多次间歇LED光照射对铁观音风味组分的影响

2018-02-28陈寿松金心怡游芳宁周子维李鑫磊郝志龙

陈寿松,金心怡,2,游芳宁,周子维,李鑫磊,郝志龙,2,孙 云,2

多次间歇LED光照射对铁观音风味组分的影响

陈寿松1,金心怡1,2,游芳宁1,周子维1,李鑫磊1,郝志龙1,2,孙 云1,2※

(1. 福建农林大学园艺学院,福州 350002; 2. 茶学福建省高校重点实验室,福州 350002)

光照是决定乌龙茶高香醇厚品质的重要因子。为了探究多次间歇LED光照射对铁观音品质的影响,该文以铁观音为研究对象,采用LED白光进行多次光照射处理试验,以全程无光照为对照(CK),通过设计3个不同次数LED光照射试验组,第1次摇青前进行第1次光照射为(S-1),第2次摇青前进行第2次光照射为(S-2),第3次摇青前进行第3次光照射为(S-3),分别进行不同处理的铁观音毛茶的儿茶素、氨基酸、香气组分测定以及感官品质审评。试验结果表明:与CK相比,S-2和S-3处理铁观音毛茶中的呈苦涩味儿茶素组分总量分别降低了29.6 %、24.4 %,游离氨基酸组分总量分别提高了20.5 %、15.4 %,毛茶酚氨比减小;适度增加LED光照射次数有利于铁观音毛茶呈花果香气味的-法呢烯和橙花叔醇相对含量的积累,其中S-2处理效果最佳,相对于CK 分别提高了56.28%、62.51%;基于香气主成分分析得出S-2处理的香气综合评价得分最高(9.88),CK得分最低(-3.48),与4个不同处理的铁观音毛茶感官审评结果排序相同。研究结果可为将来开展建设乌龙茶全天候工厂化连续化加工生产提供理论和科学参考。

照射;主成分分析;试验;铁观音;LED;多次间歇;香气组分;品质

0 引 言

铁观音是中国十大品牌茶之一,以馥郁花果香、鲜爽醇厚的优良品质广受国内外消费者青睐,其加工流程以日光萎凋为首道工序,并依次伴随着多次摇晾青、高温杀青、包揉、干燥等工序[1-2]。日光或者人工光源萎凋对于促进鲜叶的物理反应、生物代谢和化学变化等方面提供了必要的环境要求和能量需求[3-6]。春季是铁观音生产主要季节,时常遭遇阴雨天气,以致于无法正常进行日光萎凋,这也成为茶叶产区加工生产的瓶颈;所制成的毛茶香气低闷、无花果香、滋味青苦涩,产品附加值极低,导致茶农弃采现象日趋严重;因此近年来以研究应用LED光源替代日光萎凋为切入点的加工技术方法成为了研究热点问题[7-10]。

关于LED光萎凋对茶叶品质形成的影响已取得了一些相关研究成果,陈寿松等[11]开展了不同LED光质对乌龙茶品质特性影响研究,通过与无光萎凋处理相比,1次补光萎凋显著提高了铁观音毛茶的主要赋香成分-法呢烯和橙花叔醇的相对质量分数,增长率分别为11.42%、30.65%,同时促进了茶多酚的部分转化;罗玲娜等[12-14]分别开展了LED光照萎凋对白茶、红茶、绿茶品质影响研究,认为不同光质LED萎凋可降低毛茶的茶多酚或儿茶素组分含量,促进毛茶主要香气组分的积累,所制成毛茶感官品质均高于无光组。Fu等[15]研究指出光照可调控和促进乌龙茶香气的形成,同时香气合成相关基因可受光调控。陈林等[16]分析指出“晾青失水”和“多次摇青”产生的累积效应是诱发在制品代谢生成的必要条件,并可明显改变乌龙茶“黄观音”品种做青叶香气组成的化学模式。

以上研究已证实了日光或LED光源对茶叶品质形成起决定性作用。传统生产过程中铁观音采摘和萎凋的最适时段为15:00—17:00,自然环境条件仅仅满足1次的日光萎凋。针对不同次数LED光照处理对铁观音风味品质的影响,尚未见相关报道。因此,本文以铁观音作为研究对象,采用LED白光进行多次光照射试验研究,通过测定不同处理的铁观音毛茶的儿茶素、氨基酸、香气组分的含量和感官品质,以期为将来开展建设一种适合中小型乌龙茶全天候工厂化连续化生产模式提供技术支撑。

1 材料与方法

1.1 供试材料

本试验所选用的供试材料统一采摘无性系标准开面三叶铁观音品种鲜叶,鲜叶含水率为75.2%±1.0%;取自于福建省云雾香茶叶发展有限公司,地处海拔1 100 m的梅花山自然保护区。

