Microstructure, Properties, and Grain Growth Kinetics of Mo-5Ta Refractory Sputtering Targets Prepared by SPS

2024-01-03LIUDaweiYANGXiaolongHUANGLeiPANYafeiZHANGJiuxing

LIU Dawei, YANG Xiaolong, HUANG Lei, PAN Yafei*, ZHANG Jiuxing*

(1. School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China; 2. Engineering Research Center of High-Performance Copper Alloy Materials and Processing, Ministry of Education, Hefei University of Technology, Hefei 230009, China)

Abstract: Mo-5Ta targets were prepared by the spark plasma sintering (SPS) technology under the sintering temperatures of 1 400-1 600 ℃, the holding times of 0-20 min, and the axial pressure of 30 MPa.The microstructure, performance, and grain growth kinetics of Mo-5Ta sputtering targets were studied.With the increase of sintering temperatures and times, Ta can more dissolve in Mo and form a Mo(Ta) solid solution.The grain sizes of Mo-5Ta targets remain unchanged at low temperatures (1 400-1 500 ℃) while increasing significantly at high temperature (1 600 ℃) with the extension of the holding time.In addition, the densities and Vickers hardness (HV0.5) first ascend and then decrease with sintering proceeding.The thermal conductivity is positively correlated with the grain size and density, as a result of their joint action.Based on the comprehensive analysis, the grain growth is dominated by the combination of boundary diffusion and volume diffusion.When n=2, the activation energies of grain growth under holding times of 5, 10, 20 min are calculated as 762.70,617.86, and 616.52 kJ/mol, respectively.

Key words: SPS; Mo-5Ta targets; structure; properties; grain growth kinetics

1 Introduction

Benefitting from high melting point, high thermal conductivity, low impedance ratio and good corrosion resistance, molybdenum is widely used in microelectronics, display, and storage fields, especially flat coating and spin coating systems, such as TFT-LCD, CIGS,ion coating industry,etc[1-7].However, the surface layer of Mo target is prone to discoloration and fall offduring the working process.In addition, its low-temperature plasticity and workability are poor[3].The addition of tantalum can improve the specific resistance,plasticity, corrosion resistance and other properties of Mo target[8,9].Apart from maintaining the performance of Mo, Mo-Ta target also has new applications in electrode wiring films and resistive films[10].According to previous studies[11-13], the purity, density, grain size, and uniformity of composition distribution of the targets have great impact on the manufactured films in the sputtering coating industry.The development trend of Mo-Ta targets is large size, high purity, fine grain and uniform composition distribution[3].Currently, the sintering methods of Mo-Ta targets are mainly induction heating (IH), hot isostatic pressing (HIP) and cold isostatic pressing (CIP),etc[14-17].The specimens manufactured by these methods are often difficult to meet the requirements of sputtering targets in terms of grain size and density, and the effect is not very satisfactory[12,13].

Spark plasma sintering (SPS) technology is a new sintering method that has emerged in recent decades.It directly heats the mold through the combined action of strong pulsed DC current and pressure[18,19].Compared with the traditional sintering methods such as hot pressing (HP) that heats the entire cavity during sintering, SPS has the advantages of fast sintering speed, low sintering temperature and short sintering time[20-23], and is very suitable for densification sintering of refractory metals.

In this research, the Mo-5Ta targets were fabricated by SPS under the sintering pressure of 30 MPa,the sintering temperatures of 1 400 - 1 600 ℃ and the holding times of 0 - 20 min.The effects of sintering temperature and holding time of SPS on the structure,properties and grain growth kinetics of Mo-5Ta targets were investigated.The optimal sintering process for preparing Mo-5Ta targets was determined, which provided an important scientific basis for the preparation of the refractory metal targets.

2 Experimental

2.1 Sample fabrication

The molybdenum powder (particle size: 3 μm;purity: 99.95wt%) and tantalum powder (particle size:10 μm; purity: 99.99wt%) from Beijing Xingrongyuan Technology Co., Ltd.were selected as raw materials.

Mo-5Ta mixed powder was weighed according to the weight ratio and put into a cemented carbide tank for ball milling.The ball milling tank was evacuated and inflated argon in sequence and put into the QMQX omnidirectional planetary ball mill for ball milling.The ball-to-material ratio, milling time, and speed were 10:1, 20 h, and 300 r/min, respectively.

