Response of carbon footprint to plastic film mulch application in spring maize production and mitigation strategy

2021-06-02CHENBaoqingShaharBARAMDONGWenyiHEWenqingLIUEnkeYANChangrong

CHEN Bao-qing,Shahar BARAM,DONG Wen-yi,HE Wen-qing,LIU En-ke,YAN Chang-rong

1 Institute of Environment and Sustainable Development in Agriculture,Chinese Academy of Agricultural Sciences,Beijing 100081,P.R.China

2 Institute for Soil,Water and Environmental Sciences,Agricultural Research Organization (ARO),Volcani Research Center,Bet Dagan 50250,Israel

Abstract Producing more food with a lower environmental cost is one of the most crucial challenges worldwide.Plastic mulching has developed as one of the most dominant practices to improve crop yields,however its impacts on greenhouse gas (GHG)emissions during the production life cycle of a crop are still unclear.The objective of this work is to quantify the impacts of plastic film on GHG emissions and to reduce GHG emissions with innovative agronomic practices.Carbon footprint per unit of area (CFa),per unit of maize grain yield (CFy),and per unit of economic output (CFe) were evaluated for three maize cultivation systems:a no mulch system,a conventional plastic mulching system (PM) and a biennial plastic mulching pattern,namely a ‘one film for 2 years’ system (PM2),during 2015–2018 in a maize field located on the Loess Plateau of China.The results suggested that PM induced a 24% improvement in maize yields during the four experimental years compared to a no-mulch treatment (NM).However,PM dramatically increased the CFa by 69%,59% of which was created by the input of the plastic film material,and 10% was created by increases in the soil N2O emissions.The yield improvements from PM could not offset the increases in CFa,and CFy and CFe were both increased by 36%.Shifting from PM to PM2 did not reduce crop yields,but it led to a 21% reduction in CFa and 23% reductions in CFy and CFe due to the reduced input amount of plastic film,decreased soil N2O emissions,and less diesel oil used for tillage.Compared to NM,CFy and CFe were only 5% higher in PM2.This study highlights the necessity of reducing the amount of plastic film input in the development of low-carbon agriculture and shifting from conventional PM cultivation to PM2 could be an efficient option for mitigating GHG emissions while sustaining high crop yields in plastic mulched fields.

Keywords:carbon footprint,greenhouse gas,plastic film,maize

1.lntroduction

Food systems are responsible for 20–30% of total anthropogenic greenhouse gas (GHG) emissions (Hertwich and Peters 2009;Vermeulenet al.2012),and reducing GHG emissions from farmland is a critical component of climate change mitigation (Tilmanet al.2011;Lipperet al.2014).High yields from farmland are greatly reliant on input materials and energy (e.g.,fertilizer,power,and fuel);however,the production,transport,and application of agricultural inputs are usually accompanied by GHG emissions.It is estimated that the crop demand will double by 2050 (Tilmanet al.2011),and to meet the goal of insuring future food security and alleviating climate change,it is necessary to adapt agriculture technologies to achieve high crop yields with reduced GHG emissions (Chenet al.2014).

Plastic film is an agricultural input that is widely used worldwide.The history of plastic mulching technology dates back to the mid-1950s,when Dr.Emery M.Emmert of the University of Kentucky,USA first used polyethylene (PE)as a greenhouse film and detailed the principles of plastic technology (Emmert 1957;Kasirajan and Ngouajio 2012).Since then,plastic mulching practices have been adopted in many countries because of their ability to improve soil temperature,enable earlier harvests,inhibit weed growth,and conserve water (Tarara 2000;Scarascia-Mugnozzaet al.2011;Kasirajan and Ngouajio 2012).In China,the largest consumer of plastic film in the world,the area of farmland using plastic mulching has increased more than 150-fold since 1982,and in 2016,this area reached 1.8×107ha,which is equal to about 14% of the total farmland in China(NBSC 2017).The application of plastic film dramatically improved crop yields in China,and according to a review(Liuet al.2014),when plastic mulching was adopted,grain and cash crop yields increased by 20–35 and 20–60%,respectively.As such,the application of plastic film makes great contributions to improving food supplies.

During the development of plastic mulching technologies,many different types of plastic mulching patterns have been tested.Among them,the plastic mulching pattern called ‘one film for 2 years’ under no-tillage conditions(PM2) was created to reduce the negative environmental effects of plastic film application (Yanet al.2014;Chenet al.2018b;Xieet al.2018).The negative environmental effects of plastic film application are caused by two aspects:(i)plastic residue pollution and (ii) increased GHG emissions.PE is the most commonly used material for manufacturing plastic film,and it requires long periods (200–400 years) to degrade in the soil.Once PE is incorporated into the soil,its accumulation can significantly retard crop root growth and the soil’s ability to transport water and nutrients,which lead to significant yield decreases (Liuet al.2014;Gaoet al.2018).Manufacturing plastic film is a process that requires high energy consumption,and it is estimated that the input of 1 kg of plastic film in agriculture will cause 22.72 kg of CO2-eq emissions (Wanget al.2017;Xueet al.2018),which is even higher than the emission factor of N fertilizer (Chenet al.2014;Qiet al.2018).Therefore,the use of plastic film as an agricultural input has the potential to dramatically improve GHG emissions during a crop’s production life cycle.The designed PM2 system employs a no-tillage practice to prevent incorporating plastic residue into the soil and prolongs the life of the plastic film from 1 year to 2 years in order to reduce the potential GHG emissions caused by plastic film inputs.However,it is still largely unknown how GHG emissions during a crop’s production life cycle respond to different plastic mulching patterns and whether PM2 is effective in reducing GHG emissions.

