Dynamic Succession of Microbial Communities in Soybean Paste Made with Broomcorn Millet as an Additive and Its Correlation with Flavor and Nutritional Properties during the Brewing Process

2024-01-03MALixueYUQiaoruWUMengnaWANGXiaoyuSUTingtingYANGXiyuanLIUYuhangYAODiWANGChangyuan

MA Lixue,YU Qiaoru,WU Mengna,WANG Xiaoyu,SU Tingting,YANG Xiyuan,LIU Yuhang,YAO Di,WANG Changyuan

(College of Food,Heilongjiang Bayi Agricultural University,Daqing 163319,China)

Abstract: To obtain a full understanding the quality and microbial characteristics of soybean paste made from a mixture of soybean and broomcorn millet flour,its physicochemical properties (amino nitrogen and nitrite),and total phenols (TP),γ-aminobutyric acid (GABA),free amino acids (FAAs),volatile compounds,and microbial community composition were investigated.The results showed that the amino nitrogen content increased to 0.71%,and the nitrite content decreased to within the standard range (1.37 mg/kg).The contents of TP,key FAAs and volatile compounds increased significantly during the fermentation process.The core microbial communities included Enterobacter,Pseudomonas,Stenotrophomonas,Aspergillus,and Alternaria.The results of correlation analysis confirmed that bacteria (Bacillus,Knoellia,and Blastococcus)and fungi (Epicoccum and Saccharomyces) played a significant role in the bioactivity changes and flavor generation in soybean paste.This study will be of great significance for understanding the quality and flavor of novel soybean paste made with cereal flour as an additive.

Keywords: fermentation;soybean paste;broomcorn millet;microbial diversity;flavor composition;quality characteristics

Fermented food plays a beneficial role in improving food nutrition,increasing food preservation time and enhancing food safety through the action of microorganisms,therefore,it has attracted people’s attention[1].Soybeans contain high quality plant protein,rich in calcium,phosphorus,iron and other nutrients,so among fermented foods,fermented soybeans food is very common.As a functional food with potential anti-inflammatory and anti-obesity benefits,soybean paste is very popular in China,Japan,Thailand and other Asian countries due to its simple raw materials and convenient manufacturing process[2].The fermentation methods of soybean paste can be divided into natural fermentation and inoculation fermentation.Aspergillus oryzae,as a high-yield protease strain,it is often used as the starter culture for inoculation and fermentation.Hence usingA.oryzaeto ferment soybean paste not only shortens the production cycle,but also increases the stability of the product.The traditional soybean paste is made by natural fermentation of soybean and wheat flour as the main raw materials[3].However,there are many problems,such as the production environment is complex,the fermentation cycle is long,the raw material is single,and the nutrient content is only from soybeans,which leads to the immobilization and simplification of soybean paste in flavor and composition.Therefore,it is worth trying to change the nutritional quality and flavor taste of traditional soybean paste by making new grain flour instead of wheat flour.

There are many physiologically active substances in cereals,such as polysaccharide,γ-aminobutyric acid (GABA)et al.As raw materials,cereals have some defects such as the lack of certain amino acids,the existence of anti-nutrient compounds et al,but fermented cereals are superior to natural cereals in nutrition.It was found that microbial fermentation could accumulate GABA in grains,and the content of GABA in fermented broomcorn millet was higher than that in fermented wheat[4].Broomcorn millet,commonly known as rhubarb rice,is a small seed grain with a long history.It is widely cultivated in northern China and often used as a staple food on the table.It has great potential as a functional food[5].Broomcorn millet is rich in nutrients and protein,it has high biological activity value,rich in carbohydrates,fats,and has a higher diet fiber,but also contains a variety of vitamins and trace elements,the total amount of amino acids is higher than that of rice,wheat and corn.It’s importance as a nutritious grain has been emphasized.While in China,it is mainly consumed by raw grain and primary processed products with low added value[6].According to research,it contains a large number of phenolic substances,it have attracted the attention of researchers for their various potential health benefits,these phenolic substances are closely related to anti-tumor and anti-cancer,anti-cardiovascular disease,and enhancing immunity[7].Foods rich in phenolic compounds are known to have antioxidant properties and bioactivity,these phenols,exist in the bound state in unfermented grains(bound to sugars,fatty acids,or proteins).According to previous studies,fermentation enabled the biotransformation of phenolic compounds from their linked or conjugated form to free form,thereby increased the concentration of phenolic components with greater antioxidant capacity[8].Therefore,grain fermentation seems to be a suitable means to enhance its bioactive substances.