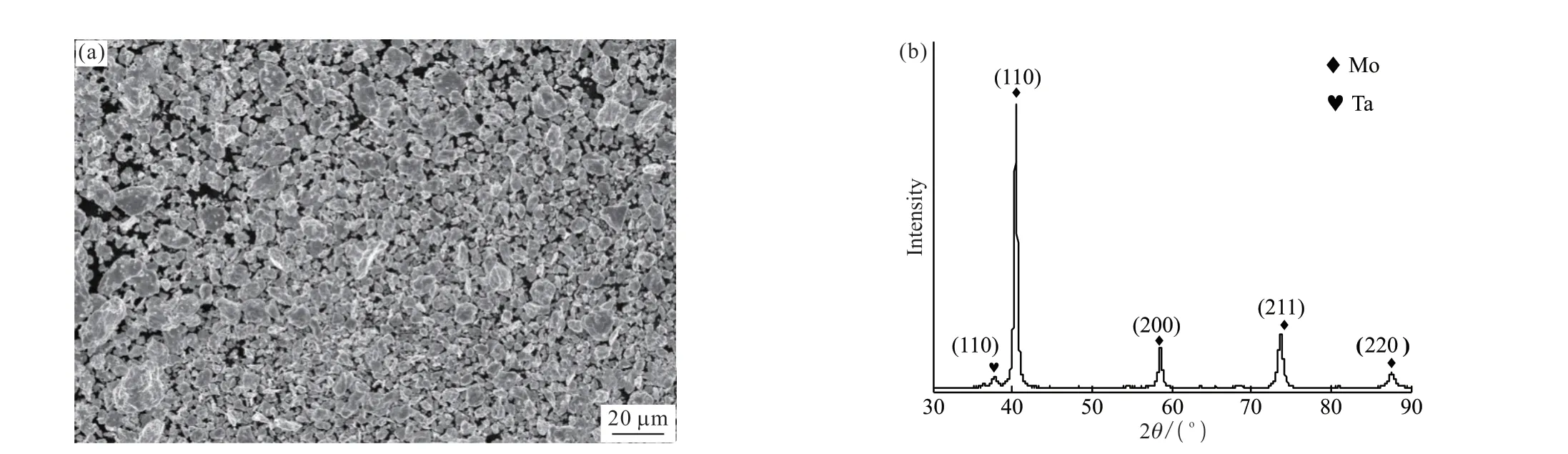

The images of scanning electron microscopy(SEM, Sigma, Zeiss, Germany) and X-ray diffraction(XRD, Smartlab, Riguka, Japan) of the Mo-5Ta mixed powder after ball milling are shown in Fig.1.It can be seen from the Fig.1(b) that the mixed powder was composed of diffraction peaks of Mo and Ta, while only a weak Ta diffraction peak was observed due to its small content.

The Mo-5Ta mixed powder was put into a graphite mold with an inner diameter of 13 mm.For the convenience of demoulding after sintering, a layer of 0.2 mm carbon paper was placed on the positions where the powder contacted the mold and the indenter.Then the mold was compacted on the hydraulic press with a pressure of 5 MPa.The surface of mold was wrapped with a layer of graphite felt to reduce the heat loss during the sintering process.The die was put into the SPS equipment (LABOX-350, Sinterland, Japan)after the above operations were completed.The samples were sintered as the following parameters when the vacuum degree reached 10 Pa.The sintering temperature was set as 1 400, 1 500, and 1 600 ℃ under the holding times of 0, 5, 10, and 20 min with the axial pressure of 30 MPa.The heating rate was scheduled as 100 ℃/min.

Fig.1 (a) SEM image and (b) XRD pattern of Mo-5Ta powder

2.2 Characterization

The sintered samples were sanded and polished.A grinding wheel was used to remove impurities on the surfaces of the samples and make the surfaces smooth.Then, the surfaces of samples were polished through a polishing machine after being ground to 2 000 mesh with SiC sandpapers.The specimens were placed in an ultrasonic instrument for cleaning after the surfaces were smooth and flat.

The density of the samples was calculated by Archimedes drainage method.The theoretical density of Mo-5Ta was calculated as 10.4 g/cm3.Each sample was measured at least 5 times in order to reduce the error.

The hardness of the samples was examined via a Vickers hardness tester (DHV-1000Z) with the loading force of 4.9 N and holding time of 15 s.10-15 points were tested for samples to guarantee authenticity.

