Measurement of alumina film induced ablation of internal insulator in solid rocket environment

2023-12-07JiYeulBaeInSikHwangYoongooKang

Ji-Yeul Bae,In Sik Hwang,Yoongoo Kang

Agency for Defense Development,160 488th Bukyuseong-street, Daejeon, South Korea

Keywords: Internal insulation Solid rocket motor Ablation Alumina

ABSTRACT This study investigates the ablation of internal insulation induced by the deposition of an alumina film with different lateral film speeds.A sub-scale test solid rocket motor (SRM) was designed in an impinging jet configuration to form an alumina film on the sample and to encourage the lateral movement of the film by a high-speed wall jet.Fifteen static fire tests of the test SRM were conducted with six different jet velocities (Vjet=100 m/s,150 m/s,200 m/s,268 m/s,330 m/s,and 450 m/s) that indirectly affected the velocity of the wall jet and the deposition rate of alumina droplets.The ablation velocity was deduced from the difference in the sample thickness after a test using a coordinate measuring machine.The droplet deposition mass flux and wall jet velocity were obtained via two-phase flow simulation with the same jet velocity and effective pressure.As a result,the characteristics of alumina-induced ablation and the changes in ablation with jet velocities were obtained.The area within 0.8×jet diameter was focused upon,where the ratio of ablation velocity to incoming alumina mass was constant for each jet velocity,and showed a similarity in jet structure.When the ablation velocity was increased from 2.05 to 9.98 mm/s with increasing jet velocity,the ratio of the ablation velocity and alumina mass flux decreased from 1.07×10-4 to 0.49×10-4 m3/kg as Al2O3-C reactions became less efficient with a reduced residence time of the film.Because the decrease in residence time by the wall jet is more pronounced for slow reactions involved in Al2O3-C reactions,fast reactions in Al2O3-C reactions are less affected and result in a convergence of the volumetric rate of ablation per unit mass of alumina.

1.Introduction

In a solid rocket motor (SRM),an internal insulator is placed between the case and propellant,whose role is to transmit the pressure load from the combustion gas to the case while maintaining the case temperature at an acceptable level for structural integrity [1].To achieve these requirements,elastic materials such as nitrile butadiene rubber (NBR) or ethylene propylene diene monomer (EPDM) reinforced with aramid or carbon fibers are commonly used as internal insulators [2].As the insulator undergoes a complex destruction process upon exposure to the combustion gas,numerous studies have been conducted to understand the destruction characteristics.

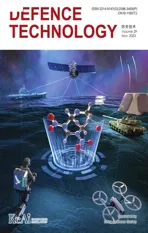

The general destruction process of an internal insulator is illustrated in Fig.1.Once the insulator is exposed to the combustion gas,the temperature of the material increases owing to convective and radiative heat transfer.When it reaches its decomposition temperature,the molecular structures in the virgin material decompose owing to endothermic chemical reactions (charring).Eventually,the material is converted into a porous char layer and pyrolysis gases.As the heating process continues,the increasing thickness of the char layer reduces the heat transfer into the virgin material.In addition,pyrolysis gases cool the char layer and reduce the heat and mass transfer on the char surface as they flow through the char layer and into the boundary layer of the combustion gas.

Fig.1.General destruction mechanism for an internal insulator.

However,the ablation of the char layer limits the heat-repelling effect of the material.One of the main reasons for ablation is the chemical reaction between the carbonaceous char and oxidizing species such as H2O and CO2in the combustion gas (chemical ablation).In addition,the mechanical strength of a highly porous char layer can be extremely low;thus,the char layer can get mechanically removed by shear stress from the flow (mechanical ablation).Finally,the alumina (Al2O3) droplets included in the combustion gas can also cause mechanical and thermochemical damage to the char surface when they are deposited on it(aluminainduced ablation).Therefore,the rate of thermal decomposition and each ablation mode of an internal insulator should be investigated under various environments before it can be applied to an actual SRM.

In the early phase of material development,the material is heated with lasers [3,4]or torches [5,6]to study its thermal destruction characteristics and to screen candidate materials.However,the chemical/thermal characteristics of actual SRM conditions cannot be closely replicated in these experiments,whose use for studies on chemical and mechanical ablations is limited.Therefore,sub-scale SRMs that develop a flow parallel to the material surface have been utilized for further investigations [7-12].These test motors are typically designed to maintain a constant flow velocity on the material surface to control the ablation rate for a given test duration.The resulting destruction of the material can be measured by comparing the thickness of the sample before and after the test[7-11]or through in-situ measurements based on indepth thermocouples [11,13]or real-time X-rays [12].And results from these tests have been widely utilized for extensive theoretical/numerical studies to predict a thermal response and destruction of the material since 1960s[14-22].In these research,decomposition of matrix usually has been modeled based on the Arrhenius equation and chemical kinetics and diffusion of the oxidizing species on the surface have been considered for thermochemical ablation of the char layer.Mechanical ablation of the char layer was modeled as proportional to the shear stress from the gas flow[21]or a concept of fail temperature[18]was utilized.Recently,a model for a formation of loose/compact char structure by the coking of the pyrolysis gas was developed [21].

