Dependence on forming parameters of an integral panel during the electromagnetic incremental forming process

2018-07-24JinqiangTANMeiZHANHongweiLI

Jinqiang TAN,Mei ZHAN,Hongwei LI

State Key Laboratory of Solidification Process,School of Materials Science&Engineering,Northwestern Polytechnical University,Xi’an 710072,China

KEYWORDS Electromagnetic incremental forming(EMIF);Forming uniformity;Integral panel;Parameters;Shape deviation

Abstract Nowadays,more and more attentions are paid to electromagnetic incremental forming(EMIF),especially for a part with a large-scale size,e.g.,an integral panel with stiffened ribs.In this work,the bending of a panel into a double-curvature profile via EMIF is carried out experimentally and evaluated by comparing the formed profile with the desired profile.During the process,discharges at four positions along different discharge paths are designed.The effects of forming parameters on the die-fittingness of the workpiece are discussed,for which two evaluation indices are used to judge forming results.The results show that a discharge voltage in an incremental mode is helpful to improve thefittingness and avoid the collision rebound against the die at the same time.Discharging at the diagonal positions with the ‘X” discharge path exhibits the minimal shape deviation and the best forming uniformity.On the contrary,discharging at the parallel positions with the ‘Z”discharge path obtains the worst forming quality.Overlap of the coil at different positions should be given during EMIF;however,a lower overlap rate of the coil helps improve the forming quality.The results obtained in this work are useful for forming integral panels with stiffened ribs via the EMIF process.

1.Introduction

Integral panels,with high-stiffener having advantages of light weight,high stiffness,and high structural efficiency,have become important structural bearings and widely used in aircraft.However,because of their large sizes,net reinforced structures and structural stiffness,and requirements of good shape precision,the manufacture of integral panels has a high demand.1The conventional plastic forming methods for integral panels contain shot peen forming,2creep age forming,3press-bending,4roll forming,etc.Some successful examples and applications have been introduced in the ‘Integral Airframe Structures(IAS)”program.5However,due to the existence ofstiffened ribs,there are many difficulties in processing compared to flat plate forming,and limitations can also be enumerated.Garie´py et al.6pointed out that for shot peen forming,the process needs complex designs mainly based on experience,and sometimes additional prestress is necessary.According to Zhan et al.,7creep age forming is limited to certain materials or occasions,and excessive time is spent in the process time including subsequent springback calibration.Since punch forces are applied directly on ribs,mentioned by Yan et al.,8instability and springback phenomena become the main problems during the brake forming process.In a word,the problems in the traditional forming methods of integral panels prompt researchers to explore novel forming technologies.

Electromagnetic forming(EMF)is an impulse or highspeed forming process using a pulsed magnetic field to apply Lorentz forces to workpieces preferably made of a highly electrically conductive material.Psyk et al.9reviewed that the formability limit can be increased and the production cycle can be shortened due to its high forming velocity.However,considering the large sizes of some parts,traditional EMF is difficult to apply directly because of the limited action scope and the depth of the magnetic field force from the coil with a fixed position.Therefore,some new methods have been proposed to overcome these difficulties.Kamal and Daehn10combined EMF and stamping via drawing to form a sheet with local features successfully.Lai et al.11utilized a large coil,of which the diameter is 860 mm,to form a large-scale sheet with a diameter of 1378 mm successfully.However,a large coil at a f i xed position was still adopted,and it is difficult to form parts with complex structures directly.

