Kevlar fabric reinforced polybenzoxazine composites filled with silane treated microcrystalline cellulose in the interlayers:The next generation of multi-layered armor panels

2022-11-28WissamBessaDjalalTracheMehdiDerradjiAhmedFouziTarchoun

Wissam Bessa ,Djalal Trache *,Mehdi Derradji ,Ahmed Fouzi Tarchoun

a Energetic Materials Laboratory,Ecole Militaire Polytechnique,BP 17,Bordj El-Bahri,16046,Algiers,Algeria

b Process Engineering Laboratory,Ecole Militaire Polytechnique,BP 17,Bordj El-Bahri,16046,Algiers,Algeria

c Energetic Propulsion Laboratory,Ecole Militaire Polytechnique,BP 17,Bordj El-Bahri,16046,Algiers,Algeria

Keywords:Polybenzoxazine Microcrystalline cellulose Kevlar fabric Mechanical properties Ballistic energy absorption

ABSTRACT The design of astonishing combinations of benzoxazine resins with various fillers is nowadays of great interest for high quality products,especially in ballistic armors.The objective of this study is to investigate a new hybrid material prepared as multi-layered composite plate by hand lay-up technique.Different composites were manufactured from Kevlar fabrics reinforced polybenzoxazine,which was filled with silane treated microcrystalline cellulose(MCC Si)at various amounts in the interlayers.The developed materials were tested for their flexural,dynamic mechanical and ballistic performance.The aim was to highlight the effect of adding different amounts of MCC Si on the behavior of the different plates.Compared to the baseline,the dynamic mechanical and bending tests revealed an obvious decrease of the glass transition of 21 °C and a notable increase in storage modulus and flexural strength of about 180%and17%,respectively,upon adding 1%MMC Si as filler.Similarly,the ballistic test exhibited an enhancement in kinetic energy absorption for which the composite supplemented with 1% MCC Si had the maximal energy absorption of 166.60 J.These results indicated that the developed panels,with interesting mechanical and ballistic features,are suitable to be employed as raw materials to produce body armor.

1.Introduction

The use of benzoxazine functional polymers,novel derivatives of phenolic resins,in various applications is strongly encouraged owing to their relevant features such as low cost,the absence of byproducts and shrinkage while curing,the unnecessary employment of curing agents in accordance with its high char yield and thermal stability[1-3].However,similar to other polymers,this resin presents some drawbacks such as toughness deficit,brittleness and low impact properties that need to be surpassed[4-6].One of the proposed solutions is the employment of polybenzoxazine as polymeric matrix for hybrid materials in order to achieve a multifunctional material and succumb the exigencies of the industry.A panoply of researches were undertaken in this context for which the polybenzoxazine was strengthened with various reinforcements from different natures to suitably increase the performance of the final products and enlarge the number of their applications[7-9].

Nowadays,benzoxazine resins present a strong base for protective equipment as body armors,principally due to their high performance.Indeed,the phenolic groups present on those resins ease the interactions with numerous fillers,which meet ballistic protection requirements[10].In this context,and in the field of developing lightweight body armor,benzoxazine resin has already been selected as a matrix,which is mixed with polyurethane(PU)and reinforced with aramid fibers,aiming to improve the ballistic performance.Interesting ballistic protection characteristics were achieved,as claimed by the different research groups[10-13].It is worthy to mention that aramid fibers,commonly employed in protective armor,display high performance and are largely considered as an ideal raw material for ballistic protection when combined with adequate matrix.Moreover,it possesses high crystalline and oriented structure,which ensures the required high sonic velocity and energy absorption[14,15].Consequently,the combination of these fibers with benzoxazine resins can be seen as a good approach for the preparation of the next generation of high performance materials.

On the other hand,many natural lignocellulosic fibers have been assessed as an alternative to the synthetic fibers in multi-layered armor systems.For instance Cyperus malaccensis sedge fibers[16],jute[17]and Piassava fiber[18]were introduced to epoxy resin and the ballistic behavior was investigated.The reported results were prominent,for which the performance was clearly improved.Besides that,the incorporation of various types of particles at different dimensions up to the nanometer to the composite plates allows the improvement of the delamination of the layers,the upgrading of the energy absorption and the enhancement of the performance.Those hybrid composites are extensively studied and numerous types of particles have been added such as nanosilica[10],alumina[19]or graphene nanoplatelets[20]in order to reach advanced features.However,to develop sustainable and bio-based materials,the incorporation of natural cellulosic fibers could be a promising way to reach the required high performance of aramid/benzoxazine-based composites.

