冷却水流量对蒸发段上移的三相闭式重力热管传热性能的影响

2022-07-04李瑞佳齐国鹏李修伦

姜 峰,李瑞佳,齐国鹏,李修伦

冷却水流量对蒸发段上移的三相闭式重力热管传热性能的影响

姜 峰1, 2,李瑞佳1,齐国鹏3,李修伦1

(1. 天津大学化工学院,天津 300350;2. 天津市化工安全与装备技术重点实验室,天津 300350;3. 天津职业大学生物与环境工程学院,天津 300410)

本文将流化床换热防垢节能技术与两相闭式重力热管相结合,设计并构建了蒸发段上移的铜/水-碳化硅三相闭式重力热管.分别采用水和碳化硅颗粒作为液相和固相工质,考察了冷却水流量(50~75L/h)、充液率(15%~30%)和加热功率(100~300W)等操作参数对闭式重力热管传热性能的影响.研究结果表明,碳化硅颗粒的加入可以明显地降低蒸发段上移的闭式重力热管的总热阻,强化传热.实验范围内,总热阻减少率最大为33.8%,相应的充液率为FR=20%,加热功率=200W,冷却水流量=100L/h.在较低的冷却水流量下,两相和三相闭式重力热管的总热阻随着冷却水流量的增加明显减小,然而,随着冷却水流量的进一步增加,总热阻减小的幅度降低.加热功率较低时,三相闭式重力热管的总热阻随充液率的增加先减小,后增大;加热功率较高时,总热阻随充液率的增加呈现出波动的趋势.构建了操作参数对总热阻减小率影响的三维图.研究结果有助于促进三相闭式重力热管的工业 应用.

三相闭式重力热管;强化传热;蒸发段上移;冷却水流量;总热阻;碳化硅

热管是依靠自身内部工质发生相变来进行传热的一种元件.闭式重力热管(TPCT),又称为热虹吸管,是结构最为简单的一种热管.其中空的金属管体,使其具有质轻的特点,而其快速均温的特性,则使其具有优异的热超导性能.此外,闭式重力热管还具有优良的热流密度可变性、环境适应性等优点[1-2],目前已被广泛应用于能源[3-5]、空调系统[6]、电子器件冷却[7-8]、核反应[9]和地热控制[10-12]等领域.

TPCT自下而上可分为蒸发段、绝热段和冷凝段.流体在TPCT蒸发段产生汽相流到TPCT冷凝段,在此段产生液相.冷凝液依靠重力回流至蒸发段,进而完成工质的循环,将热量从高温区转移至低温区[13].

目前,对TPCT传热性能强化的研究主要集中在3个方面:改变热管的内部结构[14-15]、修饰热管的内壁面[16]和选择适当的工质[17-20].与其他方法相比,选用适当的工质可以避免复杂的结构、降低设备加工和维护费用.在目前所考察的工质中,纳米流体被很多研究者证明可以强化TPCT的传热[21-23]. Ramezani-zadeh等[21]考察了3种浓度的Ni/甘油-水纳米流体对重力热管传热性能的影响.结果表明,使用适当浓度的纳米流体可以降低热管的总热阻. Parametthanuwat等[22]分别用水、水基银纳米流体、含油酸等研究了热管的换热状况.他们发现,纳米流体的有效性均优于水,可以改善热管的传热性能.Huminic等[23]发现浓度为5.3%的纳米流体的传热性能优于纯水.然而,也有一些研究发现纳米流体并不总是能够改善TPCT的传热性能.Khandekar等[24]的研究表明,采用不同的水基纳米流体作为工质,均会使TPCT的总热阻增加,传热恶化.此外,生产成本高和长期使用稳定性的问题也限制了纳米流体在工业上的应用.

流化床换热技术中流化的固体颗粒对换热壁面进行剪切和碰撞,可以破坏、减薄流动和传热边界层,增加汽化核心,延长结垢的诱导期,降低壁温,进而在线强化传热和防、除垢,节能降耗,延长换热设备的使用寿命.该技术目前已广泛应用于多个工业 领域[25-32].

将流化床换热防垢节能技术和TPCT相结合,构建汽-液-固三相闭式重力热管(THPCT),是对TPCT强化传热方式的一种有益探索.一些研究者围绕此方面已开展了初步的研究[33-35].Li等[33]构建了碳钢/碳化硅-水三相闭式重力热管,在80%的充液率下,考察了固含率、热通量和颗粒粒径等参数对于其传热性能的影响.结果表明,和TPCT相比,THPCT可以明显地强化传热;颗粒粒径对传热性能具有显著的影响.Chen等[34]设计并构建了碳钢/水-玻璃珠三相闭式重力热管,考察了充液率、固含率和加热功率等操作参数对其传热性能的影响.结果表明,玻璃珠的加入增加了蒸发段的传热系数,降低了总热阻.姜峰 等[35]考察了颗粒类型对THPCT传热性能的影响.其研究结果表明传热性能随着固含率的增加而波动,树脂颗粒具有较好的强化传热效果.

闭式重力热管蒸发段的传热包括底部液池的沸腾传热和液池上方的膜状蒸发.二者传热机理和效果不同.蒸发段加热位置的上移将影响两种传热机理对蒸发段传热的贡献,进而影响颗粒的流化和THPCT的整体传热效果[36-37].然而,上述关于THPCT传热性能的研究主要集中在以碳钢为材质的三相闭式重力热管,其加热位置固定从蒸发段底端开始,而对于蒸发段加热位置上移的情况尚鲜有探讨.同时,THPCT的传热性能是由蒸发段和冷凝段的传热共同控制的,而目前对于THPCT的研究主要考察的是蒸发段传热条件变化所带来的影响,如加热功率和热通量等,而对于冷凝段传热条件的变化,如冷却水流量等所产生的影响,则尚鲜见报道.因此,本文将水和碳化硅颗粒加入TPCT中,将TPCT的蒸发段上移40mm,研究蒸发段上移后的THPCT工作状况.铜作为热管壳体材料导热性能好;碳化硅颗粒热导率高,理化性能好.研究结果将有助于促进对THPCT的强化传热机理的深入了解,拓展其应用范围,促进其工业化使用.

