超声对激光熔覆成形中熔池润湿行为的影响研究

2022-11-08姚喆赫沈奇艳葛宏江王振董刚叶钟李琳姚建华

姚喆赫,沈奇艳,葛宏江,王振,董刚,叶钟,李琳,姚建华

超声对激光熔覆成形中熔池润湿行为的影响研究

姚喆赫1a,1b,2,沈奇艳1a,1b,2,葛宏江3,王振1a,1b,2,董刚1a,1b,2,叶钟3,李琳4,姚建华1a,1b,2

(1.浙江工业大学 a.激光先进制造研究院 b.机械工程学院,杭州 310023;2.高端激光制造装备省部共建协同创新中心,杭州 310023;3.杭州汽轮机股份有限公司,杭州 310020;4.英国曼彻斯特大学 激光加工研究中心,曼彻斯特 M13 9PL,英国)

对比有无超声作用下熔体润湿行为,阐明超声对于熔体润湿行为的影响及作用机制,为超声辅助激光熔覆高质量成形提供参考。基于高速相机拍摄研究了超声对于液滴润湿性的作用效果,进而研究了超声辅助激光熔覆过程中熔池的润湿行为,使用Canny算法提取熔池轮廓,采用体视显微镜和共聚焦显微镜观察试样宏观形貌,采用光学显微镜观察分析微观组织。将超声振动施加于金属液滴,其在基板表面润湿性增强,金属液滴与基板接触面积增大39.3%。在熔覆过程中引入超声振动,熔池面积显著增大。随着超声功率比的增强,熔覆层的熔高降低,熔深减小,熔宽逐渐增大,熔覆层逐渐由弧形轮廓变为扁平。当超声功率比为80%时,熔覆层高度为无超声下的75.2%,熔覆层和基体之间的润湿性显著改善。在微观形貌上,超声能够改变晶粒生长方向,抑制枝晶外延生长。超声振动作用于激光熔覆过程中,促进了熔体的润湿作用且加大了熔池流动性。熔体润湿行为的改变导致扁平熔覆层形状的形成,熔覆过程中熔池面积增大,熔池流动性增强,导致晶粒生长方向与枝晶长度的改变。

激光熔覆;超声振动;润湿行为;熔池;宏观形貌;微观组织

航空关键部件常服役于高温高载荷等恶劣环境,易发生损伤和失效,损伤件的换新将产生巨大的成本与浪费。基于激光熔覆成形的激光增材再制造技术在损伤件的修复与再制造中展现出显著优势和巨大潜力[1],并已在航空发动机叶片、旋转部件、支撑结构等关键航空部件的再制造中应用[2-4]。激光熔覆与再制造技术具有稀释率和热影响区域小[5]、组织致密[6]、冶金结合强度高[7]、环保[8]、节省材料等优点,同时激光热源快热快冷的特点导致成形过程常伴随着微裂纹、气孔、残余拉应力等缺陷的产生,严重影响了激光再制造的质量。

为提高激光熔覆质量,外加能场辅助成为当前研究的热点之一[9-10]。其中,超声振动作为外加能场引入激光成形在降低孔隙率、细化晶粒、提高机械性能等方面展示出了巨大的潜力。Cong等[11]在激光成形工艺中施加超声波振动,引起的声流和空化的非线性效应使孔隙率显著降低,获得了更细小的TiB晶粒,沿晶界分布且分布更均匀,同时晶粒细化进一步提高了零件的显微硬度。Todaro等[12]发现超声波的使用促进了具有随机晶体结构的细小等轴晶粒形成,施加超声可以降低熔池主体的温度梯度来增加凝固过程中的过冷度,进而有利于晶粒成核和生长。Wang等[13]研究了不同超声频率对熔覆层微观组织和机械性能的影响,超声频率越高,晶粒度越小,显微硬度越高,在超声频率25 kHz时气孔抑制效果较好,获得熔覆层耐磨性能、弹性模量更优。王新洪等[14]在激光熔覆过程中施加超声振动降低了涂层的轮廓粗糙度,但涂层的稀释度略有增加,超声振动改善了激光熔池中的传热传质,细化了微观结构,增加了陶瓷量,使陶瓷颗粒分布均匀。陈文静等[15]发现超声振动作用下,熔覆层润湿铺展程度提高,枝晶组织细化,元素分布均匀化,熔覆层显微硬度更加均匀且提高了126.2HV0.2。姜风春等[16]发现超声振动有效地削弱了织构强度并使沉积层的晶粒结构均匀化,晶粒结构的改善提高了ER321不锈钢的显微硬度和屈服强度。

上述研究探讨了超声作用下激光熔覆成形微观组织与性能的显著变化,熔体流动特性在超声作用下的变化导致激光熔覆层宏观形貌发生改变,将对多道搭接与路径规划策略产生不可忽视的影响。Cong等[17-18]利用超声振动辅助激光熔覆技术制备出了平整度更优、熔池尺寸更大的熔覆层。庄栋栋等[19]发明超声振动能有效地改善熔覆层宏微观成形质量,降低了表面粗糙度和细化晶粒,提高了熔覆层的完整性和致密性。马广义等[20-21]将超声振动引入激光熔覆,随着超声输出功率的增加,熔覆层深度增加,涂层与基材之间的润湿性增强,导致元素含量分布的变化。王维等[22]发现超声的引入改善了搭接熔覆层的表面平整性,而叠高效率降低了36.7%。上述研究表明了超声对熔覆层形貌的显著影响,而当前对于其影响规律及其机理的研究较为欠缺,仍待进一步深入研究。

