Diffusion and Regeneration Mechanism of Waste Composite Oils Rejuvenator in Aged Asphalt

2021-09-15LIHaibinYANGFayongZHANGFanZOUXiaolongZHAOGuijuan

LI Haibin, YANG Fayong, ZHANG Fan, ZOU Xiaolong, ZHAO Guijuan

(1.School of Architecture and Civil Engineering, Xi’an University of Science and Technology, Xi’an 710054, China)

Abstract: The physical performance of recycled asphalt was used as the main evaluation index to study the optimal range of a self-made rejuvenator. Through the penetration, viscosity and gel permeation chromatography (GPC) tests, the diffusion degree of the rejuvenator under different temperatures and time process was analyzed, and the diffusion efficiency of the rejuvenator was evaluated from the macro and micro perspective. The regeneration mechanism of the rejuvenator in the aged asphalt was also analyzed using the Fourier transform infrared spectroscopy (FTIR), scanning electron microscope (SEM) and chemical composition tests. The research results showed that the optimum rejuvenator content was about 3%. Higher temperature and longer time were beneficial to improving the permeability and diffusion of the rejuvenator. During the aging process, the light components were reduced, and more macromolecular asphaltenes were generated as well as a large number of carbonyl and sulfoxide. After diffusion and regeneration, the light components in the asphalt were supplemented, the wrinkles and gullies of the aged asphalt were almost improved to the surface state of the matrix asphalt.

Key words: recycled asphalt; waste engine oil; waste cooking oil; rejuvenator; regenerant diffusion;regeneration mechanism

1 Introduction

With the continuous increasing cost of construction materials and awareness of environmental protection, the recycling technology of asphalt pavement has attracted more attention in recent years[1]. Recycling asphalt mixture could reduce the use of new asphalt and new aggregates, which could greatly reduce construction costs and save resources. Based on previous studies, the aging of asphalt due to field usage was one of the most important reasons for the performance deterioration of pavement[2]. Therefore, the rejuvenator had been used to recover the performance of the aged asphalt to meet the performance requirements of virgin asphalt[3,4]. In the regeneration process of waste asphalt, the performance index of aging asphalt after regeneration was the key to directly affecting the index of the regeneration mixture. The problem of the penetration and diffusion of rejuvenator in the aging asphalt directly determined the nature of the recycled asphalt.Therefore, in the study of regeneration, the diffusion and penetration of rejuvenator on the surface of asphalt had become the key to the study[5].

Kuang D[6-8]showed that higher temperature and longer contact time between rejuvenator and aged asphalt were beneficial to improve the diffusion performance of regenerator. At the same time, experimental studies had shown that a smaller viscosity was beneficial to increase the diffusion performance of the regenerate in aged asphalt. Ma T[9]used the viscosity change of the regenerated asphalt to evaluate the diffusion and penetration behavior of the regenerant. Wang F[10]showed that when recycling SBS modified asphalt,the optimal addition rate of rejuvenator was 5%; the penetration of the regenerated asphalt obtained after 3-4 hours of the diffusion test could be used to evaluate the diffusion performance of the rejuvenator. Karlsson R[11,12]and Su J[13]used attenuated total reflection Fourier transform infrared spectroscopy to study the diffusion and permeability properties of the regenerate. The results showed that the size of the diffusion molecule,the polarity of the diffusion molecule, the diffusion temperature, and the viscosity of the regenerate had a significant effect on the ability of rejuvenator to diffuse and penetrate into the aging asphalt. Darabi M K[14]determined the experimental method for calculating the diffusion coefficient. Rad F Y[15]selected Fick’s law and Stoke-Einstein formula as the mathematical model for studying the diffusion of rejuvenator type and diffusion coefficient. As the interface temperature increased,the viscosity decreased, and the diffusion coefficient increased significantly. Baqersad M[16]found that the effect of rejuvenator was weakened with the deepening of the diffusion. The re-diffusion of large molecular weight regenerator components was hindered by agglomerated asphaltenes, thereby improving the diffusing ability of the regenerate.

The objective of this study is to evaluate the real blending status of the rejuvenator and aged asphalt in a recycled asphalt mixture. Therefore, different laboratory tests were designed to reveal the diffusion and distribution of the rejuvenator in the aged asphalt. The physical performance of recycled asphalt was used as the main evaluation index to study the optimal range of self-made rejuvenator. On this basis, the penetration,viscosity and the diffusion degree of the rejuvenator in different temperature and process time was studied.Then the diffusion efficiency of the rejuvenator was analyzed from the macro and micro perspectives. Finally,the FTIR, SEM and GPC tests were conducted to reveal the regeneration mechanism of the waste oil regenerant in the aged asphalt which then will serve as guidance for other researchers and also for the waste oil recycled asphalt application.

