杀菌方式对即食胡萝卜片挥发性风味物质的影响

2016-12-19米瑞芳刘俊梅胡小松吴继红

米瑞芳,刘俊梅,胡小松,吴继红

(中国农业大学食品科学与营养工程学院,国家果蔬加工工程技术研究中心,农业部果蔬加工重点开放实验室,北京 100083)

杀菌方式对即食胡萝卜片挥发性风味物质的影响

米瑞芳,刘俊梅,胡小松,吴继红※

(中国农业大学食品科学与营养工程学院,国家果蔬加工工程技术研究中心,农业部果蔬加工重点开放实验室,北京 100083)

为研究不同杀菌方式对即食胡萝卜片挥发性风味物质的影响,运用固相微萃取和气相色谱-质谱联用技术,分别对新鲜胡萝卜片和经巴氏杀菌、超高压杀菌、热辅助超高压杀菌处理的即食胡萝卜片及其贮藏期间(4℃,60 d)的挥发性组分进行对比分析。试验结果表明:新鲜胡萝卜片的主要芳香成分为萜烯类物质。与未杀菌组相比,经不同杀菌处理后,即食胡萝卜片的萜烯类物质含量均有所降低,其中巴氏杀菌组降低的最多。在贮藏前期(20~30 d),超高压处理即食胡萝卜片的萜烯类物质的含量最高,超高压杀菌在短期内较好地保持了胡萝卜特有的香气,即食胡萝卜片品质较好;其次是热辅助压力杀菌组,热辅助压力杀菌组即食胡萝卜片的β-蒎烯、β-石竹烯的含量较其他处理组较高,较好地保持了胡萝卜的松树树脂香气以及辛香气味;而巴氏杀菌组即食胡萝卜片的萜烯类物质含量最低,即食胡萝卜片的品质相对较差。研究结果可为新型杀菌技术在即食产品领域的应用提供参考。

杀菌;贮藏;风味;即食胡萝卜片;超高压技术;热辅助压力杀菌技术;巴氏杀菌技术

0 引言

随着生活水平的提高,人们对食品质量的要求不再仅仅局限于安全卫生,对食品的色、香、味、营养成分等也提出了更高的要求。由于传统的热杀菌技术使食品失去了其原有的新鲜度和风味,营养价值明显降低,于是推动了新型杀菌技术—超高压杀菌(high hydrostatic pressure,HHP)的发展。经超高压处理的食品能较好地保持其原有的色泽、香气、维生素等营养成分,符合现代食品“营养、健康、安全”的发展理念[1]。超高压还可和热处理结合即热辅助超高压杀菌技术(pressure-assisted thermal sterilization,PATS),能够在较低的杀菌温度下,保证食品中的营养成分不被破坏的同时,杀灭食品中的耐压菌以及低酸食品中的单增李斯特菌、肉毒杆菌及其毒素,可以有效地增加对芽孢的杀灭效果[2-4],从而使食品达到商业无菌的状态。同时PATS杀菌技术不会产生由高温而导致的蒸煮味;从而使食品较好地保留其原有的风味。目前PATS已通过了美国国家食品安全与技术中心和美国DUST(Dual Use Science and Technology)联盟成员严格的验证程序和安全评估,其加工的食品已经在伊拉克和阿富汗等战场上应用[5]。国内对该技术的工业化应用尚处于空白。

胡萝卜因含有丰富的营养物质以及低廉的价格和特有的风味,而广受消费者青睐[6]。因此可通过开发即食胡萝卜片产品,来方便人们快节奏的生活,使人们从厨房中解放出来。近年来,对胡萝卜香气成分的研究已有报道。Kjeldsen F等[7]研究了胡萝卜在冻藏和冷藏期间的香气成分变化;陈瑞娟等[8]研究了干燥方式对胡萝卜超微粉中挥发性风味物质的影响;徐丽娜[9]研究了超高压处理对胡萝卜汁香气成分的影响。而关于热辅助压力杀菌对即食胡萝卜片风味物质的影响研究尚未见报道。