1.2 试验装置

1.2.1 装置

1)总体结构

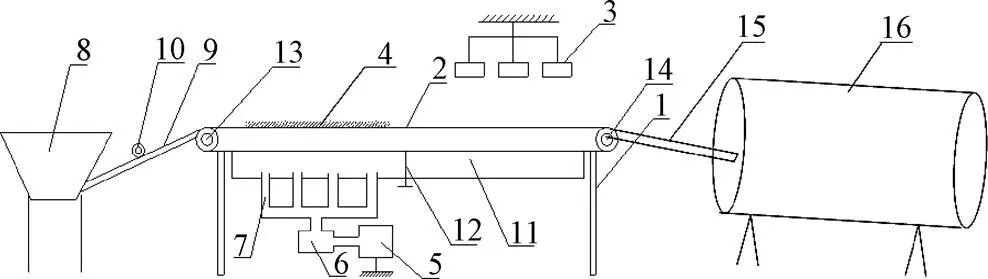

乌龙茶多次间歇LED光调控装置主要由LED光处理模块、热泵供热系统、长筒摇青机、传送台、通风槽、上叶装置、传动机构等7个部分组成(图1)。传送台绕设一条呈网孔状的传送带,位于储茶斗和摇青设备之间;通风槽呈盒状且顶部开口贴设于传送带的正下方,通风槽中间还纵向设有一滑动挡板,挡板可沿滑槽滑动;LED光谱调节模块布设于传送带的后段正上方;热泵供热系统设置于传送带的前段正中央下方,经数个通风管道引导干热风透过网孔,达到半封闭式循环;长筒型摇青机通过设定倾斜角度,可以保证摇青工序结束时鲜叶自动出叶作业。

1.传送台 2.传送带 3.LED灯板 4.鲜叶 5.轴流风机 6.热泵 7.通风管道 8.储茶斗 9.上叶输送带 10.匀叶轮 11.通风槽 12.滑动挡板 13.主动轮 14.从动轮 15.下叶输送带 16.长筒摇青机

2)工作原理

该装置所实现的技术方法主要是依靠热泵供热鲜叶脱水预处理和LED光照射替代晴天弥补光照。具体实施方式如下:将采收后的鲜叶放置储茶斗中,经匀叶轮平铺静置于传送带上,轴流风机吸入空气,通过热泵加热器后经若干通风管道将热风导入通风槽,半封闭式循环促使热风压力增大,透过网孔直接作用于鲜叶进行脱水预处理,根据生产需要也可通过滑动挡板调节部分热风进入后半段进行光照射环节供热;开启LED电源模块,启动步进电机,预处理后的鲜叶经传送带输送到LED光处理装置正下方,光照结束后输送至下一道摇青工序,通过引进多套组合装置,可进行多次光照射与多次摇晾青循环作业。

其他试验装置为乌龙茶初加工成套设备,包括6CST-30型小型摇青机、6CST-90型茶叶杀青机、6CSBG-22型茶叶速包球茶机、6CBRP-75型茶叶平板包揉机、6CSST-80型茶叶松包筛末机、6CH-54型茶叶烘干机。

1.2.2 主要试剂

色谱级甲醇、98%甲酸、质谱级乙腈、香气内标癸酸乙酯购买于美国Sigma公司。

标样:表没食子酸儿茶素没食子酸酯(epigallocatechin gallate,EGCG)、表没食子酸儿茶素(epigallocatechin,EGC)、儿茶素(catechin,C)、表儿茶素没食子酸酯(epicatechin gallate,ECG)、表儿茶素(epicatechin,EC)、没食子酸儿茶素(gallocatechin,GC)、没食子酸儿茶素没食子酸酯(gallocatechin gallate,GCG)、茶氨酸(theanine)以及18种氨基酸标准品购买于美国Sigma公司。

1.2.3 试验仪器设备

XEVO-TQS超高效液相色谱串联三重四极杆质谱仪,Waters有限公司;Agilent 6890N-5975B气相色谱-质谱联用仪,安捷伦科技有限公司;MPS型多功能进样器,德国Gerstel公司;5430R型台式高速冷冻离心机,德国Eppendorf公司;GLZ-B托普仪,浙江托普仪器有限公司;BAS124S型电子天平(精度:0.000 1 g),梅特勒-托利多仪器有限公司;LED白光灯源,深圳拓邦股份有限公司;其他常规检测仪器等。

1.3 试验方法

1.3.1 试验方案设计

以铁观音为研究对象,采用LED白光(400±10)mol/(m2·s)替代日光弥补光照进行多次光照射萎凋做青创新工艺试验。按照清香型铁观音加工工艺流程:鲜叶→光萎凋→做青(摇青⇌晾青,反复3次)→杀青→包揉→初烘→复烘→毛茶。通过设计3个不同次数LED光照射试验处理,第1次摇青前进行第1次LED光照射,即光照射1次(S-1),第1次摇青时间为4 min;第2次摇青前进行第2次LED光照射,即光照射2次(S-2),第2次摇青时间为10 min;第3次摇青前进行第3次LED光照射,即光照射3次(S-3),第3次摇青时间为16 min。每次LED光照时间为0.5 h,环境温度为25 ℃,相对湿度为60%,摊叶厚度为10mm,同时以全程无光照为对照组CK,最后分别制成铁观音毛茶,同时将4个不同试验组的毛茶样品进行真空冷冻干燥并贮存在-20 ℃低温冰箱中,用于测定铁观音毛茶的儿茶素、氨基酸、香气组分及其感官品质审评。

1.3.2 试验测定方法

1)靶向UPLC-QqQ-MS儿茶素组分测定

称取磨碎茶样0.05 g于1.5 mL离心管中,加入70%甲醇1 mL,涡旋1 min,25 ℃超声浸提20 min,然后12 000 r/min离心10 min,提取上清液并稀释400倍,采用UPLC-QqQ-MS进行定量分析。