2 Experimental

2.1 Materials

2.1.1 Matrix asphalt

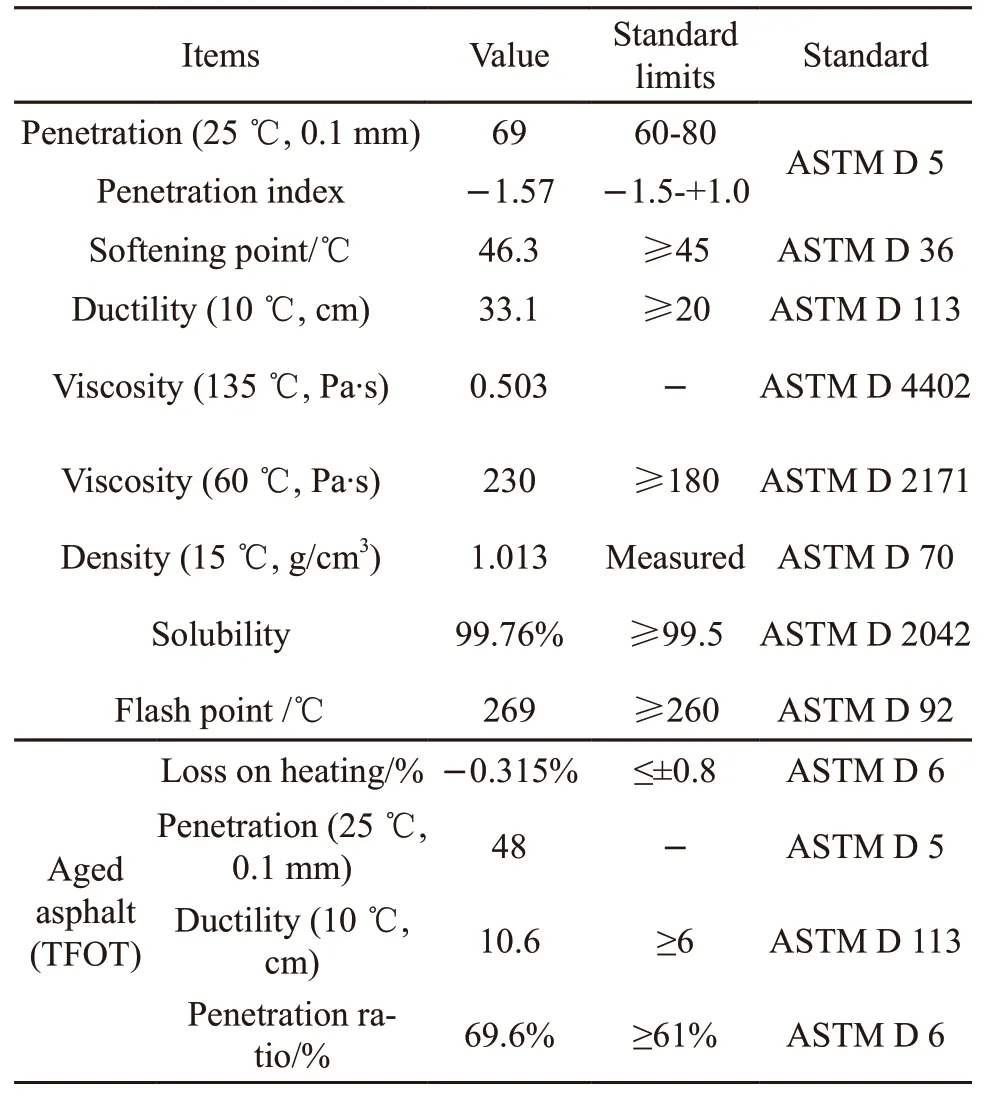

The matrix asphalt used in this study was Karamay 70 asphalt produced by China Petroleum. The basic properties of matrix asphalt are shown in Table 1.

2.1.2 Rejuvenator

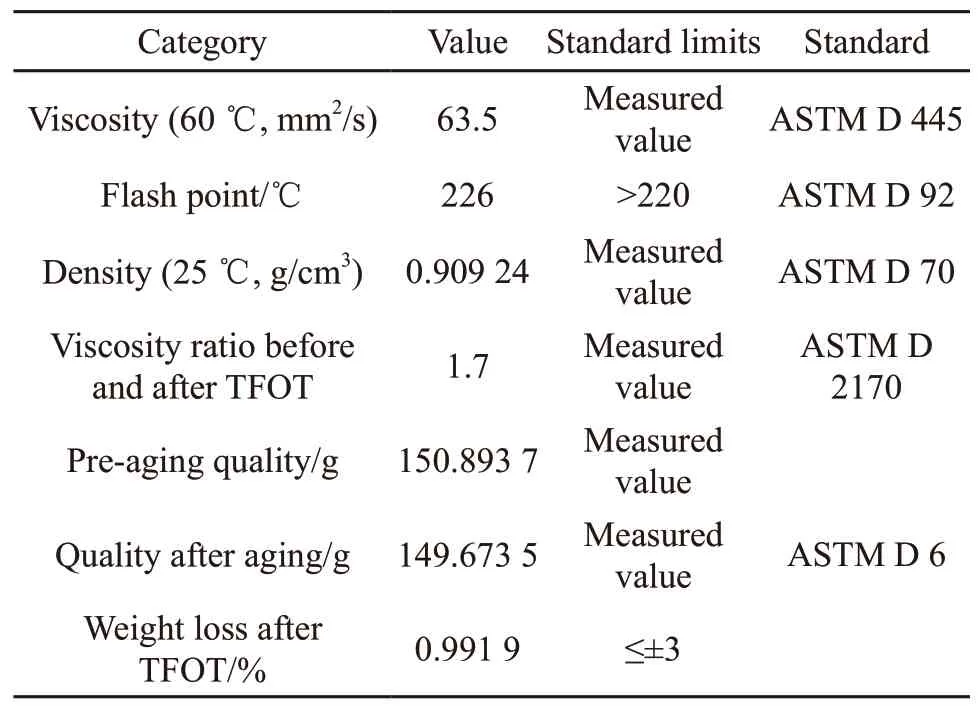

The rejuvenator used in this paper were made in the laboratory, and the main components are recycled engine oil and waste cooking oil[17]. The basic indicators of the rejuvenator are shown in Table 2.