For analyzing alumina-induced ablation [23-26],test motors were designed to deliberately provoke the impact of alumina droplets on the material.These studies mostly focused on the mechanical effect of the droplet impact,and high-speed droplets were introduced to the material surface with a controlled impact angle [23-25].Then,the relationships between the impulse of droplets,char layer strength,and ablation rate were investigated based on Wirzberger et al.’s approach[27].However,in actual SRM environments with a high droplet mass flux,droplets can aggregate on the surface to form liquid alumina film or pool.

Under such circumstances,the mechanical effect of the droplets is absorbed by the alumina film,and alumina-induced ablation is governed by the thermal/chemical interactions between the film and the surface.However,very few studies have investigated the chemical reaction between the liquid alumina film and the internal insulator.Gubertov et al.[28]studied the reaction mechanism of alumina and carbon by investigating the mass loss of a graphite sample in contact with molten alumina at elevated temperatures.In their experiments,the consumed mass ratio between carbon and alumina was approximately 0.2 with the following carbothermic reaction:

It is important to note that the stoichiometric mass ratio of the suggested global reaction was found to be approximately 0.35,instead of 0.2.They attributed this discrepancy in the mass ratio to the removal of intermediate species,such as Al2O,along with CO bubbles moving away from the char surface during the reaction.

Guan et al.[26]evaluated the ablation rate in the recirculation zone of a test motor,where alumina droplets were deposited to form a film with minimal mechanical impact.Their results showed that the ablation rate can be as high as 0.3 mm/s only through chemical reactions of the Al-O-C system between alumina and the carbonaceous char layer.In the following research,they analyzed chemical kinetics and reaction mechanism of Al2O3-C reaction by DT-TGA and summarized reaction rates for carbothermic reaction[29].Finally,based on the measured chemical kinetics of Al2O3-C reaction and heat flux from the slag pool [30],they predicted a thermal destruction and ablation of the EPDM insulator under the thermochemical influence of the alumina pool deposited on the insulator surface [31].However,thermal effect of the Al2O3-C reaction was not considered in their research.Since the thermal effect of the reaction (1) reaches 1310.2 kJ [32],the interfacial temperature between alumina and char layer would be decreased as the reaction proceed,which then reduces the reaction rate itself.This behavior can be inferred from the predicted ablation rate that initially increased to 0.48 mm/s,then decreased to the converged value around 0.38 mm/s [31].

Although the measured ablation rate would be valid if the reaction occurs beneath a stationary alumina pool,the ablation rate may become different when the deposited alumina film moves inside the motor as usually observed at an aft dome and backward side of the cylindrical section in a motor case [33-36].When the alumina film moves along the insulator surface due to a shear of the gas flow or a body force(gravity or acceleration),the reaction rate of the Al2O3-C would be changed by both supply of high temperature alumina with flow and removal of intermediate species like Al2O,Al2OC and Al4C3.Therefore,the relationship between the rate of alumina-induced ablation and movement of the alumina film should be investigated to accurately predict the behavior of the internal insulator.

In this study,a sub-scale test SRM with an impinging jet configuration was designed and test fired 15 times to study the ablation of a Kevlar-reinforced EPDM insulator induced by a deposited alumina film with lateral movement.A jet with an alumina droplet was introduced with a high mass flux for all the tests to ensure the formation of the alumina film with high temperature.The design velocity of the jet was varied from 100 to 450 m/s to change the lateral velocity of the alumina film movement along with the velocity of the wall jet.The thickness of the Kevlar/EPDM sample was measured using a coordinate measuring machine (CMM) before and after each test to deduce the ablation thickness and ablation rate.In addition,a two-phase flow simulation for each static fire test was carried out to characterize the flow inside the test SRM and to deduce the effective conditions on the sample surface,including the droplet deposition mass flux,velocity of the wall jet and wall shear stress.Finally,the measured ablation rate was analyzed along with the mass of incoming alumina droplets and the movement speed of the deposited film.

