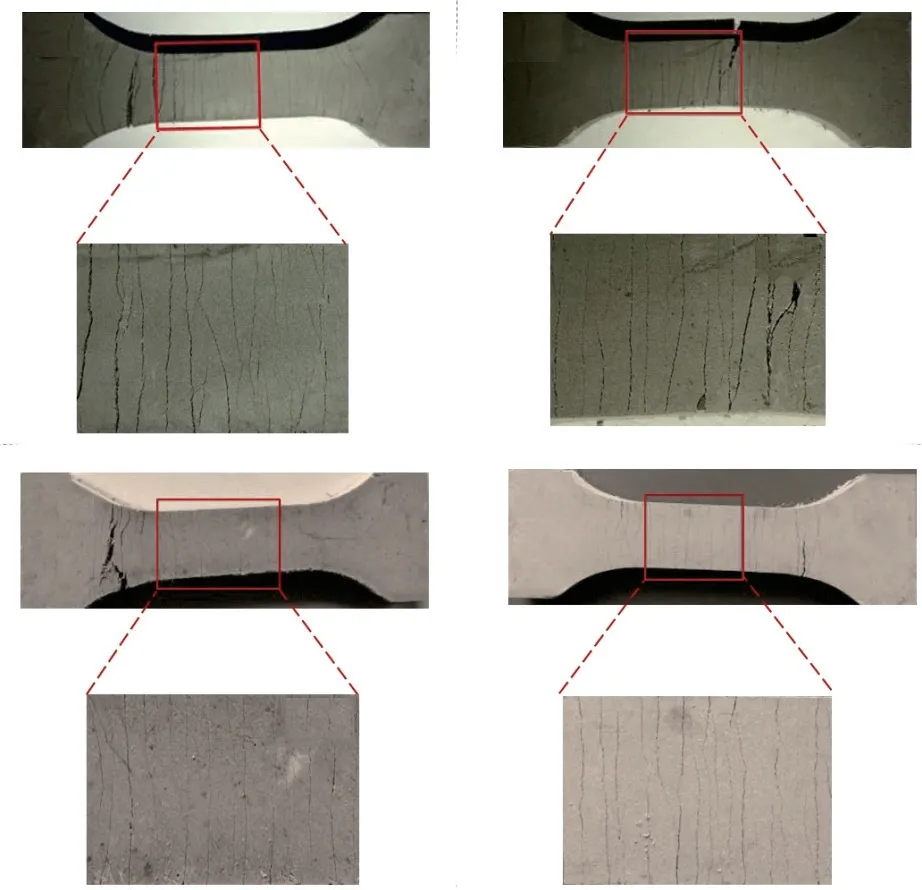

Fig.7 Crack morphologies of FA-EGC at different curing ages: (a1:3 d, a2: partial enlarged drawing of a1, b1: 7 d, b2: partial enlarged drawing of b1, c1: 14 d, c2: partial enlarged drawing of c1, d1:28 d, d2: partial enlarged drawing of d1)

Fig.7 shows the crack morphology of samples at different curing ages after uniaxial tension.With the increase of curing age, the number of cracks gradually increases and the space between cracks gradually decreases.The crack width of 14 and 28 d samples obviously decreases, and the crack distribution is more uniform and compact than that of 3 and 7 d samples.

In addition, the cracking trends of samples at different curing ages are different.The crack development directions of 14 and 28 d samples are basically the same, of which most of the cracks are in a straight state and perpendicular to the tensile direction,and simultaneously the intersection between cracks is also significantly reduces, which hinders the further development of crack width and is conducive to the development of tensile properties of samples.However,the crack development direction of 3 and 7 d samples is random, and some cracks overlap into cracks with large width.Even the cracks in the middle of the sample are curved instead of straight, and not perpendicular to the stress direction.Xu S Z[18]compared and observed the multi crack cracking forms of the two notch samples,and found that when the width of the bilateral notch is small, a number of evenly distributed fine cracks are generated on the test block; when the width of bilateral notch is large, the cracks are no longer distributed in parallel, but in an arc curve around the notch.This is because the number and width of cracks cause its deformation.The multi cracking form with more cracks and small width is better than the cracking form with less cracks and large width.In this study,with the increase of curing age, cracks with relatively small width are mostly formed on the samples, thus the cracks have excellent multi cracking forms and are approximately parallel distributed, which is the same as the multi cracking forms of Xu SZ's small notch samples.

4 Conclusions

In this paper, effects of curing age on the tensile properties of FA-EGC were studied by uniaxial tensile test and ultrasonic pulse velocity methods, the specific conclusions are shown as follows:

a)The uniaxial tensile process of FA-EGC at different curing ages shows obvious strain hardening behavior.

b)The strength of FA-EGC increases with curing age, while the strain and the toughness show the opposite trend.This phenomenon reflects the rule of strain hardening of EGC material.In addition, with the increase of curing age, the increasing range of strength and the decreasing range of strain also decrease, which is related to the high early strength of geopolymer.

c)The UPV of FA-EGC increases as curing age.This is due to the continuous geopolymerization of FA-EGC and the gradual compaction of the matrix structure.At the same time, tensile strength increases with curing age as well.This synergistic growth effect makes tensile strength and UPV of FA-EGC have a strong correlation and linear correlation fits the best.

d)With the increase of curing age, the width distribution of cracks moves towards a smaller width, the average crack width decreases.Meanwhile the total number of cracks increases, and the crack distribution tends to be parallel, uniform and compact.This is because the extension of curing age enhances the bridging effect of fiber, which is beneficial to the generation of microcracks and the development of tensile properties.

Conflict of interest

All authors declare that there are no competing interests.

杂志排行

Journal of Wuhan University of Technology(Materials Science Edition)的其它文章

- Flow Characteristics Analysis of TC18 Titanium Alloy during Hot Deformation Based on Phase Transformation

- Effect of Hydrated Calcium Aluminate Cement on the Chloride Immobilization of Portland Cement Paste

- Expansion Performance and Microstructure of High-performance Concrete using Differently Scaled MgO Agents and Mineral Powder

- A Fiber Optic Sensor for the Simultaneous Measurement of Dual-parameter Based on Hydrogelimmobilized Enzyme Complex

- Energy-dispersive X-ray Spectroscopy for the Quantitative Analysis of Pyrite Thin Specimens

- Bioprocess-inspired Actin Biomineralized Hematite Mesocrystals for Energy Storage