Experimental investigation of sound absorption in a composite absorber

2021-07-29NanshaGaoHongHou

Nansha Gao ,Hong Hou

Key Laboratory of Ocean Acoustic and Sensing, School of Marine Science and Technology, Northwestern Polytechnical University, Xi’an 710072, China

Keywords: Composite absorber Multi-layer micro-perforated plate Porous material Sub-wavelength sound absorption

ABSTRACT A composite absorber made of a polyurethane sponge and multi-layer micro-perforated plates is pre-sented in this study.Results from an acoustic impedance tube test show that the polyurethane sponge can exhibits higher low-frequency sound absorption in front of the micro-perforated plate,while sound absorption at medium and high-frequencies remains low.The physical mechanism behind this is that the micro-perforated plate increases the denpth cavity.If the polyurethane sponge is placed behind the micro-perforated plate,the amplitude of the original absorption peak will remain constant,but the ab-sorption peaks will shift to lower frequencies.The reason for this phenomenon is that porous materials with low flow resistance can be approximately equivalent to fluid,which not only does not affect the res-onance absorption coefficient of micro-perforated plate,but also makes the peaks move to low frequency.This study has the potential applications in the sound absorption design of composite structure.

Effective absorption [1,2] and isolation [3,4] of harmful noise have been the focus of acoustic research for some time.Micro-perforated plates can exhibit sound absorption peaks in the low frequency range,which is related to plate thickness,aperture,and depth of the rear cavity [5] Porous materials made of fiber [6,7] or foam [1] are primarily affected by dissipation of incident sound waves through disordered holes of different sizes.Although high frequency has the sound absorption property of wide frequency,its performance at low frequency is poor [6,7] .It has been found that filling porous material with a resonant sound absorber to form a composite structure provides higher absorption at low fre-quencies [8 -12] .Modal coupling between a periodic steel plate support structure and a in-homogeneous porous layer can pro-duce an acoustic absorption peak [8] .Resonant [9-11] and non-resonant [12] inclusions are placed in porous materials to in-crease the absorption coefficient at low frequencies.Previous stud-ies have shown that placing plates on the surface of porous ma-terials or among them is a simple method for increasing absorp-tion at low frequencies [13] .Based on this,a composite absorber was examined in this study.Experimental results from an acous-tic impedance tube test show that a porous polyurethane sponge can produce an absorption peak at middle and low frequencies and maintain good sound absorption effect at middle and high frequencies.If the polyurethane sponge is placed behind a multi-layer micro-perforated plate,multiple absorption peaks will shift to lower frequency.Compared with the membrane metamaterials [14 -16] and composite structure absorbers [17,18],the proposed design structure is simple.The classical micro-perforated panel changes the sound absorption mainly through the aperture,thick-ness and the depth of the back cavity.Through a large number of experimental datas,this study proves that the sound absorption ef-fect at low frequency can also be improved by placing the sound absorption sponge behind the multi-layer micro-perforated plate.The results from this study illustrate a method for designing com-posite absorber structures with multiple absorption peaks,and has potential application in the design of new sound absorption cur-tain wall in architectural acoustics.

