木薯高/低温二段式干燥工艺参数优化试验

2018-02-28杨潇潇丛堃林张衍国李清海

杨潇潇,丛堃林,张衍国,李清海

木薯高/低温二段式干燥工艺参数优化试验

杨潇潇,丛堃林,张衍国,李清海※

(热科学与动力工程教育部重点实验室,清华大学-滑铁卢大学微纳米能源环境联合研究中心,清华大学能源与动力工程系,北京 100084)

木薯收获时含水率约为65%~70%,为了便于储存和运输,必须在短时间内对木薯进行干燥处理。为开发和优化木薯干燥工艺,该文在干燥箱中试验研究了木薯切片厚度、干燥温度对干燥过程的影响。试验结果表明,干燥温度过高,木薯经过高温后易糊化变质,温度太低,则干燥不充分;切片太薄,干燥过程中木薯片会断裂,切片太厚,达到合格含水率所需时间将延长。用Wang and Singh模型关联木薯干燥过程,根据干基含水率曲线确定了木薯干燥过程中的临界含水率为105%。对于一段式木薯干燥工艺,木薯在干燥过程中达到临界含水率时后段干燥速率呈下降趋势,为了避免这一趋势出现而导致干燥效率下降,提出了先高温、后低温的二段式优化干燥方案,确定了各段工艺的参数,为木薯干燥设备的设计提供了必要的依据。

干燥;水分;质量控制;木薯

0 引 言

木薯是热带和亚热带根茎植物,是世界三大薯(马铃薯、木薯、红薯)之一。原产于亚马逊流域,在我国及东南亚等地被广泛种植,主要应用于食品、医药、工业等领域,有“淀粉之王”之称[1-4]。

木薯成熟时含水率在65%~70%之间,收获3~7 d内若不进行干燥则很容易变质腐烂。为便于存储和运输,收获后应尽快将其含水率降低到安全含水率以下,需利用工业化干燥设备对木薯进行快速干燥[5-10]。

截至目前,国内外已有许多学者对木薯干燥进行了大量的研究,但有关木薯干燥过程、干燥工艺及干燥设备的研究还不多见。国外研究人员大多针对太阳能干燥对木薯干燥过程进行研究,主要研究了环境温度、相对湿度、光线强度、气体流速、装载密度等因素对木薯干燥过程的影响,结果表明温度、光线强度和气体流速与干燥速率成正相关,装载密度与干燥速率呈负相关[11-14]。由于薯类作物大多含淀粉和糖分,其干燥过程具有相似性,因而其他薯类的研究可以参考。李业波等[15]对马铃薯进行了内部的传热传质研究,建立了马铃薯内部水分扩散系数的数学模型。孟岳成等[16]研究了温度、风速和厚度对红薯烦躁过程的影响,比较了12种干燥模型在红薯热风干燥中的适用性,结果表明与Wang and Singh 模型的拟合程度最高。龙铭等[17]设计了用负压气流对木薯进行干燥的设备。刘琨等[18-21]分别对木薯淀粉、木薯酒糟的干燥特性,结果表明干燥曲线为指数曲线。张鹏等[22-23]研究了红薯、马铃薯、芋头和山药在干燥过程中温度、厚度和切法对干燥特性的影响,对4种物料分别进行了干燥特性与动力学模型的拟合,结果表明,它们在热风干燥过程中各类指标变化基本一致,具有共性。上述研究分别是针对马铃薯、红薯、木薯淀粉、木薯酒糟、芋头、山药等进行的研究,但均未与木薯的干燥工艺相结合。

为了设计木薯干燥设备,本文利用干燥箱[24-25]研究了干燥过程中温度和木薯切片厚度对干燥过程的影响,并提出相应的木薯干燥工艺。

1 材料与方法

1.1 试验材料

试验采用的新鲜木薯购于广西省容县,木薯洗净晾干后密封放置在2~5℃的冰箱中冷藏备用。

1.2 试验设备及方法

用切片模具将新鲜木薯分别切成厚度分别为5、6、7、8、9 mm的圆片,再将切好的木薯片放入提前设定好温度为60、70、80、90、100 ℃的鼓风干燥箱(DGF25012C)中,利用鼓风干燥箱模拟热风干燥过程,每隔5 min从干燥箱中取出1个试样,将取出来的木薯片放入到装有变色硅胶的干燥器中冷却降温,冷却至室温后用电子天平(德国Sartorius BS210S,称量范围为0~210 g,精度为0.000 1 g)称其质量。根据实际称量的质量计算木薯的水分。