2.Experimental apparatus and procedure

2.1. Sub-scale test SRM

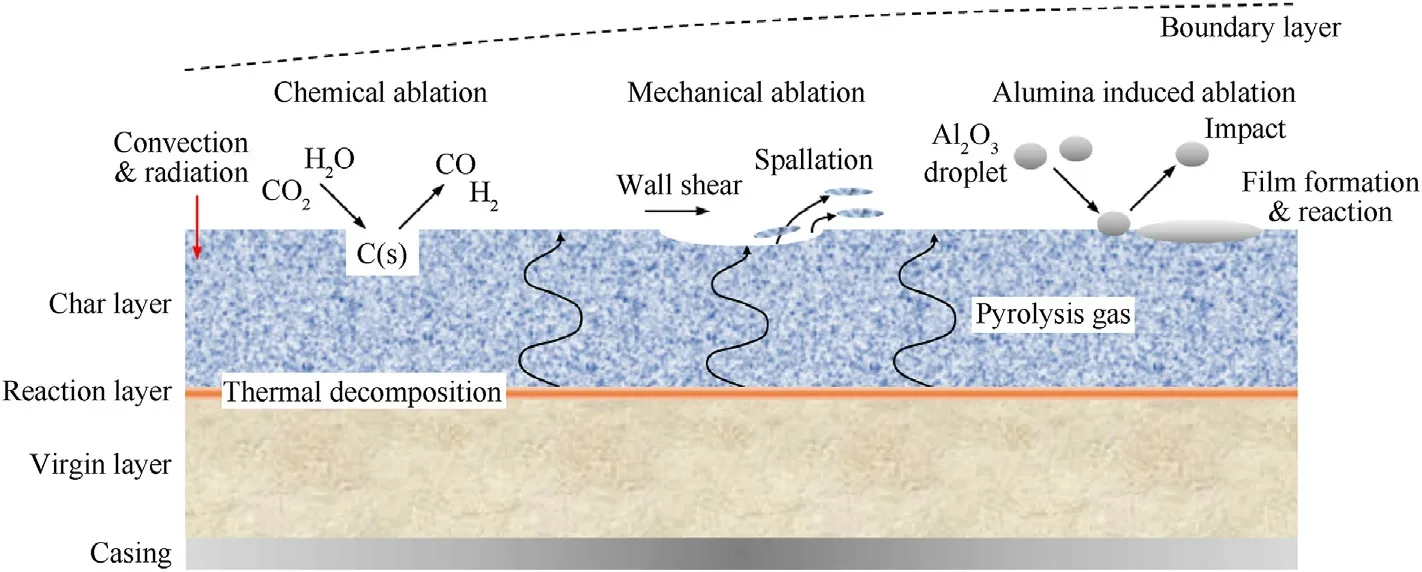

The sub-scale test SRM designed for this research has an impinging jet configuration,as shown in Fig.2.An end-burning propellant grain was used to ensure a uniform distribution of alumina droplets.When the propellant is ignited,the combustion gas,including alumina droplets,is accelerated through the jet nozzle and impinges on the surface of the test sample.Unlike other test apparatuses[23-26],high mass flux conditions were imposed at the exit of the jet nozzle to encourage the formation of a liquid film on the char surface and prevent direct impact of the droplet.The jet was located close to the test sample to form a strong pressure gradient at the stagnation point,which induces the formation of a high-speed wall jet[37].The wall jet causes the flow of the liquid film away from the stagnation point with its shear stress,thereby affecting the rate of the Al2O3-C reactions.After the impingement,small droplets and the combustion gas are discharged through two main nozzles,while large droplets are deposited and remain on the test sample in the form of a liquid film.To prevent large droplets and the liquid film from entering the nozzle,each nozzle was equipped with a blast tube that extended the position of the inlet higher than the surface of the test sample,thus reducing the pressure oscillation and clogging of the nozzle during the static fire test.

Fig.2.Schematic view of sub-scale test SRM with key components and dimensions.

The casing of the SRM was made of AISI 4130 steel and was designed to withstand a maximum test pressure of 6.9 MPa(1000 psia).Most of the internal parts,such as the jet nozzle and blast tubes,were made of chop-molded or tape-wrapped carbon/phenolic materials because of the low Mach number inside the test chamber.However,the throat inserts of the main nozzles were made of copper-infiltrated tungsten to prevent the ablation of the nozzle,which can result in a variation in exhaust pressure.Two bag igniters with BKNO3powder were attached near the entrance of the jet nozzle to evenly ignite the propellant.The igniter wires were connected through a hole in the two nozzle closures made of urethane foam.

The condition of each static fire test was determined based on the key dimensions of the test SRM.First,the average pressure and mass flow rate of the combustion gas during a test were determined by the diameters of the propellant grain,Dgrain,and the main nozzle,Dnoz.In addition,the ratio of the exit diameter of the jet nozzle,Djet,to the effective exit diameter of the two main nozzles,Dnoz,eff,controls the design velocity of the jet,Vjet.The incoming droplet mass flux also changes as the jet is concentrated in a smaller area whenDjetdecreases.Finally,the distance between the jet and the test sample,Hjet,affects the jet geometry because it is related to the curvature of the flow and pressure gradient at the stagnation point.

