Brazing of C/C composite and Ti-6Al-4V with graphene strengthened AgCuTi filler:Effects of graphene on wettability,microstructure and mechanical properties

2018-07-24DuoLIUYnyuSONGYinghoZHOUXioguoSONGWeiFUJiciFENG

Duo LIU,Ynyu SONG,Yingho ZHOU,Xioguo SONG,*,Wei FU,Jici FENG

aState Key Laboratory of Advanced Welding and Joining,Harbin Institute of Technology,Harbin 150001,China

bShandong Provincial Key Laboratory of Special Welding Technology,Harbin Institute of Technology at Weihai,Weihai 264209,China

KEYWORDS Brazing;Graphene nanosheets;Mechanical properties;Microstructure;Wetting

Abstract Graphene nanosheets(GNSs)strengthened AgCuTi composite filler(AgCuTiG)was used to braze C/C composite and Ti-6Al-4V.The effects of GNSs on the wettability of AgCuTiG filler on the C/C composite surface and the interfacial microstructure and mechanical properties of brazed joints were investigated.The results indicate that the addition of GNSs reduced the wettability of AgCuTiG.The interfacial microstructure of brazed joints evolved with the addition of GNSs,where Ti3Cu4and TiCu4were converted to TiCu and the thickness of the reaction layer adjacent to the base material decreased.The maximum shear strength of joints brazed at 0.3wt%GNSs was 23.3 MPa(880°C/10 min).Further adding GNSs deteriorated the shear strength of the joints.Fracture of the joints occurred in the C/C composite substrate and the TiC layer adjacent to C/C composite.

1.Introduction

As a promising high-temperature structure material,carbon fiber reinforced carbon matrix composite(C/C composite)possesses low coefficient of thermal expansion(CTE),good anti-fatigue ability,high thermal conductivity and hightemperature mechanical properties,and is widely utilized in aeronautics and space industries.1–3To enhance their potential for practical applications in aerospace components,it is necessary to join C/C composite to other materials.Ti-6Al-4V alloy(TC4)can be widely applied in aerospace industries owing to its excellent mechanical properties such as high specific strength and strong corrosion resistance.4,5As part of a proposed nozzle component,the bonding of C/C composite and TC4 can greatly decrease the weight and increase the efficiency of rocket engines.6

Among different kinds of joining methods,brazing is a common method to join C/C composite to metals because of its strongadaptabilityandlowcost.However,thewettabilityof filler metals on composite surface was a problem in brazing C/C composite to metals.7–11Previous research primarily focused on the effects of active elements on the wettability of filler alloy.Singh et al.investigated the effect of Ti content in different filler systems on the wettability on C/C composite surface.12The wettability of Pd-35Co,Pd-40Ni,63Ag-35.3Cu-1.75Ti and 68.8Ag-26.7Cu-4.5Ti fillers on C/C composite was reported by Asthana et al.13Several studies reported the wetting process of f i llers on C/C composite.In addition,high residual stress occurred at the brazed joints due to the diversity in elasticity modulus and CTE between C/C composite and metals.Therefore,composite filler,which is prepared by adding reinforcement particles with a high elasticity modulus and a low CTE into traditional active fillers to improve the strength of brazed joints,has attracted great interest in recent years.Lin et al.14used TiB2reinforced Cu-Ni composite filler to join C/C composite to TiBw/TC4,and the shear strength of brazed joints was improved.The use of micro-SiC particles decreased thethicknessofreactionlayersnearC/Ccompositeandreduced the mismatch of CTEs between C/C composite and TC4,which ledtoareductionoftheresidualstressofthejoints.15Zhouetal.analyzed the strengthening mechanism of nano-Al2O3particles in improving the mechanical properties of brazed joints.9Graphene,as a perfect two-dimensionalmaterialof sp2-bonded carbon atoms,has attracted wide attention owing to its excellent comprehensive properties including high Young’s modulus,fracture strength,thermal conductivity and specific surface area.16,17In addition,GNSs composed of a few graphene layers possess properties similar to those of single-layer graphene,and are more prone to produce and handle.18GNSshavebeenproposedforpotentialapplicationsinthe nanoelectronics field,19and applied to improve the mechanical properties of materials.20

Therefore,GNSs reinforced AgCuTi composite filler was selected to join C/C composite to TC4 alloy in this study.The wettability of AgCuTi filler with different GNSs contents on C/C composite was studied.The effects of the GNSs content on the interfacial microstructure and mechanical properties of brazed joints were investigated.

