含水率对玉米果穗抗压特性的影响

2018-02-28李心平耿令新姬江涛

李心平,熊 师,耿令新,姬江涛

含水率对玉米果穗抗压特性的影响

李心平,熊 师,耿令新,姬江涛

(河南科技大学农业装备工程学院,洛阳 471003)

为研究玉米果穗的抗压特性及破裂机理,探索含水率对玉米果穗抗压特性的影响,该文先分析了玉米果穗的生物特性,然后选取2个品种的玉米果穗,含水率处理至5个标准,在电子万能试验机上进行了静态压缩试验。试验结果表明:玉米芯含水率对玉米果穗抗压特性有极大影响,含水率低于13%时,随着含水率的降低果穗抗压能力小幅度增强;含水率在13%~25%内,随着含水率的增加果穗抗压能力增强;含水率高于25%后抗压能力急剧减弱;含水率为25%时玉米果穗抗压能力最强;玉米果穗的破裂是由内向外逐步破裂的过程,在受压过程中,芯髓最先破裂,随后木质环形体破裂,木质环形体是玉米果穗抗压的主要部位;玉米果穗在受压过程中存在籽粒脱落的现象,对玉米果穗施加的载荷值低于610 N不仅可以防止果穗断裂而且有利于脱粒。该研究结果可为玉米不断芯脱粒的进一步研究提供参考。

水分;农作物;压力;玉米果穗;抗压特性;含水率;试验

0 引 言

玉米果穗的不断芯脱粒是在玉米的脱粒过程中保持玉米芯完整不断裂。相对于市面上断芯的玉米脱粒机,不断芯脱粒能够简化清选环节,精简清选装置,降低脱粒机械的复杂程度,减少功耗,从而提高脱粒机械的可靠性同时降低成本,而且还可以最大程度地回收玉米芯,减少玉米芯在脱粒过程中的损耗,方便玉米芯后续的加工利用,玉米果穗的不断芯脱粒是玉米脱粒机械的重要发展方向[1-6]。

国内外对玉米脱粒的研究主要集中在籽粒特性和脱粒装置等方面。张新伟等[7]得出了玉米种子内部机械裂纹产生与扩展的微观机理;蔡超杰等[8]对发现种子玉米生物力学特性对籽粒破损率、未脱净率和含杂率有较大影响;高连兴等[9]利用籽粒破损强度、果柄强度和脱粒作用力等试验研究含水率对种子玉米脱粒性能的影响机理;张翔等[10]对立式轴流玉米单穗种子脱粒机进行了参数优化;Petkevichius等[11]研究玉米果穗的脱粒过程发现高含水率玉米果穗的脱粒损伤明显高于中等含水率的果穗;Folarin等[12]开发了新型玉米脱粒机;Steponavicius等[13]通过脱粒试验发现脱粒滚筒的惯性矩增大对脱粒过程的影响是积极的。玉米果穗在脱粒过程中会受到脱粒部件的挤压、撞击等外力作用,这些外力会导致玉米籽粒的损伤和玉米果穗的破裂。果穗的破裂直接影响不断芯脱粒的效果,而有关玉米果穗破裂方面的理论研究比较薄弱,国内外鲜有玉米果穗抗压特性方面的文献见诸报道。

对玉米果穗抗压特性进行研究,可以为脱粒部件的形状尺寸、脱粒部件对果穗作用力的大小等参数设计提供依据[14-18]。本文主要研究玉米果穗的抗压特性及破裂机理,分析应力—应变规律以及压缩破坏特征[19-24]。通过不同含水率下的压缩试验,探究含水率对玉米果穗抗压特性的影响,分析适合玉米果穗不断芯脱粒的含水率最优值、玉米果穗的抗压峰值力等参数特性。

1 玉米果穗生物特性

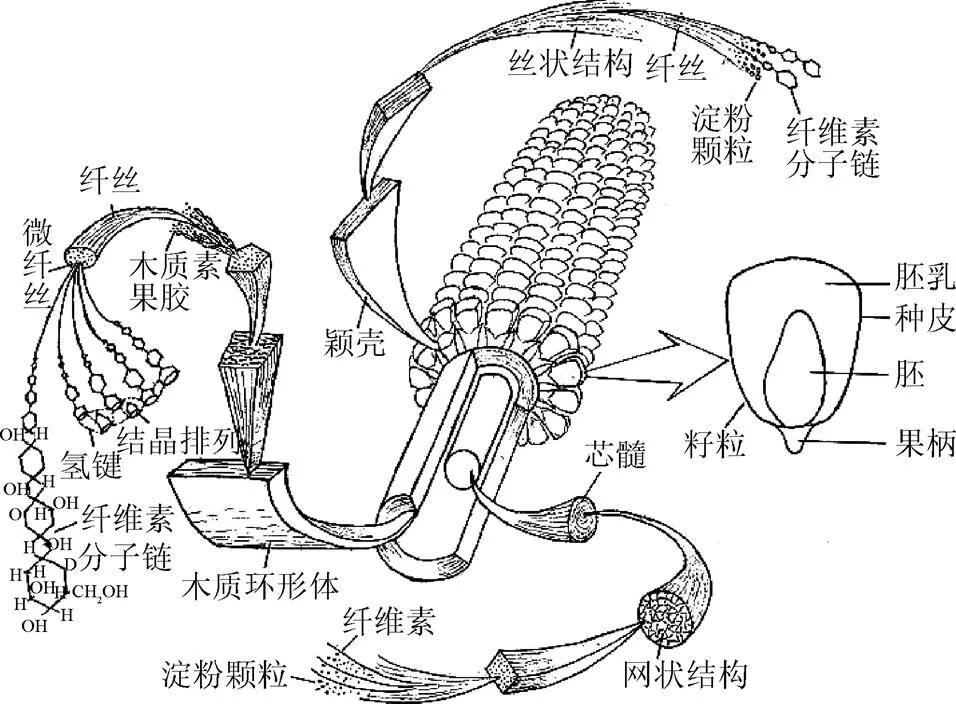

玉米果穗是由玉米芯和玉米籽粒组成,玉米芯是玉米脱去籽粒后的果轴,一般占玉米果穗总干重的20%~30%。玉米芯自内向外由芯髓、木质环形体和颖壳三部分组成[25]。玉米果穗是一种由多胞层次状生物复合材料组成的多结构物体,其物理力学性质取决于化学组成与物理构造特点。图1为玉米果穗构造形成示意图。

