Effect of flexural loading on degradation progress of recycledaggregate concrete subjected to sulfate attack and wetting-drying cycles

2019-04-04ZhaoYasongGaoJianmingQiBingLiuChuanbei

Zhao Yasong Gao Jianming Qi Bing Liu Chuanbei

(School of Materials Science and Engineering, Southeast University, Nanjing 211189, China)(Jiangsu Key Laboratory of Construction Materials, Southeast University, Nanjing 211189, China)

Abstract:The degradation progress of recycled aggregate concrete (RAC) subjected to sulfate attack under wetting-drying cycles and flexural loading is studied. Three different stress ratios (0, 0.3 and 0.5) were applied in this test. The variations of relative dynamic elastic modulus Erd and water-soluble contents in RAC were used to evaluate degradation progress. The changes in mineral products and microstructures of interior concrete were investigated by means of X-ray diffraction (XRD), the environmental scanning electron microscope (ESEM) and X-ray computed tomography (X-CT). The results indicate that flexural loading accelerates the degradation of RAC under sulfate attack and wetting-drying cycles by expediting the transmission of into interior concrete. Furthermore, the accelerated effect of flexural loading is more obvious with the increase of stress ratio, that is because higher stress ratios can accelerate the extension of microcracks and generate more channels for the transmission of Also, more expansive products (gypsum and ettringite) are generated by the reaction of Ca(OH)2 with which can further accelerate the degradation of RAC.

Key words:recycled aggregate concrete; degradation; sulfate attack; flexural loading; wetting-drying cycles

Over the past decades, vast amounts of construction and demolition wastes (C& DW) have been generated due to the urbanization in China, and waste concrete has accounted for a large proportion of C& DW. It was reported that 100 million tons of waste concrete were generated every year, and occupied about 1/3 of total C& DW[1].Therefore, the disposal of waste concrete has been an extremely urgent problem currently.

Some studies on properties of recycled concrete aggregate (RCA) have been carried out. Compared with natural aggregate, RCA from waste concrete has the properties of higher porosity, lower strength and more complicated microstructure on the surface. However, those RCA still can be used to prepare RAC[2-4]. Furthermore, some studies on high-performance concrete made with RCA also have been published[5-7]. The mechanical properties of RAC have been investigated for many years, and results indicate that adding RCA in concrete can result in the deterioration of mechanical properties[8-13]. Some research on durability of RAC has been carried out[14-16], but there is very little study on the degradation of RAC subjected to sulfate attack[17-18]. Especially in practical engineering, the RAC structure not only suffers from sulfate attack, but also will be subjected to flexural loading, which will largely affect the degradation progress of RAC under sulfate attack. Meanwhile, the status of RAC is not always be water-saturated, the wet and dry status will occur alternately. Therefore, it is necessary to investigate the effect of flexural loading on the degradation progress of RAC subjected to sulfate attack and wetting-drying cycles.

1 Experimental Program

1.1 Materials and mix proportions

42.5R (Ⅱ) Portland cement was used in this study, complying with GB 175—2007. The chemical compositions of cement are shown in Tab.1. RCA was from a demolition site in Nanjing with the maximum size of 20 mm. The properties of RCA are shown in Tab.2, and Tab.3 shows the mix proportion of RAC.

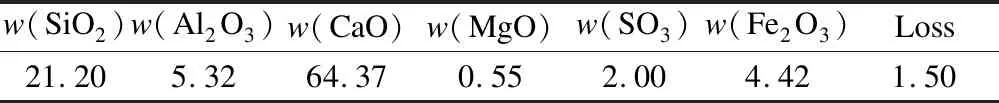

Tab.1 Chemical compositions of cement %

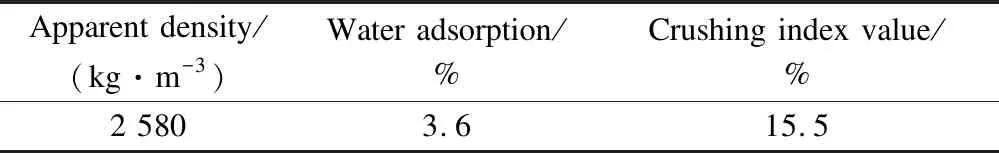

Tab.2 Physical properties of RCA

Tab.3 Mix proportion of RAC kg/m3

1.2 Test setup and instrumentation

The four-point bending load device as shown in Fig.1 was used to apply flexural loading. According to Hooke’s law, the deformation of the spring can generate load to the steel plate, and this load will be transferred onto the specimens to form the four-point bending effect. Meanwhile, the relationship between the spring deformation and the value of generated load was determined. Hence, three stress ratios (0, 0.3 0.5) corresponding to 0, 30% and 50% of the ultimate flexural load were conducted to RAC and remained in the whole exposure period.

