Research of Ultrafine Cemented Carbides for PCB Microdrills

2021-04-16ZHANGWeifengLIChunxia

ZHANG Weifeng, LI Chunxia

(Department of Electronic and Communication Technology, Shenzhen Institute of Information Technology, Shenzhen 518172, China)

Abstract: The nanocrystalline WC-10Co composite powders were produced with the processing method of spray thermal decomposition-continuous reduction & carburization. The grain growth inhibitors of 0.4wt%Cr3C2 and 0.4wt% VC were added into the composite powders to obtain advanced ultrafine hardmetals with minimal porosity, defects and discontinuous. The rod samples were formed by extrusion.They were sintered in cacuum with SIP treatment. The sintered rods were made into PCB microdrill samples after polishing.Mechanical properties(such as density, hardness, transverse rupture strenth(TRS), magnetic saturation induction and magnetic coercivity) of the sintered ultrafine cemented carbides were measured. The microstructures of them were investigated by scanning electron microscopy(SEM) and transmission electron microscopy(TEM).The experimental results show that the transverse rupture strength of the samples sintered in vacuum with sinterhip(SIP) treatment is more excellent. The grain size could be controlled in a range of 200-400 nm with the help of grain growth inhibitors. And the superfine grained materials have superior strength(3900 MPa) and high hardness(HRA = 93.3). These features are ideal for PCB microdrills.

Key words: nanocrystalline; WC-10Co; cemented carbide; nanocomposite; PCB microdrills

1 Introduction

Nowadays, there is a increasing demand for the finer grained materials to meet the different applications[1-7]: microdrills for printed circuit boards (PCBs),wear-resistant parts and coatings, wood cutting tools,pins for dot-printers, rock drills and bearings or seals exposed to polluted water. For PCB microdrills, the hardmetals with improved properties, particularly high toughness, strength and ductility coupled with high hardness and wear resistence are needed at present time,which has promoted the development of finer and finer grained powders and cemented carbides. With a reduced grain size to a submicron meter or nanometer range, these materials can meet the growing demands of the industry. Thus more and more researchers have paid their interests in the WC-based nanocrystalline materials[8-11]. New research shows that the hardness,strength and toughness of WC-Co cemented carbides improve greatly when the WC grain size is reduced to below 500 nm[12]. But meanwhile, the ultrafine WC grains grows rapidly during heating even though the liquid phase is not formed. So VC or Cr3C2are added to inhibit the grain growth[13,14]. Various sintering technologies are adopted to diminish the effect of grain growth and to achieve an efficient WC-Co material densification[15,16].

In this paper, the nanocomposite powders prepared by the spray thermal decomposition-continuous reduction & carburization process[8]were used to produce the samples by extrusion. And they were sintered in cacuum and in cacuum with SIP treatment to obtain the advanced ultrafine hardmetals.Then, the sintered rod samples were polished to manufacture microdrills for PCB. The test results proves that the properties of the advanced ultrafine cemented carbides are ideal for PCB microdrills.