本研究以即食胡萝卜片为研究对象,基于固相微萃取-气质联用(solid-phase microextraction-gas chromatographymass spectrometry,SPME-GC-MS)技术[10],通过将PATS杀菌、HHP杀菌与传统热杀菌前后产品的挥发性风味成分的变化进行比较分析,以期为新型食品杀菌技术(PATS、HHP)在即食产品领域的应用提供理论依据。

1 材料与方法

1.1 材料与试剂

胡萝卜,选购于中国农业大学家属区菜市场,品种为红芯三号,外观整齐,脆甜可口,可作鲜食与加工用。

丙酮、乙醇(色谱纯)、(R)-(+)-柠檬烯(>99%)、C5-C20烷烃系列标准样品溶液,美国Sigma-Aldrich公司;NaCl(分析纯)、萜品油烯、萜品烯、β-蒎烯(>95%)、β-石竹烯(>90%),北京信易达金生物科技有限公司;氦气(>99.999%),北京千禧京城气体有限公司。

1.2 仪器与设备

HHP-650超高压设备,包头科发新型高技术食品机械有限责任公司;HH.S11-4恒温水浴锅,北京长安科学仪器厂;CAR/PDMS/DVB萃取头、HP-5MS毛细管色谱柱(30 m×0.25 mm×0.25 μm)、Agilent7890A-5975C气相色谱-质谱联用仪,美国安捷伦公司;EY-300A分析天平,日本松下电器公司。

1.3 方 法

1.3.1 预处理

胡萝卜的预处理参照徐丽娜[9]的研究,经挑选、清洗、去皮、50 mg/L的二氧化氯消毒5 min后,切成3~4 mm的薄片,利用L-抗坏血酸溶液(0.05%~0.10%)护色5 min,并用开水烫漂15 s,快速冷却、沥干、透明蒸煮袋分装后进行真空包装。

1.3.2 杀菌处理

真空包装即食胡萝卜片的杀菌处理参照Biniam T等[11]的研究,分别采用巴氏杀菌(90℃,30 min)、HHP杀菌(550 MPa,25℃,10 min)和PATS杀菌(500 MPa,50℃,10 min)处理后,于4℃冷库中贮藏60 d,其中未杀菌处理的即食胡萝卜片作为对照组,定期进行风味分析。

1.3.3 SPME条件

即食胡萝卜片挥发性成分的提取参照Vervoort L等[12]的报道,并略作修改。按照货架期试验设计,将即食胡萝卜片从冷库取出,打浆至泥状。精确称取8.5 g胡萝卜泥放入顶空瓶中,加入15 mL饱和NaCl溶液,置于40℃恒温水浴锅中预热平衡20 min。将经老化的SPME萃取针插入顶空瓶,于40℃萃取20 min后,手动进样至GC-MS中,250℃解析5 min。

1.3.4 GC-MS分析

色谱条件:色谱柱为HP-5毛细管柱(30 m×250 μm× 0.25 μm);进样口温度250℃;升温程序:参照Vervoort L等[12]的报道,并略作修改。起始温度40℃,保持1 min,以4℃/min升至172℃,再以30℃/min升至260℃,保持5 min;载气为高纯氦气,流速1.0 mL/min;不分流进样。

质谱条件:电子轰击(electron impact,EI)离子源,电子能量为70 eV;离子源温度230℃;四级杆温度150℃;质量扫描范围:35~400 amu,采用全扫描模式采集信号。

1.3.5 即食胡萝卜片挥发性成分定性定量分析

数据分析采用NIST 08.L标准谱库检索,利用系列正构烷烃测定各组分RI值,结合保留指数及相关文献进行定性分析[13]。采用面积归一化法和外标法进行定量分析[14]。定量数据采用Origin8.1Pro进行统计分析并制图。

