移动式土壤旋耕蒸汽消毒机的研制

2018-02-28汪小旵李成光杨振杰孙国祥施印炎

汪小旵,李成光,杨振杰,孙国祥,施印炎,赵 博

移动式土壤旋耕蒸汽消毒机的研制

汪小旵1,2,李成光1,杨振杰1,孙国祥1,2,施印炎1,赵 博1

(1. 南京农业大学工学院,南京 210031; 2.江苏省现代设施技术与装备工程实验室,南京 210031)

为解决土壤连作障碍等引起的蔬菜种植问题,设计了一种可在旋耕作业的同时进行土壤蒸汽消毒的机具。机具主要由旋耕装置、蒸汽发生器、补水装置、蒸汽输送系统、消毒罩、可拆卸消毒毛管等组成。通过热量平衡分析得出,在土壤宽120 cm、深15 cm时,土壤消毒到60 ℃时所需蒸汽功率为87.78 kW,而当土壤蒸汽消毒机蒸汽发生器出口压强为0.6 MPa,温度为158.86 ℃时,能提供的蒸汽功率为97.35 kW,系统损耗为0.61 kW,可满足土壤消毒的热量需求。田间试验表明:当蒸汽发生器出口蒸汽压强为0.6 MPa,温度为158.86 ℃,机具旋耕行走速度为0.035 m/s,消毒毛管管径15 mm,间距为180 mm时,深度15 cm土壤消毒后温度在58.9~70.6 ℃之间,可满足土壤旋耕消毒的温度要求。

土壤;农业机械;设计;连作障碍;移动式;旋耕;蒸汽消毒

0 引 言

蔬菜种植由于复种指数高,再加上肥料的大量使用,极易导致土壤连作障碍、理化性能失衡和土壤板结等问题[1-4]。优质土壤是蔬菜种植的重要保障,土壤消毒是防止土壤连作障碍等问题的有效办法[5-9],其中土壤蒸汽消毒是将高温水蒸汽通入土壤中,将土壤中的细菌以及大部分杂草高温灭杀[10-16]。蒸汽消毒的同时,在水蒸汽的疏通下土壤孔隙也随之增大,并通过土壤孔隙将残留的氮磷盐带到有效耕作层下方。因此,土壤蒸汽消毒不仅无药害残留、不会产生有害生物抗药性问题,还增加了土壤的通透性与排水性,有利于改善土壤板结[17-24]。

土壤蒸汽消毒法首先由德国人Frank于1888年发明,1893年由美国人Rudd首次商业化使用[25]。蒸汽消毒一般有以下几种方法:地表覆膜蒸汽消毒法(汤姆斯法)[26],即在地表铺设一层帆布或者抗热塑料膜,在开口处通入蒸汽以达到消毒目的,其蒸汽利用效率较低;侯德森(Hodeson)管道法[27],即在地下40 cm深处铺设一层管道网,并在管网上每间隔一段距离开设一个蒸汽出口,其蒸汽利用效率较高,消毒比较彻底,但管道铺设成本较大,且不利于后期田间的耕作;负压蒸汽消毒法[28],即在地下埋设多孔的聚丙烯管道,用风机产生负压将地表的蒸汽吸入地下,该法使得土壤深层中的温度比地表覆膜高,蒸汽利用消毒效率较好,但工艺流程较为复杂;金属罩注射式消毒方法[29],该方法通过安装在拖拉机后面的蒸汽注入管注入土壤蒸汽,逐块面积分次作业,作业效率相对较低。

为提高工作效率,在牵引式锅炉[30]设计的基础上,结合蔬菜整地旋耕复式作业,本文设计了一种移动式土壤旋耕蒸汽消毒机。该机将旋耕装置和蒸汽消毒装置有机结合,在土壤旋耕的同时完成消毒作业,以期为土壤蒸汽消毒提供一种新模式。

