Lamella Multiple Grained Structure Making 2205 Duplex Stainless Steel with Superior Strength and Ductility

2021-09-15SHIYuSONGYiLAPeiqingZHENGYuehongLIZhengning

SHI Yu, SONG Yi, LA Peiqing, ZHENG Yuehong, LI Zhengning

(State Key Laboratory of Advanced Processing and Recycling of Nonferrous Metals, Lanzhou University of Technology, Lanzhou 730050,China)

Abstract: We demonstrate a 2205 duplex stainless steel (DSS) synthesized by aluminothermic reaction and followed two-step rolling which had a superior yield strength of 863 MPa, ultimate tensile strength of 1 103 MPa and an elongation of 21% at room temperature. The phase, grain size and distribution of the steel were characterized by optical microscope, X-ray diffraction, electron back-scatter diffraction and transmission electron microscope. The results show that the steel consists of lamellar ferrite and austenitic phase with multiple grain size distribution from nanoscale to microscale. The high strength is attributed to strengthening of high back stress arising from laminated dual-phase heterogeneous ultrafine grained structure and distribution.The high ductility originates from back-stress hardening and dislocation hardening.

Key words: 2205 duplex stainless steel; back stress; strength; ductility

1 Introduction

Strength and ductility are two of the key mechanical properties of steels and alloys in industrial applications[1]. According to the relation of stress:σ=P/A, increasing strength of materials (σ) leads to a reduction in cross-sectional area (A) for sustaining a certain load (F)[2]. This motivates the application of ultrahigh strength alloys and steels with light weight and energy-efficiency. High ductility of engineering materials gives a signal impending rupture by deforming to some extent before completely failure.Unfortunately, strength and ductility are mutually exclusive, most mechanisms for increasing strength leading to ductility loss[3-6]. It is well known that steels and alloys can be strengthened when their grain size is reduced to nanoscale, but which leads to deterioration of the ductility. Nanoscale materials do not avoid the strength-ductility trade-off which has been a dilemma for centuries in materials science and engineering[7-9].

To this end, inspired by the excellent fracture toughness of bones, Motomichi Koyamaet alverified the superior fatigue crack resistance in meta-stable multiphase steels. This steel with an intrinsic lamellae consisting of lamellar martensite and meta-stable austenite phase was comparable to bone structure. The results showed that adjusting the interface structure,distribution and phase stability to activating multiple crack-resistant microscopic mechanism was the key to good mechanical properties[10]. In recent years, inhomogeneous geometry, spatial distribution, multiscale grain size, multi-phase, non-uniform composition distribution and lamella structured metal materials have been used to optimizing their mechanical properties.Material experts have prepared metallic materials with nano-gradient structure[11,12], heterogeneous structure[13,14]and “bimodal” structure[15], enabling them to simultaneously obtain high strength and high plasticity. These tactics share a unifying design principle in the intentional structural heterogeneities and the nanometer-scale features. However, the influence of the resultant microstructure on the mechanical behaviors of heterogeneous nanostructured DSS has not been studied in sufficient details.Although these studies provide good design principles,the processing samples is complex and the sample size is small, limiting a wide range of industrial applications[16].

In this work, we report a 2205 DSS synthesized via aluminothermic reaction and followed by rolled deformation exhibited a superior combination of strength and ductility. The 2205 DSS was composed of twisted heterogeneous laminated (soft austenite and hard ferrite ) phase whose grain size deploy from nanoscale to microscale, similar to the substructure of bone. Thus, they possess combination of three characteristics-multiple phase, lamination, and being heterogeneous. We propose that dual-phase,hierarchical structure and multiple grain size from nanograin to micrograin configutions should be important in superior strength-ductility synergy of metals and alloys.

