Mixture Performance of Bitumen Modified with Cocamide Diethanolamide

2021-09-15znurKaradaMehmetSaltan

Öznur Karadağ, Mehmet Saltan

(1. Civil Engineering Department, Suleyman Demirel University, Isparta 32040, Turkey)

Abstract: Bituminous binders have been modified by using cocamide diethanolamide. The chemical material used in this study is used for the first-time on the purpose of modification of the bitumen. In addition to the conventional bitumen tests (penetration, softening point and ductility tests), adhesion and peeling tests (Vialit,Nicholson and California tests) were carried out on the bituminous binders which are modified with different ratios of cocamide diethanolamide. According to the results of the tests, the most appropriate additive ratio has been determined. Samples containing the reference bituminous binder and the bituminous binder modified with the most appropriate cocamide diethanolamide ratio were prepared using the superpave volumetric mix design method (SuperpaveTM). In accordance with standard method of test for resistance of compacted asphalt mixtures to moisture-induced damage (AASHTO T 283), the moisture susceptibility of prepared samples has been examined. In order to observe the changes in strength due to the temperature difference, prepared samples were subjected to the freeze-thawing test in accordance with standard test method for resistance of concrete to rapid freezing and thawing (ASTM C 666).

Key words: cocamide diethanolamide; superpaveTM; freeze-thaw cycle; moisture susceptibility; adhesion

1 Introduction

Asphalt mixtures are obtained by adding a certain amount of bituminous binder to the mixtures prepared with appropriate aggregate grading. Asphalt mixtures are realized in different ways as hot mix asphalt, warm mix asphalt, half warm mix asphalt and cold mix asphalt mix. It is necessary to know the properties of aggregates and bituminous binder used in asphalt mixtures as well as the properties of asphalt mixture formed with aggregate and bituminous binder[1]. The performance of hot mix asphalt is affected by the shape, angularity and surface of the aggregates, suitable gradation and the proportion of bituminous binders[2,3].Adhesion carried out between the aggregate and the bituminous binder is affected due to being dusty and humidity of aggregates as well as effect of rain water and traffic[4].

The lack of adhesion between the aggregate particles and the bituminous binder, and the degradation of the aggregate particles due to seasonal conditions can cause moisture damage in pavement. Loss of strength,stripping, raveling, fatigue crack and permanent deformation in the pavement are caused by moisture[5].Moisture sensitivity of asphalt mixtures prepared using aggregates (limestone and granite) coated with polyvinyl chloride which is a thermoplastic polymer has been investigated. Polyvinyl has increased adhesion between aggregate and bituminous binder. Also, asphalt mixtures prepared with polyvinyl have increased resistance to moisture sensitivity compared to neat mixtures[6].Nano zinc oxide (ZnO) additive which was added to the bituminous binder has increases the adhesion between the aggregate and bituminous binder. The conditioned and unconditioned ITS values of asphalt mixtures prepared with modified bituminous binder have significantly improved[7]. Resistance to moisture sensitivity of hot mix asphalt samples prepared with bituminous binders modified by adding nano-CaCO3to the bituminous binder in certain proportions has increased[8].

Plastic deformations which occurred in the pavement, reduce the service life of the pavement. Also, it increases the cost of its rehabilitation and maintenance which occurs due to aggregate properties, filler and bituminous binder quality. Resistance to plastic deformation of asphalt mixtures which was occurred by adding different amounts of crumb rubber modifier by using wet and dry process increased[9]. Different studies have been performed to investigate the effect of asphalt mixtures against plastic deformation[10-12]. Gene expression programming (GEP) have been developed to evaluate the effect of aggregate angularity against permanent deformations of asphalt mixtures[13]. One of the major types of deformations seen in flexible pavement is the formation of rutting. Increase in the number of heavy vehicles, increased axle weight and tire internal pressure. A number of studies have been carried out on the rutting caused by the above - mentioned reasons[14-18].

The adhesion connection formed between the aggregate and bituminous binder is affected by water.The polarity of aggregate and water is high but the polarity of bituminous binder is low. Therefore, aggregate makes easier and stronger connection with water compared to bitumen. When the bitumen – coated aggregate is exposed to water, water can separate the bituminous binder from aggregate[19]. As a result of insufficient adhesion between the aggregate and bituminous binder which form asphalt mixtures, peelings and deformations occurred in the pavement. Different studies have been carried out in order to reduce peeling in the pavement. Bituminous binders modified with organicbased zincphosphate compound (OBZPC) increased peeling resistance from 30% to 95%[20]. Thus, they explained that the problem of peeling caused by water in the pavement can be reduced by using OBZPC additive material. Bituminous binders modified with manganese abietate compound improved significantly peeling resistance of hot mix asphalt[21]. 0.1% Mg compound has been added in different proportions to the bituminous binder[19].