Fig.1 Equipment for applying flexural loading>

Sodium sulfate solution with the content of 50 g/L was used in this study to simulate the sulfate attack environment. As for wetting-drying regime, all specimens with applying flexural loading devices were immersed in a sodium sulfate solution for 21 h first, then followed by air-drying for 3 h. After that, they were dried for 45 h at a temperature of 60 ℃, then followed by air cooling for 3 h. The whole period of 72 h was regarded as a wetting-drying cycle.

The relative dynamic modulus of elasticity of the specimen,Erd, was measured by a nonmetal ultrasonic analyzer (NM-4A, transducer frequency is 50 KHz).The surface of specimens will be uneven as a result of the erosion process; therefore, vaseline was used as a coupling agent to ensure the accuracy of measured values. The test length of specimens is 280 mm. The dynamic modulus elasticity of specimensEdwas determined by Eq.(1) before the wetting-drying cycles. Then, the changes ofEdwere monitored after every 3 times of wetting-drying cycles.Erdcan be calculated by

(1)

(2)

whereEdis the dynamic modulus of elasticity of the specimen;Erdis the relative dynamic modulus of elasticity of the specimen;Vis the ultrasonic velocity, m/s;ρis the density of the specimen, kg/m3;υis the Poisson ratio;tis the sound interval, μs;Lis the test distance of the specimen, m;t0is the sound-interval for the specimen before erosion, μs;tnis the sound-interval for the specimen during the erosion test, μs.

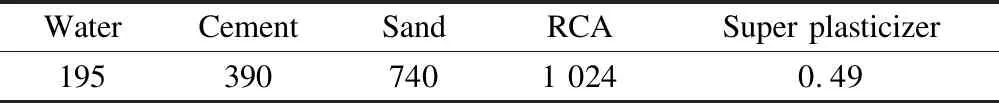

f(A)=8.715 26A2+3.383 241A-0.256 43R2=0.971 29

(3)

