Influence of Rheological Active Additives on the Properties of Self- compacting Concrete

2021-06-14AbbasGuvalovSaidaAbbasova

Abbas Guvalov, Saida Abbasova

(1. Azerbaijan University of Architecture and Construction, Azerbaijan; 2. Azerbaijan University of Architecture and Construction, Azerbaijan)

Abstract: The effect of rheological-active additives on the properties of cement suspensions and selfcompacting concrete mixtures have been studied. In order to increase the rheological matrix and provide high fluidity, stone powders were used during the crushing of local mountain rocks in self-compacting concrete.Taking into account the high dispersion of rheological-active additives, highly effective plasticizers were used to regulate the reotechnological properties of cement-based mixtures. The effect of sulfonaphthalen-formaldehyde oligomer and polycarboxylate-based hyperplasticizer on rheological properties of cement systems as plasticized additive on methodology proposed by V Kalashnikov was evaluated.The flow rate of cement suspension is determined by means of mini-viscosimeter, spreading of cement-sand mortar by means of Hegermann cone, and the slump of concrete mixture by means of Abraham’s cone. On the basis of obtained results, it was determined that limestone powder was more efficient than other stone powders. Thus, when adding 40% limestone powder to the mixture, the compressive strength of the samples taken from self-compacting concrete mixture increases by 15%-30% compared to the control samples. The optimal quantities of rheological-active additives and plasticizers have been identified and the possibility of obtaining high-strength self-compacting concrete based on them has been confirmed.

Key words: polyfunctional; cement; stone powder; hyperplasticisers; rheology matrix; dispersion aggregate

1 Introduction

Until today a fundamental change did not occur in the composition of the most common monolithic composite of concrete. However, recently an extensive research has been carried out on the development and use of new concrete modifiers, which allow regulating the rheology of concrete mixes and improving the properties of concrete. Concrete compositions obtained with the use of these modifiers in terms of quality characteristics are much higher than traditional ones[1-4].

The new generation of polyfunctional concrete can significantly increase the flow of concrete through a significant increase in the amount of rheological matrix consisting of cement, stone powder, pomegranate sand,water, super or hyperplasticizer. It is known that the amount of rheology matrix in the mixture should be sufficient to ensure high fluidity of the bubble, as well as the free movement of large and small filler in the concrete mix. Therefore, in these concrete mixtures,large fillers can be freely replaced without any impediment or resistance. Therefore, ordinary concrete is not sufficient for the rheology matrix fillers to interrupt one another freely in the process of molding.Therefore, either vibrators are used during molding such concrete or additional water is required. Adding water increases the porosity and reduces its durability.To increase the rheological matrix, the quantity of pomegranate dispersant components such as cement or stone powder should be increased[4-6].

Increasing the amount of cement is not economically efficient, because it increases the consumption of cement and the cost of the concrete,and its structure is broken due to the deformation of concrete. Thus, it is advisable to give stone powder as an optimal amount of pomegranate dispersing component in cement to mix the properties of poly functional concrete[7-11].

The most widely used pomegranate dispersion in the production of polyfunctional concrete is grated quartz sand that is added to an additional 280-400 m2/ kg special surface[12]. Pomegranate disperse quartz sand has high rheological activity and increases its density while reducing its porosity when used in concrete. Pomegranate quartz increases its strength by up to 150 MPa when it joins the optimum amount of concrete. With its high tech properties, pomegranate disperse quartz also has significant deficiencies. These deficiencies are energy expenditure on washing, drying and grinding of sand in the mold. Therefore, the study of mountain rocks that can replace quartz is very actual.

The purpose of the present study is to determine the effect of superplasticizer and mineral modifier on the properties of self-compacting cement compositions.

2 Experimental

In the present research, dust particles from grinding of rocks were used in the rare-active dispersion filler lab. The following mountain rocks are used as local raw materials for the purchase of fine dispersed powders:

limestone of Garadagh deposit, marble of Dashkesan deposit, and granite of Zurnabad bed of Khanlar District.

In the research, Glenium SKY 500, Glenium 313 hyperplasticizers and Rheobuild 878 superplasticizer derived from BASF were used as a plasticizer addition.Hyperplasticizer Glenium SKY 500 is aqueous solutions with different degrees of polymerization based on Glenium 313 polycarboxylate esters.Superplasticizer Rheobuild 878 naphthalene is an anionic surface-active agent, consisting of a mixture of oligomer and polymer compounds obtained as a result of condensation of sulfonate with formaldehyde.

The CERM I -52, 5N portlandcement of the Holcim cement plant, such as cement, was used.

Bahramtepe River sand (Mir = 2, 1) and Guba stone (Mir = 3, 4), as well as 5-10 mm Guba massage were found as large filler.