XRD was used for phase detection of the samples.The samples were scrubbed with alcohol before the test to ensure that the surface was free of impurities.The scanning range of test varied from 20° to 90°.

The laser thermal conductivity meter was used to measure the thermal conductivity of the samples.The size of the specimen wasΦ12.7 mm × 5 mm.

The polished samples were corroded and the corrosive solvent was ammonia and hydrogen peroxide solution with a volume ratio of 1:1.Then, the surface microstructure of the samples was investigated by SEM equipped with an energy dispersive spectrometer(EDS).

According to the obtained corrosion images, the grain sizes of the samples were counted through “Nano Measure” software, and each sample was counted no less than 100 grains.

2.3 Grain growth kinetics

The sintering temperature and holding time were the main factors affecting the growth of grains in the sintering procedure.Large grain size was often associated with high temperature and long time.The relationships among them are[24]:

Tsarevitch Ivan seated himself on the back of the Wolf joyfully26 enough. Take me, Gray Wolf, he said, to the Fire Bird that stole my father s golden apples, and instantly the Wolf sped away, twenty times swifter than the swiftest horse. In the middle of the night he stopped at a stone wall.

where,t(min) is the holding time,nthe grain growth index,d0anddtthe grain sizes when the holding time are 0 andtmin,K0andKare the constants,Q(kJ/mol)is the activation energy for grain growth,Ris the gas constant, andT(K) is the absolute temperature.

3 Results and discussion

3.1 Phase compositions

The XRD patterns of samples prepared at the sintering temperatures of 1 400 - 1 600 ℃ without heat preservation is shown in Fig.2(a).Fig.2(b) represents the XRD patterns of the samples under dwelling times of 0 - 20 min with the sintering temperature of 1 400 ℃.Mo and Ta had the same crystal structure of bcc.Compared with Fig.1(b), only one obvious series of diffraction peaks of bcc phase can be observed in the figures, which may be due to the low content of Ta and the dissolution of Ta in Mo matrix during sintering.As the sintering continued, the diffraction peaks of the Mo-5Ta targets were shifted to low angles.This was because the atomic radius of Ta (146 pm) was larger than that of Mo (139 pm), and the solution of Ta to Mo resulted in the increase of lattice constant and crystal plane spacing of Mo(Ta) solid solution.