The carbon footprint (CF),defined as the total amount of carbon emissions caused directly and indirectly by an activity,or the emissions that accumulate over the life cycle of a product from cradle to grave (Wiedmann and Minx 2007),has become an important method to systematically evaluate the carbon emissions caused by artificial factors in the agricultural production process.CF evaluation for crop products provides a reliable way to recognize the key sources of GHG emissions in different cultivation systems and to quantify the influences of agricultural practices and other environmental factors (Chenet al.2014;Ganet al.2014).As such,it provides the theoretical basis for optimizing agricultural management practices to reduce GHG emissions and develop low-carbon agriculture.In this study,maize (Zea maysL.)was chosen as the test crop because it is one of the three largest food staples cultivated worldwide (FAO 2018).Previous research has investigated the CF response in maize production in terms of fertilizer management practices (Grassini and Cassman2012;Maet al.2012;Haet al.2015;Wanget al.2015;Qiet al.2018;Jatet al.2019),irrigation practices (Grassini and Cassman 2012;Zhanget al.2018),tillage practices (Zhanget al.2013;Zhanget al.2016),diversified crop rotation systems (Maet al.2012;Yanget al.2014),and the spatial variation of CF on regional and national scales (Chenget al.2015;Xu and Lan 2017;Zhanget al.2017).Among previous studies that focused on the responses of carbon footprint to plastic mulching,Heet al.(2018) investigated the influences of plastic mulch technology on the carbon footprint on the national scale,and Xueet al.(2018) reported the response of the carbon footprint to different plastic mulching patterns in different winter wheat production systems.However,little has been reported on the influences of different plastic mulching patterns on the CF of maize production.

The objective of this study is to evaluate the CF response to different plastic mulching patterns in a maize field to fill the knowledge gaps in developing low-carbon crop production in fields with plastic mulching.To achieve this objective,it was hypothesized that:(i) the application of plastic mulching can lead to significant improvements in field GHG emissions,and (ii) shifting from a conventional plastic mulching pattern(PM) to PM2 is an effective way to achieve the goals of improving crop yields while mitigating GHG emissions.To test these hypotheses,the CF was evaluated based on four years of field experiments for three cultivation systems:(i)a no-mulch system (NM);(ii) a PM system with annual film replacement;and (iii) the PM2 system.

2.Materials and methods

2.1.Site description

The field experiment was carried out in the Shouyang Rainfed Agricultural Experimental Station (37°45´N,113°12´E,1 080 m altitude) in the Shanxi Province of northern China from 2015 to 2018.The research area is characterized by a temperate semiarid continental monsoon climate with four distinct seasons,and the average annual air temperature,rainfall amount,and frost-free period are 7.4°C,480 mm,and 140 days for the past 48 years (1967–2014) according to statistics from the local meteorological bureau.During the experimental year 2015–2018,rainfall data acquired from experiment observations were 386,461,482 and 362 mm,respectively.The soil texture is sandy loam,and the soil is classified as a Calcaric Cambisol,according to the world reference base for soil resources (FAO 2006).Prior to the beginning of the experiment,the upper 20 cm of the soil had a pH of 7.8,a soil organic matter content of 18.03 g kg–1,and a total N of 0.85 g kg–1.Spring maize (Zea maysL.) is the main crop cultivated in the research area;it is usually sown in late April or early May and harvested in late September or early October.After harvest,there is a fallow period until sowing the following year.

2.2.Experimental design and management

Three treatments were tested at the research site for this study:(i) the NM system,in which the maize was cultivated without the application of plastic film;(ii) the PM pattern;and(iii) the new plastic mulching pattern,PM2 (‘one film for 2 years’ under no-tillage conditions),which was designed to reduce residual pollution from plastic and the CF of the plastic mulching field.During the four experimental years,there were two cycles for PM2 (i.e.,the first cycle in 2015–2016 and the second cycle in 2017–2018).The experiment employed a completely randomized design with three replicates,and each plot area measured 60 m2(6 m×10 m).

