Dynamic rupture of metal sheet subjected to laser irradiation and tangential subsonic airflow

2018-09-19XiodongXingTeRuixingWngChenyuCoHongweiSongChengungHung

Xiodong Xing, Te M,b, Ruixing Wng, Chenyu Co,b, Hongwei Song,*, Chengung Hung

a Harbin Engineering University, Harbin 150000, China

b Key Laboratory for Mechanics in Fluid-Solid Coupling Systems, Institute of Mechanics, Chinese Academy of Sciences, Beijing 100190, China

c School of Engineering Science, University of Chinese Academy of Sciences, Beijing 100049, China

Keywords:Thermal-fluid-structure coupling Thermal elastoplastic Aerodynamic pressure Laser damage Dynamic rupture

ABSTRACT To reproduce the premature rupture process of metal sheet subjected to laser irradiation with subsonic airflow, which is an interesting phenomenon observed in the experiments given by Lawrence Livermore National Laboratory, a coupled numerical model considering the interaction and evolution of metal elastoplastic deformation and aerodynamic pressure profile is presented.With the thermal elastoplastic constitutive relationship and failure criterion, the simulated failure modes and dynamic rupture process are basically consistent with the experimental results,indicating plastic flow and multiple fracturing is the main failure mechanism. Compared with the case of non-airflow, subsonic airflow not only accelerates deformation, but also turns the bugle deformation, plastic strain and rupture mode into asymmetric.

The presence of tangential airflow may significantly change the behavior of laser interaction with materials due to the effects of shear force, oxygen supply and forced convection [1-9]. For instance, the airflow may blow away the melted metal or pyrolytical products, enhance the oxidation or combustion process, resulting in an accelerated ablation rate and a reduced burnthrough time. Recently a new effect due to airflow observed by Lawrence Livermore National Laboratory has drawn much attention [10]. When high power laser irradiated a thin aluminum sheet subjected to subsonic airflow, the target ruptures at the temperature well below the melting point. This result is different from the melting damage under a non-airflow condition. They summarized this is due to the aerodynamic effect: airflow decreases the pressure on the side of the incident beam by. They further gave a quantitative analysis of the bulge deformation due to the combining effects of material softening and pressure difference, based on an elastic model[10].

However, the essence of this case is a complex physical process including elastic bulging, plastic flow, and multiple fracturing. The elastic model can reasonably predict the bulge deformation profile, however it is not enough to capture the complete physical mechanism. Up to now no relevant work has been reported to reproduce this dynamic rupture process through a rigorous model. To reach this goal, two important steps are adopted in our case. Firstly, a coupled thermal-fluid -structure model considering the interaction of laser source, thin aluminum sheet and subsonic tangential airflow should be built [11-14]. The coupling thermal/mechanical loads induced by laser source and aerodynamic pressure decrease should be exerted to the thin target, and the influence of the thin target deformation to the airflow pattern and aerodynamic pressure should be recalculated before next time-step exertion. Similar approach has been reported by Huang et al. [15] and Song and Huang [16], when they investigated the influence of supersonic airflow on the development of laser ablation pit. Secondly, to verify that plastic flow and multiple fracturing is the main damage mechanism, a thermal elastoplastic constitutive relationship [17, 18] and failure criterion should be incorporated in the numerical model.