2.Experimental procedure

The substrate materials used in this study were C/C composite and TC4 alloy.C/C composite was cut into specimens with sizes of 20 mm×20 mm×5 mm and 5 mm×5 mm×5 mm for wetting and brazing experiments using a diamond cutting machine.TC4 alloy was cut into specimens with a size of 20 mm×10 mm×3 mm by a wire electric discharge machine.AgCuTiGfiller was prepared by adding GNSs and titanium powder (4.5wt%) into AgCu eutectic powder filler(Ag-26.7 wt%Cu).The contents of GNSs in the composite filler were 0wt%,0.1wt%,0.3wt%,0.5wt%and 0.8wt%,respectively.Then the mixture was milled for 4 hours with a speed of 150 r/min using a QM-SB planetary ball mill.The composite filler powder was pressed into a∅6 mm×4 mm cylinder under a pressure of 3 MPa.All the specimens were polished and ultrasonic cleaned in acetone for 10 min.

The wetting experiments were conducted through the sessile drop method,which were carried out in a high-temperature wetting measuring device under a vacuum of 5×10-4Pa.The processed C/C composite substrate was placed on the sample stage and adjusted to a horizontal position.AgCuTiGwas placed at the center of C/C composite.To ensure temperature consistency in the furnace,the sample assembly was firstly heated to 750 °C at a rate of 20 °C/min and held for 10 min.Then it was heated to 880 °C at a rate of 5 °C/min and held for a period of time.Finally,the assembly was cooled down to 400 °C at a rate of 5 °C/min and then furnace-cooled down to the room temperature.The brazing experiments were performed in avacuum furnaceunderavacuum of 3×10-3Pa.AgCuTiGfiller was placed between C/C composite and TC4.The process parameters were similar to those of the wetting experiments.

The polished cross-sections of wetting samples and C/C composite/TC4 brazed joints were examined with a field emission scanning electron microscope(SEM)equipped with an energy dispersive spectrometer(EDS)to observe the interfacial microstructure morphology.The phase compositions of the interface was identified by X-ray diffraction(XRD).The shear strength of the brazed joints was tested with an Instron 5967 universal material testing machine.A schematic diagram of the shear test is shown in Fig.1.The specimens were loaded by the testing machine with a constant displacement rate of 0.5 mm/min.At least 4 specimens brazed at the same brazing parameters were tested to obtain an average shear strength.The fracture surface was observed using SEM and EDS.

3.Results and discussion

3.1.Effects of GNSs on the wettability of AgCuTiG filler

Fig.1 Schematic diagram of shear test of C/C composite/AgCuTiG/TC4 joints.

Fig.2 Variations of drop height and contact angle with different GNSs contents.

Fig.2(a)shows the variation of the drop height with time for different GNSs contents during the isothermal holding at temperatureT=880°C.It can be seen from the image that the content of GNSs had a great effect on the wettability of AgCuTi filler on the C/C composite substrate.The contact angle of 7.71°and the drop height of 0.65 mm show excellent wetting between AgCuTi filler and C/C composite,as displayed in Fig.2(b).When the content of GNSs was more than 0.3wt%,the contact angle and drop height increased obviously,so the wettability of composite filler reduced.Depending on the variations of the contact angle and drop height,the wetting process of AgCuTiGfiller can be divided into three stages.(1)Rapid decrease stage(timet=0–600 s).The height of droplet decreased obviously with the increase of the holding time due to the fast wetting and spreading rate,and the initial drop height ranged from 1.25 mm to 1.95 mm when adding GNSs from 0wt%to 0.8wt%.(2)Slow decrease stage(600–2000 s).The height of droplet decreased slowly with increasing the holding time,and the slow decrease stage can last for a long period of time when the content of GNSs was below 0.3wt%.(3)Equilibrium stage(2000–4000 s).The wetting process tended to be a balance when it reached 2000 s.The f i nal drop height of 0.3–0.7 mm was obtained when the GNSs content was in the range of 0wt%–0.3wt%,indicating good wettability.

Fig.3 shows the interfacial microstructure of droplet/C/C composite at 880°C for 70 min.Fig.3(a)indicates that four different phases were distributed on the interface.The EDS results were demonstrated in Table 1.The gray phase(spot A)was Cu-based solid solution(Cu(s,s)),and the white phase(spot B)was Ag-based solid solution(Ag(s,s)).TiC(spots C and D)was distributed on the interface adjacent to the C/C composite substrate and in the molten droplet.The black phase(spot E)was GNSs.XRD analysis was performed to further confirm the phases.As presented in Fig.3(b),Ag(s,s)and Cu(s,s)were examined in the droplet without GNSs.The diffraction peaks of TiC appeared at 0.3wt%GNSs,which confirmed that Ti reacted with GNSs to form the TiC phase.When the GNSs content rose up to 0.8wt%,highly-enriched GNSs consumed Ti in the filler alloy,and residual GNSs were detected in the XRD pattern.