1.3 木薯水分的测量和表示方法

木薯的原始水分用GB28733-2012[26]的方法进行测量。

木薯的干基含水率是表示木薯在干燥过程中的某一时刻水分与干物料的比,每个样品的干基含水率按照式(1)进行计算。

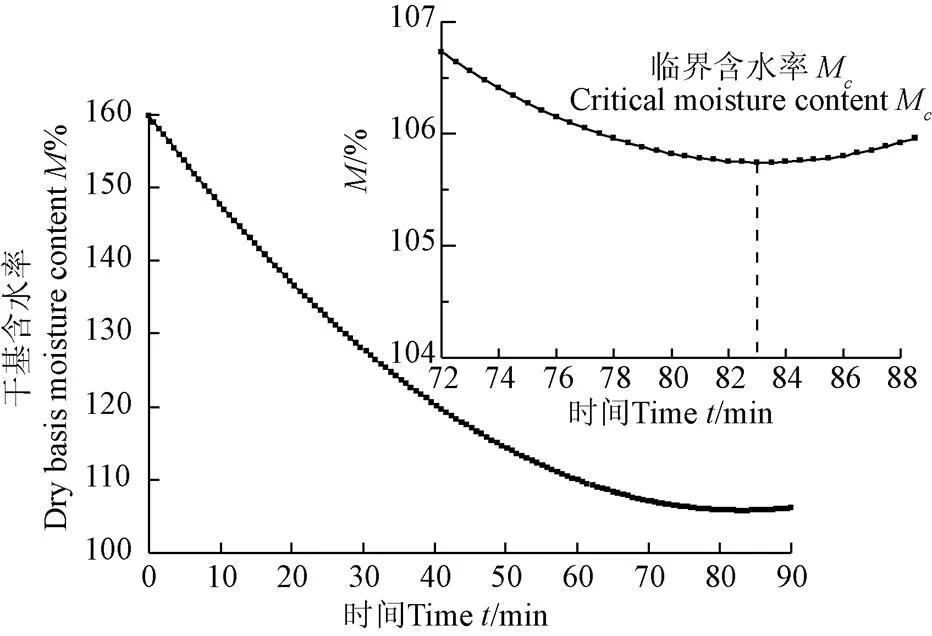

用水分比来表示一定干燥条件下的木薯的含水率,具体计算方法如下

式中MR为水分比;M为干燥过程中某一时刻样品的含水率,%;M,木薯的终点含水率,%;0为木薯的原始含水率,%。

木薯干燥过程中的干燥速率用式(3)表示。

式中为干燥速率,%/min;为干燥时间,min。

2 结果与分析

木薯的原始水分为62%,根据预试验结果,若木薯切片太薄,干燥过程中会出现断裂的现象,木薯片太厚干燥不完全,因此选取切片厚度为8 mm的试验数据研究温度对木薯干燥特性的影响。