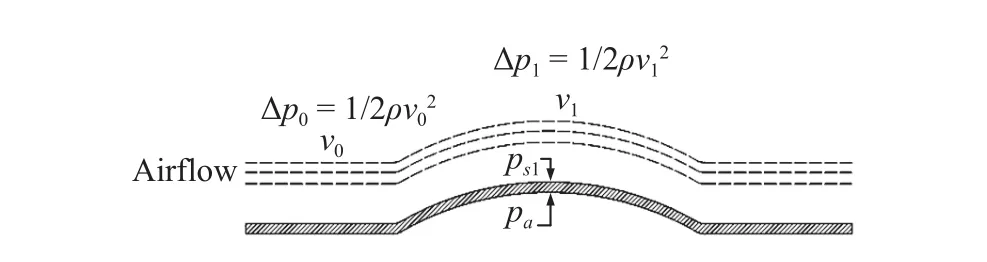

In the experiment, the pulsed solid-state laser equivalent to a continuous wave (CW) laser with an average power of 25 kW is employed. The size of laser beam is 0.13×0.13 m2, and the aluminum plate target is 0.4×0.4×0.0018 m3. On the laser irradiation side, tangential airflow with a constant velocity of 100 m/s is produced by the blowing device and the suction device. According to Bernoulli's law, the wind stream produces a pressure decrease near the airflow surface of aluminum sheet by, wherevis local airflow velocity,is gas density, where pais atmospheric pressure, psis surface pressure.In the light of Fig. 1, the pressure difference is not constant across the target. In the center of laser beam, the bulge deformation and airflow velocity v1are the highest, therefore the aerodynamic pressure decreaseis the largest. The instantaneous local deformation, airflow velocity and pressure difference at moments before rupture initiation are coupled together, and should be determined by the coupled numerical model.

Fig. 1. Physical model of local deformation, airflow velocity and pressure difference.

The bugle deformation and dynamic rupture behavior are simulated by finite element analysis (FEA) with an Abaqus code,and the airflow characteristics and aerodynamic effects are simulated computation fluid dynamics (CFD) with a Fluent code. In the coupled fluid-structure analysis, the CFD transfers instantaneous pressure decrease produced by tangential airflow to the FEA through the controlling interface, and the FEA transfers the instantaneous target deformation morphology to CFD. The staggered iteration and data exchange continues until element crack initiation in the FEA.

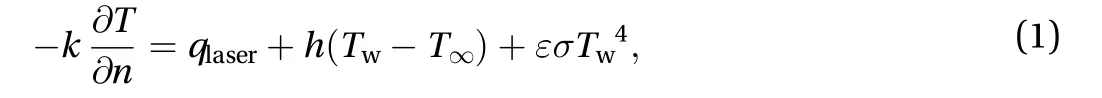

In the FEA, the essence of the target failure process is thermal elastoplastic deformation and dynamic rupture, which is related to the problems of heat transfer, physical non-linearity and geometrical non-linearity. Thermal boundary condition in the laser irradiation region is

where k is thermal conductivity,is temperature gradient,qlaseris the absorbed laser heat flux, h is convective heat transfer coefficient,is the surface wall temperature,is environment temperature,is emissivity,is Stefan-Boltzmann constant. The heat flux due to the forced convection and thermal radiation is negligible compared to heat flux of laser source (104W/m2vs. 106W/m2). The laser absorption coefficient 0.75 is adopted.

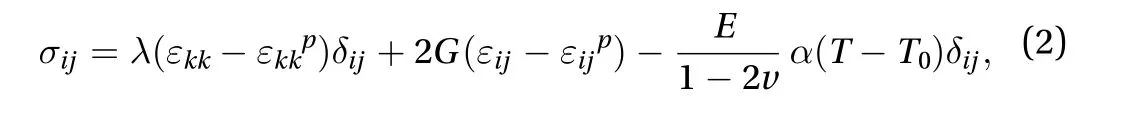

The effect of thermal softening on the mechanical strength of materials should be considered. Elastoplastic constitutive model of material is employed