Adhesion between aggregate and bituminous binder modified with 1%, 3%, 5%, 7% and 9% ratios of cocamide diethanolamide were examined by taking advantage of the adhesion of the chemical material used in this study. Conventional bitumen tests were carried out to determine the consistency of modified bituminous binders and Vialit, Nicholson and California Peeling tests were performed to examine the adhesion between aggregate and bituminous binder modified with Cocamide Diethanolamide. According to the obtained results, the most suitable Cocamide Diethanolamide ratio was determined. Samples suitable for asphalt surface course were prepared by superpave volumetric mix design method using reference bituminous binder and bituminous binder modified with 5%cocamide diethanolamide. Indirect tensile strength test was performed on the prepared samples. The moisture susceptibility of the samples was determined according to AASHTO T 283 standard. In order to observe the changes which occurred due to temperature difference,the prepared samples were subjected to freeze - thaw tests.

2 Experimental

2.1 Materials

2.1.1 Aggregates

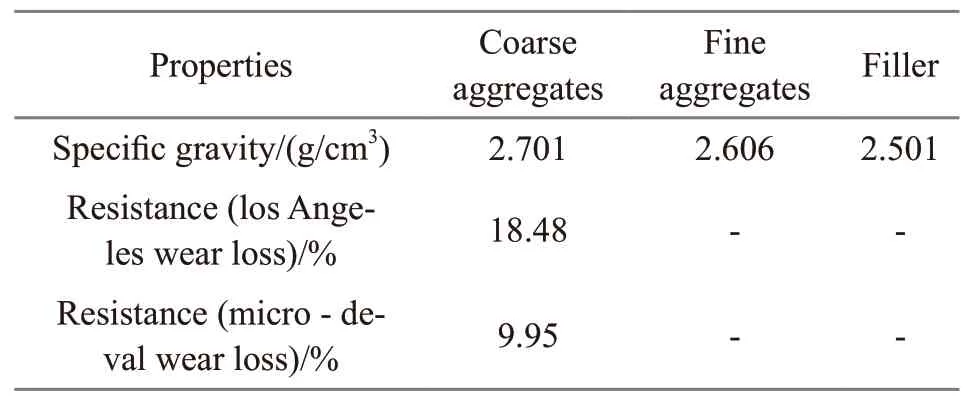

Limestone aggregates were used in this study.Specific bulk gravity[22], water absorption, Los Angeles abrasion test[23]and micro - deval abrasion test[24]were performed on limestone aggregates used in experimental studies. The results applied on coarse aggregates,fine aggregates and filler are shown in the Table 1.

Table 1 Physical properties of coarse aggregates, fine aggregates and filler

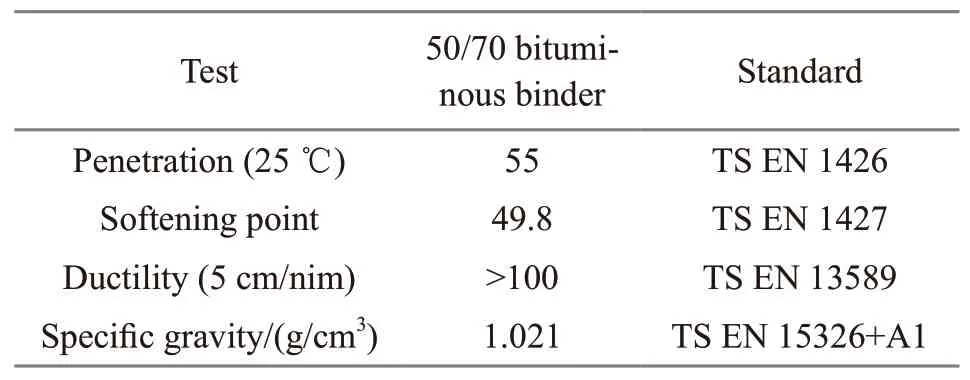

2.1.2 Bituminous binder

Bituminous binder which has a penetration class of 50/70 was used. Penetration[25], softening point[26],ductility[27], and specific gravity[28]tests were performed on the bituminous binder. Obtained results are given in Table 2. It is seen that the bituminous binder provides the specification limit values.