UPLC检测的色谱条件:色谱柱为Waters BEH C18 (100 mm×2.1 mm,1.7m);溶剂A为去离子水和体积分数为0.1%的甲酸水溶液;溶剂B为乙腈和体积分数为0.1%的甲酸水溶液;流速0.3 mL/min;柱温40 ℃;样品室温度10 ℃;进样体积1L。按表1进行儿茶素组分梯度洗脱,重复3次。

通过质谱条件优化最终确定了本批次样品的QqQ-MS质谱分析条件:ESI离子源选择正、负离子模式(正离子模式锥孔电压为10 V,毛细管电压为3 kV;负离子模式锥孔电压为30 V,毛细管电压为2 kV),除溶剂温度为400 ℃,离子源温度设定为150 ℃,气体流速设为150 L/h,除溶剂气体流量设定为800 L/h。MRM参数优化:将配置好的茶氨酸、儿茶素组分等标准品溶液分别于正、负离子模式下进行全扫描来确定母离子,然后进行子离子扫描,确定子离子,优化碰撞能量。选择MRM 模式,填入母子离子对,分别优化去簇电压(DP)、碰撞能(CE)和碰撞通道输出加压值(CXP)参数的检测值,最后分别获得样品各儿茶素组分含量。

2)靶向UPLC-QqQ-MS游离氨基酸组分测定

样品前处理与儿茶素组分测定方法相同,然后将上清液稀释10倍,采用UPLC-QqQ-MS进行定量分析。UPLC检测的色谱条件:色谱柱:MerCKZIC-pHILIC(100 mm×2.1 mm,5m);溶剂C为5 mM乙酸铵水溶液;流速:0.4 mL/min;柱温:40 ℃;样品室温度:10 ℃;进样量:2L。按表1进行氨基酸组分梯度洗脱,重复3次。QqQ-MS质谱分析条件和MRM参数与儿茶素组分测定条件相同。

表1 儿茶素和氨基酸UPLC梯度洗脱溶液体积比

注:溶剂A:去离子水和体积分数为0.1%的甲酸;溶剂B:乙腈和体积分数为0.1%的甲酸;溶剂C:乙酸铵。

Note: Solvent A represents deionized water and formic acid with a volume fraction of 0.1%; Solvent B represents acetonitrile and 0.1% (v/v) formic acid; Solvent C represents ammonium acetate.

3)HS-SPME-GC-MS香气组分测定

采用HS-SPME提取香气:称取10.0 g磨碎茶样加入2 mg/mL癸酸乙酯(内标)25L,100 mL沸腾蒸馏水,放于磁力搅拌器上(搅拌速度:450 r/min),在50 ℃烘箱中平衡5 min后再吸附40 min,最后在GC-MS进样口于230 ℃下解吸5 min,重复3次。

GC-MS条件:色谱柱:HP-5MS(30 m×0.25 mm ID×0.25m膜厚);载气为高纯氦气,99.999%;进样口温度:230 ℃;脉冲不分流,进样1L,柱流速:1 mL/min;色谱-质谱接口温度:250 ℃。离子源温度:230 ℃;离子化方式:EI;电子能量:70 eV;程序升温参数:50 ℃保持2 min,以5 ℃/min升至180 ℃,保持2 min,再以10 ℃/min升到230 ℃,保持5 min,最后进行定性和定量分析。

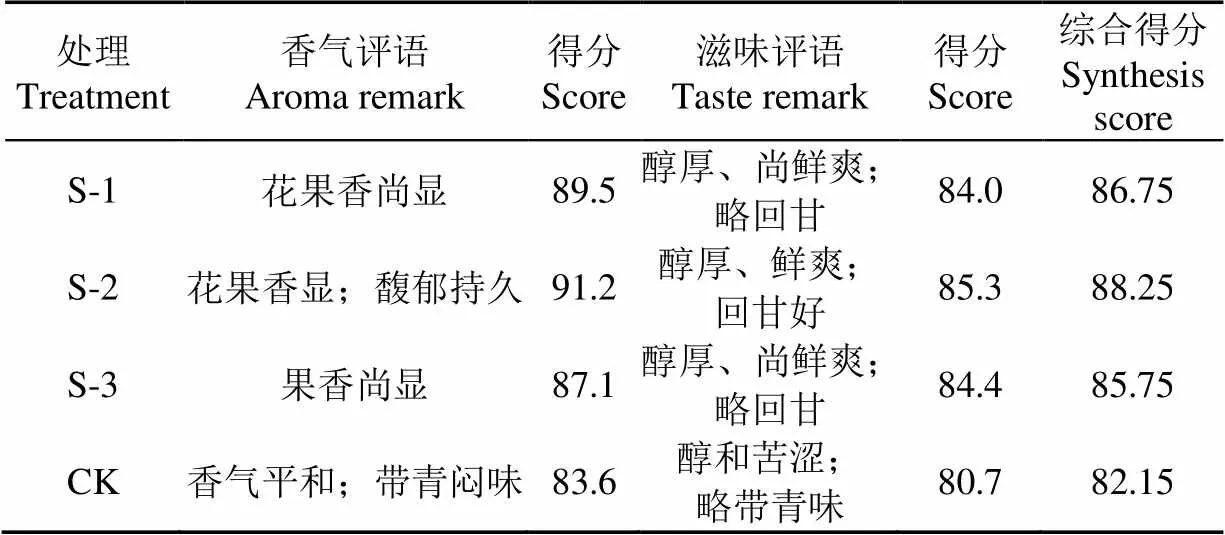

4)毛茶感官审评

按照GB/T 23776-2009[17]乌龙茶审评方法聘请5个专家进行密码审评。采用5.0 g茶样,110 mL沸水冲泡3次,以百分制为总分,并按照权重(香气50%+滋味50%)综合评定感官品质。