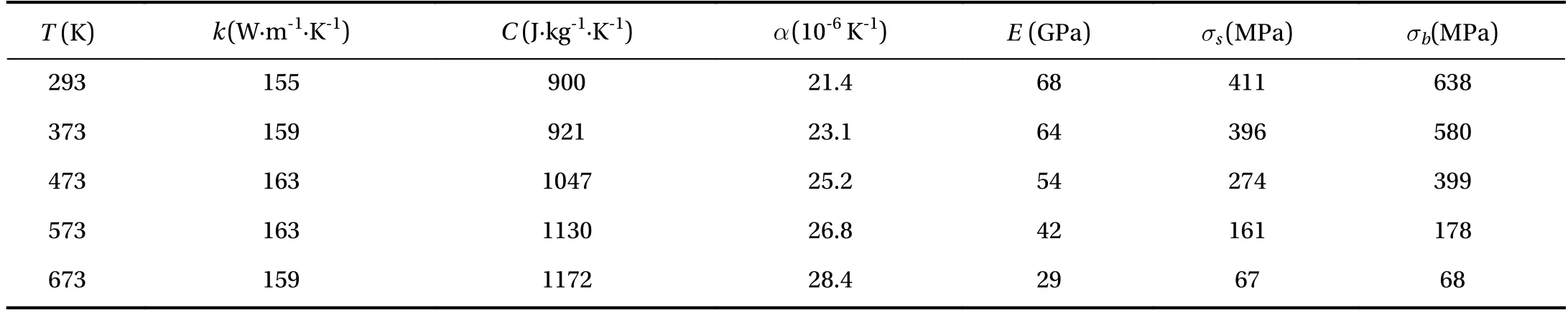

where λ and G are Lame constants, which can be obtained by Young's modulus and Poisson's ratio, E is Young's modulus, v is Poisson's ratio, α is coefficient of linear expansion, εijpis plastic strain tensor,T0is initial temperature. In the analysis the bilinear isotropic hardening model is employed. The thermal properties of the target material are listed in Table 1, whereTis temperature,Cis specific heat capacity,is yield strength,is tensile strength. And the failure mode of the target is simulated by element damage failure method, and the failure criterion is the maximum equivalent plastic strain.

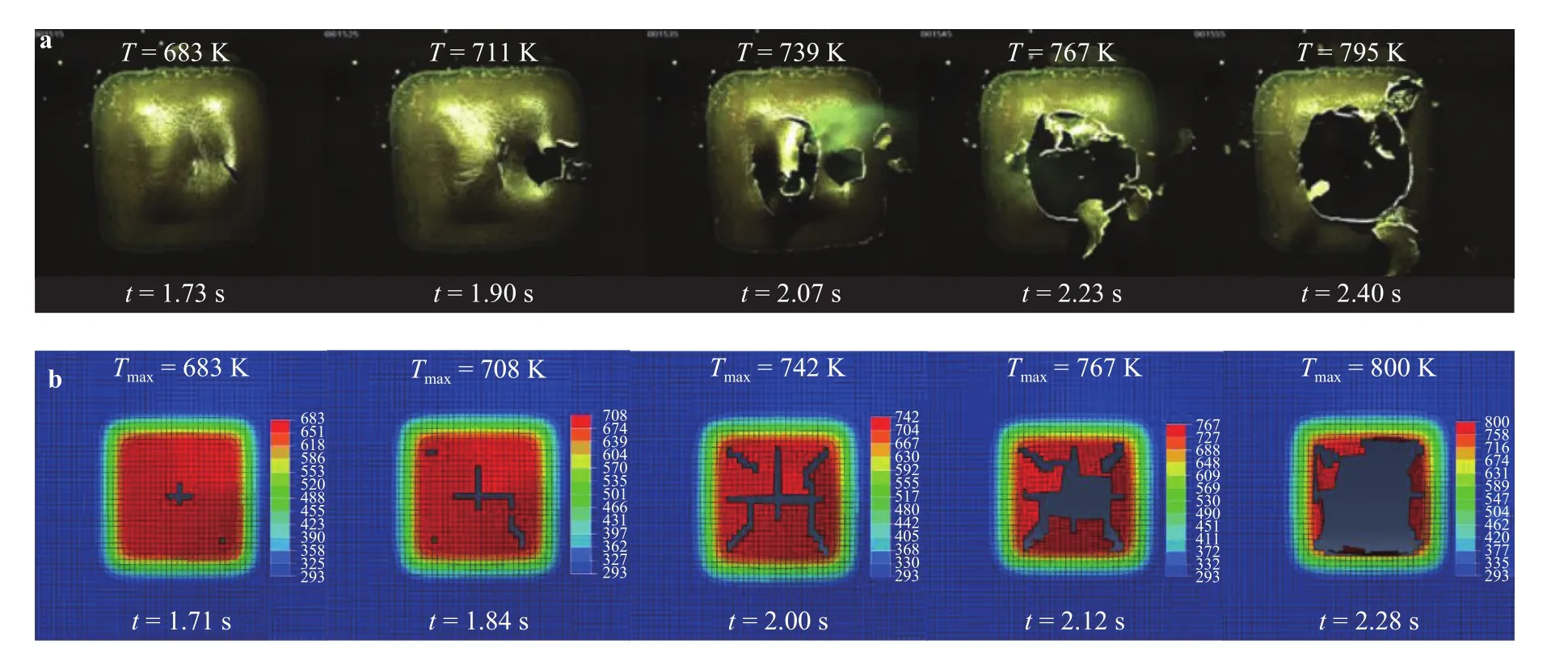

Figure 2 gives the comparison of dynamic rupture process between experimental and numerical results. The figure includes information of rupture mode, maximum temperature and time sequence. It can be seen that the numerical model basically reproduced this premature failure process before melting point. The rupture process last from 1.71 s to 2.28 s with the maximum temperature ranging from 683 K to 800 K in the numerical simulation, where it is from 1.73 s to 2.40 s with the maximum temperature from 683 K to 795 K in the experiment. At about 1.7 s, multiple cracks initiated. Under the combined effects of thermal softening and aerodynamic pressure, multiple local plastic strains reached the failure value in the thin aluminum sheet. The numerical modeling confirms that the main failure mechanism is plastic flow and fracture. As cracks propagation and convergence, multiple debris formed and removed from the target, leaving a hole in the laser irradiated area. The numerically simulated fracture mechanism and final damage morphology is resemble to that of experiment, as can be found in Figs. 2 and 4 in Ref. [10].