In this study,in order to break the current situation of single raw material of traditional soybean paste and utilize the potential of broomcorn millet fermentation,broomcorn millet flour was substituted for wheat flour and mixed with soybeans for fermentation.In general,this study aimed to 1) develop a new type of nutrient and flavor double-oriented soybean paste,explore broomcorn millet flour assisted fermented soybean paste (SMI);2) clarify its physicochemical properties,investigate its biological activities,the composition of microbial community,free amino acids (FAAs) and volatiles substance;3) assess the correlation between microorganism and quality factors.The results may provide a theoretical basis for the nutritional flavor of the new soybean paste.

1 Materials and Methods

1.1 Material and reagents

Broomcorn millet and soybeans were purchased from local farmers’ markets in Daqing City (Heilongjiang,China).

A.oryzaeCICC 2339 was purchased from Hezhong Kangyuan Biotechnology Co.Ltd.(Shandong,China);Saccharomyces cerevisiaewas purchased from Angel Yeast Co.Ltd.;Lactobacillus plantarumST 3.5 was derived from a laboratory isolated strain;methanole,sodium hydroxide,sodium carbonate anhydrous,boric acid,trichloroacetic acid and petroleum ether (analytically pure) were purchased from Quan Rui Reagent Co.Ltd.(Liaoning,China);Folinphenol reagent was purchased from Phygene Bio-Technology Co.Ltd.(Fuzhou,China);DNS solution and potassium hydrogen phthalate were purchased from Coolaber Co.Ltd.(Beijing,China);sodium tetraborate decahydrate,zinc acetate dihydrate,potassium ferrocyanide trihydrate,citric acid and sodium nitrite were purchased from Macklin Biochemical Technology Co.Ltd.(Shanghai,China);E.Z.N.A.®soil DNA kit was purchased from Omega BioTek (Norcross,GA,U.S.);AxyPrep DNA gel extraction kit was purchased from Axygen Biosciences (Union City,CA,USA);the other reagents were chromatographic grade.

1.2 Instruments and equipment

Ultraviolet spectrophotometer was purchased from Aoe Instruments (Shanghai) Co.Ltd.;pH meter was purchased from Mettler Toledo Instruments (Shanghai) Co.Ltd.;high speed freezing centrifuge was purchased from Hunan Kecheng Instrument Equipment Co.Ltd.;CNC ultrasonic cleaner was purchased from Kunshan UL trasonic Instrument Co.Ltd.;biochemical incubator was purchased from Shanghai Senxin Experimental Instrument Co.Ltd.;GeneAmp 9700 polymerase chain reaction (PCR) system was purchased from Applied Biosystems (Foster City,CA,USA);7890A-5975C GC-MS was purchased from Agilent Technology Co.Ltd.;Illumina MiSeq platform was purchased from Shanghai Majorbio Bio-pharm Technology Co.Ltd..

1.3 Methods

1.3.1 Preparation of soybean paste and sample collection

A.oryzaeCICC 2339 was used as the koji-making fungus to inoculate and ferment soybean paste.Broomcorn millet flour was used as auxiliary material,and soybean paste was fermented at a ratio of 3:7 (flour:soybean).The cooked soybeans were mixed with flour,the fungus was inoculated on its surface.L.plantarumST 3.5 (104CFU/g)andS.cerevisiae(105CFU/g) were added to assist in the late fermentation to improve the flavor of soybean paste,then fermented for 45 days.The specific steps were shown in Fig.1.

Fig.1 Fermentation process of SMI soybean paste

Samples of SMI soybean paste were collected regularly at different fermentation stages: 0 d (SMI_0),10 d (SMI _10),20 d (SMI _20),30 d (SMI _30) and 45 d (SMI _45).Samples were collected and stored at -80 ℃ until further use.