Table 2 Properties of bituminous binder

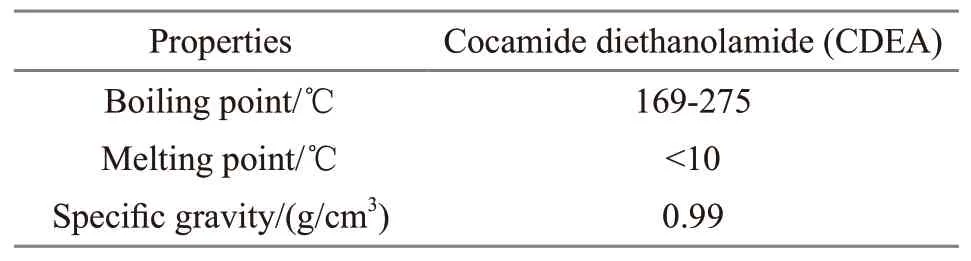

2.1.3 Cocamide diethanolamide

Cocamide diethanolamide (CDEA) is known as a surfactant material which has the chemical formula CH3(CH2)nC(=O)N(CH2CH2OH)2. It is a viscous liquid that is used as foaming and adhesion factors in personal care products such as shampoo, hand soaps, and cosmetic products. Due to the increase in the adhesion of the bituminous binder modified with this material,it was expected to strengthen the adhesion between the aggregate and the bituminous binder modified with CDEA. Bituminous hot mixtures prepared with bituminous binder modified with CDEA were also expected to improve the performance positively. The properties of the chemical material are given in Table 3.

Table 3 Chemical properties of cocamide diethanolamide

2.1.4 Bituminous binders modified with cocamidediethanolamide

Cocamide diethanolamide was added to bituminous binder at a rate of 1%, 3%, 5%, 7% and 9%. Different parameters have been tried to modify the chemical material with bituminous binder. Conventional bitumen tests were carried out on modified bituminous binders and the most suitable parameter was selected.With the help of a high shear temperature-controlled mixer, it was homogeneously mixed for 1 hour at 2 000 rpm and 165 ℃. Penetration[25], softening point[26], ductility[27]and specific gravity[28]tests were performed on bituminous binders modified with CDEA.

2.2 Methods

2.2.1 Determination of specific gravity of coarse aggregate, fine aggregate and filler

The water absorption and specific gravity values of coarse aggregates were calculated. Specific gravity and the water absorption values of fine aggregate were determined according to TS EN 1097-6 standard. Finally, the specific gravity of filler was determined.

2.2.2 Los - angeles and micro - deval abrasion test

The aggregates used in pavements must be resistant to breakage and abrasion during compression and under the influence of traffic loads. It is important to know the abrasion status of aggregates using different test methods in order to understand the actual abrasion of aggregates used in pavement[29]. According to test method for resistance to degradation of small - size coarse aggregate by abrasion and impact in the Los angeles machine (ASTM C 131-03), short term abrasion resistance of coarse aggregates used in the study was calculated. Tests for mechanical and physical properties of aggregates-part 1: determination of abrasion resistance (micro-deval) (TS EN 1097-1) was used to determine the long-term abrasion resistance of coarse aggregates.

2.2.3 Penetration, softening point and ductility tests

Penetration and softening point tests were performed to determine the consistency of the reference bituminous and bituminous binders modified with CDEA. Ductility test is one of the conventional bitumen tests performed to determine the extend ability of bitumen under slow acting loads. In accordance with standard (TS EN 13589), the amount of the extension without breaking of prepared samples was determined.

2.2.4 Adhesion and peeling tests

The Vialit, Nicholson and California peeling tests were performed to evaluate the adhesion between aggregate and bituminous binder modified with CDEA.Vialit is a test carried out to determine that how much the adhesion between aggregate and bituminous binders decreases with the effect of water. Nicholson peeling test was performed using both the reference bituminous binder and bituminous binders modified with CDEA.

In addition to the Nicholson peeling test, the California peeling test is performed on aggregates remaining above the 2.36 mm (No.8) sieve passing through a 9.5 mm (3/8 inch) sieve. 60±1 g of aggregate heated in the oven which has 110 ℃ temperature is placed in the metal mixing chamber. The bituminous binder is heated at 149±15 ℃ and then calculated the amount to be used with Eq.(1):

Aggregates and bituminous binders are mixed.Then, the sample and the container are removed from the hot plate and the prepared sample is allowed to cool for 1 or 2 hours at room temperature. The sample is placed in the oven at 60 ℃ for 15 to 18 hours and removed from the sample cup and placed in the glass jar.The glass jars are allowed to cool at 25±16 ℃. 175±4 mL of distilled or deionized water at 25±16 ℃ is added to glass jars. The glass jars are placed on the California test equipment which rotates at 43±2 rpm at 35 revolutions per minute for 15 minutes. Then the percentage of peeling of the samples in the glass jars with the help of a fluorescent light is visually estimated.

