砍切式玉米秸秆还田机的设计与试验

2018-02-28王庆杰刘正道李洪文李问盈何建怀鄢雄磊

王庆杰,刘正道,何 进,李洪文,李问盈,何建怀,鄢雄磊

砍切式玉米秸秆还田机的设计与试验

王庆杰,刘正道,何 进,李洪文※,李问盈,何建怀,鄢雄磊

(中国农业大学工学院,北京 100083)

针对中国北方一年两熟区玉米收获后地表秸秆量大,甩刀式秸秆还田机粉碎长度合格率低,影响后续小麦少免耕播种等问题,基于四连杆机构往复运动原理,利用地表作为支撑,提出了利用砍切对秸秆切段还田的思路,进而研发出一种砍切式玉米秸秆还田机。为避免后续小麦播种时出现拥堵现象,设计秸秆切断长度不超过小麦窄行行距的一半(6 cm);通过理论计算和动力学仿真分析,优化了切刀的运动轨迹并确定切秆装置各杆件尺寸并分析了机具切割功耗为28.39 kW;利用ANSYS软件对切刀进行有限元静力分析,切刀力学性能满足设计要求。田间对比试验结果表明,在玉米收获后秸秆全量保留的条件下,与甩刀式秸秆还田机相比,砍切式秸秆还田机粉碎后秸秆平均长度短0.73 cm,秸秆长度不合格率小5个百分点,秸秆长度变异系数小0.218;机具运行平稳性试验表明砍切式玉米秸秆还田机振动略大于甩刀式玉米秸秆还田机,但差异不显著,该机平稳性满足作业要求;切刀入土平均深度为7.71 cm,可明显降低0~10 cm土层土壤容重;后续播种试验试验表明在砍切式秸秆还田机作业后地表进行播种时,播种机无拥堵现象且播种深度合格率比甩刀式大2.3个百分点。该文研究成果能够为中国北方一年两熟区玉米秸秆还田提供一种新型装备,有利于促进秸秆还田技术的推广。

机械化;设计;优化;秸秆还田机;砍切;粉碎长度;四杆机构

0 引 言

中国是世界主要粮食大国,每年秸秆产量达7亿多t,其中玉米秸秆产量(2.73亿t)最大[1-2]。玉米秸秆含有丰富的农作物生长所需的各种营养元素,是农业生产中最主要的可再生资源[3]。近年来研究表明,作物秸秆直接还田有利于改善土壤结构[4],提高土壤肥力[5],促进土壤呼吸[6],增加作物产量[7],减少秸秆焚烧,简化作业工序,是实现农业生产节本增效,促进农业可持续发展的重要途径。

中国玉米种植区域主要集中在东北一年一熟区和华北、西北小麦/玉米一年两熟区。东北地区玉米收获后秸秆在地表经过长期风化、腐蚀、粉碎后力学性能减弱,且玉米为穴播,行距大,对秸秆粉碎质量要求相对较低。一年两熟区10月份玉米收获后秸秆直接覆盖还田免耕播种小麦,还田过程中玉米秸秆含水率高、韧性强,粉碎难度大,且小麦播种行距小,粉碎秸秆长短不一易造成机具堵塞、晾种等现象,影响小麦播种质量[8-11]。

目前中国应用较广泛的秸秆还田机械主要通过高速旋转的锤爪或甩刀,对秸秆进行多次高速锤击、切割和揉搓,将秸秆粉碎成丝瓤状[12-13]。该秸秆粉碎方式刀轴转速高,粉碎刀需与地表保持一定间隙,贴近地表的秸秆易出现漏粉现象,且秸秆在粉碎罩壳内随机受到锤击和切割,粉碎长度随机性较大,粉碎长度合格率不能达到小麦播种要求。目前国内对甩刀结构进行了大量研究,设计了锤爪式[14]、Y型[15-16]、L型[17]、直刀型[18]等不同结构的甩刀,在一定程度上提高了秸秆粉碎质量,但其秸秆粉碎原理和方式未发生较大改变,仍存在漏粉、粉碎不均现象。郑智旗等[19]设计了动定刀支撑滑切式秸秆粉碎装置并进行了田间试验,通过动刀定刀组合与有支撑滑切相结合,可有效提高秸秆粉碎长度合格率。

本文针对现有秸秆粉碎还田机应用过程中存在漏粉、粉碎不均问题,提出一种地面支撑砍切式玉米秸秆还田机,以期解决华北、西北小麦/玉米一年两熟区小麦播种前玉米秸秆切碎长度不合要求的问题。

1 总体结构及工作原理

1.1 总体结构

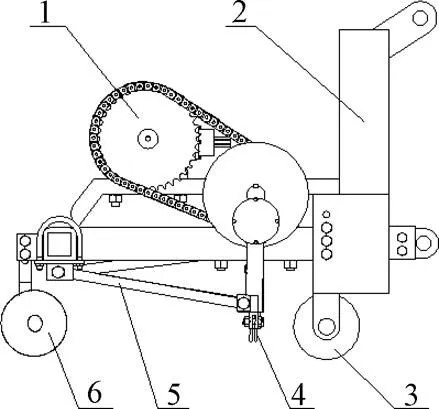

砍切式玉米秸秆还田机主要由机架、压辊、传动装置、切秆装置组成。其中压辊位于机具最前端,其主要功能是将直立或倒伏的玉米秸秆按机具前进方向压倒、铺放;传动装置由变速箱和2个左右对称的传动链轮组成;切秆装置由偏心轮盘、刀杆、切刀、摇杆组成,是机具的主要工作部件,位于压辊之后,用于将顺行铺放好的秸秆砍切成段。该机整体结构如图1所示。