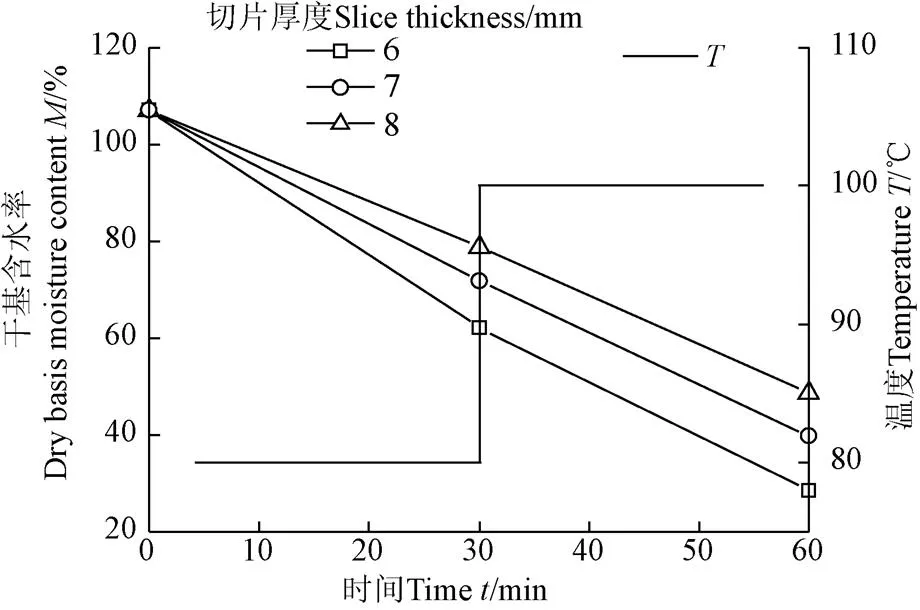

木薯主要成分为蛋白质和淀粉,由于蛋白质和淀粉在高温下易变性,因此选取干燥温度为80 ℃的试验数据分析厚度对木薯干燥特性的影响。

2.1 温度对木薯干燥特性的影响

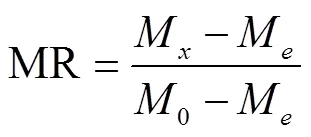

图1给出了厚度为8 mm时干基含水率随时间变化的干燥曲线。木薯与热风之间的传热传质机理主要受温差的影响,干燥过程中的温度越高,木薯与热风的温度差越大,木薯内部水分的蒸发速率加快,图1中曲线的斜率增大,即木薯的干燥速率增大。试验结果表明,提高干燥温度对木薯干燥过程有利,但考虑木薯的化学性质会随干燥温度的升高而糊化、变质,根据试验结果拟定干燥设备的干燥温度为80~100 ℃,不仅能够避免低温造成能耗损失,同时也不会出现因高温引发的木薯变质、糊化的现象。

2.2 厚度对木薯干燥特性的影响

图2给出了80℃下不同切片厚度的干燥曲线,试验结果表明,切片厚度越薄,达到特定含水率需要的时间越短。但在实际干燥过程中当切片厚度为5 mm时,由于厚度太薄,干燥一段时间后木薯片表面易产生收缩裂口最终导致木薯片断裂;当厚度为9 mm时由于木薯内部水分蒸发速率较低导致木薯干燥时间延长。木薯干燥时,薯片厚度6~8 mm为宜。

图1 厚度为8 mm时不同干燥温度下的干燥曲线

图2 温度为80 ℃时不同厚度的干燥曲线

2.3 干燥模型拟合

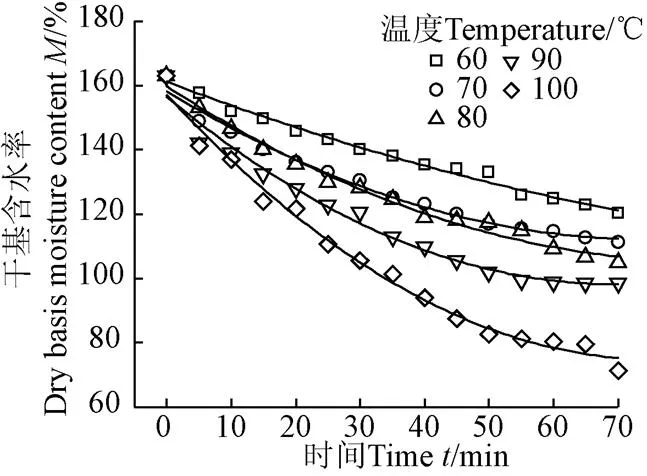

图3 温度为80℃水分比的拟合曲线

图4 厚度为8 mm比水分的拟合曲线

相同温度下5种不同厚度、相同厚度下5种不同温度的木薯水分比MR干燥模型、干基含水率模型与试验数据拟合结果的相关系数22分别见表1、表2,其中22的值均在0.98~0.99之间。根据拟合得到的水分比干燥模型方程可以对木薯实际干燥过程进行预测,便于判断某一时刻的木薯水分比MR的值;根据不同条件下木薯片干基含水率的拟合方程式可以推出木薯片在不同温度、不同厚度下的临界含水率的值,及木薯干燥过程中恒速干燥与降速干燥的临界点。确定相应的临界含水率后可得到与之对应的达到木薯片临界含水率的时间。