In NM,rotary tillage was carried out to a depth of 30 cm,and in accordance with local practice,fertilizers were applied at rates of 225 kg N ha–1(urea),162 kg P2O5ha–1(calcium superphosphate),and 45 kg K2O ha–1(potassium chloride)before sowing.Spring maize was sown at a row distance of 60 cm and plant spacing of 30 cm (i.e.,a sowing density of 55 556 plants ha–1).The maize cultivar Qiangsheng 51 was sown in early May for the four experimental years.After seedling emergence,seedling thinning was carried out manually,and herbicide was used to control weeds.The maize was harvested in early October,and maize grain drying and threshing were completed manually.All of the maize stubble was removed from the field manually for subsequent use as animal fodder.

In PM,PE plastic film with a width of 80 cm and a thickness of 10 μm was used.Between two strips covered by the plastic film,there was a bare strip with a width of 40 cm,which led to soil coverage of about 67%.The same tillage and fertilization methods used in NM were adopted for PM,and after fertilization,the maize was sown directly into the film using a hole-sowing tool,with same row distance and plant spacing as NM (60 and 30 cm,respectively).After harvest,following local practices,the film was not recycled but was incorporated into the soil during tillage,forming so-called“white pollution”(Liuet al.2014).

In PM2,a type of PE-based plastic film with antiageing additives (a mixture of hindered amine light stabilizer,an antioxidant,and ultraviolet-absorbent materials,about 3% of total weight of plastic film) was used,and the production of this kind of plastic film did not need a change in the manufacturing processes.Tillage was carried out in the first year to form a relatively smooth soil surface and reduce potential damage to the film during the film-laying process.In the subsequent three years,a no-tillage practice was adopted to prevent the potential incorporation of plastic residue into the soil.For the first growing season with PM2,the same sowing,fertilization,and tillage methods used in NM and PM were applied.In the second growing season,to prevent further film destruction,the maize was sown into bare soil near the edge of the film,and fertilizer was only applied in the middle of the bare strip.The film in PM2 was used continuously for two years,and it was removed manually and replaced with a new film prior to the sowing of the third growing season.The fertilization amount,seedling thinning,weed control,plant residue management,sowing,and harvest times were same in the NM,PM,and PM2.

2.3.Field measurements

Maize yieldThe central four rows in each plot were selected to measure maize yield at harvest in 2015–2018.For each row,the center 5 m was hand-harvested,the fresh weight and water content of the grains were measured,and then the grain yield per plot was calculated on a“wet-mass basis”(standard water content of 15.5%) (Payeroet al.2008).

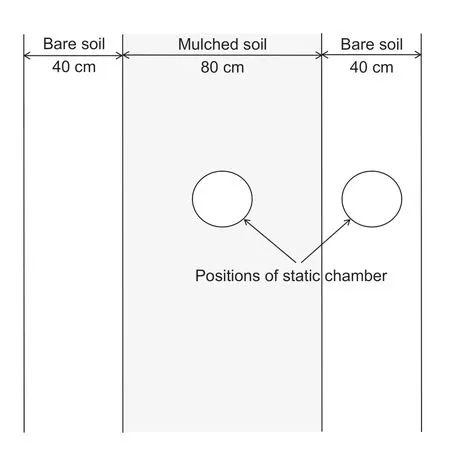

Measurement of N2O emissionsThe static closed chamber method was applied to measure the N2O emissions in different treatments (Hutchinson and Mosier 1981).The static chamber comprised an anchor with a hollow ring attached to its brim,and a chamber with an inner diameter of 24 cm and a height of 25 cm.During measurement,the hollow ring on the brim was filled with water to seal the chamber while the gas was sampled.A fan mounted inside the chamber was used to mix the head-space air,and a temperature recorder mounted inside the chamber was used to record the air temperature.In NM,the anchors were installed in the middle of the maize rows,and in PM and PM2,they were installed in the middle of the bare strip and mulched strip to account for the potential permeation of N2O through the mulch films (Fig.1;Nishimuraet al.2012,2014;Bergeret al.2013).Gases were collected between 9:00 and 11:00 a.m.weekly during the growing seasons of 2015–2018,and a sampling syringe with a volume of 50 mL was used for gas sampling at 0,20,and 40 min after chamber closure.N2O concentrations in the gas samples were analyzed with a gas chromatograph equipped with an electron capture detector and a Poropak Q column (Agilent 7890A;Agilent Technologies,Inc.,Santa Clara,USA).The N2O emission rates were calculated from the linear increase in N2O concentrations per unit of surface area of the chamber for a specific time interval,and the cumulative N2O emissions were estimated using linear interpolation,as reported by Cuelloet al.(2015).

Fig.1 Scheme of positions for gas sampling with static chamber methods in a plastic mulched field.