1.传动系统 2.机架 3.压辊 4.切刀 5.切秆装置 6.限深轮

1.2 工作原理及技术参数

该机与拖拉机采用三点悬挂。动力传递路径为:拖拉机后置动力输出轴-万向节-变速箱-链轮-偏心轮盘-刀杆。机具作业时,压辊将玉米秸秆沿机具前进方向压倒,使得秸秆与地面紧密接触,切刀在偏心轮盘的带动下做往复运动,将压紧的玉米秸秆以及在玉米收获、运输中被拖拉机压入土壤的秸秆切成段状,减少接茬小麦少免耕播种过程中产生的机具堵塞现象。砍切式玉米秸秆还田机的主要技术参数如表1所示。

表1 砍切式玉米秸秆还田机主要技术参数

2 主要部件设计

2.1 农艺要求及传动比分配

切秆装置基于四杆机构往复运动原理,实现切刀的上下往复运动,将地表秸秆砍切成段。中国目前新研制的小麦免耕播种机多为宽窄行种植,窄行行距为12~14 cm[20-22],因此要求秸秆砍切长度不超过小麦播种窄行行距的一半,即砍切后秸秆长度≤6 cm。

机具在作业过程中切刀的运动轨迹如图2所示,砍切后秸秆长度、切刀切割频率和机具前进速度之间的关系为

式中为工作时间,s;为切刀切割频率,Hz。

1.切刀运动轨迹 2.切刀 3.秸秆

1.Cutter trajectory 2.Cutter 3.Straw

注:为机具的前进速度,km·h-1;为砍切后玉米秸秆长度,cm。

Note:represents advancing speed of machine, km·h-1;represents the length of maize straws chopped, cm.

图2 切刀运动轨迹

Fig.2 Cutter trajectory

该机的总传动比为

式中为拖拉机后置动力输出轴转速,r/min。当机具传动比一定时,秸秆切断后长度随机具前进速度的增大而减小,取秸秆还田机正常作业速度为3~5 km/h,选用拖拉机后置输出轴转速为=540 r/min,为保证机具在最低正常作业速度(3 km/h)下满足秸秆切断长度要求,取式(2)中=3 km/h,则机具的总传动比=0.648。

2.2 切秆装置设计

切秆装置结构如图3所示,包括机架、偏心轮、刀杆和摇杆,计算过程将切秆装置简化为四杆机构模型如图4所示。为保证机具运动的动平衡,同一轴承座2侧的偏心轮盘成180°相位差对称安装。

1.机架 2.偏心圆盘 3.刀杆 4.摇杆 5.机架

注:A点为偏心轮盘的回转中心,D点为摇杆与机架的铰接点,AB为偏心轮盘,BC为刀杆,CD为摇杆。γmin为最小传动角,(°);ψ为摇杆的最大摆角,(°)。

工作过程中偏心轮盘(曲柄)绕点做圆周运动,带动摇杆(摇杆)绕点作最大摆角为的往复摇摆运动。为避免机具出现上下跳动,尽量降低机具的振动,以保证机具工作的稳定性,则设计该切秆装置无急回特性,令其行程速比系数=1,即偏心轮盘(曲柄)2次与刀杆(连杆)共线时位置夹角=0°(点与1、23点共线),则切刀最大行程=2。

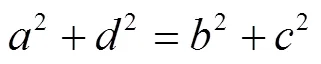

由张静等[23]按最小传动角设计的曲柄摇杆机构的解析方法可知,该机构属于型曲柄摇杆机构,取偏心轮偏心距=,刀杆长=,摇杆长=,偏心轮盘的回转中心到摇杆与机架的铰接点间的距离=,则有

根据曲柄摇杆机构的无急回特性[24-25]可知,当偏心轮盘与点2次共线时(点运动到3、4),刀杆33、44分别与摇杆3、4之间的夹角为最小传动角min和(180°−min),在三角形33中,由余弦定理可得

最终可得四杆机构中各杆件尺寸关系为

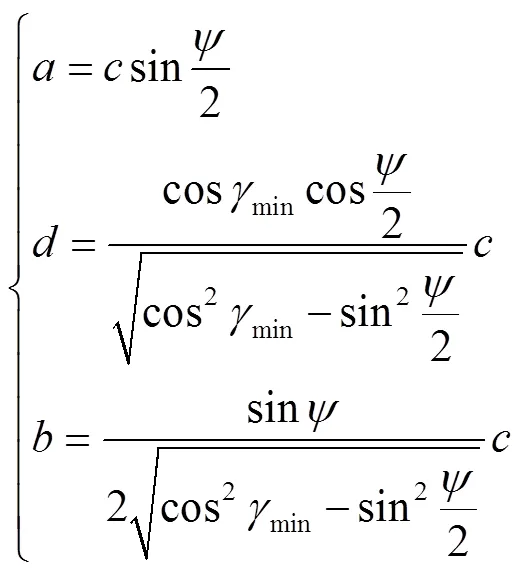

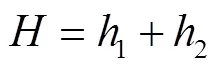

在设计的过程中,为保证切刀以最大切割力切割秸秆,当与垂直时,切刀下行切割秸秆,当点运动至最低点2,切刀达到最大入土深度。为尽量降低切刀对土壤的扰动,摇杆的摆角不宜过大,若将切刀运动轨迹近似为竖直方向的直线运动,则切刀入土深度为

式中1为切刀入土深度,mm。为避免切刀运动过程中拖动秸秆,则切刀在运动至上止点时应与地面保持一定高度;同时,为保证对压入土壤中的秸秆进行切削,则切刀应具有一定的入土深度,则切刀行程为