2.2. Conditions of static fire tests

In this study,14 static fire tests with different jet velocities and pressure were conducted to observe alumina-film-induced ablation of Kevlar/EPDM with different droplet mass fluxes and wall jet velocities.A single test was conducted with a copper test sample to capture and visualize the deposited alumina film on the sample surface.For each test,an HTPB/AP/Al propellant composed of 69% AP,19% aluminum,7.3% HTPB and other additive (without nitramine) was applied,andDgrainandDnozwere determined to achieve a design pressure of approximately 2.06 MPa (300 psia) and 6.89 MPa (1000 psia).Djetwas reduced from 36.0 to 17.5 mm to increaseVjetfrom 100 to 450 m/s and the converging half angle of the jet nozzle was 10°in all cases.TheHjet/Djetvalue for each case was held constant at 0.9 to maintain the similarity of the jet structure in all tests.For each test,the dimensions of the jet nozzle were changed according to the design jet velocity and all other components such as chamber insulation,test sample,blast tubes,and main nozzles were identically manufactured.The amount of propellant for each test was adjusted according to the anticipated thickness of alumina-induced ablation and increase inHjet/Djetto avoid an excessive change in the jet geometry.For a test with a copper sample,the minimum amount of propellant and lowestVjetwere chosen to reduce the loss of alumina film by the wall jet.

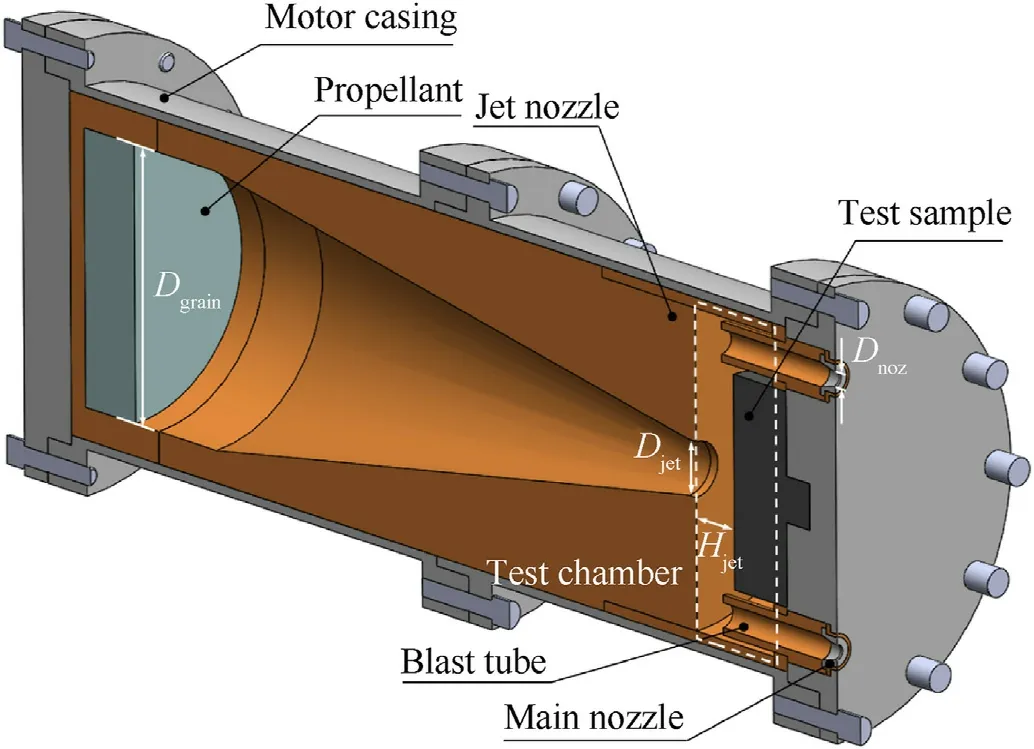

During each test,the chamber pressure was measured at two pressure holes on the SRM casing located close to the burning surface of the propellant.Hydraulic oil was filled between the pressure holes and DYNISCO G831-101 pressure sensors to protect the sensors from the high-temperature environment.The sampling rate of measurement was 1000 Hz and the measurement accuracy of the sensor was 0.25%.A typical history of the measured pressure is shown in Fig.3.The first peak originated from burnout of the igniter,and a slight increase in pressure continued until 2.4 s due to coning of the end-burning grain.The pressure was then decayed back to the atmospheric pressure.To deduce a representative condition for each test,an effective time,teff,is defined as the time between the igniter peak and the moment when a pressure becomes 10% of the maximum pressure,as shown in Fig.3.The effective pressure,Peff,is defined as the average pressure during the effective time.

Fig.3.Typical pressure curve of test SRM and definition of effective test condition.