本文通过分析超声作用下的液滴润湿过程,研究超声在熔体中的作用效果及机理,采用高速相机监测熔覆成形过程,并提取不同时刻熔池轮廓形状,分析熔体润湿行为,同时,通过有无超声作用下的对比,阐明超声对于熔体润湿行为的影响规律。通过对比不同超声功率比下的熔覆层宏微观形貌探讨形貌成形规律,讨论超声对于熔池润湿行为的影响机制,为超声辅助高质量激光熔覆成形提供参考。

1 试验

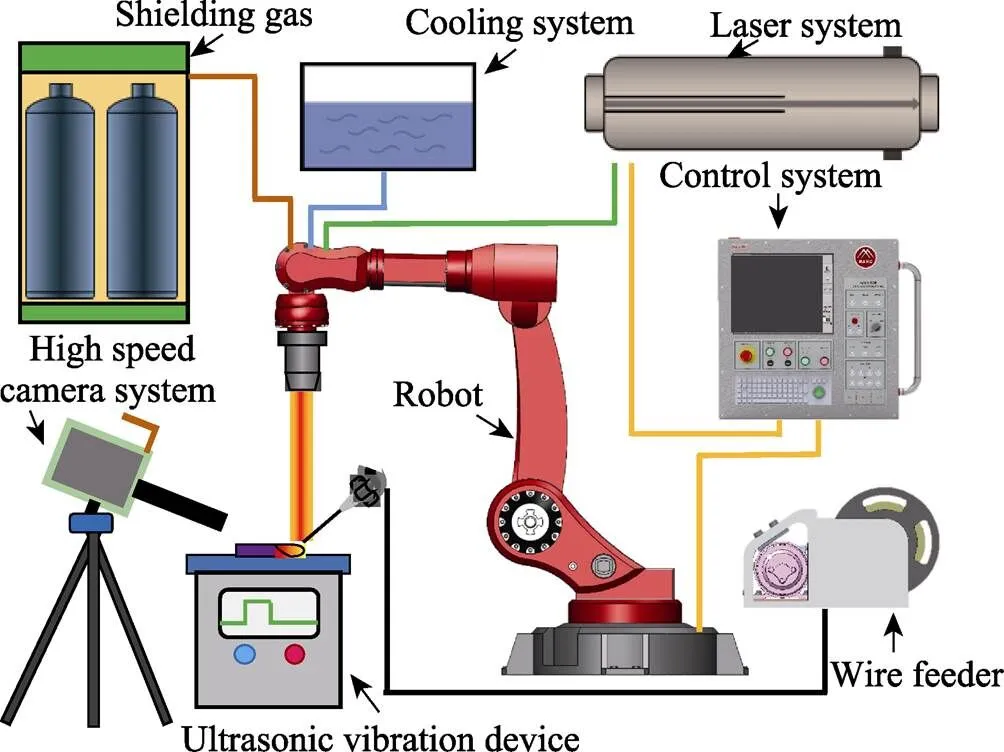

本文所采用的超声辅助激光送丝熔覆试验装置主要包括激光器、伺服送丝系统、冷却系统、超声振动系统、控制系统等,试验过程由高速相机系统拍摄与记录,试验系统示意图如图1所示。所用激光器为半导体光纤耦合激光器(武汉锐科),在本文试验中激光功率为1 kW,光斑直径为2 mm。所用超声振动系统频率为20 kHz,振幅大小通过功率比可调,100%功率比时振幅为50 μm,超声从基体底部传递至熔池。

试验所用丝材与基板材料均为IN718镍基高温合金,基板尺寸为100 mm×60 mm×5 mm,丝材直径为1.0 mm。在试验前,使用砂轮机打磨抛光基板表面去除表面杂质,并用酒精清洗去除表面油污等。试验过程中采用高速相机拍摄熔池过渡行为。试验完成后,采用体视显微镜(尼康SMZ745T)和共聚焦显微镜(基恩士VK-X1000)观测试样宏观形貌,采用光学显微镜(蔡司Axio Imager2)观测分析熔覆区显微组织。

图1 超声辅助激光送丝熔覆试验装置示意图

基于上述试验系统,在送丝方向为前置,送丝角度为45°的情况下,开展了激光熔覆工艺试验研究,以液桥过渡为目标进行工艺参数优化,优化后在本文中所用的扫描速度与送丝速度分别为8 mm/s和9.3 mm/s。

2 结果与分析

2.1 超声对金属液滴润湿行为的影响

为研究金属熔体在超声作用下的润湿行为,采用高速相机对金属液滴在有无超声作用下的润湿行为进行观测和对比研究。采用激光送丝在金属板上预置IN718金属半球,再对金属半球进行激光重熔,以1 kW的激光功率辐照1.8 s,使其完全熔化后凝固成形,采用高速相机在45°俯角下对有无超声作用下的金属半球重熔及凝固过程进行观测,结果如图2所示。金属半球在激光束加热下逐渐熔化,直至完全熔化形成金属液滴;在停止激光热源输入后,金属液滴逐渐凝固成形。在无超声作用下,金属液滴形状基本保持不变,未出现明显的润湿现象;而在超声作用下,金属液滴表面呈现出明显的波动,在激光停止辐照后,液态金属在超声的作用下向四周润湿,最终形成扁平状,润湿面积增大39.3%。上述结果显示,超声对于金属液滴的润湿行为产生了显著影响。