Microcrystalline cellulose(MCC)belongs to nanocellulose family and is classified as a nanostructured material[21].This moiety is built from a linearly arranged cellulose chains that form crystalline phases at nanometer scale[22].It is extracted from natural cellulosic fibers using several methodologies such as acid hydrolysis,alkali hydrolysis and steam explosion.MCC is a renewable and biodegradable matter that exhibits high surface area[23].Indeed,it has a surface area of(270-380 m2/g),which allows it to reinforce polymers at low loadings[24].Besides,it was reported that cellulose microcrystals depict greater elastic modulus than glass and aramid fibers[24].Nevertheless,the surface modification of MCC is an important step since it was proven that decreasing the hydrophilic character of the fibers surface is primordial to ensure the adhesion with the matrix and enhance the absorbed energy by the final product[20,25].

The present research has focused on the investigation of the effect of adding MCC to bisphenol A aniline based polybenzoxazine(poly BA-a)reinforced with Kevlar fabric.MCC was initially treated with silane coupling agent to promote the adhesion to the matrix and limit the agglomerations.The new hybrid material was then prepared as multi-layered composite plates by hand lay-up technique,where modified MCC was added in the interlayers at different ratios.The motivation was to highlight the effect of the natural reinforcement on the global behavior of poly BA-a/Kevlar composite plates in terms of mechanical properties and energy absorption efficiencies.

2.Experimental section

2.1.Materials

The bisphenol A aniline based benzoxazine resin(BA-a)was prepared following Ishida et al.method[26].Bisphenol A and aniline were supplied by Aladdin(China),while paraformaldehyde(99%)was purchased from Sigma-Aldrich.Commercial microcrystalline cellulose from cotton linter(Avicel®)was employed for the functionalization using the silane-coupling agent:Aminopropyltrimethoxysilane provided by Aladdin(China).Ethanol(96%)was purchased from by VWR-Prolabo,whereas Kevlar 29 fibers(KF-29)were procured from DuPont(USA).

2.2.Preparation

The silane modification of MCC was achieved using the method explained in detail in our previous work[27].Briefly,silanecoupling agent was first added to an ethanol/water(80 vol%ethanol,20 vol% water)solution and MCC was subsequently incorporated to the solution and stirred for 2 h.After filtration,the MCC was cured at 105°C in an oven and silanized MCC(MCC Si)was obtained.