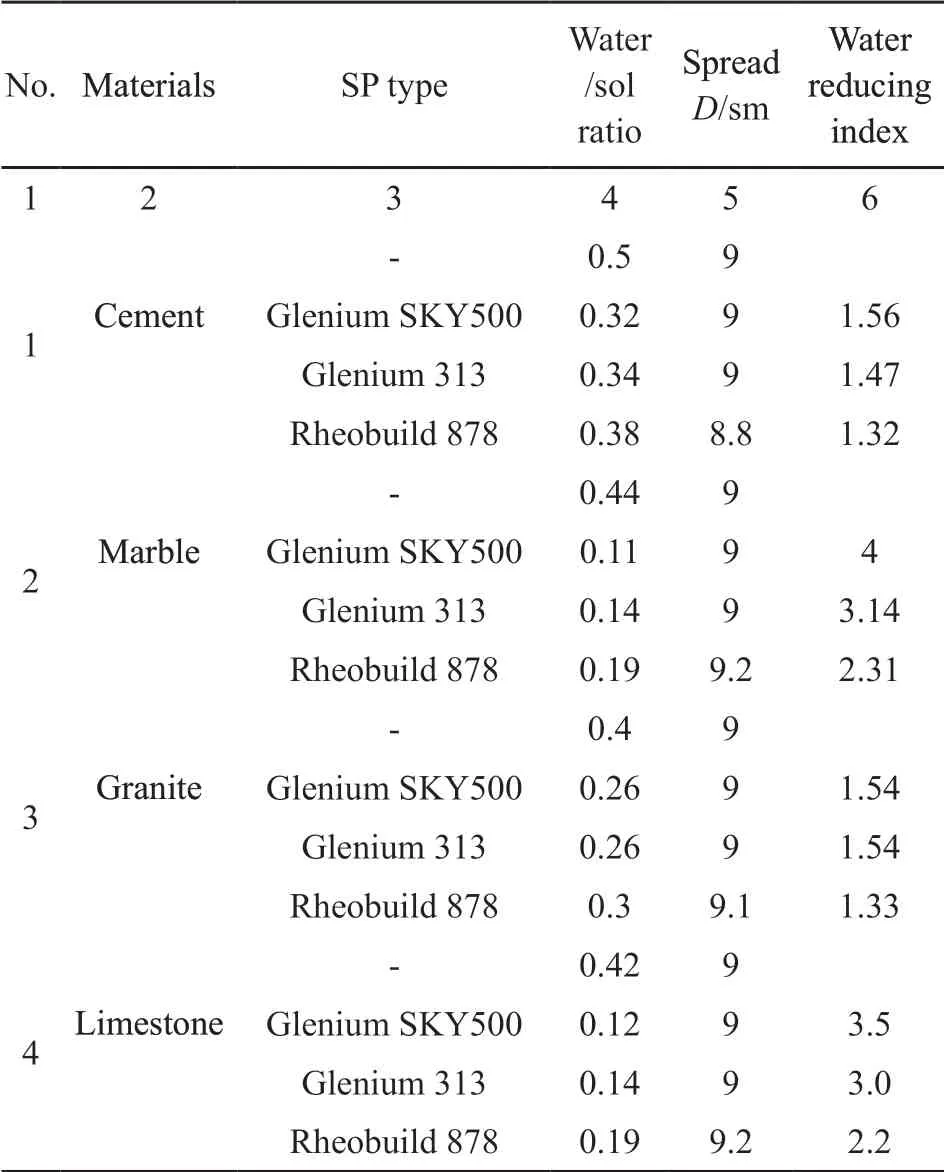

Rheological characteristics methodology proposed by V Kalashnikov was evaluated[12]. According to this method, the modified Suttard viscosimeter was used. Viscosimeter is a stainless steel cylinder with an internal diameter of 25 mm and a height of 50 mm. The change in water demand and fluidity is estimated for the spread of water-mineral mixture in the gravitational flow of the dough. In this case, the flow rate is calculated by the following formula:

where,τ0is the flow rate of the paste, Pa;his the viscometric height, m;dis the density of dough, kg /m3;kis the ratio taking into account the distribution of tension in the pulse-plastic mass 2;Dis the diameter of dough, m.