如图1所示,玉米芯主要由纤维素、淀粉、木质素和少量的灰分组成[26],木质环形体由纤维素链状分子形成单位晶胞,单位晶胞又形成纤维素基本纤丝,基本纤丝再聚集形成微纤丝后镶嵌在木质素和果胶所组成的基体中,然后形成片层结构,再由多个片层同心地形成木质环形体[27],结构密实,质地坚硬,因此木质环形体坚固而且强度大。芯髓是由纤维素形成的纤丝与淀粉颗粒相互嵌套组成基体,然后形成网状结构,再由多个网状体相互聚集形成芯髓,网状结构的特征导致其结构疏松,内部间的连接不紧密。颖壳是由淀粉颗粒包裹在纤维素周围组成基体,然后形成丝状结构,再由多条丝状体相互排列聚集形成颖壳,颖壳则比较松软,是一个一个地连接在木质环形体表面,相互之间独立没有连接,颖壳之间通过紧密地排列形成了玉米芯稳定的表面。

图1 玉米果穗的构造

2 材料与方法

2.1 试验材料与设备

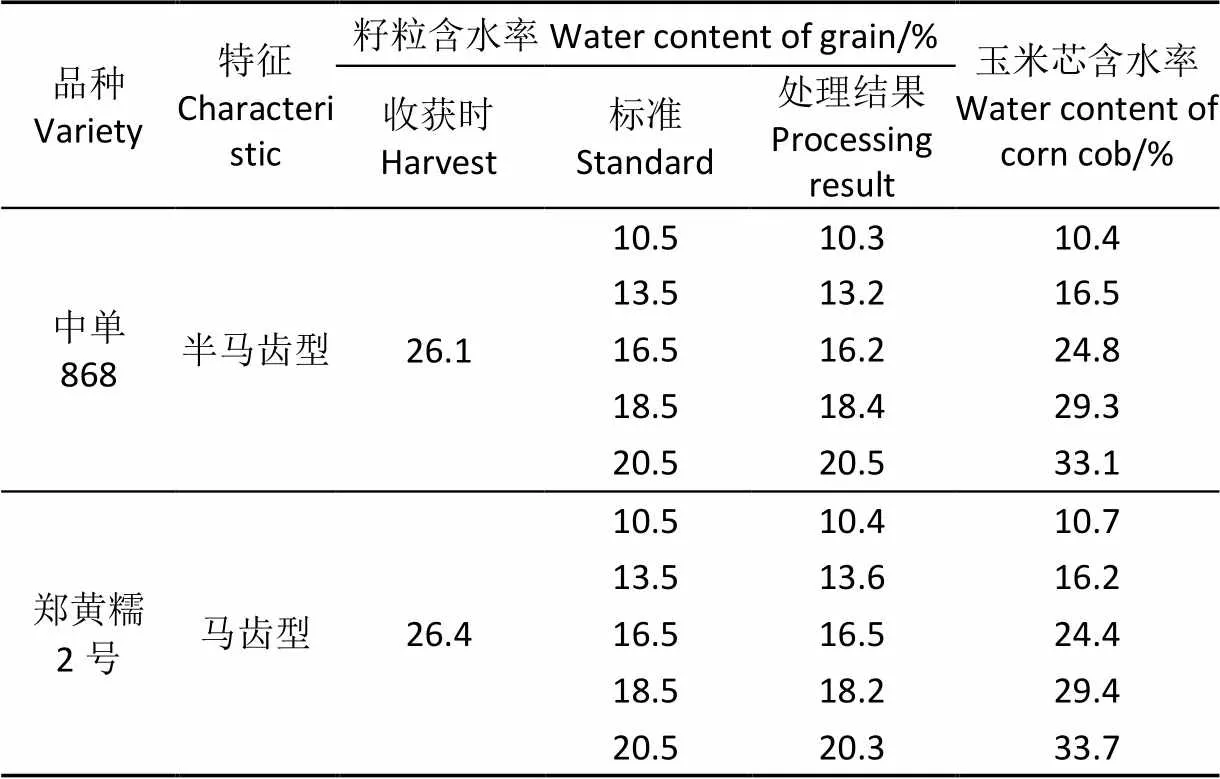

选取2个玉米品种作为试验材料,手工采摘,通过自然晾晒将籽粒含水率处理至5个标准[28],每个籽粒含水率均允许上下浮动3个单位(±0.3%),同时测出对应的玉米芯含水率,结果见表1。每个品种每一含水率均准备8个完好无损的玉米果穗,从中随机抽取6个果穗作为试验样本。

表1 试验材料参数

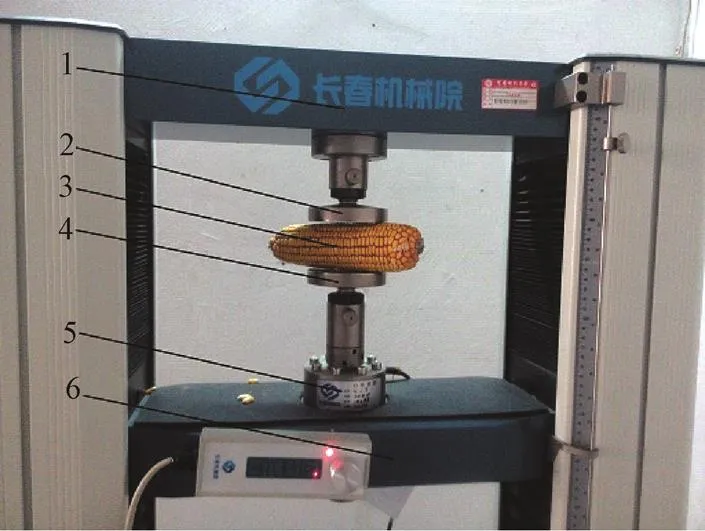

主要试验设备有DNS系列电子万能试验机,美国帝强十二型水分测试仪和DSC-W630型相机(索尼有限公司生产)。DNS系列电子万能试验机由试验机主机和计算机组成,示值误差为±0.5%,试验机主机结构如图2所示;负荷传感器采用CLY型、精度为0.02、量程为10 kN的力传感器。电子万能试验机和负荷传感器均由长春机械科学研究院有限公司生产。美国帝强十二型水分仪由DICKEY-john公司生产,示值误差为±0.5%。