1 实 验

1.1 实验设备

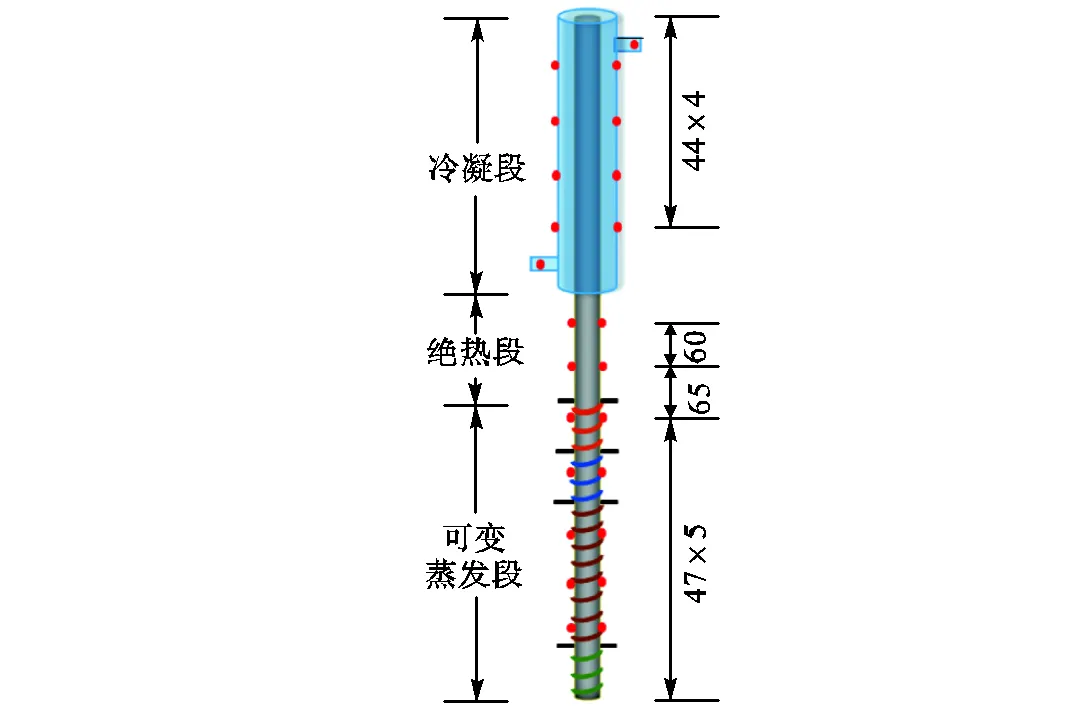

图1所示为本文设计并构建的一套蒸发段加热位置上移的三相闭式重力热管(THPCT),其主要由闭式重力热管、真空系统和数据采集系统三部分构成.闭式重力热管的管壳材料为铜,长度为600mm,直径为22mm×1.5mm.热管自下而上可分为蒸发段、绝热段和冷凝段,其中,冷凝段长度为220mm.蒸发段分为4段,自下而上长度分别为40mm、120mm、40mm和40mm,每段均可以由电加热带(材料为镍铬电阻丝)独立加热,总额定功率为600W.本文主要考察蒸发段加热位置上移后三相闭式重力热管的传热性能,蒸发段距离热管底部40mm,如图2所示.

1—电脑;2—数字显示仪表;3—冷却水进口;4—转子流量计;5—冷却水夹套;6—测温热电偶;7—压力传感器;8—三通;9—冷却水出口;10—真空泵;11—金属架;12—电阻丝;13—管壁;14—金属螺母

在该设备壁面上对称地安装有11对热电偶以测量其外壁温,其中蒸发段5对、绝热段2对、冷凝段4对,如图3所示.冷凝段安装冷凝夹套,冷却水的进、出口温度由热电偶测量,流量由转子流量计测量.整个热管外面包有保温棉,以减少热损失.

图2 蒸发段设置

图3 热电偶的分布

热管顶部装有压力传感器,通过三通与2XZ-4旋片式真空泵相连,可测量热管内的操作压力.该设备抽真空后初始操作压力为95kPa(真空度).热电偶和压力传感器在使用前已要求制造商对其进行了校准,对压力传感器进行了充分补偿,对热电偶进行 了冷端补偿和非线性补偿.相关仪表的规格如表1 所示.

表1 相关仪表的规格

实验过程中每组实验条件重复3次,以检查数据的重复性.

1.2 实验工质与操作参数

实验中,选择与铜相容性良好的自来水作为热管的液相工质,选择碳化硅颗粒作为惰性固体颗粒.碳化硅颗粒理化性质稳定,导热性能好,适于工业化推广应用.颗粒的相关物性如表2所示.

充液率为加入的液相工质体积与热管总容积之比,实验中,充液率分别设置为15%、20%、25%和30%.冷却水流量分别为50L/h、75L/h、100L/h和125L/h.加热功率分别为100W、200W和300W.实验中的固含率固定为15%,这里的固含率是指添加的固体颗粒堆体积与液相工质体积之比.

表2 颗粒的相关物性

注:沉降速度在20℃和常压下的水中测得.

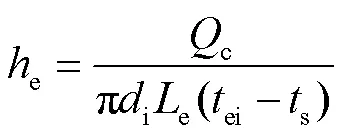

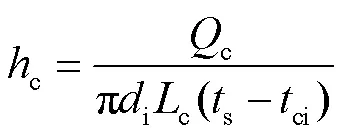

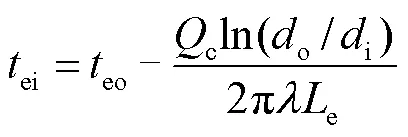

1.3 数据处理与误差分析

实验中,温度和冷却水流量的最大测量误差分别为0.1℃和1L/h.传热速率、总热阻和对流传热系数的不确定度可分别计算如下:

实验范围内,传热速率、热管总热阻、蒸发段和冷凝段对流传热系数的最大不确定度分别为2.15%、2.55%、2.21%和2.18%,满足工程计算的要求.

2 结果与讨论

2.1 蒸发段上移的三相闭式重力热管的强化传热性能

图4所示为加热位置上移的三相闭式重力热管的总热阻减少率随操作参数的变化规律.由图可知,在加热位置上移后,碳化硅颗粒的加入仍然可以明显地降低TPCT的总热阻,强化传热.实验范围内,总热阻减少率最大为33.8%,相应的充液率为FR=20%,加热功率=200W,冷却水流量=100L/h.

在THPCT中,颗粒存在于蒸发段.蒸发段液池的沸腾,导致颗粒流化.流化的颗粒会碰撞和剪切加

热壁面,减薄和破坏流动与传热边界层,减小热阻,强化对流传热;同时,颗粒与壁面的作用,还会增加壁面上的汽化核心,加快汽泡的生成和脱离频率,促进沸腾传热.此外,颗粒的流化还有利于将液池中的大汽泡破碎成小汽泡,减小汽泡离开液池时的雾沫夹带,有利于减小冷凝段的液膜厚度,降低冷凝传热热阻,强化传热.因此,在上述因素的综合作用下,碳化硅颗粒的加入,明显地降低了蒸发段和冷凝段的壁 面温差,减小了热管的总热阻,强化了传热,如图5所示.