式中2为切刀最大离地间隙。经测量得在0~6 cm土层内秸秆占被压入土壤秸秆总量的98.7%,取1≥60 mm,地上0~10 cm内秸秆占地上秸秆总量的97.24%,取2≥10 cm,则≥160 mm。为减小切刀切割过程对机具的冲击,减少机具振动,取切刀行程=160 mm,则曲柄长=/2=80 mm。在切刀行程一定的情况下,切刀最大摆角越小,切刀切秆过程垂直性越好,但机具长度越大,综合考虑取切刀最大摆角=20°,即摇杆长=460.70 mm,此时机具总长为1 100 mm。

2.3 切秆装置动力学分析

由式(3)得min<(90°−/2)=80°。四杆机构中传动角越大,机构的传动性能越好,机械效率越高,对于高速机构,最小传动角一般不小于50°。由式(5)可得,当min取不同值时,四杆机构各杆件长度如表2所示。

表2 最小传动角取不同值时各杆长度及切刀入土深度

注:为偏心轮偏心距,刀杆长度,为摇杆长度,为偏心轮盘的回转中心到摇杆与机架的铰接点间的距离。

Note:represents eccentric distance,represents the length of cutter holder,represents the length of rocker,represents the distance between the rotation center of eccentric wheel and the hinge point of rocker on frame.

切秆装置在进行往复运动的同时随机具做水平方向的平动,通过三维软件Pro/E的应用程序对四杆机构进行运动学分析,当min取不同值时切刀在竖直方向速度变化规律如图5所示。

图5 最小传动角取不同值时切刀运动速度曲线

由图5可知,当min取不同值时,切刀的运动速度变化规律基本相同,但随min角度的增大,切刀在入土过程中加速度减小,最大运动速度减小,但速度和加速度随min变化值不显著。由表2可知,随着最小传动角min的增大,偏心轮盘的回转中心到摇杆与机架的铰接点间的距离和刀杆的长度增大;当大于70°时,长度急剧增大,整个机构力学性能变差。综合考虑机具结构的紧凑性和动力学特性,取min=70°,则=267.38 mm,=526.63 mm。

在计算切削阻力时,由于玉米秸秆关节和节间的剪切强度从根部到顶部依次递减,含水率接近74%时,所需剪切力范围为919~2 233 N[26]。关节处的剪切强度略大于相邻两节间,精确计算切割阻力十分困难,本文在分析切割功耗过程中取中间值1 571 N。玉米株高为2 500 mm,株距为280 mm时每片切刀一次切割秸秆的根数为8或9根,则单个切刀砍切秸秆所受平均阻力为13 353.5 N。将切刀受力集中在切刀刀刃中点处,通过Pro/E动态分析模块对机构进行动力学分析,测量结果得单个切刀工作过程中传动系统输出轴平均转矩为81.37 N·m,机具切割总功耗为

式中为切割功耗,kW;为机具刀组数,4;为输出轴转矩,N·m。则总切割功耗为28.39 kW。

2.4 切刀设计及力学分析

常用的切刀刀刃一般有2种:两面刃(V型)和平刃。砍切过程中,平刃刀具单侧受力,且易发生偏斜,而双面刃刀具双侧受力,刀具加持机构受力均匀,因此本文选取切刀刃口类型为双面刃。在砍切过程中切刀刃角越小,锋利性越好,但刀身越薄,易出现缺口和卷刃。前人对切刀切割植物茎秆过程做了大量的研究,针对玉米秸秆[27]、龙眼树枝[28]、小型桑树[29]、甘蔗[30]等研究了不同刃角对切割性能的影响,均表明当刃角在10~20°之间时,切割性能最好。切刀砍切玉米秸秆时有一定的入土深度,考虑土壤及较硬土块对切刀的冲击,本文适当增大了切刀刃口角度,取刃角为30°,切刀厚度为6 mm,并对刀刃部分进行淬火和回火处理。玉米秸秆还田机的幅宽为2 400 mm(4行玉米),为避免切刀相互干涉,设计每片切刀的宽度为580 mm。

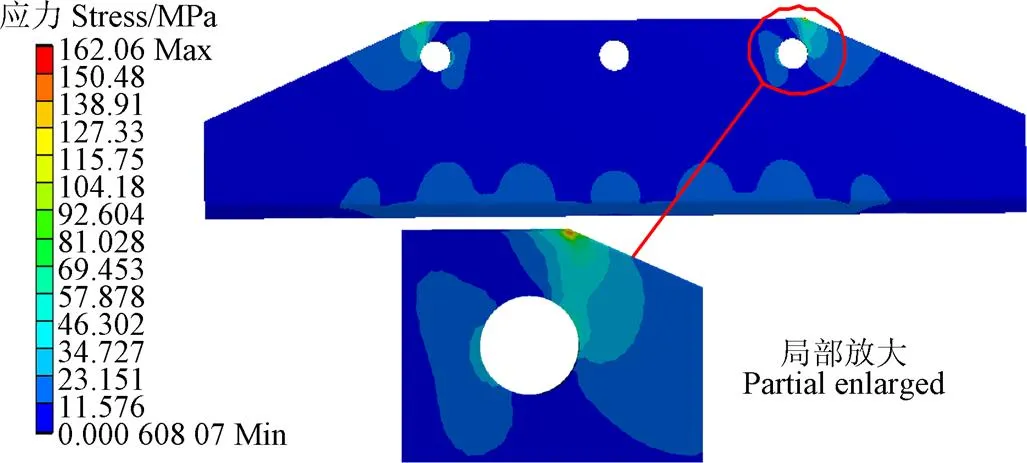

利用有限元软件ANSYS对切秆装置进行强度分析,为确保强度要求,每次切割的秸秆根数确定为9根,且每根秸秆的切割部位所需剪切力都取植株根部关节处的最大剪切力2 233 N,则刀片的切割阻力为20 098 N。切刀材料选用耐磨性较高和抗冲击韧性的65 Mn合金钢,屈服强度为430 MPa,泊松比为0.3,弹性模量为210 MPa。利用有限元软件ANSYS对切刀强度进行校核,只考虑载荷最大的工况,其结果如图6所示。