1.上横梁 2.上压盘 3.玉米果穗 4.下压盘 5.负荷传感器 6.活动横梁

2.2 试验方法

试验时,将玉米果穗放在压缩夹具下压盘工作面中央,点击开始按钮后,活动横梁开始向上移动。当压缩夹具上压盘接触到玉米果穗后,活动横梁以5 mm/min的速度均匀缓慢地向上移动,同时计算机开始记录位移-力、位移-应力的数据。试验设定的断裂敏感度为最大值的80%,因为数值下降至最大值的80%时,玉米果穗已经完全破裂,满足试验结束的要求。当达到断裂敏感度时,活动横梁停止,试验自动结束,计算机输出载荷、应力的数据以及相应的图像。用相机拍下玉米果穗破裂过程中外部变化的照片,然后将果穗沿径向切开,观察其内部变化,记录玉米果穗的破坏形式,然后进行下一次试验,每个品种每一含水率均进行6次试验。为观察记录玉米果穗的内部破裂过程,每个品种每一玉米芯含水率均额外选取一个果穗从中间径向切开,把切开的玉米果穗放到下压盘上进行试验,以果穗径向截面为观测窗口,用相机连续拍下果穗压缩试验的全过程。

2.3 试验因素和指标

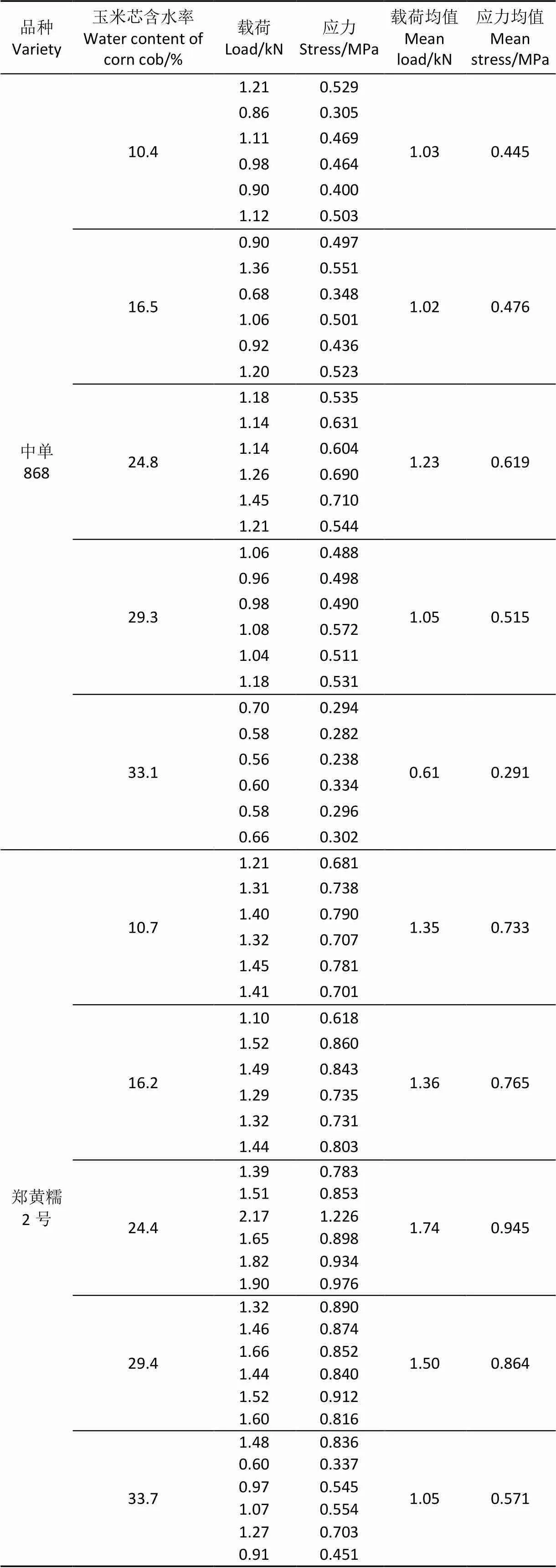

选取玉米品种、玉米芯含水率为试验因素,由于最大载荷能够直观显示玉米果穗所能承受的最大压力,最大应力是玉米果穗抗压强度的量化表示,因此把玉米果穗受到的最大载荷和最大应力作为试验指标,采用双因素随机区组试验,如表2所示。

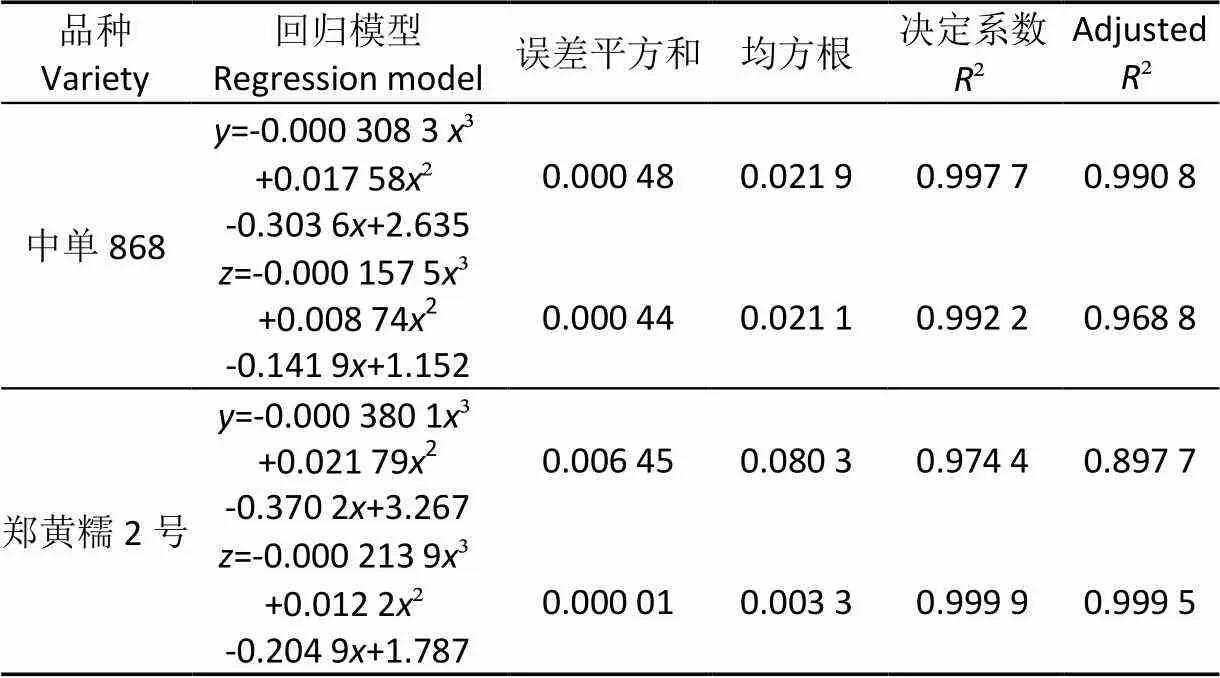

为研究玉米芯含水率对玉米果穗受压过程中载荷与应力的影响,以玉米各品种为母体、以玉米芯含水率为因素用MATLAB软件对表2进行一元非线性回归分析,对数据进行拟合,回归拟合后得到(玉米芯含水率)与(玉米果穗最大载荷)和(玉米果穗最大应力)的对应函数关系,回归分析结果见表3。