2.2 冷却水流量对三相闭式重力热管传热性能的影响

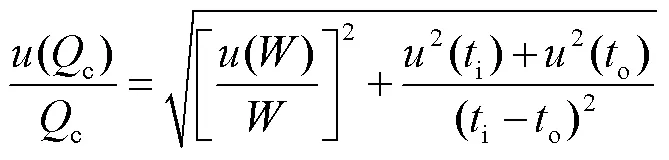

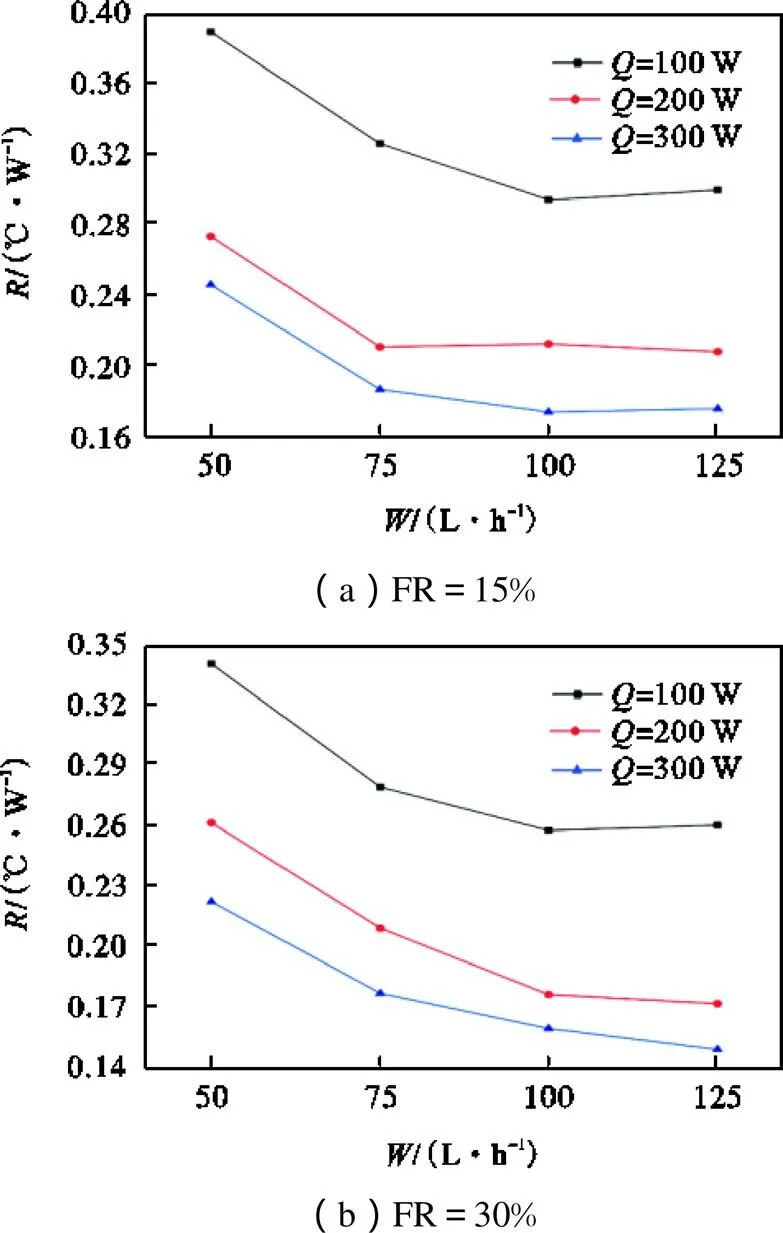

图6和图7分别为冷却水流量对两相和三相闭式重力热管总热阻的影响.由图可知,随着冷却水流量的增加,两相和三相闭式重力热管的总热阻呈现出相似的变化趋势.冷却水流量较小时,总热阻随着冷却水流量的增加而迅速降低.然而,随着冷却水流量的进一步增加,总热阻下降的幅度逐渐减小,甚至出现增大的趋势.

图4 操作参数对闭式重力热管总热阻减少率的影响

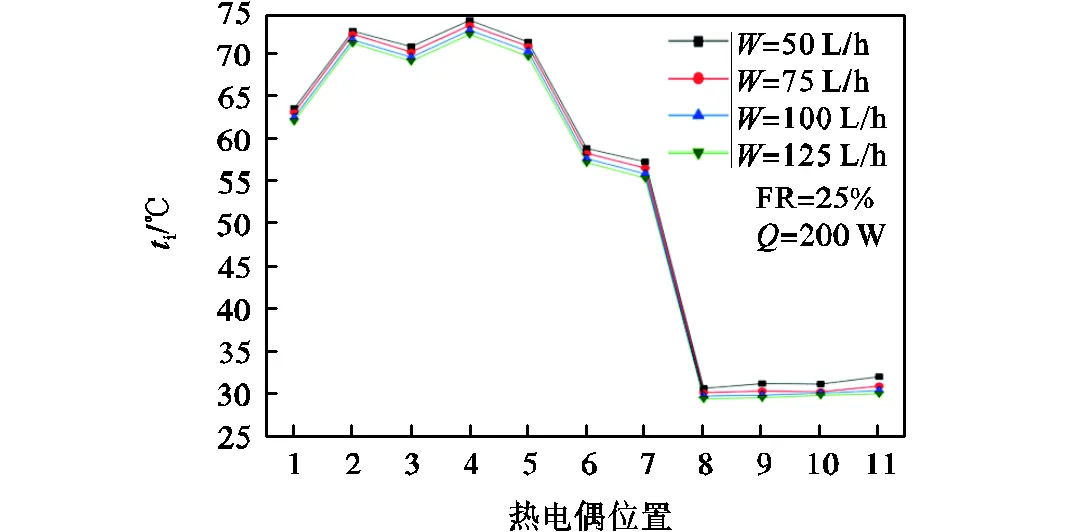

一方面,冷却水流量的增加,增大了冷却水侧的对流传热系数,导致冷凝段总传热系数也随之增大,降低了冷凝段的壁温,增加了蒸汽冷凝速率.热管冷凝段和蒸发段液池上方的操作压力下降,蒸发段液相工质的沸点降低.在一定的加热功率下,蒸发段的壁温也随之下降,如图8所示,因而有利于减小热损失,增加蒸发段的实际输入功率,促进沸腾传热,加剧对液池的扰动,促进颗粒的流化.颗粒流化程度的提高则有利于促进颗粒和加热壁面的相互作用,将大汽泡破碎成小汽泡,增加汽泡的脱离频率,促进传热,减小汽泡脱离液池上升到冷凝段时的雾沫夹带,进而减小冷凝段液膜的平均厚度,减小冷凝热阻.