In order to deal with the above challenges for large or complex parts,the idea of incremental forming was introduced by some researchers.Cui et al.12proposed an incremental forming method during EMF,called electromagnetic incremental forming(EMIF),to form large-scale sheets.In EMIF,a workpiece accumulates into the desired profile andfits well with the die gradually from one position to the adjacent via a small coil with small discharge energy moving and rotating along some certain paths in the space according to the requirement.In their study,comparing with traditional EMF,EMIF introduces some new forming parameters,such as discharge position,discharge pass,discharge path,coil overlap rate,etc.,which result in complex coupling effects.Therefore,EMIF is a more complicated process than traditional EMF.At present,only a few researchers have conducted studies on EMIF.Zhao et al.13analyzed the forming uniformity under different coil overlap rates and different loading paths during the electromagnetic incremental bulging process of tubes.The results of their study showed that the higher the coil overlap rate,the better the forming uniformity,whereas the lower forming ef ficiency.Cui et al.14analyzed the effects of coil moving path,discharge pass,and other discharge parameters on electromagnetic incremental deep drawing of sheet metals.They reported that sheet components with goodfittingness to the die were obtained by adopting reasonable process parameters.Xiong et al.15realized large-scale sheet forming via moving a coil along the axial direction.Tan et al.16investigated the EMIF process of several integral panels with different distributions of ribs.They established an FE model for the panels during the EMIF process,and discussed the distribution of electromagnetic force,the evolvement rule of velocity and height of the panels with different rib arrangements,as well as a comparison of forming quality between the panels obtained by brake forming and EMIF.

The characteristics of large sizes,high ribs,high structural rigidity,and complex and staggered high ribs grid structures of integral panels lead to that the effects of forming parameters in EMIF are different from those of pipes and metal sheets.Therefore,it is vital to study the influences of parameters in the EMIF process for designing an optimized forming scheme to obtain the ideal profile of an integral panel.This paper studies the effects of forming parameters,such as discharge parameters,geometric parameter,and discharge path on thediefi ttingness of the workpiece to the die during EMIF,and the shape deviation and the forming uniformity are also evaluated.

2.Experimental arrangement

2.1.Experimental setup

The aim of utilizing EMIF in this study is to realize the bending of a semi-finished integrally stiffened panel(by milling on a plate to a thin web with several ribs)to thefinial profile with double curvatures in two directions.The experimental installation for the integral panel is designed by Zhan et al.17and shown in Fig.1.In order to facilitate the movement of the coil in the EMIF process,it is fixed between two support trays and bolted to a platen,where the platen is pressed by a hydraulic machine and can move horizontally on the blank holders to realize the incremental movement.The distance between the coil and the blank is adjusted through changing the height of the pads set between the platen and the coil.Fig.2 shows the schematic of the forming process.

In this study,the material used in the EMIF experiments of the integral panels(Fig.2)is 2A12-T4 aluminum alloy.18The web thickness and rib width of all the blanks are both 2 mm.A f l at spiral coil is adopted,in which a copper wire,with a section area of 4 mm×2 mm,is filled of resin with the roles of insulation and reinforcement.The wire is twined to three layers,and each layer has 10 winding turns wire.The inner radius is 7 mm and the gap between two adjacent layers is 0.4 mm.Two paths along theXandYaxes are defined to observe forming displacements,which will be discussed in Section 3.In the EMIF experiments,four discharge positions are designed,as shown in Fig.2.A die with double curvatures is used in the EMIF process,as shown in Fig.3.

Fig.1 Installation schematic diagram of EMIF.

Fig.2 Schematic of the EMIF process principle.

Fig.3 Schematic diagram of the die.

2.2.Experimental procedures

In this study,the effects of process parameters,such as discharge voltage,discharge capacitance,ratio of rib-height to web-thickness,discharge path,and overlap rate of the coil,are obtained via the experimental setup described in the above section.

Fig.4 Diagram of four discharge positions.

Considering the action area of the electromagnetic forces and the sizes of the panel,four discharge positions with a rectangular distribution are designed,as shown in Fig.4,where 1,2,3,and 4 are discharge positions.Therefore,there are three different discharge paths,the ‘X” discharge path(the order of discharged at the diagonal position),the ‘U” discharge path(the order of discharged along the circumference)and the ‘Z”discharge path(the order of discharged at parallel positions),as shown in Fig.5.The discharge capacitance of the experiments is 160 μF,and the discharge paths and the position coordinates are shown in Tables 1 and 2,respectively.

Generally,the curvature radii of the integral panels are very large,which means that the forming depths are shallow.Therefore,there is only one single discharge for each position in this study.

2.3.Quantitative characterization methods

To provide a good evaluation of the forming precision of the panel,the formed profiles along two paths(Fig.2)are observed,and two evaluation indices of feature points in the formed profile(intersection points of the marked lines on the surface without ribs),including the shape deviation(the diefi ttingness gap)to the expected profile and the forming uniformity,are proposed.