由表3可知,玉米芯含水率对2个品种玉米果穗的最大载荷和最大应力影响很大,回归拟合的决定系数均在0.97以上。对回归方程的显著性及回归系数的显著性检验,其检验结果均为显著或极显著。

表2 玉米果穗压缩试验结果与处理

表3 回归分析结果

注:为玉米芯含水率,为玉米果穗最大载荷,为玉米果穗最大应力。

Note:is water content of corn cob,is maximum load of corn ear,is maximum stress of corn ear.

3 结果与分析

3.1 玉米芯含水率对玉米果穗抗压特性的影响分析

3.1.1 玉米芯含水率对玉米果穗塑性的影响

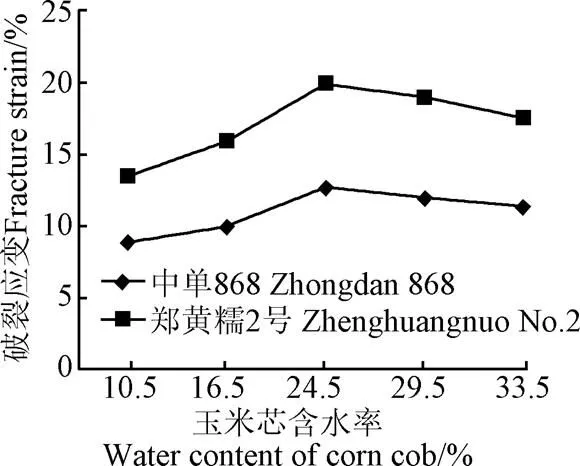

玉米果穗完全破裂时的应变值为果穗的破裂应变,2个玉米品种的果穗破裂应变与玉米芯含水率的关系如图3所示。为方便表述,2个品种的玉米芯含水率均按10.5%、16.5%、24.5%、29.5%、33.5%区分。玉米芯含水率10.5%的玉米果穗破裂应变最小,表明其塑性变形过程最短,说明低含水率下的玉米果穗塑性弱;玉米芯含水率24.5%的玉米果穗破裂应变最大,表明其塑性变形过程最长,说明玉米芯含水率为24.5%时玉米果穗塑性最强;随着含水率的增加,破裂应变值先增加后减小,说明随着玉米芯含水率的增加,玉米果穗的塑性先增强后减弱。

图3 玉米芯含水率与玉米果穗破裂应变的关系

3.1.2 玉米芯含水率对玉米果穗应力与载荷的影响

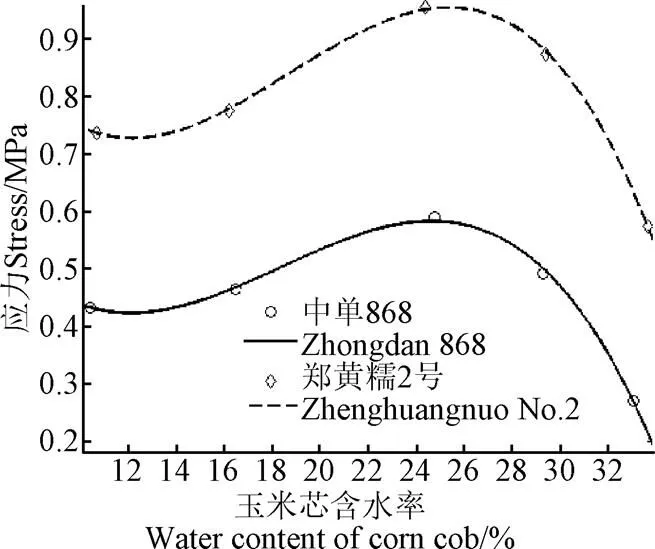

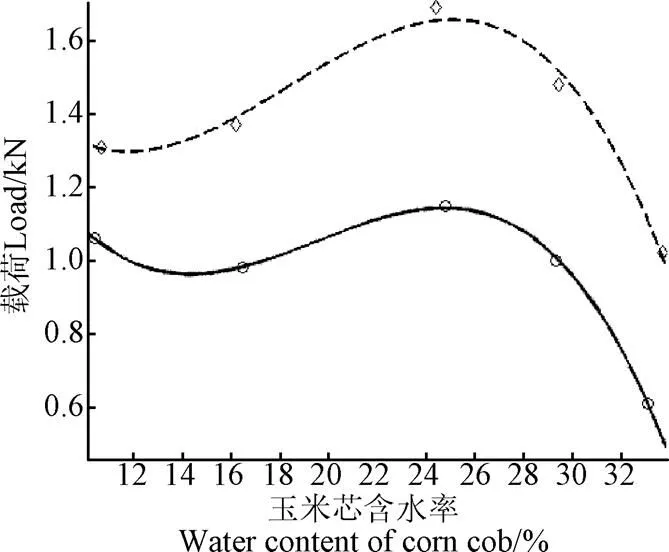

图4a表明含水率低于13%时,玉米果穗最大应力随含水率的减小而增大,且曲线较为平缓,说明其抗压强度随含水率的减小而缓慢的增大;图4b表明含水率低于13%时,玉米果穗所能承受的最大载荷随含水率的减小而缓慢的增大。由于在低含水率下,玉米果穗塑性弱,其抵抗外力作用的形变能力弱,因此低含水率下的抗压性能总体较弱。但随着含水率的减小,玉米果穗的抗压强度缓慢增强,导致玉米果穗抗压能力小幅度增强。

图4a表明在13%~25%的含水率区间内,玉米果穗最大应力随含水率的增加而增大,说明玉米果穗抗压强度随含水率的增加而提高、但变化速度较缓;图4b表明在13%~25%的含水率区间内,玉米果穗所能承受的最大载荷随含水率的增加而提高、但变化速度较缓。

a. 玉米芯含水率与玉米果穗破裂最大应力的关系

a. Relationship between water content of corn cob and maximum stress in the rupture of corn ear

b. 玉米芯含水率与玉米果穗破裂最大载荷的关系

研究发现,较低含水率段内的含水率对其塑性影响较大,随着含水率的增加其塑性增强,使玉米果穗抵抗外力作用的形变能力增强,压缩过程中产生了较为明显的塑性变形;同时果穗抗压强度也随含水率的增加而增加,从而提高了玉米果穗的抗压能力。