1.4 数据处理方法

采用Microsoft Office Excel 以及SPSS17.0统计软件(SPSS Inc., Chicago, IL, USA)进行数据处理和单因素方差(One-way ANOVA)和Duncan’s test、LSD显著性分析以及主成分分析。

2 结果与分析

2.1 不同处理的毛茶儿茶素和氨基酸组分含量

儿茶素和氨基酸是茶叶中主要呈味物质。儿茶素是类黄酮化合物之一,其组分占茶多酚含量的70%~80%,占鲜叶干物质量的12%~25%,能够直接反映茶叶苦涩味及醇厚感的重要指标之一[18-19]。茶叶加工过程中儿茶素物质受光照、温度、氧气等因素影响,极易发生一系列氧化、裂解、水解、异构化等复杂的化学变化[20-21]。

通过超高效液相色谱串联三重四极杆质谱UPLC-QqQ-MS检测分析发现,不同处理的毛茶儿茶素总量存在极显著差异(表2),按序由低到高依次为:S-2< S-3< S-1< CK。4个不同样品中被检测到的主要儿茶素组分以酯型EC、EGC以及非酯型EGCG、ECG为主,特别是EGCG含量高达49~72 mg/g,占样品中的总儿茶素含量的50%左右。与CK相比,3个处理的铁观音毛茶的酯型儿茶素EGC、GCG、EGCG与非酯型儿茶素C、EC、EGC、GC含量极显著降低;S-2、S-3处理极显著低于S-1处理,并且呈苦涩味的儿茶素组分含量较CK分别降低了29.6 %、24.4%,直接减少铁观音毛茶的苦涩感。

表2 不同处理的毛茶儿茶素组分含量

注:不同小写字母代表组间< 0.05水平显著差异,不同大写字母代表组间< 0.01水平极显著差异,S-1,S-2,S-3分别代表LED光照射1,2,3次,下同。

Note: Different lowercase letter represent statistical significance (<0.05) in different groups; Different capital letter represent statistical significance (<0.01) in different groups. The codes of S-1, S-2, S-3 represents one, two and three times of radiation by LED, the same as follows.

不同处理的毛茶氨基酸组分含量见表3。由表3可知,与CK相比,3个处理组被检测到的19种游离氨基酸组分总量显著提高,并且与S-2和S-3处理呈极显著差异,分别提高了20.5 %、15.4%。S-2处理氨基酸总量最高,达到1 273.47g/g,S-1和S-3处理的氨基酸总量差异不显著。通过比较分析发现4个样品均检测到高含量的茶氨酸Theanine,保持于500g/g以上,占游离氨基酸总量近50%;芳香族氨基酸中的色氨酸Trp以及谷氨酸Glu、天冬氨酸Asp等与鲜甜度相关的重要氨基酸组分在S-2和S-3处理的毛茶中显著提高。铁观音毛茶中的游离氨基酸组分含量的提高与采后叶片在茶叶加工过程中,特别是光照条件下其叶内蛋白质水解速率加快有关,在一定程度上可以促进铁观音毛茶香气的积累并提高滋味鲜甜感。多次LED光照处理毛茶的儿茶素含量减少和氨基酸含量增加,导致酚/氨比减小,有利于铁观音醇厚甘甜品质的提高。

表3 不同处理的毛茶氨基酸组分含量

2.2 不同处理的毛茶香气组分含量

茶叶芳香物质是由含量微少、性质不同的众多挥发性物质以不同浓度和比例组合而成[22-25]。同时,以花果香为特征气味的橙花叔醇、-法呢烯等倍半萜类化合物是铁观音中检测到的主要香气组分,并且香味阈值低,易于辨别[26-29]。不同处理的铁观音毛茶主要香气组分的相对含量见表4。

表4 不同处理的毛茶主要香气组分相对含量

注:相对质量分数(%)代表样品中各个香气组分峰面积除以内标癸酸乙酯的峰面积。

Note: Relative mass fraction (%) represents peak area ratio of volatile compounds to internal standard of ethyl decanoate.

由表4可知,3个处理组的铁观音毛茶呈花果香气味的-法呢烯和橙花叔醇的相对含量与CK相比存在显著差异。不同处理的毛茶-法呢烯相对含量按序依次为:CK< S-3< S-1< S-2;不同处理的毛茶橙花叔醇相对含量按序依次为:CK< S-3< S-1< S-2。与CK相比,S-2处理的-法呢烯和橙花叔醇的相对含量分别提高了56.28%、62.51%。S-3处理-法呢烯和橙花叔醇的相对含量低于S-1处理,说明伴随着摇青带来的叶片机械损伤,过度的LED光照射处理,叶片容易产生红变干枯,导致香气合成的作用机制受到阻碍,并且随着叶片持续失水,可以引起部分香气化合物被氧化释放。