2.2 超声对激光熔覆过程液桥过渡行为的影响

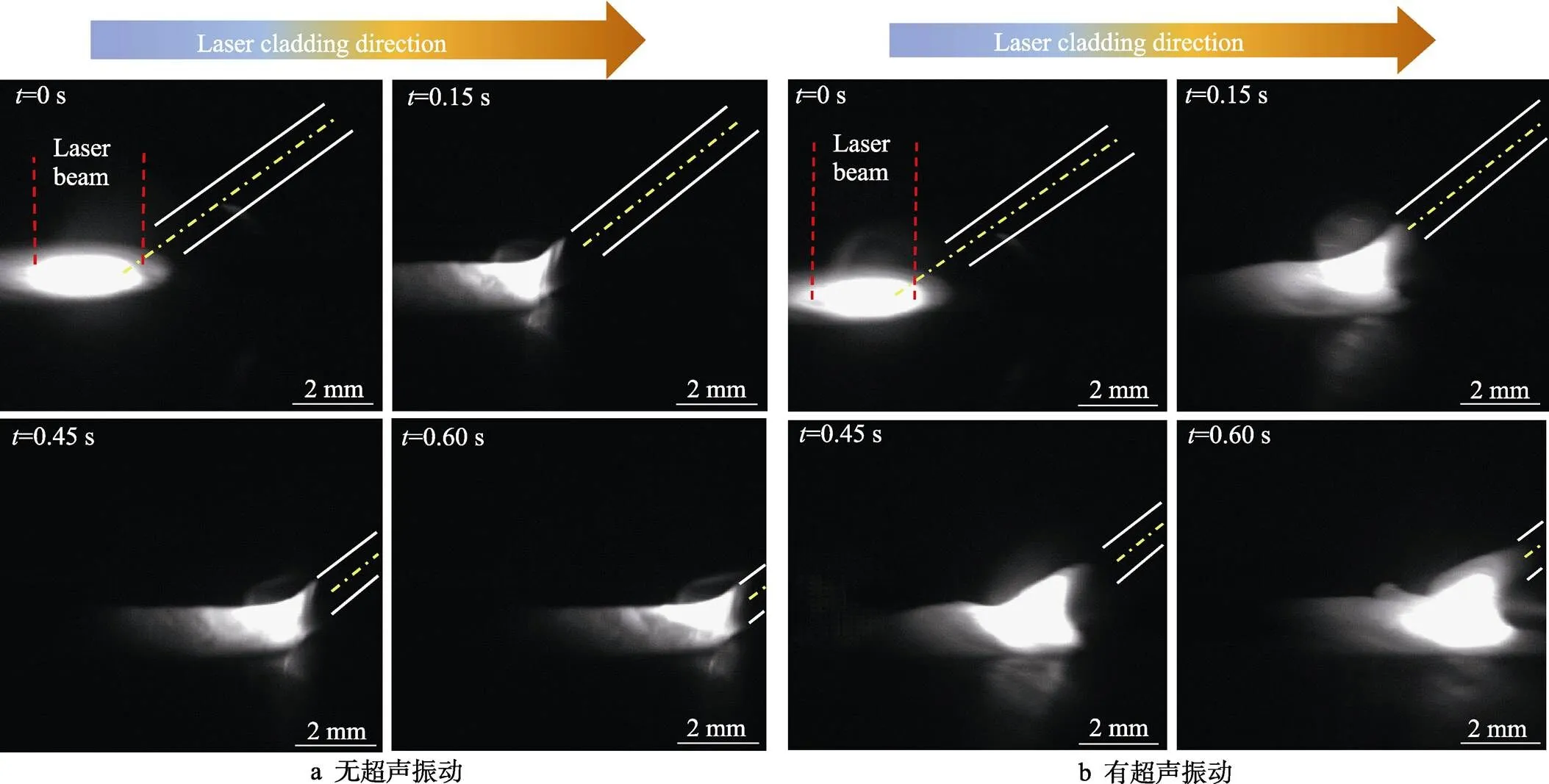

用高速相机拍摄有无超声作用下的送丝熔覆液桥过渡过程,试验结果如图3所示。当未施加超声振动时,丝材前端的熔融金属与基板接触,润湿在基板表面,熔池呈现平稳的液桥过渡,如图3a所示。当施加超声振动后,熔池在超声作用下加剧了流动,熔体与无超声时相比在基板表面润湿性增强,随后熔池沿激光扫描速度方向润湿,熔融区域进一步扩大。与此同时,超声振动加剧了液桥搭接处的流动,使丝材熔融前端流动加快,如图3b所示。

图2 金属液滴重熔及凝固过程形态

图3 激光熔覆过程液桥过渡行为监测

针对有无超声作用下的送丝熔覆液桥过渡过程的图像开展边缘轮廓提取分析。如图4所示,利用Canny算法[23-24]分析熔覆层,首先提取熔融区域高亮处的边缘,获得初步轮廓线,再对轮廓边缘进行优化,获得熔池高亮区域。在最后的结果图中红色轮廓线为熔池高亮区域轮廓,对应熔池面积,蓝色方框为高亮区域的外接矩形,外接矩形的长宽分别对应熔池的横向长度和纵向长度。观测高速相机采集结果,可得:从0 s时刻激光辐照到丝材开始,熔池面积逐渐增大,熔池的横向纵向长度均逐步增大;在无超声作用下,0.43 s时刻液桥过渡趋于稳定状态,熔池面积较小,熔池拖尾较长,横纵比较大;在超声作用下,熔池在超声作用下加剧了流动,熔池面积从0.5 s时刻液桥过渡趋于稳定,熔融区域扩大,横纵比较小。