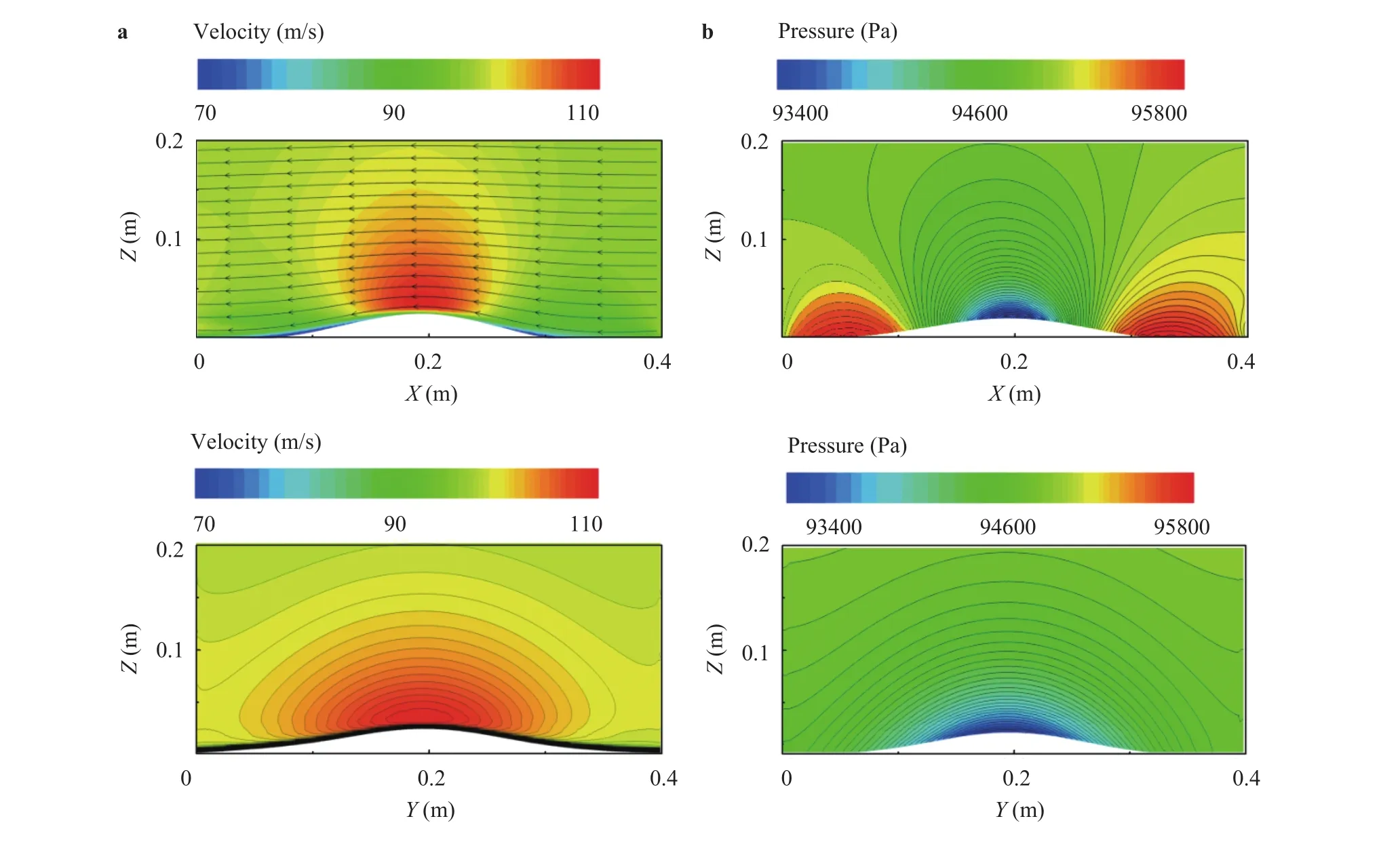

In order to give a detailed description of the effect of tangential airflow on the target, we give the characteristics of the airflow att=1.7 s, which is the moment right before rupture crack initiation, as illustrated in Fig. 3. According to Fig. 3(a), when the airflow passes through the bugled aluminum sheet, the velocity increases in the convex ridge of the bulge to a maximum value of 115 m/s, whereas it decreases at the foot of the bugle to a minim-um value of 70 m/s in the airflow direction (top figure).However, velocity profile in the cross-section of airflow demonstrate only high values, typically larger than initial airflow velocity of 100 m/s (bottom figure). This results in different pressure profiles when viewing from two cross-sections. As can be seen from Fig. 3(b), the dimension of the low pressure region in the airflow direction is smaller than the laser irradiation region (top figure), whereas it is slightly larger than laser spot in the crosssection of airflow (bottom figure). This is the reason why most cracks propagate perpendicular to the airflow direction, as can be found in the first three frames both of the experiment and numerical simulation in Fig. 2. According to the above results, we can better grasp the failure process of aluminum sheet. The first crack appears near the center of the target, then multiple cracks are initiated and propagate along the direction perpendicular to airflow, due to the asymmetric pressure distribution.

Table 1 Thermal-mechanical parameters of aluminum alloy versus temperature

Fig. 2. Comparison of dynamic rupture process. a Experiment [10]. b Numerical simulation.