In order to accurately analyze the effect of the GNSs content on the wettability of the composite filler,the interfacial microstructure of droplet/C/C composite is shown in Fig.4.The GNSs content ranged from 0wt%to 0.8wt%.Block Cu(s,s),Ag(s,s)and a thicker TiC layer adjacent to the C/C composite substrate were observed in the droplet/C/C composite interface when using AgCuTi filler without GNSs.With the addition of GNSs,the amount of block solid solution decreased.This may be attributed to the fact thatflaky GNSs impeded the diffusion of elements in filler alloy,therefore,some of these elements were distributed around GNSs.In addition,the thickness of the TiC layer decreased due to the reaction between GNSs and Ti.Residual GNSs after the reaction appeared in the interfacial microstructure at 0.8wt%GNSs.

3.2.Effects of GNSs on the microstructure of C/C composite/TC4 brazed joints

The typical interfacial microstructure of the C/C composite/AgCuTi/TC4 joint brazed at 880°C for 10 min is shown in Fig.5(a).It can be seen that the brazed joint mainly consisted of four distinct parts marked by I,II,III and IV.As shown in Table 2,there were much Ti and some Al and V in layer I.Layer II was mainly composed of Cu and Ti,according to the EDS results and phase diagram of the titanium-copper system,it can be inferred that the reaction products from spots B to E were Ti2Cu,TiCu,Ti3Cu4and TiCu4.The white phases in layer III consisted of much Ag and little Cu,so there was Agbased solid solution(Ag(s,s)).Meanwhile,Ti-Cu compounds were distributed on the Ag(s,s)substrate.Layer IV near C/C composite was TiC layer.Similar conclusions were also obtained in Ref.21.Therefore,it can be concluded that the interface structure of the C/C composite/TC4 joint brazed at 880°C for 10 min can be expressed as TC4/diffusion layer/Ti2Cu+TiCu+Ti3Cu4+TiCu4/Ag(s,s)+Ti3Cu4+TiCu4+TiCu/TiC/C/C composite.

Fig.6 shows the interfacial microstructure under different GNSs contents.When the GNSs content increased,Ti3Cu4and TiCu4were converted to TiCu in the brazing seam.The thickness of the TiC layer near C/C composite decreased while TiC particles were formed in the brazing seam(in Fig.6(a)–(d))because of the reaction between Ti and GNSs.Meanwhile,the thickness of the Ti-Cu reaction layer adjacent to TC4 alloy decreased.This may be attributed to the fact thatflaky GNSs hindered the diffusion of elements to the TC4 side.As adding 0.5–0.8wt%GNSs,the joining performance of brazed joints deteriorated because of the poorer wettability of AgCuTiGon the C/C composite surface.Combined with the prior wetting experiment results,owing to the poorer wettability of AgCuTiGfiller with more than 0.3wt%GNSs,defects were prone to occur on the interface adjacent to C/C composite.

Fig.3 Microanalysis of droplet/C/C composite interface.

Table 1 EDS results of spots marked in Fig.3(a1)–(a3)(at%).

3.3.Effects of GNSs on the shear strength of C/C composite/TC4 brazed joints

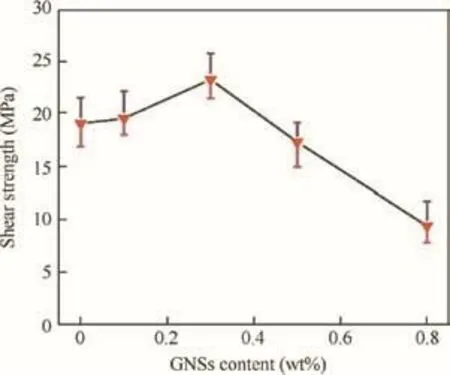

Fig.7 shows the effect of the GNSs content on the shear strength of C/C composite/AgCuTiG/TC4 joints brazed at 880°C for 10 min.It can be seen that the shear strength of brazed joints increased firstly and then decreased obviously with the increase of the GNSs content.The maximum shear strength of 23.3 MPa was obtained at 0.3wt%GNSs.The shear strength depended on the interfacial microstructure of brazed joints.Both the quantity and distribution of intermetallic compounds in the brazing seam,which were crucial factors in determining the shear strength of joints,varied with the addition of GNSs.As the GNSs content increased to 0.3wt%,the amount of block Ti-Cu intermetallic compounds decreased,and the formation of TiC particles by the reaction between GNSs and Ti in the filler could alleviate the residual stress.22With further increasing the GNSs content,owing to the impediment of GNSs,the diffusion of fewer Ti into the interlayer reduced the wetting and spreading of molten filler metal on the C/C composite surface.In addition,there existed a large mismatch of CTEs between the brazed seam and base materials at a high content of GNSs,which led to a strong residual stress in the brazed joints.Therefore,the brazed seam was prone to fracture under the condition of a high GNSs content.