图5 操作参数对蒸发段与冷凝段内壁温差的影响

图6 冷却水流量对两相闭式重力热管总热阻的影响

图7 冷却水流量对三相闭式重力热管总热阻的影响

图8 冷却水流量对三相闭式重力热管平均内壁温的影响

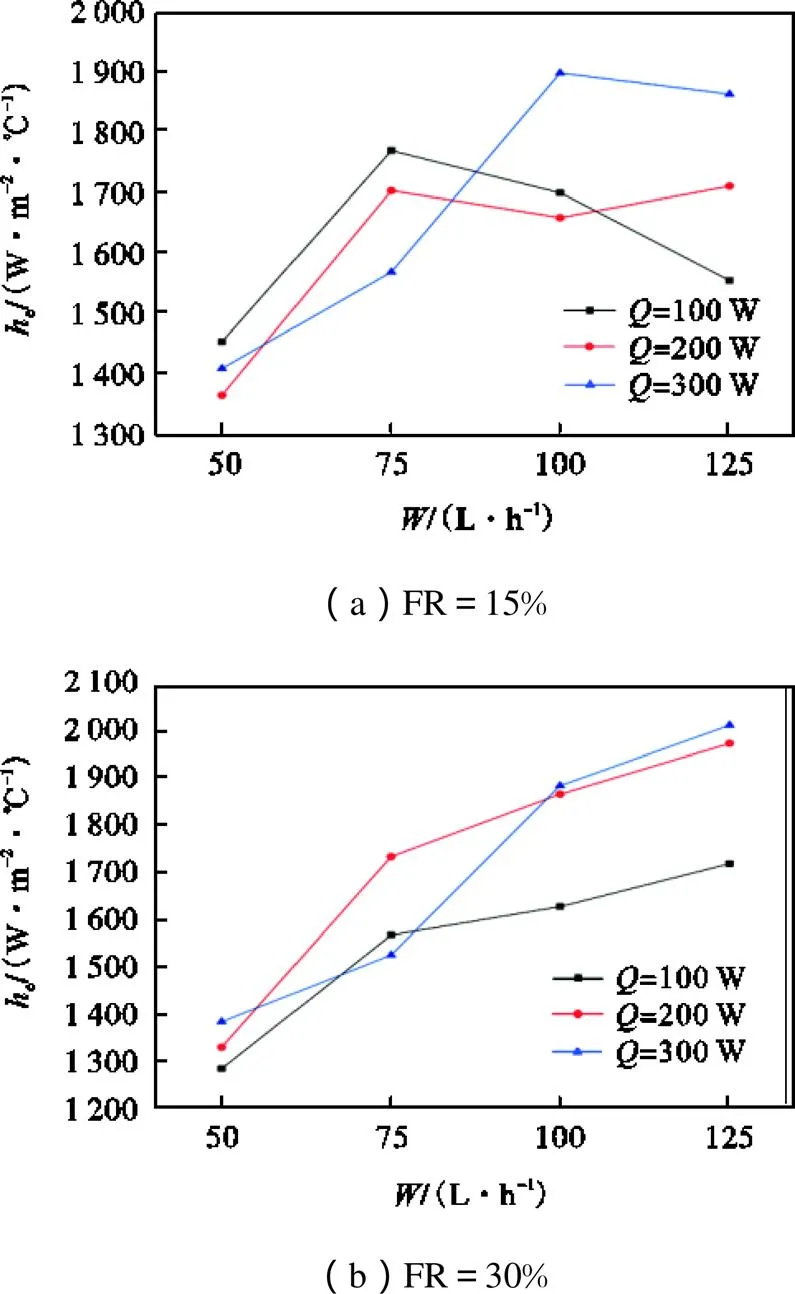

另一方面,冷却水流量增加所引起的冷凝速率增大,也会导致冷凝段平均液膜厚度增加,增大蒸汽冷凝传热热阻.同时,操作压力的降低,也增加了液体工质的黏度和表面张力,不利于沸腾传热,进而削弱了颗粒的流化程度,不利于碳化硅对THPCT的换热,最终呈现出如图9和图10所示的变化趋势.

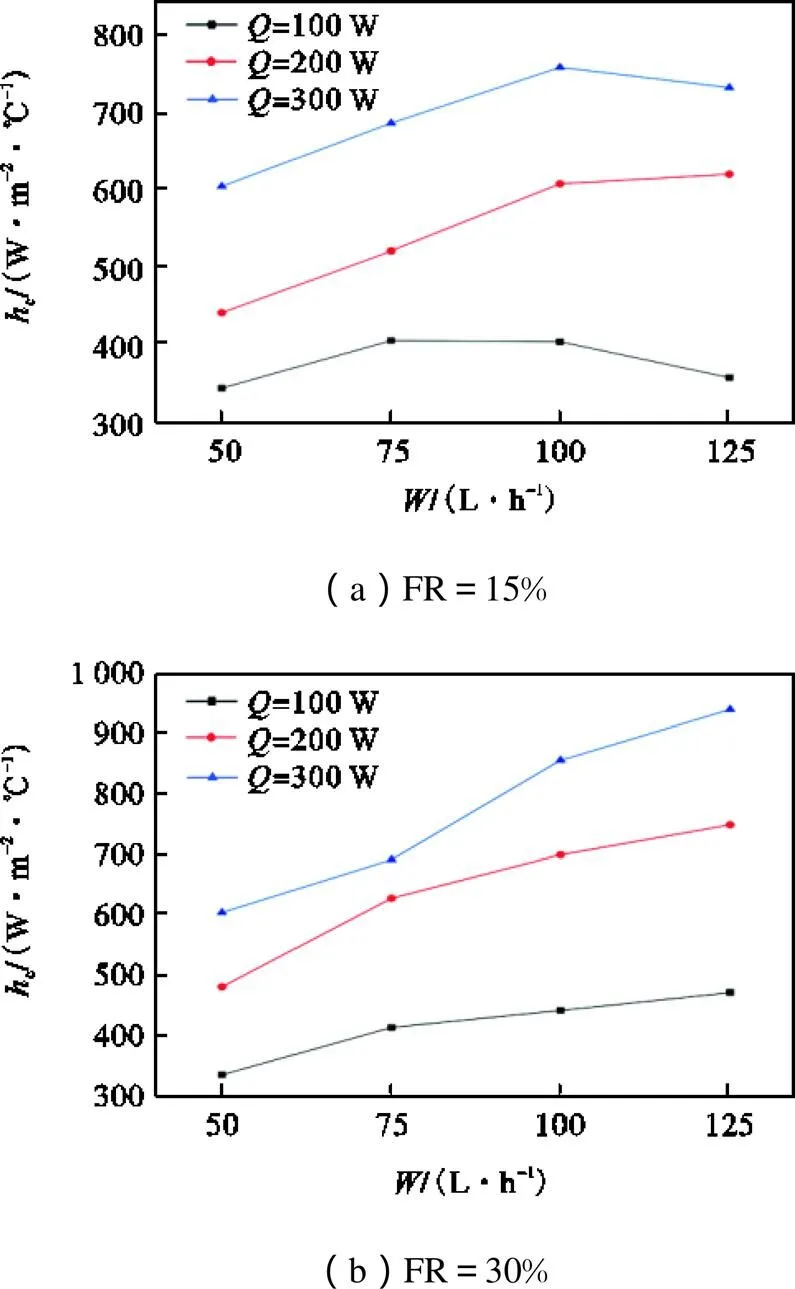

图9 冷却水流量对三相闭式重力热管蒸发段对流传热系数的影响

图10 冷却水流量对三相闭式重力热管冷凝段对流传热系数的影响

在蒸发段和冷凝段传热效果的共同作用下,冷却水流量较小时,总热阻随着冷却水流量的增加而迅速降低.然而,随着冷却水流量的进一步增加,总热阻下降的幅度逐渐减小,甚至出现增大的趋势,如图7所示.