1 蒸汽消毒机的总体结构和工作原理

1.1 结构组成

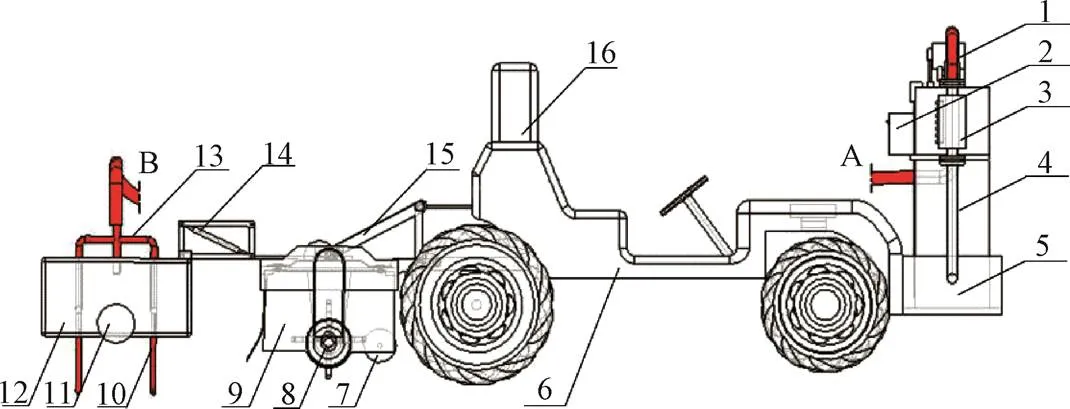

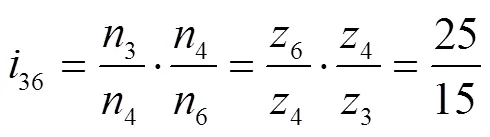

根据相应的技术设计要求,确定整机的主要技术参数如表1所示。消毒机的整体结构如图1所示,主要由燃油蒸汽发生器、旋耕装置、补水装置、蒸汽输送系统、末端执行机构组成。其中A为蒸汽发生器的蒸汽出口,B为消毒机箱的蒸汽入口,A、B通过耐高温高压的钢丝软管连接构成蒸汽输送系统。

1.燃烧器 2.控制箱 3.水位计 4.蒸汽锅炉 5.前托架 6.拖拉机 7.前滚轮 8.旋耕轴 9.旋耕机 10.消毒毛管 11.限位轮 12.消毒罩 13.消毒支管 14.液压杆 15.悬挂架 16.外置水箱

1.2 工作原理

当拖拉机牵引机具向前消毒作业时,旋耕机通过三点悬挂机构与配套拖拉机联接,拖拉机输出轴动力通过万向节与中央变速箱传动轴联接,并将动力传递给旋耕机。中央变速箱将动力传递给侧边传动箱从而带动旋耕刀轴旋转,刀轴上的刀片旋切土壤和杂草,被旋切的土壤与杂草沿着旋耕刀的切线方向向后上方抛洒,与挡泥罩碰撞后落入正下方土壤上。

表1 蒸汽消毒机主要技术参数

消毒罩通过液压缸及两侧固定机构与旋耕机相连,当拖拉机牵引旋耕机进行旋耕作业时,同时调节液压控制系统将消毒罩放下,使得末端消毒毛管插入旋耕后的土壤,打开蒸汽阀门进行移动式消毒作业。消毒深度由液压杆伸缩进行调节,限位轮控制调节深度上限。

1.3 供需热量计算

蒸汽发生器采用LSS0.12-0.7Y/Q蒸汽锅炉,理论产汽量为0.12 t/h,其产生的饱和水蒸汽的放热分为潜热放热与显热放热。

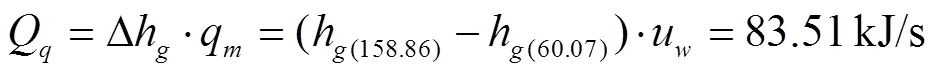

以0.6 MPa下的饱和水蒸汽为参照,查表可知0.6 MPa下的饱和水蒸汽温度为158.86 ℃,比焓为2 756.72 kJ/kg,故其降到60 ℃时潜热放热量为

显热放热量为

式中Q为总放热量,Q为潜热放热量,Q为显热放热量,kJ/s;为饱和水蒸汽温度,℃;h为水蒸汽焓值,kJ/kg;C为水的比热容,kJ/(kg×℃);为水蒸汽密度,kg/m3;u为水蒸汽流速,m/s。已知产汽量为0.12 t/h,蒸汽软管直径为25 mm,则由式(4)可得饱和水蒸汽的流速u为16.47 m/s。

故理论总放热量为

旋耕消毒作业机作业幅宽为120 cm,作业速度按照0.032 m/s计算,每根消毒管的消毒辐射范围为5 cm,消毒深度为15 cm,以10根消毒毛管计算单位时间土壤加热到60 ℃所需热量计算,则所需要热量为

式中Q为土壤达到预期温度所吸收需要的热量,kJ/s;C为土壤的比热容,kJ/(kg×℃);ρ为土壤密度1 270 kg/m3,Δv为每根消毒毛管消毒所辐射到的土壤体积,m3;为单位时间内所需消毒土壤的总质量,kg。结合式(6)、式(7)可知土壤所需蒸汽功率为87.78 kW。

蒸汽管道热损失有很多因素和条件,如果详细计算需要很多数据,忽略其他传热与热损耗,采用管道在空气中热损失(3%/100 m·h)来计算,即总流量等于管损来估算[31]。

则蒸汽在管道中的热损失为

式中Q为单位长度的热损失,W/m,T为管内维持温度158.86 ℃,T为环境温度25 ℃,0为保温层外径35 mm,1为保温层内径25 mm,为保温材料的导热系数,查表可知为0.033 W/(m·℃)参考民用建筑热工设计规范(GB 50176-1993),为保温层外表面向大气的传热系数,查表可知为6.69 W/(m2·℃)。通过计算得出蒸汽在管道中的热损失为61.1 W/m。则10 m蒸汽管道内的热损失为0.61 kW。总发热量减去管道热损失,可知高温水蒸汽提供的热功率为96.74 kW。则土壤获得热功率为96.74>87.78 kW。饱和水蒸汽提供的热量能够满足土壤消毒加热到60 ℃所需热量。

