Experimental comparison between aircraft fuel tank inerting processes using NEA and MIG

2018-07-24LeiSHAOWeihuLIUChoyueLIShiyuFENGChenhenWANGJunPAN

Lei SHAO,Weihu LIU,Choyue LI,Shiyu FENG,*,Chenhen WANG,Jun PAN

aKey Laboratory of Aircraft Environment Control and Life Support of MIIT,Nanjing University of Aeronautics and Astronautics,Nanjing 210016,China

bCollege of Aeronautics,Chongqing Jiaotong University,Chongqing 400074,China

cJiangsu Province Key Laboratory of Aerospace Power System,Nanjing Engineering Institute of Aircraft Systems,Nanjing 210016,China

KEYWORDS Dissolved oxygen;Experiment;Fuel tanks;Inert gases;Mixed Inert Gas(MIG);Nitrogen-Enriched Air(NEA);Oxygen

Abstract Fuel tank inerting technologies are able to reduce thefire risk by injection of inert gas into the ullage or fuel,the former called ullage washing and the latter fuel scrubbing.The Green On-Board Inert Gas Generation System(GOBIGGS)is a novel technology based on flameless catalytic combustion,and owning to its simple structure and high inerting efficiency,it has received a lot of attentions.The inert gas in the GOBIGGS is mainly comprised of CO2,N2,and O2(hereinafter,Mixed Inert Gas(MIG)),while that in the On-Board Inert Gas Generation System(OBIGGS),which is one of the most widely used fuel tank inerting technologies,is Nitrogen-Enriched Air(NEA).The solubility of CO2is nearly 20 times higher than that of N2in jet fuels,so the inerting capability and performance are definitely disparate if the inert gas is selected as NEA or MIG.An inerting test bench was constructed to compare the inerting capabilities between NEA and MIG.Experimental results reveal that,if ullage washing is adopted,the variations of oxygen concentrations on the ullage and in the fuel are nearly identical no matter the inert gas is NEA or MIG.However,the ullage and dissolved oxygen concentrations of MIG scrubbing are always higher than those of NEA scrubbing.

1.Introduction

Aircraft fuel tank ullage space is filled with explosive fuel–air mixtures,which is a serious threat to the safety of aircraft.1On July 17,1996,TransWorld AirlinesFlight800(TWA800),a Boeing model 747–131,exploded in flight shortly after takeoff from the Kennedy International Airport in New York,and according to the National Transportation Safety Board,this disaster was essentially caused by an explosion of theflammable mixtures in the ullage.Since this accident,the Federal Aviation Administration(FAA)has issued numerous airworthiness directives,enacted comprehensive regulations to correct potential ignition sources in fuel tanks,and conducted research on methods that could eliminate or significantly reduce the exposure of aircraft toflammable vapors.2–4Under these circumstances,fuel tank inerting technology,which has been widely employed by the US military,has attracted great attention in civil aviation.

Fuel tank inerting technology refers to the technical measure that maintains the ullage oxygen concentration below the Limiting Oxygen Concentration(LOC)that can support combustion,and ensures the safety of the aircraft fuel tank.Laboratory testing conducted by Stewart and Starkman showed that the LOC for combustion increased from less than 10%to over 13%between the sea level and 60000 ft(1 ft=0.3048 m).5Live-fire testing has demonstrated that nitrogen inerting prevented catastrophic tank over pressures with an ullage oxygen concentration from 12%and 10%at the sea level for up to 23 mm High-Energy Incendiary(HEI)rounds.6Some military requirements for aircraft that may be exposed to combat need lower oxygen concentrations,so the US military conducted fuel tank inerting tests and determined that the LOC was 9%oxygen,which was based on the threat of small armsfire up to 23 mm HEI rounds.7Tests conducted by FAA for commercial aircraft have shown that the LOC from the sea level to 12 km is approximately 12%O2.8Therefore,for the design of an aircraft inerting system,the LOCs for military and civil aircraft are 9%and 12%,respectively.