2.4.Calculation of CF

In this study,the system boundary for CF calculation was defined as the entire production life cycle,from raw material exploitation and the production and transportation of agricultural inputs (e.g.,plastic film,fertilizer,diesel,and pesticides) to the farm gates (maize harvest).In accordance with previous research on CF evaluation for maize fields (Qiet al.2018;Samarappuli and Berti 2018),three factors for the sources of GHG emissions were included in this study:(i) the manufacture,storage,and transportation of the agricultural inputs,including the plastic film,fertilizers,pesticides,and seeds to the farm gates as well as their application;(ii) the energy consumption of machinery operations,including tillage,sowing,and harvest;and (iii) field N2O emissions resulting from N fertilizer application.Soil CO2flux was not taken into account because the net flux was much less than gross CO2emissions that could be measured,and net fluxes usually contributed less than 1% to the global warming potential of agriculture on a global scale (Chenet al.2014).CH4emission may be negligible because of its small percentage in GHG emissions in drylands (Guo and Zhou 2007;Ceschiaet al.2010;Xueet al.2018;Huanget al.2019),and human labor was not taken into account because humans respired CO2regardless of whether or not they were working (West and Marland 2002).Such a CF evaluation method was in accordance with most previous research that involved short-term field studies (Liuet al.2016;Wanget al.2017;Qiet al2018;Samarappuli and Berti 2018;Xueet al.2018).The indirect total amount of GHG emissions associated with the agricultural inputs (CFinputs),the CF per unit of area (CFa),per unit of maize grain yield (CFy),and per unit of economic output (CFe) expressed in equal amounts of CO2(CO2-eq) were calculated as:

where the Qusediis the used amount for theith type of individual agricultural input (kg yr–1);δiis the emissions factor for theith type of individual agricultural input (kg CO2-eq kg–1);CFN2Ois the CF associated with soil N2O emissions(kg CO2-eq yr–1),N2Ocumuis the cumulative N2O emissions(kg NO2-N ha–1yr–1),and the global warming potential of N2O relative to CO2over 100 years was assumed to be 265 (IPCC 2014);yield is the measured maize grain yield(kg yr–1);and TE is the total economic output of the crop(CNY ha–1).Average maize grain prices from 2015 to 2018 were used for the calculation of TE,and it was 1.71 CNY kg–1(NDRC 2019).

In this study,tillage was completed with a small walking tractor,and sowing and harvest were completed manually;however,to stay in accordance with actual production,we used the surveyed oil consumption data in actual production near the experimental site for the CF calculation,and the inputted amount of diesel was converted from L ha–1to kg ha–1with a density value of 0.86 kg L–1(Samarappuli and Berti 2018).The amounts of plastic film used in PM and PM2 (Qfilm,kg ha–1) were calculated as in Chenet al.(2018b):

where Fmulchstands for the ratio of area covered by plastic film (67% in PM and PM2),Thickfilmandρfilmare the thickness and density of the plastic film (0.01 mm and 930 kg m–3,respectively).Therefore,the input amount of the plastic film was calculated as 63.0 kg ha–1in the PM and PM2 treatments.As the additives used in the plastic film of PM2 only took up a small proportion of total weight of the plastic film,the same calculation methods were adopted for PM and PM2.

The emissions factors for different inputted materials were obtained from IKE eBalance V3.0 (IKE Environmental Technology Co.,Ltd.,China;Wanget al.2017;Qiet al.2018),and the emissions factors for the seeds,urea,calcium superphosphate,potassium chloride,diesel oil,herbicide,and plastic film were 0.58,2.30,0.30,0.13,0.89,10.15,and 22.72 kg CO2-eq kg–1,respectively.The total economic output of the crop was calculated as the maize grain yield multiplied by its price (Yanget al.2014;Huanget al.2019).

2.5.Statistical analysis

The effects of PM and PM2 on crop yields and N2O emissions were analyzed with one-way analysis of variance(ANOVA) using SAS ver.8.0 Software (SAS Institute,Cary,NC,USA),and least significant differences (LSD) were used to detect the mean differences between the treatments.