2 关键部件设计

2.1 旋耕机装置设计

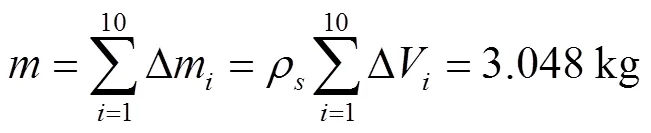

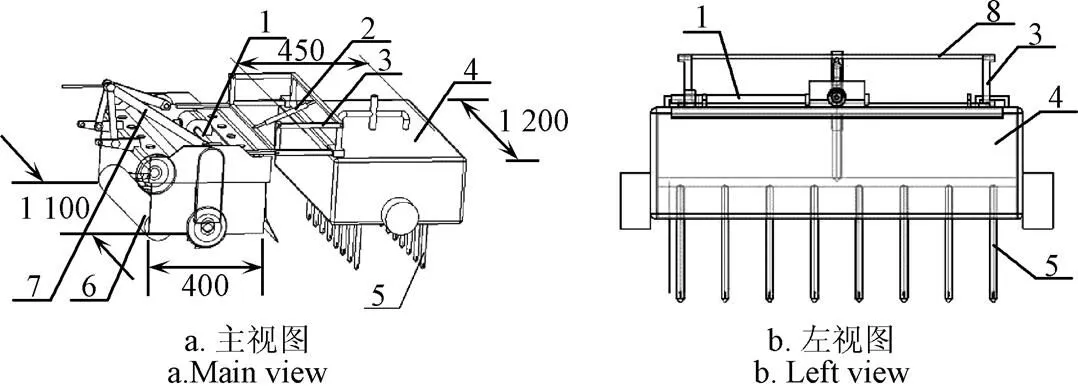

消毒机整体采用三点悬挂方式和拖拉机相连,消毒机的旋耕装置的轴连接前置传动箱的动力,拖拉机动力传递至变速箱动力输入轴,再由传动分配箱分配至旋耕刀辊。输出轴旋耕刀轴的传动形式采用的是侧边传动。侧边传动可更加便利的拆装传动装置,并且侧传动箱的制作工艺简单,相对于中间传动时搭载笨重的铸件传动箱能够大幅减轻整机的重量,另外侧边传动可以将待消毒区域充分旋耕以保护后方消毒支管。图2为旋耕消毒机的传动系统示意图,其中中央传动为一级变速,侧边传动为二级变速。拖拉机动力输出轴经过十字万向节传递给中央变速箱中的圆锥齿轮减速并改变方向后,传递给侧边传动箱中的齿轮,再由侧传动箱中的刀轴齿轮带动刀轴旋转。作业时旋耕刀辊携带切削的深层土壤、残留根茬、粉碎刀辊抛掷的混合物等越过刀辊上方并向后方抛掷,经滚轮平整形成上细下粗的待消毒层。

机具配套动力采用的是黄海金马654拖拉机,其动力输出轴转速为540~720 r/min所设计的旋耕刀轴转速为220~300 r/min左右。各级齿轮数:1为13,2为19,3为15,4为13,5为10,6为25。旋耕机构的各级传动比见式(9)、式(10)。

1.中央变速箱 2.万向节 3.圆锥齿轮 4.侧边传动箱 5.侧边传动齿轮 6.旋耕刀 7.旋耕刀轴

中央传动为单级圆锥传动,其中一级传动比为

侧边传动齿轮传动比为

故拖拉机传动轴与旋耕机传动轴之间的传动比为

由于配套黄海金马654拖拉机的输出轴转速为540~720 r/min,结合式(11)可以计算出旋耕刀轴的转速为

2.2 可升降消毒罩设计

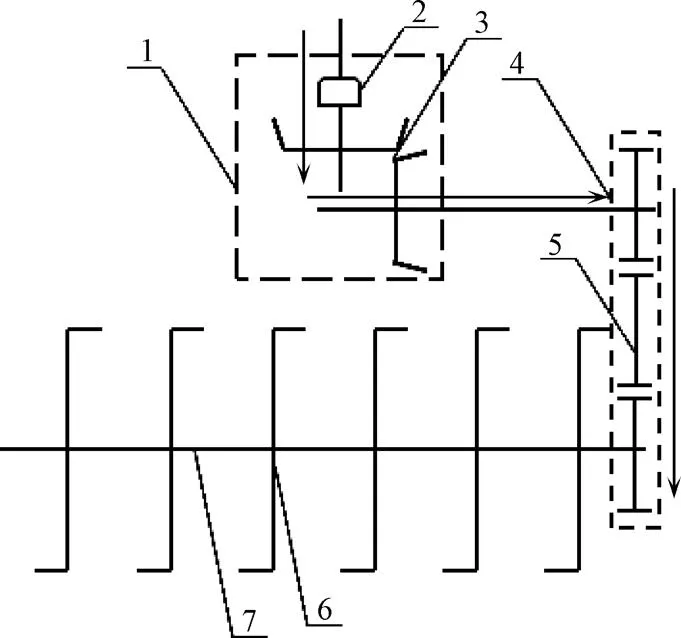

消毒罩及其中的末端消毒毛管整体机构通过液压伸缩杆与前部旋耕装置相联接,通过拖拉机上的液压开关控制消毒机构的收放,控制消毒毛管在土壤中的消毒深度。消毒作业时上方消毒罩可封住蒸汽,减少热量散失。消毒罩整体机构如图3所示。