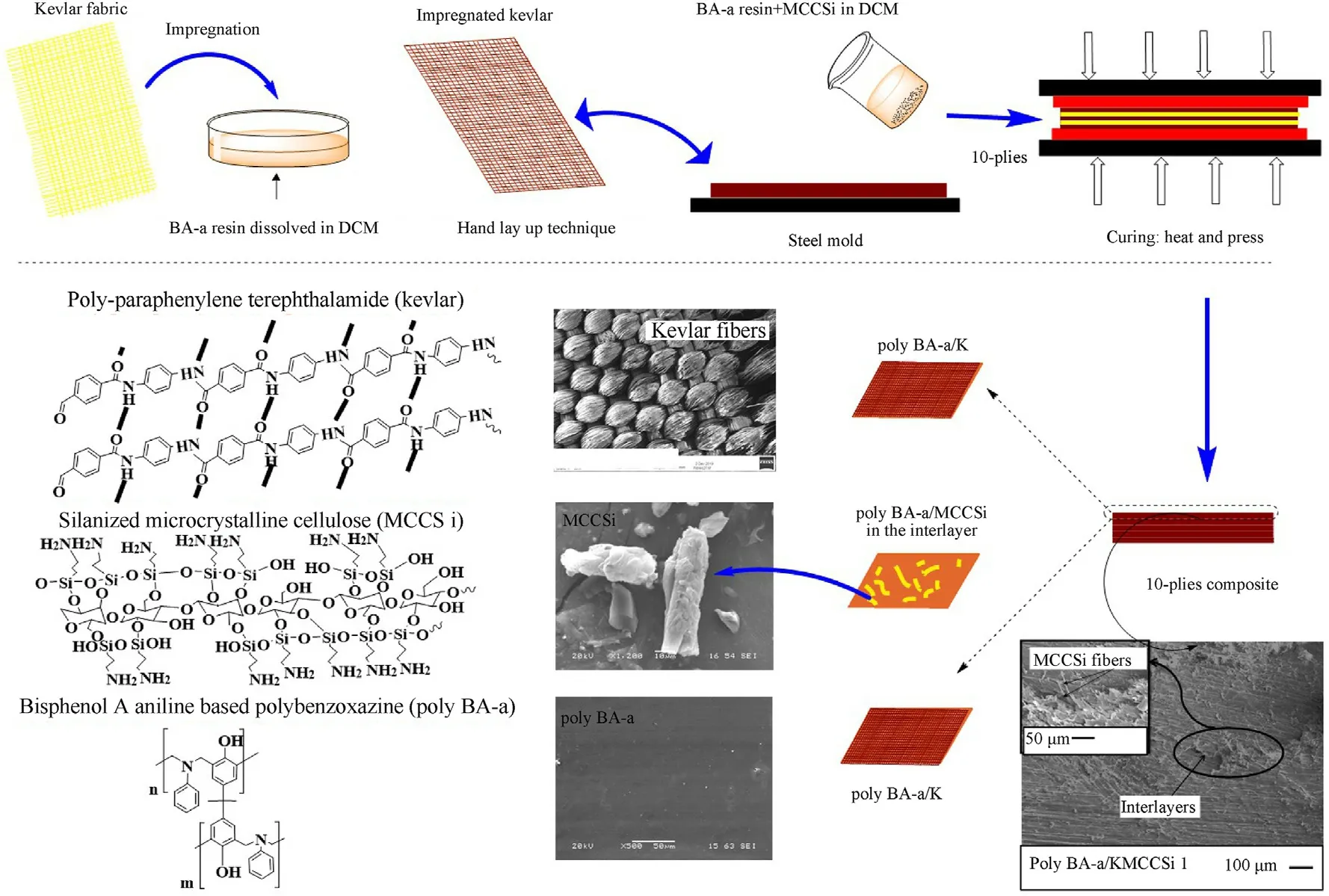

The 10-ply laminated composite plates were then prepared using compression steel mold at a dimension of 100 mm×100 mm using hand lay-up technique.The Kevlar fabrics were first impregnated in a solution of BA-a,where adequate amount of BA-a was previously dissolved in dichloromethane(DCM).Solution of MCC Si/BA-a was simultaneously prepared by dissolving the BA-a in DCM.An adequate amount of MCC Si was added followed by a stirring to ensure a homogeneous solution.This latter was poured between each layer of the impregnated Kevlar.Afterward,the obtained plates were dried at 50°C to eliminate the DCM.The mold was then closed and cured at 120°C for 2 h,165°C for 2 h and 180°C for 3 h,respectively.The weight fraction of Kevlar fibers was kept constant at approximately 75%,and the MCC-Si were added at 1,3 and 5 wt%.The obtained composite samples are respectively named as poly BA-a/K MCC Si 1,poly BA-a/K MCC Si 3 and poly BAa/K MCC Si 5.A composite plate without adding MCC Si as baseline was also prepared for comparison purpose named poly BA-a/K.

A schematic description of the whole procedure is given in Fig.1 to highlight the preparation method.

2.3.Characterization

The structural investigation of MCC Si was held using Fourier transform infra-red analyzer JASCO FT/IR-4700 type A in a wavenumber ranging from 4000 cm-1to 400 cm-1with a resolution of 4 cm-1.The TGA analysis of these natural fibers was held on a TGA Q500 V20.13 Build 39 under a constant nitrogen flow of 5 ml/min to ensure an inert atmosphere.The temperature was raised from 50°C to 450°C at a heating rate of 10°C/min.

Standard composite samples were obtained by cutting the plates by a water-jet cutting machine.The flexural tests were achieved by a universal material testing machine of LLYOD EZ 20(AMETEK LIoyd instruments,UK)at 1 mm/min crosshead speed.The dynamic mechanical analysis however were accomplished by a three-point bending mode using a DMA 242C analyzer,at temperature range from 50°C to 230°C and a ramp of 10°C/min under a frequency of 1 Hz.Three replications were achieved for each test.

Morphological examinations were performed by a Scanning Electron Microscopy machine model JEOL JSM-6360 LV.The samples surfaces were first coated with gold using a sputter coater.

The ballistic tests were performed by means of 9 mm full metal jacketed round noose standard lead-based bullets according to the standard of the National Institute of Justice(NIJ standard-0101.06-IIA)[28].