图6 切刀应力云图

分析可知,最大点应力产生在切刀两侧的螺栓孔附近,且最大应力值为162 MPa,小于切刀本身的许用应力(430 MPa)。

3 田间试验与分析

3.1 试验条件

为测试所设计砍切式玉米秸秆还田机的田间作业性能,2017年10月在河北省邯郸市鸡泽县开展田间试验,对比研究传统甩刀式秸秆还田机(对照组)和砍切式秸秆还田机的作业性能及后续播种作业效果。鸡泽县属于黄淮海小麦/玉米一年两熟区,试验地土壤类型为壤土,0~10 cm深度内土壤平均含水率为21.8%。玉米品种为登海605,收获后玉米秸秆平均直径为28.5 mm,平均含水率为76.49%,秸秆覆盖量为1.37 kg/m2。试验选用江苏清江JS-650轮式拖拉机,拖拉机后置输出轴转速为540 r/min,前进速度为4.15 km/h,测试过程如图7所示。

图7 田间性能试验

3.2 试验方法

3.2.1 秸秆粉碎长度不合格率

根据GB/T 24675.6-2009《保护性耕作机械秸秆粉碎还田机》标准要求,随机选取10个面积为1 m2的测试样点,每个测试样点随机捡拾10根切碎秸秆并测量、记录其长度数据。以6 cm为秸秆切碎合格长度上界,秸秆切碎长度不合格率的计算公式为

式中n为样点处秸秆长度大于6 cm的秸秆数,N为样点处所测秸秆的总数。

3.2.2 机具运行平稳性

机具运行平稳性是衡量机具设计合理性的重要指标,机具运行越平稳,砍切深度一致性越高,粉碎效果越好,驾驶机具也更加舒适。平稳性指标受到包括地表平整度、土壤紧实度、机具前进速度、砍切入土深度和机具本身作业方式等多方面影响。平稳性测量采用丹麦BK4370加速度传感器(频率范围:0.1~12 600 Hz,电荷灵敏度:10 pc/ms2Hz)、丹麦BK2635电荷放大器(最大灵敏度10 V/pc)和美国FLUKE F15B+数字万用表(直流电压精度0.5%),将加速度传感器固定在机架上,分别测量机具水平和竖直方向的振动,每个方向取3个不同的测量点,试验过程中记录电压值并将电压值转换为加速度值。

3.2.3 土壤物理性质

为研究切刀砍切秸秆过程中对土壤的影响,分别测量试验前后土壤容重变化及切刀入土深度。机具作业后,沿机具前进方向,每隔5 m设置一个取样点,共取10个取样点,测量土壤剖面;土壤容重采用环刀法测定。

3.2.4 播种作业效果

为了反映本文设计砍切式秸秆还田机和对照组(甩刀式)秸秆还田机作业后地表及秸秆情况对后续播种作业的影响,本文在秸秆还田试验后进行了播种试验,测试不同还田机类型作业后播种质量,测试选用河北农哈哈2BMSF-7/14型小麦免耕播种机,播种过程测试机具通过性能及播种后地表质量。

3.3 试验结果与分析

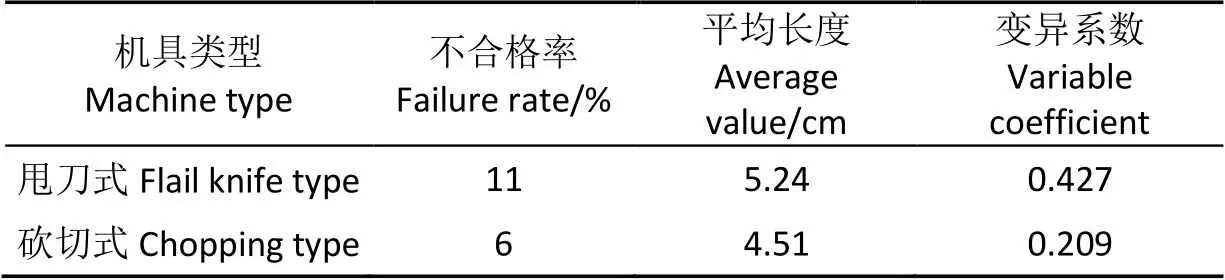

3.3.1 秸秆切碎长度不合格率

试验后分别测量秸秆切碎长度结果如表3所示,由表3可知,与对照组相比,砍切式秸秆还田机的粉碎效果具有显著优势,主要表现为:1)砍切式秸秆还田机作业后秸秆长度不合格率为6%,比甩刀式秸秆还田机小5个百分点;2)切断后秸秆平均长度为4.51 cm,比对照组短0.73 cm;秸秆长度变异系数为0.209,比对照组小0.218。