2.2.5 Evaluation of moisture sensitivity of bituminous hot mixtures

Superpave volumetric mix design method consists of four steps: material selection, aggregate gradation,bituminous binder quantity and moisture susceptibility.During all these steps, the temperatures and traffic volume are taken into consideration.

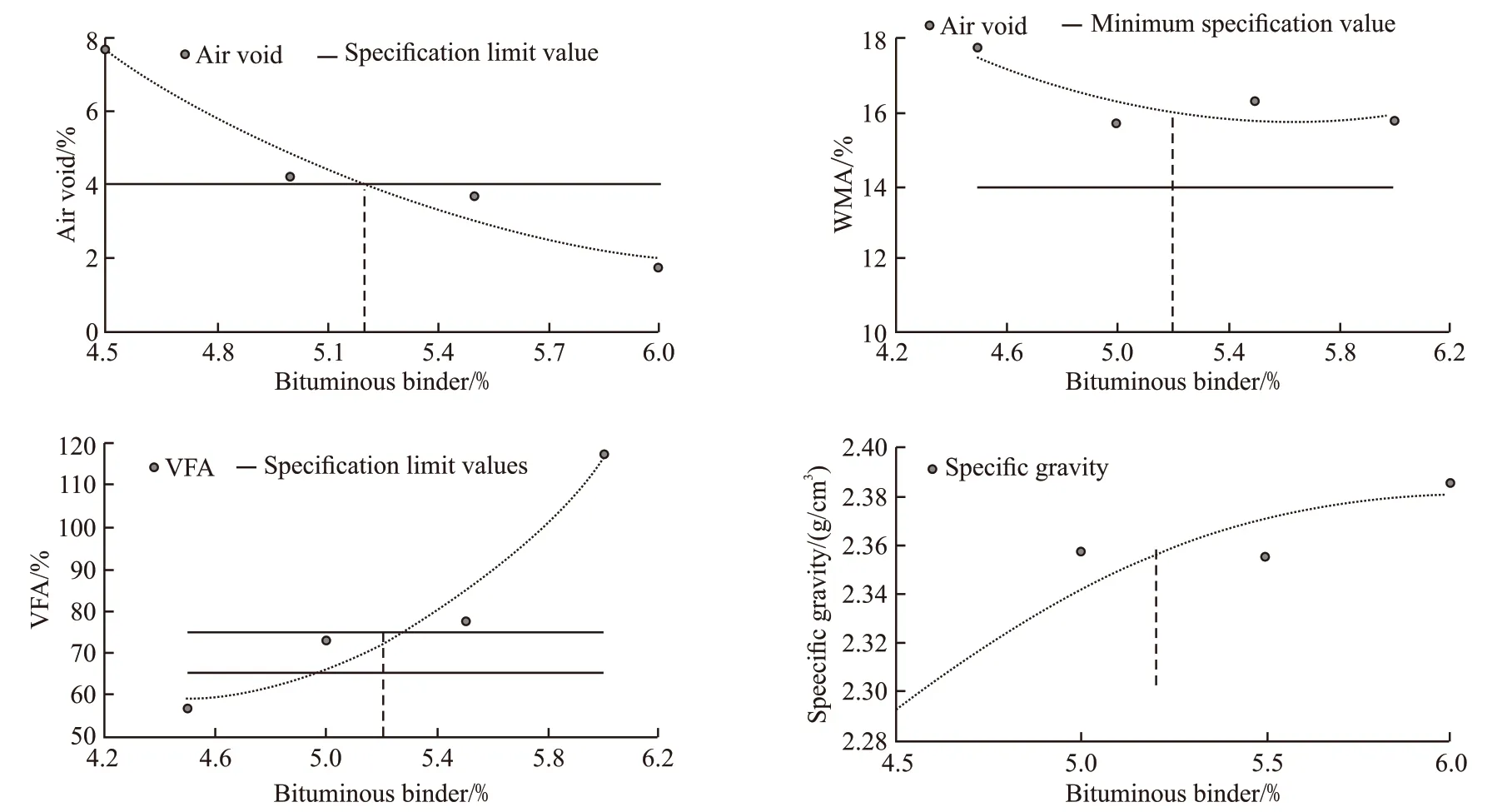

It is estimated that the number of 20 years of traffic in Isparta Province is more than 30×106ESALs.Within the scope of study, optimum bituminous binder content has been determined using volumetric mix design.Ndesignis selected as 125 gyros in accordance with the 20-year traffic load. When the optimum bituminous binder content is calculated, VMA (min 14%), VFA(%65-75) limit values and 4% air void criteria is taken into consideration.