进一步对熔池区域面积进行统计,如图5a所示。在0.15、0.45、0.60 s时刻,有无超声情况下的熔池面积均显著不同,超声作用下熔池面积分别为无超声作用下的1.52、2.07、2.80倍,结果显示,同一时刻超声作用下熔池区域面积增大。对图中熔池面积和横向纵向长度进行数值分析,如图5b所示,超声作用下熔池横向与纵向长度均显著增大。

图4 激光熔覆过程熔池图像轮廓提取

图5 激光熔覆过程熔池形貌分析

2.3 超声对激光熔覆层宏观形貌的影响

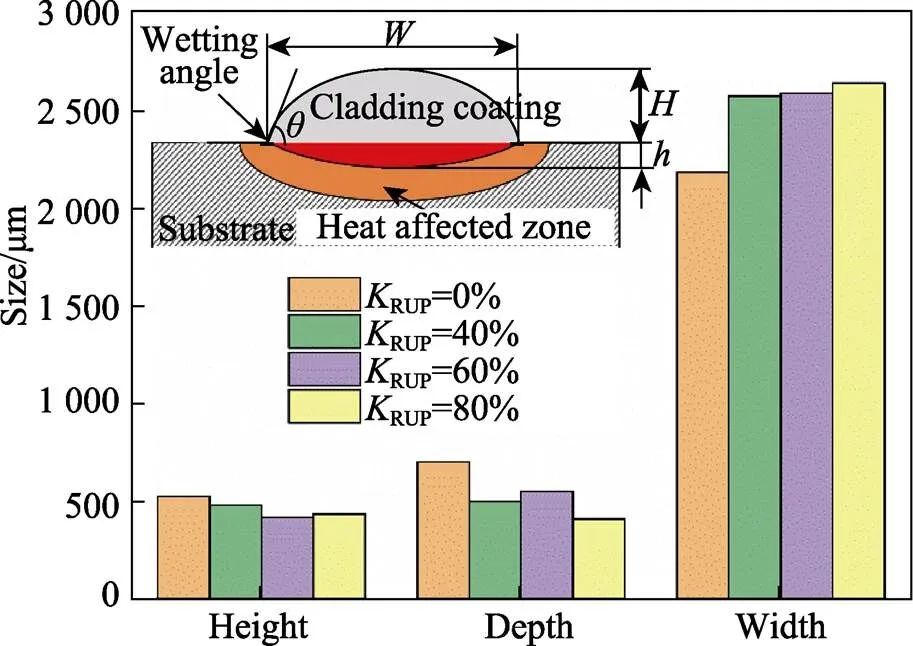

采用体视显微镜和共聚焦显微镜观察试样的宏观形貌。图6a为无超声作用下的激光送丝熔覆层宏观形貌,其表面较为平整光滑,无明显缺陷,成形质量好。图6b—d表示超声功率比(Ratio of Ultrasonic Power,RUP)分别为40%、60%、80%的试验结果,可见在超声作用下,由于凝固过程中熔池表面的超声波作用,熔覆层表面呈现波纹状,且功率比增大后波纹形貌更为细小。

对有无超声作用下的熔覆层表面轮廓进行测量分析,如图7所示。结果显示,无超声作用下的激光熔覆层的最大高度为627.7 μm,功率比为40%、60%、80%的超声振动下熔覆层最大高度分别为608.8、564.8、471.7 μm,80%超声作用下熔覆层最大高度为无超声下的75.2%。

2.4 超声对激光熔覆层微观形貌的影响

激光熔覆层的横截面金相组织如图8所示,无超声作用下的熔覆层与基体冶金结合良好,晶粒沿着热流反向生长,形成长条柱状晶,晶粒生长方向垂直于固液线。施加超声振动后,熔体向外润湿,熔宽明显增大,熔高降低。施加40%、60%、80%功率比的超声振动后,熔覆层的金相组织发生显著变化,熔池底部和中部的枝晶在高温度梯度的作用下,仍为柱状晶,但长直柱状晶明显减少,且凝固组织生长方向较为杂乱,枝晶宽度明显变小。随着超声功率比的增大,枝晶细化的程度更为明显。同时,在施加超声振动后,熔池顶部的转向枝晶区域变窄。

对于激光熔覆层金相组织进一步进行了测绘,结果如图9所示。无超声振动时,熔覆层高度为527 μm,熔覆层宽度为2 186 μm,熔覆层熔深面积为10.97×105μm²,此时熔覆层稀释率为57.1%。当施加的超声功率比分别增加到40%、60%、80%时,熔深面积分别为9.29×105、10.97×105、8.33×105μm²,呈现下降趋势。随着超声功率比的增大,熔高逐渐降低至483、419、435 μm,熔覆层宽度随着超声功率比的增大,逐渐增大至2 574、2 589、2 642 μm,稀释率分别为50.9%、56.8%、48.5%,均小于无超声作用下。随着超声功率比的增强,熔高降低,熔深减小,熔宽逐渐增大。无超声振动沉积的涂层轮廓呈现典型的弧形轮廓,而超声波输出功率比达到80%,涂层的轮廓底部较为平坦。可见,在超声振动作用下,熔体和基体之间的润湿性显著改善。