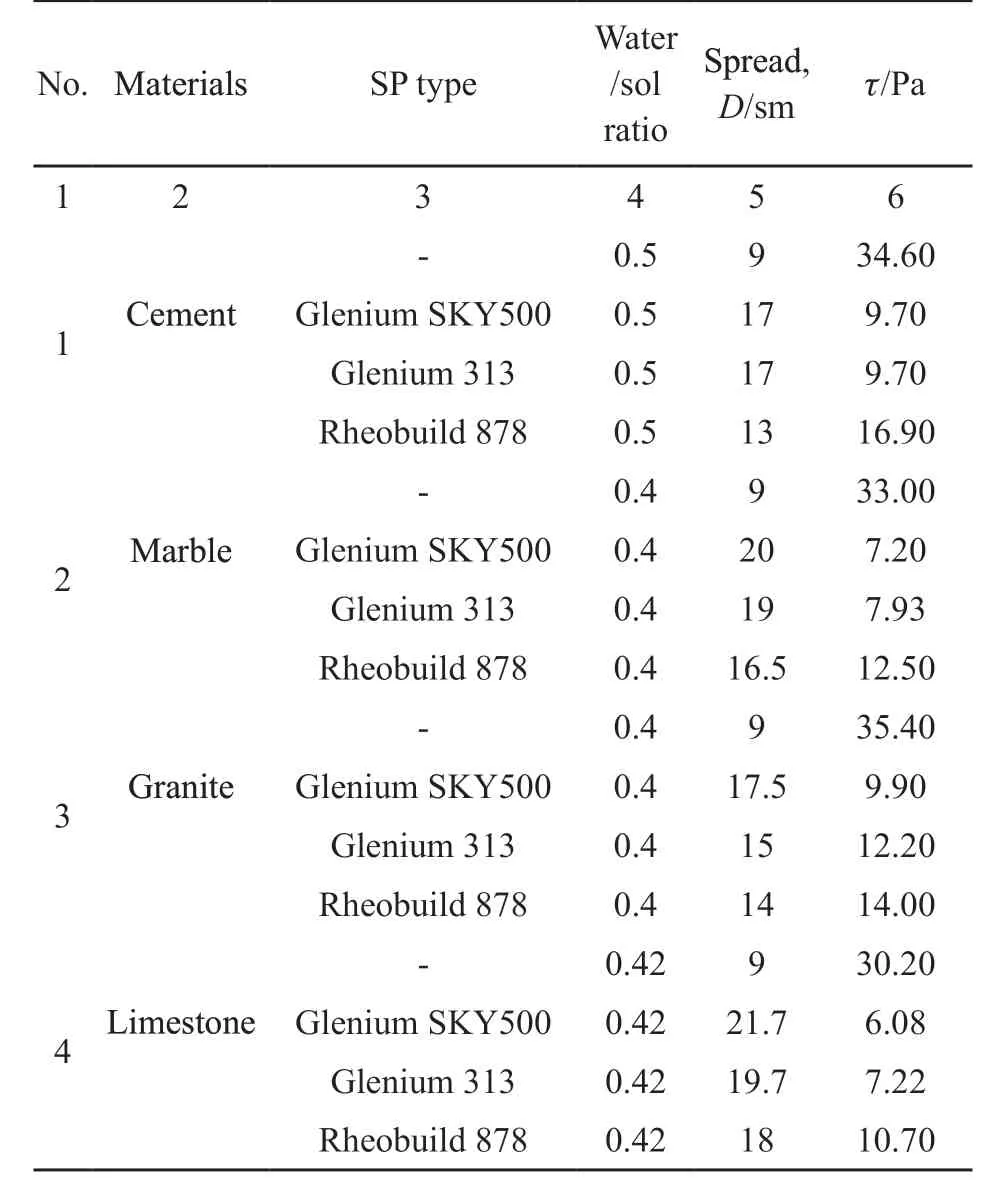

The method includes the following steps: Under 180 mm×180 mm size glass, the circular scales are placed on paper, and then the cylinder and the glass are moistened. The material sample is taken to ensure that the cylinder is full. The cylinder is removed and the diameter of the dough is measured. The density of the dough taken from each measurement is indicated.According to the results of measurements, the plastic effect is determined. Plasticizing effect is determined by the water reducing index characterizing the reduction of water consumption in the isoreological system:

where, (Water/Solid)nand (Water/Solid)plis a water/solid ratio of normal and plasticized paste. The spread of cement mortar was determined with Hegermann cone, and the spread of concrete mixture is determined by the Abrams cone[13,14]. 5 sm cube samples, based on cement paste and cement-sand solution, 15 sm cube samples based on concrete mixture were maintained in normal conditions. The content of cement paste and concrete mixture is shown in the corresponding tables.

3 Results and discussion

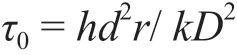

At the initial stage of the research, reotechnological properties and sedimentation effects of mineral suspensions (cement, limestone, marble and granite powder) were studied (Table 1). Three different plasticizers were used in the research. Water reducing effect of hyperplastifers is 1.56 in cement suspension,1.54 in granite, 3.5-4 in marble and lime stone.