1.传动轴 2.液压杆3.四边形支架4.消毒罩5.消毒毛管6.滚轴7.三脚架 8.上支架

消毒罩的升降主要由中部的液压杆和四边形支架两侧的丝杆螺母进行调节。两边的丝杆螺母在固定消毒罩两侧的同时还可以调节消毒罩与地面的法线角度,确保消毒罩在作业时末端与土壤保持垂直工作状态。

2.3 消毒毛管设计

为减少消毒毛管在土壤中移动消毒作业时的阻力,在前排毛管的作业方向的加装了一排犁形破土装置如图4所示,破土犁之间的间距根据消毒毛管的布置间距来对应调整,通过机构上端的固定螺母与上梁固定。其中犁长40 cm,厚度1 cm,末端是一个边长5 cm的等边倒三角犁。在消毒作业时该装置通过下方犁形面将前方土层破开,形成一排阻力较小的宽松通道便于后方的消毒毛管在土壤中移动。该机构既减少了毛管的前进阻力,也可防止土壤层中杂草对消毒支管的缠绕,同时还能有效地减少蒸汽喷口处土壤的堵塞和堆积。消毒罩的下方装有2个限位轮,确保消毒深度不超过25 cm,从而可以有效地保护消毒毛管不被深层硬质土块刮变形。

1.支架 2.毛管 3.犁形破土装置

消毒环形支管通过支管上部的螺纹接口与蒸汽软管相连,并将软管输送的高温蒸汽传输到各个消毒毛管。消毒支管由2根长120 cm、直径25 mm金属管环形联通,在支管下方每间隔60 mm处设有内螺纹结构的接口,用以装配不同管径的消毒毛管,并且可以调整毛管之间的间距以便后期试验确定较优组合方案。通过与环形支管连接的消毒毛管一共设计4种直径类型,分别为5、10、15、20 mm(参照标准SLDI 233A12-98)。消毒毛管管壁厚度选为2 mm(参照标准GB/T 20801.1-2006),每根消毒毛管的长度为400 mm,在距消毒毛管末端2 cm处以层间距5 cm分布3层孔径为3 mm消毒孔,每层3个消毒孔呈120°向后方分布(图5)。相邻毛管之间的间距也分别设有180、240、300 mm的3种分布方式,毛管通过过渡接头与环形支管相连。

1.环形支管 2.支管接口 3.过渡接口 4.消毒毛管

3 田间试验

3.1 试验条件与材料

2017年6月在江苏省盐城市试验田(120°14′40″E,33°23′12″N)内进行了移动式土壤旋耕消毒机作业性能试验。试验动力采用黄海金马654拖拉机,标定功率为47.8 kW,作业机具行走速度为0.032~0.085 m/s。该试验田土壤为沙壤土,其容重为1.27 g/cm3,砂粒质量分数为86.7%,含水率为22.9%,孔隙率为34%。

3.2 试验设计和方法

选取10块长度为10 m的区域作为试验区域,作业幅宽以120 cm为基准,在试验区域内随机选取120 cm×120 cm正方形区域进行5点采样,即确定方形区域上对角线的中点作为中心采样点,再在对角线上选择4个与中心样点距离相等的点作为采样点,采样深度为15 cm,每组试验重复3次,结果为3次试验的平均值。