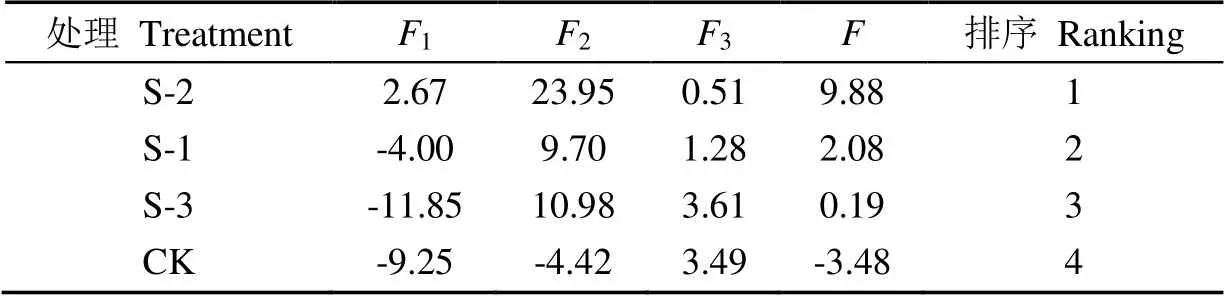

主成分分析法是利用部分代表性综合指标评价样品全部指标的一种统计方法,在农业、食品等[30-33]领域的科学研究分析中被广泛采用。本文为了综合评价不同处理铁观音毛茶的香气风味品质,将99种香气成分所构成的4×99的矩阵进行香气主成分分析。按照剔除最小特征值对应最大特征向量的变量原则,获得15种主要香气组分。通过标准化处理获得了香气各主成分的特征值和累计贡献率(表5)。

表5 香气主成分特征值与累计贡献率

由表5可知,前3个主成分的累计贡献率达到99.999%,香气主成分123的方差贡献率分别为57.708%,32.816%,9.475%,并且3个主成分的特征值>1.000,3个主成分分量包含了毛茶香气的绝大部分信息,因此选择前3个因子123进行香气主成分分析(123分别代表第一、二、三主成分),可以综合代表和评价4个不同处理的铁观音毛茶香气品质特点。将15个指标变量进行分析处理后转化为3个香气主成分123,各香气组分X对应的载荷矩阵见表6。通过计算各主成分方程载荷系数与对应香气组分X的相对含量相乘求和得出3个香气主成分123线性方程的数量值。最后以不同特征值的方差贡献率作123的加权系数,由各香气主成分F和对应的不同特征值的方差贡献率为权重相乘再求和建立综合评价模型:= 0.5771+ 0.3282+ 0.0943。根据铁观音毛茶中呈花果香气味的-法呢烯和橙花叔醇的载荷系数与122个主成分呈高度正相关,并且12累计贡献率达到90.525%,所以综合评价模型的值越大,铁观音毛茶的香气综合质量越好。因此,由综合评价函数计算得到不同处理的铁观音毛茶香气评价结果见表7。

