紫外双光栅光谱仪结构设计与波长精度分析

2018-04-19曹佃生林冠宇杨小虎张子辉闻宝朋

曹佃生,林冠宇,杨小虎,张子辉,闻宝朋

(1.中国科学院 长春光学精密机械与物理研究所,吉林 长春 130033;2.一汽轿车股份有限公司,吉林 长春 130000)

1 引 言

Introduction

太阳辐射持续为地球提供外部能量,其能量波动对地球气候变化、天气和环境异常等具有显著的影响,研制专门的仪器对太阳辐照度进行长期精确监测,对于地球科学具有重要的研究价值[1-7]。太阳光谱辐射的精确测量对提高痕量气体的反演精度等其他学科领域也具有积极的作用[3,8]。

Solar radiation continuously provides the Earth with an external source of energy, and solar energy fluctuation has a remarkable impact on Earth′s climate change, weather, environmental anomaly,etc. Therefore, the development of specialized instruments for long-term accurate monitoring of solar irradiance has important research value for geoscience[1-7]. Accurate measurement of solar spectral radiation also plays an active role in other disciplines involving the improvement trace gas inversion accuracy,etc[3,8].

太阳辐射能量具有波长依赖性,可见光和近红外波段集中了太阳辐射的大部分能量,但是在太阳周期内的变化较为平稳,紫外波段虽然能量占比不多,但是在太阳周内变化较大,并且这部分变化可能会对地球大气成分和气候造成显著影响[7]。本文设计的紫外双光栅光谱仪就是为了对紫外170~380 nm波段太阳辐射进行精确监测的仪器。为了满足波长增量和控制输入的线性关系,此类光谱仪一般采用正弦机构作为波长扫描机构[8-10,12-15],即摆杆转角的正弦值与波长值为线性关系。与采用平面光栅和CCD组合形式的光谱仪相比,扫描型光栅光谱仪具有更高的光谱分辨率,且结构简单紧凑,更容易实现小型化。扫描型光谱仪的波长重复性精度取决于波长扫描机构的精度。目前,常用的波长扫描机构有凸轮和丝杠等形式[8,10-13],基于凸轮的波长扫描机构由于凸轮自身廓线精度和体积等因素不能满足本文设计光谱仪的需要,因此,选用丝杠摆杆机构作为双光栅光谱仪的波长扫描机构。

Solar radiation energy has wavelength dependence, and the majority of solar radiation energy is concentrated at visible light and near-infrared bands, but the variation of solar radiation energy is stable within solar cycles. The proportion of energy at ultraviolet band is not high, but the energy changes greatly within solar cycles and its variation may have a remarkable impact on the Earth′s atmosphere composition and climate[7]. The ultraviolet double grating spectrometer designed in this paper is an instrument intended for accurate monitoring of solar radiation at ultraviolet 170-380 nm band. In order to reach the linear relationship between wavelength increment and control input, such spectrometer generally uses a sine mechanism as the wavelength scanning mechanism[8-10,12-15];i.e. the sine of the pendulum rod′s rotation angle has linear relationship with the wavelength. In comparison with the spectrometer using plane grating and CCD, the scanning type grating spectrometer has higher spectral resolution and simple and compact structure and achieves miniaturization more easily. The wavelength repeatability accuracy of the scanning type spectrometer depends on the accuracy of the wavelength scanning mechanism. At present, typical wavelength scanning mechanisms include the forms such as cam, lead screw,etc[8,10-13]. The cam-based wavelength scanning mechanism cannot meet the requirements of the spectrometer designed in this paper due to the factors such as cam′s profile accuracy and volumeetc. Thus,a lead screw pendulum rod mechanism is used as the wavelength scanning mechanism of the double grating spectrometer in is paper.

本文根据凹面光栅色散原理和光谱仪结构特点,推导了光学指标到结构设计输入参数的转换公式,在传统的基于丝杠摆杆的波长扫描机构的基础上,改进了设计,改进后扫描机构的零点定位精度获得提高,在整个扫描过程中,驱动力变化更加均匀。对影响波长重复性精度的误差源进行了分析,以汞灯为光源对光谱仪的波长重复性指标进行测量,以验证理论分析的正确性和指标的可实现性。

According to the concave grating dispersion principle and spectrometer structure features, conversion formulas from optical indexes to spectrometer structure parameters have been derived in this paper. In addition, the scanning mechanism design has been improved on the basis of the traditional wavelength scanning mechanism based on lead screw pendulum rod. The zero positioning accuracy of the improved scanning mechanism has been improved, and the driving force variation is more uniform in the whole scanning process. Error sources affecting wavelength repeatability accuracy have been analyzed, and the wavelength repeatability of the spectrometer has been measured using a mercury lamp as the light source so as to verify the correctness of theoretical analysis and the realizability of the index.