2.3 充液率对三相闭式重力热管传热性能的影响

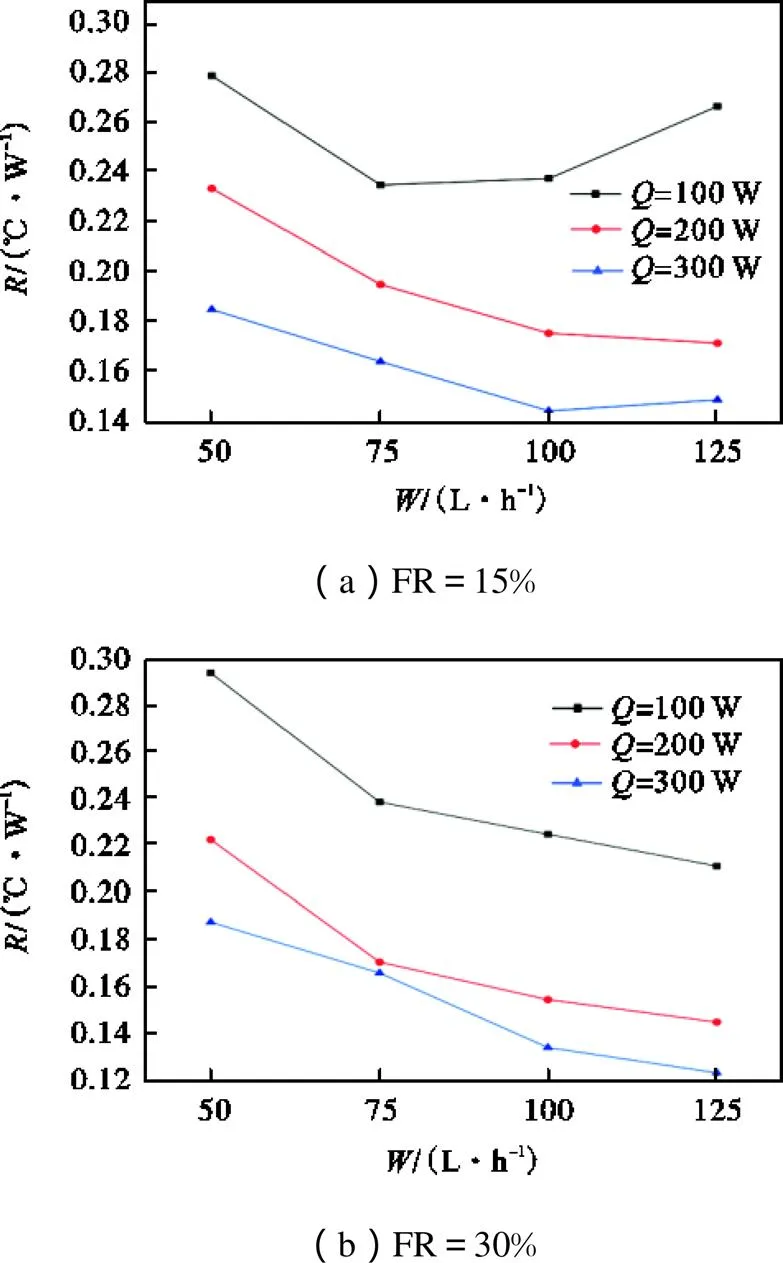

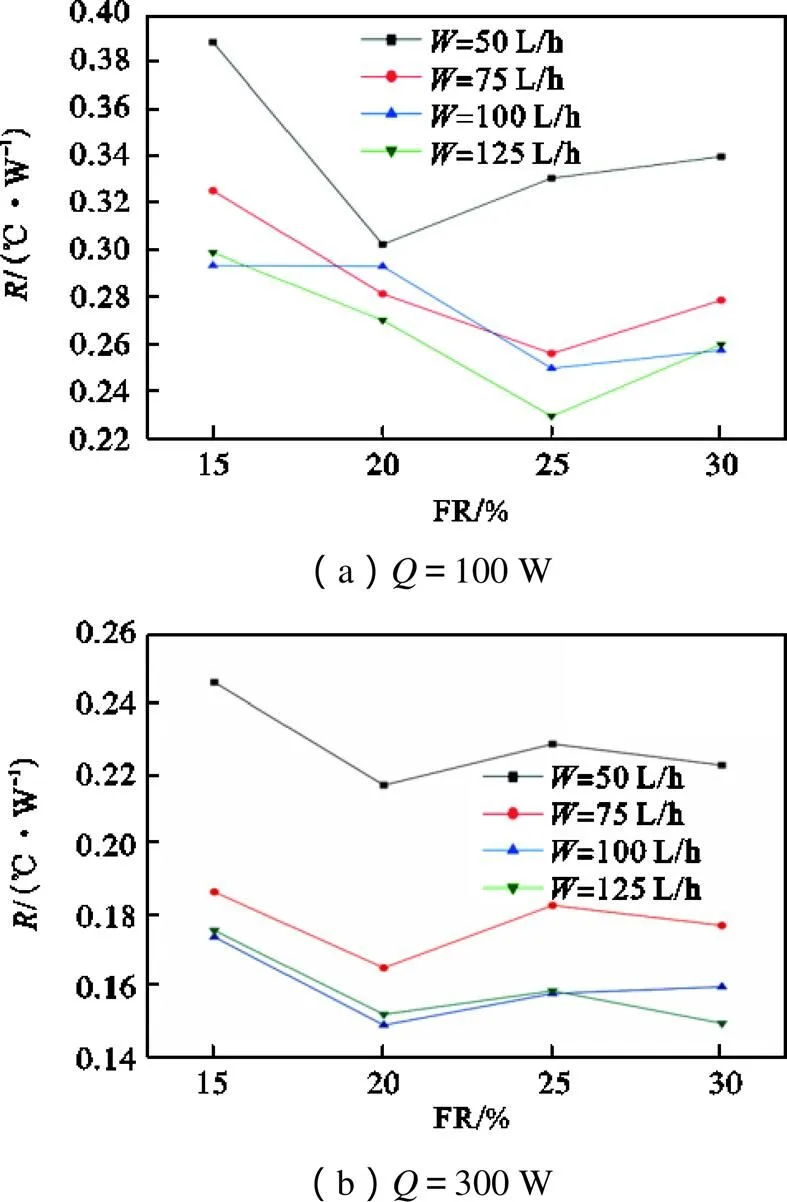

图11所示为充液率对三相闭式重力热管总热阻的影响.由图可知,在不同的加热功率下,总热阻随充液率的增加呈现出不同的变化趋势.加热功率较低时,总热阻随着充液率的增加先减小,后增大;而加热功率较高时,总热阻则随着充液率的增加呈现出波动的趋势.