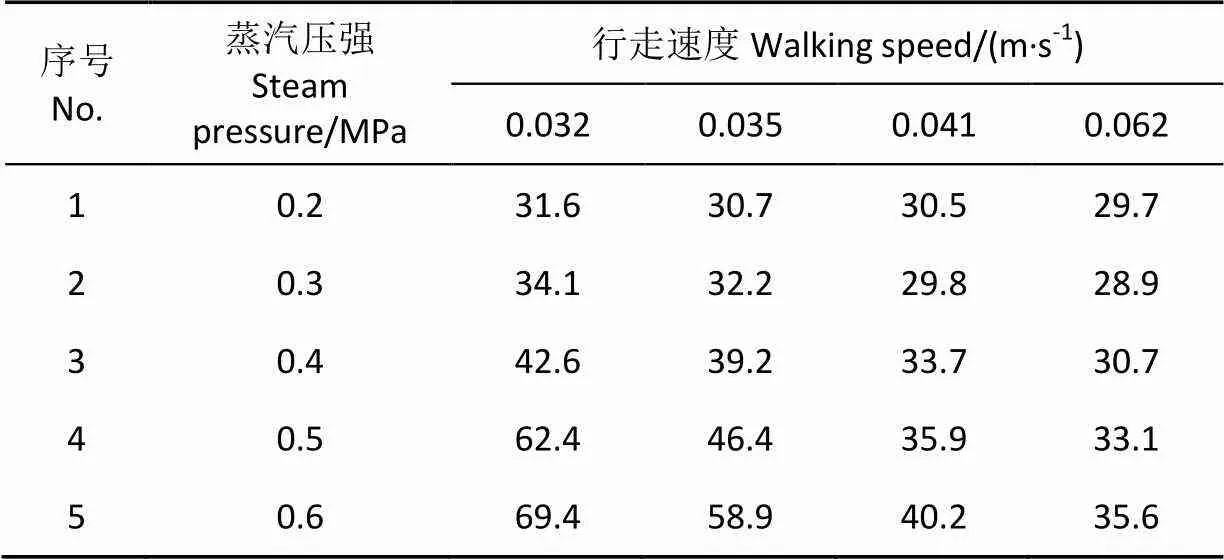

试验选取水蒸汽的压力、机具行走速度、消毒毛管直径以及管间距4个性能参数对进行田间试验验证(图6)。整机调试发现,当蒸汽压力达到0.2 MPa时,消毒毛管才有较为充足的消毒蒸汽产生,故试验蒸汽压力选取0.2、0.3、0.4、0.5和0.6 MPa共5个水平,其中每个压力水平下对应的饱和水蒸汽温度分别为120.24、133.56、143.64、151.87和158.86 ℃;行走速度选取0.032、0.035、0.041和0.062 m/s共4个水平;消毒毛管直径选取了5、10、15和20 mm共4个水平;管间距则采用了180、240和300 mm共3个水平。试验通过对比单因素在不同水平下消毒温度效果以选出最优组合。其中单因素试验一共选取3组来进行对比分析。第1组为管径15 mm,管间距180 mm,行走速度选取0.032、0.035、0.041和0.062 m/s共4个水平,蒸汽压强选取0.2、0.3、0.4、0.5和0.6 MPa共5个水平进行分析试验;第2组选行走速度为0.035 m/s,管间距为180 mm,消毒毛管直径选取5、10、15和20 mm共4个水平,蒸汽压力选取0.2、0.3、0.4、0.5和0.6 MPa共5个水平进行分析试验;第3组为管径15 mm,行走速度0.035 m/s,管间距则采用180、240和300 mm共3个水平,蒸汽压强选取0.2、0.3、0.4、0.5和0.6 MPa共5个水平进行分析试验。通过3组组合分析试验选出每个因素中的最优值。

a. 消毒作业a. Disinfection operationb. 温度采集b. Temperature collection

Fig6 Plot experiment of mobile soil rotary steam disinfection machine

3.3 结果与分析

第1组试验数据如表2所示。可以看出在管径与管距不变的情况下,消毒温度随着作业速度的增加而明显降低。作业速度为0.032和0.035 m/s,蒸汽压力为0.6 MPa时,土壤温度分别为69.4和58.9 ℃,可满足土壤消毒的温度要求[32-33]。

表2 不同机具行走速度及蒸汽压强下的土壤温度

注:管径15 mm,管距180 mm。

Note: Tube diameter is 15 mm, and tube distance is 180 mm.

但在试验中发现当作业行走速度为0.032 m/s时,旋耕机工作时旋耕转速过低,严重影响旋耕作业性能,因此在第2组和第3组试验中机具作业行走速度选取为0.035 m/s。

表3 不同管径及蒸汽压强下的土壤温度

注:机具行走速度0.035 m×s-1,管距180 mm。

Note: Walking speed is 0.035 m×s-1, and tube distance is 180 mm.

第2组试验数据如表3所示。试验发现5 mm管径的消毒毛管由于韧性较低,在消毒作业时易被土壤折弯,而20 mm管径在消毒时蒸汽液化比较严重,在消毒作业时从消毒毛管中出来的水蒸气会迅速液化,而液化的水会将与其接触的土壤间隙填满而不利于热量的传递,对消毒效果影响较大。从表3中可以看出管径为10和15 mm下的消毒温度较高,其中管径为15 mm时消毒温度最高,温度达到70.6 ℃。0.6 MPa压力下,管径为15 mm的消毒温度不仅比10 mm下的温度高出了11.71%,也比20 mm下的温度高出了15.55%,因此,为保证消毒温度最高,15 mm管径是最优选择。

第3组试验数据如表4所示。可以看出当作业速度和管径不变的情况下,消毒温度随着管距的增大而减小。当管距为180 mm,蒸汽压力为0.6 MPa时,消毒温度达到最高。

表4 不同管距及蒸汽压强下的土壤温度

注:机具行走速度0.035 m·s-1,管径为15 mm。

Note: Walking speed is 0.035 m·s-1, and tube diameter is 15 mm.

综合表2、表3、表4的试验数据可以发现管径为15 mm消毒后温度最高;管间距越小消毒温度越高;在保证旋耕质量的前提下,机具作业行走速度为0.035 m/s时,旋耕消毒整机作业性能较好且相对较为稳定。当作业速度再次提高时,蒸汽与待消毒土壤的接触时间变短,消毒机的消毒效果大大减弱,温度达不到预期要求的60 ℃。并且在过高的作业速度下,后方消毒的末端执行机构收到的阻力较大易于发生形变或脱落,同时旋耕机前侧堆土较多,因此最优组合为机具作业行走速度0.035 m/s;管径15 mm;管间距180 mm;蒸汽压0.6 MPa,蒸汽出口温度158.86 ℃。

4 结 论

本文将土壤旋耕作业与土壤蒸汽消毒技术有机结合,研制了移动式土壤旋耕蒸汽消毒机,确定了主要机构与工作参数,设计了关键部件,并对机具的作业性能进行了理论分析,对作业效果进行了试验验证。