2 光谱仪工作原理与结构设计

Operating principle and structure design of the spectrometer

2.1 凹面光栅色散和正弦机构原理

Concavegratingdispersionprincipleandsinemechanismprinciple

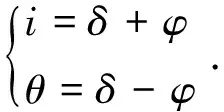

凹面光栅色散原理如图1所示。与平面光栅相似,N为凹面光栅法线,B为入射光线和衍射光线的角平分线,i为入射角,θ为衍射角,2δ为入射光线和衍射光线的夹角,φ为角平分线B和法线N的夹角。

The concave grating dispersion principle is shown in Fig.1. Similar to a plane grating, N is the normal of the concave grating, B is the angular bisector of incident light and diffraction light,iis incidence angle,θis diffraction angle, 2δis the included angle between incident light and diffraction light, andφis the included angle between angular bisector B and normal N.

图1 光栅色散原理 Fig.1 Grating dispersion principle

根据衍射型光栅的色散公式[10-13],有:

The following formula is obtained from the diffraction grating dispersion formula[10-13]:

(1)

其中,m为光栅衍射级次,d为光栅常数,λ为系统扫描波长,对于本文光谱仪系统,m=1,d=1/3600 mm。

Wheremis grating diffraction order,dis grating constant, andλis system scanning wavelength; for the spectrometer system in this paper,m=1 andd=1/3 600 mm.

由图1中的夹角几何关系可得:

The following formula can be obtained from the geometrical relationship between the included angles in Fig.1:

(2)

将公式(2)带入公式(1)并进行简化,可得:

Substitute formula (2) into formula (1) and carry out simplification to obtain:

(3)

在式(3)中,光栅常数d,入射光线和衍射光线夹角2δ和光栅衍射级次都是常数,因此只需要保证波长与角度值φ的正弦为线性关系,就能保证控制输入和波长的线性关系。波长扫描所采用的正弦机构原理图如图2所示。光栅座支撑轴承的外圈固定在光谱仪箱体壁上,内圈与光栅轴以及摆杆末端固定,使摆杆能够带动光栅转动。摆杆的另一端通过弹簧的拉力与滑块保持紧密接触,在步进电机的驱动下丝杠旋转,滑块前后移动,从而驱动摆杆带动光栅转动,完成波长扫描。

In formula (3), the grating constantd, the included angle 2δbetween incident light and diffraction light and grating diffraction order all are a constant, so the linear relationship between control input and wavelength can be guaranteed as long as the relation of wavelength and sine of angleφis linear. The schematic diagram of the sine mechanism used in wavelength scanning is shown in Fig.2. The outer circle of the grating seat support bearing is fixed on the spectrometer cabinet wall, and the inner circle is fixed with the grating shaft and pendulum tail end, so that the pendulum rod can drive the grating to rotate. The other end of the pendulum rod keeps tight contact with the sliding block depending upon the spring tension. Driven by the stepper motor, the lead screw rotates, and the sliding block moves back and forth, so that the pendulum rod drives the grating to rotate and wavelength scanning is achieved.

图2 波长扫描机构 Fig.2 Wavelength scanning mechanism

本文光谱仪工作波段为170~380 nm,对应光栅转角为18.924 4°~46.464 8°,摆杆长度140 mm,丝杠有效行程75.27 mm。

The scanning band of the spectrometer in this paper is 170-380 nm, the corresponding grating rotation angle is 18.924 4°-46.464 8°, the pendulum rod length is 140 mm, and the effective travel of the lead screw is 75.27 mm.

对于已经装调完的光谱仪结构,光栅法线N随光栅的转动而转动,角平分线B的位置是固定的。因此,在设计正弦机构时,若初始位置将摆杆与丝杠置于垂直位置,那么光栅转动时摆杆的转角α与法线N和角平分线B的夹角φ始终相等。根据几何关系,可得:

For the well-adjusted spectrometer structure, the normal N of the grating rotates with grating rotation, and the position of the angular bisector is fixed. Therefore, if the pendulum rod is vertical to the lead screw initially in the sine mechanism design, the rotation angelαof the pendulum rod is always equal to the included angleφbetween normal N and angular bisector B during grating rotation. The following formula can be obtained from the geometrical relationship:

(4)

式中,x为滑块距离初始位置的距离,l为摆杆长度。将式(4)带入式(3)可得:

Wherexis the distance from the sliding block to the initial position, andlis the pendulum rod length. Substitute formula (4) into formula (3) to obtain:

(5)

根据式(5),除滑块位置变量x之外,所有参数均为常量,滑块的位置与步进电机的步数之间为线性关系,因此,波长位置与步进电机的输入步数之间也为线性关系。通过正弦机构,简化了控制关系,为提高波长扫描精度和机构可靠性提供了保证。

According to formula (5), except the sliding block position variablex, all other parameters are a constant. The sliding block position is of linear relationship with the step number of the stepper motor, so the wavelength position also has linear relationship with the input step number of the stepper motor. The control relationship has been simplified via the sine mechanism, thus ensuring the improvement of the wavelength scanning accuracy and the reliability of the mechanism.