2.1.3 Aged asphalt

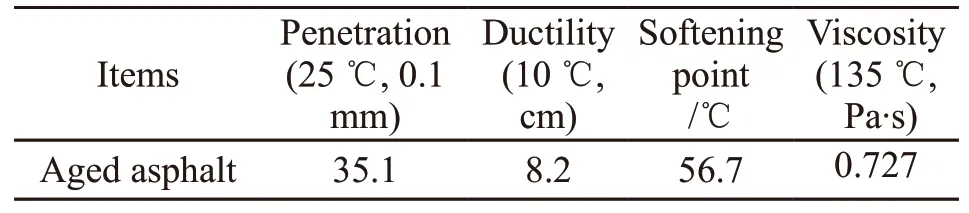

The aged asphalt used in this article is prepared by artificial simulated aging. First, the rolling thin film oven test (RTFOT) was employed to simulate short term aging according to ASTM D 2872, and then the short-term aging asphalt was placed in a pressure aging vessel (PAV) at a temperature of (100±2) ℃ for pressure aging for (20±10) h according to ASTM D 6521.Each PAV cycle simulated a 7 to 10 year period of in-service aging of asphalt binder[18-20]. The basic properties of aged asphalt are shown in Table 3.

Table 1 The basic properties of matrix asphalt

Table 2 Basic indicators of rejuvenator

Table 3 The basic properties of aged asphalt

2.2 Methods

2.2.1 Physical properties

The rejuvenator of 2%, 3% and 4% were selected to be added to the aged asphalt to prepare recycled asphalt. The penetration, ductility, softening point and viscosity of asphalt were tested in accordance with the test methods[21]T0604-2011, T0605-2011, T0606-2011, and T0625-2011 in the “Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering”, which was similar to ASTM D 5, ASTM D 113, ASTM D 36, ASTM D 4402.

2.2.2 Diffusion Test

a) Diffusion-penetration test

During the diffusion-penetration test[22], first add the aged asphalt to the penetration mold, and then add 10% of the rejuvenator by weight of the aged asphalt.The penetration samples were placed in an oven at 150,160, 170, and 180 ℃ for different time of 1, 2, 3, and 4 h. After cooling, the surface rejuvenator was rinsed.The penetration test was then conducted at 25 ℃ according to ASTM D 5.

b) Diffusion-viscosity test

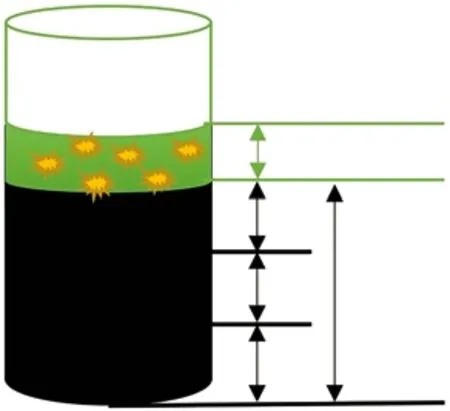

The diffusion model used in the diffusion-viscosity test is shown in Fig.1. 6 cm aged asphalt (about 30 g) was poured into aΦ30×150 aluminum foil tube and cooled at room temperature for 30 minutes. The prepared rejuvenator sample (about 3 g) was then added into the same aluminum foil tube and put it in an oven at 150, 160, 170, and 180 ℃ for different time of 1, 2,3, and 4 h. The specimen was thereafter taken out after a specified time and cooled down to room temperature.After a while, the specimen was placed in a refrigerator at -10 ℃ for 30 minutes, after which a spatula was used to remove the rejuvenator part of the specimen.Finally, the aged asphalt part of the specimen was cut into three parts and named A, B, and C respectively.The diffusion effect was evaluated from the viscosity changes at different positions (A, B, C) of the aged asphalt after diffusion[23].

Fig.1 Diffusion model

c) Gel permeation chromatography (GPC) test

The GPC techniques were used to analyze the distribution of the asphalt layer molecules from the microscopic level[24,25]. It can not only quantitatively describe the miscibility and diffusion degree of the rejuvenator and the aged asphalt, but also evaluate the rejuvenator effect of the aged asphalt according to the distribution of the molecular weight of the asphalt layer. The molecular size distribution of the recycled asphalt diffused for 1, 2, 3, and 4 hours at 170 ℃ was detected by GPC.

2.2.3 Regeneration mechanism

a) Fourier transform infrared spectroscopy (FTIR)

The FTIR test was conducted to measure the functional group changes of matrix asphalt, aged asphalt,and recycled asphalt. The FTIR is a device that uses spectral data to evaluate the absorption of the infrared spectrum of a sample and defines the absorption intensity over a wavelength. The peaks in infrared spectrum could be used to detect the chemical composition functional group of asphalt bonds. The test was performed on binders with a wavenumber of 400-4 000 cm-1[26].

b) Scanning electron microscope (SEM)

SEM can clearly and intuitively present the morphology of the asphalt surface and qualitatively characterize the microscopic characteristics of the asphalt[27]. Hitachi SEM SU 8000 was used in this test, and the magnifications used are 30 times, 500 times and 2 000 times.

c) Chemical component determination

The solvent precipitation and chromatography column method were used to analyze chemical component of different asphalts according to ASTM D 4124, including saturates, aromatics, resins and asphaltenes[28-30].