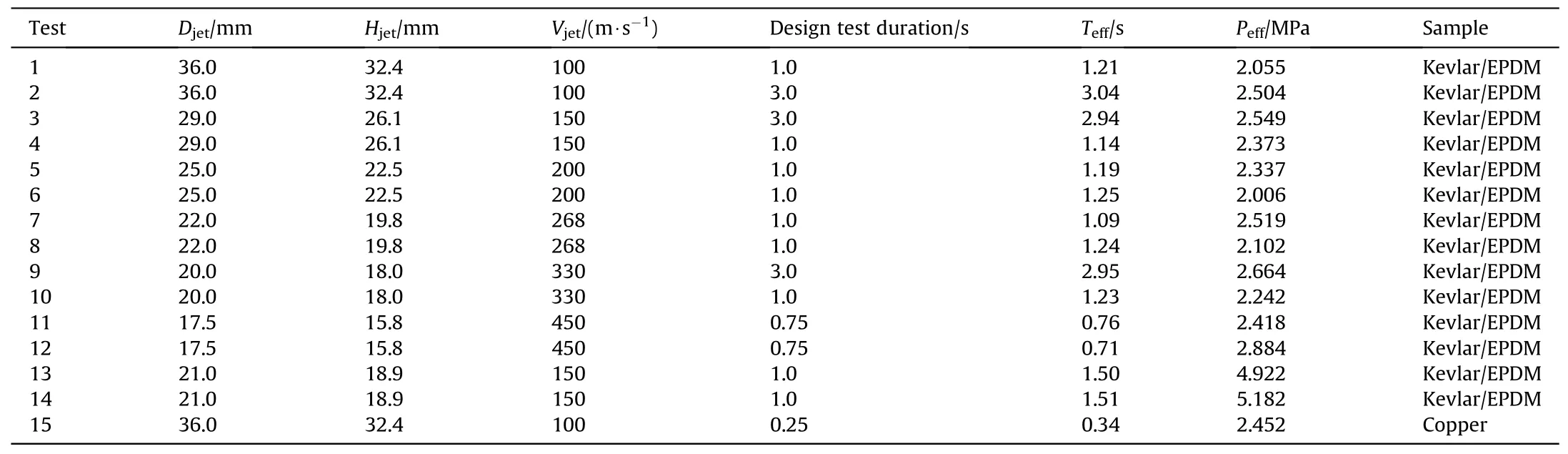

Table 1 lists the design conditions and values ofPeffandtefffor each test in this study.For tests #1,#2,#3,#4,#9,and #10,the duration of the test was intentionally varied to determine the effect of the exposure time of the sample.Thus,thePeffof the test with the same geometries and sameVjetalso varied.Pefffor these tests becomes higher with longerteffowing to a longer period with constant pressure in the pressure curve.An unintentional variation inPeffwas also observed in some tests,with an elongated tail-off pressure caused by the conning of the end-burning propellant.In such cases,Peffdecreased with increasingteffbecause the amount of propellant was fixed.

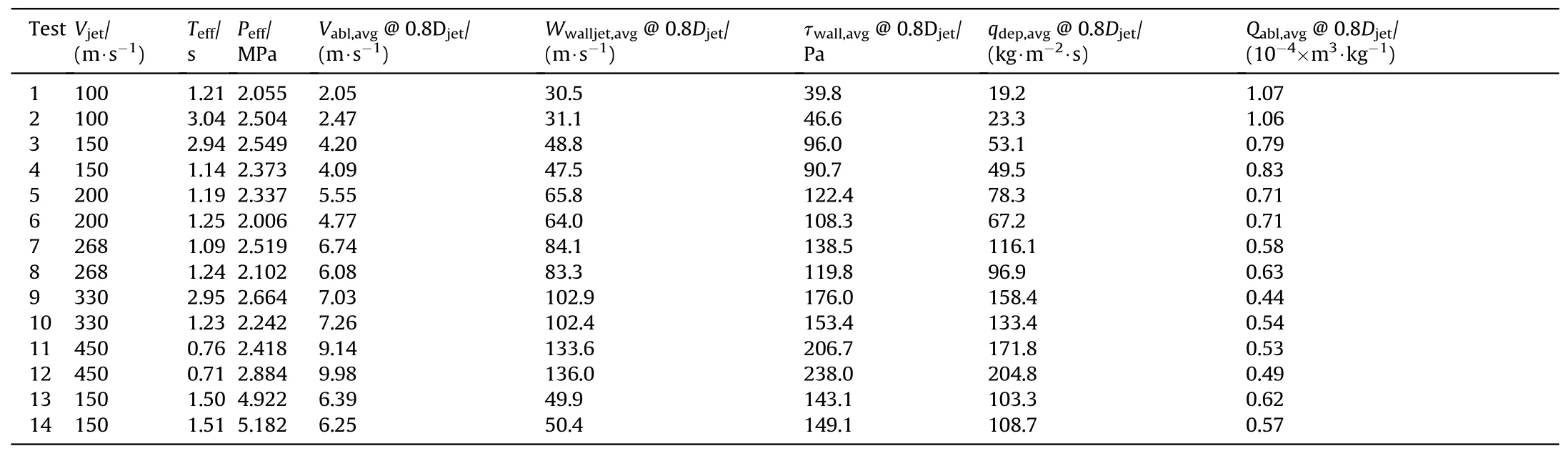

Table 1 Dimensions and effective conditions for static fire tests.