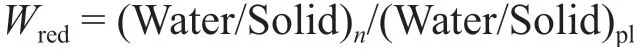

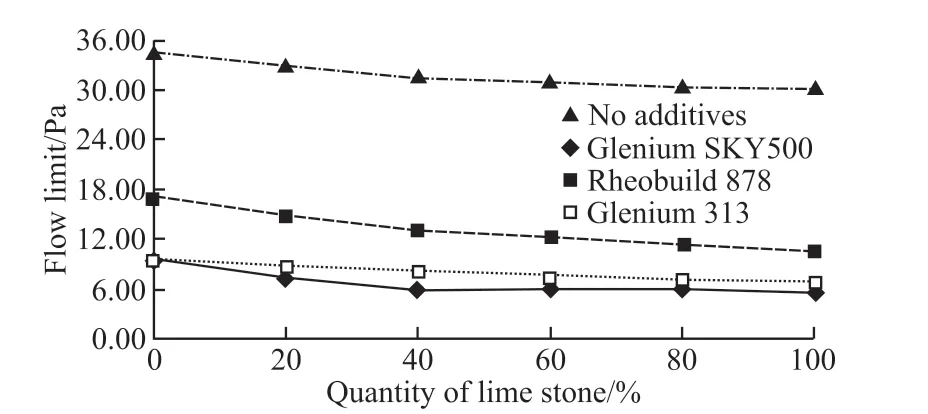

The use of 1% of the additives significantly increases the diffusion diameter of the mixture in all constituents and decreases the flow rate accordingly(Table 2). The maximum flow rate characterizing the diffusion of gravitational flow at the lime suspension is taken during use of the Glenium SKY500 plasticizer(6.08 Pa). Under the influence of the hyperplastifier,mineral absorption at this point of flow is carried out completely as a flux fluid and flows like water.

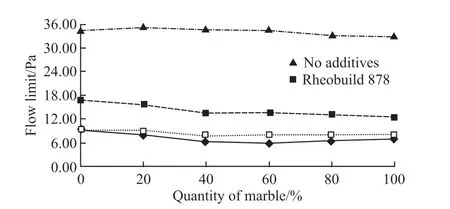

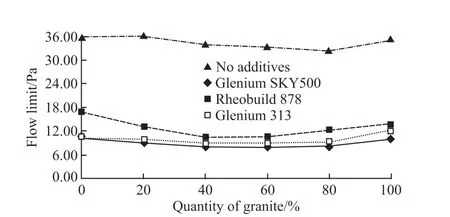

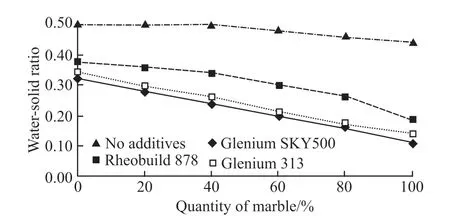

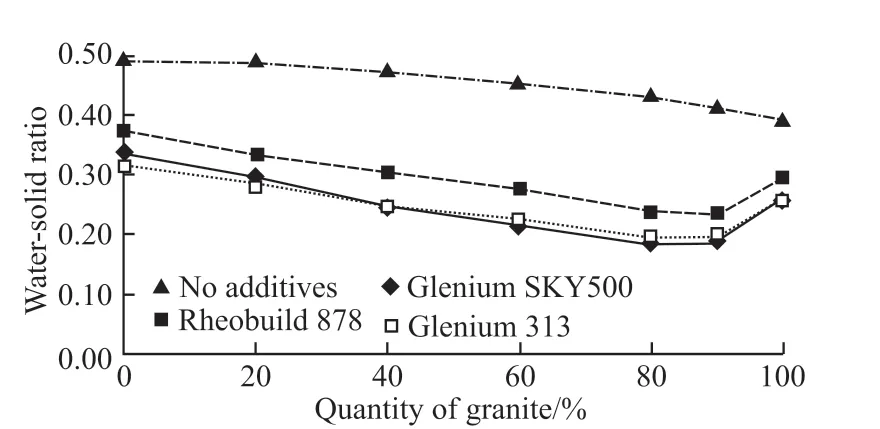

The effects of mineral supplements (limestone,marble and granite powder) on the reactor properties of cement suspensions, first of all, on the flow rate were studied with both plastifers and plasticizers (Figs.1-3). It appears that the amount of mineral supplements increases, the flow limit decreases, and the solution is well dissipated. When using plasticizers compared to pure cement, the flow rate of mineral additives decreases to 26%-37%. As the particles of the finely disperse filler are positively charged as cement, the electrostatic and steric effecting mechanisms result in the adsorption of the plasticizer, with the flow of binary mineral suspensions decreasing to the minimum. In this case, binary mineral suspensions begin to flow like newtonic fluids, not as fluid-structured liquid.