2 Experimental

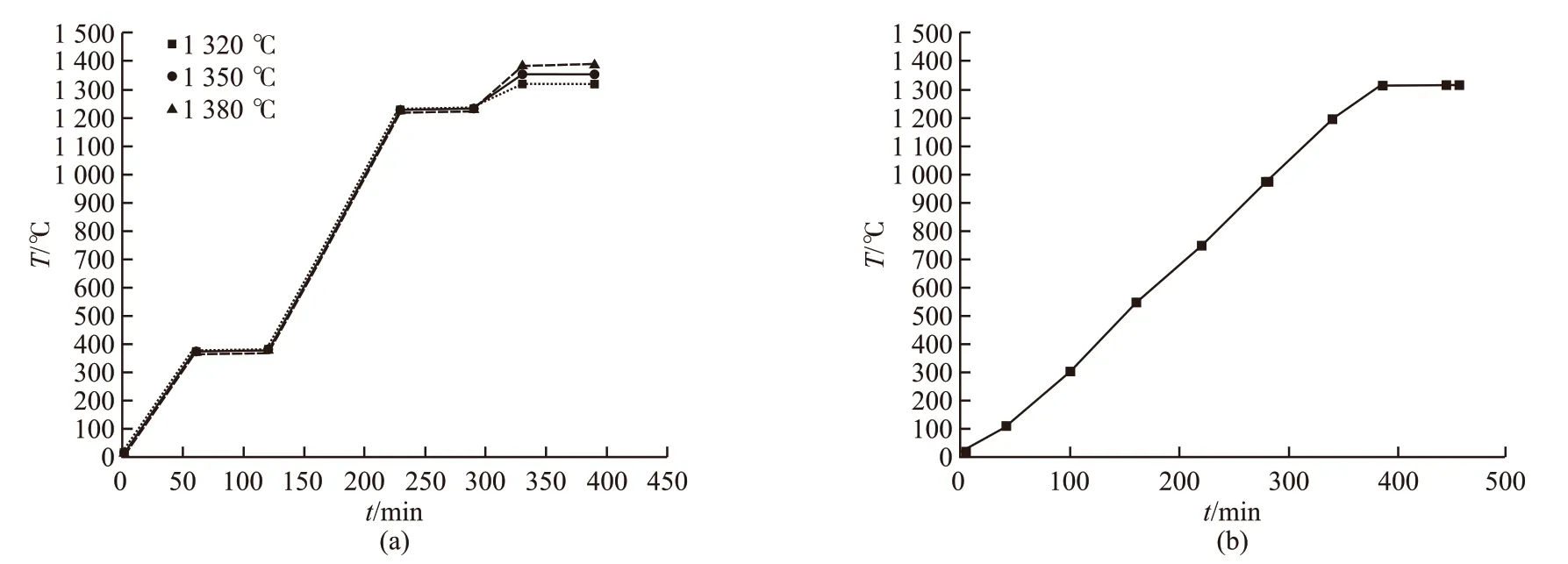

Fig.1 Vacuum sintering technology of nanocomposite WC-10Co

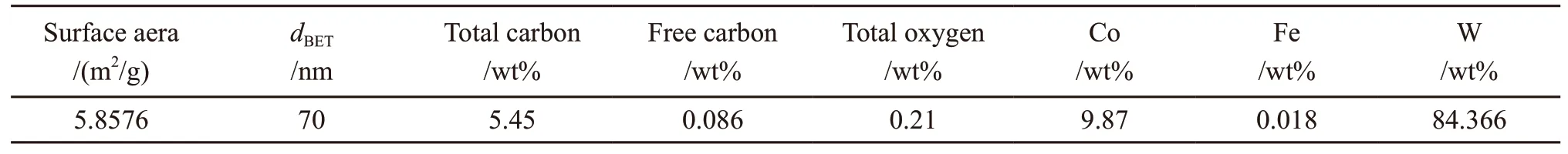

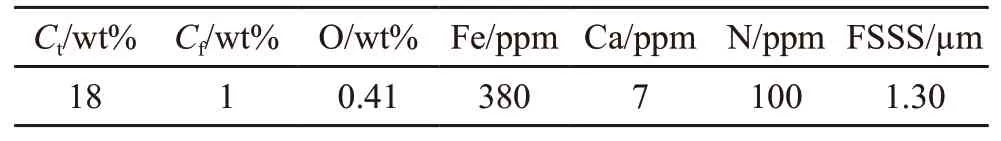

Table 1 Properties of nanocomposite powders

The WC-10Co nanocomposite powders were produced by spray thermal decomposition-continuous reduction & carburization process. The phase analysis of the powders was carried out by XRD. And the particle size and shape of them were analyzed by scanning electron microscopy (SEM) and transmission electron microscopy (TEM). At the same time, the particle size of them was characterized by BET analyer.

The nanocoposite powders were wet ball-milled in hexane for mixing with paraffin for 48 h. In order to restrict the grain growth of WC during liquid phase sintering, 0.4wt% VC and 0.4wt% Cr3C2were added into the nanocoposite powders as grain growth inhibitors during the milling. The free carbon was added to come to the theory carbon content at the same time.After milling, they were dried at 90 ℃ in a vacuum oven. Then the dried powders were palletized to small spherical shape of about 150 μm and were extruded under a pressure of 4 500 kgf at room temperature to produce rod samples. The compacted rod samples were sintered by liquid phase sintering at 1 320, 1 350, and 1 380 ℃ in vacuum under a pressure of about 5 Pa or in vacuum with SIP treatment process. The technology of sintering is showing in Fig.1.

The sintered rod samples are polished to obtain PCB microdrill samples. The microstructure of sintered samples was analyzed by scanning electron microscopy(SEM), transmission electron microscopy (TEM), and X-ray diffractometry (XRD). The density was determined by the Archimedes’ principle using water immersion. Hardness was measured with a rock well hardness tester. The distribution of grain size was carried out by mircograph particle size analyzer. The transverse rupture strenth(TRS) (according to ISO 3327), the magnetic saturation induction and magnetic coercivity were also measured.