2 Experimental

2.1 Sample Fabrication

In the present work, the initial 2205 DSS synthesized via aluminothermic reaction in a 5 MPa argon atmosphere. Details information on the processing is reported elsewhere[17]. The synthetic ingot had a dimension 150 mm of diameter and 10 mm of height and its chemical composition was Cr:21.8, Ni: 5.36, Mo: 2.68, Si: 0.74, Mn: 0.75, Al: 1.18(wt%) and Fe balance. The ingot was polished the upper and lower surfaces and then processed a strip of 100 mm×50 mm×5 mm with a wire cutter for rolling.The strip sample was placed in a resistance heating furnace heated to 1 000 ℃ at a rate of 8 ℃/min and held for 10 min. The rolling test was performed on a two-roll hot-rolling mill (main motor power:60 kW,maximum rolling force: 220 kN) at a rolling speed of 15 r/min and mean thickness reduction was 0.1 mm per pass. The rolling was carried out at 1 000 ℃ with the thickness from 5 to 3 mm strips, followed by a warm rolling to a thickness of 0.6 mm at 600 ℃. Finally, the rolled sample was air cooled to room temperature. This processed steel was herein after referred to as-rolled steel.

2.2 Microstructural characterization

Phases and microstructures of the steels were performed by D8 X-ray diffraction (XRD) using Cu-Kα radiation, MeF3 optical microscope (OM), Zeiss Ultra 55 electron back-scatter diffraction (EBSD),JSM-6700F scanning electron microscope (SEM) and JEM-2010 transmission electron microscope (TEM)operated at 200 kV. In addition, the surfaces for OM and SEM observation were etched in a corrosive solution (10 g FeCl3+ 40 mL HCl + 60 mL H2O) for 35 s. Thin foils for TEM observation were mechanically ground to a thickness of 50 µm followed by ion-beam thinning.

2.3 Mechanical property testing

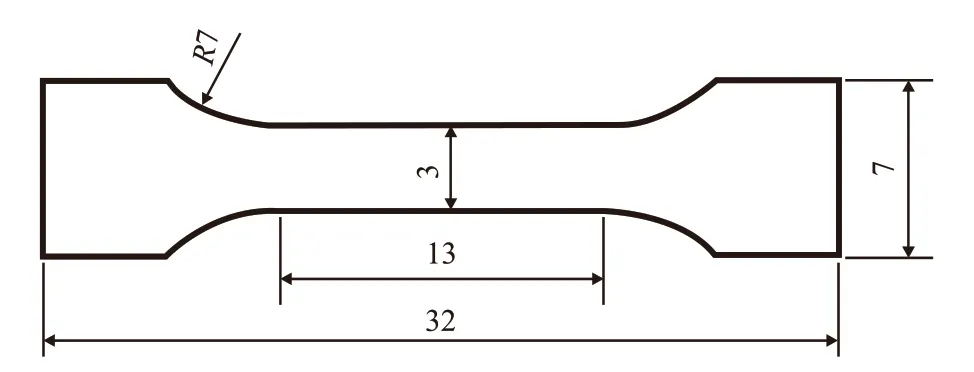

According to the metal material room temperature tensile testing requirements of the Chinese standard GB/T 228.2002, Dog-bone shaped tensile samples were machined by a wire electrical discharge milling, the cutting direction parallel to the rolling direction. And the tensile samples dimension are shown in Fig.1 As shown, the gauge length and width are 13 and 3 mm,respectively. Uniaxial tensile tests were carried out at room temperature using a AT10t universal mechanical testing machine with a maximum loading capacity of 100 kN operating at a crossing speed of 0.2 mm/min.For the same condition three samples were tested to reflect the accuracy of the experimental data.

Fig.1 Dimensions and shape of the tensile specimens (unit: mm)