3.Results and discussion

3.1.The response of maize yield to different plastic mulching patterns

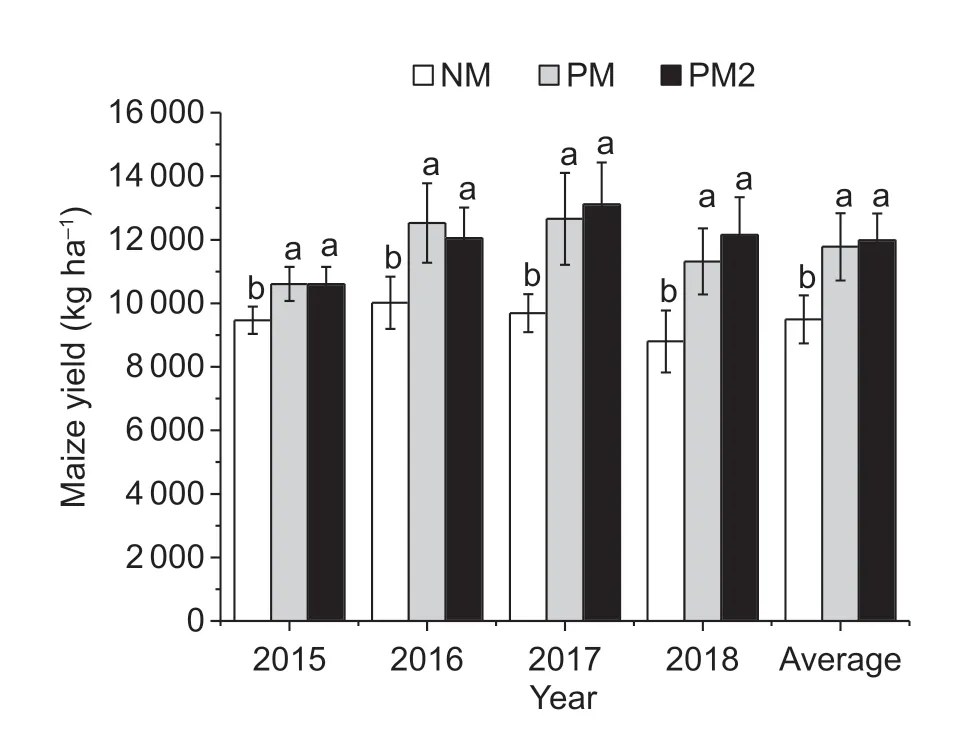

As shown in Fig.2,compared to NM,maize yields were significantly improved by 12,25,31,and 29% in PM(P<0.05),and significantly improved by 12,20,35,and 38% in PM2 for 2015,2016,2017,and 2018 (P<0.05),respectively.PM and PM2 significantly increased the four-year average yield by 24 and 26%,respectively,and no significant difference in maize yields was found for PM and PM2.

Fig.2 Maize yield in the no mulch (NM),conventional plastic mulching (PM) and ‘one film for 2 years’ plastic mulching (PM2)cultivation systems.Error bars show the standard errors (n=3).Different letters in each column indicate significant differences(P<0.05) between treatments for each experimental year and average value of the four experimental years according to LSD tests.

These results were in accordance with previous research which suggested that plastic mulching was an effective practice for improving crop yields due to its improvements of soil temperature and moisture conditions (Zhanget al.2011;Liet al.2013;Gaoet al.2018).Zhanget al.(2011) reported that maize yields were improved by 8–24% under different plastic mulching systems.Liet al.(2013) suggested that maize yields with plastic mulching were increased by 13.0%.The meta-analysis from Gaoet al.(2018) using 266 peerreviewed publications in China showed that plastic mulching increased crop yields by about 24%.The increased yields resulted mainly from reduced evaporation under the plastic film which reduced the ratio of evaporation to transpiration,leaving more water available for plant uptake (Liet al.2008;Dinget al.2013).Furthermore,the application of plastic film has been reported to improve soil temperature conditions by preventing the loss of emitted radiant energy in the long-wave spectrum,establishing an insulating air gap,and reducing latent heat loss caused by evaporation(Hamet al.1993;Hamand Kluitenberg 1994).As such,it can reduce water and temperature stress for crop growth and contribute to yield improvements.

Shifting from PM to PM2 did not result in any significant crop decline.This can be attributed to the prolonged lifetime of the plastic film.The lifetime of the plastic film is greatly influenced by the oxidation process,which occurs through photo-,thermal-,or γ-initiated oxidation (Basfar and Ali 2006);however,plastic film stability can be improved by several to a dozen times with the application of a hindered amine light stabilizer,an antioxidant,and ultravioletabsorbent materials (Basfar and Ali 2006;Al-Salem 2009).In our previous study,only slight damage was observed on the plastic film in the second year of PM2,but it did not result in significant influences on the soil moisture and temperature conditions compared to PM (Chenet al.2018b).These results are in accordance with the reports of Xuet al.(2013)and Xieet al.(2018).In Xieet al.(2018),it was found that PM2 can significantly improve maize yields compared to NM treatments,and in Xuet al.(2013),it was suggested that PM2 has similar improvement effects on maize yields compared to other plastic mulching patterns.

