Simultaneous Removal of Sulfide, Nitrate and Ammonium Ions from Wastewater in One Reactor

2020-01-13LiuChunshuangLiWeiBaiXueWangYongxingWangYongqiangLiuFangZhaoChaocheng

Liu Chunshuang; Li Wei; Bai Xue; Wang Yongxing; Wang Yongqiang; Liu Fang; Zhao Chaocheng

(1. State Key Laboratory of Petroleum Pollution Control, China Uniνersity of Petroleum, Qingdao 266580; 2. College of Chemical Engineering, China Uniνersity of Petroleum, Qingdao 266580)

Abstract: Simultaneous removal of sulfide, nitrate and ammonium salts was achieved in an upflow anaerobic sludge blanked (UASB) reactor by the start-up strategy of gradually decreasing influent nitrite to null. The sulfide/nitrate-nitrogen ratio could affect the distribution of end products of sulfur, and a sulfide/nitrate-nitrogen ratio of 1:0.76 is proposed as optimum for S0 accumulation. The Denittrasoma, Thiobacillus, and Candidatus_Kuenenia presented the functional strains in the studied reactor. This result can provide a theoretical and technical basis for the large-scale application of anaerobic ammonium oxidation process.

Key words: nitrate; sulfide; ammonium; anammox

1 Introduction

Nitrogen compounds, which are the main pollutants, should be removed from many kinds of wastewaters such as petrochemical wastewater, municipal wastewater, and landfill leachate. Usually the reduced sulfur compounds also coexist in these wastewaters[1-2]. Conventionally the ammonium ion is firstly oxidized to nitrate via nitrification, and then is reduced to N2via the denitrification process. Nevertheless, anaerobic ammonium oxidation (anammox) can directly convert the ammonium ion and nitrite to N2in one reactor[3-5]. Obviously, combined with partial nitritation, the anammox process can greatly reduce the cost of aeration energy and additional carbon sources to provides a way for achieving the sustainability of wastewater treatment process[6-7].

However, the anammox process is difficult to maintain a stable condition for treating a low-strength ammonium wastewater at low temperature due to the instability of partial nitritation process[8], although many strategies such as FNA, FA, and bioaugmentation have been proposed to limit the growth of nitration oxidation bacteria[9-11]. Since nitrite is an intermediate of denitrification process, it can be accumulated during the autotrophic denitrification process[12]. It may be feasible to simultaneously remove sulfide, nitrate and ammonium ions in one reactor by the combination of autotrophic denitrification and anammox reactions.

This study investigated the feasibility of simultaneous removal of sulfide, nitrate and ammonium ions in one reactor. The effects of influent sulfide/nitrate-nitrogen ratio and HRT were also investigated. The corresponding microbial community structure was profiled. The results may provide a theoretical and technical basis for wide application of anammox reaction.

2 Experimental

2.1 Reactor set-up

An UASB reactor with a dimension of 5 cm (diameter) ×75 cm (height), and a working volume of 1.57 L at 30 ± 1 °C, was utilized (Figure 1). An internal reflux peristaltic pump could produce an internal up-flow at a velocity of 1.2 m/s. The outside of the reactor is covered with a tin foil to avoid the influence of light on anammox bacteria.Artificial wastewater containing potassium nitrate as electron acceptor, ammonium chloride and sodium sulfide as electron donors, and sodium bicarbonate as inorganic carbon source for bacteria growth was used as the feed to the reactor[13].

The pH value of the artificial wastewater was maintained at 7.5 through dosing 1 mol/L HCl or 1 M NaOH manually. The inoculated sludge was a mixture of anammox sludge and denitrifying sludge (at a volume ratio of 3:1). Other details for the reactor set-up are available in Liu’s paper[14].

2.2 Chemical analysis

After filtration by a 0.45-ml Millipore filter, theand pH value in liquid samples were analyzed by an ion chromatograph (ICS-3000; Dionex, USA) equipped with an inhibitory type conductivity detector and an Ionpac column (AG4A AS4A-SC, 4 mm). The pH and S2-of the liquid samples, the suspended solids (SS), and the volatile suspended solids (VSS) of the sludge were measured according to Standard Methods[15]. The concentration of S0and nitrite was calculated based on mass balance calculations[16-17].