2 Results and Discussion

2.1 Variations of Erd for RAC

Fig.2 Standard curve of sodium sulfate solution

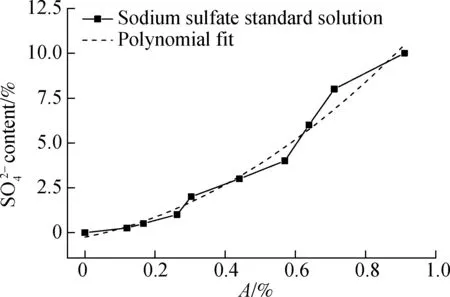

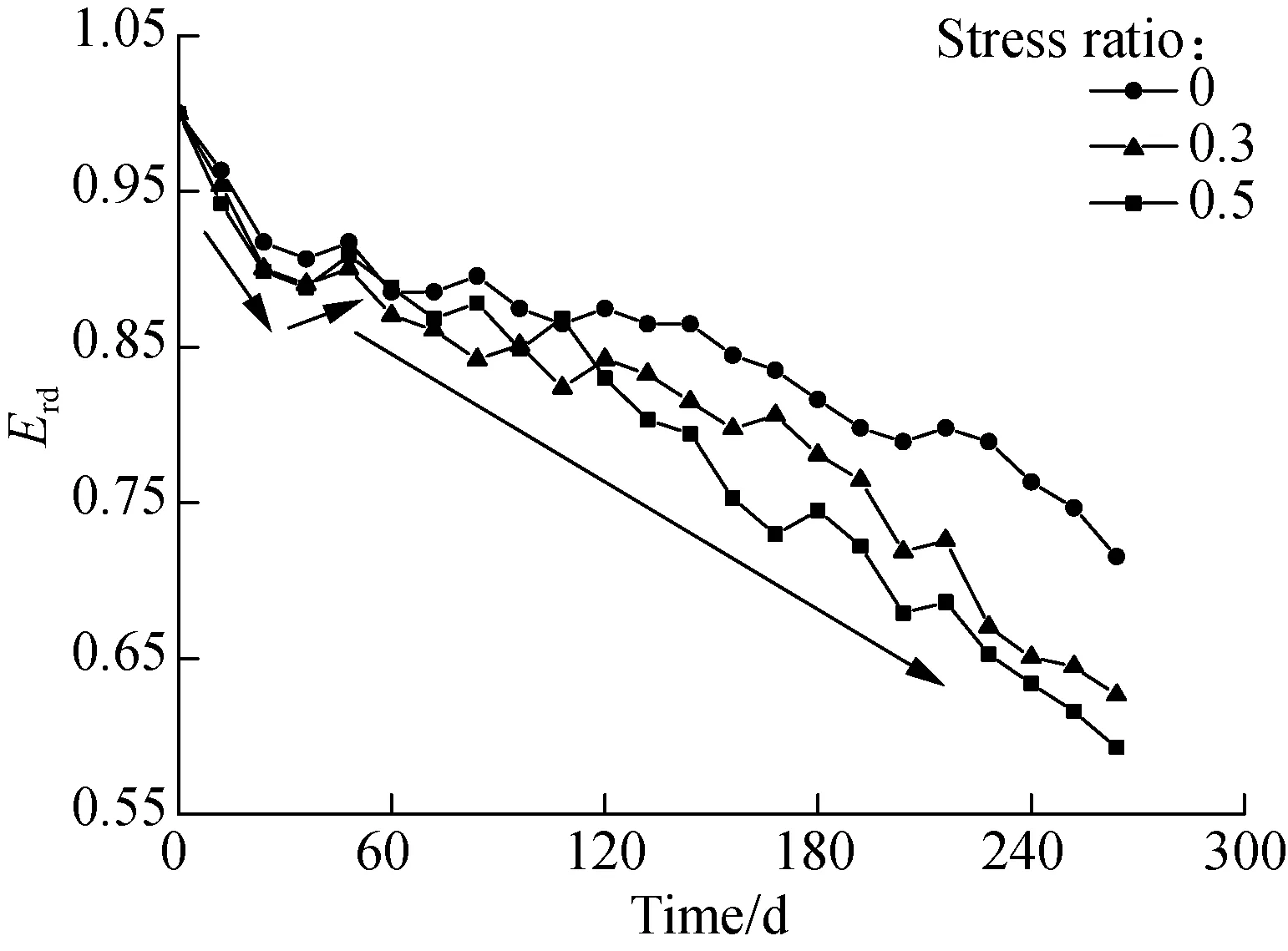

Fig.3 Erd variations for RAC under different stress ratios

Fig.3 shows that the application of flexural loading can increase the deterioration of specimens under sulfate attack and wetting-drying cycles. After 270 d, theErdvalues of specimens with stress ratios 0.5 and 0.3 are 0.593 and 0.626, respectively, which are 17.1% and 12.5% lower than those of the specimens without loading, respectively. The reason can be that microcracks are more easily generated when the flexural loading is higher, so the expansive products can penetrate into concrete more quickly and result in acceleration of degradation progress.