3.Results and discussion

3.1.Characterization of modified MCC

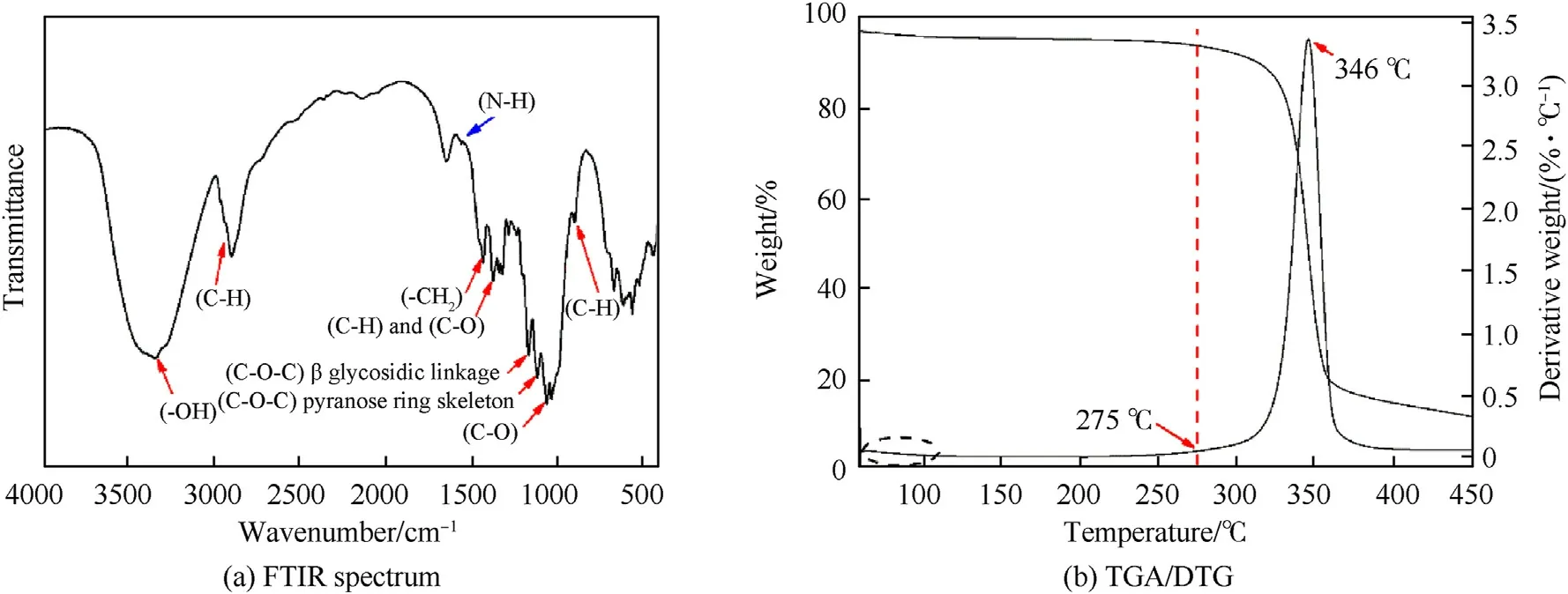

The modified microcrystalline cellulose was characterized using FTIR and TGA.

Fig.1.Explanatory scheme of the different components of the composite plates.

Fig.2.Characterization of silane modified MCC.

The infrared spectrum of MCC Si is exhibited in Fig.2(a).The broad absorption band observed from 3000 cm-1to 3600 cm-1is attributed to α-cellulose-OH stretching vibration,while the stretching vibration of cellulose C-H groups is seen at around 2898 cm-1.The peaks observed at 1432 cm-1and 1373 cm-1in the spectrum are originated from-CH2symmetric bending vibrations and the C-H and C-O of polysaccharides rings bending vibrations,respectively.The band at 1171 cm-1corresponds to C-O-C βglycosidic linkage stretching motion,whereas the peak at 1112 cm-1is related to C-O-C pyranose ring skeleton.The band at 1058 cm-1is assigned for C-O stretching and the band at around 890 cm-1is attributed to C-H vibrations of β-glycosidic linkage.The above-cited peaks refer to cellulose characteristic bands as reported in several researches[22,29-32].The N-H bending vibration of primary amine can be clearly observed at 1555 cm-1.It is attributed to the grafted silane coupling agent[31].

The thermal analysis of the prepared MCC was held to ensure the stability of MCC Si at the curing temperatures range.The TGA/DTG curves are displayed in Fig.2(b).It can be observed that two events occur;the first is assigned to the evaporation of adsorbed water and happens between 50°C and 120°C,while the second phenomenon is attributed to the decomposition of MCC,which starts at 275°C.The maximal decomposition is noted at a temperature of 346°C.This event is related to cellulose chemical structure decomposition[33].Nonetheless,the modified sample presents a good stability in the working interval.

3.2.Flexural properties of the samples

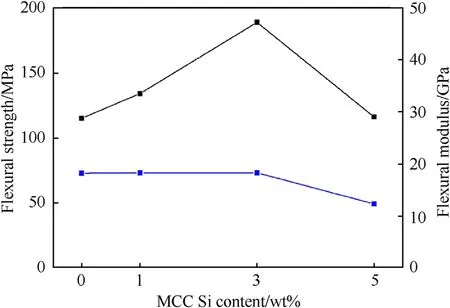

Fig.3.Flexural test measurements for different composite plates.

The flexural properties of the composite samples are highlighted in Fig.3.Initially,the flexural strength and modulus increased progressively when MCC Si loading increased from 0 to 3 wt%then decreased for composite loaded at 5 wt%of MCC Si.The obtained findings herein reveal an enhanced stress transfer through the interface for composites loaded at 1 wt%and 3 wt%of MCC Si and a good interaction between reinforcement and matrix[34],which explains the gradual increase in flexural strength compared to unloaded composite.In fact,the flexural strength increased from 115 MPa for poly BA-a/K to 134 GPa and 188 GPa for poly BA-a/K MCC Si 1 and poly BA-a/K MCC Si 3 composites,respectively.This increase corresponds to 17% and 63% average increase compared to poly BA-a/K.The flexural modulus for its part shown a slighter increase.