2.2 光谱仪结构设计

Spectrometerstructuredesign

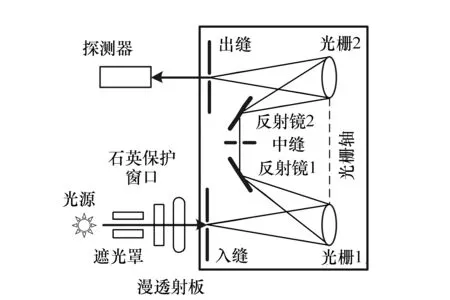

紫外双光栅光谱仪的基本结构如图3所示,主要由入缝组件、光栅、中缝组件、反射镜、出缝组件和探测器等组成。遮光罩在系统的最前端,起到减少杂光的作用。光线依次经过遮光罩、石英窗口、漫透射板和入缝,在第一个光栅上进行色散,经反射镜折射通过中缝,再经第二块反射镜和光栅汇聚在出缝处,最后到达探测器进行数据的采集和处理。两个凹面光栅参数完全一致,安装在同一个光栅座内共轴转动,光谱仪工作时,波长扫描机构驱动光栅转动,在不同转角时探测器接收到不同波长光的能量,机构连续扫描从而完成170~380 nm波段范围内连续光谱测量。

The basic structure of the ultraviolet double grating spectrometer is shown in Fig.3. The ultraviolet double grating spectrometer consists mainly of entrance slit component, gratings, intermediate slit component, reflectors, exit slit component, detector,etc. The light shield is at the foremost end of the system and plays a role in reducing stray light. Rays pass through the light shield, quartz window, diffuse transmission panel and entrance slit successively for dispersion on the first grating; refracted by the reflector, rays pass through the intermediate slit; after passing through the second reflector and grating, rays converge at the exit slit and finally reach the detector for data acquisition and processing. The parameters of the two concave gratings are completely identical and they are installed in the same grating seat to rotate co-axially. During spectrometer working, the wavelength scanning mechanism drives the grating to rotate; at different rotation angles, the detector receives the energy of lights with different wavelengths, and the mechanism performs continuous scanning so as to achieve continuous spectral measurement within the band range of 170-380 nm.

图3 紫外双光栅光谱仪结构简图. Fig.3 Schematic view of ultraviolet double grating spectrometer

由紫外双光栅光谱仪的工作原理可知,波长扫描机构是光谱仪的关键机构,其设计是否合理对光谱仪的波长重复性精度具有决定性影响。本文在传统基于丝杠摆杆的扫描机构基础上,对丝杠机构进行了改进。为了保持在整个扫描过程中滚轮能与滑块紧密接触,将预紧弹簧的固定端由箱体移动到滑块上,如图4所示。弹簧固定端在箱体壁上的方案中,弹簧固定端在整个扫描过程保持不动,随着滑块行程的增加,弹簧长度增加显著,需要步进电机的驱动力矩也随之增大。新方案中,弹簧固定端安装在滑块上,同样可以起到预紧的作用,弹簧尺寸可以显著减少。在整个扫描过程中,弹簧拉力变化量很小,且滚轮与滑块之间为滚动摩擦,步进电机的驱动力矩几乎保持不变。该方案可以有效减少对电机力矩的要求,对降低仪器在振动时弹簧的振幅也具有显著优势。

According to the operating principle of the ultraviolet double grating spectrometer, the wavelength scanning mechanism is the key mechanism of the spectrometer, and the reasonableness of the mechanism design has a decisive impact on wavelength repeatability accuracy. The lead screw mechanism has been improved on the basis of the traditional scanning mechanism based on lead screw pendulum rod in this paper. In order that the roller can tightly contact the sliding block in the whole scanning process, the fixed end of the pre-loaded spring is moved from the cabinet onto the sliding block, as shown in Fig.4. In the scheme where the fixed end of the spring is fixed on the cabinet wall, the fixed end of the spring keeps still in the whole scanning process; as the travel of the sliding block increases, the spring length increases remarkably, and the needed driving torque of the stepper motor also increases accordingly. In the new scheme, the fixed end of the spring is fixed on the sliding block, the spring also plays a role in pre-tightening, and the spring size can be reduced remarkably. In the whole scanning process, the variation of the spring tension is very small, the friction between the roller and the sliding block is rolling friction, and the driving torque of the stepper motor almost remains unchanged. This scheme can effectively reduce the required motor torque and also has remarkable advantages in reducing spring amplitude during instrument vibration.