表6 香气主成分对应的载荷矩阵

表7 香气质量综合评价

通过香气主成分综合分析得出不同处理的铁观音毛茶香气质量综合得分值由低到高依次为:CK 以香气50%、滋味50%为感官品质评价指标(表8),S-2处理的毛茶感官审评得分最高,达到88.25,S-1处理和S-3处理次之,CK的毛茶香气平和夹带青闷味、滋味苦涩略带青味,感官审评得分最低。 表8 毛茶感官品质审评结果 由此可知,适当增加光照次数可以促进铁观音滋味和香气物质代谢,提高茶叶品质。 本文以铁观音为研究对象,采用LED白光进行多次光照射处理创新工艺试验,以全程无光照为对照(CK),通过设计3个不同次数LED光照射试验组,第1次摇青前进行1次光照射,即光照射1次(S-1),第2次摇青前进行第2次光照射,即光照射2次(S-2),第3次摇青前进行第3次光照射,即光照射3次(S-3),分别制作铁观音毛茶。通过超高效液相色谱串联三重四极杆质谱UPLC-QqQ-MS以及顶空固相微萃取HS-SPME-GC-MS分别进行铁观音毛茶的儿茶素、氨基酸、香气组分的定性和定量分析。 1)与CK相比,3个不同处理的铁观音毛茶的酯型儿茶素EGC、GCG、EGCG与非酯型儿茶素C、EC、EGC、GC含量极显著降低(<0.01),游离氨基酸组分总量显著提高(<0.05);S-2和S-3处理铁观音毛茶中的呈苦涩味儿茶素组分总量分别降低了29.6%、24.4%;游离氨基酸组分总量分别提高了20.5%、15.4%,芳香族Trp以及与鲜甜味相关的Glu、Asp含量显著提高,毛茶的酚氨比减小,降低了铁观音毛茶的苦涩味并增强鲜甜口感。 2)适度增加LED光照射次数可以显著促进铁观音毛茶的-法呢烯和橙花叔醇的相对含量,与CK相比,S-2处理的-法呢烯和橙花叔醇的相对含量分别提高了56.28%、62.51%;基于香气主成分分析得出S-2处理的香气综合评价得分最高(9.88),CK得分最低(-3.48),与4个不同处理的铁观音毛茶感官审评结果排序相同。因此,多次间歇LED光照射技术可以显著提高铁观音毛茶的附加值,对于将来实现乌龙茶全天候工厂化连续化加工生产提供了有力的技术支撑。 [1] 陈宗懋,杨亚军. 中国茶经[M]. 上海:上海文化出版社,2011:565-573. [2] 宛晓春,李大祥,张正竹,等. 茶叶生物化学研究进展[J]. 茶叶科学,2015,35(1):1-10. Wan Xiaochun, Li Daxiang, Zhang Zhengzhu, et al. Research advance on tea biochemistry[J]. J. Tea Science, 2015, 35(1): 1-10. (in Chinese with English abstract) [3] Yang Z Y, Kobayashi E J, Katsuno T, et al. Characterisation of volatile and non-volatile metabolites in etiolated leaves of tea (Camellia sinensis) plants in the dark[J]. Food Chemistry, 2012, 135: 2268-2276. [4] 王登良,张灵枝,毛明辉. 不同光照强度晒青对单枞茶香气成分的影响[J]. 园艺学报,2005,32(4):669-672. Wang Dengliang, Zhang Lingzhi, Mao Minghui, et al. Effects of different light-intensity withering on aroma of Dancong tea[J]. Acta Horticulture Sinica, 2005, 32(4): 669-672. (in Chinese with English abstract) [5] 陈济斌,金心怡,郝志龙,等. 节能日光萎凋设施及其对白茶萎凋效果研究[J]. 农业工程学报,2012,28(19):171-177. Chen Jibin, Jin Xinyi, Hao Zhilong, et al. Research of sunlight withering room and its withering effect on white tea[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(19): 171-177. (in Chinese with English abstract) [6] Akhmetkhanov R S, Gudushauri E G, Modestov M B, et al. Modeling of thermal processes in the tea withering chamber[J]. Journal of Machinery Manufacture & Reliability, 2017, 46(2): 193-198. [7] 滑金杰,袁海波,江用文,等. 萎凋过程鲜叶理化特性变化及其调控技术研究进展[J]. 茶叶科学,2013,33(5):465-472. Hua Jinjie, Yuan Haibo, Jiang Yongwen, et al. A review on the regulation technique of withering process and the change in physical and chemical properties of leaves[J]. J. Tea Science, 2013, 33(5): 465-472. (in Chinese with English abstract) [8] 俞少娟,王婷婷,陈寿松. 光对茶树生产与茶叶品质影响及其应用研究进展[J]. 福建茶叶,2016(5):3-5. [9] 王登良,张灵枝,谭新东,等. 乌龙茶晒青(萎凋)工艺研究现状与进展[J]. 广东茶业,2000(4):40-42. [10] Ai Z, Zhang B, Chen Y, et al. Impact of light irradiation on black tea quality during withering[J]. Journal of Food Science & Technology, 2017, 54(5): 1-16. [11] 陈寿松,金心怡,林宏政,等. 乌龙茶LED 补光萎凋品质特性研究[J]. 农业机械学报,2016,46(7):282-289. Chen Shousong, Jin Xinyi, Lin Hongzheng, et al. Research on quality characteristic using LED as supplementary lighting during withering process in Oolong Tea[J]. Transactions of the Chinese Society for Agricultural Engineering, 2016, 46(7): 282-289. (in Chinese with English abstract) [12] 罗玲娜,林永胜,周子维,等. 不同LED 光质萎凋对白茶品质的影响[J]. 福建农林大学学报:自然科学版,2016,45(3):262-268. Luo Lingna, Lin Yongsheng, Zhou Ziwei, et al. Effect of different LED lights in withering on quality of white tea[J]. Journal of Fujian Agriculture and Forestry University (Natural Science Edition), 2016, 45(3): 262-268. (in Chinese with English abstract) [13] 黄藩,陈琳,周小芬,等. 蓝光/红光对工夫红茶萎凋中鲜叶氨基酸和儿茶素组分含量的影响[J]. 福建农业学报,2015,30(5):509-515. Huang Fan, Chen Lin, Zhou Xiaofen, et al. Effect of red and blue light exposure during withering on amino acid and catechine contents of congou black tea[J]. Fujian Journal of Agricultural Sciences, 2015, 30(5): 509-515. (in Chinese with English abstract) [14] 袁林颖,杨娟,钟应富,等. LED光质萎凋对绿茶品质的影响研究[J]. 南方农业,2016,10(16):90-92. [15] Fu X M, Chen Y Y, Mei X, et al. Regulation of formation of volatile compounds of tea (Camellia sinensis) leaves by single light wavelength[J]. Scientific Report, 2015, 5: 16858-16869. [16] 陈林,陈键,陈泉宾,等. 做青工艺对乌龙茶香气组成化学模式的影响[J]. 茶叶科学,2014,34(4):387-395. Chen Lin, Chen Jian, Chen Quanbin, et al. Effects of green-making technique on aroma pattern of Oolong tea[J]. J. Tea Science, 2014, 34(4): 387-395. (in Chinese with English abstract) [17] 中华人民共和国国家质量监督检验检疫总局.茶叶感官审评方法:GB/T 23776-2009 [S]. 北京:中国标准出版社,2009. [18] 宛晓春,夏涛. 茶树次生代谢[M]. 北京:科学出版社,2015:145-149. [19] 陈林,陈键,张应根,等. 清香型乌龙茶品质形成过程中儿茶素类和嘌呤碱指纹图谱变化规律[J]. 