1.3.2 Determination of physicochemical characteristics

5 g samples were placed in a weighing bottle,spread them out evenly,dried them in an oven at 80 ℃,took them out and cool them in a drying oven,weighed them until reached constant weight,and calculated the moisture content of the sample.The fat content was determined by reference to GB 5009.6-2016[9]Determination of Fat in Food.The pH value determination referred to the method of GB 5009.237-2016[10]Fetermination of pH in Food,and the total acid content was determined according to the method of GB 12456-2021[11]Fetermination of Fotal Acid in Food.The determination of amino acid nitrogen referred to the method of GB 5009.235-2016[12]Determination of Amino Acid Nitrogen in Food,the determination of nitrite content referred to the method of GB 5009.33-2016[13]Determination of Nitrite and Nitrate in Food.The contents of total phenols (TP)was measured by Folin-Cioealteu.GABA was determined by high performance liquid chromatography (Thermo Fisher Scientific U3000),chromatographic condition were as follows: mobile phase A,acetonitrile:0.1 mol/L sodium acetate solution (3:97,V/V) (adjusted pH 6.5 with acetic acid);mobile phase B,acetonitrile:water (4:1,V/V),the flow rate: 1.0 mL/min,column temperature: 40 ℃,the detection wavelength: 254 nm.

1.3.3 Analysis of volatile compounds in SMI soybean paste

The volatile compounds in SMI soybean paste were analyzed by headspace solid-phase microextraction coupled with gas chromatography mass spectrometry (HS-SPMEGC-MS).The sample bottle of soybean paste was heated at 60 ℃ (30 min),and the extraction needle was inserted into the sample (60 ℃,30 min).Subsequently,the volatile compounds were detected using chromatography-mass spectrometry (GC-MS) with a HP-5 MS column (60 m ×0.25 mm,0.25 μm).Programmed temperature rised: the temperature was kept at 50 ℃ (1 min),then increased to 100 ℃ at 5 ℃/min,warmed up to 180 ℃ at 4 ℃/min (3 min),finally to 250 ℃ at 5 ℃/min (5 min).The MS conditions were as follows: electron impact ionization,230 ℃,the temperature of quadrupole was 150 ℃,electron ionization 70 eV,and full scan 35–550 Da.The flavor compounds were measured by comparison retention index (RI) values with the national institute of standards and technology (NIST17) mass spectra library.Isoamyl phenylacetate was used as internal standard for composition analysis.

1.3.4 Detection of FAAs in SMI soybean paste

0.5 g SMI soybean paste were placed in a 10 mL centrifuge tube for pre-treatment.The HPLC conditions were as follows: ZORBAX Eclipse AAA column (4.6 mm ×150 mm,3.5 μm);Detection signal: UV detection equipped with 338 nm (0–19 min),266 nm (19.01–25 min);Mobile phase A: 40 mmol/L sodium dihydrogen phosphate (pH 7.8);Mobile phase B: acetonitrile:methanol:water (45:45:10,V/V);Flow rate: 1.0 mL/min.FAAs content was determined and quantified by the residence time of standard.

1.3.5 DNA extraction and high-throughput sequencing

Genomic DNA was extracted from samples using an E.Z.N.A.®soil DNA kit according to the manufacturer’s protocol.NanoDrop2000 was used to detect DNA purity and concentration.Bacterial primers 338F and 806R were used to amplify the V3–V4 domain of 16S rRNA gene.Fungal DNA was assayed using primers ITS1F and ITS2R to amplify the internal transcribed spacer (ITS) in a thermal cycle PCR system.PCR products were identified by 2% agarose gel electrophoresis and further purified using AxyPrep DNA gel extraction kit.NEXTFLEX rapid DNA-SEQ kit was used to construct MiSeq amplified library.Then High-throughput sequencing.Sequence data associated with this project have been deposited in the national center for biotechnology information (NCBI) short read archive database (accession number: SRP417404).

1.3.6 Bioinformatics analysis

HiSeq data was combined into a single sequence,and its quality was controlled and filtered,then the raw data was compared to a species-annotated database.The chimera sequence was optimized to obtain effective data.Effective labels were obtained by identifying and removing chimeras.The USEARCH11-uparse algorithm was used to cluster labels with OTU ≥ 97%.The relationships between samples and species were depicted by visual circles,the Kyoto Encyclopedia of Genes and Genomes (KEGG)function of 16S rRNA genes was labeled by Tax4Fun and Silva databases.Finally,the correlation between main microorganisms with flavor substances and FAAs was analyzed by spearman correlation coefficient.