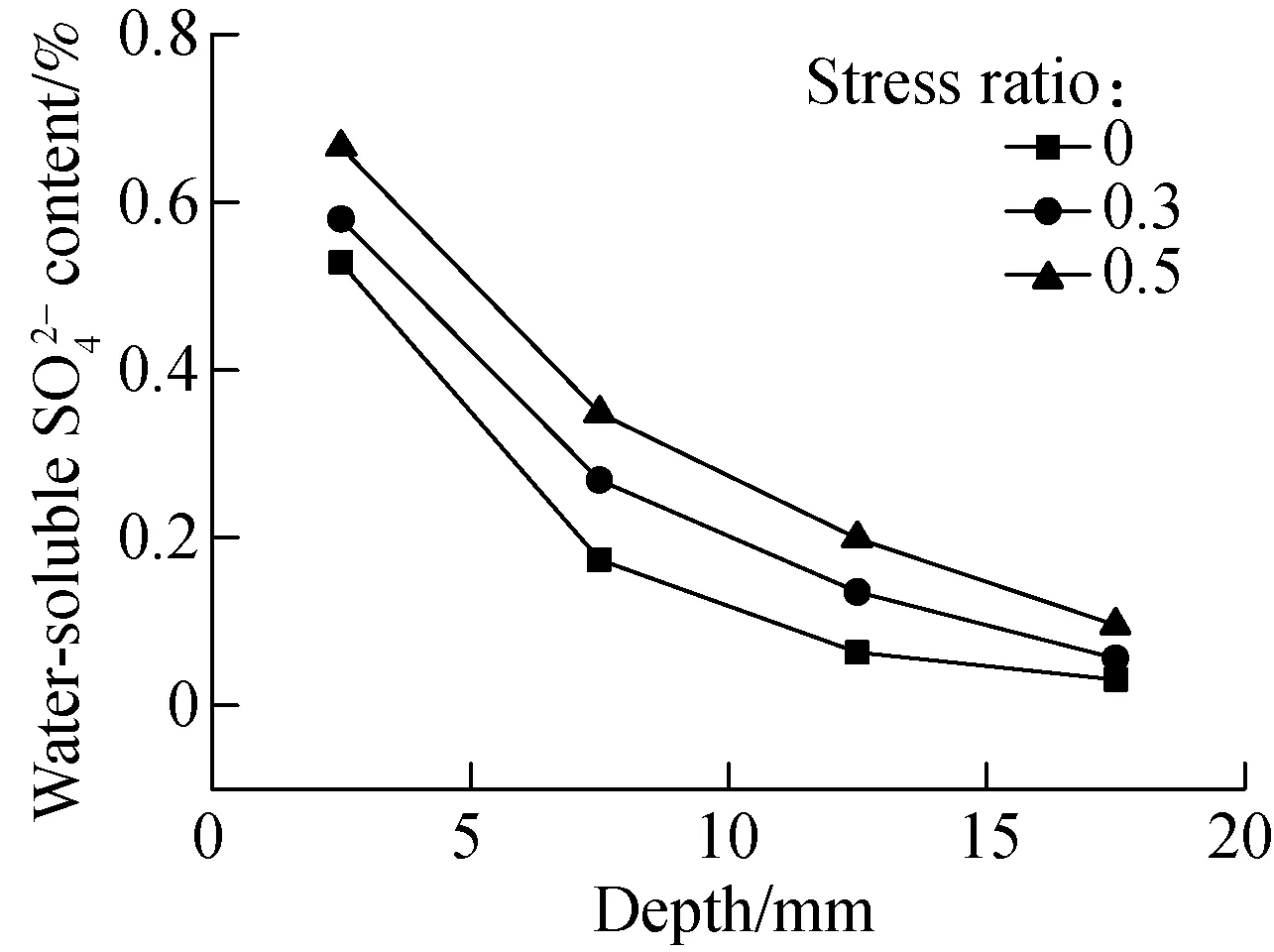