图11 充液率对三相闭式重力热管总热阻的影响

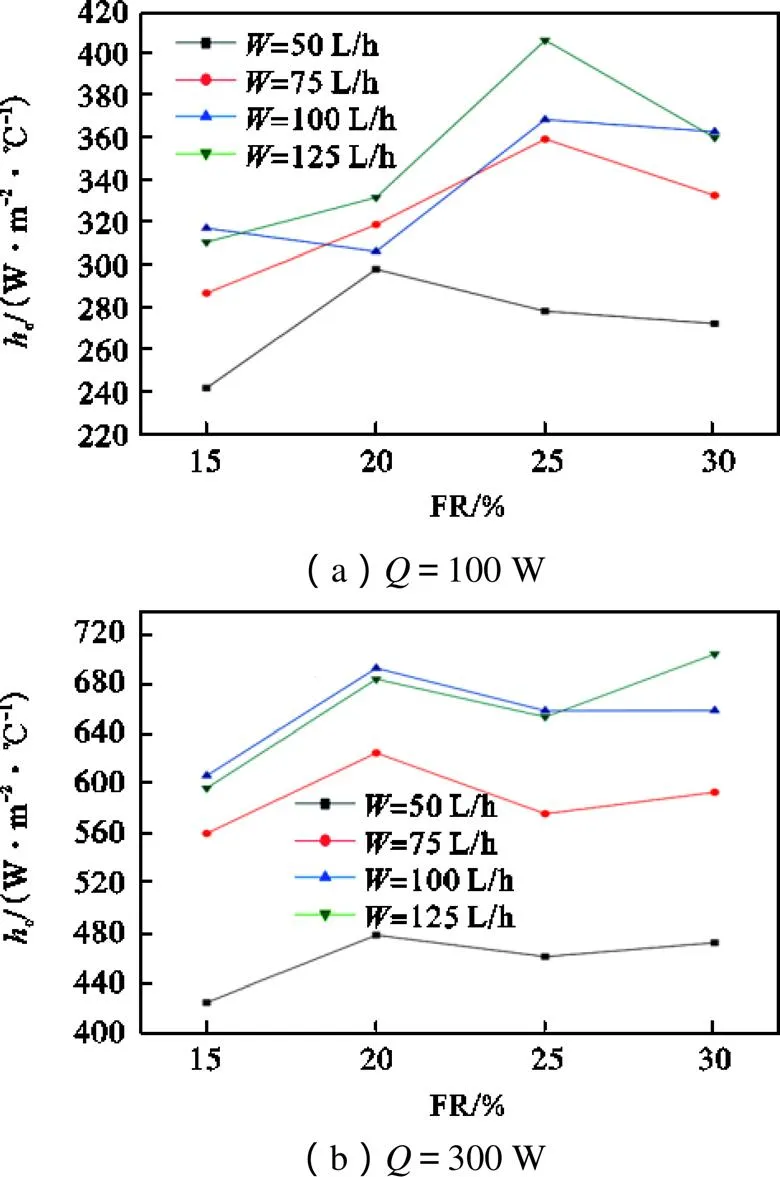

如前所述,闭式重力热管蒸发段的传热包括底部液池的沸腾传热和液池上方的膜状蒸发.充液率的增大,增加了蒸发段液池的高度,一方面提高了液池中的沸腾传热对蒸发段传热的贡献,有利于增加沸腾核心和汽泡的生成频率,加剧对液池的扰动,促进颗粒的流化.颗粒流化程度的提高则有利于促进颗粒和加热壁面的相互作用,将大汽泡破碎成小汽泡,增加汽泡的脱离频率,减小汽泡脱离液池上升到冷凝段时的雾沫夹带,进而减小冷凝段液膜的平均厚度,减小冷凝热阻.另一方面,液池高度的进一步增加,也增大了汽泡从液池中逸出的难度,因此抑制了沸腾传热,削弱了汽泡对液池的扰动程度,不利于颗粒的流化,增大了汽泡脱离液池时的尺寸,加剧了雾沫夹带.因此,在上述因素的共同作用下,加热功率较低时,蒸发段和冷凝段的对流传热系数基本上随着充液率的增加先增大,后减小,如图12(a)和图13(a)所示,进而导致总热阻随着充液率的增加先减小,后增大.

图12 充液率对三相闭式重力热管蒸发段对流传热系数的影响

图13 充液率对三相闭式重力热管冷凝段对流传热系数的影响

加热功率的增大,增加了蒸发段壁面的过热度和沸腾核心,强化了沸腾传热,增加了蒸发段的上升蒸汽量,加剧了对冷凝段液膜的扰动,有利于传热;但同时,蒸汽量的增加也加剧了雾沫夹带,增加了冷凝液膜沿壁面下流的阻力.此时,充液率的增加对蒸发段沸腾核心和雾沫夹带影响的程度减小,如图12(b)和图13(b)所示,但蒸发段和冷凝段的对流传热系数均随着充液率的增加而波动,因此也导致总热阻随着充液率的增加呈现出波动的趋势.