1.4 Statistical analysis

The results were calculated and analyzed by SPSS 22.0 software.Each experiment was repeated 3 times,and the results were expressed with± s.P<0.05 was statistically significant.The results were drawn with Origin 64 software.

2 Results and Analysis

2.1 Analysis of physical and chemical properties

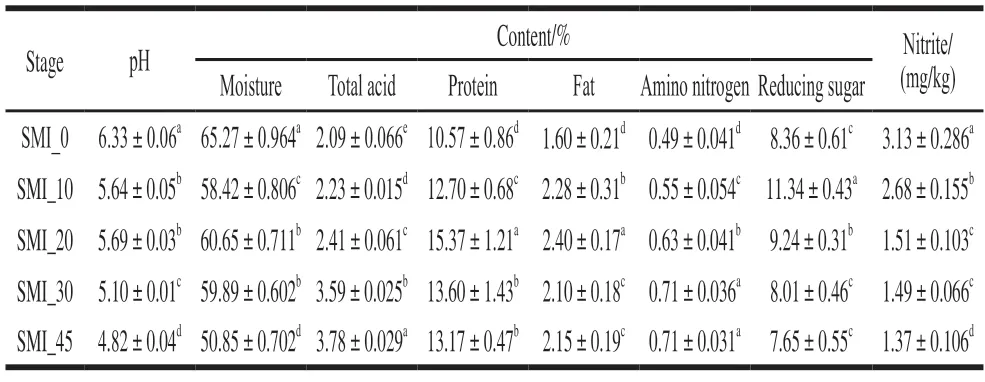

The change of physicochemical index content in the fermentation process played an important role in the quality of soybean paste.Results in physicochemical properties of SMI soybean paste during fermentation were shown in Table 1.The ripening process of soybean paste was a typical multienzyme fermentation.Miosture content directly affected the growth and metabolism of microorganisms,and then affected the production and activity of various enzymes,thus affected the final quality of soybean paste[14].With the progress of fermentation,as the moisture was partly volatilized and partly used by microorganisms,the moisture gradually decreased.In the fermentation process,carbohydrates and fats in fermented grains were decomposed and some small organic acids were produced[15],which led to the continuous increase of total acid content and the gradual decrease of pH value.In the later stage of fermentation,the total acid content and pH value gradually tended to be stable.Both fat and protein showed a trend of first increasing,then slightly decreasing.With the growth of microorganisms,the microbes adhered on the surface of the soybean paste,the chemical composition of soybean paste would occur some changes,microbes decomposed some nutrients of it into small molecules,such as alcohols and acids were esterified to produce ester substances,thus increased the fat content[16].Microbial metabolism was mainly produced by microorganisms of the raw material in the environment,which could decompose saccharide substances,reduce the content of it,resulted in an increase in the relative proportion of protein.With the progress of fermentation,amylase produced byA.oryzaefurther decomposed starch in raw materials,increased the content of saccharide and decreased the proportion of proteins accordingly[17].Meanwhile,proteases produced by strain ofA.oryzaecould also degrade proteins into small molecules such as FAAs,which was also the reason for the decline in the proportion of proteins in the late fermentation period[18],the protein content of SMI at the end of fermentation was 13.17%.The standard of GB 2718-2003[19]Hygienic Standard for Saucesstipulated that the content of amino nitrogen in soybean paste is more than 0.6%,which was considered as the mature soybean paste.Table 1 showed that the amino nitrogen content increased significantly due to the higher protease activity in the early stage of fermentation.At the late stage of fermentation,the increase of organic acid metabolism decreased the activity of protease,which slowed down the rate of amino acid nitrogen production.At the end of fermentation,the content of amino nitrogen in SMI was 0.71%,and it was edible when ripe.In the fermentation process of soybean paste,reducing sugar increased first and then decreased.In this study,the strain ofA.oryzaewas koji.In the early stage of fermentation,amylase and glycosylase produced by the strain rapidly hydrolyzed starch in raw materials to produce reducing sugar,which reached the maximum value (11.34%) at 10 d.The fermentation process was a synergistic result of a variety of microorganisms.While some microorganisms that could ferment saccharide and produce acid,other microorganisms also decomposed starch and produced saccharide at the same time.Although the inoculation of lactic acid bacteria (LAB) at the later stage of fermentation contributed to utilize reducing sugars and increase the acidity of soybean paste,the increased acidity of LAB also affected the metabolic activities and reduced other sugar-utilizing bacteria,this might be one of the reasons why the reducing sugar content was reduced from 11.34% to 7.65%.Nitrite was accumulated in the process of fermented food,which was harmful to food safety and affected human health.In this study,the content of nitrite showed an overall decreasing trend and stabilized at 1.37 mg/kg after fermentation for 45 d.The low pH caused by LAB inhibited the microorganisms that reduced nitrate to nitrite.Some nitrite reductases might also be produced by LAB and had degradation effects on nitrite[20].In addition,according to the national health standards,the limit of nitrite content was 20 mg/kg,so the result of SMI indicated that it was acceptable for consumption[21].Complex chemical changes during fermentation combined to form the unique flavor of soybean paste.