表1 80℃下不同厚度木薯片水分比MR和干基含水率M的拟合方程式

表2 8 mm切片厚度下不同温度木薯片水分比MR和干基含水率M的拟合方程式

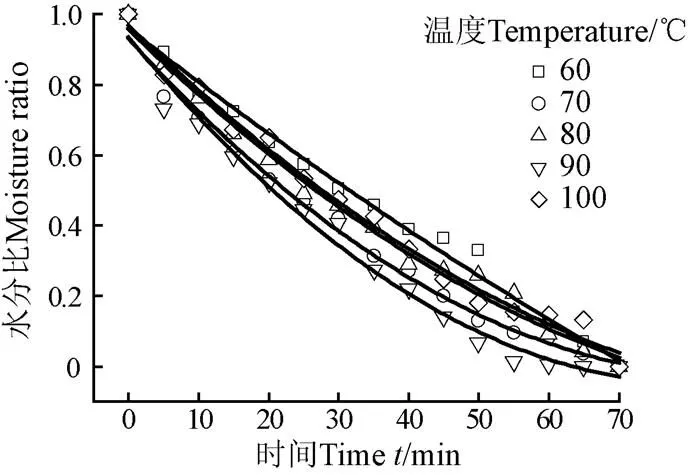

2.4 临界含水率

图5 厚度8 mm木薯片在温度80 ℃时的干燥速率曲线

2.5 干燥工艺的设计

干燥过程中为了避免干燥速率下降的情况,木薯干燥设备的设计过程中一般木薯的干燥过程可分为恒温一段式干燥和变温分段式干燥[30]。试验结果表明,采用恒定温度的一段式干燥方案在70 min内只能将木薯的含水量降到35%左右,并不能满足在60 min内将木薯含水率降到安全含水率的设计要求。因此在实际干燥工艺的设计过程中考虑采用二段式干燥方案,即干燥过程中前后两段选取不同的干燥温度,利用前半段时间将含水率降低到原始水分的一半,后半段时间将含水率降到安全含水率。