图6 熔覆层宏观形貌

图7 熔覆层表面轮廓分析

图8 激光熔覆层微观组织形貌

图9 超声功率对熔覆层几何形貌的影响

3 讨论

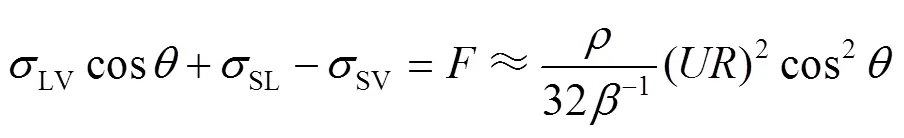

通过对超声作用下液滴润湿行为的观测(如图2所示),发现润湿角在超声作用下显著降低,可见超声振动破坏了液滴的初始界面力平衡。对超声振动作用下的液滴界面力变化进行分析,如图10所示,在无超声时,液滴的气液固三相边界在边界力的作用下处于平衡状态;引入超声振动后,由于超声振动在液滴固液边界处产生动量传递层,引发了使液滴向三相边界外侧运动的额外作用力,进而破坏了初始平衡状态,提升了液滴在基板上的润湿效果[25]。在液滴润湿发生改变后,超声振动引起的额外作用力与新的三相边界力达到平衡,该平衡可表示为[26-27]:

式中:σLV为液-气界面表面张力;σSL为固-液界面表面张力;σSV为固-气界面表面张力;F为由超声振动引起的附加声张力;θ为动态接触角;U为基板振动振幅;R为液滴接触半径;β‒1为黏性动量传递层,其值与液体黏度μ、密度u及振动角频率ω有关。由于超声振动引起的额外作用力平行于接触线处的基板,根据分子动力学理论[27],接触线的移动与能量耗散有关,能量耗散通常为作用在移动接触线上的摩擦力做功。随着三相线的外移,液滴接触半径R增大,动态接触角θ减小,三相边界处径向声张力随之增大,与液-气界面表面张力σLV、固-液界面表面张力σSL、固-气界面表面张力σSV实现表面力平衡,液滴三相线不再外移。图4中熔池图像轮廓的变化体现了熔体在超声作用下润湿效果的提升,结合式(1),可见超声振幅的增加使得超声的额外作用力提升,因此在超声功率增加时,熔覆层润湿效果提升,与图8结果相符。

在激光熔覆过程中,熔池底部作为形核基底开始凝固,枝晶生长方向与热流方向相反,在超声作用下熔体流动加速,熔池内流场的变化改变了温度场分布与热流方向,使得枝晶生长方向较为杂乱。前期研究[28]表明,随着超声功率比的增加,熔池表面温度逐渐降低,熔池温度梯度减小,在流场和温度场的共同作用下,柱状晶外延生长受阻,枝晶长度显著变短,同时由于润湿性提升而产生的扁平熔覆层形状也进一步抑制了晶粒的外延生长。无超声作用下,当凝固到顶部时,由于顶部与外界环境存在直接的热交换,导致热流方向发生变化,外延枝晶生长方向和最大局部热梯度方向之间的生长偏角过大[29],故在顶部能观察到明显的转向枝晶。在超声作用下,熔体表面高频振动,带动熔池顶部热流方向的紊乱,抑制了转向枝晶的形成。

超声振动引起的润湿作用也对激光熔覆成形工艺窗口和成形质量产生影响。在激光送丝熔覆过程中,常出现工艺不匹配导致的顶丝而熔覆中止,高质量的熔覆成形工艺窗口较窄[30-31]。而引入超声振动后,熔池波动促进了丝材与熔池间的热量传递,加速了丝材在熔池内部时的熔化,一定程度上避免了顶丝发生,增大了送丝熔覆工艺窗口。在超声辅助激光送粉熔覆中,超声引起的搅拌作用减少了熔覆中的球化现象,提高了熔覆层成形质量[15,20]和粉末沉积过程中的粉末使用率[17]。低润湿角、小稀释率的单道熔覆是实现表面平整、稀释率小且无孔隙的多道搭接熔覆的必要条件[32-33]。已有学者模拟了不同润湿角和稀释率的熔覆层在多道熔覆下的温度场分布,模拟结果显示,低润湿角、小稀释率的熔覆层单位面积吸收能量升高,更利于多道搭接熔覆[34]。无超声振动沉积的涂层轮廓呈现典型的弧形轮廓,而随着超声功率比的增强,熔覆层形状逐渐发生改变,呈现低润湿角和小稀释率的单道形貌,为高质量的多道搭接熔覆建立了基础。

4 结论

1)超声作用下,金属液滴表面发生剧烈波动,表面润湿性显著提高,液滴趋于扁平,润湿面积增大39.3%。

2)熔池在超声作用下加剧流动,熔池往激光扫描速度方向润湿,熔融区域面积扩大。超声的引入加剧了液桥搭接处的流动,使丝材熔融前端流动加快,促进了熔池的润湿行为,增大了熔体与空气的接触面积。

3)超声的施加使熔覆层由典型的弧形轮廓变为扁平,随着超声功率比的增大,熔覆层最大高度逐渐减小,超声功率比为80%作用下的熔覆层高度为无超声情况下的75.2%。

4)施加超声振动使熔体润湿性增强且流速加快,加速了熔池与外界的热交换,熔池顶部转向枝晶减少,凝固组织生长方向较为杂乱,长直柱状晶明显减少。

[1] 姚喆赫, 姚建华, 向巧. 激光再制造技术与应用发展研究[J]. 中国工程科学, 2020, 22(3): 63-70.