3 Results

3.1 Microstructures of the as-synthesized 2205 DSS

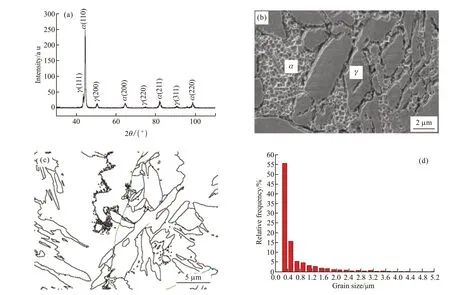

The microstructures of the as-synthesized 2205 DSS are shown in Fig.2. It can be seen that the assynthesized steel consists of austenite phase (γ) and ferrite phase (α) (Fig.2(a) and 2(b)). Strip and islandγis embedded inα. Theγarea fraction is 58%, and theαarea fraction is 42%. The GB is clear inαwhile is not observed inγby the SEM examinations owing to excellent corrosion resistance ofγ(Fig.2(b)). EBSD GB maps exhibits an in-homogeneous grain size (Fig.2(c))distribution. Corresponding statistical distribution histogram of grain size from Fig.2(c) is shown in Fig.2(d). It can be found that grain size distributes from nanoscale (fine grain) to microscale (coarse grain) in the as-synthesized specimen. And after calculation, the average grain size of the steel is 0.875 µm.

Fig.2 Microstructures of the as-synthesized 2205 DSS: (a) XRD spectra; (b) SEM image, convex area is austenite phase (γ) and concave area is ferrite phase (α); (c) EBSD grain boundaries (GBs) maps; (d) Grain size distribution

3.2 Microstructures of the as-rolled steel

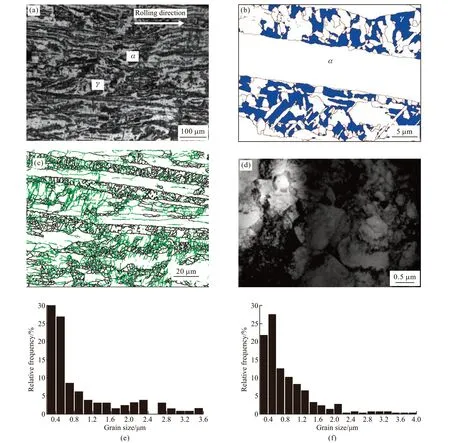

At multiple length scales the microstructure features of the as-rolled steel are illustrated in Fig.3.The optical micrograph of the as-rolled steel is shown in Fig.3(a). Bothγandαare clearly visible. The bright area isγ, while the dark one isα. The rolling elongated theγandαof as-synthesized steel into a twisted lamella structure along rolling direction which is indicated by a white arrow. EBSD phase map reveals that the asrolled steel consists of heterogeneous elongated lamellaγandα(Fig.3(b)), while GBs map indicates that grain size is also nonuniform (Fig.3(c)). The volume fraction of theαincreased to 65% from initial 58%. Average aspect ratio of the grain is 2.28 determined from EBSD.Fig.3(d) shows the bright-field TEM micrograph of the rolled steel. It is clear that there are fine grains and coarse grains in Fig.3(d). The heterogeneous microstructure consisted of nano/ultrafine grain (UFG)and a proper amount of micro grains which embed in the nano/ultrafine grain matrix. In addition, the dislocations are accumulated and tangled with each other around GBs as well as inside grains. Statistical distribution histogram ofγandαgrain obtained from EBSD is exemplified in Fig.3(e) and Fig.3(f), which shows that the average grain size ofγandαis 0.901 and 0.954 µm, respectively. After rolled processing the majority of the grains still distribute below 1 µm.

Fig.3 Microstructures of the as-rolled steel: (a) Optical micrograph; (b) EBSD phase maps; (c) EBSD GBs maps, dotted line represents lowangle GB (2°< misorientation angle ≤ 10°) and black line represents high-angle GB (misorientation angle >10°); (d) Bright field TEM image; (e) Grain size distribution of the austenite phase; (f) Grain size distribution of the ferrite phase