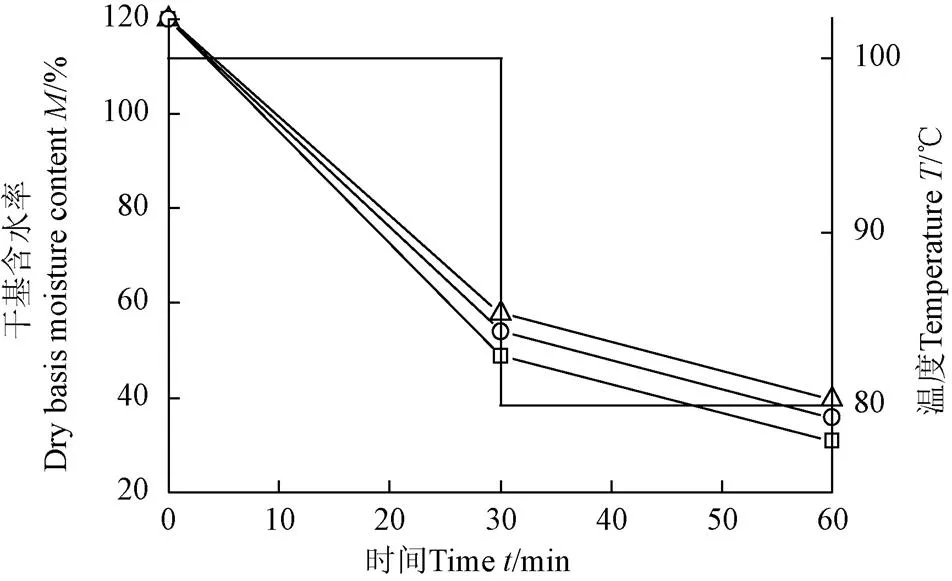

二段式干燥试验分别在不同的温度和不同的时间内完成,将木薯切片后分别放入鼓风干燥箱,在1温度下干燥1时间后,将鼓风干燥箱的温度调至2温度继续干燥2时间,最终将木薯取出,分别测得在不同试验工况下干燥后木薯的含水率,以判断经过木薯是否达到安全含水率。其中设计的2种干燥试验方案见表3,其中方案1设定先低温后高温的干燥方案,即前半段干燥温度为80 ℃,干燥时间为30 min,后半段干燥温度为100 ℃,干燥时间为30 min;方案2设定先高温后低温的干燥方案,即前半段干燥温度为100 ℃,干燥时间为30 min,后半段干燥温度为80 ℃,干燥时间为30 min。

表3 二段式干燥试验方案

图6a是先低温后高温的二段式干燥方案结果,图6b是先高温后低温的二段式干燥方案结果。对比以上二段式干燥试验结果,发现木薯干燥过程中方案2的最终含水率均低于方案1的最终含水率。根据试验结果,拟定木薯干燥工艺中采用第一段温度为100 ℃、第二段温度为80 ℃的二段式干燥方案。

a. 第1干燥段80 ℃,第2干燥段100℃

a. 80℃at first stage and 100℃ at second stage

b. 第1干燥段100℃,第2干燥段80℃

b. 100℃at first stage and 80℃ at second stage

注:为分段干燥温度。

Note:is stage drying temperature.

图6 不同温度的二段式木薯干燥工艺对比图

Fig.6 Comparison chart of two-stage cassava drying process at different temperatures

图7给出了木薯干燥工艺方案示意,该方案的设备主要包括风机、给料机、第一干燥段、第二干燥段、热交换器等。实际干燥过程中将具有一定原始含水率的木薯切成6~8 mm的片状,用给料机将切好的木薯片送入第一干燥段内,其中第一干燥段内的热风由风机1提供,经热交换器1加热到1=100 ℃,第一干燥段的干燥时间1=30 min。经第1干燥段干燥后的中间产品被送入第二干燥段,第二干燥段的干燥时间2=30 min,经第二干燥段处理后的木薯达到13%的安全含水率,能够进行大量的储存和运输。

其中干燥工艺的第二干燥段的热风由风机2提供,并由热交换器2加热,其热风温度为2=80 ℃。由于第1干燥段反应后的气体湿度较大不适合被循环利用,因此直接经干燥气流出口排放到大气中。第二干燥段出口流出的气体湿度小,因此设计将第二干燥段反应后的干燥气体流出后返回到热交换器2中继续循环利用,这样在增加了第二干燥段循环风流量的同时,提高了木薯的传热传质效率,加快木薯实际的干燥速率、节约了大量的能源。

图7 木薯二段式干燥工艺流程图

3 结 论

在干燥箱内模拟木薯干燥设备,对不同温度、不同厚度的木薯片进行了干燥试验。试验研究发现,干燥温度过低则干燥时间延长,温度过高木薯则会变质、糊化;木薯片厚度太薄,则在干燥过程中易断裂;木薯片厚度太厚,达到安全含水率所需时间过长。用Wang and Singh模型对木薯干燥过程的水分比进行了拟合,吻合较好。利用干基含水率曲线确定了木薯干燥的临界含水率为105%。本文结果表明,干燥温度取80~100 ℃、厚度选6~8 mm为宜,采用先高温后低温的二段式木薯干燥方案。

[1] 董丹丹,赵黛青,廖翠萍,等. 木薯燃料乙醇生产技术提升机全生命周期能耗分析[J]. 农业工程学报,2008,24(7):160-164.

Dong Dandan, Zhao Daiqing, Liao Cuiping, et al. Energy consumption ananlysis in life cycle of cassava fuel ethanol production and the advantages of the new technology in energy consumption[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(7): 160-164. (in Chinese with English abstract)

[2] 蒋小静,吕飞杰,吕小文,等. 热处理对木薯全粉品质的影响[J]. 农业工程学报,2012,28(9):257-263.