2.3 Microbial community

The DNA of sludge samples were extracted from 0.15 g to 0.25 g of dried sludge utilizing FastDNA (Qbingene, Carlsbad, CA) according to the manufacturer’s instructions[17]. The bacterial V3-V4 region of the 16S rRNA gene was amplified using the forward primers 338F (50-ACT CCT ACG GGA GGC AGC AG-30) and the reverse primer 806R (50-GGA CTA CHV GGG TWT CTA AT-30). The detailed PCR mixture and reaction procedure can be referred to the papers of Liu, et al.[18]and Shi, et al.[19]The PCR product was purified by a GeneJetPCR purification kit (Thermo Scientific), prior to being put for sequencing on the Illumina Miseq PE300 platform (Illimina, USA).

3 Results and Discussion

3.1 Performance of the reactor

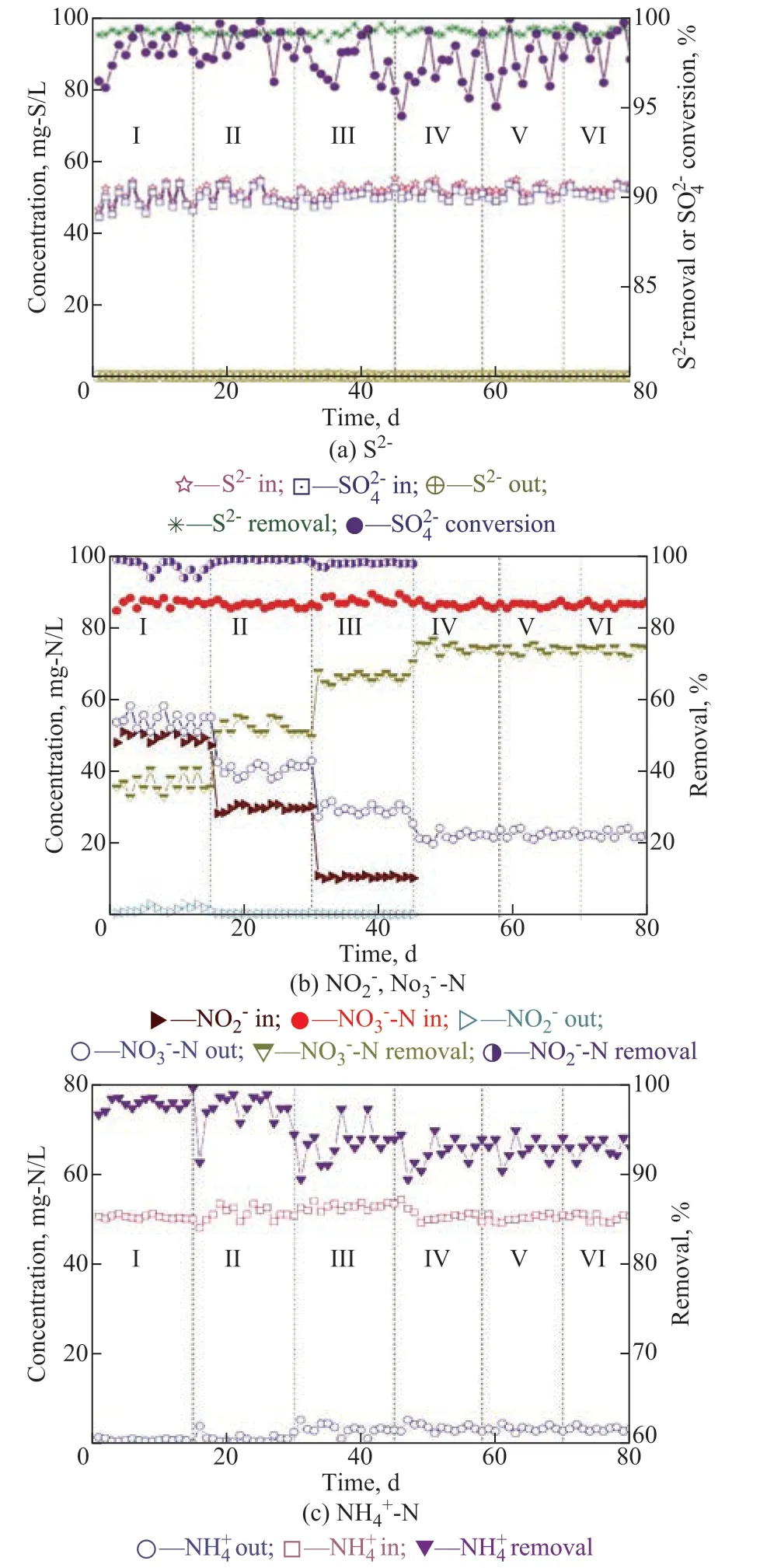

In order to maintain the activity of anammox bacteria during the start-up process, special strategy of gradually reducing the influent nitrite concentration to null was adopted. The influent concentrations of ammonium ions, nitrate and sulfide were maintained at 50 mg-N/L, 87 mg-N/L and 50 mg-S/L, respectively. However, the concentration of influent nitrite was gradually decreased from 50 mg-N/L to 30 mg-N/L, 10 mg-N/L, and then 0 mg-N/L (from Stage I to Stage VI). At stage I, the concentration of ammonium ions removal reached as high as 99%. However, the nitrate removal was only 40% due to the presence of 50 mg-N/L of nitrite (with theremoval efficiency reaching >97%). Nearly all sulfide species were removed and mostly were converted to sulfate (Figure 1).

Figure 1 Changes in operational performance of the reactor at each stage

With the influent nitrite decreasing from 50 mg-N/L to 30 mg-N/L (stage II) and to 10 mg-N/L (stage III), the nitrate removal increased from 40% to 50%, and then to 65%, respectively. The sulfide removal was maintained at >97% across the two stages. All sulfide species were removed and converted to sulfate species. The ammonium ions removal slightly decreased from 97% to 93% at the stage III.

When the nitrite species were removed from the influent at stage IV, the nitrate removal rate continuously increased to 74% with the efficiency for removal of ammonium ions and sulfide species being maintained at >92%. Simultaneous removal of sulfide, nitrate and ammonium species was achieved in one reactor by using the strategy of gradually decreasing the influent nitrite species to null. Shortening of HRT from 10 h to 8 h (stage V), and then to 6 h (stage VI) had little effect on the reactor performance. Finally, the loading rates reached 0.2 kg-N/(m3·d), 0.2 kg-N/(m3·d), and 0.8 kg-S/(m3·d), respectively, for nitrate, ammonium, and sulfide species, respectively.