YAO Zhe-he, YAO Jian-hua, XIANG Qiao. Development of Laser Remanufacturing Technology and Application[J]. Strategic Study of CAE, 2020, 22(3): 63-70.

[2] ZHU Li-da, YANG Zhi-chao, XIN Bo, et al. Microstructure and Mechanical Properties of Parts Formed by Ultrasonic Vibration-Assisted Laser Cladding of Inconel 718[J]. Surface and Coatings Technology, 2021, 410: 126964.

[3] ZHONG Chong-liang, CHEN Jing, LINNENBRINK S, et al. A Comparative Study of Inconel 718 Formed by High Deposition Rate Laser Metal Deposition with GA Powder and PREP Powder[J]. Materials & Design, 2016, 107: 386-392.

[4] LIU Fen-cheng, LYU Fei-yue, LIU Feng-gang, et al. Laves Phase Control of Inconel 718 Superalloy Fabricated by Laser Direct Energy Deposition viaAging and Solution Treatment[J]. Journal of Materials Research and Technology, 2020, 9(5): 9753-9765.

[5] LI Mei-yan, HAN Bin, SONG Li-xin, et al. Enhanced Surface Layers by Laser Cladding and Ion Sulfurization Processing towards Improved Wear-Resistance and Self- Lubrication Performances[J]. Applied Surface Science, 2020, 503: 144226.

[6] WANG Shu-hao, ZHU Li-da, FUH J Y H, et al. Multi- Physics Modeling and Gaussian Process Regression Analysis of Cladding Track Geometry for Direct Energy Deposition[J]. Optics and Lasers in Engineering, 2020, 127: 105950.

[7] ZHOU Sheng-feng, DAI Xiao-guang, ZENG Xiao-yan. Effects of Processing Parameters on Structure of Ni- Based WC Composite Coatings during Laser Induction Hybrid Rapid Cladding[J]. Applied Surface Science, 2009, 255(20): 8494-8500.

[8] DUTTA MAJUMDAR J, GALUN R, MORDIKE B L, et al. Effect of Laser Surface Melting on Corrosion and Wear Resistance of a Commercial Magnesium Alloy[J]. Materials Science and Engineering: A, 2003, 361(1-2): 119-129.

[9] 陈健, 姚喆赫, 姚建华, 等. 超声振动辅助激光熔覆技术研究进展综述[J]. 航空制造技术, 2021, 64(12): 36-46.

CHEN Jian, YAO Zhe-he, YAO Jian-hua, et al. State-of-Art Review on Ultrasonic Vibration-Assisted Laser Cladding[J]. Aeronautical Manufacturing Technology, 2021, 64(12): 36-46.

[10] NING Fu-da, CONG Wei-long. Ultrasonic Vibration- Assisted (UV-a) Manufacturing Processes: State of the Art and Future Perspectives[J]. Journal of Manufacturing Processes, 2020, 51: 174-190.

[11] NING Fu-da, HU Ying-bin, CONG Wei-long. Microstructure and Mechanical Property of TiB Reinforced Ti Matrix Composites Fabricated by Ultrasonic Vibration- Assisted Laser Engineered Net Shaping[J]. Rapid Prototyping Journal, 2019, 25(3): 581-591.

[12] TODARO C J, EASTON M A, QIU D, et al. Grain Refinement of Stainless Steel in Ultrasound-Assisted Additive Manufacturing[J]. Additive Manufacturing, 2021, 37: 101632.

[13] WANG Hui, HU Ying-bin, NING Fu-da, et al. Ultrasonic Vibration-Assisted Laser Engineered Net Shaping of Inconel 718 Parts: Effects of Ultrasonic Frequency on Microstructural and Mechanical Properties[J]. Journal of Materials Processing Technology, 2020, 276: 116395.

[14] ZHANG M, ZHAO G L, WANG X H, et al. Microstructure Evolution and Properties of In-Situ Ceramic Particles Reinforced Fe-Based Composite Coating Produced by Ultrasonic Vibration Assisted Laser Cladding Processing[J]. Surface and Coatings Technology, 2020, 403: 126445.

[15] 陈林, 陈文静, 黄强, 等. 超声振动对EA4T钢激光熔覆质量和性能的影响[J]. 材料工程, 2019, 47(5): 79-85.

CHEN Lin, CHEN Wen-jing, HUANG Qiang, et al. Effect of Ultrasonic Vibration on Quality and Properties of Laser Cladding EA4T Steel[J]. Journal of Materials Engineering, 2019, 47(5): 79-85.

[16] YUAN Ding, SUN Xiao-jing, SUN Lai-bo, et al. Improvement of the Grain Structure and Mechanical Properties of Austenitic Stainless Steel Fabricated by Laser and Wire Additive Manufacturing Assisted with Ultrasonic Vibration[J]. Materials Science and Engineering: A, 2021, 813: 141177.

[17] CONG Wei-long, NING Fu-da. A Fundamental Investigation on Ultrasonic Vibration-Assisted Laser Engineered Net Shaping of Stainless Steel[J]. International Journal of Machine Tools and Manufacture, 2017, 121: 61-69.