Jiang Xiaojing, Lü Feijie, Lü Xiaowen, et al. Preparation and functional properties of whole cassava flour[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(9): 257-263. (in Chinese with English abstract)

[3] 柴沁虎,申威,张阿玲,等. 中国木薯产业的供给价格弹性[J]. 清华大学学报:自然科学版,2009,49(6):913-916.

Chai Qinhu, Shen Wei, Zhang Aling, et al. Chinese cassava industry price supply elasticity[J]. Journal of Tsinghua University(Science and Technology), 2009, 49(6): 913-916. (in Chinese with English abstract)

[4] 陈晓明,李开绵,台建祥,等. 超声波辅助提取木薯皮活性物质工艺[J]. 农业工程学报,2011,27(增刊1):389-396.

Chen Xiaoming, Li Kaimian, Tai Jianxiang, at al. Technology of ultrasonic-assisted extracting active substance from cassava peel[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(Supp.1): 389-396. (in Chinese with English abstract)

[5] 张芹,李广利,于迎辉,等. 我国木薯深加工现状及发展分析[J]. 粮食与饲料工业,2017,12(1):31-34.

Zhang Qin, Li Guangli, Yu Yinghui, et al. Present situation and development analysis of cassava deep processing in China[J]. Cereal & Feed Industry, 2017, 12(1): 31-34. (in Chinese with English abstract)

[6] Ye F, Li Y, Lin Q, et al. Modeling of China’s cassava-based bioethanol supply chain operation and coordination[J]. Energy, 2017, 120, 217-228.

[7] 梁海波,魏云霞,黄洁,等. 世界木薯生产对中国的启示[J]. 中国农学通报,2016,32(9):94-99.

Liang Haibo, Wei Yunxia, Huang Jie, et al. Enlightenment of world cassava production to China[J]. Chinese Agricultural Science Bulletin, 2016, 32(9): 94-99. (in Chinese with English abstract)

[8] 杨丽英, Sriroth K, Piyachomkwan K, 等. 泰国木薯淀粉特性研究[J]. 云南大学学报:自然科学版,2003,25(增刊):110-114.

Yang Liying, K Sriroth, K Piyachomkwan, et al. Thailand cassava starch phy-chemical properties analysis[J]. Journal of Yunnan University: Natural Sciences, 2003, 25(Supp.): 110-114. (in Chinese with English abstract)

[9] 田宜水,孙丽英,孟海波,等. 中国木薯燃料乙醇原料供需现状和预测[J]. 农业现代化研究,2011,32(3):340-343.

Tian Yishui, Sun Liying, Meng Haibo, et al. Status and forecast of cassava fuel feedstock demand and supply in China[J]. Research of Agricultural Modernization, 2011, 32(3): 340-343. (in Chinese with English abstract)

[10] 文玉萍. 我国木薯产业的发展趋势与市场分析[J]. 热带农业科学,2014,34(5):81-85.

Wen Yuping. Development trend of cassava industry and market analysis in China[J]. Chinese Journal of Tropical Agriculture, 2014, 34(5): 81-85. (in Chinese with English abstract)

[11] Njie D N, Rumsey T R. Influence of process conditions on the drying rate of cassava chips in a solar simulator[J]. Drying Technology, 1998, 16(1/2): 181-197.

[12] Anyanwu C N, Oparaku O U, Onyegegbu S O, et al. Experimental investigation of a photovoltaic-powered solar cassava dryer[J]. Drying Technology, 2012, 30(4): 398-403.

[13] Monroy-Rivera J A, Angulo O, Sanchez T, et al. Elimination of cyanogenic compounds of cassava curing solar drying[J]. Drying Technology, 1996, 14(10): 2371-2385.

[14] Njie D N, Rumsey T R. Experimental study of cassava sun drying[J]. Drying Technology, 1997, 15(3/4): 921-938.

[15] 李业波,于庆龙,赵丽华. 土豆干燥过程中内部传热传质的试验研究[J]. 农业工程学报,1996,12(4):62-65.

Li Yebo, Yu Qinglong, Zhao Lihua. Experiment and study on the heat and mass transfer in potato during drying[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 1996, 12(4): 62-65. (in Chinese with English abstract)

[16] 孟岳成,王君,房升,等. 熟化红薯热风干燥特性及数学模型适用性[J]. 农业工程学报,2011,27(7):387-392.

