龙鳞展厅,坦佩雷,芬兰/香港,中国

2012-07-27建筑设计坦佩雷理工大学EDGE建筑与城市研究实验室建筑与设计探索实验室有限公司

建筑设计:坦佩雷理工大学EDGE建筑与城市研究实验室,建筑与设计探索实验室有限公司

ARCHITECTS: Edge Laboratory for Architectural and Urban Research (Tampere University of Technology) , Laboratory for Explorative Architecture & Design Ltd.

1 坦佩雷理工大学内的龙鳞/Dragon Skin-pavilion at Tampere University of Technology(摄影/Photo: Emmi Keskisarja)

“龙鳞”展厅是一个建筑艺术装置,挑战并发掘了空间、触觉,以及当前数字建造技术革命带来的材料可能性。

龙鳞展厅在材料设计和数字制造工作坊中完成的,该工作坊由坦佩雷理工大学、建筑与设计探索实验室有限公司(LEAD)合作举办。在2011年“坦佩雷建筑周”期间,来自坦佩雷理工大学、奥卢大学和阿尔托大学的学生们共同设计和建造了“龙鳞”——这个临时性的装置展厅。工作坊活动的的目标是在10天内创作出一个基于后成型Grada胶合板(UPM-Kymmene公司提供)的构造物。

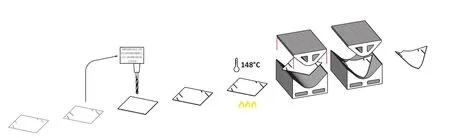

这个项目的建造受到了制造方法、材料特性和展厅的临时性等方面的限制。展厅由自相似、批量生产的组件构成,这些构件经过工业炉的加热在单独模具中弯曲成型。而作为连接系统,设计小组选择了简单的滑动关节,以沟槽的方式连接各部分组件,以此确保拆装便利,也无需使用胶水和螺丝。

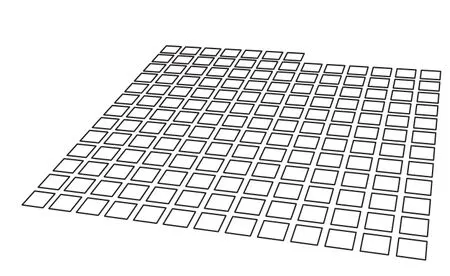

我们建立了一个计算机模型,用于计算并从整体中抽取形体,以此模型为依据,为各部分绘制建造图纸,并优化材料用量以及建造组装的时间。双曲线的展厅由163块经过弯曲的矩形薄板制成,它们具有相似的尺寸和曲率。通过3D模型,我们根据槽接的位置和角度确定了板面的微妙差异。曲率依靠材料性质加以优化,而槽口则只放在最终壳体的平直位置上。

2012年2月15 日至4月23日,龙鳞展厅的第二个原型在2012深圳·香港城市建筑双城双年展上展出。我们从平滑表面到减少几何形变和内表面张力等方面入手,重新设计了这第二个龙鳞。减小后的板片尺寸增加了整体强度,也减少了材料浪费(8×4的木板正好可以制作8块板片)。胶合板壳体在芬兰制作压弯,而后运抵香港最终组装成型。□(叶扬 译)

2 细部/Detail(摄影/Photo: Emmi Keskisarja)

3 细部/Details(摄影/Photos: Erkka Peltonen)

4 细部/Details(摄影/Photos: Erkka Peltonen)

5 细部/Details(摄影/Photos: Erkka Peltonen)

6 细部/Details(摄影/Photos: Erkka Peltonen)

7 曲线网格/Grid to curve

8 曲线网格/Grid to curve

The Dragon Skin Pavilion is an architectural art installation that challenges and explores the spatial,tactile and material possibilities architecture is offered today by revolutions in digital fabrication and manufacturing technology.