1)通过热量平衡分析得出,在土壤幅宽120 cm,深度15 cm时,土壤消毒到60 ℃时所需蒸汽功率为87.78 kW,而当土壤蒸汽消毒机蒸汽发生器出口压强为0.6 MPa,温度为158.86 ℃时,能提供蒸汽功率为97.35 kW,系统损耗为0.61 kW,满足土壤消毒的热量需求。

2)通过田间试验确认了最优组合,即当蒸汽发生器出口蒸汽压强为0.6 MPa,温度为158.86 ℃,机具旋耕行走速度为0.035 m/s,消毒毛管管径15 mm,间距为180 mm时,深度15 cm土壤消毒后温度在58.9~70.6 ℃之间,可满足土壤旋耕消毒的温度要求。

[1] 郭军,顾闽峰,祖艳侠,等. 设施栽培蔬菜连作障碍成因分析及其防治措施[J]. 江西农业学报,2009,21(11):51-54.

Guo Jun, Gu Minfeng, Zu Yanxia, et al. Causes and control measures of continuous cropping obstacle in facility vegetable cultivation[J]. Acta Agriculturae Jiangxi, 2009, 21(11): 51-54. (in Chinese with English abstract)

[2] 孙光闻,陈日远,刘厚诚. 设施蔬菜连作障碍原因及防治措施[J]. 农业工程学报,2005,21(增刊2):184-188.

Sun Guangwen, Chen Riyuan, Liu Houcheng. Causes and control measures for continuous cropping obstacles in protected vegetable cultivation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2005, 21(Supp.2): 184-188. (in Chinese with English abstract)

[3] 余海英,李廷轩,周健民. 设施栽培中逆境对园艺作物生长发育及其病害的影响[J]. 土壤通报,2006,37(5):1027-1032.

Yu Haiying, Li Tingxuan, Zhou Jianmin. Effects of adversities on the development and diseases of horticultural crops in greenhouse cropping systems[J]. Acta Pedologica Sinica, 2006, 37(5): 1027-1032. (in Chinese with English abstract)

[4] 葛晓颖,孙志刚,李涛,等. 设施番茄连作障碍与土壤芽孢杆菌和假单胞菌及微生物群落的关系分析[J]. 农业环境科学学报,2016,35(3):514-523.

Ge Xiaoying, Sun Zhigang, Li Tao, et al. Soil pseudomonas spp., bacillus spp., and microbial communities under tomato continuous cropping in greenhouse production[J]. Journal of Agro-Environment Science, 2016, 35(3): 514-523. (in Chinese with English abstract)

[5] 陈云林. 盐城市盐都区草莓连作障碍原因调查及防治技术[D]. 南京:南京农业大学,2015.

Chen Yunlin. The Causes Investigation and Corresponding Prevention & Control Technologies of Strawberry Continuous Cropping Obstacle in Yandu District Yancheng City[D]. Nanjing: Nanjing Agricultural University, 2015. (in Chinese with English abstract)

[6] 李萍萍. 设施园艺中的土壤生态问题分析及清洁生产对策[J]. 农业工程学报,2011,27(增刊2):346-351.

Li Pingping. Soil ecological problem and its resolvent in greenhouse horticulture[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(Supp.2): 346-351. (in Chinese with English abstract)

[7] 李兴龙,李彦忠. 土传病害生物防治研究进展[J]. 草业学报,2015,24(3):204-212.

Li Xinglong, Li Yanzhong. Research advances in biological control of soil-borne disease[J]. Pratacultural Science, 2015, 24(3): 204-212. (in Chinese with English abstract)

[8] 孙雪婷,龙光强,张广辉,等. 基于三七连作障碍的土壤理化性状及酶活性研究[J]. 生态环境学报,2015,24(3):409-417.

Sun Xueting, Long Guangqiang, Zhang Guanghui, et al. Properties of soil physical-chemistry and activities of soil enzymes in context of continuous cropping obstacles for panax notoginseng[J]. Ecology and Environmental Sciences, 2015, 24(3): 409-417. (in Chinese with English abstract)

[9] 曹坳程,刘晓漫,郭美霞,等. 作物土传病害的危害及防治技术[J]. 植物保护,2017,43(2):6-16.

Cao Youcheng, Liu Xiaoman, Guo Meixia, et al. Incidences of soil-borne diseases and control measures[J]. Plant Protection, 2017, 43(2): 6-16. (in Chinese with English abstract)

[10] 朱加繁,张汝坤,杨陆强,等. 自走式温室育苗槽基质蒸汽消毒机的设计[J]. 农机化研究,2017,39(4):78-82,87.

Zhu Jiafan, Zhang Rukun, Yang Luqiang, et al. Research design on a directional seeding mechanism for big seeds of grafting[J]. Journal of Agricultural Mechanization Research, 2017, 39(4): 78-82, 87. (in Chinese with English abstract)

[11] 辜松,王忠伟. 日本设施栽培土壤热水消毒技术的发展现状[J]. 农业机械学报,2006,37(11):167-171.

Gu Song, Wang Zhongwei. Soil disinfection with hot water in Japan[J]. Transactions of The Chinese Society for Agricultural Machinery, 2006, 37(11): 167-171. (in Chinese with English abstract)

[12] 喻自荣,朱加繁,彭继文,等. 桁架式温室育苗槽基质蒸汽消毒机设计[J]. 农机化研究,2016,38(11):154-157,161.