Table 1 Chemical characteristics of SMI soybean paste at different fermentation stages

2.2 Analysis of microbial community dynamics of bacteria and fungi

The species diversity of microbial communities at different stages was compared,β-diversity analysis was conducted to explore the similarity or difference of community composition among different groups.The results showed that the contribution rates of the first and second principal components of bacteria were 75.82% and 11.04%respectively (Fig.2A1),SMI_0 and SMI_10,SMI_20 and SMI_30 had strong similarity and repeatability,while SMI_45 had some differences from the first four stages.The microbial community composition of soybean paste showed dynamic changes with the progress of fermentation,leaded to difference of principal component 1 and 2 in different stages.There were some discrepancy between the microbial communities at different stages of soybean paste.The contribution rates of the first and second principal components of fungi were 38.78% and 56.18%respectively (Fig.2A2),the group comparison of fungal species diversity was similar to that of bacteria,and each species was in the confidence interval.

The microbial community composition of SMI at different fermentation stages was analyzed according to the visual circle plot,and the high quality sequencing results were classified at the phylum and genus levels.The analysis of phylum level showed that Proteobacteria dominated the whole fermentation process,Firmicutes also had a certain abundance 10 d before fermentation,Actinobacteriota and Acidobacteriota appeared at the later stage of fermentation(Fig.2B1).The phylum of the fungi showed that Ascomycota was the key to the fermentation of soybean paste (Fig.2B2).At the genus level of bacteria,Enterobacter(73.32%–90.41%)as a major genus of bacteria,played an important role in the maturation process of SMI,ExiguobacteriumandEnteroccuswere important genera in the first 10 d of fermentation,Pseudomonasalso occupied a certain abundance at 20 d(3.10%) and 30 d (2.41%) of fermentation (Fig.2C1).At the genus level of fungi,A.oryzaeparticipated in the fermentation of soybean paste as a starter,so the abundance ofAspergilluswas very high throughout the fermentation process.Alternariaemerged at 45 d of fermentation with an abundance of 3.97% (Fig.2C2).

2.3 Network inference of microbial species in SMI soybean paste

Based on the correlation network diagram,the relationships among microorganisms in SMI soybean paste were studied,and the clustering coefficients among different species were calculated (Fig.3).The microbe single factor network diagram showed that there were significant interactions among different microbe genera(positive correlation in red,negative correlation in green;the thickness of the line indicates the magnitude of the correlation coefficient).Fig.3A showed that there were complex correlations among bacteria genera,thePantoeawas significantly positively correlated withEnterobacterandPseudomonas,with a clustering coefficient of 0.717 35 and 0.695 89 (clustering refered to the clustering coefficient of the node;the larger the node,the more important it was),Lactococcuswas significantly positively correlated withEnterococcus,Staphylococcuswas negatively correlated withPaenibacillus,Gaiella,SolirubrobacterandStreptomyces.Previous studies had shown thatLactococcus,Pseudomonas,AcinetobacterandWeisselahad key contributions in the production of fermented foods such as soybean paste,soy curd,soy sauce,white wine and vinegar[22-23].In addition,the largest number of bacteria genera related toSolirubrobacterandNocardioides(degree=26),the results indicated these two bacteria played an important role in the fermentation process of SMI soybean paste.