由图4a可知,含水率高于25%后,玉米果穗最大应力随含水率的增加而降低且变化速度较快,说明玉米果穗抗压强度随含水率的增加而急剧减小;由图4b可知,含水率高于25%后,玉米果穗所能承受的最大载荷随含水率的增加而降低且变化速度较快。高含水率段玉米果穗抗压强度减弱严重,同时玉米果穗的塑性也在降低,导致玉米果穗抵抗破裂的能力变弱,降低了玉米果穗的抗压能力。

由图4可知,在含水率为25%时,玉米果穗的最大应力和最大载荷均达到峰值,说明玉米芯含水率25%的玉米果穗抗压能力最好。

3.2 玉米果穗受压过程中的破裂分析

3.2.1 玉米果穗内部变化与破裂机理

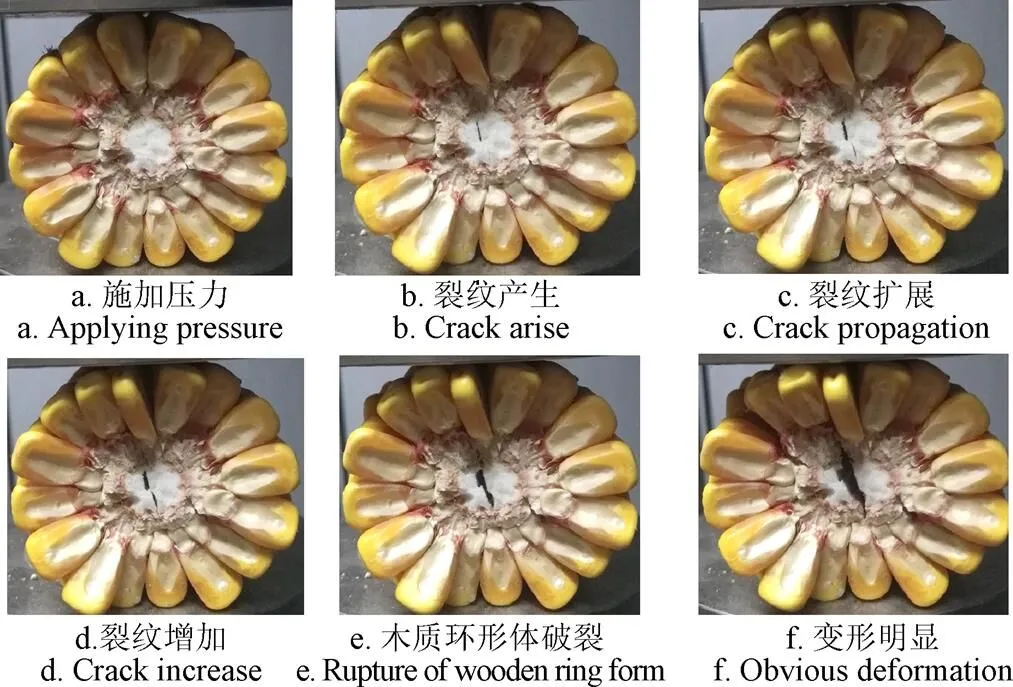

分析比较果穗在试验过程中的径向切面照片可知,不同品种不同含水率的玉米果穗在压力作用下破裂的内部过程均相似,破裂过程如图5所示。

图5a显示压盘开始接触果穗;随着压力的不断增大,如图5b所示,玉米果穗开始破裂,芯髓最先出现裂纹;图5c~图5d显示裂纹逐渐变长变宽,裂纹从芯髓部分向上、下2个方向同时扩展,逐渐接近木质环形体;图5e~图5f显示顺着裂纹扩展的方向,木质环形体逐渐破裂,裂缝快速变大,果穗被压扁,变形明显。

图5 玉米果穗破裂过程

在玉米果穗竖直方向施加压力后,如图6所示,外加压力作用在籽粒上后分为指向玉米芯的力1和侧向压力2。1顺着籽粒传递到颖壳深处,并继续传递到木质环形体。在初始阶段,压力一直由木质环形体承受,并没有作用到芯髓上,芯髓受到了木质环形体的保护。但随着压力的逐渐增加,玉米果穗开始出现变形,同时木质环形体也开始出现微弱变形,逐渐地由圆形变为椭圆状。此时木质环形体传递的力环向作用于芯髓四周,该环向分布的力可正交分解为竖直方向的压力3和水平方向的张力4。在3的挤压和4的拉伸作用下,芯髓内部间的连接遭到破坏,芯髓中部开始出现裂纹,随着力的增大,裂纹缝隙变宽,向上下2个方向扩展,因此裂纹一般都是竖直方向的。裂纹扩展接近木质环形体后,木质环形体与裂纹接触处最为脆弱,当压力超过木质环形体的破裂极限值时,木质环形体与裂纹接触的地方破裂,从而使裂纹从内部一直扩展到果穗外部。

注:F为施加的压力,kN;F1为指向玉米芯的力,kN;F2为侧向压力,kN;F3为竖直压力,kN;F4为水平张力,kN。

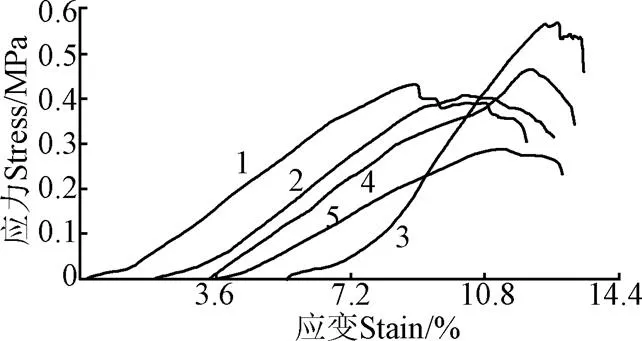

图7反映了不同玉米芯含水率下应力与应变的关系,5种含水率的曲线走势比较相似,分析应力-应变曲线可知[29-30]:随着应变的增加,应力逐渐增大,玉米果穗发生塑形变形,应力到达峰值后开始减小,曲线呈锯齿形波动,进入屈服阶段。在玉米果穗径向切面的压缩试验过程中,当芯髓出现裂纹时观察发现计算机输出的应力曲线并没有下降,反而继续上升,直到木质环形体出现裂纹时,曲线才开始下降。这说明芯髓的破裂对果穗的抗压性能没有影响,木质环形体的破裂导致了果穗内部稳定性的明显破坏。由于木质环形体坚固且强度大,在受压过程中能一直承受主要的载荷,因此木质环形体是玉米果穗抗压的主要部位。