图4 弹簧设计改进 Fig.4 Diagram of improvemental spring design

为了提高波长扫描机构的回零定位精度,采用精定位和粗定位结合的方式进行零点定位,如图5所示。粗定位传感器安装在滑块上做直线运动,用于快速寻找零位,精定位传感器安装在联轴器上,随着电机的旋转而旋转。寻零位操作时,电机快速反转达到粗定位传感器位置,然后慢速正向旋转,找到精定位传感器位置,整个扫描过程中,电机始终正向转动,可以有效减小丝杠回程间隙误差,提高重复定位精度。

In order to improve the zero returning positioning accuracy of the wavelength scanning mechanism, the method of combining rough positioning with precise positioning is used in zero positioning, as shown in Fig.5. The rough positioning sensor is installed on the sliding block to make linear motion and quickly search zero position; the precise positioning sensor is installed on the coupling and rotates with motor rotation. During zero position searching operation, the motor rotates reversely at quick speed and reaches the rough positioning sensor position; then the motor rotates positively at slow speed and finds the precise positioning sensor position. The motor always rotates positively in the whole scanning process, which can thus effectively reduce the lead screw backlash error and improve repeatability accuracy.

图5 粗、精定位方式 Fig.5 Rough and precise positioning method

光谱仪整机结构如图6所示,为保证光谱仪整机结构刚度,光谱仪壳体采用一体化加工方式,通过筋板对不同组件进行分仓,提高刚度的同时可以减少杂散光对系统的影响。三个狭缝组件通过对研的不锈钢片拼接而成,狭缝尺寸在50倍显微镜下进行调试,狭缝尺寸均为0.4 mm×1 mm。探测器采用光电倍增管,安装时与出缝组件紧密安装,避免杂光进入。

The structure of the whole spectrometer is shown in Fig.6. In order to ensure the rigidity of the whole spectrometer structure, the housing of the spectrometer uses the integral machining mode, and different components are partitioned with rib plates, which can reduce the impact of stray lights on the system while increasing the rigidity. The three slit components are sliced from stainless steel sheets. The slit size is adjusted and tested under a 50-power microscope, and the size of all the three slits is 0.4 mm×1 mm. The detector uses photomultipliers and is tightly installed with the exit slit component to prevent stray lights from entering.

图6 光谱仪整机结构图 Fig.6 Structure diagram of spectrometer model

3 波长重复性误差分析

Wavelength repeatability error analysis

波长重复性精度高是光谱仪完成太阳光谱170~380 nm波段范围内精确扫描需要保证的基本要求,是后续波长线性标定和光谱测量的前提。光谱分辨率由入缝和出缝宽度决定,宽度越低,光谱分辨率越高,但是进入光谱仪系统的能量也会减少,降低系统的信噪比,所以需要综合考虑,满足信噪比指标的同时实现较高的光谱分辨率。本文所设计的紫外双光栅光谱仪设计指标为:光谱分辨率为1 nm,波长重复性为±0.02 nm。

High wavelength repeatability accuracy is the basic requirement satisfied to achieve accurate scanning within the solar spectral band range of 170-380 nm using the spectrometer and also the premise for subsequent linear calibration of wavelength and spectral measurement. Spectral resolution is decided by the width of the entrance slit and exit slit. The smaller the width, the higher the spectral resolution; but the energy entering the spectrometer system will also be reduce so as to reduce the system's SNR. Therefore, the width shall be considered comprehensively to achieve high spectral resolution while meeting the requirement of the SNR index. The design indexes of the ultraviolet double grating spectrometer in this paper:spectral resolution 1 nm, wavelength repeatability ±0.02 nm.