The final step of the superpave volumetric mix design method is to determine the moisture susceptibility of the prepared mixtures. In order to determine the moisture susceptibility, indirect tensile strength test(ITS) is performed on the prepared mixtures in accordance with AASHTO T-283 standard. According to the determined optimum bituminous binder content, the prepared mixtures are compressed with Superpave Gyratory Compactor. Two sets which have three samples are prepared and while one of them is conditioned, other set is unconditioned. The prepared samples are kept in the oven which has 40 ℃ temperature for 72 hours.Conditioned samples are placed in a water bath at 25℃ for 24 hours. The remaining samples are placed in the oven at 25 ℃ for testing at the same time with the conditioned samples. Then the samples are taken from the water bath and saturated with the help of vacuum until the saturation level of the sample is remaining between 60% and 80%. The samples that reached the saturation level, are put into deep-freezer at -18 ℃ for 16 hours. After 16 hours they are put into a water bath at 60 ℃ for 24 hours. And lastly, samples are put into a 25 ℃ water bath for 2 hours. When all conditioned and unconditioned samples are at 25 ℃, the indirect tensile strength of the samples are determined. For all samples,unconditioned (ITSdry), conditioned (ITSwet) values are recorded and the TSR (indirect tensile strength) values are calculated with Eq.(2). The limit of TSR values is 80%[30].

2.2.6 Freeze - thaw test

Cracks occur in flexible pavement in a short time due to the difference in a temperature day and night and freezing-thawing events in winter. The freeze –thaw cycle affects the mechanical properties of asphalt mixes. For example, it was observed that as the freeze– thaw cycle increases, the compression strength and elastic modulus of asphalt mixtures decrease[31]. In this study, the difference between day and night temperatures which create the cracks on bituminous hot mixture samples prepared in laboratory environment has been tried to be simulated by freezing-thawing cabinet.By the help of standard[32], it was aimed to determine the resistance of samples exposed to repeated freezethaw cycles in accelerated manner by using two different methods - method A (rapid freeze-thaw in water)and method B (rapid freezing in air, rapid thawing in water). Method A was applied in the way that frozen at -20±2 ℃ for 3 hours and then dissolved in water at 20±2 ℃ for 2 hours at room temperature. Freezing and thawing in water is accepted as 1 cycle. In this study,24 bituminous hot mixture samples were prepared to perform 4, 20, 40 and 70 cycles.

3 Results and dicsussion

3.1 Results of conventional bitumen tests

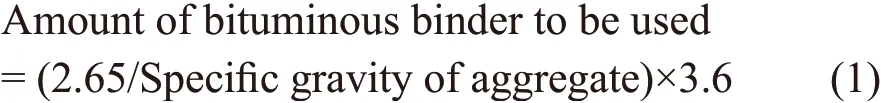

According to the penetration test results given in Fig.1, it was observed that the penetration value of the bituminous binder modified with 9% CDEA increase by 100% according to the reference bituminous binder.According to the reference bituminous binder, the softening point value of the bituminous binder modified with 9% CDEA was seen to be reduced by 16.27%. According to obtained results, the viscosity of bituminous binder modified with CDEA decreased.

Fig.1 Results of penetration and softening point tests

According to the ductility test results, both reference bituminous binder and bituminous binder modified with CDEA at different ratios provide the specification limit value.

3.2 Results of adhesion and peeling tests

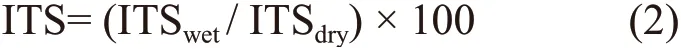

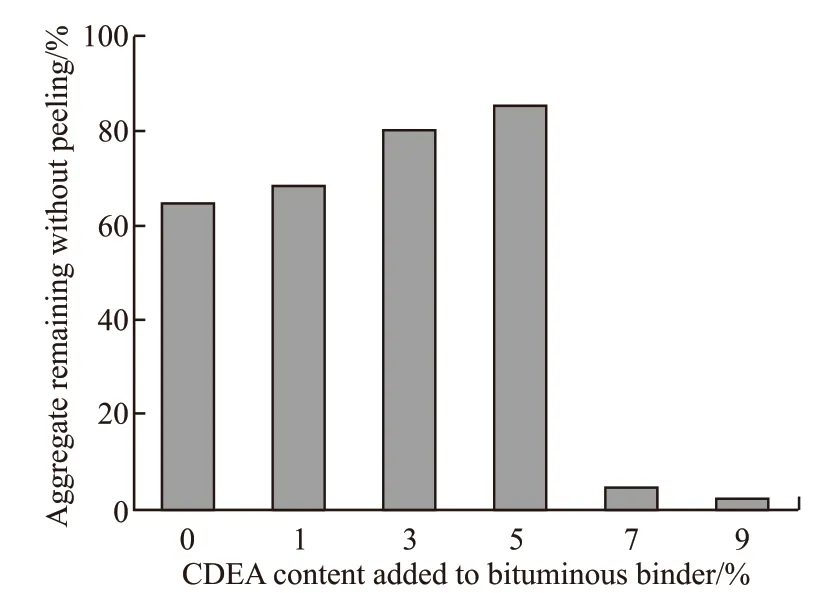

As shown in Fig.2, as the amount of CDEA added to bituminous binder increase, adhesion property of bituminous binder increased by 87.5%. The falling aggregate number of the bituminous binder modified with 7% and 9% CDEA is equal.