3.2 Microstructure

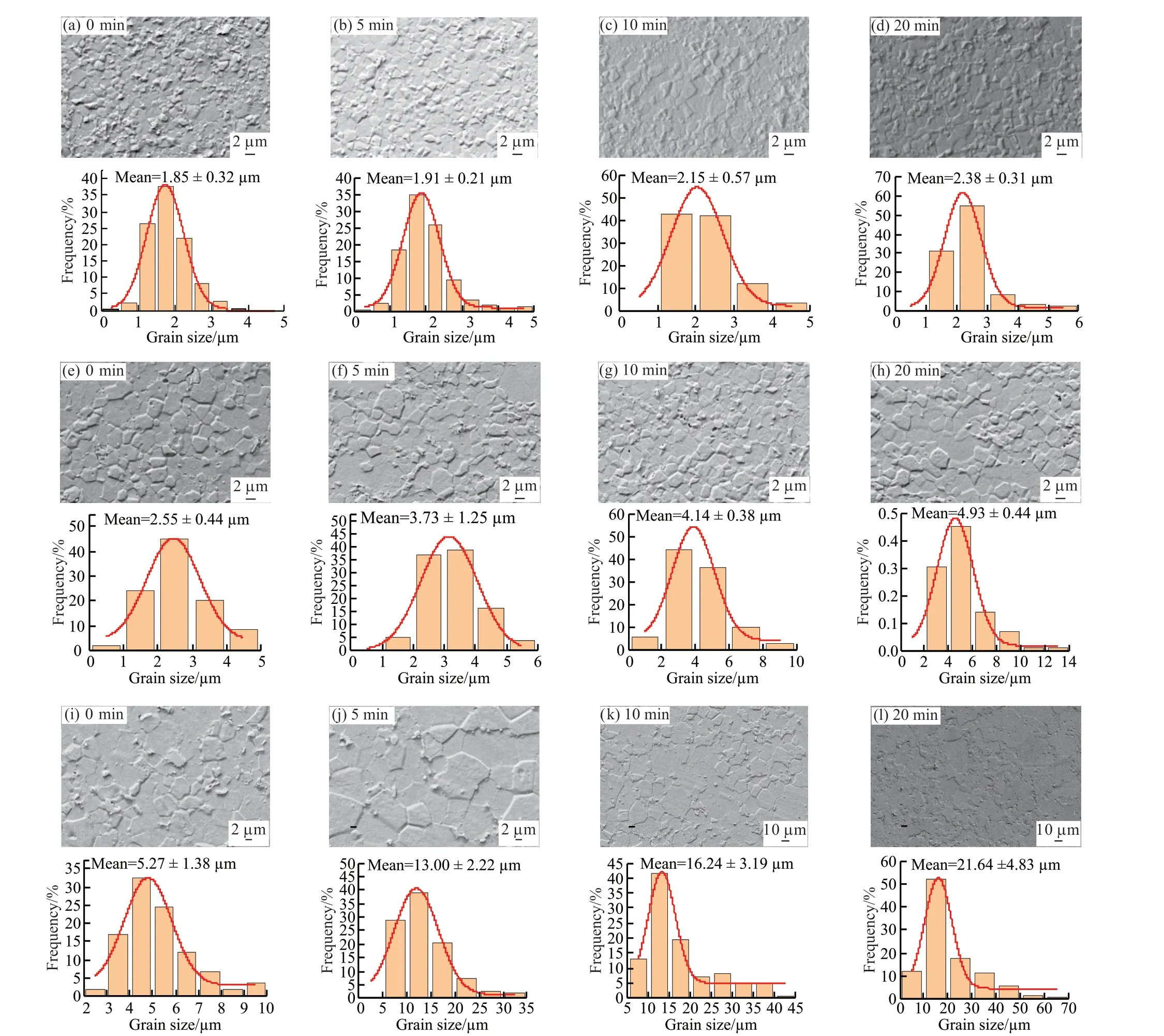

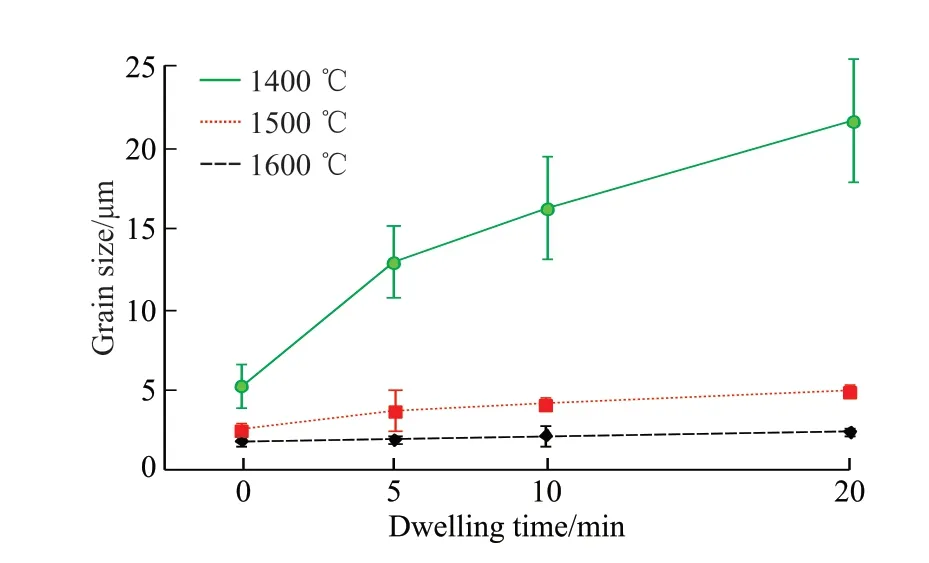

The microstructure and size distribution of the Mo-5Ta sintered targets are shown in Fig.3.As can be seen from the figures, the grain sizes of each sintered sample presented a normal distribution, without abnormal grain growth, and very few pores can be observed.The grain sizes were positively correlated with sintering temperature and holding time and reached maximum when the sintering temperature was 1 600℃ at the sintering time of 20 min.Fig.4 illustrates the relationship for grain sizes with temperatures and times.The ability for element diffusion of SPS methods was mainly controlled by temperature[25].At lower temperatures (1 400 and 1 500 ℃), the diffusion ability of atoms was weaker and the grain boundary migration rate and variation of grain size were slower.At higher temperature (1 600 ℃), the atomic diffusion ability was stronger, the migration rate of grain boundary became faster, and the grains grew up obviously.In the present work, the grain sizes of Mo-5Ta targets at 1 600 ℃were obviously larger than those at 1 400 and 1 500 ℃.