表3 秸秆粉碎质量

3.3.2 机具运行平稳性试验

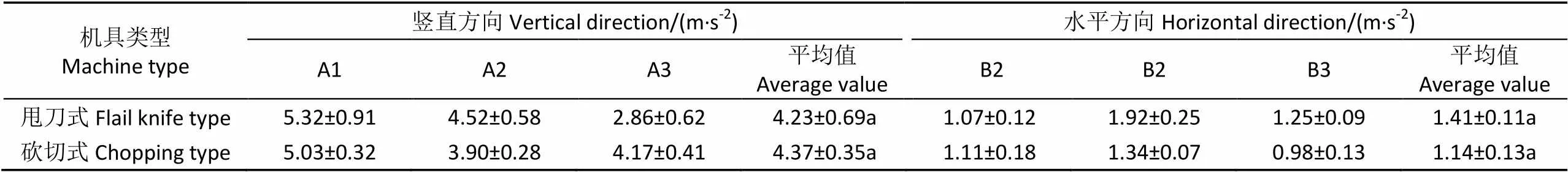

机具平稳性试验结果如表4所示。试验结果表明:1)在竖直方向上,砍切式秸秆粉碎还田机的振动强度大于甩刀式秸秆粉碎还田机,但无显著差异;2)2者在水平方向上的振动较小,且无显著差异;3)2种类型还田机平稳性均可满足机具作业要求。砍切式秸秆还田机振动主要由于切刀规律性砍切秸秆和土壤产生的竖直方向上的振动,振幅较大,但频率较小;甩刀式秸秆还田机的振动由高速旋转的甩刀受到地面和秸秆冲击产生,振动频率高,但振幅相对较小。

表4 机具振动加速度数据

注:A1、A2、A3分别表示竖直方向上的3个测量点,B1、B2、B3分别表示水平方向上的3个测量点。

Note: A1, A2 and A3 represent 3 measuring points in the vertical direction respectively. B1, B2 and B3 represent 3 measuring points in the horizontal direction respectively.

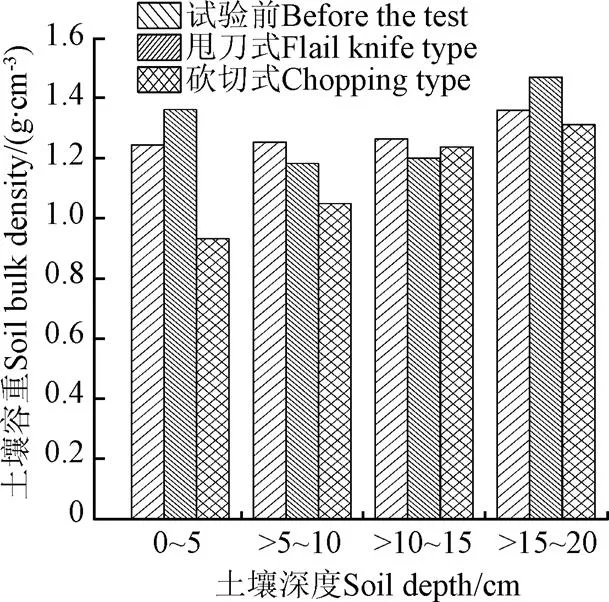

3.3.3 作业后土壤物理性质

试验后测得砍切式秸秆还田机切土平均深度为7.71 cm,对照组还田机切刀未入土。不同深度土壤容重测量结果如图8所示,砍切式秸秆还田机经切刀高频入土砍切作用后,0~10 cm深度的土壤容重明显降低,其中0~5 cm深度土壤容重降低最为显著,降低了25.4个百分点,5~10 cm深度土壤容重降低较为显著,降低了14.67个百分点,土壤深度大于10 cm后,容重基本没有变化;甩刀式秸秆还田机作业前后0~20 cm各土层土壤容重基本没有变化。由于切刀的高频入土切割作用,且刀片入土深度在7~8 cm范围,使得深度在0~10 cm深度土层疏松而向上膨胀,土壤密度减小,容重降低,为后续播种作业提供良好的土壤环境;而甩刀式秸秆还田机作业过程仅对地表秸秆进行粉碎,刀具不入土,作业前后土壤容重变化不大。

图8 试验前后不同深度土壤容重对比

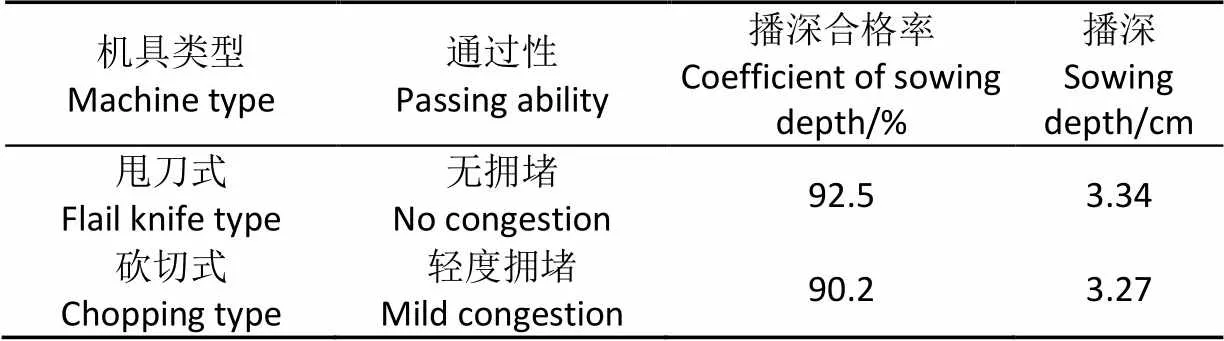

3.3.4 播种作业效果

分别在2种秸秆还田机作业后地表进行播种试验,试验结果如表5所示。试验结果表明在砍切式秸秆还田机作业后地表播种,无拥堵现象;在甩刀式秸秆还田机作业后地表播种时出现轻度堵塞,但随机具前进,被拥堵秸秆自行后流,不需停机疏通。播种质量测试表明在甩刀式秸秆还田机作业后地表播种时出现晾种现象,且播种深度合格率比砍切式小2.3个百分点,主要由于在甩刀式秸秆还田机作业后地表播种时出现轻度拥土现象,影响播种质量。