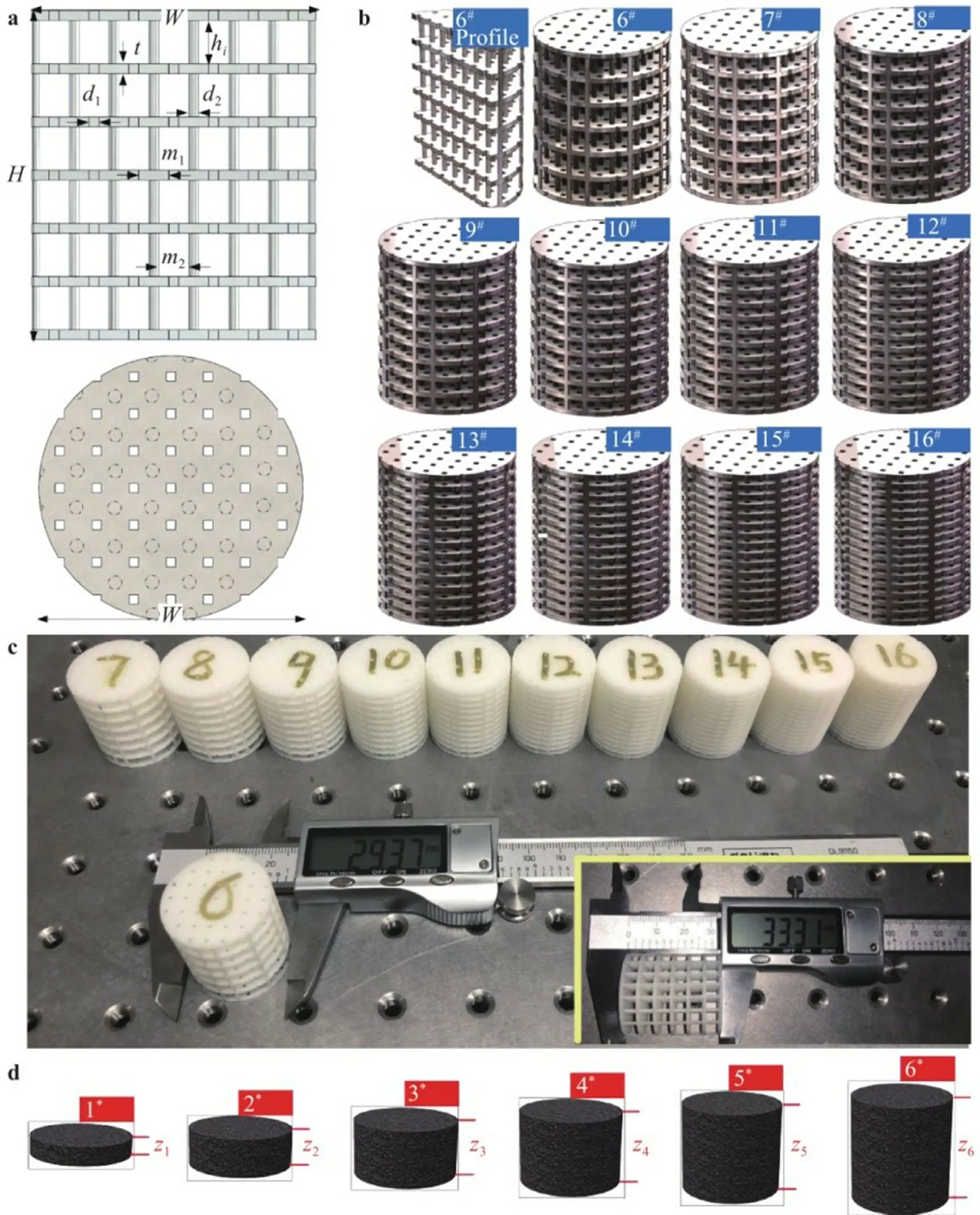

The multi-layer micro-perforated plate structure presented in this section is a cylindrical unit,as shown in Fig.1 a.His the height of the cylinder,Wis the diameter,the thickness of each layer of the micro-perforated plates ist.d1 is the side length of the square micro-holes,d2 is the connecting column diameter of each layer of the micro-perforated plates,m1 is the hole gap,andm2 is di-atance between adjacent holes.The micro-holes are arranged in a periodic square lattice.When a cylindrical element hasnlay-ers,layer spacinghi=[(H-t)/n]-t.The specific dimensions of the structure are shown in Table 1 .We designed a cylinder unit with 6-16 layers,named structure 6#-16#,respectively (see Fig.1 b).A 3D printing system (nanoArchR○P130) was used to fabricate the structures from photosensitive resins.

Fig.1. a Side and top views of multi-layer micro-perforated plates.b Multi-layer micro-perforated plate models numbered 6#-16#.c Test samples made with bright resin molding technology. d Polyurethane sponges of different thicknesses (z1 - z6),which are named 1*-6*.

Table 1 Geometric parameters of multi-layer micro-perforated plates.