2 结果与分析

2.1 不同杀菌方式对即食胡萝卜片中挥发性成分的分析

利用HS-SPME-GC-MS对3种杀菌方式处理的即食胡萝卜片和未杀菌即食胡萝卜片(对照组)在贮藏期主要挥发性组分的定性与面积归一化分析结果如表1所示。由表1可以看出,未杀菌即食胡萝卜的挥发性成分有萜烯化合物、酯类、醛类、醇类、酮类等,主要以萜烯类化合物为主,占胡萝卜总挥发性成分的40%以上。检测出萜烯类物质主要有(1R)-(+)-α蒎烯(松树树脂香气)、β-蒎烯(松树树脂香气)、莰烯、月桂烯(清淡的香脂气味)、右旋萜二烯、萜品烯(柑橘和柠檬香气)、萜品油烯、β-石竹烯(木香、柑橘香以及温和的丁香气味)等[15],其中β-石竹烯所占的比例较大,这与Kjeldsen F[7]、陈瑞娟[8]和Alasalvar C[16]的研究结果一致。醛类物质主要有β-环柠檬醛(似紫罗兰酮的香气),还有少量的正庚醛、正辛醛。酮类物质主要有甲基庚烯酮(新鲜的青香和柑橘样气息);醇类物质较少;另外还检测到少量的芳香烃类。上述这些挥发性成分所呈现出的香气共同构成了即食胡萝卜片特有的香味。

图1 贮藏期不同杀菌处理即食胡萝卜片萜烯类和醛类物质的百分含量变化Fig.1 Changes in contents of terpenes and aldehydes in prepared carrot slices carrots during refrigerated storage

不同杀菌处理的即食胡萝卜片在贮藏期间挥发性成分的种类和百分含量均不同。结合表1和图1可知,未杀菌、HHP、PATS、巴氏杀菌处理的即食胡萝卜片在贮藏初期,萜烯类物质质量分数分别为40.97%、35.32%、40.96%和32.15%。随着贮藏时间的延长,各处理组的萜烯类化合物的含量整体均呈下降趋势。而Kjeldsen F等[7]研究发现胡萝卜在冷藏期间萜烯类化合物的含量是增加的,与本研究结果不一致,可能是因为研究所用胡萝卜的预处理不同导致。

未杀菌、HHP、PATS、巴氏杀菌的即食胡萝卜片在贮藏初期,醛类物质百分含量分别是1.65%、1.49%、4.79% 和9.85%。与未杀菌组相比,经巴氏杀菌处理后即食胡萝卜片的醛类含量增加最多,其次为PATS处理组,这是因为热杀菌能够促进不饱和脂肪酸氧化生成醛类物质[17]。随着贮藏时间的延长,各处理组醛类物质呈增加趋势,醛类物质的增加主要是由于脂肪的氧化降解[11],且HHP 和PATS处理组醛类物质高于巴氏杀菌组,可能是由于高压处理对样品的溶氧量有影响,但还需做进一步的研究[17]。

图2 贮藏期不同杀菌处理即食胡萝卜片酯类和醇类物质的百分含量变化Fig.2 Changes in contents of esters and alkohols in prepared carrot slices carrots during refrigerated storage

结合表1和图2可知,在贮藏期不同处理组间酯类物质的含量较低且保持相对稳定,主要有左旋乙酸冰片酯。到贮藏后期,PATS和巴氏杀菌组检测到少量的乙酸橙花酯和辛酸乙酯。在贮藏期各处理组检测到的醇类主要是4-萜烯醇,各处理组的醇类物质含量整体呈增加趋势,且HHP和PATS处理组高于巴氏杀菌组,可能是由于高压能够促进萜烯类物质氧化生成萜烯醇,进而导致高压处理组的醇类物质高于巴氏杀菌组[17]。