Meng Yuecheng, Wang Jun, Fang Sheng, et al. Drying characteristics and mathematical modeling of hot air drying of cooked sweet potatoes[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(2): 387-392. (in Chinese with English abstract)

[17] 龙铭,凌江华. 木薯淀粉干燥设备的设计[J].中国农机化,2003(5):43-44.

Long Ming, Ling Jianghua. The design of cassava starch dryness equipment[J]. Chinese Agricultural Mechanization, 2003(5): 43-44. (in Chinese with English abstract)

[18] 刘琨,康洪. 木薯酒糟机械脱水及干燥方法的研究[J]. 广西大学学报:自然科学版,1996,21(2):190-193.

Liu Kun, Kang Hong. Mechanical dewatering and drying methods of cassava alcohol distiller’s grains[J]. Journal of Guangxi University: Natural Science Edition, 1996, 21(2): 190-193. (in Chinese with English abstract)

[19] 刘琨,康洪. 木薯酒糟临界含水量与干燥曲线[J]. 化学工程,1999,27(3):21-23.

Liu Kun, Kang Hong. The critical water content and drying curves of a distiller’s grains[J]. Chemical Engineering, 1999, 27(3): 21-23. (in Chinese with English abstract)

[20] 刘琨. 木薯酒糟在旋转闪蒸干燥器中的干燥特性[J]. 化学工程,2003,31(3):17-19.

Liu Kun. Basic drying characteristics of the cassava lees in spin flash dryer[J]. Chemical Engineering, 2003, 31(3): 17-19. (in Chinese with English abstract)

[21] 刘琨. 木薯淀粉渣的干燥特性探讨[J]. 广西大学学报:自然科学版,2001,26(3):165-167.

Liu Kun. Research in drying characteristics of cassava starch dregs[J]. Journal of Guangxi University: Natural Science Edition, 2001, 26(3): 165-167. (in Chinese with English abstract)

[22] 张鹏,赵士杰,赵满全. 4种薯类作物热风干燥特性的比较[J]. 农机化研究,2016(9):239-243.

Zhang Peng, Zhao Shijie, Zhao Manquan. Comparative study of drying characteristics of hot air drying of four root and tuber crops[J]. Journal of Agricultural Mechanization Research, 2016(9): 239-243. (in Chinese with English abstract)

[23] 张鹏. 薯类作物热风干燥特性与动力学模型研究[D]. 呼和浩特:内蒙古农业大学,2016.

Zhang Peng. Hot Air Characteristics and Dynamic Model for Root and Tuber Crops[D]. Huhhot: Inner Mongolia Agricultural University, 2016. (in Chinese with English abstract)

[24] 李清海,甘超,蒙爱红,等. 干燥对乏垃圾热值影响的试验研究[J]. 清华大学学报:自然科学版,2011,51(12):1865-1868.

Li Qinghai, Gan Chao, Meng Aihong, et al. Expermental study on effect of drying on heating value of spent waste[J]. Journal of Tsinghua University: Science and Technology, 2011, 51(12): 1865-1868. (in Chinese with English abstract)

[25] 陈梅倩,蒙爱红,阮仔龙,等. 高水分垃圾基元中温干燥特性的试验研究[J]. 清华大学学报:自然科学版,2010,50(11):1838-1842.

Chen Meiqian, Meng Aihong, Ruan Zilong, et al. Experimental investigation of medium-temperature drying behavior of MSW matrix[J]. Journal of Tsinghua University: Science and Technology, 2010, 50(11): 1838-1842. (in Chinese with English abstract)

[26] 固体生物质燃料全水分的测定方法:GB/T 28733-2012[S]. 北京:中国标准出版社,2012.

[27] Wang C Y, Singh R P. A Single layer drying equation for rough rice[J]. In: ASAE Paper, 1978: 3001.

[28] Babalis S J, Papanicolaou E, Kyriakis N, et al. Evaluation of thin-layer drying models for describing drying kinetics of figs (Ficus carica)[J]. Journal of Food Engineering, 2005, 75(2): 205-214.