Inert gases are mainly liquid/gas nitrogen,halon 1301,and Nitrogen-Enriched Air(NEA)that is produced by an Air Separation Module(ASM)based on Hollow-Fiber Membrane(HFM)technology.However,the weight of a liquid/gas system leads to a large fuel penalty,and halon 1301 is too costly for full-time protection and can harm the environment.Therefore,an On-Board Inert Gas Generation System(OBIGGS)with ASMs is the most widely used aircraft fuel tank explosion suppression technology because of its light weight,simplicity,few moving parts,and high reliability,which can provide full-time inerting during entire flight,and has been widely adopted on the A320,B747,C-5,C-17,and F22.9–13

Although the OBIGGS is the most popular fuel tank inerting technology,there are still some inherent disadvantages of this technology,such as large amount of bleed air from the engine,which leads to a large fuel penalty;the high-pressure requirement of the inlet of the hollow fiber membrane,which results in the incapability of its use in many aircraft(such as helicopters);the small fiber membrane and pore size,which cause blockages;the ozone in the bleed air,which degrades the fiber membrane performance;and the displaced and discharged fuel vapor,which pollutes the environment.14,15

TheGreenOn-BoardInertGasGenerationSystem(GOBIGGS)has attracted considerable attention in recent years because of its simple process,closed-loop system,high efficiency,compact size,and light weight.16–18The basic principle of the GOBIGGS is derived from the flameless combustion of air and fuel vapor in the fuel tank ullage through a catalytic reactor.After the water vapor is condensed and the liquid water is removed in a separator,the remaining Mixed Inert Gas(MIG),which consists of CO2,N2,and O2,is reinjected into the fuel tank ullage,gradually reducing the oxygen concentration until it reaches below the LOC.

specifically,there are two methods for reducing the oxygen concentration by filling inert gas into the ullage space or fuelphase.The former is called ullage washing,and the latter fuel scrubbing.In the ullage washing process,inert gas is directly injected into the fuel tank ullage to displace the existing ullage gases and gases evolved from the fuel,and then the resulting mixture is vented overboard through a climb valve.The ullage washing approach is used more often in civil aircraft because of its high efficiency to decrease the ullage oxygen concentration.In the fuel scrubbing process,inert gas is introduced in the form of a multitude of small bubbles at the bottom of the fuel tank,and as the bubbles rise upward through the fuel,the dissolved oxygen is removed while the dissolved nitrogen is added in the fuel.The fuel scrubbing approach is used more often in military aircraft,because it can reduce the total oxygen in the fuel tank.15,19

Studies have been reported concerning aircraft fuel tank inerting systems that are mostly based on the OBIGGS,in which the inert gas is NEA.For example,in the investigation made by Burn and Cavage,a simple rectangular fuel tank was employed to simulate a fuel tank in a commercial transport airplane,and the ullage of the fuel tank was washed under variable NEA oxygen concentration and flow rate.20Cavage adopted a simulated fuel tank to study the relationship between the quantity of NEA and fuel load during the fuel scrubbing inerting process.21Cai et al.performed an experimental study on a simulated fuel tank using nitrogen and NEA,and obtained the ullage and dissolved oxygen concentrations over time under different flow rates and fuel loads.22However,in the GOBIGGS,the MIG contains CO2.CO2readily dissolves in the fuel,and its solubility in the fuel is considerably higher than that of nitrogen or oxygen.The solubility of different gases in the fuel differs greatly,and it can be calculated using the Ostwald coefficient.23,24This paper calculates the Ostwald coefficients of oxygen,nitrogen,and carbon dioxide of 4 types of fuel at different temperatures,as illustrated in Fig.1,and taking the RP-3 fuel as an example,the solubility of CO2is approximately 20 times higher than that of nitrogen at a temperature of 0°C and a pressure of 1 atm(1 atm=101325 Pa).Therefore,the difference between solubility of gases may have a considerable effect on the gas composition on the ullage during the inerting process.However,the current reported studies concerning the GOBIGGS are mostly focused on system design,and there are few studies concerning the different inerting capabilities of NEA and MIG during the ullage washing or fuel scrubbing inerting process.