3 Results and discussion

3.1 Evaluation of regeneration effect of rejuvenator

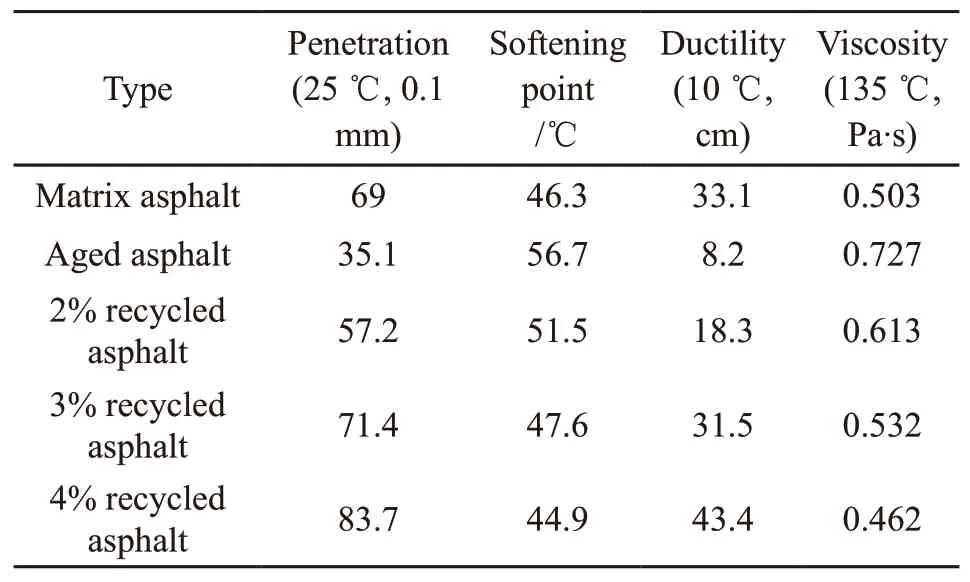

The rejuvenator of 2%, 3%, and 4% were selected to be added to the aged asphalt to prepare the recycled asphalt to test the regeneration effect. The basic physical performance test results of the recycled asphalt are shown in Table 4 and Fig.2.

Table 4 The basic physical properties test results of recycled asphalt

Fig.2 shows that with the increase in the amount of rejuvenator, all indicators of the aged asphalt have recovered. The penetration, softening point, ductility and viscosity indexes of 2% recycled asphalt were respectively 96.7%, 102.8%, 55.3% and 114.5% of matrix asphalt. The penetration of the recycled asphalt with 2% rejuvenator had met the technical index requirements of 70# road petroleum asphalt, but the ductility of the aged asphalt had not been restored to the matrix asphalt level. The penetration, softening point,ductility and viscosity indexes of recycled asphalt with 3% rejuvenator were respectively 112.8%, 100.8%,95.2% and 91.5% of the original asphalt. The penetration of the recycled asphalt with 3% rejuvenator had reached the level of the matrix asphalt. The rejuvenator significantly improved the ductility of the recycled asphalt, which was close to the original asphalt level. As the content of rejuvenator was further increased to 4%,the performance indicators of recycled asphalt were further improved, and all performances were effectively restored.

Fig.2 Performance test results of recycled asphalt with different rejuvenator content

Based on the above analysis of the regeneration performance of the rejuvenator, it could be seen that the rejuvenator had a good comprehensive regeneration effect on the aged asphalt. The penetration of the recycled asphalt at the level of 2% mixed rejuvenator had completely restored to the matrix asphalt level, but the effect of improving ductility was not obvious. The 3%rejuvenator could restore the performance of the aged asphalt to the matrix asphalt level, and the recovery effect was better. The performance of recycled asphalt with a 4% rejuvenator had been further restored. However, as the permeability increased greatly, it was not conducive to the high temperature stability of the recycled asphalt. Therefore, the optimum amount of rejuvenator used is 3%.

3.2 Diffusion

3.2.1 Results and analysis of the diffusion-penetration test

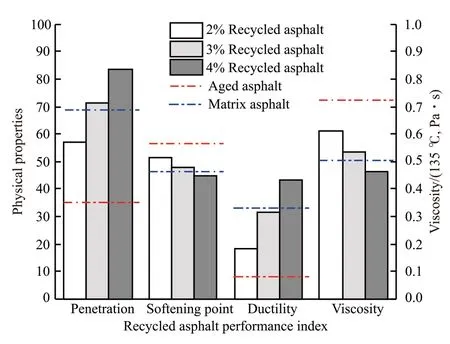

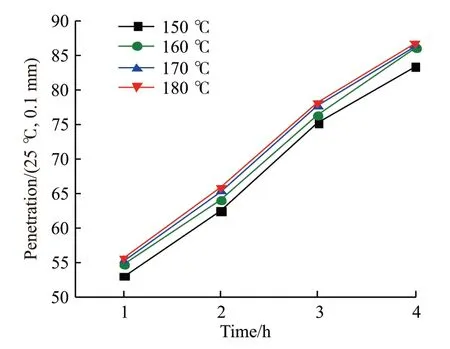

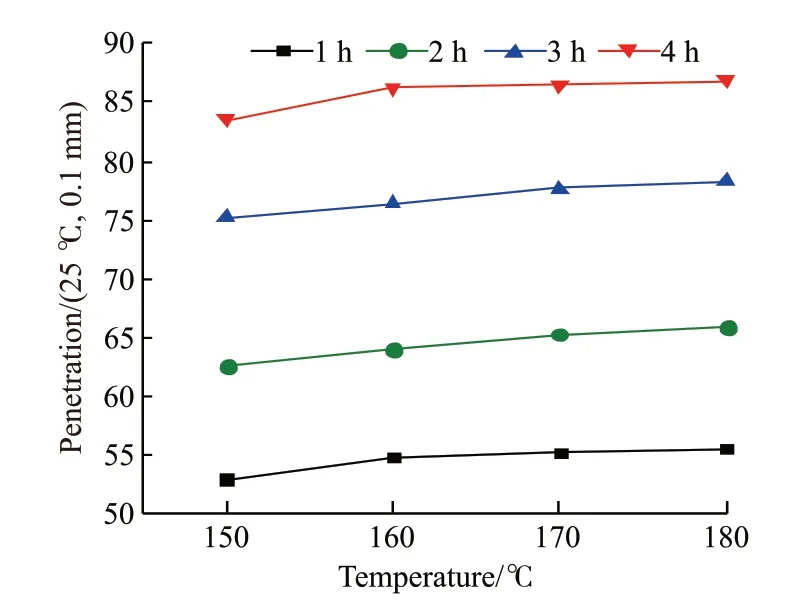

The test results of penetration of the rejuvenator after diffusion are shown in Table 5. The influence of the diffusion time and temperature of the degree of diffusion is shown in Fig.3 and Fig.4.