3.2 Effect of sulfide/nitrate-nitrogen ratio

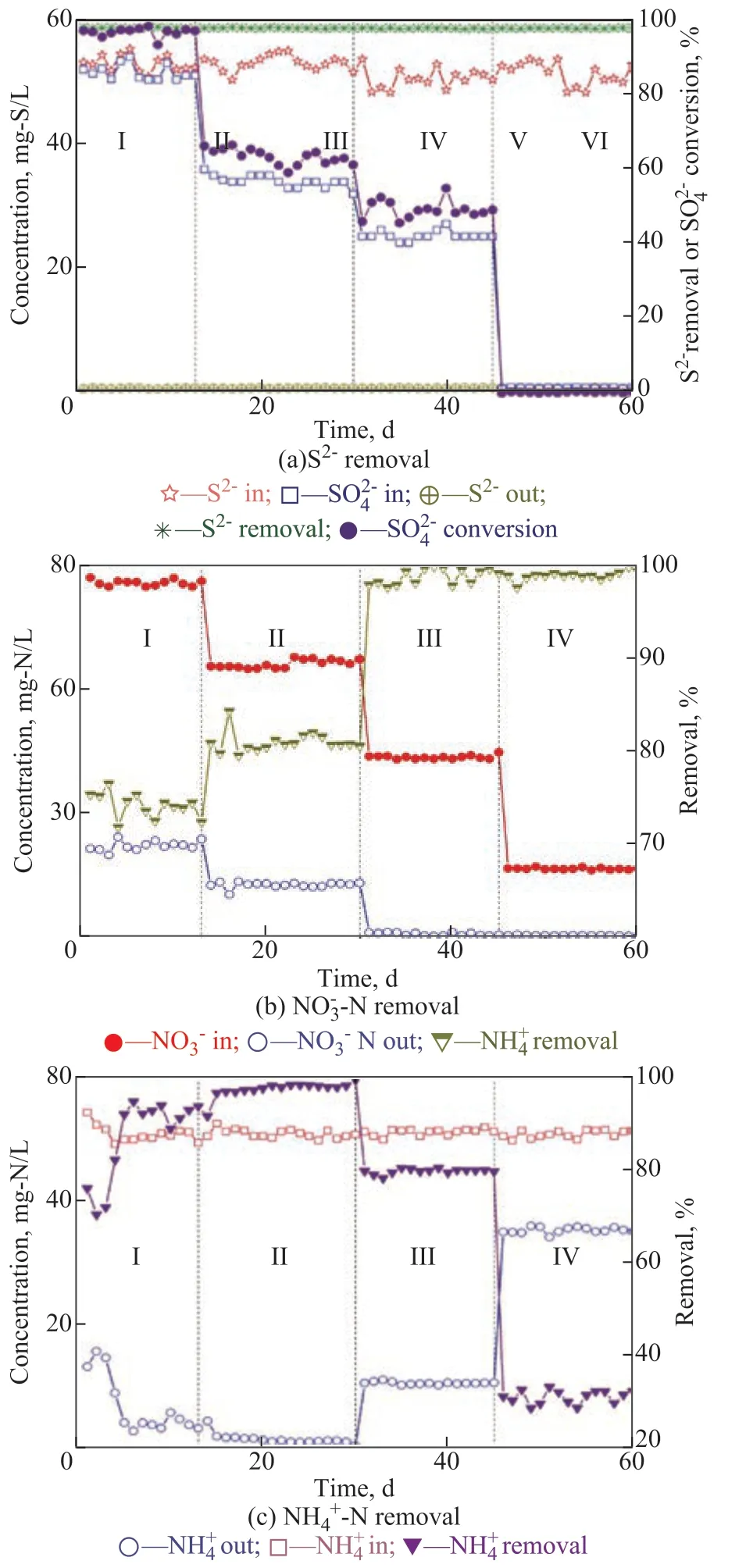

At a fixed sulfide to ammonium ratio of 1:1 and a HRT of 6 h, four sulfide to nitrate ratios — viz.: 1:4, 1:3, 1:2, and 1:0.76 — were applied to the UASB reactor, with the results shown in Figure 2. When both the sulfide loading rate and the ammonium loading rate were 0.2 kg-S/(m3·d) and 0.2 kg-N/(m3·d), respectively, the nitrate-nitrogen loading was introduced at 0.8, 0.6, 0.3 and 0.152 kg-N/(m3·d) in stage I, II, III, and IV, respectively, into the UASB reactor.

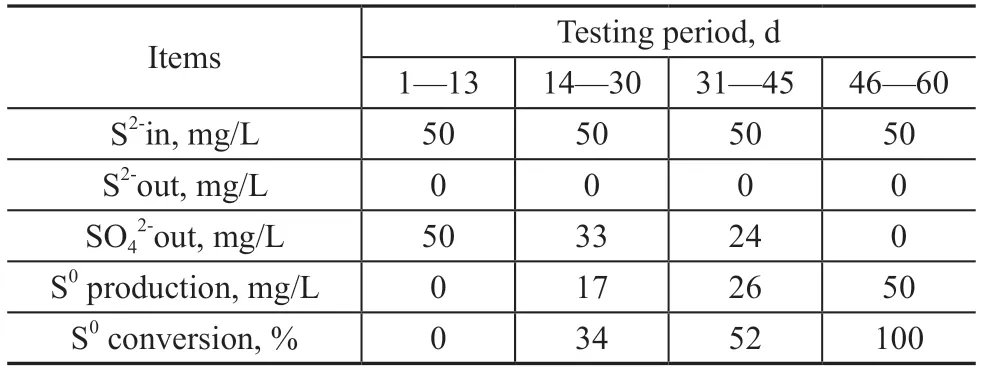

Table 1 S0 production and conversion at different stages

At a sulfide/nitrate ratio of 1:4, the sulfide and ammonium removal rates were all greater than 97 % (Figure 2(a) and 2(c)), with sulfide species being completely converted to sulfate (Table 1). The corresponding nitrate removal was about 74%. At a sulfide to nitrate ratio of 1:3, the efficiency for removal of sulfide and ammonium ions was maintained at >97%, with the effluent sulfate concentration decreasing from 50 mg-S/L to 33 mg-S/L. The granular and filamentous precipitates in yellow color were observed in the reactor liquor and effluent. Chemical analysis confirmed that the precipitate was S0. The mass balance calculation revealed that S0conversion was around 34%. The corresponding nitrate removal increased from 74% to 80%.