Fig.5 shows the EDS of the sintered samples under dwelling times of 5 min and sintering temperature of 1 500 ℃.It can be seen from the figures that Ta was evenly distributed on the Mo matrix, indicating that the elements were fully diffused during sintering, while the distribution strength of Ta was low due to its small content.

3.3 Performances

Fig.2 XRD patterns of Mo-5Ta targets at different temperatures with (a) no holding time and (b) different holding time at 1 400 ℃

Fig.3 The morphologies of the Mo-5Ta targets prepared by SPS under different holding time: (a)-(d) 1 400 ℃; (e)-(h) 1 500 ℃; (i)-(l) 1 600 ℃

Fig.4 Grain sizes of targets under different sintering temperatures and holding time

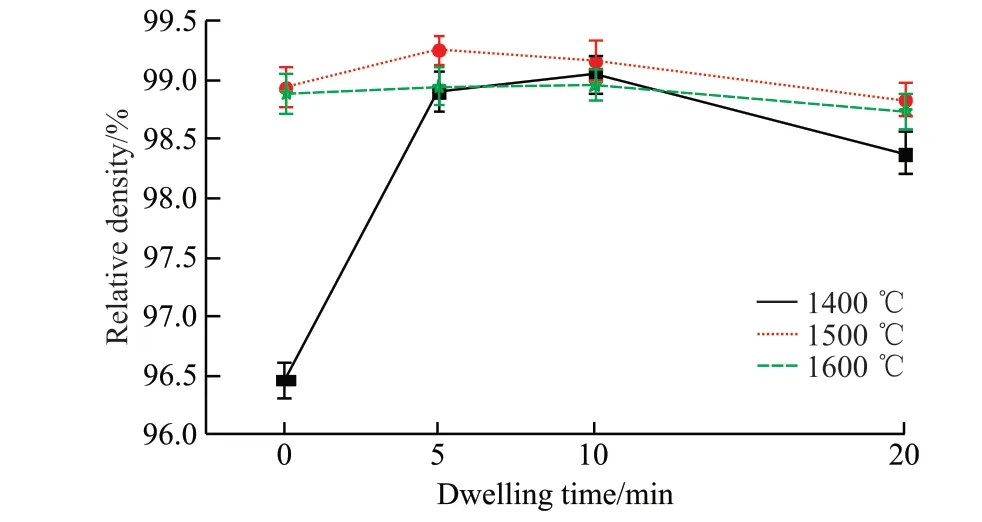

Fig.6 presents the relative density of the Mo-5Ta targets with the variation of the sintering temperatures and holding times.The density of the specimen prepared under the temperature of 1 400 ℃ without heat preservation was the lowest, which was 96.46%.Except for this sample, the relative densities of all the Mo-5Ta targets reached more than 98%.The densities of the sintered samples at 1 500 and 1 600 ℃ were very similar under different holding times.The densities of the sintered specimens increased first and then declined as the augment of the sintering temperature and dwelling time.The change in density was related to the diffusion rate of the elements in the grains, which was affected by the sintering temperature and holding time.With the increase of holding times, the atoms fully diffused and the density increased.However, with the further increase of time, the grain began to grow, the pores formed closed pores from open pores, and some residual closed pores gradually grew, resulting in the decrease of density.

Fig.6 Relative densities of Mo-5Ta targets under different sintering temperatures and holding time