The shape deviation of the panel is evaluated by the root mean square error(RMSE),i.e.,

wherefmea,iis the measured value of the forming depth at feature pointi(i=1,2,...,n)along path X or path Y,nthe number of feature points,andfdes,ithe desired value of the forming depth at pointi,i.e.,the depth of the die corresponding to the feature point(Fig.6(a)).Fig.6(b)shows the measured data of these two indices,whereRmea,iandRavehave an identical curvature center with the desired profile(R).

The forming uniformity degree of the panel is represented by the standard deviation of the shape deviation SD,i.e.,

whereRmea,iis the measured distance between feature pointi(i=1,2,...,n)on the experimental panel and the curvature center of the die along path X or path Y,nthe number of feature points,andRavethe average value ofRmea,i.

3.Results and discussion

The effects of five parameters,two electromagnetic parameters(discharge voltage and discharge capacitance),one geometric parameter(ratio of rib-height to web-thickness),and two positional parameters(discharge path and overlap rate of the coil)on the forming displacement in theZdirection are studied.The die-fittingness of the panels to the die and the forming uniformity are evaluated.

3.1.Effect of discharge voltage

The discharge voltage is one of the most important parameters in the EMF process,and it is useful to improve the formability due to increased discharge energy(Psyk et al.9;Cui et al.12).The effect of discharge voltage for the workpiece on the diefi ttingness under the same capacitance(C=320 μF)and the same ratio of rib-height to web-thickness(5:1)is studied.The ‘X” discharge path is chosen for the four discharges,and the voltages at different positions are listed in Table 3.The discharge sequences and two paths defined to measure the profiles are shown in Fig.7(a).From Fig.7(b),the profile along path X indicates that the formed profile is uneven,and the largest forming depths occur in the region near the free edge along the negative direction of theXaxis,because the initial discharge voltage is lower than those of the subsequent three discharges.The incremental voltages in the second and third discharges enhance the formability.Since the workpiece has no contact with the die in the deformation region in the first set of experiments,a higher initial voltage is adopted in the subsequent experiments.It can be found in Fig.7(c)that the forming depths under higher initial voltages in the rest two sets of experiments get worse,especially in the third set of experiments.The reason is that a higher voltage makes the workpiece undergoes collision rebound,as shown in Fig.7(d).profile curves in Fig.7(b)and(c)show that the uniformity and forming depth are improved with a lower initial discharge.From Fig.7,the largest forming depth is mainly determined by the subsequent three discharges.The error analysis in Fig.8 shows that the shape deviation(RMSE)increases with the voltage groups,and the forming uniformity in the first group is the best,followed by the third,and the worst in the second group.

Fig.5 Schematic diagrams of three discharge path modes.

Table 1 Detailed discharge paths in EMIF experiments.

Table 2 Discharge positions in EMIF experiments.

Fig.6 Distribution graph of feature points and measured data in RMSE and SD for the formed profile.

Table 3 Different discharge voltage groups along discharge path 1→4→3→2.

Since the die used in this study is useful to expel the air,the problem occurred in the study of Cui et al.14can be neglected,where vent holes are necessary for a conical die with a flat bottom,and it is hard to improve the forming depth by increasing the voltage due to the resistance of high-speed compressed air.Thus,as shown in Fig.7,it is possible to obtain good forming quality via selecting suitable voltage groups for the four discharge positions.In addition,the uniformity of the forming depth in Fig.7(b)is lower than that in Fig.7(c),and the distance between two adjacent positions along path Y is larger than that along path X,which indicates that the discharge voltage must also be designed carefully.

3.2.Effect of discharge capacitance

The effect of the discharge capacitance with the same discharge energy at each position is studied,and the conditions are shown in Table 4.The same ratio of rib-height to webthickness(2:1)and discharge path(the ‘X” path)are used.Fig.9 shows the final profiles at different discharge capacitances along path X and path Y.It can be observed from Fig.9(a)that under the same discharge energy,the profile curves express different results.The workpiece shows a similar f i ttingness for capacitances equal to 80 μF and 160 μF,and a goodfit occurs in the region near the free end in the positive direction of theXaxis.However,the forming depth for a capacitance of 320 μF expresses an opposite phenomenon,where the largest depth is distributed in the region of the negative direction of theXaxis,and the die-fittingness ofC=320 μF is worse than those of the other two conditions.Fig.9(b)also shows that similar depth distributions and better f i t abilities for the two smaller capacitances.The shape deviation and forming uniformity of the surface profile in Fig.10 also indicate that largest errors come from the condition whenC=320 μF,and the obtained best shape deviation and forming uniformity are fromC=80 μF andC=160 μF,respectively.It is found that a lower capacitance and higher voltages are useful to improve the forming quality.