Table 1 Impact of mineral suspensions on water / solids ratio of plasticizers

Table 2 Impact of plastifiers on the spread of mineral suspensions

Fig.1 The effect of plasticizers on the flow rate of cement-marble solution on the amount of marble

Fig.2 The effect of plasticizers on the flow rate of the cementgranite solution on the granite content

Fig.3 The effect of plasticizers on the flow rate of cementlimestone solution on the amount of limestone

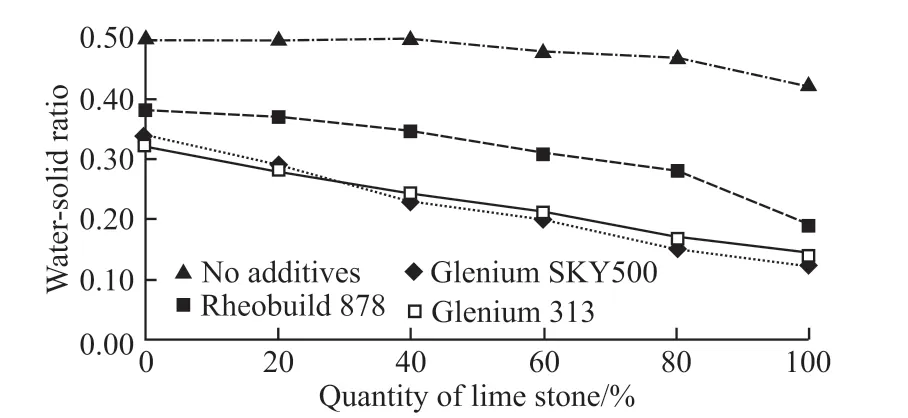

Fig.4 Dependence of the effect of the cement-limestone solution on the water-solids ratio of the plasticizers to the amount of limestone

The influence of plasticizers on water/solid matter ratio was studied in the research process depending on the quantity of mineral supplements. The results show that the ratio of water/solids to cement decreases in cement-limestone (Fig.4) and cement-marble (Fig.5),in proportion to the increase in mineral supplements.

Fig.5 Dependence of cement-marble mortar on the solids content of the plasticizers depending on the amount of marble

Fig.6 Dependence of the effect of the cement-granite solution on the solid substance ratio of the plasticizers to the amount of granite

In cement-granite suspension (Fig.6), the results are somewhat different. Thus, the ratio of water / solid to a substance is reduced by 80%, and then begins to increase. None of the selected plastids after this range affects the spread of cement-granulose suspension.

This can be explained by the weak absorption of the superplasticizer in the aqueous suspensions to the surface of the granite particles, which is due to the negative loading of the granite particles. It is enough to add a small amount of cement (up to 5%-10% of the mineral component) to mineral suspension to re-fill the granite particles, to increase the plasticizer effect of superplasticizers and hyperplasticizers.

The effectiveness of the cement-limestone and cement-marble binary systems are closely related to each other. It is explained by the fact that both of these marble and lime stone are composed of CaCO3and effects are similar when used with cement and plasticizer. Therefore, it is better to give priority to the selection of pomegranate dispersions in cementmineral powder systems rather than marble. Ther are limited resources in Azerbaijan, but a large number of deposits and cheaply financed limestone. Thus, the use of limestone beds for the acquisition of rheologicalactive stone powder is more promising.

An important criterion for the selection of powders is the compatibility of cement with chemical and mineral supplements. Additionally, additives must satisfy the following requirements:

a) It should be sufficiently dense to prevent the movement of water and hyperplasticizer in particle pores.

b) High-density dispersion and special surface should be between 300-500 m2/ kg.

c) Have a rheological activity.

d) The particles of the finely disperse filler must be positively charged. Because super and hyperplasticizers are anionic, and their loaded functional groups should be adsorbed to the surface of the particles and increase the flow rate.