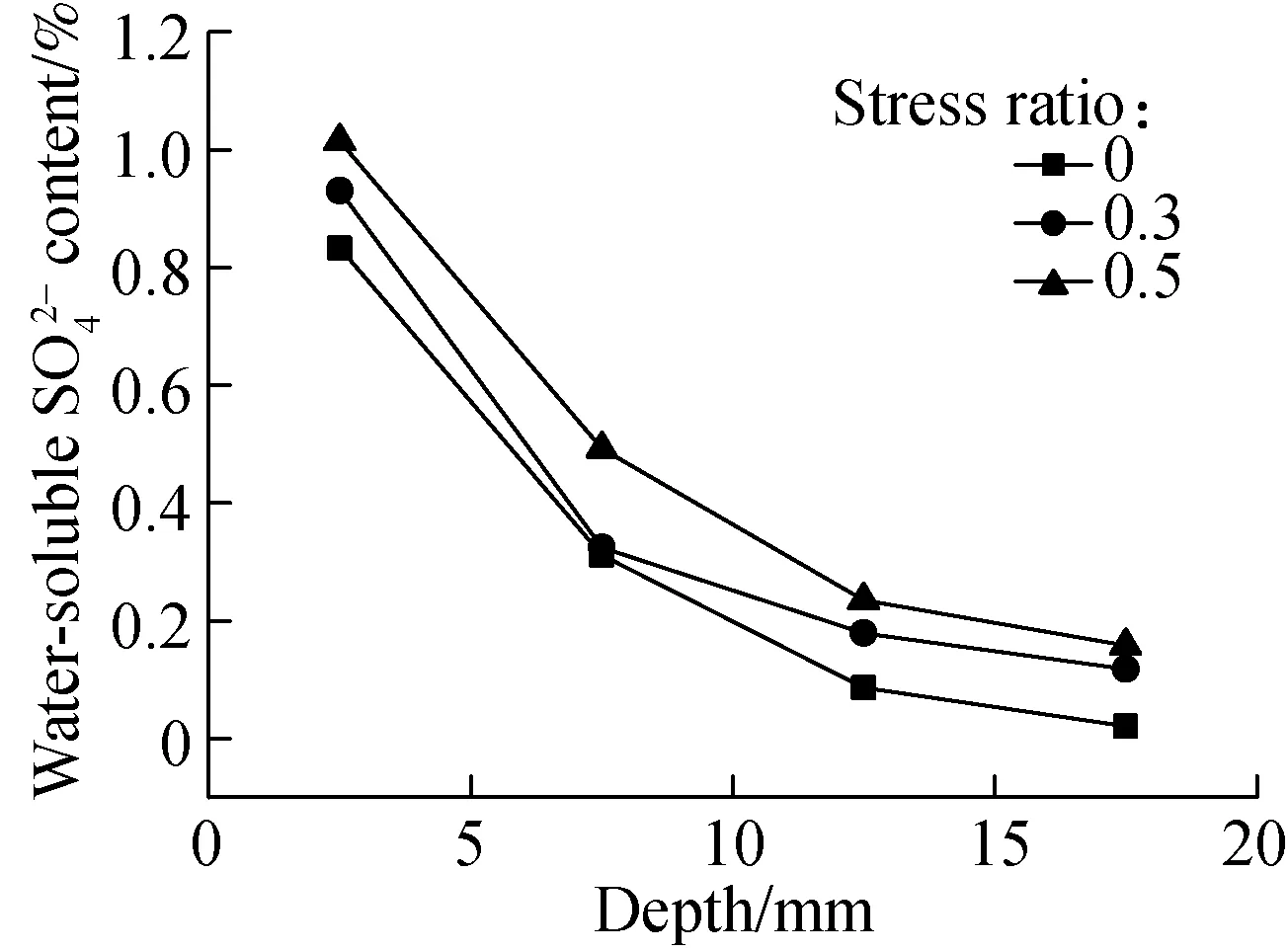

(a)