茶叶科学,2011,31(6):493-503. Chen Lin, Chen Jian, Zhang Yinggen, et al. Variation of catechins and purine alkaloids fingerprints during the formation of fresh scent-flavor Oolong tea[J]. J. Tea Science, 2011, 31(6): 493-503. (in Chinese with English abstract) [20] 夏涛,高丽萍. 类黄酮及茶儿茶素生物合成途径及其调控研究进展[J]. 中国农业科学,2009,42(8):2899-2908. Xia Tao, Gao Liping. Advances in biosynthesis pathways and regulation of flavonoids and catechins[J]. Scientia Agriculture Sinica, 2009, 42(8): 2899-2908. (in Chinese with English abstract) [21] 夏涛,高丽萍,刘亚军,等. 茶树酯型儿茶素生物合成及水解途径研究进展[J]. 中国农业科学,2013,46(11):2307-2320. Xia Tao, Gao Liping, Liu Yajun , et al. Advances in research of biosynthesis and hydrolysis pathways of gallated catechins in Camellia sinensis[J]. Scientia Agriculture Sinica, 2013, 46(11): 2307-2320. (in Chinese with English abstract) [22] Yang Z Y, Baldermann S, Watanabe N, et al. Recent studies of the volatile compounds in tea[J]. Food Research International, 2013, 53: 585-599. [23] Zheng X Q, Li Q S, Xiang L P, et al. Recent advances in volatiles of teas[J]. Molecules, 2016, 21: 338-350. [24] 孔滢,孙明,潘会堂,等. 花香代谢与调控研究进展[J]. 北京林业大学学报,2012,34(2):146-154. Kong Ying, Sun Ming, Pan Huitang, et al. Advances in metabolism and regulation of floral scent[J]. J. Beijing Forestry University, 2012, 34(2): 146-154. (in Chinese with English abstract) [25] 王力,林智,吕海鹏,等. 茶叶香气影响因子的研究进展[J]. 食品科学,2010,31(15):293-298. Wang Li, Lin Zhi, Lü Haipeng, et al. Research progress in affecting factors of tea aroma[J]. Food Science, 2010, 31(15): 293-298. (in Chinese with English abstract) [26] 陈寿松,林宏政,孙云,等. 乌龙茶萜类物质及其代谢调控研究进展[J]. 中国农业科技导报,2016,18(5):72-80. Chen Shousong, Lin Hongzheng, Sun Yun, et al. Research progress on terpenoids and metabolic regulation in Oolong Tea[J]. Journal of Agricultural Science and Technology, 2016, 18(5): 72-80. (in Chinese with English abstract) [27] Zhu J C, Chen F, Wang L Y, et al. Comparison of aroma-active volatiles in Oolong tea infusions using GC-Olfactometry, GC-FPD and GC-MS[J]. Journal of Agriculture Food Chemistry. 2015, 63: 7499-7510. [28] 陈泉宾,张应根,陈林,等. 不同类型乌龙茶香气差异分析[J]. 茶叶科学技术,2013,4:25-30. Chen Quanbin, Zhang Yinggen, Chen Lin, et al. Aroma difference analysis in different Oolong tea[J].Tea Science Technology, 2013, 4: 25-30. (in Chinese with English abstract) [29] 钟秋生,吕海鹏,林智,等. 东方美人茶和铁观音香气成分的比较研究[J]. 食品科学,2009,30(8):182-186. Zhong Qiusheng, Lü Haipeng, Lin Zhi, et al. Comparison of aroma constituents between Oriental Beauty tea and Tieguanyin tea[J]. Food Science, 2009, 30(8): 182-186. (in Chinese with English abstract) [30] 叶秋萍,金心怡,徐小东,等. 茉莉花释香吸香装置研制及香气吸附试验[J]. 农业工程学报,2014,30(21):316-323. Ye Qiuping, Jin Xinyi, Xu Xiaodong, et al. Development of device for releasing and collecting jasmine flower fragrance and its adsorption test[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(21): 316-323. (in Chinese with English abstract) [31] 岳田利,彭帮柱,袁亚宏,等. 基于主成分分析法的苹果酒香气质量评价模型的构建[J]. 农业工程学报,2007,23(6):223-227. Yue Tianli, Peng Bangzhu, Yuan Yahong, et al. Modeling of aroma quality evaluation of cider based on principal component analysis[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2007, 23(6): 223-227. (in Chinese with English abstract) [32] 霍丹群,张苗苗,侯长军,等. 基于主成分分析和判别分析的白酒品牌鉴别方法[J]. 农业工程学报,2011,27(14):297-301. Huo Danqun, Zhang Miaomiao, Hou Changjun, et al. Recognition method of liquor brands based on principal component and linear discriminant analysis[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(14): 297-301. (in Chinese with English abstract) [33] 张雪波,肖世青,杜先锋,等. 基于主成分分析法的安溪铁观音香气质量评价模型的构建[J]. 食品科学,2012,33(22):225-230. Zhang Xuebo, Xiao Shiqing, Du Xianfeng, et al. Modeling for aroma quality evaluation of Anxi Tieguanyin tea based on principal component analysis[J]. Food Science, 2012, 33(22): 225-230. (in Chinese with English abstract) Influence of multi intermittence radiation by LED on flavor components in Tieguanyin tea Chen Shousong1, Jin Xinyi1,2, You Fangning1, Zhou Ziwei1, Li Xinlei1, Hao Zhilong1,2, Sun Yun1,2※ (1.,350002,; 2.,350002,) Light is an important factor, which decides joyful aroma and mellow taste in Oolong tea. Solar withering is the first and essential process, and a large number of primary and secondary metabolites are induced and regulated under several minutes of radiation during Oolong tea manufacturing. However, rainy days usually take place in fastigium production period, and thus quality of Oolong tea has no fruit floral odor and taste is niffy. In recent years, many scholars selected LED (light emitting diode) as an artificial light source to improve quality of special tea. In order to explore the influence of multi intermittence radiation radiation with different times by LED on