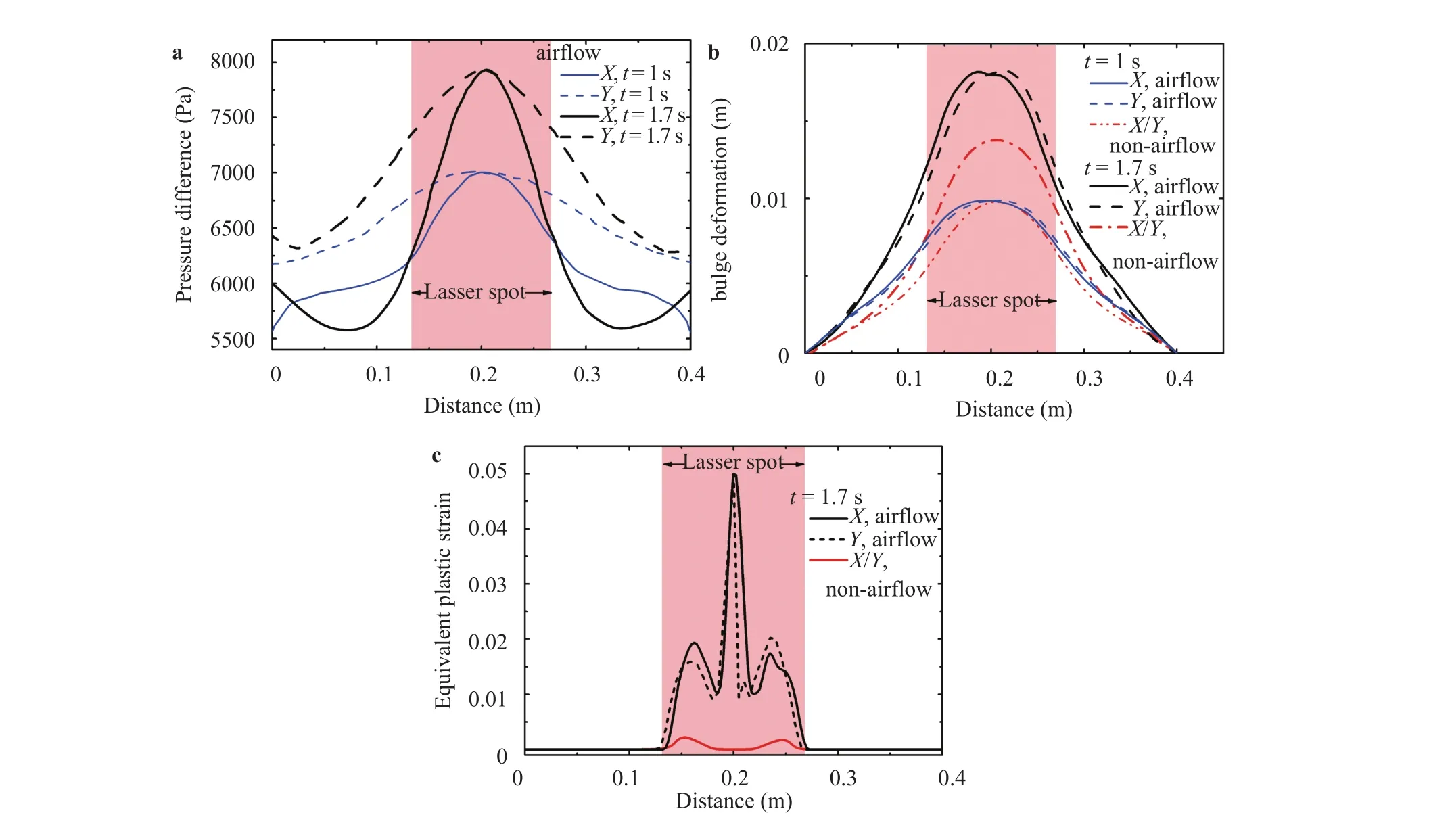

We have also simulated the case of laser irradiation without airflow. Comparison of deformation and equivalent plastic strain on the transverse and longitudinal lines at the center of the laser spot for the cases with airflow and without airflow is shown in Fig. 4. This figure also includes information of aerodynamic pressure evolution and bulge deformation evolution with irradi-ation time, see Fig. 4(a) and 4(b). In the early stage of laser irradiation, the tangential airflow has little influence on the deformation of the target since the temperature is relatively low, e.g., 1 s in Fig. 4(b). When the aluminum sheet is heated up to 650 K,thermal softening effect becomes dominant and the strength nearly vanishes. Meanwhile, with the increase of bugle deformation, the local airflow velocity near the sheet surface accelerates,resulting an increase of aerodynamic pressure difference. At the 1.7 s moment, the largest deformation is 0.0183 m and 0.0137 m for airflow condition and non-airflow condition, respectively. In contrast, the largest deformation given by elastic model is 0.0153 m [10], which is about 16.4% error from the elastoplastic model and coupling analysis. Meanwhile, in the case of non-airflow the deformation field is symmetric, whereas the aerodynamic force breaks this symmetry. In Fig. 4(c), the equivalent plastic strain in an airflow case shows a main peak at the center of the laser spot, so the first crack typically appears here. It also has two sub-peak areas, which can explain the multiple cracks formed around the center in the subsequent time step. In a nonairflow case, the equivalent plastic strain is very low. At the 1.7 s moment, the target is far from the fracture condition, and it will fail in the form of melting later on.

Fig. 4. The effect of airflow on target (X is along airflow view, Y is cross-section view of airflow). a Aerodynamic pressure difference. b Deforma-