3 Results and discussion

3.1 Properties of nanocomposite powders

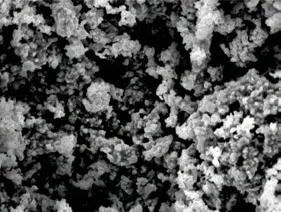

Fig.2 SEM image of the WC-10Co nanocomposite powder

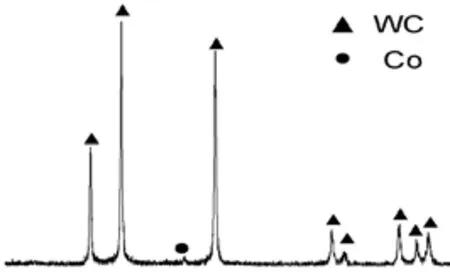

Fig.3 The X-ray diffraction pattern of the WC-10Co nanocomposite powder

The properties of the nanocomposite powders are summarized in Table 1. From it, we can see that carbon content is fewer than the theoretical value. This is mainly caused by the shorter carbonization time.The specific surface area of the WC-Co nanocomposite powde is 5.8576 m2/g and the average size of composite particle in the nanocomposite powders was about 70 nm. SEM images shows that the grain is finer and the grain size distribution is homogeneous(see Fig.2).Fig.3 shows XRD pattern of the composite powder. It can be seen that there is noηphase and the oxide is completely carbonized.These characteristics ensure that the nanocomposite powders are suitable for the production of cemented carbide.

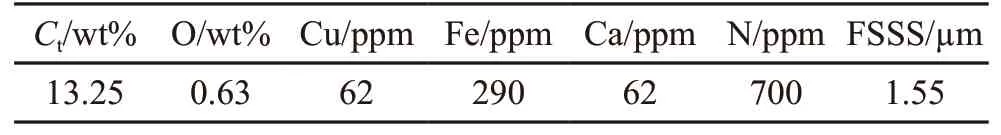

Table 2 Properties of VC powders

Table 3 Properties of Cr3C2 powders

Table 2 and Table 3 show the properties of VC powders and Cr3C2powders, which were added to the nanocomposite powders to inhibit the grain growth.

3.2 Mechanical properties of nanocomposite WC-10Co cemented carbides

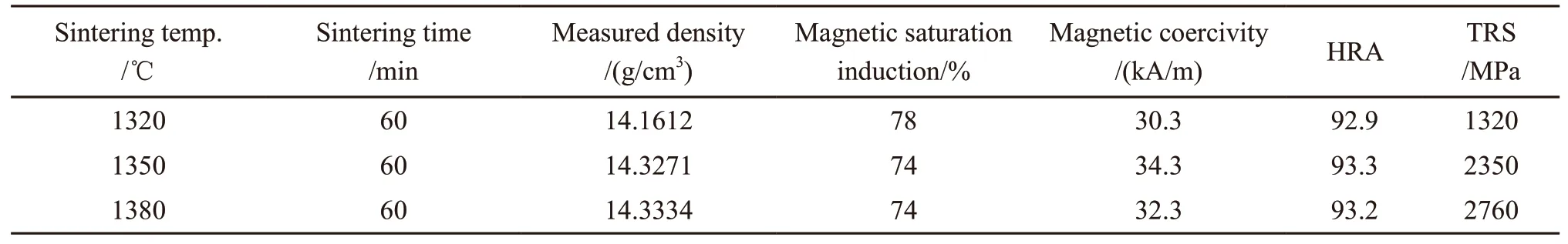

The polished rod samples for PCB microdrills sintered from nanocomposite WC-10Co cemented carbides are shown in Fig.4. The mechanical properties of nanocomposite WC-10Co cemented carbides samples sintered at 1 320 ℃, 1 350 ℃, 1 380 ℃ for 1 h in vacuum are summarized in Table 4. The results show that the density increases with the increase of sintering temperature, and the properties of samples sintered at 1 320 ℃ are not ideal. However, compared with 1 380 ℃, with the increase of sintering temperature,the magnetic force and hardness of the alloy decrease,the magnetic saturation changes little, and the bending strength increases with the increase of sintering temperature. Therefore, 1 380 ℃ can be selected as the sintering temperature. But the carbon content is too low. So the magnetic saturation induction is low. And according to the magnetic coercivity value, the grain is larger. This is mainly caused by the grain growth with the rise of temperature.