根据对波长扫描机构原理的分析,光谱仪中波长位置与结构参数的关系可以由公式(5)确定,同时公式(5)的推导依赖于公式(4)成立的假设,即在光栅零级时摆杆与丝杠垂直。由此可知,影响光谱仪波长重复性精度的误差源有[8,11,13,15]:(1)光栅常数d;(2)光栅入射光线和衍射光线夹角2δ;(3)摆杆长度误差Δl;(4)滚轮在滑块上的跳动量Δe;(5)摆杆在弹簧作用下的变形量Δl′;(6)光栅轴轴系晃动误差Δβ;(7)丝杠机构回零位重复性误差ΔXj;(8)丝杠机构的重复定位误差Δx′。

According to the analysis of the principle of the wavelength scanning mechanism, the relation of the wavelength position in the spectrometer with the structure parameter can be determined from formula (5); in addition, formula (5) is derived depending on the assumption that formula (4) is workable;i.e. the pendulum rod is vertical to the lead screw at grating zero order. It can be seen from this that the error sources affecting the wavelength repeatability accuracy of the spectrometer include the following[8,11,13,15]:(1)grating constantd; (2)included angle 2δbetween incident ray and diffraction ray of grating; (3)pendulum rod length error Δl; (4)run-out of the roller on the sliding block Δe; (5)pendulum rod deformation under the action of the spring Δe; (6)waggling error of grating shaft system Δβ; (7)zero returning repeatability error of the lead screw mechanism ΔXj; (8)repeatability error of the lead screw mechanism Δx′.

在本光谱仪系统中,误差源(1)、(2)和(3)在光栅选定后就已经确定,若存在加工误差,也不随波长扫描过程发生变化,属于固有的系统误差,只影响波长与步进电机步数之间的当量,即波长线性,而不会影响波长重复性,波长线性可以进行测量来标定。由于本设计中,对弹簧拉紧方式进行了改进,选取较大刚度系数弹簧对滚轮进行预紧,滑块接触面进行精研,选用高精度的深沟球轴承作为滚轮,其径向跳动量也可以忽略不计[8,14]。另外,由于弹簧不再对摆杆整体进行拉紧,因此,摆杆的变形量也可以忽略不计。光栅轴采用一对高精度背靠背安装的角接触球轴承进行支撑,经过精密装调后对光栅轴端部进行测量,其径向跳动量小于1 μm,对于本仪器是可以忽略的。

In our spectrometer system, error sources (1), (2) and (3) have been determined after selecting gratings; if there is a machining error, they will not change with the wavelength scanning process, are inherent system errors, and affect only the equivalent between wavelength and the step number of the stepper motor,i.e. wavelength linearity. Wavelength linearity can be calibrated through measurement. The spring tension mode has been improved in this design. Moreover, the spring with large rigidity coefficient is used to pre-tighten the roller, the sliding block contact surface is finely ground, and a high-precision deep groove ball bearing is used as the roller, so the radial run-out can be neglected[8,14]. In addition, the spring doesn′t tension the pendulum rod integrally, so pendulum rod deformation can also be neglected. The grating shaft is supported by a pair of back-to-back mounted high-precision angular contact ball bearings. The measurement of the grating shaft end after precise adjustment shows that the radial run-out is less than 1 μm, which can be neglected for this instrument.

根据实际测试结果,采用粗定位的方式,随着定位磁钢和霍尔传感器之间的感应距离不同,其定位精度ΔXc一般在3~5 μm,可以推导安装在旋转轴上精定位的定位精度为:

According to the actual test result, rough positioning method is adopted. As the induction distance between positioning magnet steel and Hall sensor is different, the positioning accuracy ΔXcranges from 3 μm to 5 μm in general. The positioning accuracy of the precise positioning sensor installed on the rotating shaft can be deduced as follows:

(7)

其中,R为磁钢沿丝杠轴的回转半径,p为丝杠螺距。本丝杠机构中,R=10 mm,p=0.5 mm。将系统参数带入式(7)可得,精定位的重复定位精度约为0.04 μm。丝杠机构使用步进电机驱动,步进电机的步距角误差会对定位精度造成影响。本文使用的步进电机为德国进口步进电机,步距角1.8°,步距角误差优于3%。因此,受步进电机步距角精度限制,波长扫描机构的实际回零误差为1.8×0.03/360×0.5 mm=0.075 μm,该回零精度远高于丝杠的重复定位精度,在计算时可以忽略不计。

WhereRis the turning radius of magnet steel along the lead screw axis, andpis lead screw pitch. For the lead screw mechanism,R=10 mm andp=0.5 mm. By substituting system parameters into formula (7), the obtained repeatability accuracy of the precise positioning sensor is about 0.04 μm. The lead screw mechanism is driven by a stepper motor. The step angle error of the stepper motor will have an impact on positioning accuracy. The stepper motor used in this paper is a stepper motor imported from Germany, its step angle is 1.8°, and its step angle error is better than 3%. Hence, limited by the step angle precision of the stepper motor, the actual zero returning error of the wavelength scanning mechanism is 1.8×0.03/360×0.55 mm=0.075 μm. The zero returning accuracy is far too higher than the repeatability accuracy of the lead screw and can be neglected in calculation.