As know,the composites characteristics are affected by the grade of the interface,in other words,the interfacial stiffness and adhesion strength are key parameters that govern the composite’s final properties.In the case of nanocomposites,this statement has a greater impact because of the high interface area,where strong bonding and interfacial stiffness induce high composite modulus[35].Thus,adding modified microcrystalline cellulose ensured a high strain transmission and a great interlocking with the matrix,which result in enhanced flexural features.However,the poly BA-a/K MCC Si 5 composite flexural parameters are minimal compared to the other composites including the baseline poly BA-a/K composite.This result shows the weak behavior and resistance to the bending test,which results in a reverse effect,revealing that the MCC Si loading was excessive.Movva et al.[36]reported similar observation when reinforcing polyester matrix with cellulose extracted from pistachio shell.Indeed,high amount of cellulose gives rise to agglomerations that limit stress transfer,and hence reducing the flexural properties.It is also important to mention that higher amount of MCC Si involves lower amounts of BA-a resin,which results in less loading transfer as well.

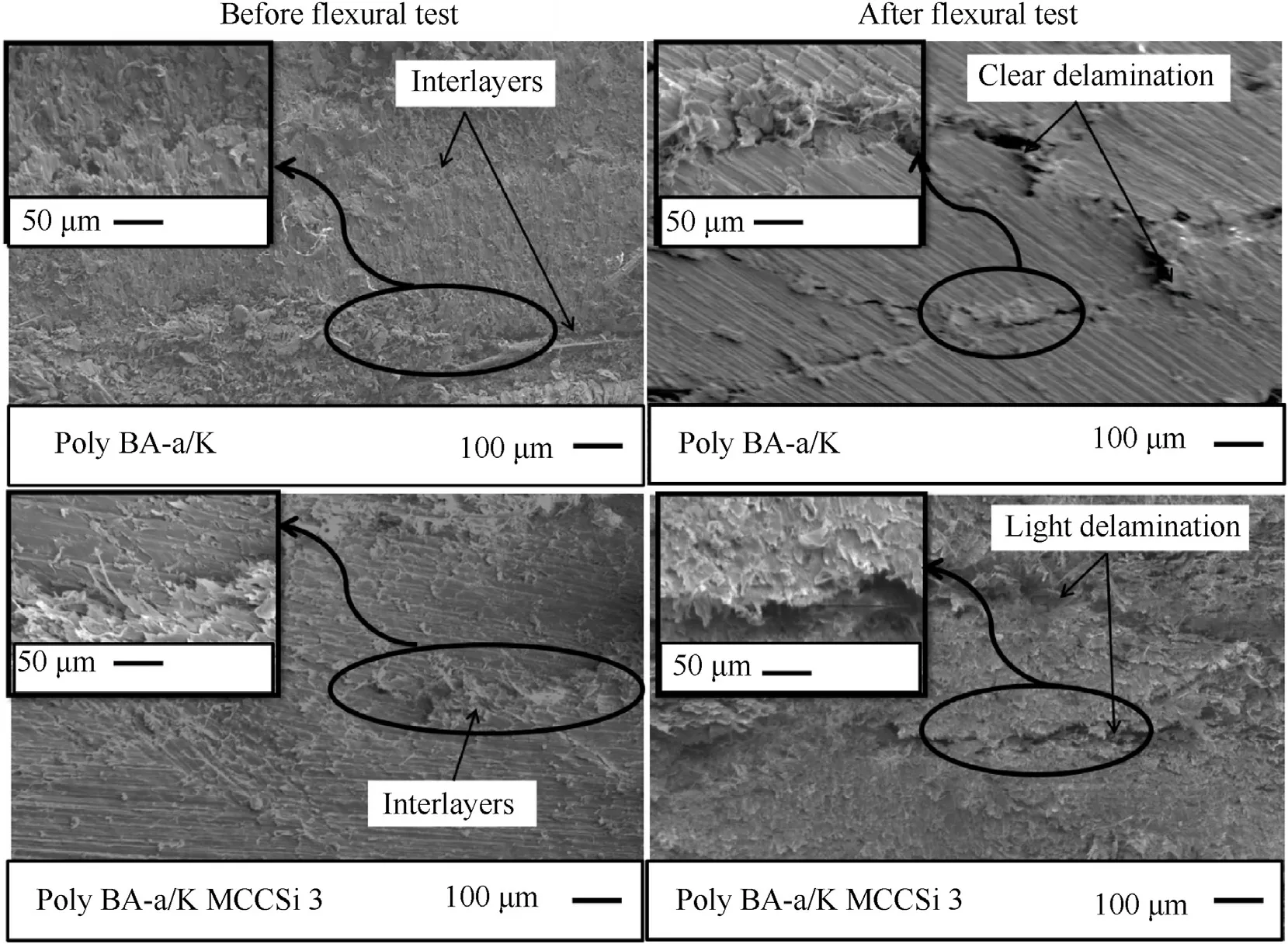

Surface morphology investigation has been held on two samples(Poly BA-a/K and Poly BA-a/K MCC Si 3)which were subjected to the flexural test.The aim was to highlight the changes that may occur after the mechanical test.The obtained micrographs are exhibited in Fig.4.It can be observed that before the test,the Kevlar fabric is well covered by the resin and the layers are tightly attached either with or without the presence of MCC Si.On the other hand,the observation of the fractured surface after the test reveals an appearance of severe delamination when MCC Si is not added,whereas at 3% of MCC Si,a good interlocking is still ensured.