表5 播种质量对比

4 结 论

1)基于四杆机构往复运动原理,设计了一种砍切式玉米秸秆还田机,该机能够通过四杆机构驱动切刀实现地表支撑式秸秆砍切,一次作业可实现玉米秸秆的顺行压倒和垂直切割,同时保证玉米秸秆切段长度符合后续小麦少免耕播种要求,提高后续播种质量。

2)通过理论计算和仿真分析,对砍切式玉米秸秆还田机的切秆机构进行理论分析和运动模拟,确定该机摇杆的最大摆角为20°,最小传动角为70°,偏心轮偏心距为80 mm,刀杆长267.375 mm,摇杆长460.702 mm,偏心轮盘的回转中心到摇杆与机架的铰接点间的距离为526.627 mm。

3)通过田间对比试验表明,与甩刀式秸秆还田机相比,砍切式秸秆还田机粉碎后秸秆平均长度小0.73 cm,秸秆长度不合格率小5个百分点,秸秆长度变异系数小0.21,粉碎效果明显优于甩刀式;切刀入土平均深度为7.71 cm,可明显降低0~10 cm土层土壤容重;机具竖直方向振动幅度略大于甩刀式秸秆还田机,但仍满足机具作业要求。后续播种试验试验表明在砍切式秸秆还田机作业后地表进行播种时,播种无拥堵现象且播种深度合格率比甩刀式大2.3个百分点。

[1] 井良霄.干青玉米秸秆厌氧发酵特性与优化工艺研究[D].杨凌:西北农林科技大学,2013.

Jing Liangxiao. Study on Anaerobic Digestion Properties and Process Technology Optimizations of Corn Stalks[D]. Yangling: Northwest Agriculture and Forestry University, 2013. (in Chinese with English abstract)

[2] 毕于运,王亚静,高春雨. 中国主要秸秆资源数量及其区域分布[J]. 农机化研究,2010,32(3):1-7.

Bi Yuyun, Wang Yajing, Gao Chunyu. Straw resource quantity and its regional distribution in China[J]. Journal of Agricultural Mechanization Research, 2010, 32(3): 1-7. (in Chinese with English abstract)

[3] 王金武,唐汉,王金峰. 东北地区作物秸秆资源综合利用现状与发展分析[J]. 农业机械学报,2017,48(5):1-21.

Wang Jinwu, Tang Han, Wang Jinfeng. Comprehensive utilization status and development analysis of crop straw resource in northeast China[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(5): 1-21. (in Chinese with English abstract)

[4] 刘哲,韩霁昌,孙增慧,等. δ13C法研究砂姜黑土添加秸秆后团聚体有机碳变化规律[J]. 农业工程学报,2017,33(14):179-187.

Liu Zhe, Han Jichang, Sun Zenghui, et al. Change law of organic carbon in lime concretion black soil aggregates with application of straw by δ13C method[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(14): 179-187. (in Chinese with English abstract)

[5] 朱强根,朱安宁,张佳宝,等. 保护性耕作下土壤动物群落及其与土壤肥力的关系[J]. 农业工程学报,2010,26(2):70-76.

Zhu Qianggen, Zhu Anning, Zhang Jiabao, et al. Relation of agricultural soil fauna and soil fertility under conservation tillage systems[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(2): 70-76. (in Chinese with English abstract)

[6] 赵亚丽,薛志伟,郭海斌,等.耕作方式与秸秆还田对土壤呼吸的影响及机理[J]. 农业工程学报,2014,30(19):155-165. Zhao Yali, Xue Zhiwei, Guo Haibin, et al. Effects of tillage and crop residue management on soil respiration and its mechanism[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(19): 155-165. (in Chinese with English abstract)

[7] 周怀平,解文艳,关春林,等. 长期秸秆还田对旱地玉米产量、效益及水分利用的影响[J]. 植物营养与肥料学报,2013,19(2):321-330.

Zhou Huaiping, Xie Wenyan, Guan Chuanlin, et al. Effects of long-term straw-returning on corn yield, economic benefit and water use in arid farming areas[J]. Plant Nutrition and Fertilizer Science, 2013, 19(2): 321-330. (in Chinese with English abstract)

[8] 张喜瑞,何进,李洪文,等. 小麦免耕播种机驱动链式防堵装置设计[J]. 农业机械学报,2009,40(10):44-48.

Zhang Xirui, He Jin, Li Hongwen, et al. Design of the powered-chain anti-blocking mechanism for wheat no-till planter[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(10): 44-48. (in Chinese with English abstract)

[9] Brandelero E M, de Araujo A G, Ralisch R. Soil mobilization and seeding depth by no-till seeder mechanisms for residue management[J]. Engenharia Agricola, 2014, 34(2): 263-272.

[10] 卢彩云,赵春江,孟志军,等. 基于滑板压秆旋切式防堵装置的秸秆摩擦特性研究[J]. 农业工程学报,2016,32(11):83-89.