Fig.1 Relationship between gas solubility of different fuels and temperature.

In essence,the dissolution of gas is not only related to the solubility,but also related to the contact area between gas and fuel and the diffusion of gas in fuel.During ullage washing,because the state of fuel is relatively static,and the contact area between gas and fuel is limited,so there may be a relatively weak influence on the mass transfer.However,during fuel scrubbing,tiny bubbles are directly mixed with fuel,and thus the contact area between gas and fuel is significantly increased,which may enhance the mass transfer process.Therefore,more related investigations are essential.

To evaluate the inerting capabilities of NEA and MIG,a simulated aircraft fuel tank inerting test bench has been established,and experiments are divided into two approaches:ullage washing and fuel scrubbing.Experiments have been performed under different flow rates,fuel loads,and gas compositions.On this basis,this paper compares the inerting capabilities of NEA and MIG,and analyzes the variations of the ullage and dissolved oxygen concentrations for different operation conditions.

2.Experimental systems and methods

A schematic diagram of experimental apparatus is shown in Fig.2,and an apparatus was constructed as shown in Fig.3.The test bench consists of a fuel tank,a scrubber,a gas supply system,and a measurement system.The transparent acrylic fuel tank size is 250 mm×50 mm×180 mm(L×W×D)and its volume is 2.25 L.The gas supply system includes a high-pressure CO2/O2/N2cylinder,an air compressor,a pressure regulator(IR2000-02),a throttle,and so on.The bottom of the fuel tank is installed with a microporous scrubber that is connected to the gas supply system.The measurement system includes an O2sensor(MAX250B),a CO2sensor(COZIR-W),a dissolved oxygen concentration sensor(KDS-25B),a pressure transducer(HSTL-800),a thermostatic water bath(DC-8030),a condenser,and an oil separator.When measuring the ullage oxygen concentration,the gas is condensed and separated by the condenser and the oil separator,respectively,which reduces the influence of the fuel vapor on the O2sensor to the minimum.The fuel loaded in the experiments is RP-3,theambienttemperatureand pressureare20°C and 101 kPa,respectively,and the dissolved oxygen concentration in ambient conditions is approximately 2.25 × 10–3mol/L.24The experiments consisted of four parts:preparation of the inert gas,fuel scrubbing using air,ullage washing,and fuel scrubbing.

(1)Preparation of the inert gas:Firstly,open the shut-off valves F2 and F3.Then,open the vacuum pump to evacuate the inert gas tank.After the pressure reading in the inert gas tank stabilizes,close the shut-off valve F2,open the shut-off valve F1,and then the inert gas tank is filled with a specific proportion of CO2,O2,and N2using the CO2/O2/N2high-pressure gas cylinder,respectively.For example, firstly,the inert gas tank is filled with 20 kPa O2,then filled with 76 kPa N2,and finally filled with 304 kPa CO2;thus,the proportion the inert gas is 5%O2,19%N2,and 76%CO2.Four types of inert gas including NEA(5%O2,95%N2),MIG-A(5%O2,19%N2,76%CO2),MIG-B(5%O2,50%N2,45%CO2),and MIG-C(5%O2,80%N2,15%CO2),in which a 5%oxygen concentration is the most commonly used in an aircraft inerting system,were adopted in the experiments.

(2)Fuel scrubbing using air:Firstly,close the shut-off valve F5.Then,open the air compressor and use the pressure regulator to adjust the outlet pressure in a safety value,to prevent system pressure overload.Next,open the valve F6 and use air to scrub the fuel until the ullage oxygen concentration is approximately 21%,the dissolved oxygen concentration is approximately 2.25 × 10–3mol/L,and the CO2concentration on the ullage is less than 0.1%,which is the value corresponding to equilibrium with the ambient.

Fig.2 Schematic diagram of experimental apparatus.

Fig.3 Experimental apparatus.