These results reflect the good bending values obtained,and hence reinforcing the idea of the good distribution of the stress,provided by the MCC Si.

3.3.Dynamic mechanical properties

Dynamic mechanical analysis measures the viscoelastic response of the material within a temperature range.This latter can be expressed in terms of storage and loss moduli or in terms of damping factor(tan delta).Fig.5 exhibits the extracted dynamic mechanical parameters of the prepared samples,the reported data are presented in Table 1.

Table 1Dynamic mechanical analysis data.

The variation of the storage modulus(E′),which is related to the material’s stored energy during a loading cycle,is plotted in Fig.5(a).As observed,the curves of the modulus pass through three regions,glassy,transition and rubbery region.The same shape is noted for all plots,where a decrease is recorded when increasing the temperature,especially in the transition region when passing from glassy to rubbery state.Another observation is that the storage modulus is affected by the amount of MCC Si added.Indeed,E′is strongly enhanced for composites at 1 wt%and 3 wt%of MCC Si in both glassy and rubbery regions.This reveals the superior reinforcing ability of the added moieties that help in reducing molecular mobility by forming strong intermolecular forces[37]and ensuring a better stress transfer.The increase in temperature causes an increase in mobility and a weakening of the intermolecular forces.Thus,a drop in storage modulus occurs,revealing a loss in stiffness.The storage modulus at 60°C passes from 2.65 GPa for poly BA-a/K to 7.43 GPa and 4.85 GPa for poly BA-a/K MCC Si 1 and poly BA-a/K MCC Si 3 composites,respectively.This results in an enhancement of 180%and 83%in accordance.Moreover,the enhancement was of 40%and 12%at 220°C for poly BA-a/K MCC Si 1 and poly BA-a/K MCC Si 3 composites,respectively,showing that the superior properties were conserved in the rubbery region as well.

It is however important to note that composite loaded at 1 wt%of MCC Si possesses the highest storage modulus compared to the 3 wt%reinforced one.This may be related to the higher amounts of reinforcement that causes the formation of bulk molecules and reduces the storage properties.The 5 wt%reinforced composite for its part exhibited lower modulus than the unfilled composite.This means that higher loadings results in a loss of properties and a decrease in storing energy ability.This observation consolidates the results obtained in bending test.

The loss modulus(E′′),which indicates the material’s dissipated energy during one wavering cycle,is plotted in Fig.5(b).E′′values increase with temperature to reach maximum heat dissipation,which corresponds to the glass transition temperature(Tg)[38],afterward,the values decrease.The recorded values follow similar behavior as the storage modulus.The loss modulus increases for 1 wt% and 3 wt% reinforced composites compared to unloaded composite,while the poly BA-a/K MCC Si 5 exhibited the lowest behavior.The increase in E′′represents higher energy dissipation.

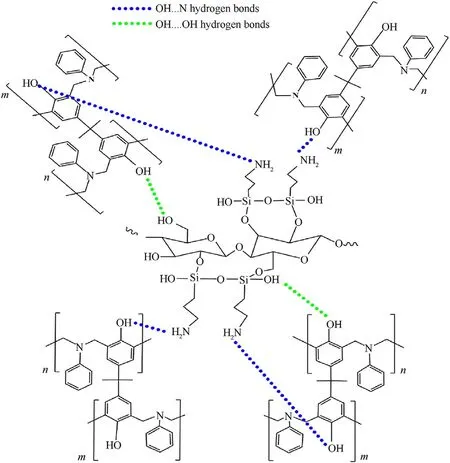

The glass transition temperatures decrease when comparing to the unloaded composite.Actually,the values go from 182°C for poly BA-a/K to 161°C,173°C and 168°C for composites loaded at 1 wt%,3 wt% and 5 wt% of MCC Si.Nevertheless,the Tg decreases when compared to poly BA-a/K and increases when enhancing the loading from 1 wt% to 3 wt%.This behavior was explained in previous works as being due to a modification in crosslinking density due to unreacted BA-a particles that may connect to the MCCSi alkyl amine groups[34,35,39,40].In point of fact,Benzoxazine resins are well-known for their thermally induced ring opening polymerization of cyclic monomers[41,42],where the oxazine ring opening engenders free phenolic groups that further speed up the ring opening reaction[43-46].Those groups may connect with MCC Si alkyl amine groups,which may diminish further ring opening,and thus inhibiting the crosslinking.Fig.6 presents an explicative scheme of the possible connections between MCC Si and Poly BA-a.