Yu Zirong, Zhu Jiafan, Peng Jiwen, et al. Design of matrix steam sterilization machine for truss type greenhouse[J]. Journal of Agricultural Mechanization Research, 2016, 38(11): 154-157, 161. (in Chinese with English abstract)

[13] 喻自荣. 移动式温室育苗基质蒸汽消毒机设计与研究[D]. 昆明:云南农业大学,2016.

Yu Zirong. The Design and Research on Mobile Steam Sterilizer of Greenhouse Seeding Substrate[D]. Kunming: Yunnan Agricultural University, 2016. (in Chinese with English abstract)

[14] 周雪青,张晓文,邹岚,等. 设施农业土壤消毒方法比较[J]. 农业工程,2016,6(3):109-112.

Zhou Xueqin, Zhan Xiaowen, Zou Lan, et al. Comparison of soil disinfection methods in facility agriculture[J]. Agricultural Engineering, 2016, 6(3): 109-112. (in Chinese with English abstract)

[15] 杨雅婷,胡桧,赵奇龙,等. 土壤物理消毒装备研究进展[J]. 农业工程,2015,5(增刊1):43-48.

Yang Yating, Hu Hui, Zhao Qilong, et al. Research progress of soil physical disinfection equipment[J]. Agricultural Engineering, 2015, 5(Supp.1): 43-48. (in Chinese with English abstract)

[16] 苏琦,黄欢. 从专利视角看全球土壤蒸汽消毒技术发展[J]. 安徽农学通报,2016,22(11):68-69.

Su Qi, Huang Huan. Technology development of global sterilizing soil by steam from the perspective of patent[J]. Anhui Agricultural Science Bulletin, 2016, 22(11): 68-69. (in Chinese with English abstract)

[17] 肖占山. 注水井井下温度场数值模拟[D]. 大庆:东北石油大学,2002.

Xiao Zhanshan. Numerical Simulation for Wellbore and Formation Temperature in Water Injection Wells[D]. Daqing: Northeast Petroleum University, 2002. (in Chinese with English abstract)

[18] 杨文哲. 蒸汽在油藏多孔介质中的热质传递机理及数值模拟[D]. 大庆:东北石油大学,2010.

Yang Wenzhe. Heat and Mass Transfer Mechanism and Numerical Simulation of Steam in Reservoir Porous Media[D]. Daqing: Northeast Petroleum University, 2010. (in Chinese with English abstract)

[19] 韩冰冰,程文龙,年永乐,等. 热采井注蒸汽与注多元热流体井筒流动与传热对比分析[J]. 工程热物理学报,2016,37(9):1867-1874.

Han Bingbing, Cheng Wenlong, Nian Yongle, et al. Analysis for flow and heat transfer of thermal recovery well with steam and multiple thermal fluids injection[J]. Journal of Engineering Thermophysics, 2016, 37(9): 1867-1874. (in Chinese with English abstract)

[20] Rabiey L, Flick D, Duquenoy A.3D simulations of heat transfer and liquid flow during sterilisation of lark particles in a cylindrical vertical can[J]. Food Engineering, 2007, 82(4): 409-417.

[21] Dabbene F, Gay P, Tortia C. Modelling and control of steam soil disinfestation processes[J]. Biosystems Engineering, 2003, 84(3): 247-256.

[22] Berruto R, Gay P, Piccarolo P, et al. Grey-box models for steam soil disinfestation simulation[J]. Mathematics & Computers in Simulation, 2004, 65(1/2): 191-200.

[23] Fennimore S A, Miller T C, Broome J C, et al. Evaluation of a mobile steam applicator for soil disinfestation in california strawberry[J]. Hortscience a Publication of the American Society for Horticultural Science, 2014, 49(12): 1542-1549.

[24] Kokalis-Burelle N, Rosskopf E N, Hong J C, et al. Anaerobic soil disinfestation (ASD) and steam as alternatives for parasitic nematode control in florida floriculture[J]. Journal of Nematology, 2013, 45(4): 298-299.

[25] Gay P, Piccarolo P, Aimonino D R, et al. A high efficiency steam soil disinfestation system, part I: Physical background and steam supply optimisation[J]. Biosystems Engineering, 2010, 107(2): 74-85.

[26] Gay P, Piccarolo P, Aimonino D R, et al. A high efficacy steam soil disinfestation system, part II: Design and testing[J]. Biosystems Engineering, 2010, 107(3): 194-201.

[27] Gay P, Piccarolo P, Aimonino D R, et al. Soil parameters effects on steam disinfestation efficiency[C]//Agricultural and Biosystems Engineering for a Sustainable World. International Conference on Agricultural Engineering, Hersonissos, Crete, Greece, 23-25 June, 2008. European Society of Agricultural Engineers (AgEng), 2008.

[28] Minuto G, Gilardi G, Kejji S, et al. Effect of physical nature of soil and humidity on steam disinfestation[C]//VI International Symposium on Chemical and non-Chemical Soil and Substrate Disinfestation-SD2004 698. 2004: 257-262.

[29] Runia W T, Molendijk L P G, Gamliel A, et al. Physical methods for soil disinfestation in intensive agriculture: old methods and new approaches[C]//VII International Symposium on Chemical and Non-Chemical Soil and Substrate Disinfestation, Leuven, Belgium. 2010, 883: 249-258.