Table 5 Test results of penetration

Fig.3 Effect of diffusion time on penetration

Fig.4 Effect of diffusion temperature on penetration

It can be found from Fig.3 that under four different temperatures, as time increased, the penetration value of the recycled asphalt increased from more than 50 to more than 80, an increase of 57%. It can be seen from Fig. 4 that as the diffusion temperature increased,the diffusion effect of the rejuvenator gradually became better. For every 10 ℃ increased, the corresponding increase in penetration was 2.7%, 1.14% and 0.6% respectively. When the diffusion temperature was 170 ℃,the increase in penetration tended to be gentle, therefore, the rejuvenator that the optimal diffusion temperature of the waste composite oils rejuvenator used in this paper is 170 ℃.

The above results indicate that the diffusion time had a greater influence on the diffusion effect of the rejuvenator in the asphalt than the diffusion temperature. The diffusion effect of the rejuvenator in the recycled asphalt would gradually become better with the increase of diffusion temperature and time. The light components in the rejuvenator were gradually penetrated into the aged asphalt, the light components in the aged asphalt were replenished, and the asphalt performance was gradually restored. Therefore, appropriately extending the mixing time and increasing the mixing temperature would help to better exert the effect of the rejuvenator in practical applications.

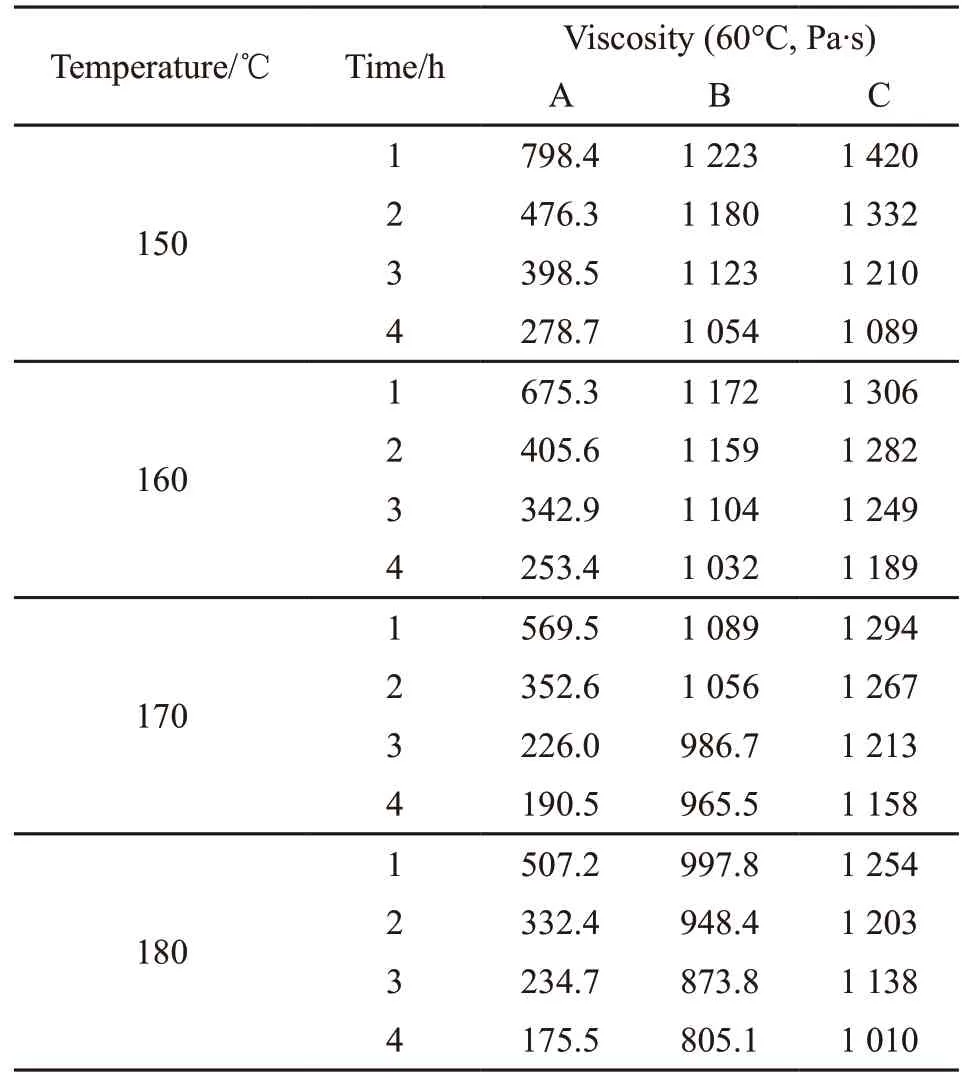

3.2.2 Results and analysis of the diffusion-viscosity test

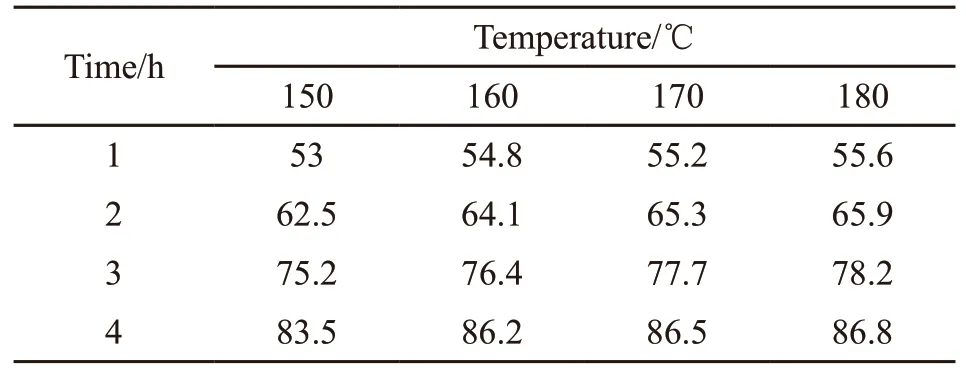

Table 6 shows the viscosity test results at different positions (A, B, C) of the recycled asphalt after diffusion under different diffusion temperature and time.