At a sulfide/nitrate ratio of 1:2, the nitrate removal efficiency further increased to 97%. The sulfide removal was maintained at >98%, however, the effluent sulfate concentration decreased from 33 mg-S/L to 24 mg-S/L. The S0conversion increased from 34% to 52%, while the ammonium ion removal decreased from 97% to 80%. This fact might be attributable to the insufficient nitrate supply for converting ammonium to N2. At a sulfide/nitrate ratio of 1:0.76, the nitrate and sulfide removal efficiencies were all equal to greater than 99%, with all sulfide species being completely converted to S0. The corresponding ammonium ions removal decreased to 30% at this stage.

Figure 2 Effect of sulfide/nitrate-nitrogen ratio on reactor performance

3.3 Microbial community structure

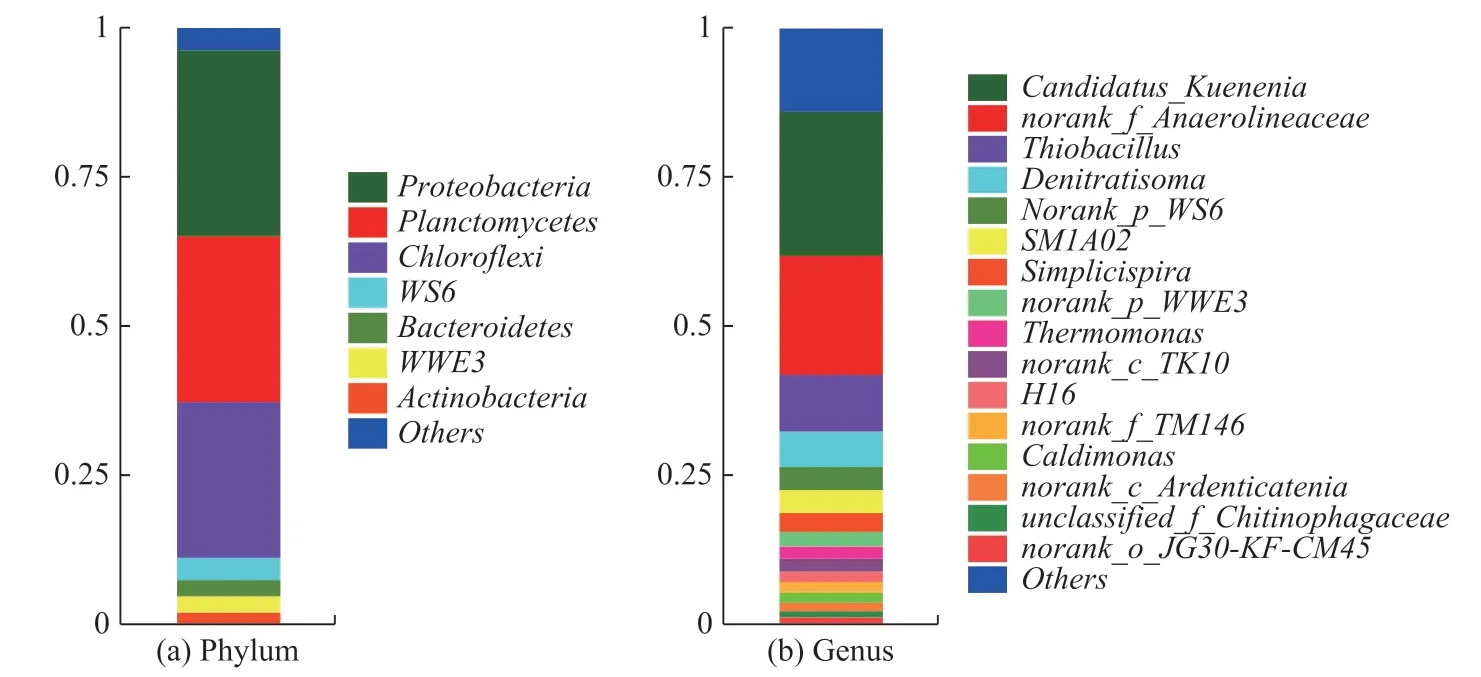

Seven phyla were detected in the sludge sample collected on the day 80 (Figure 3(a)). They were Proteobacteria (31.22%), Planctomycetes (27.96%), Chloroflexi (26.12%), Bacteroidetes (2.74%), Actinobacteria (2.21%), WS6 (3.87%), and WWE3 (2.46%) (Figure 3(a)). The identified dominant genera in the reactor under steadystate operation included Candidatus_Kuenenia (24.26%), norank_f_Anaerolineaceae (20.25%), Thiobacillus (9.19%), and Denittrasoma (6.27%) (Figure 3(b)).