(b)

(c)

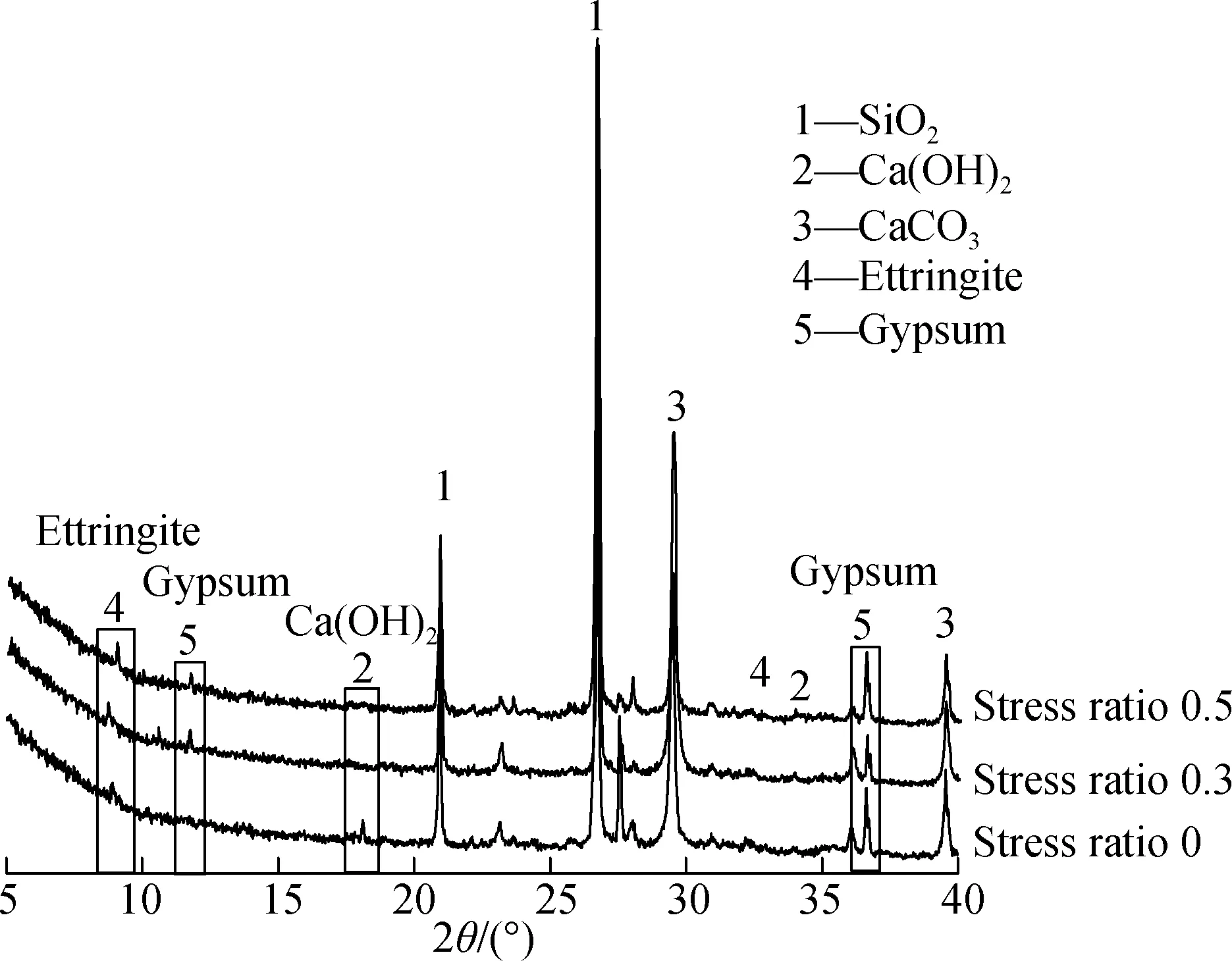

2.3 XRD analysis

Fig.5 XRD patterns of RAC under different stress ratios after 270 d immersion

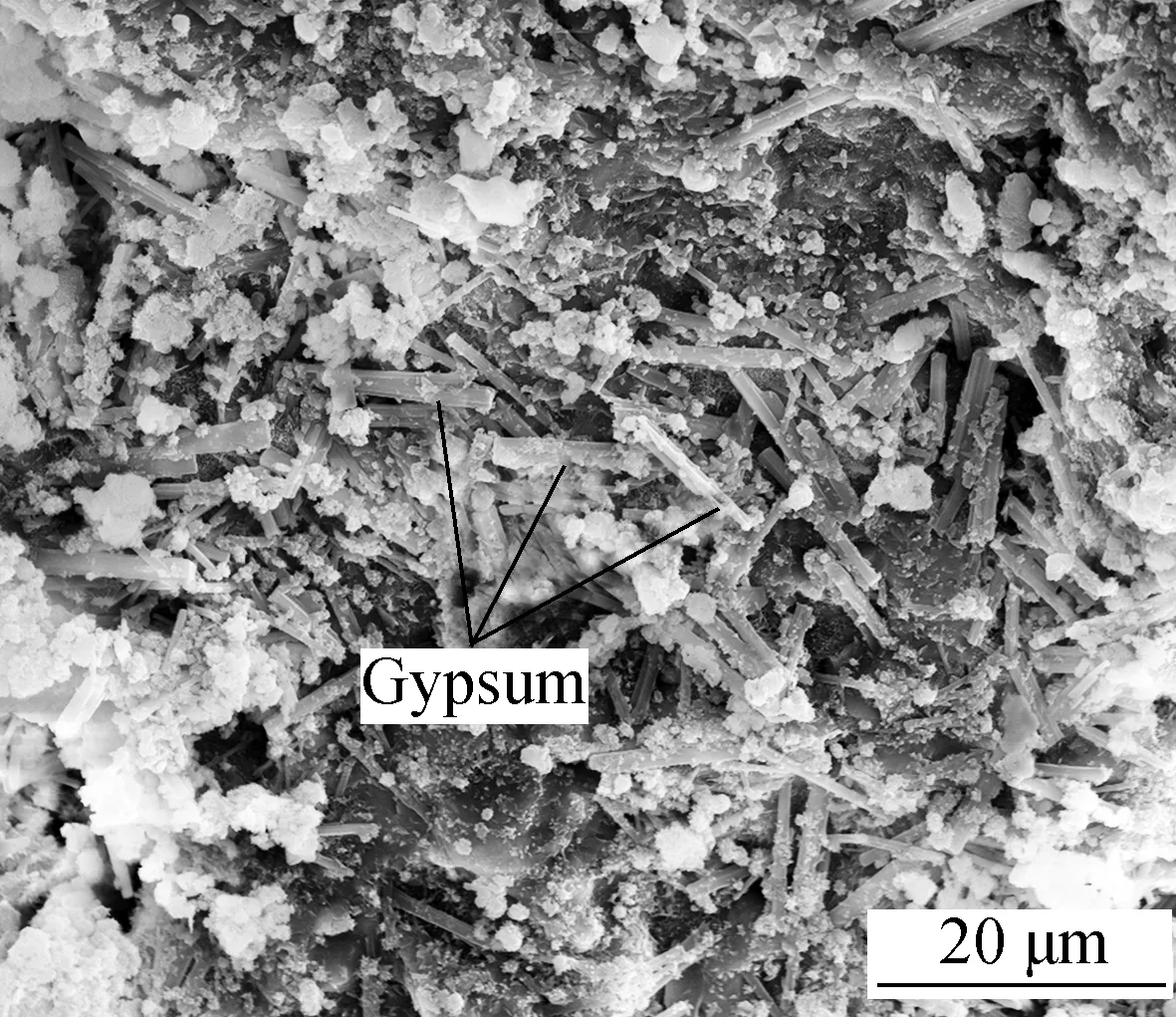

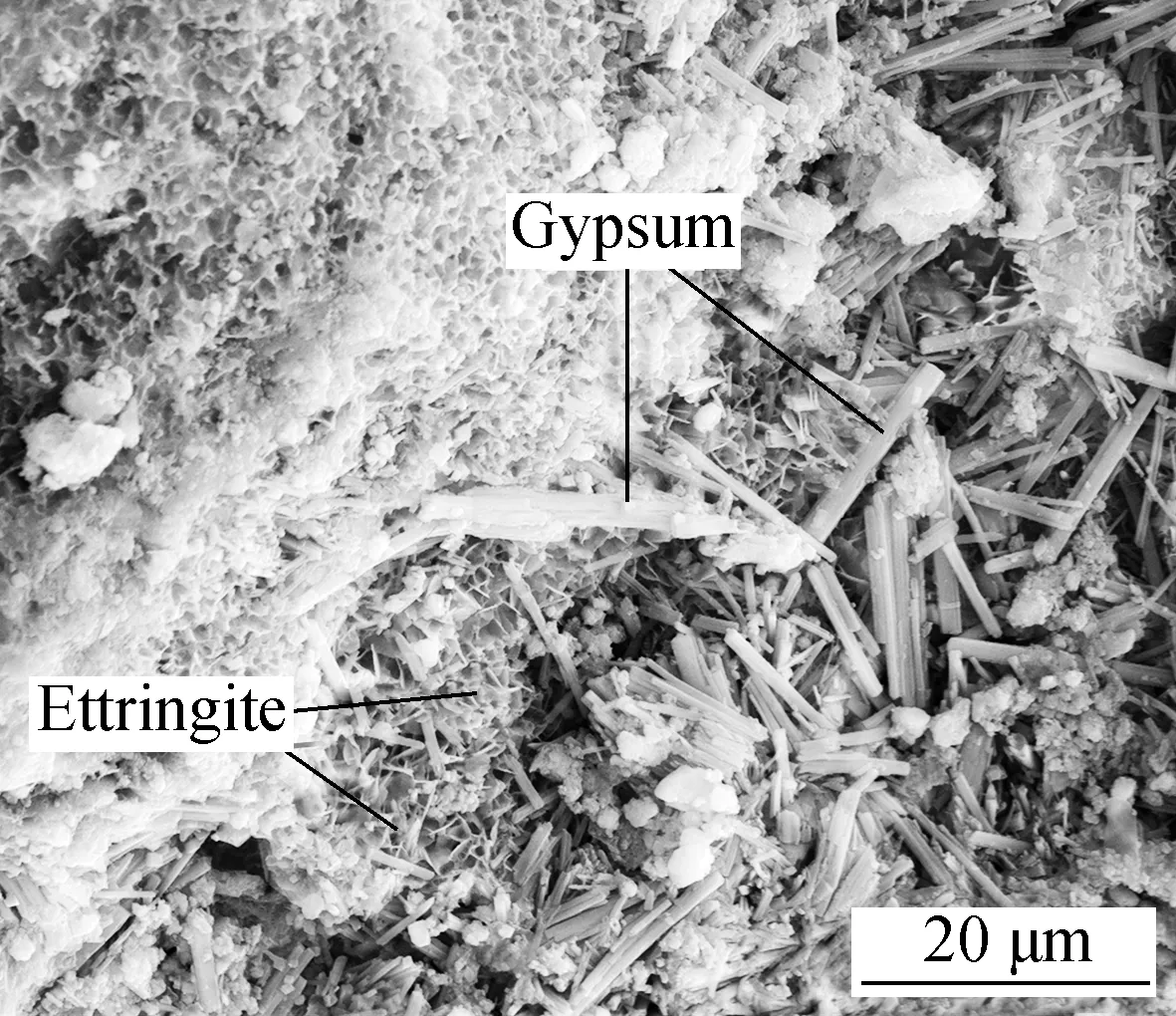

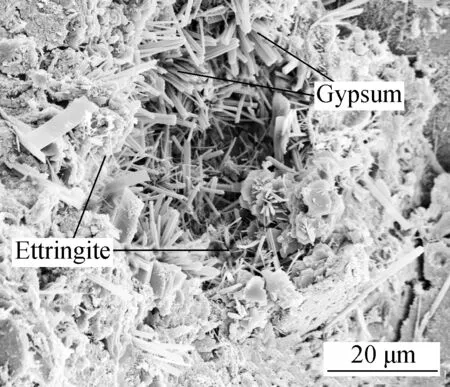

2.4 Environmental scanning electron microscope (ESEM)

(a)

(b)

(c) Fig.6 ESEM images of RAC under different stress ratios after 270 d immersion. (a) Stress ratio is 0; (b) Stress ratio is 0.3; (c) Stress ratio is 0.5