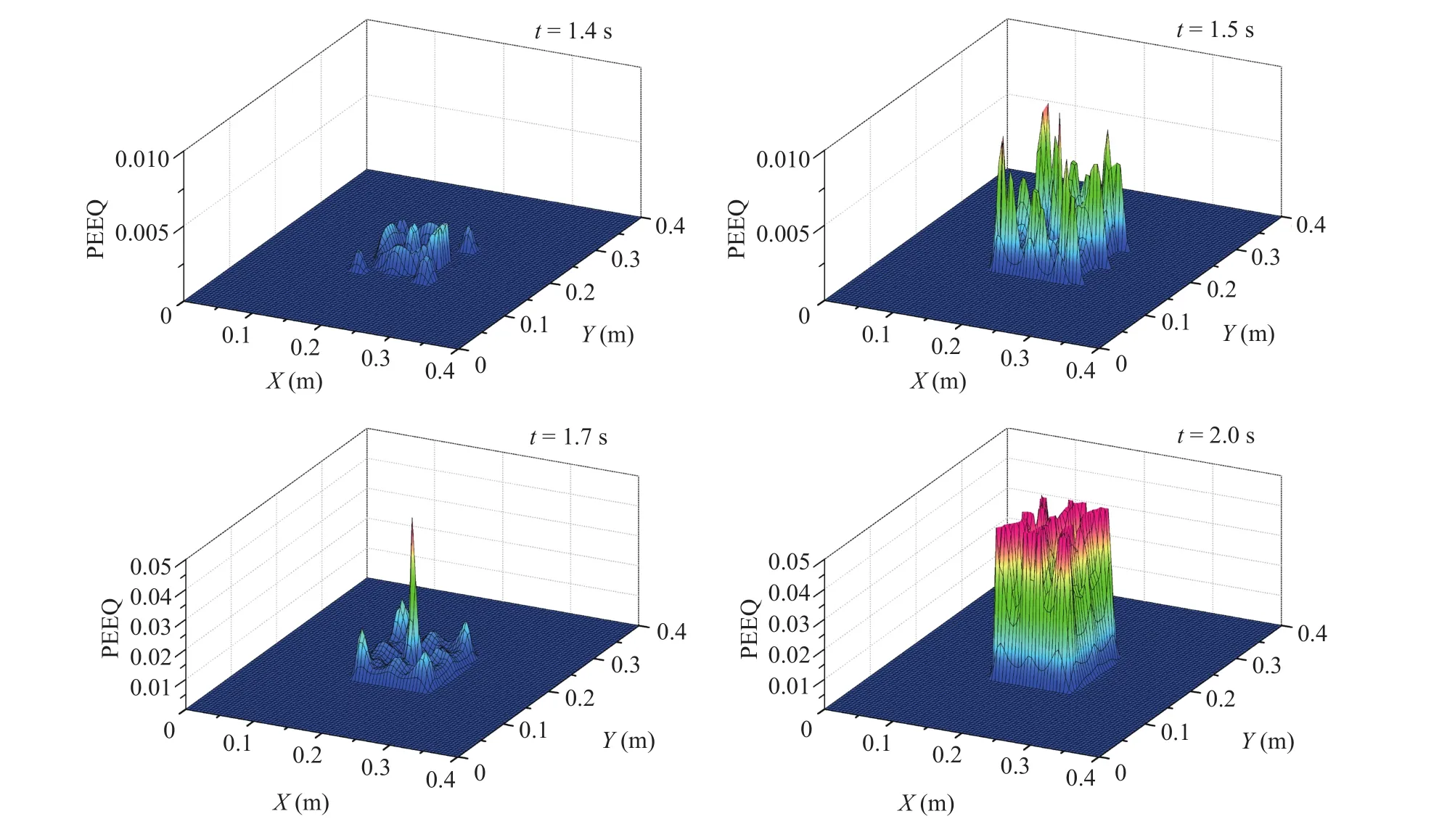

Fig. 5. Evolution of equivalent plastic strain (PEEQ).

Figure 5 gives the evolution of equivalent plastic strain from 1.4 s to 2.0 s. The plastic strain increased significantly during this period, mainly due the rapid increase in target temperature. The temperature at 1.4 s is 616 K, where as at 1.7 s is 681 K. According to Table 1, the elastic modulus drops from 42 GPa to 29 GPa when temperature rise from 573 K to 673 K. The coupled effects of material softening, bugle deformation and aerodynamic pressure lead to a rapid failure in this period.

In summary, we have proposed a coupled thermal-fluidstructure model include thermal elastoplastic constitutive relationship to investigate the coupled deformation and dynamic failure process of laser irradiated metal sheet under the tangential subsonic airflow. The behavior of target rupture at the temperature well below the melting point induced by the thermal softening and aerodynamic pressure decrease is reproduced,and the mechanisms of multiple cracks initiation is revealed. It is found that plastic flow and multiple fracturing is the main failure mechanism, and the nonlinear elastoplastic constitutive relationship of the material must be considered. The coupled analysis with thermal elastoplastic bugle deformation is 16.4% larger in comparison with the decoupled elastic model. Compared with the case of non-airflow, subsonic airflow enlarges the bugle deformation from 0.0137 m to 0.0183 m, which is about 33.6% increase. Meanwhile, it turns the bugle deformation, plastic strain and rupture mode into asymmetric.

Acknowledgements

This research is supported by the National Natural Science Foundation of China (11472276, 11332011, and 11502268) and the National Defense Basic Scientific Research Program of China(JCKY2016130B009).

杂志排行

Theoretical & Applied Mechanics Letters的其它文章

- Estimation of the effective properties of two-dimensional cellular materials:a review

- A data-based CR-FPK method for nonlinear structural dynamic systems

- Collinear micro-shear-bands model for grain-size and precipitate-size effects on the yield strength

- On the interaction between bubbles and the free surface with high density ratio 3D lattice Boltzmann method

- Principal and internal resonance of rectangular conductive thin plate in transverse magnetic field

- Piezoelectric energy harvesting from flexible delta wings