(3)Ullage washing:After the parameter readings stabilize,the F3 and F4 shut-off valves are opened,and the flow rate is controlled to a specified value by adjusting the throttle.Then,inert gas is directly introduced into the ullage to vent the ullage air out of the fuel tank,and the out flow goes through the condenser and the oil separator and then flows into the O2/CO2measurement device,while the experimental data is obtained through the data logger LR8432.According to the above steps,ullage washing experiments were performed under different compositions of inert gas, flow rates of 0.1,0.2,0.3,and 0.4 L/min,and fuel loads of 30%,50%,and 70%,respectively.

(4)Fuel scrubbing:Open the shut-off valves F3 and F5,and use the throttle to adjust the flow rate to a specified value.Then,the inert gas is broken into small bubbles by a scrubber and mixed with the fuel;thus,the ullage and dissolved oxygen concentrations will gradually decrease.After recording the data,repeat the experiments under different compositions of inert gas, flow rates of 0.1,0.2,0.3,and 0.4 L/min,and fuel loads of 30%,50%,and 70%,respectively.

The parameters and accuracy of the instruments utilized in the experiments are shown in Table 1.The ullage and dissolved oxygen concentration sensors are Clark electrode sensors,which have the characteristics of fast response and no influence of CO2,and have been widely used in the petrochemical industry.25,26

3.Ullage washing

3.1.Inert gas composition

To examine the phenomena of ullage washing using different inert gases,several inerting runs were conducted at a 50%fuel load and a flow rate of 0.1 L/min,and NEA(5%O2,95%N2),MIG-A(5%O2,19%N2,76%CO2),95%MIG-B(5%O2,50%N2,45%CO2),and 95%MIG-C(5%O2,80%N2,15%CO2)were adopted for these tests,respectively.The variations of the ullage and dissolved oxygen concentrations over time for different inert gases are presented in Fig.4.The time required for the ullage oxygen concentration to decrease to 9%in this experiment is referred to as the inerting time in this paper.The inerting time can be used to evaluate the inerting capabilities of different inert gases.During inerting processes,the dissolved oxygen in the fuel is also an important parameter for determining the inerting capability,and thus,the relevant experimental data is shown in Table 2.

It is observed in Fig.4 that the ullage and dissolved oxygen concentrations of different inert gases are nearly identical no matter the inert gas is NEA or MIG.Table 2 shows that the inerting times of different inert gases are 1636,1542,1506,and 1564 s,and the dissolved oxygen concentrations at the inerting time are 2.122×10-3,2.138×10-3,2.128×10-3,and 2.140×10-3mol/L;the data is very similar.The experimental results reveal that during the ullage washing process,when the inert gas has the same oxygen concentration,the variations of the oxygen concentrations on the ullage and in the fuel are nearly identical no matter the inert gas is NEA or MIG.In essence,the mass transfer process is divided into diffusion and convection;in the process of ullage washing,the state of the fuel is relatively static,and the contact area between the gas and the fuel is limited,so the mass transfer mainly depends on diffusion.However,the diffusion process is relatively slow.Thus,the dissolved oxygen slowly decreases from 2.25×10-3to 2.122×10-3mol/L.Therefore,gas dissolution is very small,and almost same amounts of inert gases are used to displace the ullage gases;thus the variations of the ullage oxygen concentration are nearly identical.

3.2.Flow rate

To compare the difference between ullage washing with different volume flow rates of NEA and MIG-A,a series of tests was performed with four different volume flow rates at a fuel loadof 50%,and the NEA(5%O2,95%N2)and the MIG-A(5%O2,19%N2,76%CO2)were adopted in the experiments.Fig.5 illustrates the ullage and dissolved oxygen concentrations over time,and comparisons of the relevant experimental data are shown in Table 3.

Table 1 Experimental equipment and parameters.

Fig.4 Comparison of oxygen concentrations over time for different gas compositions(ullage washing,fuel load:50%,flow rate:0.1 L/min).

Table 2 Experimental data of ullage washing for different gas compositions.