2.3. Conditions on sample surface

To determine the relationship between the characteristics of the liquid alumina film and ablation of the test sample,the deposition rate of alumina droplets on the sample surface should be derived first.Not all droplets in the exhaust gas would be deposited on the sample because small alumina droplets with low inertia would be pushed away by the pressure gradient at the stagnation point and may not reach the surface.In addition,the speed of the alumina film movement on the surface should be determined to correlate it with the Al2O3-C reaction between the alumina film and the test sample.However,it is difficult to obtain these conditions using a theoretical approach or experimental measurement as these values are related to a two-phase flow under thermally harsh conditions.Thus,in this study,a numerical simulation was utilized to deduce the conditions on the sample surface necessary to analyze the experimentally measured ablation of the sample.Since the deposition of droplet is mostly affected by the freestream flow structure and droplet/wall interaction,complicated interactions between the flow and surfaces of the test SRM including reactive/blowing wall condition,gas/particle radiation were not considered.Instead,steady state solutions of combustion gas flow coupled with alumina droplet trajectories at average test conditions were obtained to deduce a flow structure and average droplet deposition rates.

2.3.1.Numerical setup for two-phaseflow

To predict the conditions on the sample surface,we calculated the two-phase flow inside the test SRM for each condition.Because of the high mass fraction and low volume fraction of alumina droplets in the combustion gas,gas-phase conservation equations and droplet trajectories were solved based on the Euler-Lagrange approach using ANSYS Fluent.For the gas phase,compressible three-dimensional RANS equation was solved using a two-equation SST k-ω model.A second-order upwind scheme was used for all the conservation equations.For the discrete phase,the velocity and position of each droplet in the Lagrangian frame were deduced by stepwise integration of a discretized particle force balance equation based on a trapezoidal rule [38].The drag from the gas phase was assumed to be the only force acting on the droplet,and the drag coefficient of the droplet was taken from the work of Gilbert et al.[39],shown below.

Even though there are complicated drag models that consider the effect of the Mach number between the gas phase and droplets[40],the above model of the spherical particle is sufficient for this study because most of the area inside the test SRM,including the test chamber,is in a subsonic condition.Collision,breakup and turbulent dispersion of the droplet were neglected as most of droplets were rapidly accelerated thorough the converging jet nozzle into the sample surface and would not be greatly affected by those phenomena.After calculating each droplet trajectory,the result of momentum/energy exchanges between the gas phase and droplets was considered as the source term in the gas-phase equations to accomplish the global conservation of momentum and energy.

When a droplet reaches the sample surface,an appropriate wall interaction model should be applied to predict the deposition and post-collision behavior of the droplet.Numerous studies have been conducted on the droplet-wall interaction model,including the works of Mundo et al.where the Sommerfeld number was used to determine the fate of a droplet being trapped or splashed [41,42],and the study by Wang et al.of a deposition probability criterion based on the Weber number [43].However,the effect of the deposited film on the post-collision behavior of the droplet was not considered in these models.Therefore,the model used for this research is the Stanton-Rutland wall film model adopted in ANSYS Fluent,in which the fate of a droplet incident on a wall or a liquid film is divided into stick,spread,splash,and rebound.Number of smaller drops generated by a splash was set as the default value of 4.For the other walls inside the test SRM,an elastic collision between a droplet and wall was assumed.