Fig.2 Results of Vialit test

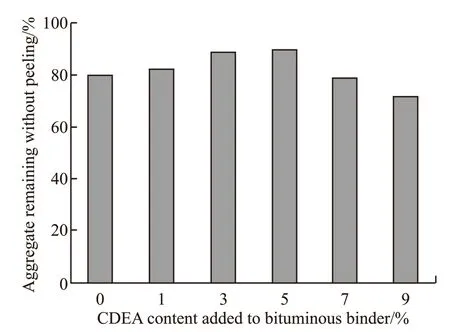

It can be seen from Fig.3 that the specification limit value determined as 60% has been provided. But,peeling percentage of bituminous binder modified by using 9% CDEA increased by 96.92% compared to the reference bituminous binder. Almost all of the aggregates in the samples prepared with bituminous binder modified by using CDEA were observed to be peeled off. It is not recommended to use because there is no good adhesion between the aggregate and bituminous binder modified with CDEA at ratios of 7% and 9%.

Fig.3 Results of Nicholson peeling test

In the California test, according to the reference bituminous binder, it has been observed that the peeling percentage of bituminous binder modified by using 9% CDEA increased by 10%. The results of the peeling tests supported each other. It was observed that bituminous binders modified with CDEA higher than 5% lost their adhesion when exposed to moisture in the oven with 60 ℃. According to obtained results, the percentage of peeling increases as the amount of CDEA added to the bituminous binder increases (Fig.4).