注:玉米芯含水率:1. 10.5%2. 16.5%3. 24.5%4. 29.5%5. 33.5%

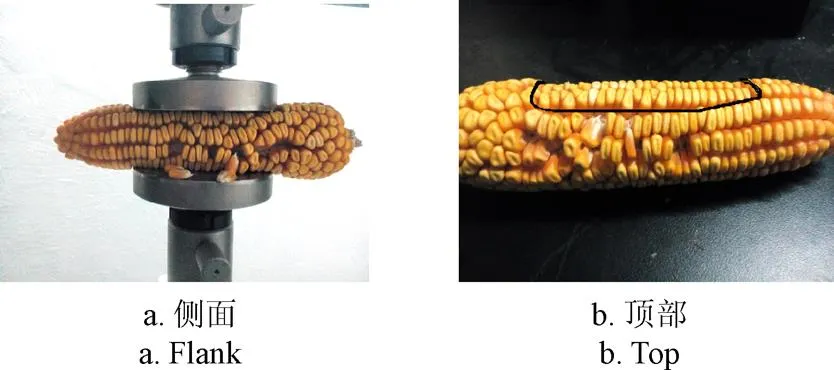

3.2.2 玉米果穗外部变化与分析

图8a记录了在压缩试验中完整玉米果穗受压破裂时果穗侧面的变化情况,由图8a可知,玉米果穗出现变形,侧面籽粒出现松动、脱落现象,籽粒排列杂乱,但并无籽粒破裂的情况。图8b记录了果穗受压破裂时果穗顶部的变化情况,图中黑线圈出的区域为果穗承受正压的籽粒,图片显示承受正压的籽粒排列完好、无脱落现象,籽粒也没有破裂。

图8 玉米果穗外部变化

对玉米果穗施加压力后,压力的一部分分解为籽粒的侧向挤压力2,上下两处的侧向挤压力同时向果穗侧面籽粒传递,玉米果穗侧面单个籽粒的受力分析如图9所示。

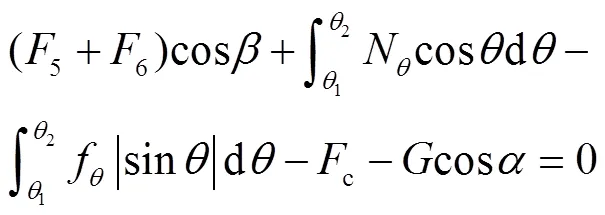

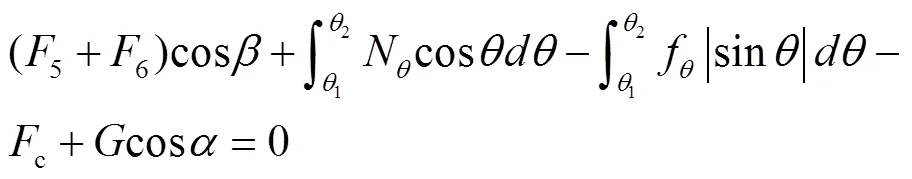

籽粒受到外力后的径向平衡方程如式(1)所示。

式中1为的最小值;2为的最大值。

果穗受外力作用时,籽粒与玉米芯连接力c的方向为指向轴负方向,颖壳对籽粒的摩擦力变为向内,玉米果穗侧上方籽粒受力均满足平衡方程(1),而侧下方籽粒的受力与侧上方籽粒不同,由于籽粒位置的变化导致籽粒重力在轴上分力方向变为指向轴正方向,因此侧下方籽粒受力满足径向平衡方程(2)。

1.籽粒 2.颖壳 3.木质环形体 4.芯髓

1.Grain 2.Glume shell 3.Wooden ring form 4.Core pulp

注:为籽粒重力,kN;c为籽粒与玉米芯连接力,kN;为支撑力与轴的夹角;为挤压力与轴的夹角;为重力与轴的夹角;N为角度为时颖壳对籽粒的支撑力,kN;f为角度为时颖壳对籽粒的摩擦力,kN;5为来自上侧相邻籽粒的压力,kN;6为来自下侧相邻籽粒的压力,kN。

Note:is grain gravity, kN;cis connection force of grain and corn con, kN; is angle of support force andaxis;is angle of pressure andaxis;is angle of gravity and y axis;Nis support force of glume shell on grain when angle is, kN;fis friction of glume shell on grain when angle is, kN;5is pressure from upper adjacent grain, kN;6is pressure from basiscopic adjacent grain, kN.

图9 玉米果穗受压时径向受力分析

Fig.9 Force analysis of corn ear in radial direction

由上述平衡方程可知,在压力施加的初始阶段,果穗侧面籽粒能够保持径向受力的平衡,籽粒不会脱落,但随着压力的增大,籽粒间的相互挤压力增大,导致籽粒与玉米芯连接力逐渐增加到最大值,也就是果柄的断裂极限值,随后平衡方程会被破坏,果柄断裂,籽粒出现脱落现象。果穗顶部和底部的籽粒受到压盘的直接压力,随着压力不断增大,果柄会断裂,籽粒逐渐被压入颖壳深处,颖壳对籽粒的紧密包裹是籽粒没有脱落的原因,但承受正压的籽粒与果穗实际已经分离。机械脱粒时确保脱粒装置对玉米果穗施加的载荷值低于610 N不仅可以防止果穗断裂而且有利于脱粒。

4 结 论

1)玉米芯含水率对玉米果穗抗压特性有极大影响,含水率低于13%时,随着含水率的降低,果穗塑性减弱,抗压强度缓慢增加,导致抗压能力小幅度增强;含水率在13%~25%内,随着含水率的增加,果穗塑性增强,抗压强度增加,导致抗压能力增强;含水率高于25%后,果穗塑性减弱,抗压强度减小,使其抗压能力急剧减弱;玉米芯含水率为25%时的玉米果穗抗压能力最强,最适合玉米的不断芯脱粒。

2)玉米果穗的破裂是由内向外逐步破裂的过程,在受压过程中,芯髓最先破裂,然后木质环形体破裂;裂纹是在果穗内部竖直方向压力和水平方向张力的共同作用下产生的,并在竖直方向扩展;木质环形体结构密实坚固,是玉米果穗抗压的主要部位。

3)玉米果穗在受压过程中,压力会传递给周向分布的籽粒,籽粒间挤压力的增大会破坏籽粒的径向受力平衡,导致果柄断裂,籽粒脱落。机械脱粒时确保脱粒装置对玉米果穗施加的载荷值低于610 N不仅可以防止果穗断裂而且有利于脱粒。

[1] 何晓鹏,刘春和,师建芳,等. 挤搓式玉米脱粒机的研制[J]. 农业工程学报,2003,19(2):105-108.