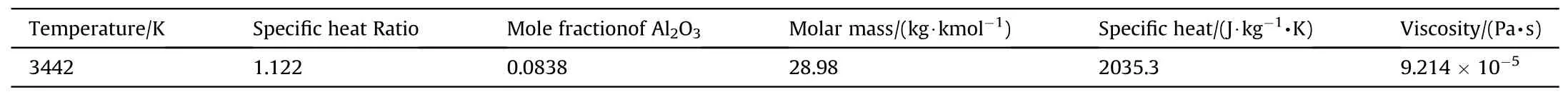

The equilibrium composition of the exhaust gas and alumina mass fraction atPeffwas calculated using the approach of Gordon and McBride [44],and the properties related to the gas phase at chamber condition are provided in Table 2.The combustion gas was assumed as ideal gas.The properties of the droplet required for trajectory prediction are summarized in Table 3.The droplet properties are based on the experimental results of previous studies [45,46]and extrapolated to an exhaust temperature of 3442 K to consider the effect of temperature on the properties.The size distribution of alumina droplets at the nozzle inlet was deduced using an in-house program for agglomeration prediction that considers the packing of aluminum powder in the propellant and agglomeration with a stochastic pocket model [47,48].As AP powders with two distinct diameters were used in the propellant,alumina droplet showed a trimodal size distribution including smokes and agglomerates with maximum diameter around 200 μm.In the deduced size distribution,the mass fraction of droplets with diameters less than 1.5 μm(smoke)was 23.4% of total alumina,and the mass mean diameter of the droplets was 13.67 μm.In order to apply the derived droplet distribution for the simulation,it was divided into 11 sections(i.e.,Section 1 for droplet diameter from 0.0 to 1.0 μm and Section 2 for droplet diameter from 1.0 to 2.0 μm).Then,identical droplets for each section with the median diameter and mass fraction were released from the propellant surface.

Table 2 Exhaust gas properties for gas-phase simulation.

Table 3 Droplet properties for trajectory simulation.

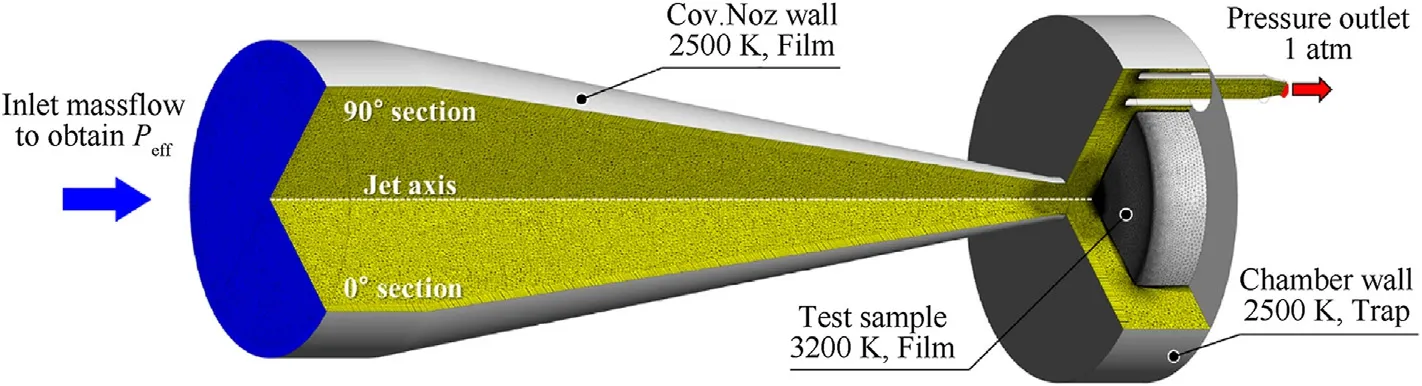

Fig.4 shows the computational grid and applied boundary conditions for the test apparatus with aVjetvalue of 200 m/s(Djet=25.0 mm).Because the adoption of a symmetry condition could distort the droplet distribution at the jet axis,a full volume of fluid inside the test SRM was modeled.An unstructured tetrahedral/prism mesh with approximately 9 million cells was generated for each jet velocity.The average first cell height on the sample surface withinDjetwas adjusted from 3.1×10-6to 9.3×10-6m according toVjetto ensure thaty+is around 1.0 in the area of the interest.The spatial resolution of the mesh on the area near the stagnation point withinDjetwas approximately 2.5×10-4m.

Fig.4.Domain,mesh and boundary conditions for two-phase flow simulation (Vjet=200 m/s).

The inlet and outlet of the computational domain corresponded to the initial surface of the propellant and exit planes of the two main nozzles.The mass flow rate was applied at the inlet for the gas phase instead of the inlet pressure.This was done to fix the ratio of the mass flow between the gas phase and droplets to the value calculated using the CEA program.However,several calculations with different total mass flow rates were carried out to determine the absolute value of the mass flow that makes the simulated inlet pressure equal to thePeffvalue of each test.The deduced total mass flow rate was larger than the choked mass flow rate calculated usingPeffwithDnoz,eff(i.e.,around 20% higher mass flow rate compared to the theoretical value atPeffto achieve same pressure).This discrepancy was caused by the deposition and recirculation of the alumina droplet,which led to a significant loss of mass inside the test SRM.For all cases,the temperatures of the gas phase and droplet at the inlet were assumed to be equal and set to 3442 K.The initial speed of injected droplets was also assumed to be identical with that of the gas phase on the propellant surface around 4.5 m/s.The condition at the exit of the two main nozzles was set as the atmospheric pressure,as the flow was supersonic at the exit and not affected by the given condition.