Fig.5 shows that under the same operating conditions,the ullage and dissolved oxygen concentrations of NEA washing are almost the same as those of MIG-A washing.As shown in Table 3,the inerting times of N2washing at four flow rates are 1636,784,536,and 354 s,respectively,while those of MIG-A washing are 1542,736,484,and 318 s,respectively.The inerting times of NEA and MIG-A washing are both decreased with an increase of the flow rate.Table 3 shows that when the ullage of the fuel tank is inerted to a 9%oxygen concentration,the dissolved oxygen concentrations of NEA washing are 2.122×10-3,2.112×10-3,2.121×10-3,and 2.116×10-3mol/L,while those of MIG-A washing are 2.140×10-3,2.160×10-3,2.146×10-3,and 2.134×10-3mol/L,respectively.The experimental results also reveal that under the same flow rate,when the inert gas has the same oxygen concentration,the variations of the oxygen concentrations on ullage and in fuel are nearly identical no matter the inert gas is NEA or MIG.

3.3.Fuel load

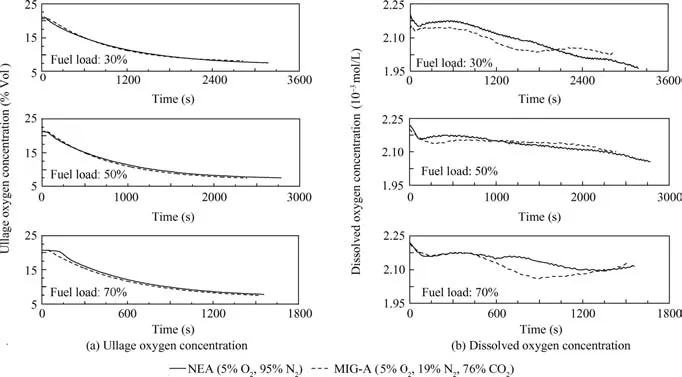

The inerting capabilities of NEA and MIG-A washing were investigated by experiments in this work with different fuel loads.Fig.6 presents the variations of the ullage and dissolved oxygen concentrations over time for different fuel loads at a flow rate of 0.1 L/min.A comparison of the experimental data is shown in Table 4.

It can be seen in Fig.6 that the variations of ullage oxygen concentrations are almost the same between NEA and MIG-A washing.As shown in Table 4,when using NEA washing,the inerting times at 30%,50%,and 70%fuel loads are 2048,1636,and 1060 s,respectively.When using MIG-A washing,the inerting times at 30%,50%,and 70%fuel loads are 2030,1542,and 980 s,respectively,which indicates that the inerting times of NEA and MIG-A are both decreased with an increasing fuel load.Moreover,when the ullage of the fuel tank is inerted to a 9%oxygen concentration,the dissolved oxygen concentrations of NEA washing for 30%,50%,and 70%fuel loads are 2.030×10-3,2.122×10-3,and 2.116×10-3mol/L,respectively,and those of MIG-A washing are 2.058×10-3,2.141×10-3,and 2.072×10-3mol/L,respectively.

Fig.5 Comparison of oxygen concentrations over time for different flow rates(ullage washing,fuel load:50%).

Table 3 Experimental data of ullage washing for different flow rates.

4.Fuel scrubbing

4.1.Inert gas composition

In this section,experiments of fuel scrubbing were performed with different inert gases at a fuel load of 50%and a flow rate of 0.1 L/min.During the scrubbing process,an inert gas of a 5%oxygen concentration means that the dissolved oxygen concentration can be reduced to 0.563×10-3mol/L,which can be calculated from the equilibrium theory by using the Ostwald coefficient.23Therefore,the time of the dissolved oxygen concentration reaching 0.781×10-3mol/L was adopted in this paper to evaluate the effectiveness of fuel scrubbing,and thus comparisons of the experimental data are shown in Table 5.

It can be seen in Fig.7 that the ullage oxygen concentration of MIG scrubbing decreases slowly,and the MIG-C,which has the lowest CO2concentration,is almost the same as in NEA scrubbing.As shown in Table 5,the inerting times of four types of inert gases are 1590,1620,2030,and 2312 s,and the inerting time is increased with an increasing concentration of CO2.It is concluded from the experimental results that,when the inert gas has a higher concentration of CO2,the rate of decrease of the ullage oxygen concentration is reduced.