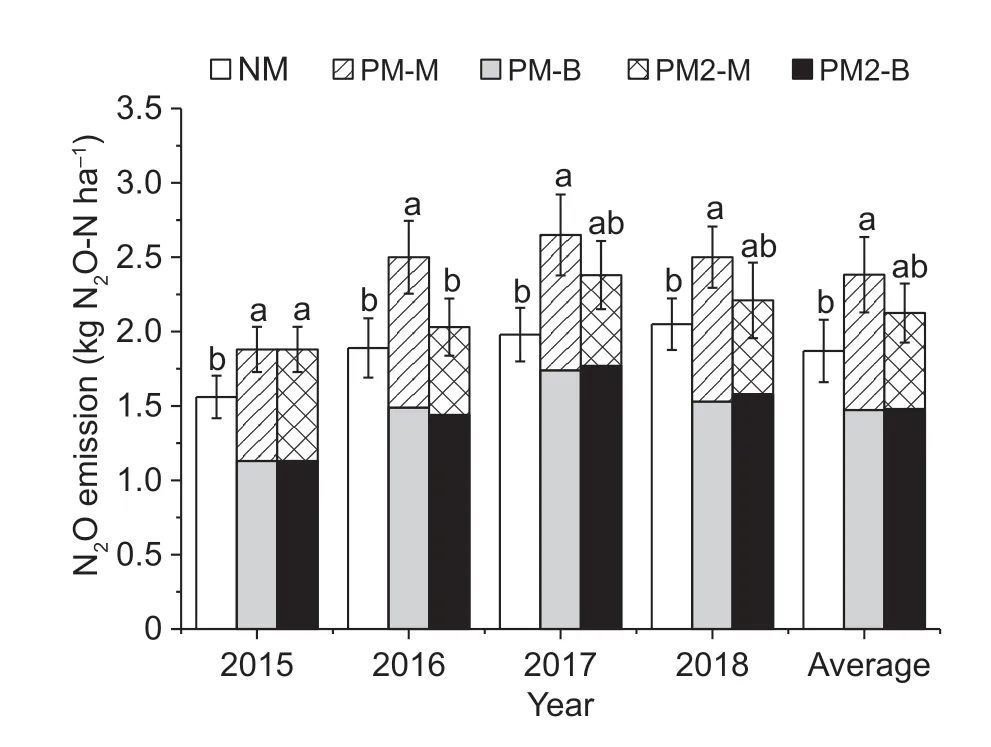

3.2.Response of N2O emissions to different plastic mulching patterns

In this study,the measured yearly N2O emissions ranged from 1.56–2.65 kg N2O-N ha–1,which equaled 0.69 to 1.18%of the applied nitrogen fertilizer (Fig.3).These values are comparable to the report from IPCC (2013),which suggests that direct N2O emissions from agriculture are estimated to be equal to 1% of the applied nitrogen,with an uncertainty range of 0.3–3.0%.

Fig.3 N2O emission in no mulch (NM),conventional plastic mulching (PM) and ‘one film for 2 years’ plastic mulching (PM2)cultivation systems.N2O emission in PM and PM2 is comprised of emissions from the bare strip (B) and the mulched strip (M),and total N2O emission is the sum of B and M.Error bars show the standard errors (n=3) and different letters over error bars indicate the significant differences between treatments at P<0.05.

Compared to NM,PM induced significantly higher N2O emissions over the four experimental years.In the PM treatment,the N2O emissions from the mulched strip accounted for 34–40% of the total N2O emissions,and 60–66% of the N2O emissions were produced from the bare strip.This is in accordance with previous reports suggesting that N2O can permeate the mulch film and that it plays an important role in N2O emissions in plastic mulched fields (Nishimuraet al.2012,2014;Bergeret al.2013).In Nishimuraet al.(2014),the contribution of N2O emissions from the permeation of the mulch film was found to range from 33 to 53% of the total emissions in plastic mulched fields.The increase in N2O emissions with plastic mulching may be attributed to a higher availability of mineral N,reduced soil aeration,and improved soil temperature and moisture conditions (Nishimuraet al.2012;Cuelloet al.2015;Zhanget al.2018).Nitrification and denitrification are two biochemical processes responsible for N2O emissions.These processes are largely influenced by the availability of mineral N (Das and Adhya 2014;Pajares and Bohannan 2016) and are highly sensitive to soil aeration (Barnardet al.2005;Gillamet al.2008).The application of plastic mulching has been shown to improve the mineral N availability in soil due to improved soil temperature and moisture (Zhanget al.2012;Tianet al.2013).These enhanced conditions,along with a reduction in the gas exchange between the soil and the air,lead to a higher N2O emission rate.As such,in most studies,it has been confirmed that the application of plastic mulching could increase N2O emissions (Nishimuraet al.2012;Cuelloet al.2015;Nanet al.2016;Zhanget al.2018).However,the responses of soil N2O emission to plastic mulching are also highly dependent on the soil and climate conditions.In two consecutive wheat–maize rotation cycles,Chenet al.(2017) observed annual N2O emission decreased in the field with plastic mulching compared to no mulch field in one cycle,while it increased in another cycle.Bergeret al.(2013) observed plastic mulching decreased N2O emission in sandy soils because in sandy soil it is usually difficult to maintain soil moisture.

Compared to PM,N2O emissions were found to be significantly lower in PM2 in 2016 and also slightly lower in the other experimental years.Previous research suggests that the effects of plastic mulching on soil moisture and temperature generally declined from the middle of the mulched strip to the center of the bare strip (Chenet al.2018a,2019).Accordingly,in PM2,when fertilizer was only applied to the bare strip,it effectively avoided the effects of higher moisture and temperature on the N2O emissions caused by plastic mulching.