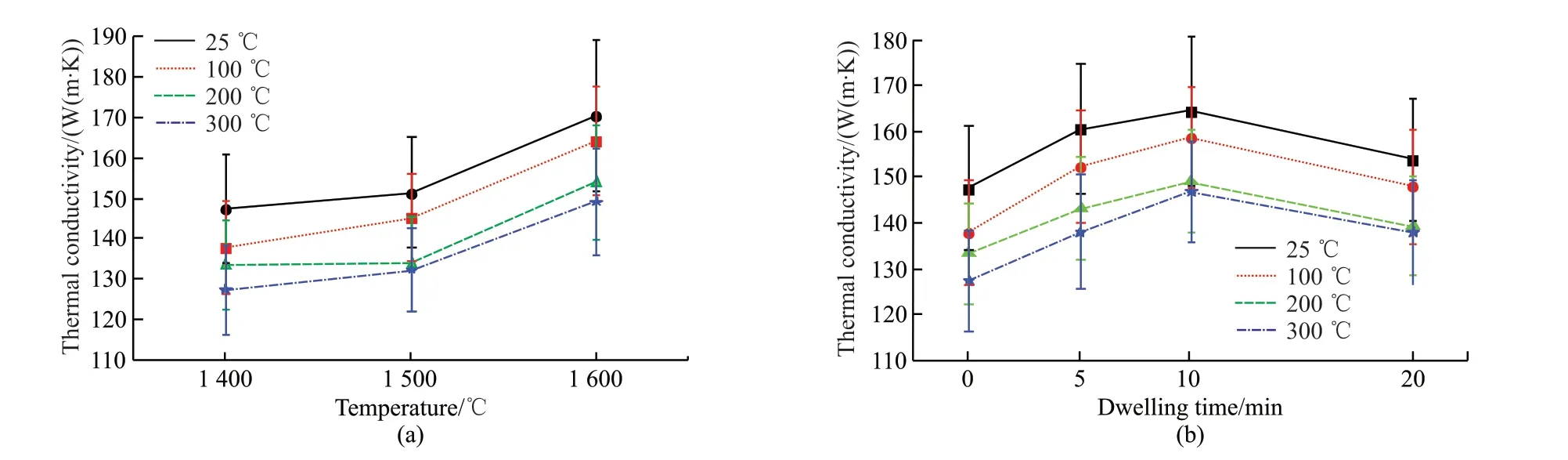

Fig.8 Thermal conductivities of Mo-5Ta targets at different temperatures (a) without holding time and (b) at 1 400 ℃ for different holding time

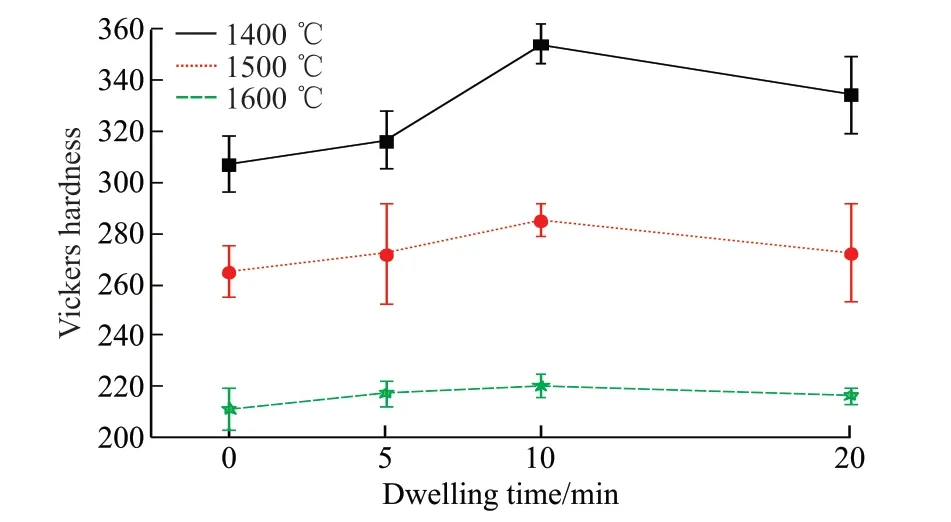

Fig.7 Vickers hardness with different sintering temperatures and holding time

Vickers hardness (HV0.5) of Mo-5Ta sintered targets is shown in Fig.7.Grain size and density were the key factors affecting Vickers hardness[26].According to the Hall-Petch relationship, the finer the crystal grains,the greater the resistance to movement of dislocations in the crystal, and the higher the hardness.With the increase of sintering temperature, the grain size increased and the Vickers hardness decreased.With the extension of holding time under the unchanged sintering temperature, the relative density of samples first increased and then decreased.The Vickers hardness showed a similar trend and reached a maximum value at the holding time of 10 min.