Fig.3 Network analysis of the top 30 bacterial and fungal species in SMI soybean paste at different fermentation stages

The correlations between the fungal genera had obvious stages characteristics (Fig.3B).Most fungus had a significant negative correlation withAspergillus,such asSaccharomyces,PseudocercosporaandFilobasidium,correlation coefficient was 0.789 71,0.618 77 and 0.667 63 respectively.There was a significant positive correlation among the other fungi genera,13 fungi genera (Pseudocercospora,Filobasidium,andAlternariaet al.) were positively associated withSaccharomyces.In all fungi,the largest number of genera related to g__unclassified_c__Sordariomycetes (degree=27),it could be seen that it played a vital role in promoting the fermentation of soybean paste.In short,the correlation between fungi genera was similar,and most of the different fungi genera were positively correlated.

2.4 Analysis of the correlation between bioactive constituents and microorganisms

In the process of fermentation,the TP content of soybean paste showed an overall upward trend.The content of SMI increased from 332.23 mg/100 g (gallic acid equivalent,dry mass) to 934.81 mg/100 g at 0–30 d(Fig.4A),its trend was similar to Tartary buckwheat soybean paste (1 260 mg/100 g) in enrichment of phenolic compounds[15].SMI decreased to 724.27 mg/100 g at 45 d,but it was still twice as original content,it could be seen that fermentation was beneficial to the enrichment of TP.Some studies had reported that fermentation was able to increase the bioconversion of phenolic compounds from their linked or conjugated forms to the corresponding free forms,the decrease of phenolic content might be caused by the rearrangement of some phenolic structures after the selfpolymerization process induced by acidic conditions in late fermentation[8].Microbial metabolism and enzyme activity of grain were interdependent[24],in the process of fermentation,broomcorn millet was rich in phenolic substances,and its enzymatic transformation and microbial metabolism were related to it.It also showed that the addition of broomcorn millet flour was more valuable to increase the nutritional properties of soybean paste.

Fig.4 Changes of TP and GABA contents in SMI soybean paste during different fermentation stages and heatmap of the correlation between biological activity and microorganisms of SMI soybean paste

The content of GABA in the fermentation process of SMI was shown in Fig.4B.The initial content of GABA was 318.55 mg/kg,and then with the fermentation,its content showed a dynamic change,at the fermentation of 10 d,the content of GABA was decreased,and at the 20 d of fermentation,it increased again (276.46 mg/kg),and gradually decreased at the later stage of fermentation.The decreased of GABA content in early stage might be caused by insufficient protein decomposition.Studies had found thatA.oryzaeusesL-glutamic acid as substrate to produce a large amount of GABA under the catalysis of glutamic acid decarboxylase[25].In this study,A.oryzaeplayed a huge role as the starter culture of SMI.Therefore,in the fermentation process of soybean paste,whenA.oryzaehad high biological activity,it might promote the production of GABA.In order to make soybean paste fermentation more mature and thicker,Saccharomyceswas added at the later stage of fermentation in the experiment.In addition,other yeast participated in the fermentation process,and these yeast used GABA as a good nitrogen source,which would also lead to the reduction of GABA content[26].

The heat map of the relationship between bioactive substances and bacteria was shown in Fig.4C,TP was positively correlated with more bacteria,such as norank_f__Geminicoccaceae,Bacillus,ArthrobacterandStreptomyces,it was negatively correlated withStaphylococcus,Lactococcus,WeissellasandEnterococcus.Few microorganisms were associated with GABA,and onlyAcinetobaterandStenotrophomonaswere significantly positively correlated with GABA,but not with other microorganisms.The correlation with fungi was shown in Fig.4D,TP was positively correlated withSaccharomyces,unclassified_o_Saccharomyces,Cladosporium,AlternariaandVishniacozyma,studies had reported thatS.cerevisiaecould promote the production of TP[27].Aspergillushad a small but not significant boost to GABA.Although some microorganisms had an insignificant effect on GABA,most of them promoted the release of TP.Therefore,the effect of microorganisms on the biological activity of SMI cannot be ignored.