根据以上分析,丝杠机构的重复定位误差决定了波长扫描的重复性精度。根据误差的独立性,将式(5)对丝杠行程x取微分可得:

The above analysis indicates that the repeatability error of the lead screw mechanism decides wavelength scanning repeatability accuracy. According to error independence, differentiate formula (5) by the lead screw travelxto obtain:

(8)

当波长重复性误差为Δλ=±0.002 nm时,丝杠的重复定位误差Δx应优于±5.3 μm。选用丝杠机构的重复定位精度标称值为±2 μm,在装配前进行实测,重复定位精度为±1.8 μm,满足波长重复性要求。

When the wavelength repeatability error is Δλ=±0.02 nm, the repeatability error Δxof the lead screw shall be better than ±5.3 μm. The nominal value of the repeatability accuracy of the used lead screw mechanism is ±2 μm. The measurement before assembling indicates that the repeatability accuracy is ±1.8 μm, which meets wavelength repeatability requirements.

4 实验验证

Experimental verification

使用汞灯253、296、313和365 nm等4个特征波长对光谱仪进行波长重复性验证,,如图7所示。测量时,汞灯放在入缝前,汞灯发出的光经漫透射板之后进入光谱仪,PC机发送控制指令驱动波长扫描机构回零,根据计算的全程扫描步数,从零点扫描到丝杠指定行程处,探测器对出射狭缝的光进行采集,可以得到在所扫描波段的能量分布情况。根据理论公式,将步进电机的步数转换为对应波长数,一个扫描周期的测量结果如图8所示。根据波长间隔,确定4个特征波长的位置,对于其他不显著波长不进行处理。

图7 测量装置及测量原理图 Fig.7 Measurement equipment view and its measurement schematic diagram

图8 一个扫描周期测量结果 Fig.8 Measurement result within one scanning period

4 characteristic wavelengths of a mercury lamp including 253 nm, 296 nm, 313 nm and 365 nm have been used to carry out wavelength repeatability verification of the spectrometer, as shown in Fig.7. During measurement, the mercury lamp is placed before the entrance slit; the lights emitted by the mercury lamp enter the spectrometer after passing through the transmission panel; the PC sends out a control command to drive the wavelength scanning mechanism to return to zero. According to the calculated whole-process scanning steps, scanning is performed from zero to the designated lead screw travel. The detector acquires the lights out of the exit slit, and the energy distribution at the scanned band can be obtained. According to theoretical formulas, the step number of the stepper motor is converted into the corresponding wavelength number. The measurement result within one scanning period is shown in Fig.8. The position of the 4 characteristic wavelengths is determined according to the wavelength interval, and other non-significant wavelengths are not processed.

重复扫描5次,对每次扫描的4个峰值处数据进行高斯拟合,确定各个特征波长测量的实际中心波长和半高宽。取同一特征波长处5次拟合中心波长与其平均值的偏差作为该特征波长处的波长重复性误差,4个特征波长的重复性误差统计结果如表1所示。

Scanning is carried out for 5 times. Gaussian fitting of the data at 4 peak valve positions each time of scanning is performed to determine the actual central wavelength and full width at half maximum measured for each characteristic wavelength. The deviation between the central wavelength from 5 times of fitting for the same characteristic wavelength and the average value is taken as the repeatability error of the characteristic wavelength. The statistical results of the repeatability errors of the 4 characteristic wavelengths are shown in Tab.1.

表1 4个典型波长重复性误差

根据测量结果,在4个特征波长处的重复性在-0.005~+0.007 nm之间,光谱分辨率优于0.8 nm,满足紫外双光栅光谱仪波长重复性±0.02 nm和光谱分辨率1 nm的要求。该结果与光谱仪波长扫描机构理论分析结果相符,说明光机参数转换公式推导正确,机构设计合理,误差分析与实际机构设计吻合。

According to the measurement result, the repeatability errors of the 4 characteristic wavelengths are between -0.005 nm and +0.007 nm, and the spectral resolution is better than 0.8 nm, which meets the requirements of wavelength repeatability ±0.02 nm and spectral resolution 1 nm of ultraviolet double grating spectrometer. This result is consistent with the theoretical analysis result of the wavelength scanning mechanism of the spectrometer, indicating that the derived optical-mechanical parameter conversion formulas are correct and that the mechanism design is reasonable. The error analysis is in line with the actual mechanism design.