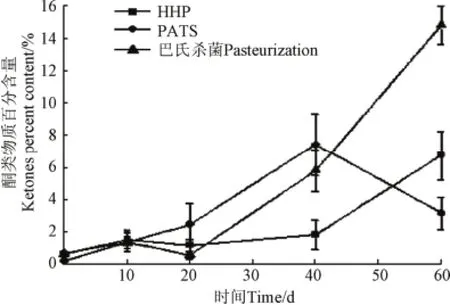

图3 贮藏期不同杀菌处理即食胡萝卜片酮类物质的百分含量变化Fig.3 Changes in contents of ketones in prepared carrot slices carrots during refrigerated storage

结合表1和图3可知,α-紫罗兰酮(紫罗兰型香气、花香味)和β-紫罗兰酮(柏木香气)是β-胡萝卜素的降解产物,在未杀菌的即食胡萝卜片中未检测到,而经3种杀菌处理的即食胡萝卜片在贮藏20 d后才开始陆续检测到这2种物质,且随着贮藏时间的延长不同处理组的酮类物质含量总体呈增加趋势,其中巴氏杀菌组的增幅最大,说明巴氏杀菌组的β-胡萝卜素损失最多,这也体现了超高压杀菌能够较好地保持产品的营养成分,这与Kim Y S[18]研究结果一致。烷烃类对胡萝卜的香气贡献不大,其含量相对比较稳定。

2.2 即食胡萝卜片中几种特征性萜烯类香气组分的定量分析

选取胡萝卜中几种比较典型的且含量较高的特征萜烯类香气化合物:β-蒎烯、月桂烯、右旋萜二烯(柠檬烯)、萜品烯(γ-松油烯)、萜品油烯(异松油烯)、β-石竹烯[19-20],利用标准曲线法进行定量分析。由图4可知,经3种杀菌处理的即食胡萝卜片萜品烯含量随着贮藏时间的延长总体呈下降趋势,但HHP处理组含量相对较高,可能是由于PATS和巴氏杀菌较高的温度促进了萜品烯的氧化反应。在贮藏初期,经HHP和PATS杀菌后即食胡萝卜片的β-石竹烯含量降低,巴氏杀菌未发生变化,可能是由于HHP和PATS处理组的压力促使酶和底物的接触,从而诱导酶促反应发生[11],但还需做进一步的研究。而在贮藏期开始后只有PATS组的含量呈先增加后降低的趋势,在第10天增到164.37 ng/g,直到60d才降低。可能是PATS由于结合了高压和温度而促使其他萜类物质转化生成β-石竹烯,但随着贮藏时间的延长,β-石竹烯又会发生氧化反应而导致其含量下降[17],仍需做进一步的研究。说明在贮藏前期PATS杀菌能够较好的保持甚至增强胡萝卜的丁香气味。

图4 贮藏期不同杀菌处理即食胡萝卜片萜品烯和β-石竹烯的含量变化Fig.4 Changes in contents of terpinene and β-caryophyllene in prepared carrot slices carrots during refrigerated storage

由图5可知,经HHP杀菌后的即食胡萝卜片中右旋萜二烯含量呈先下降又上升后下降的趋势,而PATS处理组在贮藏前期呈上升趋势,并在第30天时达到高峰后又呈下降趋势;巴氏杀菌组在第20天时下降到最低点,且均低于HHP和PATS组。即食胡萝卜片经HHP杀菌后萜品油烯质量分数显著上升达到108.76 ng/g,比对照组高21 ng/g,PATS和巴氏杀菌组萜品油烯的含量降低,且在贮藏前30 d,HHP处理组的萜品油烯含量始终高于PATS和巴氏杀菌组。可能是由于巴氏杀菌和PATS的高温均促进了萜品油烯的氧化反应[17],因此HHP杀菌较好地保持了即食胡萝卜片萜品油烯的含量,从而保持胡萝卜的松木清香味。