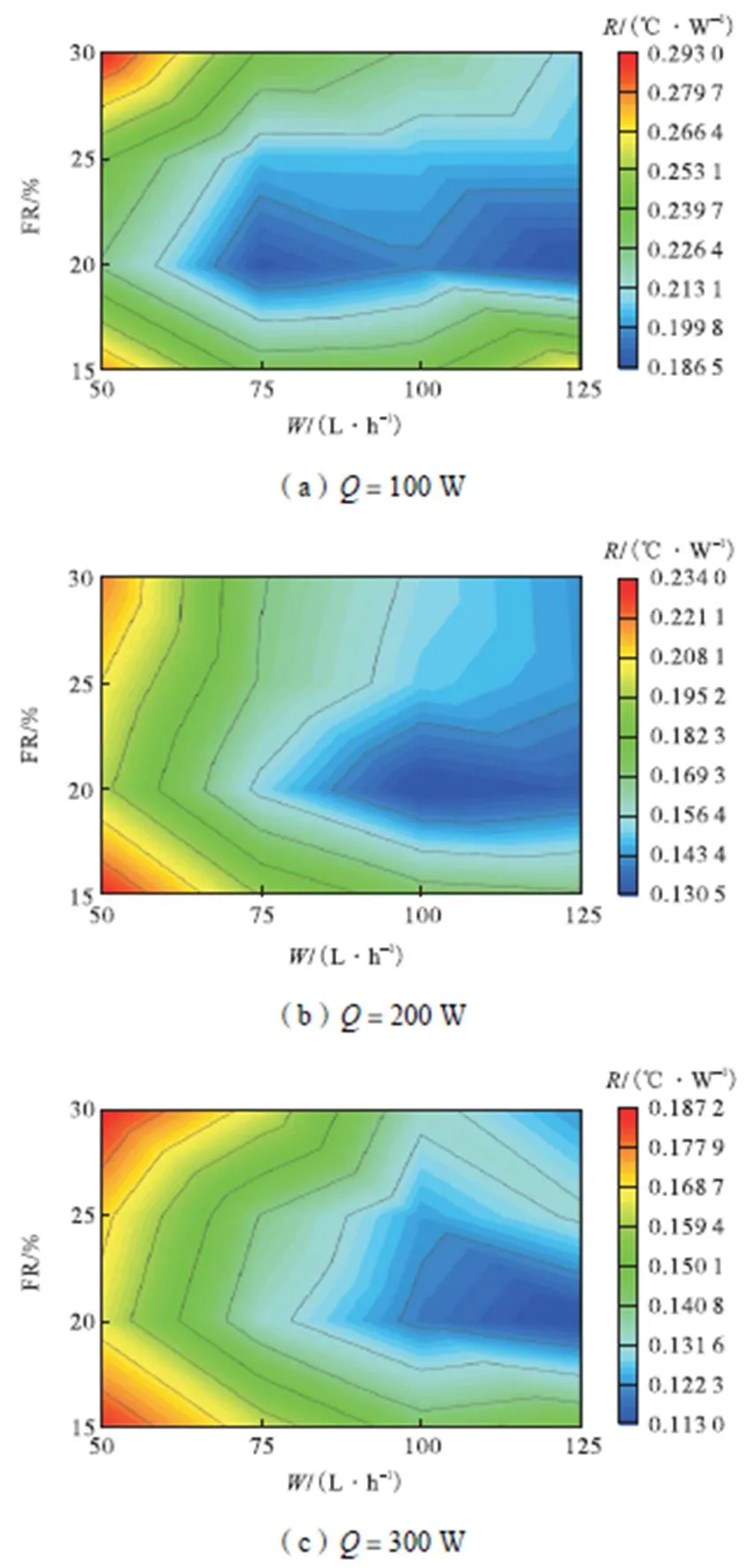

图14为操作参数对三相闭式重力热管总热阻影响的三维图.该图可以综合反映操作参数对THPCT传热性能的影响,有助于确定闭式重力热管的最优操作条件,并为其工业应用提供参考.

图14 操作参数对THPCT总热阻影响的三维图

3 结 论

(1) 碳化硅颗粒的加入可以明显地强化蒸发段上移的闭式重力热管的传热性能.实验范围内,总热阻减少率最大为33.8%,相应的充液率为FR=20%,加热功率=200W,冷却水流量=100L/h.

(2) 冷却水流量较小时,总热阻随着冷却水流量的增加而迅速降低.随着冷却水流量的进一步增加,总热阻下降的幅度逐渐减小,甚至出现增大的趋势.

(3) 总热阻在加热功率较低时,随着充液率的增加先减小,后增大;而在加热功率较高时,随着充液率的增加呈现出波动的趋势.

(4) 构建了操作参数对总热阻影响的三维图,以反映THPCT传热性能的变化规律.

(5) 后续研究将进一步考察固含率和颗粒类型等操作参数对蒸发段上移的三相闭式重力热管传热性能的影响,同时开展相应的数值模拟.

[1] Guichet V,Almahmoud S,Jouhara H. Nucleate pool boiling heat transfer in wickless heat pipes(two-phase closed thermosyphons):A critical review of correla-tions[J]. Thermal Science and Engineering Progress,2019,13:100384.

[2] Anand R S,Jawahar C P,Solomon A B,et al. A re-view of experimental studies on cylindrical two-phase closed thermosyphon using refrigerant for low-temperature applications[J]. International Journal of Refrigeration,2020,120:296-313.

[3] Dehaj M S,Mohiabadi M Z. Experimental investigation of heat pipe solar collector using MgO nanofluids[J]. So-lar Energy Materials and Solar Cells,2019,191(3):91-99.

[4] Wenceslas K Y,Ghislain T. Experimental validation of exergy optimization of a flat-plate solar collector in a thermosyphon solar water heater[J]. Arabian Journal for Science and Engineering,2018,44(3):2535-2549.

[5] Jafari D,Franco A,Filippeschi S,et al. Two-phase closed thermosyphons:A review of studies and solar applications[J]. Renewable and Sustainable Energy Re-views,2016,53:575-593.

[6] Eidan A A,Najim S E,Jalil J M. An experimental and a numerical investigation of HVAC system using thermo-syphon heat exchangers for sub-tropical climates[J]. Applied Thermal Engineering,2017,114:693-703.

[7] Putra N,Yanuar,Iskandar F N. Application of nanoflu-ids to a heat pipe liquid-block and the thermoelectric cooling of electronic equipment[J]. Experimental Ther-mal and Fluid Science,2011,35(7):1274-1281.

[8] Narcy M,Lips S,Sartre V. Experimental investigation of a confined flat two-phase thermosyphon for electronics cooling[J]. Experimental Thermal and Fluid Science,2018,96:516-529.

[9] Kusuma M H,Putra N,Antariksawan A R,et al. In-vestigation of the thermal performance of a vertical two-phase closed thermosyphon as a passive cooling system for a nuclear reactor spent fuel storage pool[J]. Nuclear Engineering and Technology,2017,49(3):476-483.

[10] Ebeling J C,Luo X,Kabelac S,et al. Dynamic simu-lation and experimental validation of a two-phase closed thermosyphon for geothermal application[J]. Propulsion and Power Research,2017,6(2):107-116.

[11] Pei W,Zhang M,Li S,et al. Geotemperature control performance of two-phase closed thermosyphons in the shady and sunny slopes of an embankment in a perma-frost region[J]. Applied Thermal Engineering,2017,112:986-998.

[12] Gao J Q,Lai Y M,Zhang M Y,et al. The thermal effect of heating two-phase closed thermosyphons on the high-speed railway embankment in seasonally frozen re-gions[J]. Applied Thermal Engineering,2018,141:948-957.

[13] Faghri A. Heat pipe science and technology[J]. Fuel and Energy Abstracts,1995,36(4):285-285.

[14] Chang S W,Yu K C. Thermal performance of reciprocating two-phase thermosyphon with nozzle[J]. International Journal of Thermal Science,2018,129:14-28.

[15] 徐晓萍,史金涛,姜 峰,等. 具有内置管的多相流闭式重力热管传热性能[J]. 天津大学学报(自然科学与工程技术版),2014,47(10):928-933.

Xu Xiaoping,Shi Jintao,Jiang Feng,et al. Heat trans-fer performance of multiphase flow closed thermosyphon with a built-in pipe[J]. Journal of Tianjin University (Science and Technology),2014,47(10):928-933(in Chinese).

[16] Brusly S A,Arun M,Ramachandran K,et al. Thermal performance of anodized two phase closed thermosy-phon(TPCT)[J]. Experimental Thermal and Fluid Sci-ence,2013,48:49-57.

[17] Long Z Q,Zhang P. Heat transfer characteristics of thermosyphon with N2-Ar binary mixture working fluid [J]. International Journal of Heat and Mass Transfer,2013,63:204-215.

[18] Oh S H,Choi J W,Lee K J,et al. Experimental study on heat transfer performance of a two-phase single ther-mosyphon using HFE-7100[J]. Journal of Mechanical Science and Technology,2017,31(10):4957-4964.

[19] Sarafraz M M,Pourmehran O,Yang B,et al. Assess-ment of the thermal performance of a thermosyphon heat pipe using zirconia-acetone nanofluids[J]. Renewable Energy,2019,136:884-895.

[20] Das S,Giri A,Samanta S,et al. An experimental in-vestigation of properties of nanofluid and its performance on thermosyphon cooled by natural convection[J]. Jour-nal of Thermal Science and Engineering Applications,2019,11(4):044501.

[21] Ramezanizadeh M,Nazari M A,Ahmadi M H,et al. Experimental and numerical analysis of a nanofluidic thermosyphon heat exchanger[J]. Engineering Applica-tion of Computational Fluid Mechanics,2019,13(1):40-47.