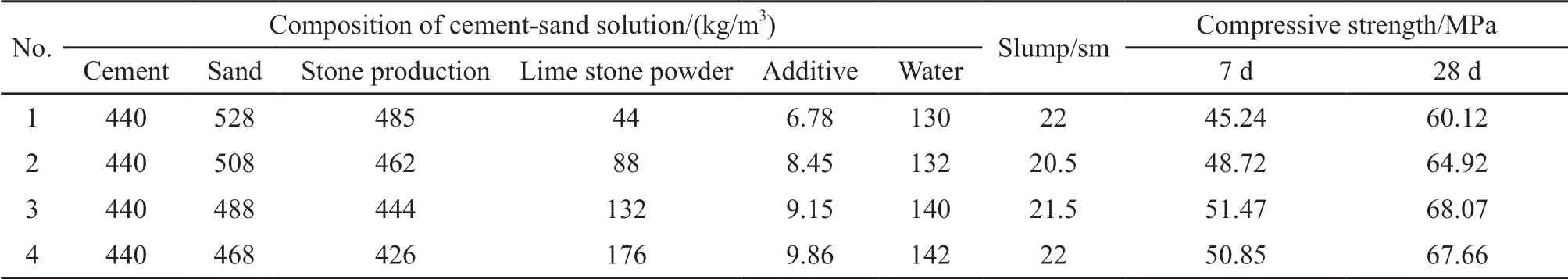

Table 3 Effects of lime powder on the properties of the cement mortar

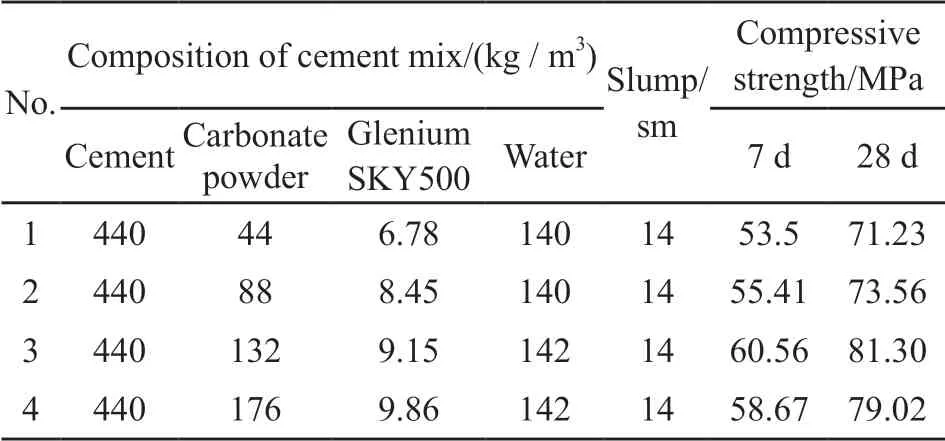

Investigation of the self-compacting mixtures(cement mortar, cement-sand and concrete) was carried out with the use of stone powder based on heavyduty limestone stone. In the preparation of these mixtures, because of the use of only narcotic powder,pomegranate dispersions were considerably lower than the cost of the concrete. Since the self-propelled concrete mix has a high flow rate, its preparation is based on mechanical noise,i e,without vibration. On the other hand, mixtures have enough self-esteem,and there is no violation of their equivalence and the process of segregation of large fillers. In addition to the dispersed mineral additive, Garadagh limestone powder(carbonate powder), as a hyperplasticizer Glenium SKY 500 was used in the present research to fulfill these two requirements (Table 3).