The discharge capacitance is relative to the frequency of the discharge current and the skin depth,9and thus,it is necessary to select a reasonable capacitance in this study.Although the discharge energy is the same for each position of the three capacitances,the skin depth of the induced eddy is proportional to the capacitance;therefore,a larger capacitance increases the skin depth.In this study,the thickness of the web is 2 mm,and the skin depths for the three capacitances from small to large are about 1.73 mm,2.06 mm,and 2.45 mm,respectively.A skin depth near the thickness of the web means a higher energy efficiency.Therefore,from an economic standpoint,the capacitance should be set to 80 μF or 160 μF in this study.It can be found that the forming depths along the two paths are very close atC=80 μF andC=160 μF,and the worst forming depth is obtained atC=320 μF;therefore,the intermediate value of the capacitanceC=160 μF may be the most suitable option because the forming quality in this condition requires lower voltages.The study of the effect of discharge capacitance on forming of an integral panel is similar to that by Guo et al.,19where a panel was expected to be formed to a profile with a single curvature with three discharge positions.

3.3.Effect of ratio of rib-height to web-thickness

Obviously,the geometric stiffness of the workpiece is largely influenced by the geometric sizes of the panel,such as the height of the rib and the thickness of the web,especially the rib.In addition,the simulation research by Tan et al.16showed that there are electromagnetic forces on the rib and the web at the same time,and the largest forces on the rib are higher than those on the web.Therefore,it is important to discuss the effect of these sizes.Here,the ratio of rib-height to webthickness is selected as an observed variant.The consistency conditions for the experiments are the same capacitance(C=320 μF),discharge path(the ‘X”discharge path),the distance(6 mm)between the coil and the top of the rib,and discharge voltages of 4.5 kV,5 kV,6 kV,and 5.5 kV for positions 1,2,3,and 4,respectively.Considering an increased rib-height,the deformation for the workpiece becomes much more dif ficult.Therefore,the forming depth in Fig.11 shows inverse proportional to the rib-height generally for both of the two observed paths.Lei et al.20suggested that normal electromagnetic forces increase linearly on the ribs,and approximately remain unchanged on the web with an increase of the ribheight when discharging in the center of the integral panel once.That means the drive of deformation for the integral panel changes from the electromagnetic forces on the web at lower ribs to the electromagnetic forces on the ribs at higher ribs;however,the increased rib-height in turn results in greater deformation resistance and smaller electromagnetic forces on the web.

The shape deviation and forming uniformity in Fig.12 both show that the forming quality gets worse at a high ratio of ribheight to web-thickness.The best results are obtained when the ratio equals to 3:1,not 2:1,which can be explained by that there occurs collision rebound when the ratio equals to 2:1 under the conditions in this study.

Although the distance between the rib and the coil is identical among all the five ratios,the electromagnetic forces under the five conditions are different.The forming quality generally gets worse at high ratios,excepth/t=4:1,and this reduction of the forming depth is not linear.Therefore,varied suitable discharge conditions such as voltage groups also need to be devised according to the ratio.Considering the exception of a ratio ofh/t=4:1,it may be because the change of the geometric stiffness is nonlinear with an increase of the ratio.

3.4.Effect of discharge path

Fig.7 Results at different discharge voltage combinations.