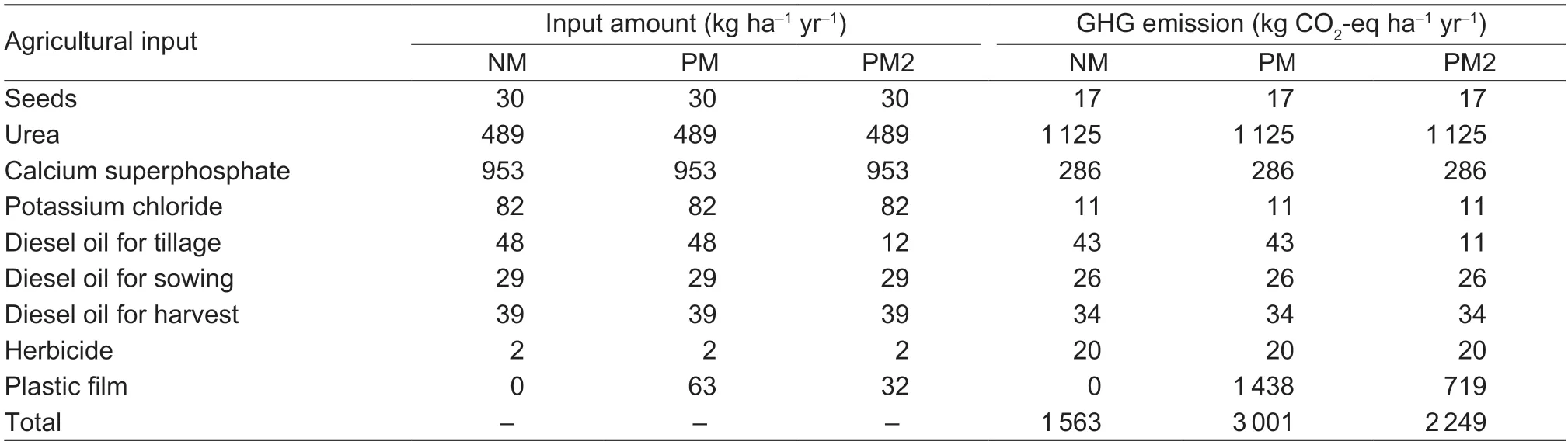

3.3.GHG emissions associated with agricultural inputs

In the NM,PM,and PM2 systems,GHG emissions associated with agricultural inputs (CFinputs) were 1 563,3 001,and 2 249 kg CO2-eq ha–1yr–1,respectively (Table 1).The range of CFinputsin the current study was lower than that of Qiet al.(2018),in which maize was cultivated with irrigation and a larger fertilizer load,while it was similar to that of Shiet al.(2011),in which maize was cultivated with medium amounts of fertilizer.The differences in CFinputsin different studies can be explained by the requirements for input materials under different management practices.

In NM,urea accounted for 72% of CFinputsand was the largest contributor to CFinputs,which is in accordance with previous research carried out in NM maize fields (Chenet al.2014;Qiet al.2018).In PM,most CFinputscame from the inputs of plastic film and urea,which were 48 and 37%of GHG emissions associated with agricultural inputs,respectively.The calculated GHG emissions associatedwith the input of plastic film (1 438 kg CO2-eq ha–1yr–1) were similar to the values reported in a wheat field (1 022–2 726 kg CO2-eq ha–1yr–1;Xueet al.2018).In PM2,the inputs of plastic film and urea contributed 32 and 50% of the CFinputs.Across treatments,diesel oil contributed 3–6% of the CFinputs(accounting for tillage,sowing and harvest processes),with the lowest contribution in the PM2 treatment where tillage was carried out only in the first year,and no-tillage practice was employed for the other three years.Compared to NM,CFinputswas increased by 92 and 44% in PM and PM2,respectively (Table 1),as a result of the input of plastic film.Compared to PM,CFinputswas reduced by 21% because of the lower input amount of plastic film and the reduction in diesel oil for tillage.

Table 1 Greenhouse gas (GHG) emissions caused by the input of materials in no mulch (NM),conventional plastic mulching (PM)and ‘one film for 2 years’ plastic mulching (PM2) cultivation systems

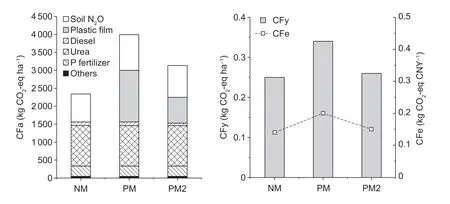

3.4.Carbon footprint

During the experimental years,CFa was 2 341,3 993 and 3 134 kg CO2-eq ha–1yr–1,CFy was 0.25,0.34 and 0.26 kg CO2-eq kg–1,and CFe was 0.14,0.20 and 0.15 kg CO2-eq CNY–1for NM,PM,and PM2,respectively (Fig.4).The urea input and soil N2O emissions were the two most important sources of CF in the NM system,and contributed 48 and 33% of the CFa,respectively.In the PM system,the most important source of GHG emissions was the input of plastic film (36% of the total GHG emissions),followed by the input of urea (28%) and soil N2O emissions (25%).In the PM2 system,the inputs of urea,plastic film,and soil N2O emissions accounted for 36,23,and 28% of CFa,respectively.Compared to NM,CFa was 70% higher in PM,of which 61% was contributed by the input of plastic film,and 9% was contributed by higher soil N2O emissions.Although crop yield was improved by PM,it failed to offset the huge increases in CFa,and this led to a 37% higher CFy.Shifting from PM to PM2 reduced the CFa by 22%as a result of the reduction in the inputs of plastic film,N2O emissions,and diesel for tillage.These reductions led to the PM2 system having a CFy value that is only 6% higher than that of the NM.