[18] NING Fu-da, JIANG Da-yue, LIU Zhi-chao, et al. Ultrasonic Frequency Effects on the Melt Pool Formation, Porosity, and Thermal-Dependent Property of Inconel 718 Fabricated by Ultrasonic Vibration-Assisted Directed Energy Deposition[J]. Journal of Manufacturing Science and Engineering, 2021, 143(5): 256.

[19] ZHUANG D D, DU B, ZHANG S H, et al. Effect and Action Mechanism of Ultrasonic Assistance on Microstructure and Mechanical Performance of Laser Cladding 316L Stainless Steel Coating[J]. Surface and Coatings Technology, 2022, 433: 128122.

[20] WU Dong-jiang, GUO Min-hai, MA Guang-yi, et al. Dilution Characteristics of Ultrasonic Assisted Laser Clad Yttria-Stabilized Zirconia Coating[J]. Materials Letters, 2015, 141: 207-209.

[21] MA Guang-yi, YAN Shuai, WU Dong-jiang, et al. Microstructure Evolution and Mechanical Properties of Ultrasonic Assisted Laser Clad Yttria Stabilized Zirconia Coating[J]. Ceramics International, 2017, 43(13): 9622- 9629.

[22] 王维, 郭鹏飞, 张建中, 等. 超声波对BT20钛合金激光熔覆过程的作用[J]. 中国激光, 2013, 40(8): 70-74.

WANG Wei, GUO Peng-fei, ZHANG Jian-zhong, et al. Ultrasonic Effect on Laser Cladding BT20 Titanium Alloy Process[J]. Chinese Journal of Lasers, 2013, 40(8): 70-74.

[23] 陈明曦, 侯涛, 赵晏章, 等. 基于新型改进Canny算法的铁轨边缘检测研究[J]. 国外电子测量技术, 2021, 40(11): 48-52.

CHEN Ming-xi, HOU Tao, ZHAO Yan-zhang, et al. Research on Rail Edge Detection Based on New Improved Canny Algorithm[J]. Foreign Electronic Measurement Technology, 2021, 40(11): 48-52.

[24] 李靖, 王慧, 闫科, 等. 改进Canny算法的图像边缘增强方法[J]. 测绘科学技术学报, 2021, 38(4): 398-403.

LI Jing, WANG Hui, YAN Ke, et al. Improved Canny Algorithm for Image Edge Enhancement[J]. Journal of Geomatics Science and Technology, 2021, 38(4): 398- 403.

[25] KIM P, DUPRAT C, TSAI S S H, et al. Selective Spreading and Jetting of Electrically Driven Dielectric Films[J]. Physical Review Letters, 2011, 107(3): 034502.

[26] 俞伟元, 邢春晓, 林巧力. 超声波振动对水/E-GaIn在不同基板表面润湿的影响[J]. 工程热物理学报, 2020, 41(5): 1186-1191.

YU Wei-yuan, XING Chun-xiao, LIN Qiao-li. Effect of Ultrasonic Vibration on Wetting of Water/E-GaInon Different Substrate Surfaces[J]. Journal of Engineering Thermophysics, 2020, 41(5): 1186-1191.

[27] MANOR O, DENTRY M, FRIEND J R, et al. Substrate Dependent Drop Deformation and Wetting under High Frequency Vibration[J]. Soft Matter, 2011, 7(18): 7976- 7979.

[28] 俞晓文. 超声振动在激光熔覆成形中的作用机制及其建模方法[D]. 杭州: 浙江工业大学, 2020.

YU Xiao-wen. Mechanism and Modeling Method of Ultrasonic Vibration in Laser Cladding Forming[D]. Hangzhou: Zhejiang University of Technology, 2020.

[29] CHEN Yuan, ZHANG Qin, GUO Yan-bing, et al. Dendritic Growth Transition during Laser Rapid Solidification of Nickel-Based Superalloy[J]. JOM, 2021, 73(5): 1538-1545.

[30] 郭一蒙, 彭勇, 江俊龙. 4043铝合金激光熔丝增材制造工艺研究[J]. 热加工工艺, 2019, 48(5): 245-247, 255.

GUO Yi-meng, PENG Yong, JIANG Jun-long. Study on Laser Additive Manufacturing Technology with 4043 Aluminum Alloy Melting Wire[J]. Hot Working Technology, 2019, 48(5): 245-247, 255.

[31] 果春焕, 严家印, 王泽昌, 等. 金属激光熔丝增材制造工艺的研究进展[J]. 热加工工艺, 2020, 49(16): 5-10.

GUO Chun-huan, YAN Jia-yin, WANG Ze-chang, et al. Research Progress on Metal Laser Fuse Additive Manufacturing Process[J]. Hot Working Technology, 2020, 49(16): 5-10.

[32] ABIOYE T E, FOLKES J, CLARE A T. A Parametric Study of Inconel 625 Wire Laser Deposition[J]. Journal of Materials Processing Technology, 2013, 213(12): 2145- 2151.

[33] VUNDRU C, SINGH R, YAN Wen-yi, et al. Effect of Spreading of the Melt Pool on the Deposition Characteristics in Laser Directed Energy Deposition[J]. Procedia Manufacturing, 2021, 53: 407-416.