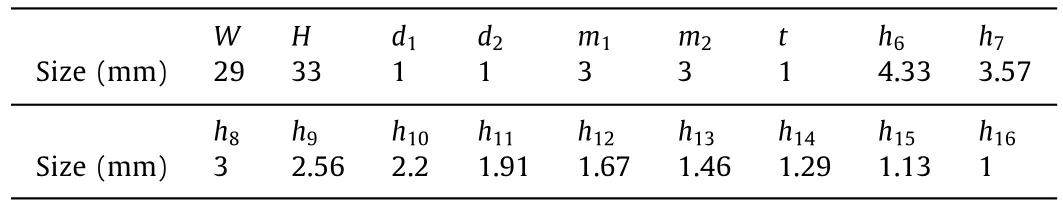

A porous sponge made of polymer polyurethane fiber was provided by Shenzhen Jiexin Rubber Sponge Product Co.,Ltd.The six sponge samples shown in Fig.1d have different thicknesses,z1=5 mm,z2=10 mm,z3=15 mm,z4=20 mm,z5=25 mm,z6=30 mm,but all have the same diameter of 30 mm.Scan ning electron microscope (SEM,Carl Zeiss Gemini SEM300) images were gathered to examine the morphology of the porous sponge.The shape of the pores approximately resembles a regular poly gon,which is conducive to acoustic absorption [19].An industrial 3D computed tomography (CT) scanner (Phoenix Vtomex-S,Shang hai Yinghua Inspection and Testing Co.,Ltd.) was used to accu rately determine the porosityφ.The dimensions of the scanning sample were 10 mm × 10 mm × 10 mm.100 X-ray scans were performed in three orthogonal directions on each sample.After performing 100 cross-sectional scans of the sample in three di rections,the porosity of each slice was calculated,and an accu- rate average porosityφ=97.54% was obtained.Figure 2a shows a sample of polyurethane sponge used for characterization.Figure 2b shows that the interior is a continuous through-hole with fiber distribution.Figure 2c and 2d shows that the microscopic morphology of pore size is polygonal,with both millimeter-level macropores and micron-level micropores.Sound absorption tests in acoustic impedance tubes (Brüel &Kjær) are performed in accordance with the ISO 10534-2 standard.Figure 2e shows the measurement setup in an anechoic chamber.According to Chung and Blaser’s results [20],the complex sound reflection coefficient is:

Fig.2. a Polyurethane sponge sample. b Industrial CT image. c, d scanning electron SEM images. e Acoustic impedance tube test site.

whereH12 is transfer function relationship between sound pressure at two microphone positions,the wave numberk=2πf/c,lis the distance between two microphones (Fig.2) and test samples,andsis the distance between the two microphones.The sound absorption coefficient at normal incidenceαnis defined as follows [1]

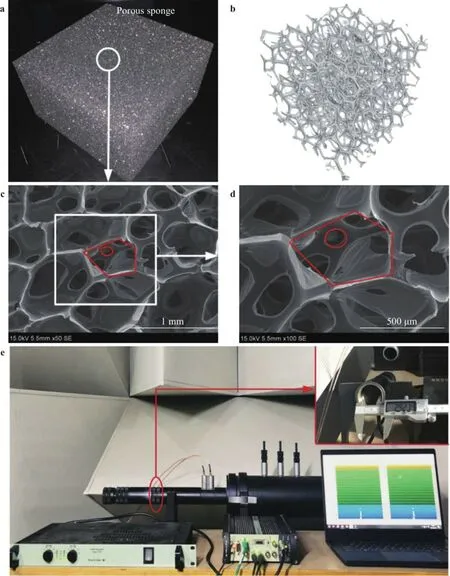

Fig.3. a-c Sound absorption coefficients of structures 6#-11#,12#-16#,and sponge 1*-6*.d Comparison of sound absorption coefficients between composite absorbers(sponge 6*+structure 14#(9#),structure 14#(9#)+sponge 6*) and contrast sponge.

Figure 3 a and 3b shows the sound absorption coefficient measured for structures 6#-16#.Three distinct sound absorption peaks are present in cylindrical units with different layers.Structure 6#exhibits the smallest first absorption peak,while the second and the third absorption peaks are somewhat larger.The first sound absorption peak in structures 6#-11#is gradually raised and the its corresponding location moves to the low frequency.The second absorption peak also increases,but the third absorption peak decreases.Figure 3b shows that the first absorption peak does not change when the number of layers increase from 12#to 16#,and the absorption peak moves towards lower frequencies.The replication of the second and third sound absorption peaks drops significantly,and these peaks initially move to lower frequencies and then return to higher frequencies.In structures 6#-16#,the first absorption peak sub-wavelength sound absorption in the multilayer micro-perforated plate.The corresponding absorption coeffi-cient also increases,and the corresponding peak frequency basically tends to move to low frequency.