3.3 Mechanical properties and strain hardening

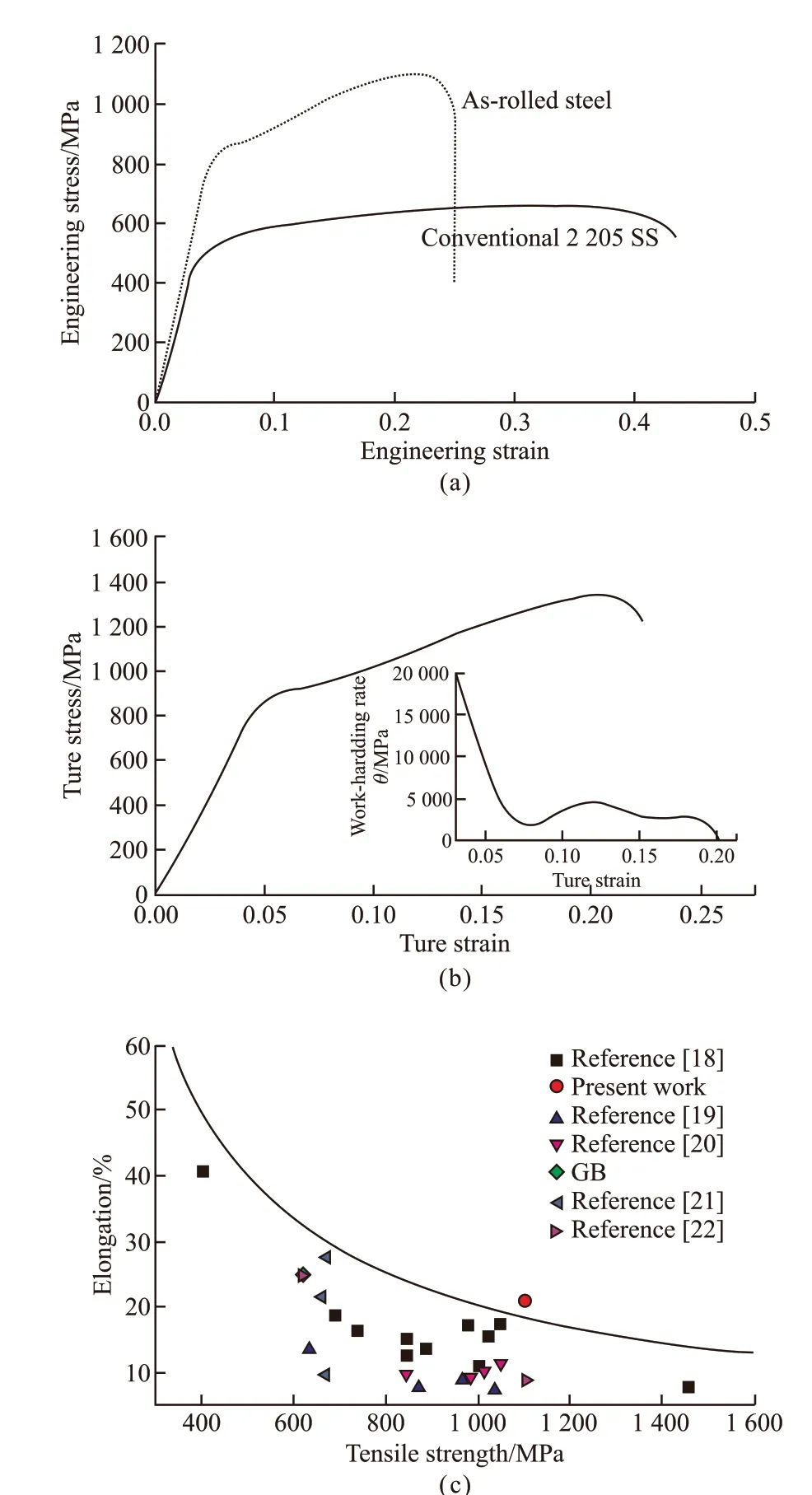

Room-temperature tensile properties of the asrolled steel compared with selected duplex stainless steel are present in Fig.4. Fig.4(a) exhibits the uniaxial tensile engineering stress-strain curves of the present as-rolled steel and conventional 2205 DSS where the tensile direction was parallel to the rolling direction.It can be seen that the strength of the present as-rolled steel increases a lot compared with that of conventional counterpart. The as-rolled steel shows exceptional engineering tensile elongation to fracture (21%) even at high yield strength (863 MPa) and ultimate tensile strength (1 103 MPa). There is a long yield platform in yield stage, which also indicating the rolled 2205 DSS has a good plasticity. Notably the rolled steel still shows a relatively high yield-to-tensile strength ratio(YS/UTS=0.78), indicating that the steel has good resistance to deformation and is less prone to plastic deformation, against the general rule of traditional homogeneous steel, also exhibiting a good plasticity.