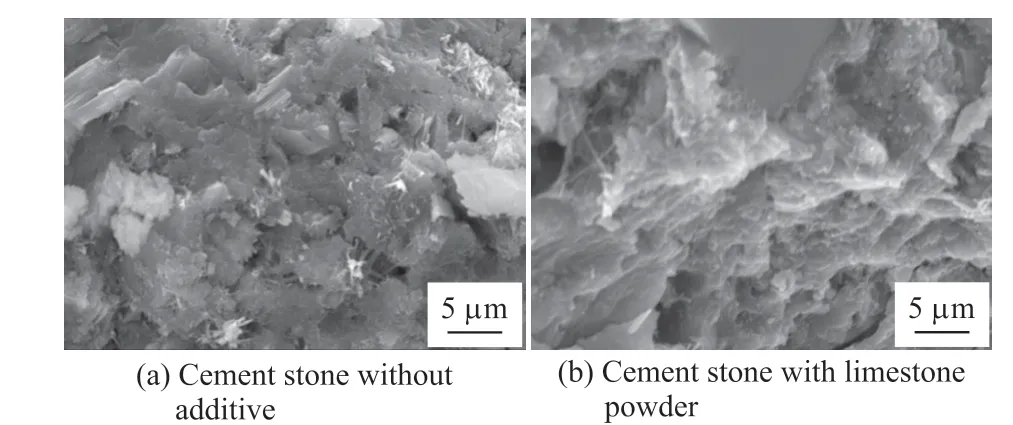

When applying lime stone powder, the effectiveness of the cement mix increases. Its particles are distributed between cement particles and form a threedimensional spatial carcass with larger particles. This spherical carcass consists of chains and aggregates created by numerous coagulant connections. As a consequence, as the result of increasing the viscosity,plastic strength, corrosion and thixotropy of the mixture, the segregation process is eliminated and the system becomes self-destructive. Studies have shown that when the stone does not add to the powder, the cement mortar has a sharp contraction when it raises the spread of the thread up to 14 cm, which can not be mixed with the mixture. The thickness of cement crusher obtained with application of lime powder is at 71.23-81.30 MPa. When the amount of lime powder is increased from 10% to 40%, the cement density,based on the same fluidized cement solution, increases by 10 MPa. Microscopic analysis was performed in an electron microscope after curing under normal conditions for 28 days of samples added to 30%limestone powder (Fig.7).

Fig.7 Microstructure of cement stone

As can be seen, the structure of the cement stone without an additive is not homogeneous (Fig.7(a)). Its structure was grouped as a group of portlandite crystals and was described as a weak crystallization layer with a high content of calcium hydrocrystals. When limestone powder is added due to fine particles, a homogeneous structure of the cement stone is formed (Fig.7(b)).Thin crystals of portlandite are observed only in closed pores, and the crystallization of which occurs after the formation of the basic structure of cement.

The properties of the cement-sand solution obtained after adding a small filler made of sand and stones were investigated without changing the proportion of water-solids content (Table 4). The mechanism of carbonate powder impact on the cement-sand solution is similar to the cement solution.According to Hegermann, when the cement-sand solution is dissolved in 22 cm, it pays off the demands on mixed dissolved mixtures. Carbonate powder is close to cement activity because it has a rheological activity. Therefore, cement water demand only increases to 10%-15%. When the amount of carbonate powder increases from 10% to 40%, the water requirement of 1 m3of the self-compacting mixture is only 12 lbs, and the strength of the compacted concrete is increased from 60.12 to 68.07 MPa.

In experiments by increasing the volume of rheology matrix consisting of cement, stone powder and water to extract the self-extracting mixture is achieved. From economic point of view, the increase amount of cement is not effective, because the amount of stone powder increases up to 40%, as the pomegranate disperses.

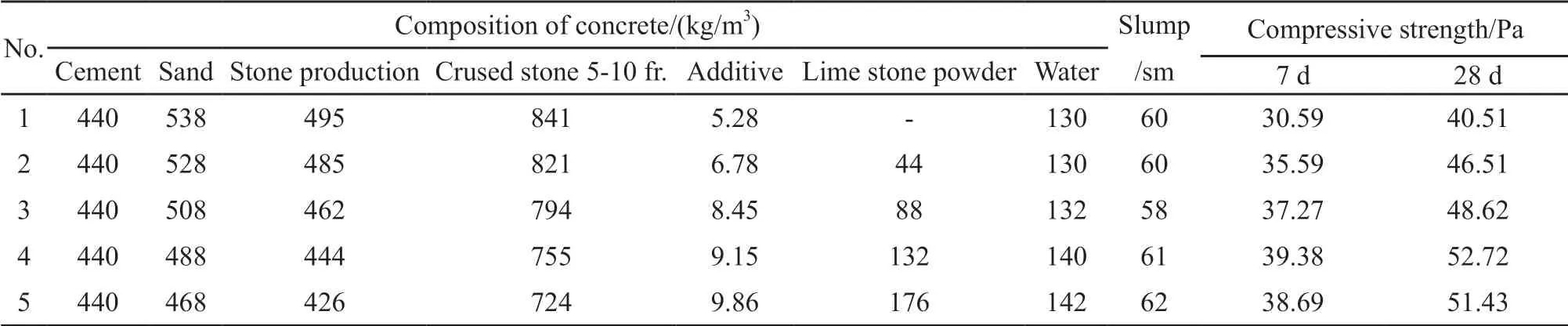

Only 5-10 fractions of large fillers have been added to the fine-grained concrete to obtain a selfcompacting concrete mix without touching the rheological matrix. The properties of the obtained self-compacting concrete mixture and its concrete properties are given in Table 5.

Table 4 Effects of carbonate powder on properties of self- compacting cement-sand solution

Table 5 Impact of carbonate dust on the properties of self-compacting concrete

It is difficult to get normal self-compacting concrete because it does not contain carbonate powder as it seems. Therefore, the strength of such concrete in compressing within 28 days is less than 40.51 MPa.When the amount of carbonate powder was increased by 10%-40%, the severity of squeezing was greater than 15-30%. When carbonate powder was 40%, the strength of concrete was 10% higher than the 10%carbonate powder used content.