Figure 3c shows the absorption coefficient of polyurethane.The absorption coefficient from 0 to 6.5 kHz is much larger when the thickness was increased to 5 mm.Sponge 6*has the best sound absorption characteristics.Some fluctuations in the absorption coefficient curve for polyurethane sponge come from the fact that porous samples cannot be confined to the inner wall when installed in the acoustic impedance tube,so absorption fluctuates at some frequencies.

We tested the sound absorption coefficients of structures 6#-16#and sponges 1*-6*,the resulsts are shown in Fig.3a-3c.Due to the typical cavity resonance absorption effect of multilayer micro-perforated plate,there are many high absorption peaks in the whole frequency domain.The sound absorption effect of porous sponge is closely related to its thickness.As shown in Fig.3c,the sound absorption coefficient curve of porous sponge increases with the increase of thickness.In order to explore and confirm the effect of different combination on sound absorp-tion,we also tested the composite absorber.One should note that sound waves first enter the cylinder unit of the multi-layer micro-perforated plate,and then pass through the polyurethane sponge in one of the composite absorbers (e.g.,structure 14#+sponge 6*).

In Fig.3d,polyurethane sponge 6#is placed in front of structure 14#or 9#,which can provide higher absorbance at low frequencies.In particular,there will be an obvious absorption peak within 1 kHz,but absorption at medium-high frequencies does not change.If the polyurethane sponge is placed in front of the multi-layer micro-perforated plate,which is equivalent to adding a sound absorption resonance structure effectively behind the porous materials,therefore,the sound absorption performance of first peak would be improved.But for high frequency sound waves,polyurethane sponge could absorb the almost all the acoustic energy,so the multi-layer micro-perforated plate does not work.The combination with polyurethane sponge 6*behind structure 14#or 9#still exhibits three sound absorption peaks,as was the case in the multi-layer micro-perforated plate,but the peak heights are lower and the peaks are shifted to lower frequencies.Due to the high porosity of the polyurethane sponge used in this study,placing a polyurethane sponge behind structure 14#or 9#is equivalent to adding a cavity behind the structure.Noting that because of micro-perforated plate would reflex the highfrequency sound wave,therefore,there is no opportunity for the polyurethane sponge to absorb sound energy.To sum up,composite absorbers (structure 14#or 9#+sponge 6*) has stronger absorption due to resonance at low frequencies,and weaker absorption at high frequencies.Compared with polyurethane sponge with the same thickness,this combination of composite absorber still has advantages at low frequency.