Careful insight into the flow stress implies the strain hardening capacity, as quantified by strain hardening rate (Θ=dσ/dε). The as-rolled steel has much higher strain hardening rate, especially at large strain (Fig.4(b)). Θ shows a drop at first and then upturn, which has never been observed in traditional homogeneous metals, indicating a discontinuous yielding. High Θ of the specimen is responsible for its high ductility.

Fig.4(c) shows the ultimate tensile strengthversuselongation to fracture plot. Evidently, strength elongation of the present as-rolled steel falls above strength elongation line corresponding to 20 GPa%.The present as-rolled steel possesses an ultrahigh combination of strength and elongation compared with other DSSs.

Fig.4 (a) Tensile engineering stress-strain curves of the as-rolled and conventional 2205 DSS; (b) Representative true stress−strain curves from (a). (Inset exhibits the strain-hardening rate (Θ)-true strain curves); (c) Strength-elongation plot of selected DSS[18-22]

3.4 Microstructure of the as-rolled steel after tensile test

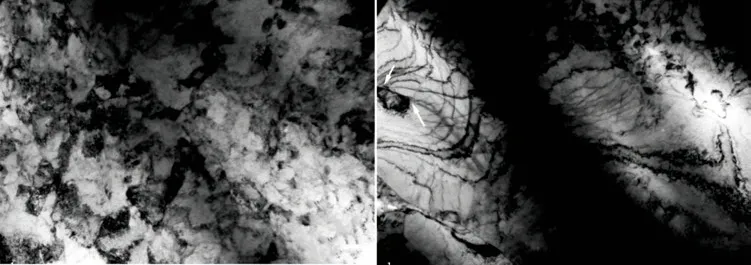

It is believed that the microstructure after tensile testing provides a useful means to fully understand the deformation mechanisms[23]. The TEM images of the as-rolled steel extracted near the fracture zone of the tensile samples are shown in Fig.5(a) and 5(b).An extremely high density of dislocations in the UFG form dislocation cells which consist of cell interior with low dislocation density and cell wall with high dislocation density. The catastrophic release and glide of the dislocations from the cell wall leads to the collapse and break of original cell boundaries and formation of elongated dislocation cell structure after tensile fracture (marked by the white arrows in Fig.5(a)), which are confirmed by comparing Fig.3(d)and Fig.5(a). The interaction of dislocations in coarse grain with fine grain indicated by the white arrows in Fig.5(b) and numerous pile-ups of dislocations between the boundaries and interfaces are also marked by black arrows. This observation strongly supports that the heterogeneous lamella dual-phase microstructure is not only effective blocks to impede the movement of dislocations by multiple interfaces but also to elevate the storage of dislocations by coarse grains.

4 Discussion

The as-rolled steel with heterogeneous lamellar mixture ofγandαshows hierarchical and graded microstructure, quite similar to the microstructure of bone. In bone, strength coexists with toughness(properties usually considered mutually exclusive) by virtue of bone’s twisted hierarchical and heterogeneous mixture (soft and hard ) substructure which simultaneously activates to exceptional improvements stiffness and toughness. We hypothesized that a similar mechanical response can be transferred to the steels by processing a similar duplex phase heterogeneous hierarchical microstructure to benefit from the discontinuous yielding and interface structure and distribute effects.

When a dual-phase heterogeneous-grained metal is under tensile loading, coarse grains and soft phase will be the onset of plastic deformation while they are resisted by adjacent small grains and hard phase, so that coarse grains and soft phase are not free to deformation. As a result, dislocations in coarse grains are piled up and accumulated at the GBs and interfaces (Fig.5(b)), which is known as geometrically necessary dislocations (GNDs) to accommodate the plastic strain discontinuity at the soft and hard domain boundaries[24,25]. This would lead to a long-range back stress to impede dislocations to slip in coarse grains and then result in significant strengthening of the soft grains and phase until the neighboring hard grains start to yield, providing work hardening of the global sample. Therefore, the present hierarchical duplex phase heterogeneous microstructural steel produces a higher yield strength than the conventional counterpart.Experiment in heterogeneous lamella structure Ti verified that back stress was high near the yield point,even higher as tensile strain increasing[13]. The soft micro grains need to overcome the additional large back stress to deform which contributes evidently to the high yield strength. The phenomenon is agreement with the high yield strength produced by back stress in gradient nano-grained structure materials[12,26,27].