Fig.4.SEM micrographs of Poly BA-a/K and Poly BA-a/K MCCSi 3 before and after flexural test.

Fig.5.Dynamic mechanical behavior of the composite plates.

The damping factor,known as tan delta,is defined as the ratio between the dissipated energy to the stored energy during on cycle of wavering,in other words,it is the ratio between loss and storage modulus.This parameter gives information about the molecular motions at the interfaces[47]for which the high reinforcementmatrix adhesion provides a limited mobility and a low damping[37,48].The reported plots are exhibited in Fig.5(c).The peak heights are reduced after adding MCC Si.This indicates that a greater molecular restrictions occur due to the interactions and adhesions between the MCC Si and matrix,which promotes the energy dissipation[34].

3.4.Ballistic performance of the samples

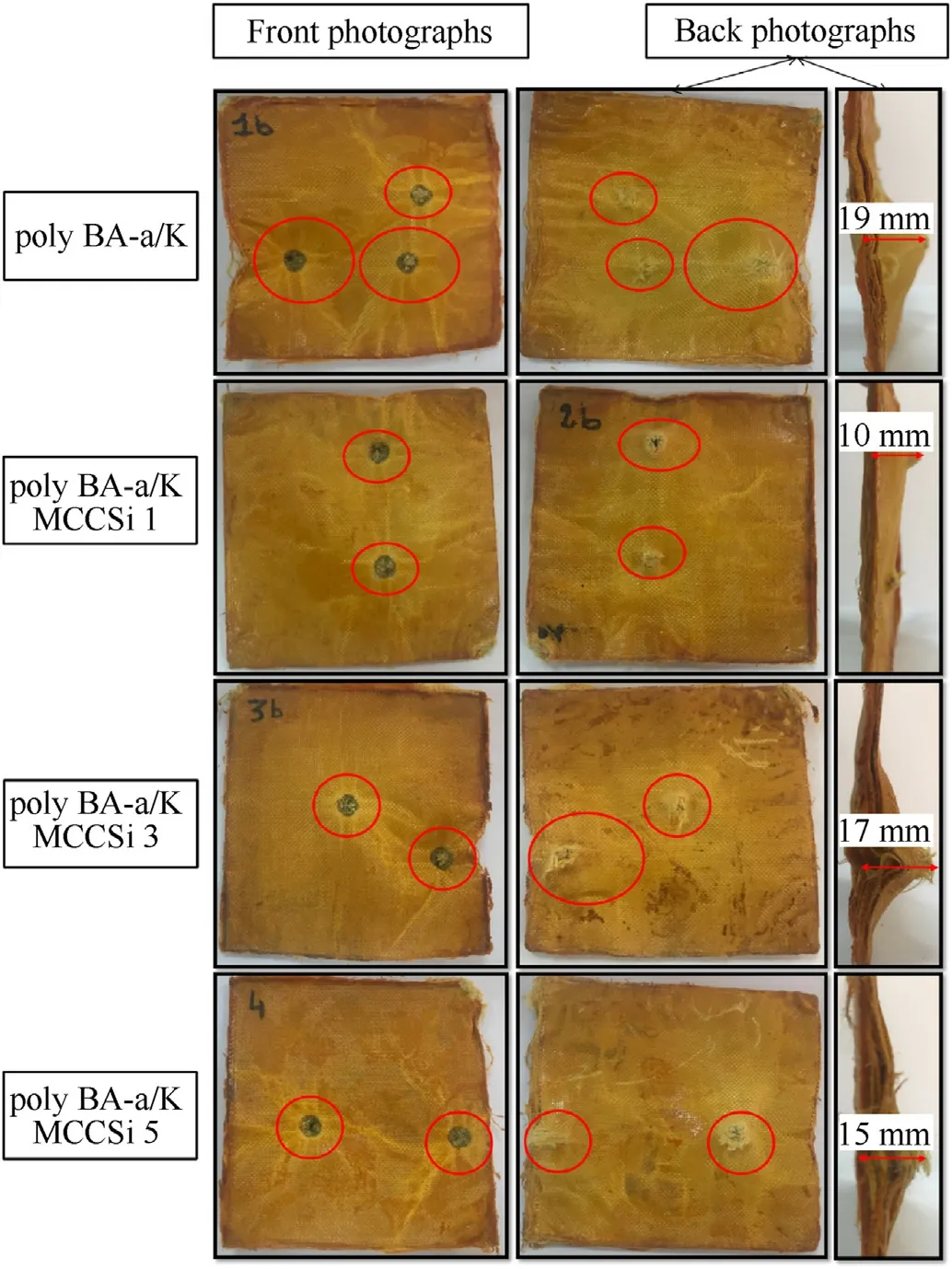

The ballistic properties of 10-ply laminates were analyzed to emphasize the effect of adding modified MCC on the residual velocity.The polymer composites handle the ballistic impact by reducing the kinetic energy of the bullet.This mode of action includes the following mechanisms;tensile failure,elastic deformation,interlayer delamination and shear between layers in the laminates.Herein the composite panels were subjected to a complete penetration so that residual velocity could be measured and the absorbed energy can be calculated.The pictures of tested samples are presented in Fig.7.