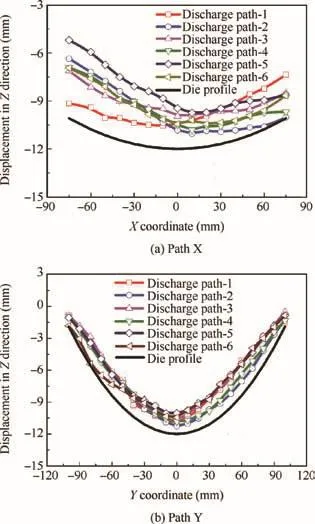

In the EMIF process,the discharge path has an important influence on the forming result.In order to design reasonable discharge paths for obtaining high forming precision,it is necessary to study the effect of the discharge path on the forming process.The forming depths of workpieces along path X and path Y under different discharge paths in Table 1 are shown in Fig.13,where the discharge voltages at the four discharge positions 1,2,3,and 4 are 4 kV,5 kV,6 kV,and 6.5 kV,respectively.The distances between the positions parallel to theYaxis and theXaxis are 70 mm and 50 mm,respectively.The capacitance is set to 320 μF,and the ratio of rib-height to webthickness is 2:1.From Fig.13(a),the discharge path mode has an effect on the forming depth.The overall forming depth under the ‘X” discharge path mode(discharge path-1 and 2)is the largest,followed by that of the ‘U” discharge path mode(discharge path-3 and 4),and the forming depth under the ‘Z”discharge path mode(discharge path-5 and 6)is the smallest.Except discharge path-1,the forming depth variation laws of the other five discharge paths are consistent:along the positive direction of theXaxis,the forming depth firstly increases rapidly,and then decreases slowly.For discharge path-1,the trend of the depth curve is opposite to those of the other paths.The difference between discharge path-1 and path-2,both of which under the same discharge path mode(the ‘X”discharge path),comes from the position selected in the third discharge.For discharge path-1,the position of the third discharge is located at position 3,while for discharge-2,at position 2.Therefore,the third discharge at position 2(X>0)results in a larger forming depth in the regionX>0 than that in the regionX<0,and so does the discharge at position 3.From Fig.13(a),the workpiece along discharge path-1 achieves the maximal forming depth and the bestfit with the die.The differences of the forming depth along path Y in Fig.13(b)are not obvious,and the largest depth is obtained when discharging along path-2.

Fig.8 Error analysis of different voltage combinations during EMIF.

Due to the voltage increasing gradually during the four discharges,the previous deformation region can be influenced by the subsequent deformation,as shown in Fig.13(a)where the forming quality varies on both sides of theXaxis,and the depth atX<0 is better than that atX>0.Meantime,the forming profiles in the same path mode,such as path-1 and path-2(both mode ‘X”),are also different from each other.That is because the panel is rectangular,and the distances between two adjacent discharge positions along the length direction(e.g.,distance between positions 1 and 2)and the width direction(e.g.,distance between positions 2 and 3)influence deformation results.Furthermore,for path mode ‘X”,the voltages at the subsequent positions atX>0 should be enhanced to improve the forming quality in this region when discharge path-1 is chosen.Conversely,the voltages should be reduced at the subsequent positions atX>0 in order to weaken the influence from the subsequent discharges on the previous ones when discharge path-2 is chosen.The effect of the discharge path on the shape of the panel indicates that for a large workpiece with a non-circular shape,it is necessary to design a suitable discharge path in the EMIF process.

The shape deviations and the forming uniformity of the workpiece under different discharge paths are obtained,as shown in Fig.14.From Fig.14,it can be found that the workpiece under an ‘X” discharge path achieves the bestfit with the die.It is illustrated that the diagonal movement of the coil can reduce uncoordinated deformation,as well as the influence ofthe deformation of the subsequent passes on the formed area.The shape deviations of the workpiece under the ‘Z” discharge path are the worst comparing with those under the other two discharge path modes.Fig.14 also expresses that the general trends of the forming uniformity of these workpieces tend to be consistent with that of the shape deviation.

Table 4 Different discharge capacitances under the same energy along discharge path 1→4→3→2.

Fig.9 Panel profiles at different discharge capacitances along two paths.

3.5.Effect of overlap rate of coil

Fig.10 Error analysis at different discharge capacitances during EMIF.