2.5 Analysis of the correlation between flavor composition and microorganisms

Soybean paste contained many different aroma components,formed its unique flavor.The flavor components of the samples were determined on the 20 d and 45 d of fermentation (Table 2).These volatile compounds were divided into 8 groups,which were alcohols,esters,aldehydes,ketones,acids,ethers,alkanes and others,the variation of flavor concentration of different categories was shown in Fig.5A.These volatile substances were different in the two fermentation stages.Compared with SMI_20 (53 compounds),SMI_45 (61 compounds) had a larger variety and a higher content of flavor compounds.Among them,many flavor compounds existed in the middle fermentation stage,but disappeared in the later fermentation stage.The main reason might be that many flavor compounds were synthesized from various precursor substances such as acids and alcohols,which affected the composition of some flavor compounds[28].Alcohols (phenylethyl alcohol) were detected in two stages,with floral and rose-colored odors.The variety of alcohols at the 45 d was less than that at the 20 d,this might be due to the slow metabolism of yeast in soybean paste under environmental stress in the late fermentation period.The variation of flavor substance content was closely related to FAAs.For example,phenylethyl alcohol could be produced by oxidative deamination of FAAs precursor (LEU) by Ehrlich mechanism[29].Besides,the ester content at the 45 d of fermentation was the highest among all stages.This had an essential effect on the formation of soybean paste flavor(Table 2).The synthesis of volatile components was varied and complex.For example,aldehydes,alcohols and esters in fermentation were formed by a series of reactions such as decarboxylation,deamination and esterification of amino acids.In addition,some other aromatic compounds,such as phenols and indoles,were also found in our sample,which played an important role in the formation of SMI flavor.

Fig.5 Contents of flavor compounds (A),heatmap of the correlation between selected dominant flavor compounds and microorganisms of SMI soybean paste (B and C),concentrations of different flavor amino acids (FAAs) (D) and heatmap of the correlation between FAAs and microorganisms of SMI soybean paste (E and F)

The delicious taste of soybean paste could not be separated from microbes.The correlation between the high content flavor compounds in two fermentation stages and the microorganisms in the fermentation process was analyzed.The heat map of its correlation with bacteria showed that was regularly divided into four parts (Fig.5B),acetic acid,phenylethanal,isovaleraldehyde,2-methyl-butanal and methy palmitate were significantly positively correlated compared withKnoellia,BlastococcusandSolirubrobacter,these flavor components were significantly negatively correlated withStaphylococcus,Enterococcus,PantoeaandPseudomonas.Fig.3A showed the importance ofSolirubrobacter,which added an ester flavor to soybean paste.On the contrary,phenol,tetradecamethyl-cycloheptasiloxane,dodecamethylcyclohexasiloxane,decamethyl-cyclopentasiloxane,1,4,7,10,13,16-hexacycioocadecane,methyl phenylacetate and 3-octanone with the bacteria described above had an inverse relationship.Fig.5C had shown thatEpicoccum,Sporidiobolus,SarocladiumandSaccharomycescould promote the generation of acetic acid,phenylethanal,isovaleraldehyde,2-methyl-butanal,methy palmitate,gamma-butyrolactone,mashroom alcohol and phenethyl alcohol,Aspergilluswas less friendly to these flavors,but it was a major donor of some alkanes,such as tetradecamethylcycloheptasiloxane,dodecamethyl-cyclohexasiloxane,decamethyl-cyclopentasiloxane,1,4,7,10,13,16-hexacyciooca decane,however,Epicoccum,Sporidiobolus,SarocladiumandSaccharomyceswere negatively correlated with these flavors.

2.6 Analysis of the correlation between FAAs composition and microorganisms

During the fermentation process,protein degradation released FAAs fermentation substrate[18],FAAs could be converted into aromatic compounds by the action of microorganisms[30],which was one of the reasons for the formation of soybean paste aroma.The content and composition of FAAs could partly reflect the quality characteristics of soybean paste.In this study,24 kinds of FAAs were identified and their content variation on the 20 d and 45 d of fermentation were given in Table 3,through the comparison of two stages,the FAAs content of most of them increased stably.Furthermore,the 24 FAAs were classified into four groups according to taste: umami taste (glutamic acid (Glu) and aspartic acid (Asp),they determined the palpability of soybean paste),sweetness(threonine (Thr),serine (Ser),glycine (Gly),alanine (Ala),proline (Pro)),bitterness (histidine (His),isoleucine (Ile),valine (Val),leucine (Leu),tyrosine (Tyr),arginine (Arg),methionine (Met),phenylalanine (Phe) and lysine (Lys)),and others (cysteine (Cys),asparagine (Asn),glutamine(Gln),D-citrulline (Cit),L-norvaline (Nva),tryptophan (Trp),hydroxyproline (Hyp),sarcosine (Sar)) (Fig.5D)[31].Taste activity value (TAV) was the ratio of FAAs concentration to its threshold value,which reflected the intensity of a certain component in the sample to taste,the higher the TAV value was,the greater the influence of amino acids on taste.Therefore,in this experiment,it could be seen that umami FAAs had the greatest influence on SMI (Table 3).Some studies had found that Asp,Glu determined the sensory ability of soybean paste,Tyr and Phe promoted the production of clove flavoring substances,and Cys and Met were precursors of pyrazine flavoring ingredients[32].