Table 6 Test results of viscosity

It can be seen from Table 6 that the diffusion time and temperature affected the diffusion of the rejuvenator in the aged asphalt. As diffusion time increased, the diffusion rate decreased significantly. After more than 4 h, the diffusion gradually tended to equilibrium. It showed that in the initial state, the concentration difference between the rejuvenator and the aged asphalt was relatively large, and the interaction between molecules was more frequent, so the diffusion effect was obvious.As time goes by, the concentration difference between the rejuvenator and the aged asphalt decreased, so the diffusion efficiency gradually decreased and became static after a long time.

In the same diffusion time, the diffusion efficiency increased significantly as the diffusion temperature increased. The molecular movement between rejuvenator and recycled asphalt could be regarded as Brownian motion. The increase in temperature could increase the intensity of molecular motion, promoted Brownian motion, and strengthened the diffusion effect. Furthermore, the diffusion temperature would affect the viscosity of the asphalt. At high temperatures, the viscosity was too small and the intermolecular forces became smaller, which was beneficial to the diffusion process.

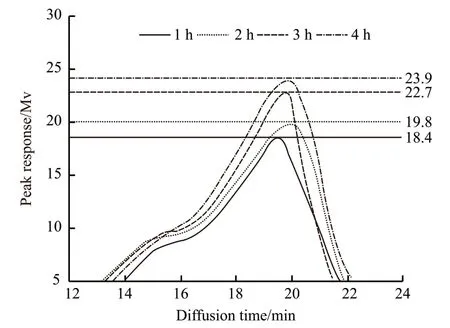

3.2.3 Results and analysis of the GPC test

GPC test was used to detect the molecular weight of recycled asphalt under different diffusion time, and the test results are shown in Fig.5.

Fig.5 The molecular weight of recycled asphalt under different diffusion time

It can be found from Fig.5 that the longer the diffusion time of the rejuvenator at a constant temperature of 170 ℃, the greater the number of macromolecules in the recycled asphalt. The constant temperature diffusion time was increased from 1 to 4 h, and the number of macromolecules in recycled asphalt increased from 18 to 23.7 Mv, an increase of more than 31.6%. When the diffusion time increased from 3 to 4 h, the number of macromolecules in the regenerated asphalt increased from 23.1 to 23.7 Mv, an increase of 2.6%.

It showed that the diffusion efficiency of the rejuvenator gradually increased with the extension of the diffusion time. Macroscopically, the penetration of recycled asphalt increased and the viscosity decreased,and microscopically it showed that the number of macromolecules in recycled asphalt increased. The growth rate of macromolecules in the recycled asphalt increased first and then decreased, indicating that the rejuvenator had gradually diffused completely with the extension of the diffusion time.

3.3 Analysis of regeneration mechanism

3.3.1 Analysis of carbonyl and sulfoxide functional groups

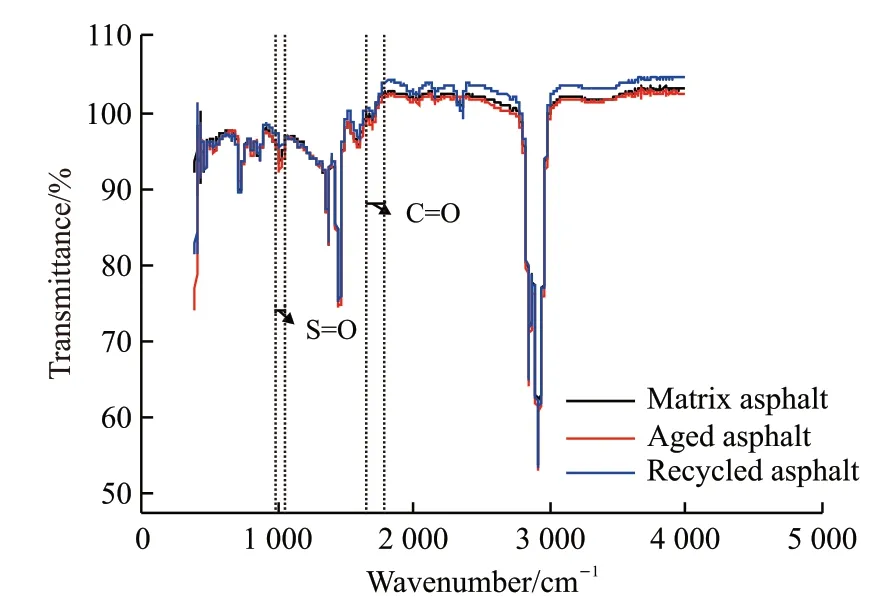

Fig.6 and Fig.7 show the infrared spectrum of the matrix asphalt, aged asphalt and recycled asphalt.