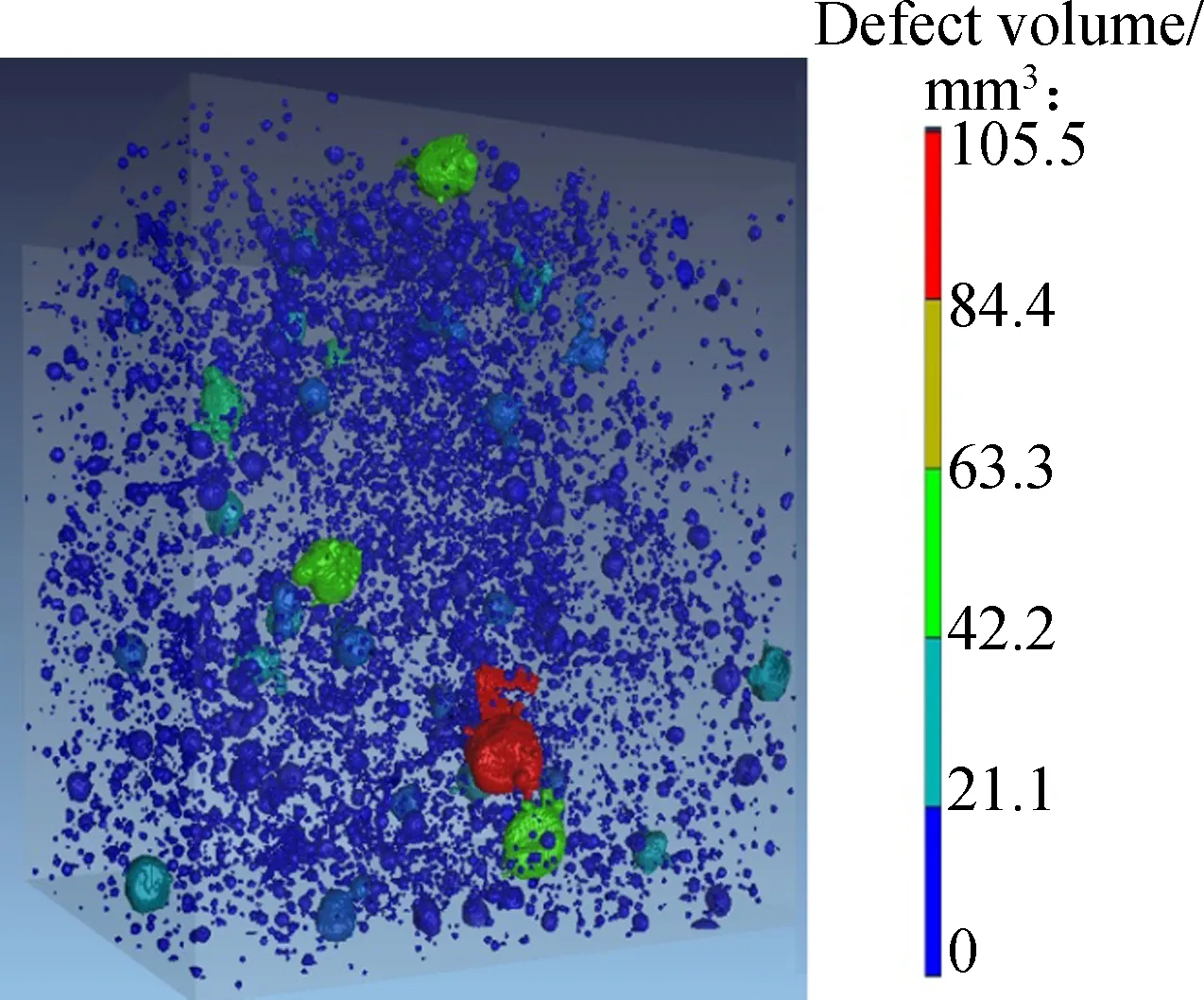

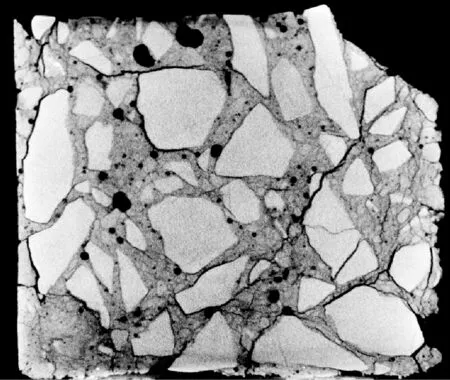

2.5 X-ray computed tomography (X-CT)

X-CT was used to analyze the distribution of pores and cracks of RAC. After 270 d sulfate attack, the middle part of the experimental specimen (70 mm×70 mm×70 mm) was cut out to be used as X-CT samples. The 3D stereograms and 2D slice diagrams of RAC under different stress ratios are shown in Fig.7. The specimen in Figs.7 (a) and (b) is RAC without flexural loading.It can be observed that the damage of RAC under sulfate attack and wetting-drying cycles is concentrated on the surface of the specimen, and a small number of cracks can be found in the interior of RAC.The cracks of RAC without loading are mainly caused by the salt crystallization and the formation of expansive corrosion products.Figs.7 (c) to (f) reveal that the number of cracks of RAC rises obviously with the increase of stress ratio. In particular, more cracks are found inside the specimen when the stress ratio is 0.5. Therefore, when the flexural loading is applied on RAC, the degradation of RAC is not only caused by the salt crystallization and the formation of expansive corrosion products, the flexural loading can also accelerate the expansion of microcracks generated by corrosion, and this effect will be more pronounced with the increase of corrosion time. Hence, flexural loading can accelerate the degradation progress of RAC under a sulfate attack and wetting-drying cycles.

(a)

(d)

3 Conclusions

1) The degradation progress of RAC under sulfate attack and wetting-drying cycles can be divided into three stages: The initial damage stage caused by wetting-drying cycles, the increasing and accelerated decreasing stages caused by expansive products generated by sulfate attack.

3) The main corrosion products of RAC subjected to sulfate attack under drying-wetting cycles and flexural loading are gypsum and ettringite. The flexural loading can accelerate the generation of corrosion products.

杂志排行

Journal of Southeast University(English Edition)的其它文章

- Influence of image data set noise on classification with a convolutional network

- A low-cost personal navigation unit

- Flexural behavior of steel reinforced engineered cementitious composite beams

- Compact passing algorithm for signalized intersection management based on vehicular network

- Analysis of conflict factors between pedestrians and right-turning vehicles at signalized intersections

- Effect of contract choice on upstream carbon emission reduction considering carbon taxation