When dissolved oxygen concentration reaches 0.781×10-3mol/L,the inerting times of four types of inert gas are 1354,1440,1826,and 2020 s,which are also increased with an increasing concentration of CO2.The main reason for those phenomena could be that when the inert gas has a higher concentration of CO2,a greater amount of CO2is dissolved into the fuel,and the CO2used to remove the dissolved oxygen is insufficient,so as a consequence,a smaller amount of evolved inert gases is used to displace the ullage gases.Therefore,under the same operating condition,the ullage and dissolved oxygen concentrations decrease more slowly when the inert gas has a higher CO2concentration.

Fig.6 Comparison of the oxygen concentrations over time for different fuel loads(ullage washing, flow rate:0.1 L/min).

Table 4 Experimental data of ullage washing for different fuel loads.

Table 5 Experimental data of fuel scrubbing for different gas compositions.

4.2.Flow rate

Fig.8 gives the variations of the ullage and dissolved oxygen concentrations with different volume flow rates using NEA and MIG-A.Comparisons of the relevant experimental data are shown in Table 6.

It is observed in Fig.8 that the ullage and dissolved oxygen concentrations of MIG-A scrubbing are significantly higher than those of NEA scrubbing.As shown in Table 6,the inerting times of N2scrubbing at four flow rates are 1590,814,528,and 372 s,respectively,while those of CO2scrubbing at four flow rates are 2312,1214,742,and 570 s,respectively.The inerting times of NEA and MIG-A are both decreased with an increase of the flow rate,while the inerting time of MIG-A scrubbing is about 1.5 times that of NEA scrubbing.

Moreover,the variation trend of theullage oxygen concentration has a considerable difference between NEA and MIG-A scrubbing.The ullage oxygen concentration of NEA scrubbing decreases rapidly in the initial stage,but as the time increases,the rate of decrease tends to be slow.However,the ullage oxygen concentration of MIG-A scrubbing decreases slowly in the initial stage,particularly at a small flow rate,and the rate of decrease accelerates at first but then decelerates.The main reason for this behavior could be that,when using MIG-A to scrub the fuel,in the initial stage,a large amount of CO2is dissolved into the fuel,and the CO2used to displace the ullage air is insufficient,so that the ullage oxygen concentration decreases slowly;with an increase of the scrubbing time,the fuel will be gradually saturated with CO2,which induces more CO2into the ullage of the fuel tank and accelerates the rate of decrease of the ullage oxygen concentration.Finally,because the oxygen concentration difference between the ullage and the inert gas is decreased,the rate of decrease of the ullage oxygen concentration will gradually decelerate.

Fig.7 Comparison of oxygen concentrations over time for different gas compositions(fuel scrubbing,fuel load:50%,flow rate:0.1 L/min).

Fig.8 Comparison of the oxygen concentrations over time for different flow rates(fuel scrubbing,fuel load:50%).

Table 6 Experimental data of fuel scrubbing for different flow rates.

The times of the dissolved oxygen concentration reaching 0.781×10-3mol/L of NEA scrubbing are 1354,780,548,and 410 s,respectively,while those of MIG-A scrubbing are 2020,948,716,and 568 s,respectively.These results reveal that under fuel scrubbing,an increase in the flow rate will accelerate the decrease ofthe dissolved oxygen concentration.Besides,when dissolved oxygen concentration reaches 0.781×10-3mol/L,the time of MIG-A scrubbing is much longer than that of NEA scrubbing,which is mainly because the large amount of CO2dissolved into the fuel,and the amount of CO2used to remove the dissolved oxygen is much smaller than that of N2.

4.3.Fuel load

Fig.9 presents the variations of the ullage and dissolved oxygen concentrations over time for different fuel loads at a flow rate of 0.1 L/min,and a comparison of the experimental data is shown in Table 7.

Fig.9 Comparison of the oxygen concentrations over time for different fuel loads(fuel scrubbing, flow rate:0.1 L/min).

Table 7 Experimental data of fuel scrubbing for different fuel loads.