Fig.6 Infrared spectrum of three asphalt

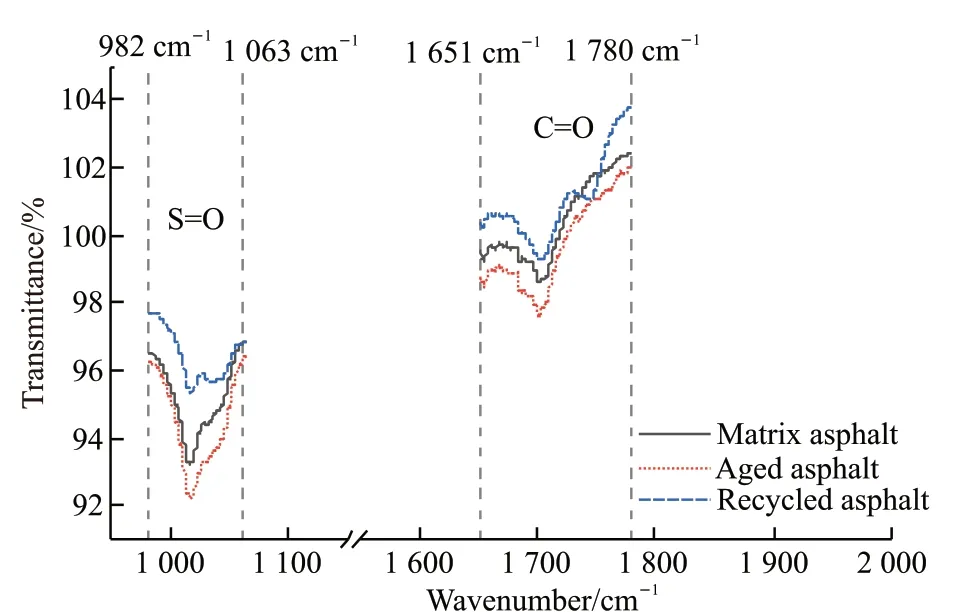

Fig.7 Infrared spectrum of S=O and C=O

By comparing the absorption peaks of functional groups in the spectrum of Fig.6, it could be found that no new functional group types were generated in the matrix asphalt, aged asphalt and recycled asphalt,but the original functional group concentration had changed.

Comparing the infrared spectrum of the matrix asphalt and the aged asphalt, it could be found that the asphalt had undergone oxidation, condensation and dehydrogenation reactions, resulting in the carbonyl absorption peak near 1 703 cm-1(C=O) and the sulfoxide absorption peak near 1 030 cm-1(S=O) continuously increased. The characteristic absorption peaks of the carbonyl and sulfoxide groups in Fig.7 were integrated,and the relative carbonyl index (CI) and relative sulfoxide index (SI) were calculated. The greater the increase in CI and SI, the more serious the asphalt aging. The functional group absorption characteristic peak index is shown in Table 7.

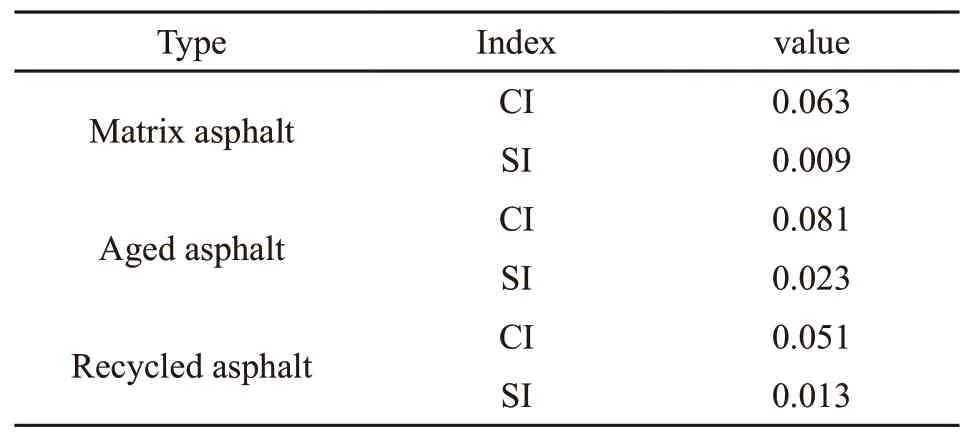

Table 7 The functional group absorption characteristic peak index

It could be seen from Table 7 that the CI and SI of the matrix asphalt increased after aging. After regeneration by the rejuvenator, the two characteristic absorption peak index values in the aged asphalt had decreased and returned to the same level as the matrix asphalt. Compared with the SI, the addition of rejuvenator had a greater impact on the C=O characteristic absorption peak area, and the CI decreased more significantly. In the process of thermal oxidative aging of asphalt, oxidation was the main reaction, which was manifested by the formation of carbonyl and sulfoxide groups. Adding regenerating agent to supplement C and S elements in the aged asphalt, and the relative content of C=O and S=O was reduced, the aging phenomenon was effectively restored.

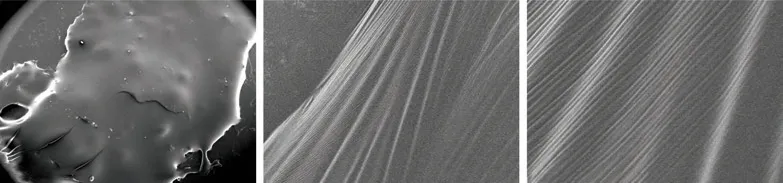

3.3.2 Analysis of asphalt surface morphology

The scanning electron microscopes of matrix asphalt, aged asphalt and recycled asphalt are shown in Figs.8-10.