Lu Caiyun, Zhao Chunjiang, Meng Zhijun, et al. Straw friction characteristic based on rotary cutting anti-blocking device with slide plate pressing straw[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(11): 83-89. (in Chinese with English abstract)

[11] 张喜瑞,李洪文,何进,等. 旋转拨刀式小麦免耕播种机的设计与试验[J]. 农机化研究,2012,34(3):149-151,158.

Zhang Xirui, Li Hongwen, He Jin, et al. Experiment and design of rotating and dialing knife type no-till wheat planter[J]. Journal of Agricultural Mechanization Research, 2012, 34(3): 149-151,158. (in Chinese with English abstract)

[12] 付雪高,李明,卢敬铭,等. 秸秆粉碎还田机甩刀的研究进展[J]. 中国农机化学报,2011(1):83-87.

Fu Xuegao, Li Ming, Lu Jingming, et al. Research on the cutter of straw crushing machine to field[J]. Chinese Agricultural Mechanization, 2011(1): 83-87. (in Chinese with English abstract)

[13] Johnson J M F, Acostamartinez V, Cambardella C A, et al. Crop and soil responses to using corn stover as a bioenergy feedstock: Observations from the northern US corn belt[J]. Agriculture, 2013, 3(1): 72-89.

[14] 姚燕,姬裕江. 基于锤爪式动刀的小麦秸秆粉碎装置试验研究[J]. 农机化研究,2010,32(1):156-158.

Yao Yan, Ji Yujiang. Test study on smashing devices of sweat stalks[J]. Journal of Agricultural Mechanization Research, 2010, 32(1): 156-158. (in Chinese with English abstract)

[15] 潘佛雏,康建明,颜利民,等. Y型甩刀式秸秆粉碎还田机关键部件的设计与性能试验[J]. 农业现代化研究,2015,36(5):912-915.

Pan Fuchu, Kang Jianming, Yan Limin, et al. Design and experiment to key components of Y type cutting device of smashed straw machine[J]. Research of Agricultural Modernization, 2015, 36(5): 912-915. (in Chinese with English abstract)

[16] 林静,马铁,李宝筏. 1JHL-2 型秸秆深埋还田机设计与试验[J]. 农业工程学报,2017,33(20):32-40.

Lin Jing, Ma Tie, Li Baofa. Design and test of 1JHL-2 type straw deep burying and returning machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(20): 32-40. (in Chinese with English abstract)

[17] 蒲永锋. 9YG-2.0型圆捆打捆机捡拾粉碎装置参数设计与仿真分析[D]. 长春:吉林大学,2015.

Pu Yongfeng. Parameter Design and Simulation Analysis on Pick-crushing Device of 9YG-2.0 Round Baler[D]. Changchun: Jilin University, 2015. (in Chinese with English abstract)

[18] 孙宏宇,董玉平,吴云玉,等. 基于COSMOSWorks的还田机直刀有限元分析[J]. 农机化研究,2011,33(1):69-71.

Sun Hongyu, Dong Yuping, Wu Yunyu, et al. Finite element analysis of straw machine straight knife based on COSMOSWorks[J]. Journal of Agricultural Mechanization Research, 2011, 33(1): 69-71. (in Chinese with English abstract)

[19] 郑智旗,何进,李洪文,等. 动定刀支撑滑切式秸秆粉碎装置设计与试验[J]. 农业机械学报,2016,47(增刊1):108-116.

Zheng Zhiqi, He Jin, Li Hongwen, et al. Design and experiment of straw-chopping device with chopping and fixed knife supported slide cutting[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(Supp.1): 108-116. (in Chinese with English abstract)

[20] 吴红丹,李洪文,梅峰,等. 一沟双行小麦施肥播种单体的设计与试验[J]. 中国农业大学学报,2016,12(2):50-53.

Wu Hongdan, Li Hongwen, Mei Feng, et al. Design and experimental study on a combined fertilizing and seeding opener for wheat of two rows in one furrow[J]. Journal of China Agricultural University, 2016, 12(2): 50-53. (in Chinese with English abstract)

[21] 刘正道. 小麦免耕播种关键技术研究与装备研发[D]. 杨凌:西北农林科技大学,2016.

Liu Zhengdao. Research and Development of Key Technology and Equipment for Wheat No-tillage Drill[D]. Yangling: Northwest Agriculture and Forestry University, 2006. (in Chinese with English abstract)

[22] Wang Qingjie, Zhao Hongbo, He Jin, et al. Design and experiment of blades-combined no and minimum-till wheat planter under controlled traffic farming system[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(17): 12-17.

[23] 张静,王占英,刘春东,等. 按最小传动角设计曲柄摇杆机构的解析方法[J]. 机械设计,2008,25(10):63-65.

Zhang Jing, Wang Zhanying, Liu Chundong, et al. Analytical method for designing crank-rocker mechanism according to minimum transmission angle[J]. Journal of Machine Design, 2008, 25(10): 63-65. (in Chinese with English abstract)

[24] 刘志刚,王德成,翟改霞,等. 往复式双动刀灌木收割机设计与试验[J]. 农业机械学报,2013,44(增刊2):102-106.

Liu Zhigang, Wang Decheng, Zhai Gaixia, et al. Design and experiment on reciprocating double knife shrub harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(Supp.2): 102-106. (in Chinese with English abstract)

[25] 彭松林. 基于曲柄摇杆机构的扑翼微飞行器的研究[D]. 上海:上海交通大学,2010.

Peng Songlin. Study of Flapping Wing Micro Aerial Vehicle Based on Crank Rocker Mechanism[D]. Shanghai: Shanghai Jiao Tong University, 2010. (in Chinese with English abstract)

[26] 高欣.玉米秸秆力学特性试验研究[D]. 武汉:华中农业大学,2013.