The fracture surface of C/C composite/TC4 brazed joints was investigated,and fracture morphologies after the shear test were examined by SEM,as shown in Fig.8.Different types of fracture modes were observed in the brazed joints at different GNSs contents.It indicated that fracture positions were closely related to the GNSs content and the directions of carbon fibers.When the GNSs content was low,the TiC layer could be a weak area of the joints due to the high residual stress caused by the mismatch of CTEs among AgCuTi,TiC and C/C composite.The shear strength of joints was relatively low,and crack mainly originated in the TiC layer.In the fracture process,the crack propagation was impeded by carbon fibers perpendicular to the brazing seam.However,due to the low bonding strength between carbon fibers parallel to the brazing seam and the C/C composite substrate,some carbon fibers were peeled off from C/C composite with the further increase of load.Thus,fracture occurred in C/C composite with carbon fibers parallel to the brazing seam while fracture appeared in the TiC layer with carbon fibers perpendicular to the brazing seam(Fig.8(a)and(b)).As adding GNSs to 0.3wt%,TiC particles were formed in situ,and GNSs reduced the CTE of braze alloy,thus relieving the residual stress of the bonding interface.A large amount of carbon fibers were pulled out,as shown in Fig.8(c).The pulling out of carbon fibers would consume energy,which led to the increase of the shear strength of joints.Fracture mainly occurred in C/C composite.The TiCu phase,Ag(s,s)and Cu(s,s)were observed at the fracture surface of joints with further increased GNSs.Fracture of joints occurred in the brazing seam,as shown in Fig.8(e).It indicated that more Ti in filler alloy would react with GNSs at a high GNSs content,resulting in weak bonding of joints.

Fig.4 Interfacial microstructure of droplet/C/C composite with different GNSs contents.

Fig.5 Interfacial microstructure of the C/C composite/AgCuTi/TC4 brazed joint.

Table 2 EDS results of chemical compositions at each spot marked in Fig.5(at%).

Fig.6 Interfacial microstructure of C/C composite/TC4 brazed joints with different GNSs contents.

Fig.7 Effect of GNSs content on the shear strength of joints(T=880°C,t=10 min).

4.Conclusions

Sound brazing of C/C composite and TC4 alloy was realized using the GNSs reinforced AgCuTi composite filler in this study.The effects of the GNSs content on the wettability of AgCuTiGcomposite filler and the interfacial microstructure and mechanical properties of brazed joints were investigated.The following main conclusions were drawn:

(1)The TiC layer was a key for filler alloy to wet C/C composite.GNSs,however,impeded the diffusion of Ti to the droplet/C/C composite interface.Therefore,the addition of GNSs reduced the wettability of filler on the C/C composite substrate.

(2)With the increase of the GNSs content,the thickness of the reactive layer between the interface and base materials reduced,and the amount of block Ti-Cu compounds decreased.

(3)The maximum shear strength of the joint brazed at 880°C for 10 min with 0.3wt%GNSs was 23.3 MPa.Further increasing the GNSs content deteriorated the shear strength of brazed joints.Fracture surface was observed for samples brazed with different GNSs contents.Fracture positions were related to the GNSs content and the directions of carbon fibers.Fracture paths extended from C/C composite to the brazing seam with the increase of GNSs.

Acknowledgements

We are grateful for thefinancial supports to this study from the National Natural Science Foundation of China–China(Nos.51505105 and 51775138),the Natural Science Foundation of Shandong Province–China(No.ZR2014EEQ001),and the International Science&Technology Cooperation Program of China–China(No.2015DFA50470).

Fig.8 Fracture morphologies of C/C composite/TC4 joints with different GNSs contents.

杂志排行

CHINESE JOURNAL OF AERONAUTICS的其它文章

- Particle image velocimetry for combustion measurements:Applications and developments

- Abnormal changes of dynamic derivatives at low reduced frequencies

- A new hybrid aerodynamic optimization framework based on differential evolution and invasive weed optimization

- Experimental study of an anti-icing method over an airfoil based on pulsed dielectric barrier discharge plasma

- Envelope protection for aircraft encountering upset condition based on dynamic envelope enlargement

- Effects of the radial blade loading distribution and B parameter on the type of flow instability in a low-speed axial compressor