由图6可知,经HHP杀菌的即食胡萝卜片β-蒎烯的含量在贮藏期前10 d均高于未杀菌组;PATS处理组β-蒎烯的含量在整个贮藏期间保持较高水平;巴氏杀菌组的含量呈现先上升后下降又上升的趋势。HHP和PATS处理组的月桂烯含量随贮藏时间的延长呈现先上升后下降的趋势,且在贮藏10 d后HHP处理组的月桂烯含量总体高于PATS组,巴氏杀菌处理组总体呈下降趋势。说明超高压处理的β-蒎烯和月桂烯的氧化反应较热杀菌弱,在一定程度上较好地保留了胡萝卜原有的风味。这一研究可为新型杀菌技术在即食产品领域的应用提供一定的参考。

图5 贮藏期不同杀菌处理即食胡萝卜片右旋萜二烯和萜品油烯的含量变化Fig.5 Changes in contents of D-limonene and terpinolene in prepared carrot slices carrots during refrigerated storage

图6 贮藏期不同杀菌处理即食胡萝卜片β-蒎烯和月桂烯的含量变化Fig.6 Changes in contents of β-pinene and myrene in prepared carrot slices carrots during refrigerated storage

与对照组相比,经HHP杀菌处理后即食胡萝卜片的右旋萜二烯、萜品烯、萜品油烯含量均增加,β-蒎烯的含量变化较小,月桂烯和β-石竹烯的含量有所下降;而PATS处理组除β-蒎烯的含量上升,其他组分均降低,且PATS组降低最多,巴氏杀菌组β-蒎烯和月桂烯的含量上升,其余组分也呈下降趋势。可能是因为试验所用胡萝卜经切分后氧化反应已开始,再加上热杀菌促进了这些物质的氧化反应[21],PATS又结合超高压使这一反应更加剧烈,但关于这些物质发生氧化反应的机理还需做进一步的研究,而HHP杀菌则较热杀菌和PATS杀菌在一定程度上较好地保留了胡萝卜原有的风味,而对即食胡萝卜片整体品质的评价还需进一步结合感官试验以及电子舌或电子鼻等仪器检测试验[22]。

3 结论

1)未杀菌、超高压杀菌、热辅助超高压杀菌、巴氏杀菌处理即食胡萝卜片中分别鉴定出25、24、23和26种组分,包括萜烯类、酯类、醛类、醇类、酮类等,其中萜烯类化合物的种类最多。主要有(1R)-(+)-α蒎烯、莰烯、β-蒎烯、月桂烯、右旋萜二烯、萜品烯、萜品油烯、β-石竹烯等香气物质,构成了即食胡萝卜片青鲜的特殊香气。

2)定量分析结果显示,在60d贮藏期间,各处理组的香气成分均有变化,共鉴定出41种挥发性成分,萜烯类物质最多,共18种。在贮藏初期,与未杀菌组相比,经不同杀菌处理后即食胡萝卜片的萜烯类物质含量均有所降低,其中巴氏杀菌组降低的最多。在贮藏前期(20~30 d),超高压杀菌处理组的即食胡萝卜片的萜烯类物质的含量较高,其中萜品烯、萜品油烯含量最高,较好地保持了胡萝卜片清淡的香脂气味以及松木芳香味,即食胡萝卜片的风味品质较好;热辅助超高压杀菌技术处理组的含量次之,热辅助超高压杀菌技术处理组β-蒎烯、β-石竹烯的含量较其他处理组较高,较好地保持了胡萝卜的松树树脂香气以及辛香气味;而巴氏杀菌组即食胡萝卜片的萜烯类物质含量最低,即食胡萝卜片的品质较差。

[1] Jung L S, Lee S H, Kim S, et al. Effect of High Pressure Processing on Microbiological and Physical Qualities of Carrot and Spinach[J]. Food Sci. Biotechnol, 2012, 21(3): 899-904.