[34] 俞晓文, 姚喆赫, 张操棋, 等. 多维高频振动对激光熔覆成形几何形貌的影响研究[J]. 表面技术, 2020, 49(10): 286-293, 315.

YU Xiao-wen, YAO Zhe-he, ZHANG Cao-qi, et al. Effects of Multi-Dimensional High Frequency Vibration on Geometrical Morphology of Laser Cladding Forming[J]. Surface Technology, 2020, 49(10): 286-293, 315.

Influence of Ultrasound on the Wetting Behavior of Molten Pool in Laser Cladding

1a,1b,2,1a,1b,2,3,1a,1b,2,1a,1b,2,3,4,1a,1b,2

(1. a. Institute of Laser Advanced Manufacturing, b. College of Mechanical Engineering, Zhejiang University of Technology, Hangzhou 310023, China; 2. Collaborative Innovation Center of High-end Laser Manufacturing Equipment, Hangzhou 310023, China; 3. Hangzhou Steam Turbine Co., Ltd., Hangzhou 310020, China; 4. Laser Processing Research Centre, University of Manchester, Manchester M13 9PL, UK)

Laser additive remanufacturing technology based on laser cladding has shown significant advantages and great potential in the repair and remanufacturing of damaged parts. However, the rapid heating and cooling process during laser cladding leads to the formation of micro-cracks, pores, residual tensile stress, etc. in the cladding layer. In order to improve the quality of laser cladding, ultrasonic assisted laser cladding has become one of the hot spots in current research. In this study, the wetting behaviors of the molten pool with and without ultrasonic vibration were compared to investigate the influence and mechanism of ultrasonic vibration on the wetting behavior, providing reference for high-quality ultrasonic assisted laser cladding.

Inconel 718 substrates were polished and cleaned by alcohol to remove surface impurities. A laser beam with power of 1 kW and a spot diameter of 2 mm was used. Ultrasonic vibration with a frequency of 20 kHz and amplitude of 50 μm was transmitted from the bottom of the specimen to the molten pool. A forward wire feeding with a feeding angle of 45° was applied. The scanning speed and the wire feeding speed were 8 mm/s and 9.3 mm/s, respectively. During the experiments, the transition behaviors of the molten pool were captured by a high-speed camera, and the profiles of the molten pool were extracted by Canny algorithm. After the experiments, the macro morphology of the specimens was observed using a stereo microscope (Nikon, SMZ745T) and a confocal microscope (Keyence, VK-X1000). An optical microscope (Zeiss, Axio Imager2) was used to observe and analyze the microstructure of the cladding zone.

Significant fluctuation occurred on the surface of metal droplet with ultrasonic vibration. And the contact area between the metal droplet and the substrate increased by 39.3% with the effect of ultrasonic vibration, indicating the increase of wettability. The area of the molten pool in the laser cladding increased significantly caused by ultrasonic vibration. When a stable liquid-bridge transition was reached in the laser cladding, the area of the molten pool with ultrasonic vibration was 2.8 times of that without ultrasonic vibration. With the increase of ultrasonic power, the height and depth of the cladding layer decreased while the width increased. The dilution rate of the cladding layer was also reduced by ultrasonic vibration. And the cladding layer gradually varied from an arc profile to be relatively flat. When the ultrasonic power ratio was 80%, the height of the cladding layer was 75.2% of that without ultrasound, suggesting significant improvement of the wettability between the cladding and the substrate. In addition, the growth direction of the grains changed and the epitaxial growth of dendrites was inhibited. In addition, the turning dendritic structure at the top of the cladding layer became narrow with ultrasonic vibration. The mechanisms of ultrasonic vibration on the molten pool were discussed based on the experimental results.

In the laser cladding process, ultrasonic vibration is able to promote the wetting of melt and accelerate the melt flow of the molten pool, which leads to a relatively flat cladding layer. The area of molten pool increased, resulting in the variation of the grain growth direction and the length of dendrites.

laser cladding; ultrasonic vibration; wetting behavior; molten pool; macroscopic morphology; microstructure

V261.8

A

1001-3660(2022)10-0020-10

10.16490/j.cnki.issn.1001-3660.2022.10.003

2022–07–19;

2022–09–24

2022-07-19;

2022-09-24

国家自然科学基金(52175443、U1809220);浙江省属高校基本科研业务费专项资金(RF-B2020002);浙江省公益技术应用研究项目(LGG20E050019)

Supported by the National Natural Science Foundation of China (52175443, U1809220); the Fundamental Research Funds for the Provincial Universities of Zhejiang (RF-B2020002); Public Welfare Project of Zhejiang Province (LGG20E050019)

姚喆赫(1987—),男,博士,副研究员,主要研究方向为能场复合激光制造。

YAO Zhe-he (1987-), Male, Doctor, Associate professor, Research focus: energy field hybrid laser manufacturing.

姚建华(1965—),男,博士,教授,主要研究方向为激光制造。

YAO Jian-hua (1965-), Male, Doctor, Professor, Research focus: laser manufacturing.

姚喆赫, 沈奇艳, 葛宏江, 等.超声对激光熔覆成形中熔池润湿行为的影响研究[J]. 表面技术, 2022, 51(10): 20-29.

YAO Zhe-he, SHEN Qi-yan, GE Hong-jiang, et al. Influence of Ultrasound on the Wetting Behavior of Molten Pool in Laser Cladding[J]. Surface Technology, 2022, 51(10): 20-29.

责任编辑:万长清