When using NEA scrubbing,the inerting times at 30%,50%,and 70%fuel loads are 1988,1590,and 1192 s,respectively,which indicates that the inerting time is decreased with increasing the fuel load.When using MIG-A scrubbing,the inerting times at 30%,50%,and 70%fuel loads are 2182,2312,and 2454 s,respectively.Thus,the inerting time is increased with an increase of the fuel load,in contrast to that of NEA scrubbing.The reason for this behavior could be that when the fuel load increases,the volume of the ullage decreases,and thus the fuel tank is more easily inerted,which decreases the inerting time,which in turn has a positive effect on the inerting.On the other hand,an increase of the fuel quantity means that more gas could dissolve into the fuel,and therefore,there is a negative effect that the dissolution effect increases the inerting time.This is a combined effect of a larger fuel load having a greater amount of gas dissolve into the fuel and a smaller ullage to affect.For NEA scrubbing,due to the small solubility of N2in the fuel,when the fuel load increases,the inerting capability is mainly affected by the ullage,and the N2dissolution effect can be negligible.Therefore,the inerting time decreases with an increase of the fuel load.For MIG-A scrubbing,when the fuel load increases,both effects are large due to a reduction of the ullage volume and the large solubility of CO2in the fuel.However,from the experimental data,the dissolution effect is obviously larger,and thus the inerting time increases with an increase of the fuel load.

When the dissolved oxygen concentration reaches 0.781×10-3mol/L,the times of NEA scrubbing for 30%,50%,and 70%fuel loads are 1134,1354,and 1694 s,respectively,and those of MIG-A scrubbing are 1674,2020,and 2404 s,respectively.This indicates that when the fuel is scrubbed at a higher fuel load,the dissolved oxygen concentration will also be relatively higher.The main reason for this is that when the fuel load increases,the total quantity of dissolved oxygen in the fuel increases too,but the capability of unit inert gas to displace dissolved oxygen is limited.

5.Conclusions

Experiments of aircraft fuel tank inerting processes have been performed under different flow rates,fuel loads,and inert gas compositions.The results of a comparison between the uses of MIG and NEA reveal the following:

For ullage washing,the variations of the oxygen concentrations on the ullage are nearly identical no matter the inert gas is NEA or MIG,and the ullage washing inerting approach has a small effect on the dissolved oxygen concentration.The inerting times of NEA and MIG washing are both decreased with increases of the flow rate and the fuel load.

For fuel scrubbing,owning to the higher solubility of CO2in jet fuels,under the same operating condition,the ullage and dissolved oxygen concentrations of MIG scrubbing are always higher than those of NEA scrubbing.The variation trend of the ullage oxygen concentration has a considerable difference,particularly at a small flow rate.The ullage and dissolved oxygen concentrations decrease more slowly when the inert gas has a higher CO2concentration.The inerting time reduces with an increase of the flow rate for either MIG or NEA scrubbing.For NEA scrubbing,the inerting time decreases with an increase of the fuel load,while for MIG scrubbing,in contrast,the inerting time increases with an increase of the fuel load.

Acknowledgements

This work was supported by Funding of Jiangsu Innovation Program for Graduate Education of China (No.KYLX15_0231),Postgraduate Research&Practice Innovation Program of Jiangsu Province of China (No.KYCX17_0279),the Fundamental Research Funds for the Central Universities,Aviation Industry Corporation of China Technology Innovation Fund for Fundamental Research(No.2014D60931R),and Funding of Ministry of Industry and Information Technology for Civil Aircraft.

杂志排行

CHINESE JOURNAL OF AERONAUTICS的其它文章

- Particle image velocimetry for combustion measurements:Applications and developments

- Abnormal changes of dynamic derivatives at low reduced frequencies

- A new hybrid aerodynamic optimization framework based on differential evolution and invasive weed optimization

- Experimental study of an anti-icing method over an airfoil based on pulsed dielectric barrier discharge plasma

- Envelope protection for aircraft encountering upset condition based on dynamic envelope enlargement

- Effects of the radial blade loading distribution and B parameter on the type of flow instability in a low-speed axial compressor