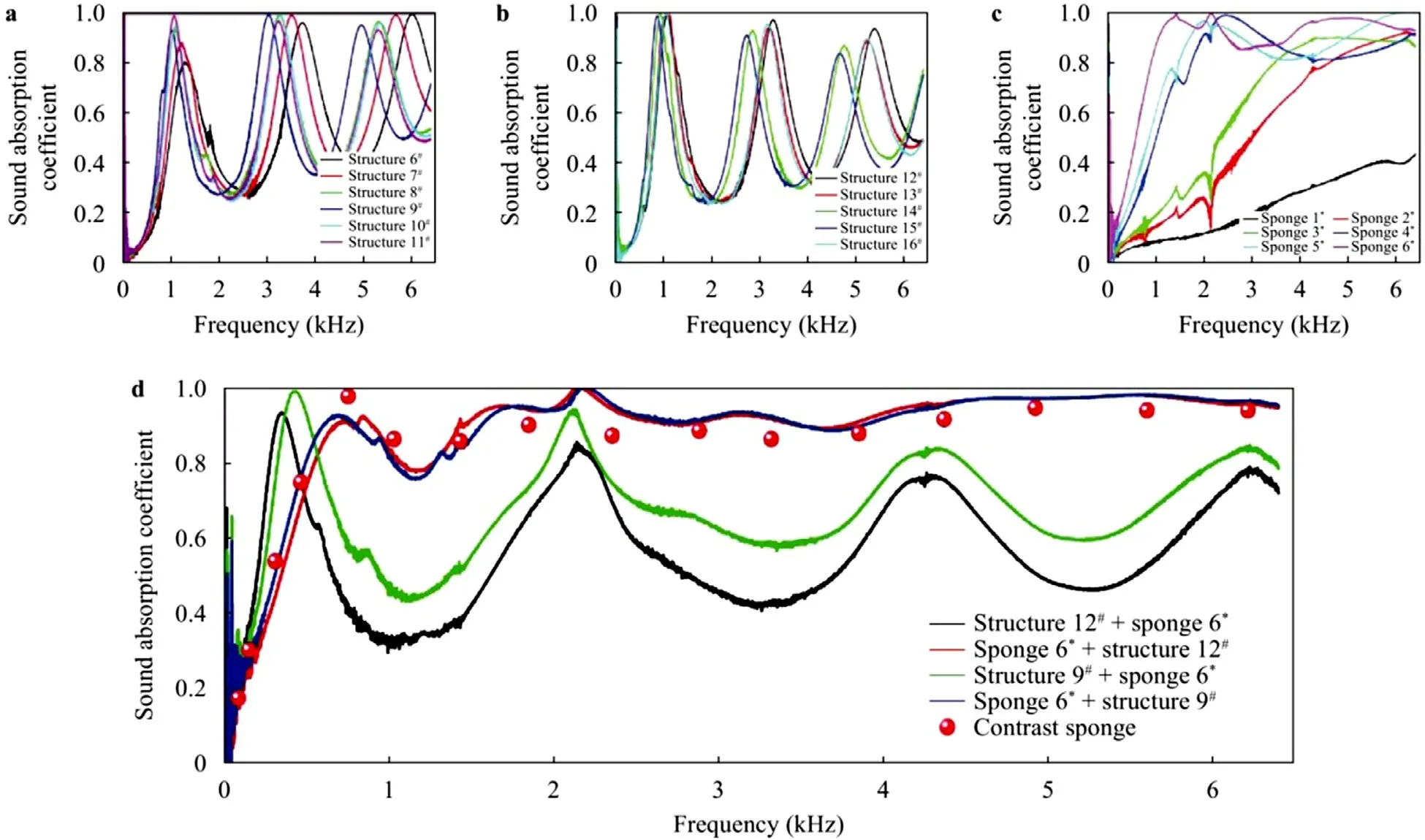

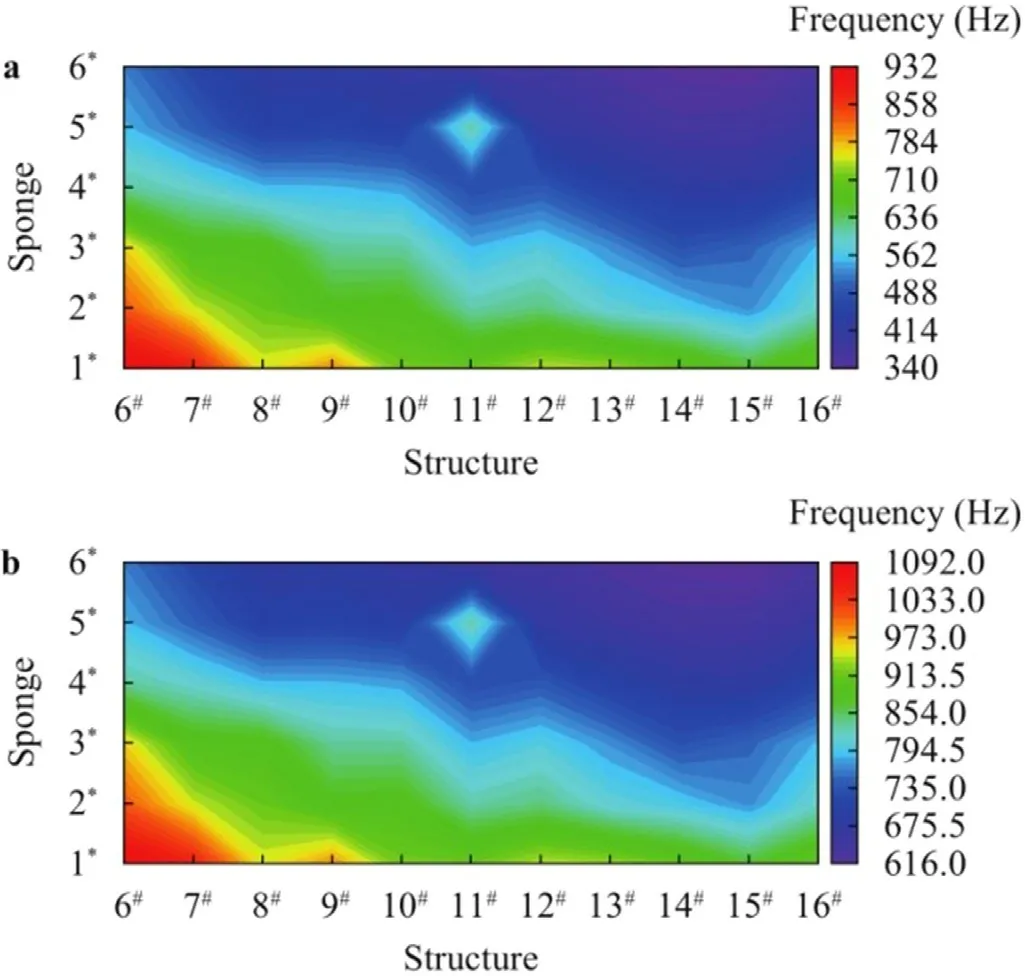

Low frequency noise reduction is the key point in engineering.Therefore,in order to reveal the effect of the relative position of two different absorbers (porous material and multi-layer microperforated plate) on the low-frequency sound absorption,we con-ducted 132 groups of tests in the acoustic impedance tube,and the frequency position of the first absorption peak is shown in Fig.4.When different multi-layer micro-perforated plates are placed in front of the polyurethane sponge,its frequencies of first sound absorption peak are given in Fig.4a.It is evident that the first absorption peak moves towards lower frequencies (down to 340 Hz)when the polyurethane sponge is thicker and the micro-perforated panel has more layers.The composite absorber is only 63 mm thick,providing subwavelength absorption of 1/16.It is also found that the thickness of the polyurethane sponge has a greater influence on the first absorption peak frequency than increasing or decreasing the number of layers in the structure.In the other combination,the first absorption peak in polyurethane sponge before the multi-layer micro-perforated plate is shown in Fig.4b.The main influencing factor is still the polyurethane sponge.The first absorption peak is at a lower frequency when the structure contains fewer layers.Therefore,the sound absorption rule of the superposition of polyurethane sponge and multi-layer micro-perforated plate was obtained through 132 experimental data of different combinations,which provided guidance for the further design of sound absorption structure on demand.

Fig.4. Frequencies of the first absorption peak for different combinations of composite absorbers.a Multi-layer micro-perforatedplates are placed in front of the polyurethane sponge.b Multi-layer micro-perforatedplates are placed behind the polyurethane sponge.