He Xiaopeng, Liu Chunhe, Shi Jianfang, et al. Research and design on corn sheller by extruding and rubbing method[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2003, 19(2): 105-108. (in Chinese with English abstract)

[2] 赵武云,郭康权. 变径变间距螺旋板齿式玉米脱粒机设计与试验[J]. 干旱地区农业研究,2013,31(1):226-230.

Zhao Wuyun, Guo Kangquan. Design and experiment of corn thresher with varied-diameter and varied-spacing spiral plate tooth[J]. Agricultural Research in the Arid Areas, 2013, 31(1): 226-230. (in Chinese with English abstract)

[3] 李心平,马义东,金鑫,等. 玉米种子仿生脱粒机设计与试验[J]. 农业机械学报,2015,46(7):97-101.

Li Xinping, Ma Yidong, Jin Xin, et al. Design and test of corn seed bionic thresher[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(7): 97-101. (in Chinese with English abstract)

[4] 廖庆喜,万星宇,李海同,等. 油菜联合收获机旋风分离清选系统设计与试验[J]. 农业工程学报,2015,31(14):24-31.

Liao Qingxi,Wan Xingyu,Li Haitong,et al. Design and experiment on cyclone separating cleaning system for rape combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(14): 24-31. (in Chinese with English abstract)

[5] 付宏,吕游,李艳双,等. 基于离散元法的玉米脱粒过程分析[J]. 吉林大学学报:工学版,2012,42(4):997-1002.

Fu Hong, Lü You, Li Yanshuag, et al. Analysis for corn threshing process based DEM[J]. Journal of Jilin University: Engineering and Technology Edition, 2012, 42(4): 997-1002. (in Chinese with English abstract)

[6] Rosli W I W, Chow Y N. Effects of young corn ear addition on nutritional composition and acceptability of malaysian star cake (baulu cermai)[J]. Sains Malaysiana, 2014, 43(10): 1503-1508.

[7] 张新伟,李心平,杨德旭,等. 玉米种子内部机械裂纹产生与扩展的微观机理[J]. 农业机械学报,2012,43(12):72-76.

Zhang Xinwei, Li Xinping, Yang Dexu, et al. Micromechanism of inner mechanical cracks generation and expansion of corn seed kernel[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(12): 72-76. (in Chinese with English abstract)

[8] 蔡超杰,陈志,韩增德,等. 种子玉米生物力学特性与脱粒性能的关系研究[J]. 农机化研究,2017,4(4):192-196.

Cai Chaojie, Chen Zhi, Han Zengde, et al. Study on relationship of biomechanical characteristics of corn seed and threshing performance[J]. Journal of Agricultural Mechanization Research, 2017, 4(4): 192-196. (in Chinese with English abstract)

[9] 高连兴,李飞,张新伟,等. 含水率对种子玉米脱粒性能的影响机理[J]. 农业机械学报,2011,42(12):92-96.

Gao Lianxing, Li Fei, Zhang Xinwei, et al. Mechanism of moisture content affect on corn seed threshing[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(12): 92-96. (in Chinese with English abstract)

[10] 张翔,杨然兵,尚书旗. 立式轴流玉米单穗种子脱粒机试验参数优化[J]. 农业机械学报,2014,45(增刊1):73-79.

Zhang Xiang, Yang Ranbing, Shang Shuqi. Experimental parameter optimization of vertical axial-flow single panicle thresher for corn[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(Supp.1): 73-79. (in Chinese with English abstract)

[11] Petkevichius S, Shpokas L, Kutzbach H D. Investigation of the maize ear threshing process[J]. Biosystems Engineering, 2008, 99(4): 532-539.

[12] Folarin A A, Kosemani B S. Development of a guinea corn thresher[C]//2011 ASABE Annual International Meeting Paper1111268, 2011.

[13] Steponavicius D, Butkus V, Kiniulis V, et al. Influence of inertia momentum of cylinder on power consumption during corn ear threshing[C]//12th International Scientific Conference on Engineering for Rural Development Proceedings, 2013.

[14] 韩绿化,毛罕平,胡建平,等. 穴盘苗自动移栽钵体力学特性试验[J]. 农业工程学报,2013,29(2):24-29.

Han Lühua, Mao Hanping, Hu Jianping, et al. Experiment on mechanical property of seedling pot for automatic transplanter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(2): 24-29. (in Chinese with English abstract)

[15] 张涛,张锋伟,孙伟,等. 大豆籽粒的化学-力学特性灰色关联度及本构模拟[J]. 农业工程学报,2017,33(5):264-271.

Zhang Tao,Zhang Fengwei,Sun Wei,et al. Gray relation degree and constitutive modeling of chemo-mechanical properties for soybean seed[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(5): 264-271. (in Chinese with English abstract)

[16] Xu Yunfeng, Zhang Xiliang, Sun Xiaojia, et al. Tensile mechanical properties of greenhouse cucumber cane[J]. Int J Agric & Biol Eng, 2016, 9(5): 1-8.

[17] Spokas L, Steponavicius D, Butkus V. Substantiation of the rational technological parameters for threshing high-moisture corn ears[C]//6th International Scientific Conference on Rural Development Innovations and Sustainability, 2013.

[18] Lu Bing, Hu Can, Wang Xufeng, et al. Compressive mechanical properties test and finite element analysis of winter jujube during crisp ripe period in South Xinjiang, China[J]. IAEJ, 2016, 25(4): 245-256.

[19] 陈红,徐翔宙,尹伊君,等. 宽皮柑橘移动夹持剥皮力学特性与果皮分离特性试验研究[J]. 农业工程学报,2017,33(14):25-31.

Chen Hong,Xu Xiangzhou,Yin Yijun,et al.Experimental study on mechanical properties and peel separation characteristics of citrus reticulate blanco with peel clamped moving[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(14): 25-31. (in Chinese with English abstract)

[20] Shi Yinyan, Chen Man, Wang Xiaochan, et al. Experiment and analysis on mechanical properties of Artemisia selengensis stalk[J]. Int J Agric & Biol Eng, 2017, 10(2): 16-25.