Fig.4 Results of California peeling test

3.3 Evaluation of moisture sensitivity

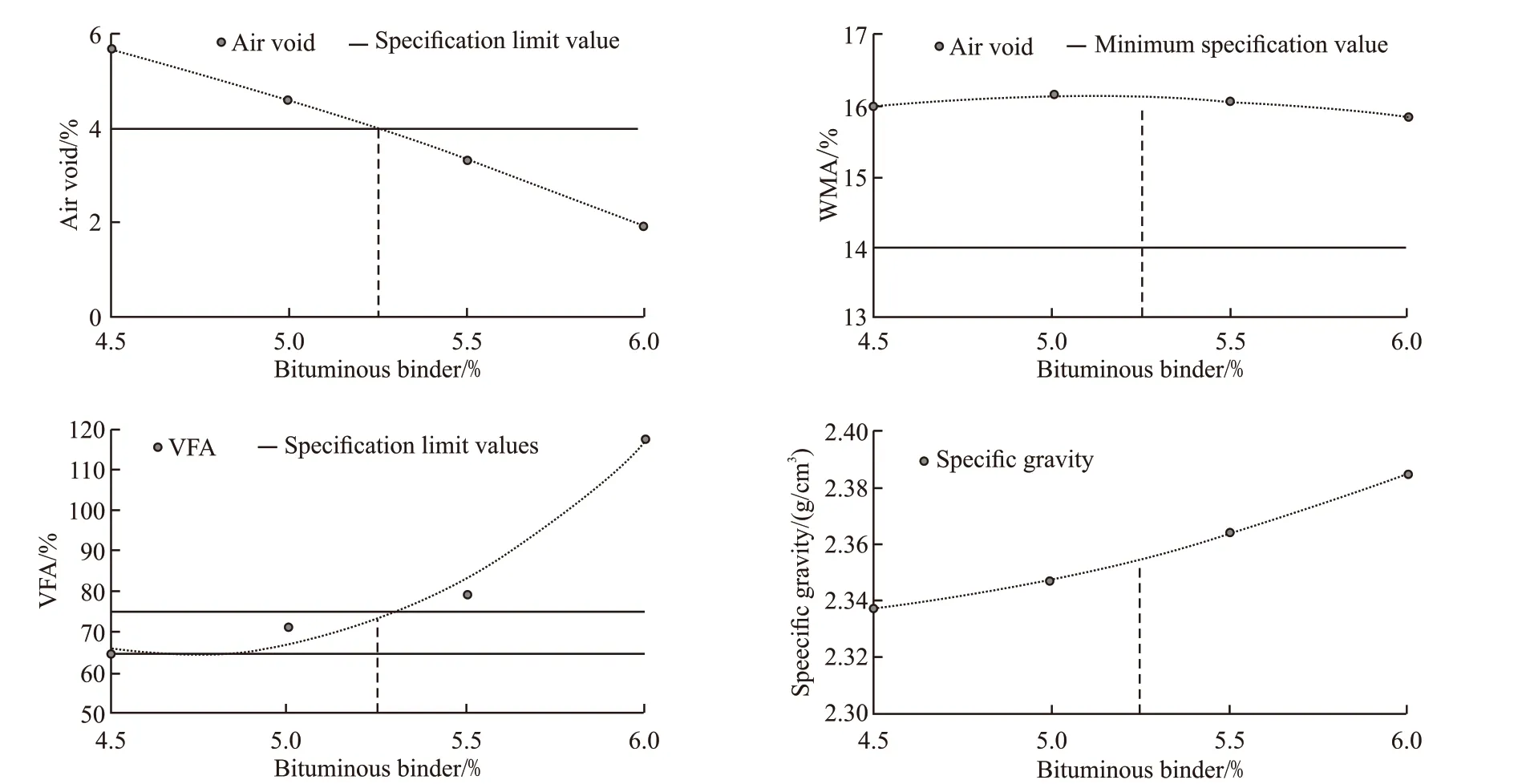

As a result of conventional bitumen tests and adhesion and peeling tests, the adhesion property of bituminous binder modified with 5% CDEA increased by 79.17%, 30.77% and 12.5% in Vialit test, Nicholson peeling test and California peeling test, respectively.Bituminous binder modified with 7% and 9% CDEA were not selected because adhesion property of bituminous binders modified with CDEA lost when exposed to moisture consisted of oven with 60 ℃. Optimum rate of modified bitumens which were prepared with cocamide diethanolamide was determined as 5%. In order to provide the 4% air void criteria of the mixtures prepared by using superpave volumetric mix design method, 4.5%, 5%, 5.5% and 6% bituminous binders were added and the aggregates were mixed until completely coated with bituminous binder. Then the mixture was compressed with gyratory compactor. Firstly,the amount of bituminous binder corresponding to 4%air void was determined from the air void graph. It was checked whether the determined amount of bituminous binder has a minimum value of 14% on the VMA graph and 65%-75% on the VFA graph. After all these steps were carried out, the optimum bitumen content for reference bituminous binder and bituminous binder modified with 5% CDEA were determined as 5.20%and 5.25%, respectively. Graphs of obtained results are given in Figs.5-6.

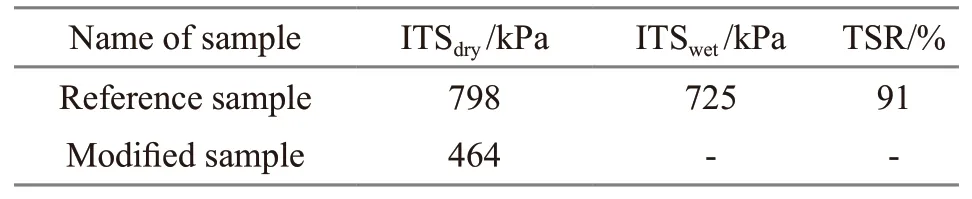

The final step of the superpave volumetric mix design method is to determine the moisture susceptibility of the prepared mixtures. In order to determine the moisture susceptibility, indirect tensile strength test (ITS) was performed on the prepared mixtures according to AASHTO T-283 standard. Unconditioned(ITSdry), conditioned (ITSwet) and TSR values were found for all samples. TSR value of the samples prepared with reference bituminous binder is above the specification limit, 80%. The obtained results are given in Table 4.

Table 4 Indirect tensile strength of samples

ITSwetstrength of samples prepared by using bituminous binder modified with 5% CDEA could not be tested. In the conditioning stage, after the sample was placed in a water bath which have 60 ℃ temperature,separation of the aggregates from the bituminous binder was observed. When the bituminous binder modified with CDEA was exposed to a water bath which have 60 ℃ temperature, no adhesion between bituminous binder and aggregate form. According to the obtained results, it was concluded that the samples prepared with bituminous binder modified with 5% CDEA had no effect on strength.