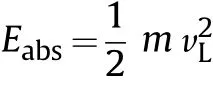

The energy absorbed(Eabs)by the target is measured as the bullet’s kinetic energy variation and is defined as follows[49]:

wheremis the mass of the projectile,viandvRare the projectile’s velocity before and after impact.

Fig.6.Explicative scheme of the possible connections between MCC Si and Poly BA-a.

Fig.7.Images of the front and back of the composite plates after ballistic impact.

The choice of appropriate defense armor materials is critical in enhancing mobility and ensuring safety.The added MCC are likely to absorb energy and reduce the residual energy.Indeed,as seen in Table 2,the absorbed ballistic energy increased from 121.22 for poly BA-a/K to 166.60 J for poly BA-a/K MCC Si 1 panel.Additionally,the presence of MCC Si had a positive impact on the energy absorption of the plates at various loadings.Eabswas enhanced by 37%,21%and 6% when MCC Si loading was of 1 wt%,3 wt% and 5 wt%,respectively.

Strong interactions between poly BA-a and Kevlar are reported in previous researches.They result from the formation of polar interactions between ether and carboxyl groups of the aramid fibers and the hydroxyl groups of poly BA-a[11].Due to this strong adhesion,the projectile penetrates the plate easily,and thus less energy is absorbed,resulting in low ballistic properties[11].

Finding a balance in fiber-matrix adhesion is primordial when it comes to ballistic protections.In fact,weak interaction is advantageous in this field because it eases the debonding of the fibers,which results in supplementary energy absorption in the same time.Moreover,it is mandatory that plates possess good structural integrity and stiffness[50].

The presence of MCC Si has proven its effectiveness in energy absorption as seen in the reported values.This behavior is explained by the moderate interfacial adhesion ensured by the availability of MCC Si.The poly BA-a/K MCC Si 1 composite plate,which presented the highest storage modulus compared to other composites,had the maximal energy absorption.This observation allowed us to conclude that this composition is the best one since it ensures the greatest structural integrity.

The limit velocity represents the critical velocity at which the armor is perforated.The limit velocity(vL)is calculated according to the following equation[10]:

wherevLis an important parameter that considers the velocity after impact equal to zero,which means that the projectile is completely stopped by the composites plate.From Table 2,it can be seen that the plates employed at 10 layers are not able to completely stop the bullet.Nonetheless,the projectile can be stopped at bullet rate of 139 m/s-164 m/s depending on the MCC Si amount.Therefore,it is recommended to increase the number of layers or employ it as part of multi-layered armor system for an efficient real ballistic protection.

Table 2Energy absorption abilities of the composite plates at various MCC Si percentages.

Side images of the tested plates are observed in Fig.7 as well.It is known that during impact,the plate absorb energy from the projectile as explained above.The absorbed energy is simultaneously transferred to the surrounding area,which results in a deformation of the panel[13].The cone formation observed herein is explicated by transversal wave spread all through impact[51].The cone depth observed at the side of the plates is reduced after adding MCC Si particles,what can be explained by the increase of frictional contact between the composite plate and the bullet when adding MCC Si.Thus,yarn slippage decreases and results in lower depth and a better structural integrity[11].

4.Conclusions

Based on the obtained results in this research paper,the following conclusions can be drawn:

·Cellulosic fibers can form a great alternative to ceramics and synthetic fillers;

·According to the bending test,filling the plates with 3 wt% of MCC Si ensures better flexural strength and modulus;

·The dynamic mechanical analysis revealed enhanced storage ability for composite at 1 wt% of MCC Si;

·Both flexural and DMA tests demonstrated that reaching 5 wt%of cellulosic filler induced a loss in properties;

·The ballistic test was held according to NIJ standard-0101.06-IIA and the multi-layered plates showed enhanced kinetic energy absorption compared to unfilled composite plate;

·Finally,it can be stipulated that plate manufactured with one wt.% of MCC Si presented the best and the optimized composition because it ensured high dynamic mechanical and ballistic performances.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

杂志排行

Defence Technology的其它文章

- Modified couple stress and thickness-stretching included formulation of a sandwich micro shell subjected to electro-magnetic load resting on elastic foundation

- Recent advances in the synthesis and energetic properties of potassium-based potential green primary explosives

- Investigation of normal,lateral,and oblique impact of microscale projectiles into unidirectional glass/epoxy composites

- A quasi-isentropic model of a cylinder driven by aluminized explosives based on characteristic line analysis

- Experimental study on the cavity evolution and liquid spurt of hydrodynamic ram

- Preparation of ammonium nitrate-based solid composite propellants supplemented with polyurethane/nitrocellulose blends binder and their thermal decomposition behavior