The Dragon Skin pavilion was developed during the Material Design and Digital Fabrication workshop, organized by Tampere University of Technology in collaboration with LEAD (Laboratory for Explorative Architecture & Design Ltd.). It was built and designed by students from Tampere University of Technology, University of Oulu and Aalto University as a temporary installation for the Tampere Architectural Week 2011. The goal of the intense workshop was to create in ten days a component based structure from a new material:post-formable Grada plywood (UPM-Kymmene).

The project was built up with the constraints of the fabrication methods, material specifications and temporary nature of the pavilion in mind. It was built out of self-similar, mass-produced wooden components, bent onto one single mold after heating in an industrial oven. As a connection system the design team opted for an easy sliding joint slotconnection between the components which allowed for easy assembly and dismantling as no glues nor screws were needed. A computer model was used to evaluate and extract from a global shape the fabrication drawings for all components optimizing material use, manufacturing and assembly time.The double curved shape is made from 163 bent rectangular panels with similar size and bending radius. The variation follows from slightly differing slot locations and angles, meticulously generated by a 3d master-model. The bending radius is optimized to the material's properties and slots are only placed in the flat parts of the final shells.

A second prototype of the Dragon Skin pavilion is currently exhibited at the prestigious 2012 Shenzhen & Hong Kong Bi-City Biennale of Urbanism Architecture from 15 February to 23 April 2012. This second versioned was fully redesigned starting from an equilibrium surface to reduce geometry deformations and internal surface forces.The sizes of the pieces were reduced to increase strength and reduce material waste (an 8×4 sheet produced exactly 8 squares). The plywood shells were manufactured and bent in Finland and shipped to Hong Kong for assembly.□

设计团队/Design Team: Emmi Keskisarja (EDGE),Pekka Tynkkynen (EDGE), Kristof Crolla (LEAD),Sebastien Delagrange (LEAD) with Gilles Retsin, Toni Österlund, Kimmo Ylä-Anttila, Anssi Joutsiniemi

材料工程师/Material Engineers: Juhana Liimatainen and Antti Lankinen

建筑系学生/Students of Architecture: Frank Ho,Anes Jacupovic, Ilkka Lindberg, Milla Vuorinen,Olli Hongisto, Ilkka Ala-Fossi, Maria Laisi, Hannu Saunaluoma, Jyri Tartia, Jonathan Hilden, Aleksi Rastas, Joonas Ala-Karvia, Ville Leivo, Thomas Miyauchi, Tomi Itäniemi, Lilli Mustila, Erkka Peltonen, Markus Heinonen, Saana Koivusalo, Antti Keskinen, Katja Virta, Olli Metso, Anna Hakula, Aija Rimpeläinen

主任/Dean: Stattan Lodenius

赞助商/Sponsors: UPM Kymmene, Tampereen Arkkitehtuuriviikko, Pipu Oy

9 在Grasshopper里创建数字模型/The digital model was created in Grasshopper

10 学生在Pipu公司使用数控切割机/The students got to explore the CNC-cutters at Pipu Oy

11 学生在Pipu公司使用数控切割机/The students got to explore the CNC-cutters at Pipu Oy

12 生产线制作弯曲组件需要工业炉、模具和细致的建筑学学生/The production line needed for the bending of the components consisted of an industrial oven, a mold and meticulous architecture students

14 建造序列/Building sequence

16 面板制作流线/Panel production line

15 连接系统/Connection system

13 模具安装在冲床上,通风口的排扇可以让它冷却/The mold wasused by a lifter. A ventilator was installed in the mold to cool it down(9-13 摄影/Photos: Jyri Tartia, Markus Heinonen, Joonas Ala-Karvia)

18 龙鳞在在2011深圳·香港城市建筑双年展/Dragon Skin-pavilion at the SZHK Architecture biennale in Hong Kong(摄影/Photo: Kevin Ng)

19 龙鳞在在2011深圳·香港城市建筑双年展/Dragon Skin-pavilion at the SZHK Architecture biennale in Hong Kong(摄影/Photo: Pekka Tynkkynen)