[2] Yi Gong, Yu Jianyong, Ping Qian, et al. Comparative Study of the Microbial Stability and Quality of Carrot Juice Treated by High-pressure Processing Combined with Mild Ttemperature and Conventional Heat Treatment[J]. Journal of Food Process Engineering, 2015, 38(4): 395-404.

[3] Hosahalli S. Ramaswamy, Shao Yanwen. High Pressure Destruction Kinetics of Clostridium Sporogenes Spores in Salmon Slurry at Elevated Temperature[J]. International Journal of Food Properties, 2010, 13: 1074-1091.

[4] 王标诗,李汴生,曾庆孝,等. 热压协同处理对接种于鸡腿菇中的细菌芽孢灭活效果的影响[J]. 高压物理学报,2010,24(2):136-142. Wang Biaoshi, Li Biansheng, Zeng Qingxiao, et al. Inactivation effects of coprinus comatus inoculated with bacterial spores by high-pressure thermal processing[J]. Chinese Journal of High Pressure Physics, 2010, 24(2): 136-142. (in Chinese with English abstract)

[5] 章中,胡小松,廖小军,等. 温压结合超高压处理对芽孢杀灭作用的研究进展[J]. 高压物理学报,2013,27(1):147-152. Zhang Zhong, Hu Xiongsong, Liao Xiaojun, et al. Review on sterilization effects of high pressure thermal sterilization on bacterial spores[J]. Chinese Journal of High Pressure Physics, 2013, 27(1): 147-152. (in Chinese with English abstract)

[6] 宫元娟,曾日新,田素博,等. 胡萝卜精细加工技术及其综合应用[J]. 农业工程学报,2006,22(4):199-203. Gong Yuanjuan, Zeng Rixin, Tian Subo, et al. Review of refining processing and comprehensive utilization of carrot[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2006, 22(4): 199-203. (in Chinese with English abstract)

[7] Kjeldsen Frank, Christensen Lars P, Edelenbos M. Changes in volatile compounds of carrots (Daucus carota L.) during refrigerated and frozen storage[J]. Journal of Agricultural and Food Chemistry, 2003, 51(18): 5400-5407.

[8] 陈瑞娟,毕金峰,陈芹芹,等. 不同干燥方式对胡萝卜粉香气成分的影响[J]. 食品与发酵工业,2013,39(9):70-76. Chen Ruijuan, Bi Jinfeng, Chen Qinqin, et al. Effect on aroma components in carrot powder prepared by different drying methods[J]. Food and Fermentation Industries, 2013, 39(9): 70-76. (in Chinese with English abstract)

[9] 徐丽娜. 超高压处理对胡萝卜汁中类胡萝卜素及香气成分的影响[D]. 镇江:江苏大学,2009.

[10] 孙婕,张华,尹国友,等. 固相微萃取技术在食品分析领域中的应用[J]. 东北农业大学学报,2011,42(8):154-158. Sun Jie, Zhang Hua, Yin Guoyou, et al. Application of solid-phase microextraction in food sample analysis[J]. Journal of Northeast Agricultural University, 2011, 42(8): 154-158. (in Chinese with English abstract)

[11] Biniam T Kebede, Tara Grauwet, Stijn Palmers, et al. Investigating chemical changes during shelf-life of thermal and high-pressure high-temperature sterilised carrot purees: A ‘fingerprinting kinetics’ approach[J]. Food Chemistry, 2015, 185: 119-126.

[12] Liesbeth Vervoort, Tara Grauwet, Daniel M Njoroge, et al. Comparing thermal and high pressure processing of carrots at different processing intensities by headspace fingerprinting[J]. Innovative Food Science and Emerging Technologies, 2013, 18: 31-42.