4 Conclusions

a) The rheological activity of the used stone powders was close to the rheological activity of cement.The rheological activity of the used stone powders was close to the rheological activity of cement and the flow rate of the cement suspension at the use of the Glenium SKY500 plasticizer is 9.7 and 6.08 Pa in the lime suspension.

b) When 10%-40% limestone powder as rheological active additive was used, the strength of cement stone was 71.23-81.30 MPa.

c) When the amount of lime powder rose from 10% to 40%, the compressive strength of fine-grained concrete, based on the self-compacting mixture,increased from 60.12 to 68.07 MPa. As the result of an electron microscope analysis, the lime stone powder was added, and the increase in strength was associated with the formation of a dense, homogeneous structure of cement stone at the expense of finely dispersed particles.

d) Polyfunctional concrete with a compressive strength of 52.72 MPa was obtained on compression based on the self-compacting concrete mixture of 61 cm by adding coarse aggregates of fraction 5-10 to the fine-grained concrete without touching the rheological matrix.

Referrences

[1] Guvalov A A, Abbasova S I. Magnification of High-strength Concrete with Application of Modifiers[J].Building Materials, 2015(12): 78-80

[2] Kalashnikov V I. Rational Rheology - In Future Concrete[J].Technology of Concrete, 2013(1): 22-26

[3] Falikman V R. New Effective High-functional Concrete[J].Concrete and Reinforced Concrete, 2011, (2): 78-84

[4] Guvalov A A, Abbasova S I, Geydarova E A. Current Issues of the LIX International Conference[R].Materials and Contest Reports, 2017

[5] Kalashnikov V I, Moskvin R N, Belyakova E A,et al. Highly Disperse Fillers for Powder-Activated Concretes of a New Generation[J].Systems Methods Technology, 2014, 22 (2):113-118

[6] Westerholm M, Lagerblad B, Silfwerbrand J,et al. Influence of Fine Aggregate Characteristics on the Rheological Properties of Mortars[J].Cem. Concr. Comp., 2008,30: 274-282 http://dx.doi.org/10.1016/j.cemconcomp.2007.08.008

[7] Bian R B, Miao C W, Shen J. Review of Chemical Structures and Synthetic Methods for Polycarboxylate Superplasticizers[R].ACI International Conference, Sorrento, Italy, 2006

[8] Fan W, Stoffelbach F, Rieger J,et al.A New Class of Organosilanemodified Polycarboxylate Superplasticizers with Low Sulfate Sensitivity[J].Cement and Concrete Research, 2012, 42: 166-172

[9] Vovk A I. Additions to the Underlying Polycarboxylates[J].Technology of Concrete, 2013(4): 13-15

[10] Zhang Y, Kong X. Correlations of the Dispersing Capability of NSF and PCE Types of Superplasticizer and Their Impacts on Cement Hydration with the Adsorption in Fresh Cement Pastes[J].Cem.Concr. Res., 2014, 69: 1-9. http://dx.doi.org/10.1016/j. cemconres.2014.11.009

[11] Alonso M M, Palacios M, Puertas F. Compatibility between Polycarboxylate Based Admixtures and Blended-cement Pastes[J].Cem.Concr. Comp., 2012, (35):151-62. http://dx.doi.org/ 10.1016/ j.cemconcomp. 2012.08.020.

[12] Kalashnikov V I, Korovkin M O, Khvastunov R A,et al. Methodology of Definition of Rheological Properties of Structured Suspensions[C].Scientifically-technical Conference of Professors and Teachers of Scientific Staff, Graduate Students of Russian HIGHER SCHOOLS, 1999

[13] Guvalov A A, Abbasova S I. Self-adhering Concrete and Methods of Heredity[J].Ecology and Water Industry Scientific-Technical and Production Journal, 2011(3): 65-73

[14] Okamura H, Ouchi M. Self-Compacting Concrete[J].Journal of Advanced Concrete Technology, 2003,1(1): 5-15

杂志排行

Journal of Wuhan University of Technology(Materials Science Edition)的其它文章

- Effect of Nano Silver Modification on the Dielectric Properties of Ag@TiO2/PVDF Composites

- Preparation and Photocatalytic Performance of Double-Shelled Hollow W18O49@C3N4@Ti3C2 Microspheres

- Effects of Cracks on the Mass Transfer of Polymer Electrolyte Membrane Fuel Cell with High Performance Membrane Electrode Assembly

- Refinement of TiB2 Powders with High-speed Planetary Mill and Its Effect on TiB2 Sinterability

- Fabrication of Ordered Meso-macroporous HPW/TiO2 Catalyst for Efficient Heterogeneous Oxidative Desulfurization

- The Preparation of Porous Activated Slag Granules/TiO2 Photocatalyst and Its De-NOx Performance