In the EMIF process,there may be overlap for the coil between two adjacent discharge positions,which means that the latter discharge has an effect on the former one.In this study,the concept of overlap rate represents the percentage of the overlap area for the coil at two positions along the width of the workpiece of the total coil area.Three overlap rates are designed,and the position coordinates of the coil with these three overlap rates are shown in Table 5.Fig.15 indicates that a smaller overlap rate is useful to improve the ability of die-fittingness along both paths.Therefore,a larger overlap results in a smaller effective action area,which can be explained that an increased overlap rate improves diefi ttingness in the region under the electromagnetic forces but weakens forming in the region far from the forces such as the free ends,as shown in Fig.15.In addition,insufficient deformation occurs if there is no overlap,and thus it can be concluded that there is an appropriate overlap rate which is the best for EMIF.From Fig.15,furthermore,inhomogeneous plastic deformation can also be observed,especially along path X in Fig.15(b).The error analysis in Fig.16 also shows that a lower overlap rate is suitable for obtaining good forming quality in EMIF.

Cui et al.14discussed the effect of the number of discharge regions on final sheet shapes.In their study,three conditions were used,i.e.,the number was set to 3,4,and 5,corresponding to overlap rates of zero,smaller,and larger,respectively.Compared with the desired profile,the forming qualities with the three overlap rates from priority to inferiority were 4,5,and 3,and the forming results for the first two conditions were very close,except in the corner regions.It indicated that there was insufficient deformation at a larger overlap rate(number=5)due to decreased electromagnetic forces when the distance between the coil and the sheet was increased more obviously than that at a smaller overlap rate.In this study from Fig.15,however,the profiles at overlap rates of 20%and 40%are superior to that at 60%,which means a smaller overlap rate is useful to improve the forming quality,which differs from the results from Cui et al.14.That difference may be because the action area in this study is smaller than that in their study.Therefore,considering the forming efficiency,a smaller overlap rate is enough to obtain good forming quality in this study.

Fig.11 Panel profiles at different rib-height/web-thickness ratios along the two paths.

Fig.12 Error analysis at different ratios of rib-height to webthickness during EMIF.

4.Conclusions

Fig.13 Panel profiles at different discharge paths along the two paths.

Fig.14 Error analysis at different discharge paths during EMIF.

In this study,a double-curvature integral panel is formed with EMIF via discharging at four positions.Forming experiments are implemented to study the effects of forming parameters,including discharge voltage,capacitance,ratio of rib-height to web-thickness,discharge path,and overlap rate of the coil,on the die-fittingness,as well as to evaluate the forming quality of the panel workpiece.The obtained results show that an incremental voltage with a lower initial one is helpful to improve the die-fittingness and avoid the collision rebound of the workpiece against the die.Under the condition of the same discharge energy,the capacitance of a relatively lower value can achieve goodfittingness to the die and meanwhile enhance the energy efficiency due to the skin effect.Discharging at the diagonal positions along the ‘X” discharge path achieves the minimum shape deviation and the best forming uniformity of the workpiece,while discharging at the parallel positions with the ‘Z” discharge path gets the worst.A lower overlap rate of the coil is helpful to improve the forming quality.

Table 5 Different overlap rates along discharge path 1→4→3→2.

Fig.15 Panel profiles at different overlap rates along the two paths.

Fig.16 Error analysis at different discharge overlap rates during EMIF.

Acknowledgements

This work was supported by the National Science Fund for Distinguished Young Scholars of China(No.51625505),the Key Program Project of the Joint Fund of Astronomy and NationalNaturalScience Foundation ofChina (No.U1537203),and the National Key Basic Research Program of China(No.2011CB012804).The authors would also like to thank the Wuhan National High Magnetic Field Center at Huazhong University of Science and Technology for the help on the experiments.

Appendix A.Supplementary material

Supplementary data associated with this article can be found,in the online version,at https://doi.org/10.1016/j.cja.2018.04.005.

杂志排行

CHINESE JOURNAL OF AERONAUTICS的其它文章

- Particle image velocimetry for combustion measurements:Applications and developments

- Abnormal changes of dynamic derivatives at low reduced frequencies

- A new hybrid aerodynamic optimization framework based on differential evolution and invasive weed optimization

- Experimental study of an anti-icing method over an airfoil based on pulsed dielectric barrier discharge plasma

- Envelope protection for aircraft encountering upset condition based on dynamic envelope enlargement

- Effects of the radial blade loading distribution and B parameter on the type of flow instability in a low-speed axial compressor