We have sound absorption in a porous composite material formed from a polyurethane sponge and a micro-perforated panel.The structure of the multi-layer micro-perforated plate has three resonance absorption peaks below 6.4 kHz,while absorption in the polyurethane sponge increases as its thickness increases.If the polyurethane sponge is placed in front of the multi-layer microperforated plate,there will be an absorption peak at low frequency,and resonance in the multi-layer micro-perforated plate will react on the sponge.When the polyurethane sponge is placed on the multi-layer micro perforated plate,the original three resonance absorption peaks will move to lower frequencies.Meanwhile,the effect of the polyurethane sponge is equivalent to increasing the effect similar to the back cavity.The effects of the number of micro-perforated plate layers and the thickness of polyurethane sponge on the first absorption peak was determined from 132 experiments.Different physical mechanisms reveal the effects of different combinations on sound absorption characteristics.Compared with the traditional structure with single absorption mechanism,this study combines the two typical structures of sound absorption mechanism to broaden the design of composite absorbers and has potential applications in architectural acoustics.Future work will continue to discuss the material properties of porous polyurethane and the role of resonant rigid absorbers in increasing acoustic absorption at low frequencies.

DeclarationofCompetingInterest

We declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

Acknowledgments

This work was supported by Aeronautical Science Foundation of China (Grant 20181553015),Foundation of Shaanxi Educational Committee (Grant 2018BSHYDZZ03),the National Natural Science Foundation of China (Grant 11704314) and China Postdoctoral Science Foundation (Grant 2018M631194).

杂志排行

Theoretical & Applied Mechanics Letters的其它文章

- Physics-informed deep learning for digital materials

- A study of inner-outer interactions in turbulent channel flows by interactive POD

- A study on equivalence of nonlinear energy dissipation between first-order computational homogenization (FOCH) and re duce d-order homogenization (ROH) methods

- Stable heat jet approach for temperature control of Fermi-Pasta-Ulam beta chain

- Rotational dynamics of bottom-heavy rods in turbulence from experiments and numerical simulations

- Wall-resolved large-eddy simulation of turbulent channel flows with rough walls