As maize is a commonly cultivated crop worldwide,the CF for its production has been investigated widely.In a project comparing the CF under different cultivation systems in 153 site-year field experiments in China,it was suggested that the CFa for maize ranged from 2 273–8 269 kg CO2-eq ha−1,and the CFy ranged from 0.287–1.179 kg CO2-eq kg–1(Chenet al.2014).In an irrigated maize field located in central Nebraska,Grassini and Cassman (2012)reported CFy as 0.23 kg CO2-eq kg–1.In a rain-fed maize field located in Ottawa,Canada,Maet al.(2012) reported that the CFa ranged from 243 to 5 284 kg CO2-eq ha–1in different fertilization and crop rotation systems.Using farm survey data from eastern China,Yanet al.(2015)estimated the CFa and CFy in this region were (2.3±0.1) t CO2-eq ha−1and (0.33±0.02) kg CO2-eq kg−1,respectively.Although large variations in CF have been found among these different cases due to variations in environmental conditions and cultivation methods,most of those cases suggest that N fertilizer is the greatest source of CF in fields with plastic mulching.This was confirmed by the NM treatment of this study.However,our study suggests that when plastic film is applied in maize production,the total CF is dramatically improved,and the largest source of total GHG emissions shifts from the input of N fertilizer to the input of plastic film.Considering the demand for food driven by a growing population (Tilmanet al.2011),it is difficult to stop the use of plastic film,especially in regions where crop production is limited by water or temperature stress.As such,this study suggested that shifting from PM to PM2 is a promising means to improve maize yield while reducing the carbon footprint in the maize production system with plastic mulching.

Fig.4 Carbon footprint per unit of area (CFa),carbon footprint per unit of maize grain yield (CFy) and carbon footprint per unit of economic output (CFe) in no mulch (NM),conventional plastic mulching (PM) and ‘one film for 2 years’ plastic mulching (PM2)cultivation systems.Greenhouse gas emission caused by soil N2O emission,inputs of plastic film,diesel,urea,phosphate fertilizer and other materials (seeds,herbicides and potassium chloride) were taken into account for the calculation of carbon footprint.Data presented are the averages of the experimental years 2015–2018.

In addition,it should be noted that the CF was estimated based on a four-year field experiment in this study,and the soil carbon sequestration was not considered in the CF evaluation because the experimental period was relatively short.However,the no-tillage practice which was employed in PM2 has been widely recognized as a kind of agricultural practice to improve the soil carbon sequestration in longterm usage (Bakeret al.2007;Luet al2009),and long-term application of PM2 might result in a lower carbon footprint.Moreover,accumulation of plastic residue in PM had been proven to lower the crop yield in long-term application (Gaoet al.2018;Zhanget al.2020),which might further improve the CFy and CFe in PM.For verification,further long-term observations need to be carried out in the future.

4.Conclusion

Although the application of plastic film in conventional patterns can improve crop yields,it leads to dramatic increases in CFa and CFyas a result of indirect greenhouse emissions caused by the input of plastic film materials and higher soil N2O emissions.Shifting from a conventional plastic mulching pattern to a PM2 cultivation system did not lead to any decline in yield,but it effectively reduced the CFy to a level similar to that in the NM cultivation system.It was concluded that reducing indirect GHG emissions caused by the input of plastic film materials is extremely important to control the CF of plastic mulched fields,and PM2 is an efficient option for achieving the goals of mitigating GHG emissions and improving crop yields at the same time.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (31901477,31871575 and 3191101554)and the Central Public Interest Scientific Institution Basal Research Fund,Institute of Environment and Sustainable Development in Agriculture,Chinese Academy of Agricultural Sciences (BSRF201909).

Declaration of competing interest

The authors declare that they have no conflict of interest.

杂志排行

Journal of Integrative Agriculture的其它文章

- Monilinia fructicola on loquat:An old pathogen invading a new host

- Mechanization and efficiency in rice production in China

- Farmers’ risk preference and fertilizer use

- Simple method for extracting the seasonal signals of photochemical reflectance index and normalized difference vegetation indexmeasured using a spectral reflectance sensor

- Winter wheat yield estimation based on assimilated Sentinel-2 images with the CERES-Wheat model

- Monthly composites from Sentinel-1 and Sentinel-2 images for regional major crop mapping with Google Earth Engine