[22] Parametthanuwat T,Rittidech S,Pattiya A,et al. Application of silver nanofluid containing oleic acid surfactant in a thermosyphon economizer[J]. Nanoscale Research Letters,2011,6:315.

[23] Huminic G,Huminic A,Morjan I,et al. Experimental study of the thermal performance of thermosyphon heat pipe using iron oxide nanoparticles[J]. International Journal of Heat and Mass Transfer,2011,54(1/2/3):656-661.

[24] Khandekar S,Joshi Y M,Mehta B. Thermal perform-ance of closed two-phase thermosyphon using nanoflu-ids[J]. International Journal of Thermal Sciences,2008,47(6):659-667.

[25] Wen J P,Zhou H,Li X L. Performance of a new vapor-liquid-solid three-phase circulating fluidized bed evapo-rator[J]. Chemical Engineering Processing,2004,43(1):49-56.

[26] Liu M Y,Yang Y,Li X L. Concentration of Geng-nian’an extract with a vapor-liquid-solid evaporator[J]. AIChE Journal,2010,51(3):759-765.

[27] Lim D H,Jang J H,Jin H R,et al. Heat transfer in three-phase(G/L/S)circulating fluidized beds with low surface tension media[J]. Chemical Engineering Science,2011,66(14):3145-3151.

[28] Guo Q J,Qi X,Wei Z,et al. Experimental study on hydrodynamic performance and heat transfer mechanism of vapor-liquid-solid three-phase fluidized bed[J]. Inter-national Journal of Heat and Technology,2016,34:537-544.

[29] 姜 峰,王兵兵,齐国鹏,等. 汽-液-固多管循环流化床蒸发器中固体颗粒的分布[J]. 天津大学学报(自然科学与工程技术版),2013,46(2):133-137.

Jiang Feng,Wang Bingbing,Qi Guopeng,et al. Solid particle distribution in vapor-liquid-solid multi-pipe cir-culating fluidized bed evaporator[J]. Journal of Tianjin University(Science and Technology),2013,46(2):133-137(in Chinese).

[30] Hu X Y,Xu T,Li C Y,et al. Catalytic cracking of n-heptane under activation of lattice oxygen in a circulating fluidized bed unit[J]. Chemical Engineering Journal,2011,172(1):410-417.

[31] Pronk P,Ferreira C A I,Witkamp G J. Mitigation of ice crystallization fouling in stationary and circulating liquid-solid fluidized bed heat exchangers[J]. Interna-tional Journal of Heat and Mass Transfer,2010,53(1/2/3):403-411.

[32] Blaszczuk A,Pogorzelec M,Shimizu T. Heat transfer characteristics in a large-scale bubbling fluidized bed with immersed horizontal tube bundles[J]. Energy,2018,162:10-19.

[33] Li H J,Jiang F,Qi G P,et al. Effect of particle size and solid holdup on heat transfer performance of a SiC/water three-phase closed thermosyphon[J]. Applied Thermal Engineering,2018,132:808-816.

[34] Chen X L,Jiang F,Qi G P,et al. Experimental invest-tigation on a three-phase closed thermosyphon with glass beads/water[J]. Applied Thermal Engineering,2019,154:157-170.

[35] 姜 峰,刘 泽,王兵兵,等. 三相流闭式重力热管传热性能[J]. 天津大学学报(自然科学与工程技术版),2013,46(6):553-558.

Jiang Feng,Liu Ze,Wang Bingbing,et al. Heat trans-fer performance of three-phase flow closed gravity heat pipe[J]. Journal of Tianjin University(Science and Tech-nology),2013,46(6):553-558(in Chinese).

[36] 姜 峰,景文玥,齐国鹏,等. 蒸发段可变的三相闭式重力热管的传热性能[J]. 天津大学学报(自然科学与工程技术版),2021,54(7):661-671.

Jiang Feng,Jing Wenyue,Qi Guopeng,et al. Thermal performance of a three-phase closed thermosyphon with variable evaporation section[J]. Journal of Tianjin University(Science and Technology),2021,54(7):661-671(in Chinese).

[37] 姜 峰,沈 宇,齐国鹏,等. 液-固循环流化床锅炉中的颗料分布[J]. 天津大学学报(自然科学与工程技术版),2021,54(6):607-616.

Jiang Feng,Shen Yu,Qi Guopeng,et al. Particle dis-tribution in liquid-solid circulating fluidized bed boiler[J]. Journal of Tianjin University(Science and Technology),2021,54(6):607-616(in Chinese).

Effect of Cooling Water Flow Rate on the Thermal Performance of a Three-Phase Closed Thermosyphon with an Upward-Moving Evaporation Section

Jiang Feng1, 2,Li Ruijia1,Qi Guopeng3,Li Xiulun1

(1. School of Chemical Engineering and Technology,Tianjin University,Tianjin 300350,China;2. Tianjin Key Laboratory of Chemical Process Safety and Equipment Technology,Tianjin 300350,China;3.School of Biological and Environmental Engineering,Tianjin Vocational Institute,Tianjin 300410,China)

In this study,a copper(Cu)/water-silicon carbide(SiC)three-phase closed thermosyphon with an upward-moving evaporation section is designed and built by combining fluidized bed heat transfer and fouling prevention technology with a two-phase closed thermosyphon. Water and SiC solid particles are used as the liquid and solid working media,respectively. The effect of the operating parameters,namely the cooling water flow rate(50—75L/h),filling ratio(15%—30%),and heating power(100—300W),on the heat transfer performance of the three-phase closed thermosyphon is studied. The results show that adding SiC particles can obviously reduce the overall thermal resistance and enhance the heat transfer of the closed thermosyphon with an upward-moving evaporation section. The maximum reduction rate of the overall thermal resistance was up to 33.8% at FR=20%,=200W,and=100L/h within the experimental range. The overall thermal resistance of the two- and three-phase closed thermosyphons decreased with the increase in the cooling water flow rate when the cooling water flow rate was low. However,the extent of the decline decreased with a further increase in the cooling water flow rate. The overall thermal resistance of the three-phase closed thermosyphon initially decreased,and then increased with the increase in the filling ratio at a low heating power but fluctuated with the increase in the liquid filling ratio at a high heating power. Three-dimensional diagrams of the effect of the operating parameters on the reduction rate of the overall thermal resistance are established. The obtained findings are beneficial to the industry application of the three-phase closed thermosyphon.

three-phase closed thermosyphon;heat transfer enhancement;upward-moving evaporation section;cooling water flow rate;overall thermal resistance;silicon carbide

TQ051.5

A

0493-2137(2022)09-0909-10

10.11784/tdxbz202104035

2021-04-19;

2021-06-08.

姜 峰(1975— ),男,博士,副教授.

姜 峰,jiangfeng@tju.edu.cn.

化学工程国家重点实验室开放基金资助项目(SKL-ChE-18B03).

the Open Foundation of State Key Laboratory of Chemical Engineering(No. SKL-ChE-18B03).

(责任编辑:田 军)