quality in Oolong tea, in this study, Tieguanyin was taken as research material, and dark treatment (CK) was used as control. Meanwhile, 3 treatments were performed by white LED, one time radiation (S-1), which was conducted before the first assignment in turning over process, the other two treatments (S-2, S-3) were designed by adding radiation for 1 time and 2 times before the second and third assignment in turning over process, respectively. The parameters of environment were set as follows: Photosynthetically active radiation (PAR) was set as (400±10)mol/(m2·s), duration of illumination was set as 30 min for each time, temperature was set as 25 ℃, relative humidity was set as 60%, and thickness of leaves was set as 10 mm. Then, 4 samples of primary tea were made following technological process of fen-flavor Tieguanyin, and were frozen in refrigerator at -20 ℃. Catechins, amino acids, aroma and sensory evaluation in Tieguanyin primary tea were performed for all samples by UPLC-QqQ-MS and HS-SPME-GC-MS. Firstly, the multi intermittence radiation device by LED in Oolong tea was developed by ourselves. The device mainly included LED panel, heat pump, rocking device, transfer platform, ventilating slot, superior lobe device, and transmission mechanism. Several set devices would perform cycle operation of different times in light radiation and turning over process. Secondly, compared to control treatment, contents of all nongallated and gallated catechins including C (catechin), EC (epicatechin), GC (gallocatechin), EGC (epigallocatechin), GCG (gallocatechin gallate), ECG (epicatechin gallate), EGCG (epigallocatechin gallate) were significantly reduced in different times of radiation. The contents of total catechins in 4 samples with ascending order were showed as follows: S-2, S-3, S-1, CK. The contents of catechins were very dramatically decreased in S-2 and S-3 by LED, and it showed a reduction of 29.6 % and 24.4 %, respectively, and had a lower bitterness in primary tea. However, the total content of amino acids was enhanced, especially in S-2 and S-3 treatment, and it showed a rise of 20.5 % and 15.4 %, respectively. The content of total amino acids in 4 samples with ascending order was showed as follows: CK, S-1, S-3, S-2. Several aromatic and fresh-sweet amino acids including Trp, Glu, Asp showed an obvious increasing trend, which resulted in more brisk and sweet taste in primary tea. Accordingly, the ratio of phenols to amino acids showed a decrease variation, and can improve taste sensory in primary tea. Thirdly, volatile components of different treatments were assayed by gas chromatography mass spectrometry (GC-MS). Principal component analysis method was also used to evaluate the results. Relative content of alpha-farnesene and nerolidol in 4 samples with ascending order was showed as follows: CK, S-3, S-1, S-2. In contrast to the CK, the relative contents of alpha-farnesene and nerolidol in S-2 treatment were increased by 56.28% and 62.51%, respectively. The comprehensive evaluation score of volatile quality in S-2 treatment was the highest, approached to 9.88, S-3 treatment ranked the second and the CK ranked the last. The sensory evaluation results of quality in primary tea showed a similar sort to principal component analysis of volatiles. In conclusion, the taste and volatile of Oolong tea can be regulated and improved by adding the appropriate times of light radiation, especially in S-2 treatment. It can be a promising technology, especially for the factorization and standardization on rainy days during Oolong tea manufacturing. radiation; principal component analysis; test; Tieguanyin; light emmiting diode; multi intermittence; volatile components; quality 10.11975/j.issn.1002-6819.2018.02.042 S571.1 A 1002-6819(2018)-02-0308-07 2017-07-07 2018-01-07 “十二五”科技支撑计划项目(2014BAD06B06-06)、国家现代农业(茶叶)产业技术体系建设专项资金项目(CARS-19)、国家重大农技推广服务试点项目(KNJ-151063)和福建省现代农业茶产业体系建设项目(NYT2017001) 陈寿松,男(汉族),福建仙游人,博士生,主要从事茶叶加工与加工工程研究。Email:css7788531@163.com 孙 云,女(汉族),福建宁德人,教授,博士生导师,主要从事茶叶加工与品质研究。Email:sunyun1125@126.com 陈寿松,金心怡,游芳宁,周子维,李鑫磊,郝志龙,孙 云. 多次间歇LED光照射对铁观音风味组分的影响[J]. 农业工程学报,2018,34(2):308-314. doi:10.11975/j.issn.1002-6819.2018.02.042 http://www.tcsae.org Chen Shousong, Jin Xinyi, You Fangning, Zhou Ziwei, Li Xinlei, Hao Zhilong, Sun Yun. Influence of multi intermittence radiation by LED on flavor components in Tieguanyin tea[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(2): 308-314. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.02.042 http://www.tcsae.org2.3 不同处理的毛茶感官品质评价

3 结 论