It can be seen from Fig.8 that the surface of the matrix asphalt was very uniform under the scanning electron microscope of different magnifications. It could be seen that the surface of the matrix asphalt sample exhibited a silky-smooth state on the whole,basically a homogeneous structure. It can be seen from Fig. 9 that the aged asphalt sample could not form a whole structure, and the whole was in a loose and diluted state, and the ravine phenomenon was obvious. A lot of rough textures appeared on the surface of the asphalt sample, showing a large number of dense folds. It can be seen from Fig. 10 that the recycled asphalt sample was reclassified into a whole structure. The wrinkled texture of the aged asphalt had disappeared, and the surface became a smooth appearance similar to the matrix asphalt.

Fig.8 SEM of matrix asphalt

Fig.9 SEM of aged asphalt

Fig.10 SEM of recycled asphalt

To sum up, after the aging of the matrix asphalt,the state of the sample changed from the whole to loosen, and could not be integrated into a whole plate shape, a large number of wrinkled textures appeared on the surface, and the performance decreased. After adding the rejuvenator, the light components in the asphalt were replenished, and the macromolecular structure underwent a reduction reaction, which reproduced the surface state of the matrix asphalt. Therefore, the waste composite oils rejuvenator could restore and improve the physical properties of the aged asphalt.

3.3.3 Analysis of chemical component

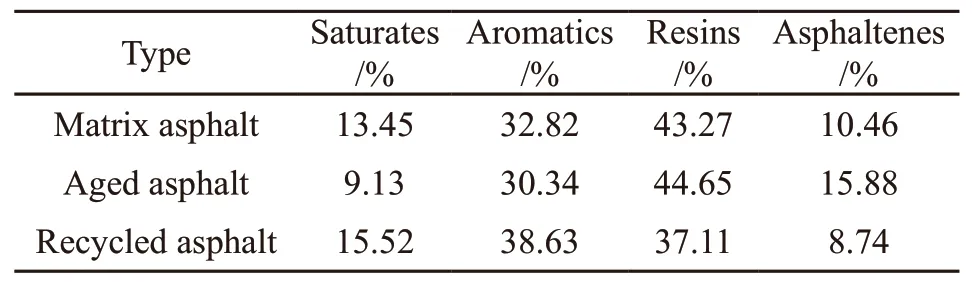

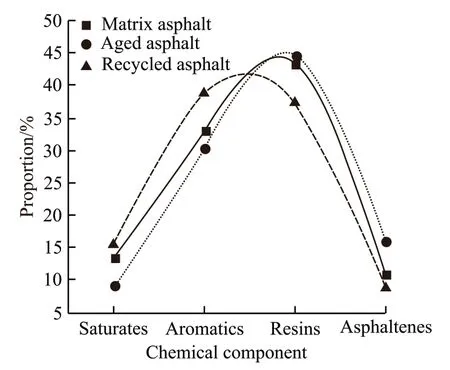

The chemical content of matrix asphalt, aged asphalt and recycled asphalt were tested. The specific results are shown in Table 8 and Fig. 11.

According to the test results of the content of saturates, aromatics, resins and asphaltenes in Table 8 and Fig. 11, when the matrix asphalt was aged, the oil will be lost serious, macromolecular asphaltenes would be formed, the content of saturates and aromatics components in the asphalt would be significantly reduced, and the content of asphaltenes increased, resulting in chang-es in its viscosity and penetration, which corresponds to the previous conclusions. After being regenerated by the rejuvenator, the content of each component in the aged asphalt changed significantly. The smaller light component molecules penetrated into the asphalt structure and dissolved with the original oils in the aged asphalt together as the dispersion medium of macromolecular asphaltenes. It was manifested as a significant increase in saturates and aromatics content in recycled asphalt.

Table 8 Chemical content of three asphalt

Fig.11 Chemical component of three asphalts

4 Conclusions

a) The self-made waste composite oils rejuvenator had a good comprehensive regeneration effect on the aged asphalt, and could restore and improve the physical properties of the aged asphalt. The performance index of the recycled asphalt with 3% rejuvenator had been restored to the matrix asphalt level.

b) The diffusion effect of the rejuvenator in the recycled asphalt would gradually become better with the increase of diffusion temperature and time. The optimal diffusion temperature of the waste composite oils rejuvenator used in this paper is 170 ℃. The diffusion time had a greater influence on the diffusion effect of the rejuvenator in the asphalt than the diffusion temperature. As the diffusion deepens, the regeneration effect weakens and more macromolecules are generated.Asphaltene hinders the redistribution of rejuvenator,and the diffusion efficiency gradually decreases.

c) After the matrix asphalt had been aged, a lot of rough textures appeared on the surface of the asphalt sample, showing a large number of dense folds. A large amount of carbonyl and sulfoxide groups would be formed inside, and macromolecular asphaltenes will be formed. After regeneration by the rejuvenator, the two characteristic absorption peak index values in the aged asphalt had decreased and returned to the same level as the matrix asphalt. The light components in the asphalt were replenished, and the wrinkle and ravine phenomenon of the aged asphalt had been greatly improved,which reproduced the surface state of the matrix asphalt.

杂志排行

Journal of Wuhan University of Technology(Materials Science Edition)的其它文章

- Poly(dopamine)-assisted Bioactive Coating on the Surface of Porous Poly (Ether Ether Ketone) to Promote Osteogenic Differentiation of rBMSC

- Influence of Heat Treatment on Microstructure and Mechanical Properties of Plasma Sprayed FeCrMoCBY Amorphous Coatings

- Lamella Multiple Grained Structure Making 2205 Duplex Stainless Steel with Superior Strength and Ductility

- Progress in Light-weight High Entropy Alloys

- Synthesis and Characterization of Polyaniline/MgTiO3 Composite with Excellent Thermal and Electrochemical Performance

- Synthesis and Characterization of Hyperbranched Epoxy with Terminal Ally Group and Its Application of Toughen Bismaleimide