[30] 施印炎,李成光,汪小旵,等. 可移动式土壤蒸汽消毒机的设计[J]. 中国农机化学报,2017,38(1):56-59.

Shi Yinyan, Li Chengguang, Wang Xiaochan, et al. Design of removable soil steam sterilization machine[J]. Journal of Chinese Agricultural Mechanization, 2017, 38(1): 56-59. (in Chinese with English abstract)

[31] 刘晓宇,刘东,苗青,等. 上海石化蒸汽输热管道的实测与评价[J]. 节能技术,2008,26(2):140-144. Liu Xiaoyu, Liu Dong, Miao Qing, et al. Test And evaluation of SPC's steam heat supply pipeline[J]. Energy Conservation Technology, 2008, 26(2): 140-144. (in Chinese with English abstract)

[32] Loenen M C A V, Mullins C E, Wilson M J. Low temperature/ short duration steaming as a sustainable method of soil disinfection[C/OL]//Archived at http://orgprints.org/8261, 2002.

[33] Rouxmichollet D, Czarnes S, Adam B, et al. Effects of steam disinfestation on community structure, abundance and activity of heterotrophic, denitrifying and nitrifying bacteria in an organic farming soil[J]. Soil Biology & Biochemistry, 2008, 40(7): 1836-1845.

Development of mobile soil rotary steam disinfection machine

Wang Xiaochan1,2, Li Chengguang1, Yang Zhenjie1, Sun Guoxiang1,2, Shi Yinyan1, Zhao Bo1

(1.,,210031,; 2.,210031,)

China has been a great producer and consumer of vegetables all the time, and with the continuous development of vegetable cultivation, a series of problems have appeared, which have caused the tremendous pressure on the soil. For example, a tremendous use of fertilizer has led to many terrible results, like soil nutrient imbalance, soil continuous cropping barriers, imbalance of soil physical and chemical properties, soil consolidation, and so on. Every issue would cause serious damages to vegetable growth, yield and quality. In order to deal with the problem of vegetable planting caused by soil continuous cropping obstacle, a kind of steam disinfection machine was designed. This machine combined the rotary tillage device with the steam sterilizer effectively, and made it possible to complete the disinfection work while doing the soil rotary tillage. It was mainly composed of 6 parts: the rotary tiller, the steam generator, the water supply device, the steam delivery system, the disinfection cover and the detachable disinfection capillary. Compared with chemical disinfection, soil steam disinfestation was an ecological technique used in intensive agriculture to reduce soil pests before planting crops, which had the advantages of safe operation. Soil steam disinfection made high temperature water vapor into the soil, and could kill most bacterias and weeds in the soil so as to achieve the effect of disinfection. Also, high temperature steam sent the residual nitrogen and phosphorus under the effective tillage layer through the pore of the soil; at this time, the pore of the soil would also be heated by the high temperature water vapor, and the pore of the soil was enlarged with the dredging of the water vapor simultaneously. Therefore, this soil vapor disinfection increased the permeability and drainage of the soil, which was beneficial to the improvement of soil texture. By the way, it could be learnt through the analysis of the heat balance that the steam power required for the soil disinfection at 60 ℃ was 87.78 kW when the soil body was 120 cm wide and 15 cm deep, while when the steam generator outlet pressure of the steam sterilizer was 0.6 MPa and the temperature was 158.86 ℃, the steam power of the steam generator was 97.35 kW and the system loss was 0.61 kW, which could meet the heat demand of soil disinfection. And through the plot experiments, the main parameters affecting the steam disinfection performance of soil, including steam pressure, speed of machine running, diameter of capillary tube and spacing between tubes were determined, and relevant theoretical analysis was performed at the same time. Plot experiments showed that under the steam pressure of 0.6 MPa, the temperature of 158.86 ℃,and the rotary working speed of 0.035 m/s, 15 cm depth of soil temperature can reach 58.9-70.6 ℃ under the condition of the capillary tube diameter of 15 mm and separation distance of 180 mm. This study provides not only a reference for further improving the performance of soil steam sterilizer, but also a choice for the farmers using the soil steam disinfection system.

soils; agricultural machinery; design; continuous cropping obstacle; mobile; rotary tillage; steam disinfection

10.11975/j.issn.1002-6819.2018.02.003

S225.92

A

1002-6819(2018)-02-0018-07

2017-09-04

2017-11-15

江苏省农业科技自主创新资金项目CX(16)1002

汪小旵,男,教授,博士生导师,主要从事农业机械自动控制方向的研究。Email:wangxiaochan@njau.edu.cn

汪小旵,李成光,杨振杰,孙国祥,施印炎,赵 博. 移动式土壤旋耕蒸汽消毒机的研制[J]. 农业工程学报,2018,34(2):18-24. doi:10.11975/j.issn.1002-6819.2018.02.003 http://www.tcsae.org

Wang Xiaochan, Li Chengguang, Yang Zhenjie, Sun Guoxiang, Shi Yinyan, Zhao Bo. Development of mobile soil rotary steam disinfection machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(2): 18-24. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.02.003 http://www.tcsae.org