Fig.8(a) shows the thermal conductivity of the samples under the sintering temperatures of 1400 to 1 600 ℃ without heat preservation, while Fig.8(b) presents the thermal conductivity of the samples at the sintering temperature of 1 400 ℃ with the holding times of 0-20 min.As the test temperature increased, the thermal conductivity of the Mo-5Ta targets decreased.This was because that metal had a positive temperature coefficient of resistance, the higher the temperature,the higher the resistance, the lower the thermal conductivity.The thermal conductivity of metals was affected by the thermal movement of electrons and phonons in the crystal.Generally, the longer the mean free path of electrons and phonons, the higher the thermal conductivity.The grain size increased with temperature, the average free path of motion of electrons and phonons in the crystals raised, resulting in an augment of thermal conductivity, as can be seen in Fig.8(a).Although the grain size also increased with the extension of the holding time, the decrease of the density in the later period of the sintering process meant the increase of residual pores volume in the crystals, which hindered the movement of electrons and phonons and relatively shortened the mean free path of electron and phonon movement, so the thermal conductivity increased first and then dropped, as can be seen in Fig.8(b).

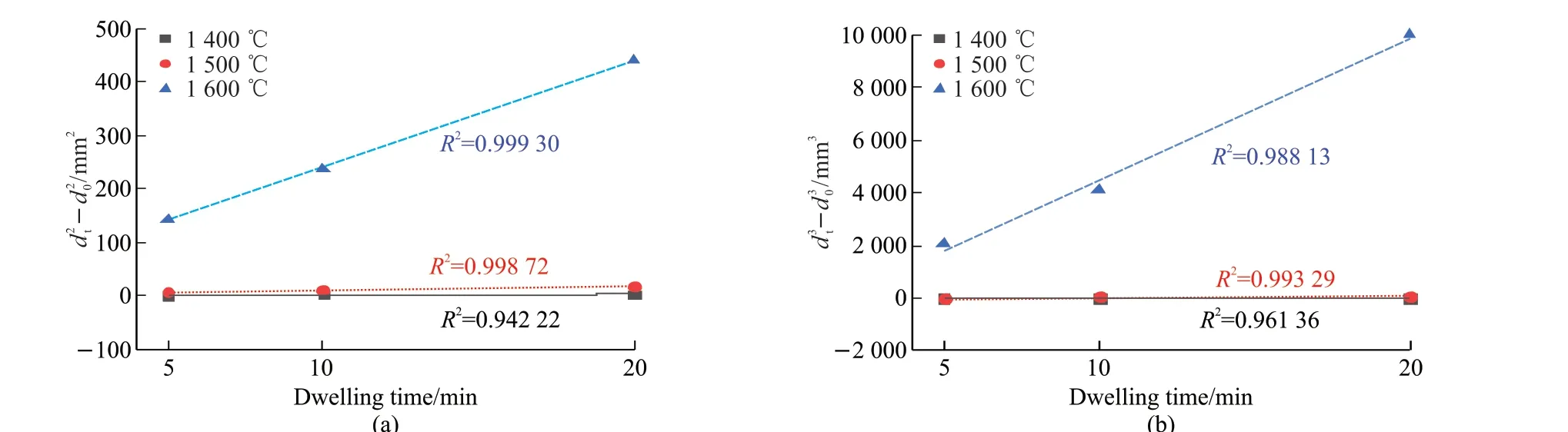

Fig.9 The relationship between (dtn-d0n) and t of Mo-5Ta targets: (a) n=2 and (b) n=3

Table 1 Comparison of Mo-Ta targets prepared by different sintering methods and its properties

3.4 Grain growth kinetics

The growth mechanism of Mo-Ta grains was mainly controlled by grain boundary diffusion and volume diffusion.The type of growth mechanism was represented by the grain growth index (n), in which the grain growth coefficient ofn=2 corresponded to grain boundary diffusion andn=3 corresponded to volume diffusion[12].The relationship between (dtn-d0n) andt(min) of Mo-5Ta sintered targets is shown in Fig.9.The result showed that the regression coefficientsR2for 1 500 and 1 600 ℃ were more closer to 1 whenn=2,and theR2for 1 400 ℃ was closer to 1 whenn=3.Therefore, the grain growth mechanism of Mo-5Ta targets was the combination of boundary diffusion and volume diffusion.