[29] Fatemeh N, Saman A M. An Investigation into the effect of drying conditions on kinetic drying of medicinal plant of echium amoenum[J]. International Medical Journal, 2017, 24(1): 87—91.

[30] 刘广文. 干燥设备设计手册[M]. 北京:机械工业出版社,2009.

Optimization experiment on two-stage drying process of high and low temperatures for cassavas

Yang Xiaoxiao, Cong Kunlin, Zhang Yanguo, Li Qinghai※

(,-/&,,,100084,)

Cassava is widely distributed in tropical and subtropical regions of the world. Cassava, potato and sweet potato are known as the world’s 3 major potatoes. Cassava is native to the Amazon basin, which are now widely grown in China and Southeast Asia. Cassava is mainly used in food, medicine, industry and other fields, and known as the king of starch. Cassava has to be dried in a period of short time prior to storage or transportation, since the water content of the fresh cassava is as much as 65%-70% at harvest. Up to now, many scholars have done a lot of research on cassava. However, there are few studies on the drying process, drying technology and drying equipment for cassava. In order to develop and optimize drying process of cassava, the effects of the thickness of cassava slices and the temperature of drying process were experimentally investigated. Fresh cassavas were obtained from Rongxian County, Guangxi Zhuang Autonomous Region. They were washed and dried before being stored in a fridge at 2-5 ℃. Cassavas were cut into 5-9 mm pieces, and then were placed in a drying oven with a preset temperature that could be adjusted from 60 to 100 ℃ with a 10 ℃ interval for different cases. The drying process by hot air was simulated with an electric drying oven with forced convective air flow. The samples were taken from the oven every 5 min during the experiment. The cassava slices taken from the drying oven were placed in a silica gel dryer. The cassava slices were cooled to room temperature and weighed with an electronic balance. The moisture of cassava was calculated according to the actual weight change. The effects of different temperatures and different thicknesses on the drying process of cassava were compared. The results showed that cassavas were denatured due to the high temperature, however, the low temperature made water evaporation incomplete. The slice with thinner thickness was prone to be broken up, and on the contrary, the thicker thickness prolonged the drying time to reach the targeted water content. The experimental results show that the drying temperature of 80-100 ℃ and the thickness of 6-8 mm are better. It was found that the cassava drying process was fitted well with the Wang and Singh model. Based on the water content curves on dry basis, the critical water contents of cassava with different thicknesses were obtained. The experimental results show that the one-stage scheme with constant temperature can only reduce the water content of cassava to about 35% when being dried for 70 min, and fails to reduce moisture content of cassava to safe moisture in the limited short time. In order to avoid the undesired sharp decrease in the drying rate as the water content reached the critical value during single-stage drying process, an optimal two-stage drying scheme of first low temperature and then high temperature was proposed. According to the two-stage drying scheme, the cassava drying process was also proposed. The equipment of the proposed drying process mainly includes the fan, the feeder, the first drying section, the second drying section, the heat exchanger, and so on. The cassava slices of 6-8 mm in thickness were fed into the first drying section by feeder. After the moisture content was reduced to a certain value, the cassavas were fed into the second drying section. Finally, the cassava slices eventually reached the safe moisture content. This cassava drying process provides a good solution for cassava drying and production.

drying; moisture; quality control; cassava

10.11975/j.issn.1002-6819.2018.02.037

S375

A

1002-6819(2018)-02-0272-06

2017-09-22

2017-12-29

国家重点研发计划资助(No. 2017YFB0603901)

杨潇潇,工程师,主要从事热能转换与利用方向的研究。Email:yangxiaoxiao2589@126.com。

李清海,副研究员,博士,博士生导师,主要从事热能转换与利用的研究。Email:liqh@tsinghua.edu.cn

杨潇潇,丛堃林,张衍国,李清海. 木薯高/低温二段式干燥工艺参数优化试验[J]. 农业工程学报,2018,34(2):272-277. doi:10.11975/j.issn.1002-6819.2018.02.037 http://www.tcsae.org

Yang Xiaoxiao, Cong Kunlin, Zhang Yanguo, Li Qinghai. Optimization experiment on two-stage drying process of high and low temperatures for cassavas[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(2): 272-277. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.02.037 http://www.tcsae.org