Table 3 Changes in FAA contents of soybean paste at the medium and late stages of fermentation

Spearman correlation analysis was used in this study to explore the correlation between the dominant bacteria and fungal genus with FAAs of SMI (Fig.5E).At the level of bacteria,Knoellia,Blastococcus,RB41,Solirubrobacter,Streptomyces,Lysobacterand norank_f__Vicinamibacteraceae were the donors that promoted the production of umami amino acids (Asp,Glu) and sweet amino acids (Thr,Ser,Gly,Ala,Pro).While the umami and sweet amino acid withStaphylococcus,Enterococcus,Pantoea,Exiguobacterium,Stentruphomonas,EnterobacterandPseudomonasinto a significant negative correlation.Notably,these bacteria also had a negative relationship with bitter amino acids (His,Ile,Val,Leu,Tyr,Arg,Met,Phe,Lys),this suggested that bacteria such asEnterococcuscould inhibit bitter taste.Bitter amino acids,which were closely related to microorganisms,played a role in flavor regulation of soybean paste,but high concentration of salt and acid could inhibit the perception of bitter taste and balance the flavor of soybean paste[33].Surprisingly,Glu accounted for a higher proportion of fermentation products (Table 3).It has been reported that some bitter FAAs co-exist with glutamate to promote umami production[34].Similarly,fungi and FAAs could be divided into four clusters according to their correlation characteristics(Fig.5F).Fig.3B showed that there was a strong correlation between fungi and FAAs,which might have contributed to the rich taste of SMI.For example,Alternaria,Epicoccum,Sporidiobolus,SaccharomycesandApiotrichumwere strongly positively correlated with g__unclaified_c__Sordariomycetes could promote the production of three flavor amino acids (umami,sweet and bitter).Asperilluswas significantly positively correlated with Trp,Cys,Asn and Gln,and negatively correlated with other FAAs.

3 Conclusion

In this study,the nutrient composition,flavor characteristics,microbial community and their relationship of a new raw material of broomcorn millet flour assists soybean paste in the fermentation process were discussed.The fat and protein as a crucial physicochemical index,their contents were 2.15% and 13.17% when the fermentation was complete.The amino nitrogen reached 0.71% at 30 d and stabilized to mature state until to 45 d,the content of sodium nitrite was reduced to 1.37 mg/100 g,which was within the safety limit and it was allowed to be safe to eat.When fermentation was complete,the TP content of SMI soybean paste was doubled compared to the initial value,the GABA content of mature SMI soybean paste was 180.69 mg/kg.Fermentation on 45 d compared with 20 d,10 flavor components were added,the content of most FAAs and key volatiles (esters,acids,aldehydes) increased significantly during fermentation.

In SMI soybean paste,the core communities includedEnterobacter,Pseudomonas,Stenotrophomonas,Aspergillus,Alternaria.Furthermore,correlation analysis of bioactive substances and metabolites with microorganisms confirmed that there was a significant correlation between microorganisms and the dominant flavor compounds,bacteria(Bacillus,Knoellia,Blastococcus) and fungi (Epicoccum,Saccharomyces) played an important role in the bioactivity changes,FAAs and flavor substance of SMI soybean paste.

For future work,these potential microorganisms could be isolated and identified from SMI soybean paste.The results comprehensively revealed the quality characteristics,biological activity,flavor characteristics and microbial community changes during SMI fermentation.It was important for understanding the nature of broomcorn millet assisted fermentation of soybean paste,it had a certain contribution to further study of the nutritional characteristics of broomcorn millet.Moreover,some potentially dominant species could be isolated and identified from the fermentation of SMI.These microorganisms were inoculated and fermented to further verify the correlation between microorganisms and soybean paste quality.