[13] 张逸君,郑福平,张玉玉,等. MAE-SAFE-GC-MS法分析道口烧鸡挥发性成分[J]. 食品科学,2014,35(22):130-134. Zhang Yijun, Zheng Fuping, Zhang Yuyu, et al. Analysis of Volatile Components in Daokou Roasted Chicken by MAE-SAFE-GC-MS[J]. Food Science, 2014, 35(22): 130-134. (in Chinese with English abstract)

[14] Kjeldsen Frank, Christensen, Lars P Edelenbos M. Quantitative analysis of aroma compounds in carrot (Daucus carota L.) cultivars by capillary gas chromatography using large-volume injection technique[J]. Journal of Agricultural and Food Chemistry, 2001, 49: 4342-4348.

[15] 李瑜. 新鲜胡萝卜和胡萝卜混汁挥发性风味物质的研究[J].江苏农业科学,2009(5):253-255.

[16] Cesarettin Alasalvar, John M Grigor, Donglin Zhang, et al. Comparison of volatiles, phenolics, sugars, antioxidant vitamins, and sensory quality of different colored carrot varieties[J]. Journal of Agricultural and Food Chemistry, 2001, 49(3): 1410-1416.

[17] Biniam T Kebede, Tara Grauwet, Stijn Palmers, et al. Effect of high pressure high temperature processing on the volatile fraction of differently coloured carrots[J]. Food chemistry, 2014, 153: 340-352.

[18] Kim Y S, Park S J, Cho Y H, et al. Effect of combined treatment of high hydrostatie Pressure and mild heat on the quality of carrot juice[J]. Joumal of Food Science, 2001, 66(9): 1355-1360.

[19] Tara Grauwet, Biniam T Kebede, Rosa M Delgado, et al. Evaluating the potential of high pressure high temperature and thermal processing on volatile compounds, nutritional and structural properties of orange and yellow carrots[J]. European Food Research and Technology, 2015, 24(1): 183-198.

[20] Soria Ana C, Sanz J, Villamiel M. Analysis of volatiles in dehydrated carrot samples by solid-phase microextraction followed by GC-MS[J]. Journal of separation science, 2008, 31(20): 3548-3555.

[21] Vervoort L, Grauwet T, Njoroge D M, et al. Comparing thermal and high pressure processing of carrots at different processing intensities by headspace fingerprinting[J]. Innovative Food Science & Emerging Technologies, 2013, 18: 31-42.

[22] 王俊,胡桂仙,于勇,等. 电子鼻与电子舌在食品检测中的应用研究进展[J]. 农业工程学报,2004,20(2):292-295. Wang Jun, Hu Guixian, Yu Yong, et al. Research and application of electronic nose and electronic tongue in food inspection[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2004, 20(2): 292-295. (in Chinese with English abstract)

Effect of sterilization methods on volatile flavor compounds of instant carrot slices

Mi Ruifang, Liu Junmei, Hu Xiaosong, Wu Jihong※

(College of Food Science & Nutritional Engineering, China Agricultural University, National Engineering & Technology Research Centre for Fruits & Vegetable Processing, Key Laboratory of Fruits and Vegetables Processing, Ministry of Agriculture, Beijing 100083, China)