Fig.5 (a) Microstructure after tensile test of the as-rolled steel; (b) TEM image of the tensile sample near the fracture zone

Beyond the yield point all of heterogeneous grains will occur deformation but the soft grains would experience a larger strain than hard grains.Strain gradients will build up in the vicinity of domain boundaries when adjacent domains subject to various levels of strain. This produces strain partitioning where soft grains carry much larger deformation than hard grains and strain gradient becomes larger with increasing plastic strain, generating significant back stress strain hardening[28]. In other words, back stress strain hardening in the rolled steel during plastic deformation is ascribed to the existence of the hard and soft modes of dislocation slip behavior in heterogeneous grains with different hardness domains,resulting in high strength and ductility.

In addition to back stress, dislocation hardening is also responsible for the high strength and ductility. The heterogeneous lamella dual-phase microstructure can induce the generation and accumulation of two types of the dislocations under tensile stress. One is the GNDs to accommodate the plastic strain incompatibility, and the other is incidental type of dislocations. Another significant mechanics effect is that the multiaxial stress states may be developed under uniaxial loading conditions due to the strain incompatibility interplay between the soft and hard domains. As an consequence,the multiaxial stress can promote the activation of more slip systems and dislocation accumulation[29], similar to what occurs in gradient structures[12,26]. This will effectively increase the dislocation density.

The heterogeneous lamella dual-phase microstructure can be considered as a derivatives of bimodal structure, but is more effective in retaining work hardening than the bimodal structure[13,30].Compared with the bimodal structure, the heterogeneous lamella dual-phase microstructure possesses the following unique features that are essential for producing the high strength coexists with high ductility: (i) the graded hierarchical nature of the structure, (ii) the duplex mixture and multiple grains, and (iii) the high density of twisted lamella interfaces. First, it has been verified that the elongated grains produce higher work hardening than equiaxed ones, especially when its long axis is along the loading direction[31], which is the case in this work.Second, the duplex mixture and multiple grains can induce multiple plastic strain gradients under uniaxial loading conditions to develop complex back stresses than the bimodal grain. Third, the heterogeneous lamella dual-phase microstructure has high density of interlamella interfaces, where dislocation can pile up and accumulate to enhance back stress hardening and dislocation hardening.

5 Conclusions

In the present study, inspired by the substructure of bone, the 2205 DSS with heterogeneous lamella dualphase nanostructure was processed by aluminothermic reaction and multiple rolling. In essence, the lamella geometry, dual-phase and multiscale grain size distribution simultaneously activate the multiple plastic deformation mechanisms, enabling the steel effective for developing back stress and dislocations hardening which are mainly responsible for the observed high strength and large ductility. This work opens a novel processing method toward extraordinary tensile ductility without sacrificing strength of nano/UFGstructured steel, as opposed to the traditional strengthductility trade-off dilemma of their homogeneous counterparts.

杂志排行

Journal of Wuhan University of Technology(Materials Science Edition)的其它文章

- Mechanical Properties and Microstructure of Al2O3/SiC Composite Ceramics for Solar Heat Absorber

- Effect of Friction Stir Welding on Bulk Metallic Glasses

- Effects of Lay-up Types of Out-of-autoclave Prepregs on Preparation Quality of L-shape Composite Laminates

- Hypereutectic Al-Si Matrix Composites Prepared by In Situ Fe2O3/Al System

- Preparation of Heavyweight Ultra-high Performance Concrete Using Barite Sand and Titanium-rich Heavy Slag Sand

- Effects of Shale and CaO Incorporation on Mechanical Properties and Autogenous Deformation of Early-age Concrete