Denittrasoma can use multiple electron acceptors for reducing nitrate to nitrite, which is likely one of the autotrophic denitrifiers for the present system. Thiobacillus is an autotrophic denitrifier used in the denitrifying process for sulfide removal which can oxidize sulfide to S0and reduce nitrate toCandidatus_Kuenenia is a typical anammox bacterium. Collaboration of Denittrasoma,

Thiobacillus, and Candidatus_Kuenenia is supposed to be the main functional strains for the studied simultaneous removal of sulfide, nitrate and ammonium ions.

Phyla and genera making up less than 0.5% of total composition in the sample were classified as ‘‘others’’.

Jin, et al. claimed[21]that the activity of anammox bacteria was easily inhibited in the presence of 32 mg-S/L. The present study successfully operated the UASB reactor to simultaneously convert 0.8 kg-S/(m3·d) of S2-, 0.2 kg-N/(m3·d) of nitrate, and 0.2 kg-N/(m3·d) of ammonium ions toand N2without significant sulfide inhibition effects. Likewise, since the inoculated autotrophic denitrifiers could quickly convert sulfide toor S0, the sulfide inhibition effects on anammox bacteria were minimized.

The sulfide to nitrate ratio presented a key process parameter for the distribution of end products of sulfur. At a sulfide/nitrate ratio of 1:4, all sulfide species were converted to sulfate species. When the sulfide/nitrate ratio increased from 1:4 to 1:3, and further to 1:2, S0was formed and the conversion of sulfate was decreased successively from 100% to 66%, and then to 48%. When the sulfide/nitrate ratio reached 1:0.76, the conversion of S0was nearly complete. It was very likely that the sulfide/nitrate ratio could affect the end products of autotrophic denitrification process (Eq. (1) and Eq. (2)).

S0may cause odor and corrosion under anaerobic condition in wastewater treatment system. It is better to control the influent sulfide/nitrate ratio at lower than 1:4 to avoid the accumulation of S0. Besides, high sulfide might cause inhibition of many biological processes. Further tests are under investigation to examine the effects of higher sulfide concentration (>100 mg-S/L) on reactor performance.

4 Conclusions

It is feasible to start up the UASB reactor with a strategy of gradually decreasing the influent nitrite concentration to null. The present reactor simultaneously can convert 0.8 kg-S/(m3·d) of sulfide, 0.2 kg-N/(m3·d) of nitrate, and 0.2 kg-N/(m3·d) of ammonium ions toand N2with insignificant sulfide inhibition. The sludge acclimated in the reactor contains Denittrasoma, Thiobacillus, and Candidatus_Kuenenia representing respectively the autotrophic denitrifiers and anammox bacteria in the reactor. The sulfide/nitrate ratio was proposed to be a key process parameter for the distribution of end products of sulfur. A ratio lower than 1:4 was necessary for avoiding S0accumulation in the effluent.

Figure 3 Taxonomic classification of the bacterial communities at phylum and genus levels

Acknowledgements:This research was supported by the National Natural Science Foundation of China (21307160), the Natural Science Foundation of Shandong Province, China(ZR20192019MEE038), the Fundametal Research Funds for the central Universities(19cx02038A), the Open Project of Key Laboratory of Environmental Biotechnology, CAS (Grant No. kf2018003), and the Open Project Program of State Key Laboratory of Petroleum Pollution Control (Grant No. PPC2018006), and the CNPC Research Institute of Safety and Environmental Technology.

杂志排行

中国炼油与石油化工的其它文章

- Comparison on Adsorptive Separation of n-Paraffins Based on Binderless and Binder-containing Zeolite 5A Pellets

- Effect of Doped Vanadium Dioxide on Oxidative Desulfurization Reaction

- CoMnMgAl Hydrotalcite-like Compounds and their Complex Oxides: Facile Synthesis and FCC SOx Removal

- Boosting the Photocatalytic Activity of WO3 by Highly Dispersed CoWO4 or CuWO4

- Discussion on the Mechanism of Boric Acid and Phosphoric Acid to Improve the Hardening of Complex Calcium Lubricating Grease

- Effect of Zeolite 5A Particle Size on Its Performance for Adsorptive Separation of Ethylene/ Ethane