5 结 论

Conclusion

本文根据凹面光栅色散原理,对紫外双光栅光谱仪的波长扫描机构进行了理论计算,针对结构设计中对波长重复性精度有影响的误差源进行了分析,确定了丝杠重复定位误差是影响波长重复性的主要误差源,根据理论计算结果选择高精度的丝杠机构,并对波长扫描机构进行了改进,完成了整机结构设计。以汞灯为光源,选用其4个特征波长对波长重复性精度进行了验证,实验结果表明,波长重复性满足±0.02 nm的指标要求,为后续波长线性标定等工作提供了基础。本文的波长扫描机构设计和误差分析方法对同类型光谱仪的设计具有参考价值。

In this paper, the wavelength scanning mechanism of the ultraviolet double grating spectrometer has been theoretically calculated according to the concave grating dispersion principle, the error sources affecting wavelength repeatability accuracy in the structure design have been analyzed, and the repeatability error of the lead screw has been determined to be the main error source. According to the theoretical calculation result, a high accuracy lead screw mechanism has been selected, the wavelength scanning mechanism has been improved, and the design of the whole spectrometer structure has been completed. Using a mercury lamp as the light source, the wavelength repeatability accuracy has been verified with 4 characteristic wavelengths of mercury lamp. The experiment result indicates that the wavelength repeatability meets the requirements of ±0.02 nm index, thereby providing a foundation for subsequent linear calibration of wavelength,etc. The wavelength scanning mechanism design and the error analysis method in this paper have a reference value for the design of like spectrometers.

参考文献:

[1]THUILLIERG,FOUJOLST,BOLSEED,etal.. SOLAR/SOLSPEC:scientific objectives, instrument performance and its absolute calibration using a blackbody as primary standard source[J].SolarPhys.,2009,257:185-213.

[2]陈祥子,方伟,杨振岭,等.太阳辐照绝对辐射计主光阑面积测量[J].光学学报,2015,35(9):0912003.

CHEN X Z,FANG W,YANG ZH L,etal.. Main aperture area measurement of the SIAR[J].ActaOpticaSinica,2015,35(9):0912003.(in Chinese)

[3]刘成保,王维和,杨磊.FY-3C/臭氧总量探测仪太阳辐照度偏差的修正[J].光学 精密工程,2015,23(7):1859-1867.

LIU CH B,WANG W H,YANG L. Revision of solar irradiance of FY-3C/TOU[J].Opt.PrecisionEng.,2015,23(7):1859-1867.(in Chinese)

[4]陈诗吉,周立旻,郑祥民.太阳总辐照度的监测与重建研究进展[J].地理科学进展,2013,32 (10):1567-1576.

CHEN SH J,ZHOU L M,ZHENG X M. Research progress in monitoring and reconstruction of total solar irradiance[J].ProgressinGeography,2013,32(10):1567-1576.(in Chinese)

[5]方伟,禹秉熙,王玉鹏,等.太阳辐照绝对辐射计及其在航天器上的太阳辐照度测量[J].中国光学与应用光学,2009,2(1),23-28.

FANG W,YU B X,WANG Y P,etal.. Solar irradiance absolute radiometers and solar irradiance measurement on spacecraft[J].ChineseJournalofOpticsandAppliedOptics,2009,2(1),23-28.(in Chinese)

[6]刘恩超,李新,张艳娜,等.高精度太阳辐照度仪的光谱仪扫描测量[J].光谱学与光谱分析,2014,34(3):609-613.

LIU E CH,LI X,ZHANG Y N,etal.. Spectral scanning measurement of high-precision solar irradiance-meter[J].SpectroscopyandSpectralAnalysis,2014,34(3):609-613.(in Chinese)

[7]徐景晨,李可军.太阳辐照的观测研究进展[J].天文学进展,2011,29(2),132-147.

XU J CH,LI K J. Progress in the measurement and study of solar irradiance[J].ProgressinAstronomy,2011,29(2),132-147.(in Chinese)

[8]林冠宇.紫外臭氧垂直探测仪波长精度分析与波长定标新方法的研究[J].仪器仪表学报,2010,31(12):2668-2674.

LIN G Y. Analysis of wavelength accuracy and study on new wavelength calibration method for ultra violet ozone vertical probe[J].ChineseJournalofScientificInstrument,2010,31(12):2668-2674.(in Chinese)

[9]陈至坤,王淑香,王玉田,等.光栅光谱仪光路结构的设计[J].应用光学,2015,36(5):704-708.

CHEN ZH K,WANG SH X,WANG Y T,etal.. Design of grating spectrometer optical structure[J].JournalofAppliedOptics,2015,36(5):704-708.(in Chinese)

[10]卢启鹏,宋源,龚学鹏,等.极高分辨变包含角平面光栅单色器关键技术及检测方法研究[J].中国光学,2016,9(2):284-295.

LU Q P,SONG Y,GONG X P,etal.. Key technologies and the performance measuring methods in variable includedangle plane grating monochromator[J].ChineseOptics,2016,9(2):284-295.(in Chinese)

[11]施建华,伏思华,谢文科.光栅光谱仪光谱响应误差校正[J].中国光学,2014,7(3):483-490.