Gao Xin. Experimental Study of Mechanical Properties of Corn Stalks[D]. Wuhan: Huazhong Agricultural University, 2013. (in Chinese with English abstract)

[27] 袁洪方,王德成,王光辉,等. 秸秆铡切揉搓装置优化设计与试验[J] .农业机械学报,2012,43(增刊1):153-157.

Yuan Hongfang, Wang Decheng, Wang Guanghui, et al. Design and experiment of straw cutting and rubbing process device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(Supp.1): 153-157. (in Chinese with English abstract)

[28] 吴良军,杨洲,段洁利,等.龙眼树枝修剪机具刀片切割力的影响因素试验[J]. 农业工程学报,2012,28(24):8-14.

Wu Liangjun, Yang Zhou, Duan Jieli, et al. Experiment on influencing factors of cutting force of blades of trim tool for longan branch[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(24): 8-14. (in Chinese with English abstract)

[29] 赖仁盛,孙永厚,靳国才.小型桑树伐条机切割部分试验研究[J].农机化研究,2013,35(2):150-153.

Lai Rensheng, Sun Yonghou, Jin Guocai. Experimental investigation of the cutting part for mini-type mulberry branch cutting machine[J]. Journal of Agricultural Mechanization Research, 2013, 35(2): 150-153. (in Chinese with English abstract)

[30] 向家伟,杨连发,李尚平.小型甘蔗收获机切割器试验研究[J]. 农业工程学报,2007, 23(11):158-163.

Xiang Jiawei, Yang Lianfa, Li Shangping. Experimental investigation of the base cutter for mini type sugarcane harvester[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2007, 23(11): 158-163. (in Chinese with English abstract)

Design and experiment of chopping-type maize straw returning machine

Wang Qingjie, Liu Zhengdao, He Jin, Li Hongwen※, Li Wenying, He Jianhuai, Yan Xionglei

(,,100083,)

In annual double cropping areas in northern China, the straw is directly returned to the field after maize harvest, and the wheat is sown by no-tillage planter. However, the high water content and strong toughness of maize straw result in the low qualification rate of traditional rotary flail knife type returning machine, which can easily lead to straw blocking and thereby affect wheat sowing quality. To address the above problems, in this paper, a chopping method based on the principle of four-bar linkage mechanism was put forward. The maize straw was chopped using ground as the support. A chopping-type straw returning machine, composed of the frame, pressure roller, transmission device and straw cutting device, was developed. The pressure roller was located at the front of the machine, and was designed to press the standing or lying straws forward in the direction of machine movement. The cutting device was at the back of the roller, and was designed to cut the lying parallel straw into segments. To avoid straw blocking, maize straw was chopped into segments with the length less than 6 cm, and the length was half of the narrow row spacing of wheat. Based on theoretical calculation and motion simulation, the size of 4-link mechanism of cutting device was designed and the cutters’ movement trajectory was optimized. In 4-link mechanism, the minimum transmission angle was 70°, the maximum swing angle of rocker was 20°, the eccentric distance of eccentric wheel was 80 mm, and the lengths of cutter holder (connecting rod) and rocker were 267.375 and 460.702 mm, respectively. The distance between the rotation center of eccentric wheel and the hinge point of rocker on frame was 526.627 mm. According to the finite element static analysis by using ANSYS software, the maximum stress of the cutter was calculated as 162 MPa generated near the bolt holes on both sides, which met the design requirements. The field performance experiment was conducted in Hebei Province to compare the chopping-type straw returning machine and traditional flail knife type machine. The comparison and research objects included the unqualified rate of straw length, working stability, soil physical property and the subsequent sowing operation effect. The experiment results showed that the average length of the straw with the designed machine was 4.8 cm, the unqualified rate was 6% and the coefficient of variation was 0.209, which were all superior to the traditional machine. The vibration of the designed one was slightly larger than that of traditional one with no significant difference, and both of the machines worked stably. The cutting depth of new cutter reached 7.71 cm averagely, and soil bulk density in 0-10 cm depth decreased obviously. The subsequent wheat seeding experiments were carried out, and the results showed that there was no straw blocking during seeding when the seeder operated on the surface on which the chop-cutting straw returning machine worked, and the coefficient of sowing depth was 92.5% and it was significantly higher than another one. This study provides a new equipment for the maize straw returning in the double cropping areas in northern China, and it is also conducive to the popularization of straw returning technology.

mechanization; design; optimization; straw returning machine; chopping-type; cutting length; 4-link mechanism

10.11975/j.issn.1002-6819.2018.02.002

S224.3

A

1002-6819(2018)-02-0010-08

2017-09-13

2017-12-30

公益性行业(农业)科研专项经费项目-作物秸秆还田技术(201503136)

王庆杰,副教授,博士生导师,主要从事保护性耕作技术与装备研究。Email:wangqingjie@cau.edu.cn

李洪文,教授,博士生导师,主要从事保护性耕作技术与装备研究。Email:lhwen@cau.edu.cn

王庆杰,刘正道,何 进,李洪文,李问盈,何建怀,鄢雄磊. 砍切式玉米秸秆还田机的设计与试验[J]. 农业工程学报,2018,34(2):10-17. doi:10.11975/j.issn.1002-6819.2018.02.002 http://www.tcsae.org

Wang Qingjie, Liu Zhengdao, He Jin, Li Hongwen, Li Wenying, He Jianhuai, Yan Xionglei. Design and experiment of chopping-type maize straw returning machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(2): 10-17. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.02.002 http://www.tcsae.org