The purpose of this paper was to study the effect of 3 different sterilization methods on the flavor of prepared carrot slices from raw materials during cold storage at 4℃ . The samples were pretreated by pasteurization (90℃ , 30 min), high hydrostatic pressure sterilization (550 MPa, 25℃ , 10 min), pressure-assisted thermal sterilization (550 MPa, 50℃ , 10 min) and stored at 4℃ for 60 d. The solide-phase micro-extraction (SPME)/chromatography-mass spectrometry (GC-MS) technology was used to detect and analyze the volatile flavor compounds in fresh carrot and sterilized carrot slices during storage. Results showed that carrots had a complex volatile characteristic. Fresh carrot sample’s volatiles mainly consisted of terpenes, esters, aldehydes, alcohols, ketones and alkanes. Among these, terpenes were considered to be the most important volatile compounds, such as α-terpinene, terpinolene, β-caryophyllene, β-pinene and D-limonene, which impart the characteristic aroma of fresh carrots. First, a comparison was made between the untreated carrots, pasteurizated carrots, high hydrostatic pressure treated carrots and pressure-assisted thermal treated carrots. In the second step, the volatile compounds of different processing were compared in shelf life of 60 d. The volatile compounds were various in carrot slices during storage, which were treated by different sterilization processing. Firstly, the amount of terpene compounds in each treatment group was declined during the whole storage, and terpenes’ oxidation reactions possibly could be the source of this observation. The level of aldehydes was the highest in pasteurizated carrot slices, but the lowest in high hydrostatic pressure sterilizated carrot slices. Furthermore the content of hexanal, pungent and rancid flavor, was increased significantly during the whole storage. The aldehydes were mainly related to unsaturated fatty acid oxidation. Hence, this suggested that pasteurization might result in a decline in the quality of carrot slices, compared to other treatments. The β-carotene degradation products, α-ionone (violet’s flower aromas) and β-ionone (Cedar’s wood aromas), were detected in sterizated carrot slices 20 d after storage. The level of ionone in high hydrostatic pressure sterilizated carrots was lower than other treatments, which indicated that high hydrostatic pressure sterilization could keep a higher level of β-carotene as well. In other words, the high hydrostatic pressure sterization could keep the quality of carrot slices better. In addition, the levels of esters and alkanes had less change during the storage. The main alcohol was 4-terpineol, the oxidation product of terpinolene. The content of terpenoids decreased after sterilization treatment. And it was higher in high hydrostatic pressure and pressure-assisted thermal sterilizated carrots compared to pasteurizated carrots in 30 d, which might be due to the thermal processing inducing terpinene oxidation. However, the content of β-caryophyllene decreased obviously in high hydrostatic pressure and pressure-assisted thermal sterilizated carrot slices. Pressure could induce membrane damage and bring enzymes and substrates into contact, which would not or less occur during thermal processing. And high hydrostatic pressure sterilizated carrot slices had a higher level of myrcene and terpinolene at earlier storage compared with others, which resulted in a better light balsam smell and pine fragrance kept. Pressure-assisted thermal sterilizated carrot slices had a higher content of β-pinene and β-caryophyllene, and there was better pine resin and spicy aroma. The quality of high hydrostatic pressure sterilizated and pressure-assisted thermal sterilizated carrot slices was superior to pasteurizated carrot slices. The results can provide a reference for the applications of new sterilization technologies in ready-to-eat products.

sterilization; storage; flavors; prepared carrot slices; high hydrostatic pressure sterilization; pressure-assisted thermal sterilization; pasteurization

10.11975/j.issn.1002-6819.2016.09.037

TS255.36

A

1002-6819(2016)-09-0264-07

米瑞芳,刘俊梅,胡小松,吴继红. 杀菌方式对即食胡萝卜片挥发性风味物质的影响[J]. 农业工程学报,2016,32(9):264-270.

10.11975/j.issn.1002-6819.2016.09.037 http://www.tcsae.org

Mi Ruifang, Liu Junmei, Hu Xiaosong, Wu Jihong. Effect of sterilization methods on volatile flavor compounds of instant carrot slices[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(9): 264-270. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2016.09.037 http://www.tcsae.org

2015-08-24

2016-03-15

北京市科技计划课题(Z131100003113001);国家支撑计划课题(2014BAD04B04)

米瑞芳,女,陕西人,主要从事果蔬食品风味化学方面研究。北京 中国农业大学食品科学与营养工程学院,国家果蔬加工工程技术研究中心,农业部果蔬加工重点开放实验室,100083。Email:ruifangmi216@163.com

※通信作者:吴继红,女,教授,博士生导师,2011年赴美国伊利诺伊大学访问研究,主要从事果蔬食品风味化学方面研究。北京 中国农业大学食品科学与营养工程学院,国家果蔬加工工程技术研究中心,农业部果蔬加工重点开放实验室,100083。Email:wjhcau@hotmail.com