[21] Botlhoko OJ, Ramontja J, Ray SS. Thermal, mechanical, and rheological properties of graphite- and graphene oxide-filled biodegradable polylactide/poly(-caprolactone) blend composites[J]. Journal of Applied Polymer Science, 2017, 134(40): 16-25.

[22] Nam K, Wolfenstine J, Choi H, et al. Study on the mechanical properties of porous tin oxide[J]. Ceramics International, 2017, 43(14): 10913-10918.

[23] Simon Marc, Dokukin Maxim, Kalaparthi Vivekanand, et al. Load rate and temperature dependent mechanical properties of the cortical neuron and its pericellular layer measured by atomic force microscopy[J]. Langmuir, 2016, 32(6): 1111-1119.

[24] Razavi S M A, Edalatian M R. Effect of moisture contents and compression axes on physical and mechanical properties of pistachio kernel[J]. International Journal of Food Properties, 2012, 15(3): 507-517.

[25] 陈志强,李爱华,张凌青,等. 宁夏不同地区玉米芯营养成分分析[J]. 粮食与饲料工业,2010,12:51-53.

[26] 于亚军,周海玲,付宏,等. 基于颗粒聚合体的玉米果穗建模方法[J]. 农业工程学报,2012,28(8):167-174.

Yu Yajun, Zhou Hailing, Fu Hong, et al. Modeling method of corn ears based on particles agglomerate[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(8): 167-174. (in Chinese with English abstract)

[27] 邵卓平. 植物材料(木、竹)断裂力学[M]. 北京:科学出版社,2012.

[28] 李心平. 种子玉米脱粒损伤机理及5TYZ-1型定向喂入式脱粒机研究[D]. 沈阳:沈阳农业大学,2007.

Study on Threshing-damage Mechanism and 5TYZ-1 Type Directional -Feeding Thresher of Seed Corn[D]. Shenyang: Shenyang Agricultural University, 2007.

[29] 张乾能,朱国,宗力. 鲢鱼鱼体抗压特性的研究[J]. 食品科学,2009,30(11):95-98. Zhang Qianneng, Zhu Guo, Zong Li. Study on compressive properties of silver carp[J]. Food Science, 2009, 30(11): 95-98. (in Chinese with English abstract)

[30] 张云伟,喻勇,王大龙,等. 植物根系抗拉力学特性便携式测试系统[J]. 农业机械学报,2014,45(6):58-63. Zhang Yunwei, Yu Yong, Wang Dalong, et al. Design of portable test system for tensile property of plant roots[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(6): 58-63. (in Chinese with English abstract)

Influence of water content on anti-pressing properties of corn ear

Li Xinping, Xiong Shi, Geng Lingxin, Ji Jiangtao

(,471003,)

The corn threshing without cob fracture can greatly simplify cleaning link. The rupture of corn ear can directly affect the effect of the core threshing without cob fracture. In order to study the anti-pressing properties and rupture laws of corn ear and explore the effect of water content on anti-pressing properties, the static compress experiments were carried out on the electronic universal testing machine. The analysis of the biological characteristics of corn ear showed that the wooden ring form had compact structure and its strength was big. And the core pulp and the glume shell had loose structure and small strength. The corn varieties selected by experiment were Zhongdan 868 and Zhenghuangnuo No. 2. The water content of each variety was treated as 5 criteria. Four tests were done for each test level. The corn variety and the water content of corn cob were used as test factors. The maximum load and the maximum stress of corn ear were used as the test indices. The experimental data were analyzed by MATLAB software and the function relation between water content of corn cob and test indices was obtained. The relationship between water content of corn cob and fracture strain of corn ear indicated that the plasticity of corn ear was firstly enhanced and then declined with the increase of the water content of corn cob. Through the analysis of the fitting curves between the water content of corn cob andthe test indices, it was known that the water content of corn cob had a tremendous effect on the anti-pressing properties of corn ear. When the water content was below 13%, with the decrease of water content, the plasticity of corn ear decreased and the compressive strength increased slowly, which resulted in a slow enhancement of the anti-pressing ability of corn ear. When the range of water content was 13%-25%, with the increase of water content, the plasticity and the compressive strength of corn ear both increased, which resulted in the enhancement of the anti-pressing ability. When the water content was higher than 25%, the plasticity of corn ear was weakened and the compressive strength decreased with the increase of water content, which resulted in a sharp decline of the anti-pressing ability. To observe the internal fracture process of corn ear, samples were cut in radial direction and then the cut samples were put on the test bench to do experiment. Using the radial section of corn ear as the observation window, the whole process of corn ear compression test was recorded by camera. Through the analysis of the photos of corn ear in the process of compression, it was known that the core pulp firstly ruptured and the crack was extended in vertical direction. Then the crack gradually approached to the wooden ring form. Finally, the wooden ring form ruptured and corn ear presented obvious deformation. The analysis of the strain-stress curves indicated that stress gradually increased and corn ear showed plastic deformation with the increase of strain. Stress began to decline after peak. Curves showed jagged wave and the yield stage was entered. The rupture of the wooden ring form led to the decline of stress curves. So the wooden ring form was the main anti-pressing part of corn ear. In the process of compression, corn ear showed the phenomenon of grains falling. The radial balance equations of grain were established by force analysis. Analysis indicated that pressure would be transmitted to the grains in the circumferential distribution. The increase of the pressure between grains would destroy the radial force balance of grains, resulting in the fracture of the carpopodium. Test results showed that the anti-pressing ability of corn ear was the strongest when the water content of corn cob was 25%, and this water content of corn cob was the most suitable for the corn threshing without cob fracture. The rupture of corn ear was a gradual rupture process by the inside-out. Applying pressure less than 610 N to corn ear could not only prevent the fracture of corn ear but facilitate threshing. The research results can provide data reference and theoretical support for the further research of the corn threshing without cob fracture.

moisture; crops; pressure; corn ear; anti-pressing properties; water content; experiment

10.11975/j.issn.1002-6819.2018.02.004

S513

A

1002-6819(2018)-02-0025-07

2017-08-07

2018-01-04

国家自然科学基金与河南人才培养联合基金资助项目(U1204514)

李心平,教授,博士,主要从事农产品收获与加工机械研究。Email:aaalxp@126.com

李心平,熊 师,耿令新,姬江涛. 含水率对玉米果穗抗压特性的影响[J]. 农业工程学报,2018,34(2):25-31. doi:10.11975/j.issn.1002-6819.2018.02.004 http://www.tcsae.org

Li Xinping, Xiong Shi, Geng Lingxin, Ji Jiangtao. Influence of water content on anti-pressing properties of corn ear[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(2): 25-31. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.02.004 http://www.tcsae.org