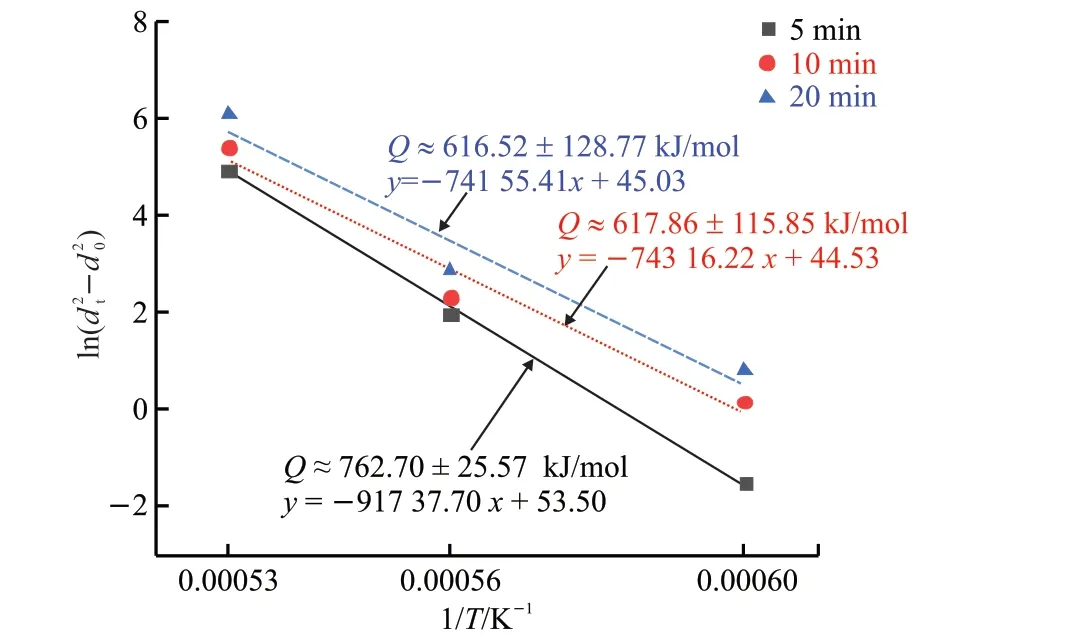

By introducing the data into Eq.(3), the grain growth activation energy (Q), can be calculated, as shown in Fig.10.When the holding timet= 5, 10, and 20 min, the activation energy (Q) of grain growth are 762.70, 617.86, and 616.52 kJ/mol, respectively.

In this experiment, Mo-Ta alloys were prepared by SPS, and its microstructure, properties and grain growth kinetics were systematically studied and compared with the traditional sintering methods, as shown in Table 1.It can be found from the data that compared with the traditional sintering methods, the Mo-Ta alloys prepared by SPS had great advantages in sintering time,density and grain size.

Fig.10 The activation energy of grain growth at different holding time (n=2)

4 Conclusions

The properties of the Mo-5Ta alloy targets sintered under the conditions of SPS at the sintering pressure of 30 MPa, the sintering temperatures of 1 400 -1 600 ℃, and the holding times of 0 - 20 min were studied.

During sintering, Ta dissolved into Mo to form solid solution.Compared with these at 1 400 and 1 500℃, the samples sintered at 1 600 ℃ had a significant increase of grain sizes.As the sintering temperatures and holding times increased, the relative density increased first and then declined.The Vickers hardness and thermal conductivities of the Mo-5Ta targets showed the relevant variation trend, which was the joint effect of grain size and density.In addition, the combination of boundary diffusion and volume diffusion controlled the grain growth of Mo-5Ta in SPS.Whenn=2, the activation energies of grain growth were calculated to be 762.70 (t= 5 min), 617.86 (t= 10 min), and 616.52 kJ/mol (t= 20 min).

Conflict of interest

All authors declare that there are no competing interests.

杂志排行

Journal of Wuhan University of Technology(Materials Science Edition)的其它文章

- Enhanced Electrochemical Performances of Ni Doped Cr8O21 Cathode Materials for Lithium-ion Batteries

- Design on the Prestressed Concrete Frame Beam-column

- Synthesis and Flocculation of Polyacrylamide with Low Water Absorption for Non-dispersible Underwater Concrete

- Experimental Behavior of Recycled Aggregate Concrete Filled Steel Tubular Columns

- Impact-abrasive Wear Behavior of ZTA and NbC Reinforced Fe60 Matrix Composites

- Synthesis and Characterization of Hollow Strontium Carbonate Pompons by Composite Soft Template Method