Fig.4 Rod samples for PCB microdrills

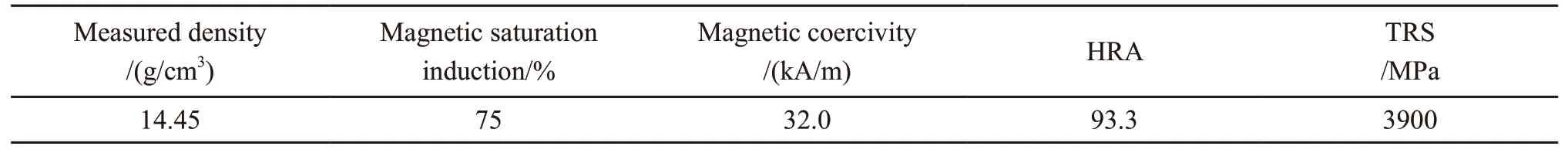

In the study, the materials sintered in vacuum at 1 380 ℃ were treated in sinter-HIP furnace . The properties of it were showed in Table 5. Sinter-HIP can effectively improve the density and bending strength of cemented carbide, which is helpful to improve the properties of cemented carbide. So the properties of the treated samples are finer than vacuum sintering samples except for magnetic coercivity(see Table 5).

3.3 Microstructures of nanocomposite WC-10Co cemented carbides

The fractured surface of the WC-10Co cemented carbides sintered at 1 380 ℃ for 1 h are illustrated in Fig.5(vacuum sintering) and Fig.6(sinter-HIP). Fig.5 shows that the fracture surface of WC-Co alloy is even.Most of the grains are fine and uniform, and the grain size is about 0.2-0.3 μm (200-300 nm). The grain size of samples treated by sinter-HIP is more uniform, but the grain size is larger. The grain size is about 0.3-0.4 μm (300-400 nm)(see Fig.6).

Fig.5 SEM image of nanocomposite WC-10Co cemented carbides sintered in vacuum

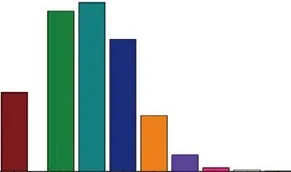

Fig.7 shows the distribution of the grain size of samples treated by sinter-HIP which is measured bymircograph particle size analyzer. The average grain size is about 0.35 μm which is the same to the result of Fig.6. From the results, we can know that the grain size of sintered cemented carbides could be controlled in a rage of 200-400 nm. VC and Cr3C2can inhibit the growth of the WC grains.

Table 4 Properties of nanocomposite WC-10Co cemented carbides sintered in cacuum

Table 5 Properties of nanocomposite WC-10Co cemented carbides treated by sinter-HIP

Fig.6 SEM image of nanocomposite WC-10Co cemented carbides treated by sinter-HIP

Fig.7 Grain size distribution of carbides sintered in vacuum

Fig.8 TEM image of nanocomposite WC-10Co cemented carbides treated by sinter-HIP

TEM image of nanocomposite WC-10Co cemented carbides treated by sinter-HIP is shown in Fig.8. Most WC particles which are surrounded by Co body exhibit simple geometric forms with straight edges, which are the same as in conventional samples except for a much smaller grain size. This microstructure of the sintered samples is critical to the mechanical properties of the composite.

4 Conclusions

Nanocomposite WC-Co powders with an average grain size of about 70 nm could be produced by the spray thermal decomposition-continuous reduction& carburization process. The grain size of sintered cemented carbides could be controlled in a rage of 200-400 nm with VC and Cr3C2as grain growth inhibitors. The mechanical properties of cemented carbides sintered with the superfine nanocomposite WC-Co powders in vacuum with sinter-HIP treatment are more excellent. The obtained superfine grained materials sintered in vacuum with sinter-HIP treatment have superior strenth(3 900 MPa) and high hardness (HRA 93.3).The superfine cemented carbides with high strenth and high hardness can be used in microdrills for printed circuit boards (PCBs).

杂志排行

Journal of Wuhan University of Technology(Materials Science Edition)的其它文章

- Experimental Study on Viscosity Characteristics of Expanding Polymer Grout

- Thermal-responsive Photonic Crystals based on Physically Cross-linked Inverse Opal Nanocomposite Hydrogels

- Evalution of Thermal Oxidative Degradation of Trimethylolpropane Trioleate by TG/DTA/DSC

- Transformation Characteristics and Microstructure of Rail under Low Stress during Continuous Cooling

- Formation Mechanism and Existing Form of Sb in Heat Resistance Mg-Gd-Y-Sb Alloy

- Rapid Dendrite Growth in Solidification of Highly Undercooled Alloys