Fig.5 Graphs of reference bituminous binder

Fig.6 Graphs of bituminous binder modified with 5% CDEA

3.4 Results of freeze – thaw test

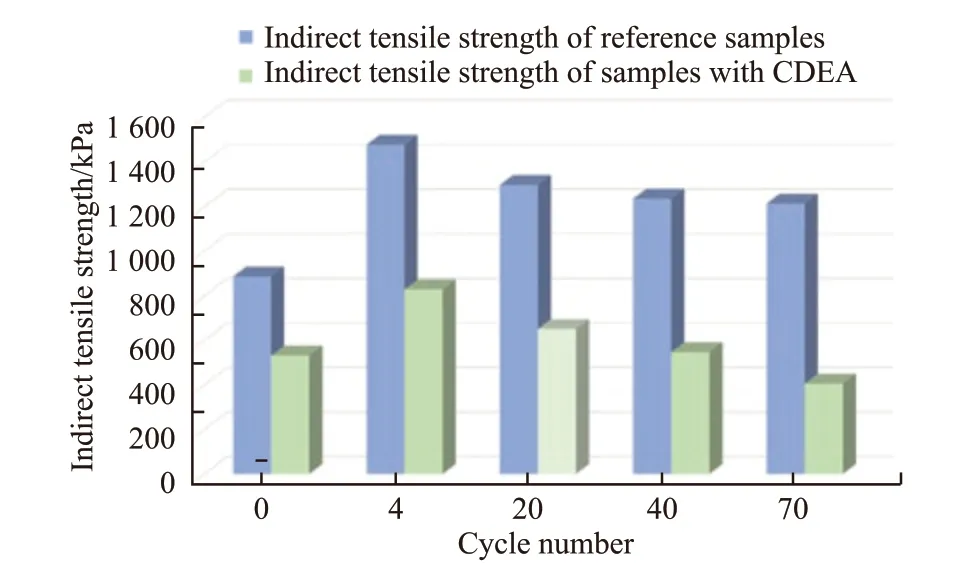

According to ASTM C 666 standard, rapid freezethaw test was performed on samples prepared with reference bituminous binder and bituminous binder modified with 5% CDEA. For 4, 20, 40 and 70 cycle which have three samples, 24 samples were prepared.After the freeze-thaw test was completed, indirect tensile strength test was performed on the samples. The obtained results are shown in Fig.7.

Fig.7 Results of freeze - thaw test

As the number of cycles increases, it is seen that the strength of the samples prepared with reference bituminous binder is higher than the strength of samples prepared with bituminous binder modified with 5%CDEA.

4 Conclusions

a) The bituminous binders were modified with cocamide diethanolamide which is a chemical material at the ratios of 1%, 3%, 5%, 7% and 9%. Bituminous binders modified with CDEA chemical material is fluid and soft. The viscosity of modified bituminous binders decreases. Additionally, it is thought that adhesion property of bituminous binder modified by using CDEA decreases when exposed to moisture in oven with 60 ℃. According to the results obtained, modified bituminous binder is thought to be suitable to be used in cold climatic regions.

b) According to the vialit test results, since bituminous binders modified with CDEA increase the adhesion property of bituminous binder, it is considered suitable for use in chip seal.

c) The strength of samples prepared with bituminous binder modified with 5% CDEA could not be calculated. Asphalt mixtures prepared with bituminous binder modified with 5% cocamide diethanolamide decreased the resistance to moisture sensitivity. It is concluded that the samples prepared with bituminous binder modified with 5% CDEA are not suitable for use in the asphalt surface course.

d) It was observed that both the strength of the samples prepared with reference bituminous binder and the strength of samples prepared with bituminous binder modified with 5% CDEA have been decreased as the number of cycles increases. It was found that the strength against temperature changes of the samples prepared with bituminous binder modified with 5%CDEA is lower than the samples prepared with reference bituminous binder.

Subsequent studies are planned to work on chip seal due to the increased adhesion between aggregate and the bituminous binder modified with cocamide diethanolamide. It is planned to make ‘storage stability’test on modified bituminous binders by using these results and performing ‘rotational viscometer method’.

杂志排行

Journal of Wuhan University of Technology(Materials Science Edition)的其它文章

- Poly(dopamine)-assisted Bioactive Coating on the Surface of Porous Poly (Ether Ether Ketone) to Promote Osteogenic Differentiation of rBMSC

- Influence of Heat Treatment on Microstructure and Mechanical Properties of Plasma Sprayed FeCrMoCBY Amorphous Coatings

- Lamella Multiple Grained Structure Making 2205 Duplex Stainless Steel with Superior Strength and Ductility

- Progress in Light-weight High Entropy Alloys

- Synthesis and Characterization of Polyaniline/MgTiO3 Composite with Excellent Thermal and Electrochemical Performance

- Synthesis and Characterization of Hyperbranched Epoxy with Terminal Ally Group and Its Application of Toughen Bismaleimide