SHI J H,FU S H,XIE W K. Error correction of spectral response characteristic of grating spectrometer[J].ChineseOptics,2014,7(3):483-490.(in Chinese)

[12]刘怡轩,颜昌翔,李先锋,等.分光测色仪中的光谱仪系统[J].光学 精密工程,2015,23(7):1965-1971.

LIU Y X,YAN CH X,LI X F,etal.. Design of spectrometer in color measuring spectrophotometer[J].Opt.PrecisionEng.,2015,23(7):1965-1971.(in Chinese)

[13]吴坤,薛松,卢启鹏,等.SX-700单色器光栅正弦机构转角重复精度的模拟分析与测量[J].光学 精密工程,2010,18(1):45-51.

WU K,XUE S,LU Q P,etal.. Simulation analysis and measurement of rotation angle repeatability for grating sine mechanism of SX-700 monochromator[J].Opt.PrecisionEng.,2010,18(1):45-51.(in Chinese)

[14]马磊,卢启鹏,彭忠琦.变包含角平面光栅单色器的性能检测[J].光电子激光,2011,22(4):589-592.

MA L,LU Q P,PENG ZH Q. Performance measurement for variable-included-angle plane grating monochromators[J].JournalofOptoelectronicsLaser,2011,22(4):589-592.(in Chinese)

[15]林雪松,王淑荣,李福田.双模式紫外光谱辐射计的波长机构精度分析[J].光学仪器,2007,29(5):55-59.

LIN X S,WANG SH R,LI F T. Analysis of wavelength mechanism accuracy for the double model ultraviolet spectroradiometer[J].OpticalInstruments,2007,29(5):55-59.(in Chinese)

曹佃生(1987—),男,山东日照人,博士,助理研究员,2007年于吉林大学获得学士学位,2012年于中国科学院长春光学精密机械与物理研究所获得博士学位,主要从事空间光学遥感仪器光机结构设计方面的研究。E-mail:caodiansheng1987@163.comCAO Dian-sheng(1987—), male, born in Rizhao, Shandong, doctor, research assistant. He was received a B.S. degree from Jilin University in 2007 and a doctor′s degree from Changchun Institute of Optics, Fine Mechanics and Physics, Chinese Academy of Sciences, and is engaged mainly in the research on the optical-mechanical structure design of space optics remote sensing instruments. E-mail:caodiansheng1987@163.com

《发光学报》

—EI核心期刊(物理学类;无线电电子学、电信技术类)

《发光学报》是中国物理学会发光分会与中国科学院长春光学精密机械与物理研究所共同主办的中国物理学会发光分会的学术会刊。 该刊是以发光学、 凝聚态物质中的激发过程为专业方向的综合性学术刊物。

《发光学报》于1980年创刊, 曾于1992年, 1996年, 2000年和2004年连续四次被《中文核心期刊要目总览》评为“物理学类核心期刊”, 并于2000年同时被评为“无线电电子学、 电信技术类核心期刊”。2000年获中国科学院优秀期刊二等奖。 现已被《中国学术期刊(光盘版)》、 《中国期刊网》和“万方数据资源系统”等列为源期刊。 英国《科学文摘》(SA)自1999年; 美国《化学文摘》(CA)和俄罗斯《文摘杂志》(AJ)自2000年; 美国《剑桥科学文摘社网站》自2002年; 日本《科技文献速报》(CBST, JICST)自2003年已定期收录检索该刊论文; 2008年被荷兰“Elsevier Bibliographic Databases”确定为源期刊; 2010年被美国“EI”确定为源期刊。2001年在国家科技部组织的“中国期刊方阵”的评定中, 《发光学报》被评为“双效期刊”。2002年获中国科学院2001~2002年度科学出版基金“择重”资助。2004年被选入《中国知识资源总库·中国科技精品库》。本刊内容丰富、 信息量大,主要反映本学科专业领域的科研和技术成就, 及时报道国内外的学术动态, 开展学术讨论和交流, 为提高我国该学科的学术水平服务。

《发光学报》自2011年改为月刊, A4开本, 144页, 国内外公开发行。 国内定价: 40元, 全年480元, 全国各地邮局均可订阅。 《发光学报》欢迎广大作者、 读者广为利用, 踊跃投稿。

地址: 长春市东南湖大路3888号

《发光学报》编辑部

邮编: 130033

电话: (0431)86176862, 84613407

E-mail: fgxbt@126.com

国内统一刊号: CN 22-1116/O4

国际标准刊号: ISSN 1000-7032

国内邮发代号: 12-312

国外发行代号: 4863BM

http://www.fgxb.org