The wall temperature inside the test SRM was fixed at 2500 K for the carbon/phenolic parts and 3200 K for the EPDM test sample,considering the thermal diffusivity of each material and previous literature on material temperature [49-51].The Stanton-Rutland wall film model was applied to the surface of the test sample and jet nozzle,where the formation of the liquid film was observed in a test SRM after a static fire test.However,the droplets colliding on the chamber wall were assumed to be trapped on the surface to prevent the continuous accumulation of droplets in the simulation by a recirculating flow.An elastic collision was assumed for all other walls,including the blast tubes and main nozzles.

2.3.2.Droplet deposition massflux

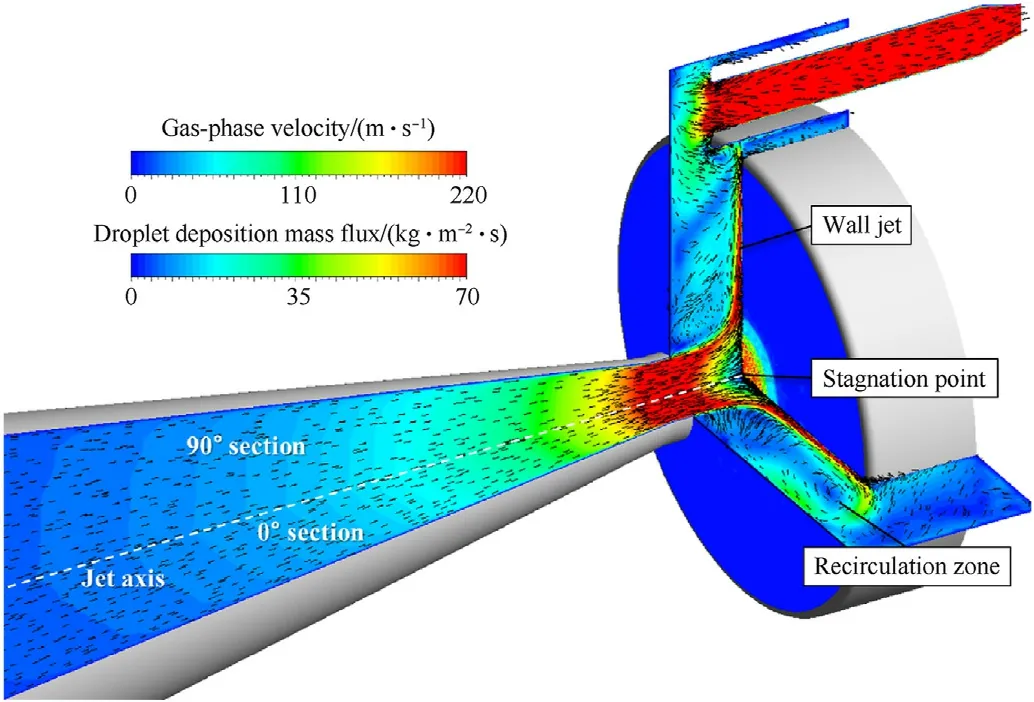

Fig.5 shows the distribution of two-phase flow near the test sample for aVjetvalue of 200 m/s.Both the gas phase and droplets are accelerated through the jet nozzle and impinge on the sample surface.The actual jet velocity at the nozzle exit is higher than the design value,approximately 220 m/s,owing to a higher mass flow through the jet nozzle incurred by the aforementioned loss of alumina inside the test SRM.A large number of droplets is deposited near the jet axis and form a plateau of droplet deposition mass flux on the sample surface.Subsequently,the mass flux gradually decreases away from the center as smaller droplets are pushed away by the pressure gradient at the stagnation point.Droplets with even lower inertia (diameters smaller than 5.5 μm for a jet velocity of 200 m/s)cannot reach the sample surface because they are carried away by the gas phase.The gas-phase flow is also turned and pushed away by the pressure gradient and forms a radially propagating wall jet.As the incoming jet pushes the wall jet against the sample,the boundary layer of the wall jet becomes very thin and exerts a high shear stress on the deposited alumina film.At the edge of the sample in the 0°section,the wall jet separates from the sample and forms a recirculating flow that impinges on the bottom of the jet nozzle.Then,the flow circles around the test sample toward the 90°section and discharges through the blast tube and main nozzle.The recirculating flow slightly reduces the speed of the wall jet as it takes momentum from the wall jet while moving around the test sample.On the contrary,the wall jet at 90°section directly hits the blast tube and is split into two streams,showing a different flow structure from that of 0°section.However,the effect of this flow disturbance does not appear in the central region,especially in the area withinDjet,owing to the high strength of the jet.

Fig.5.Contours of velocity and velocity vectors at 0°,90° section of the test SRM along with droplet deposition mass flux on the sample surface.

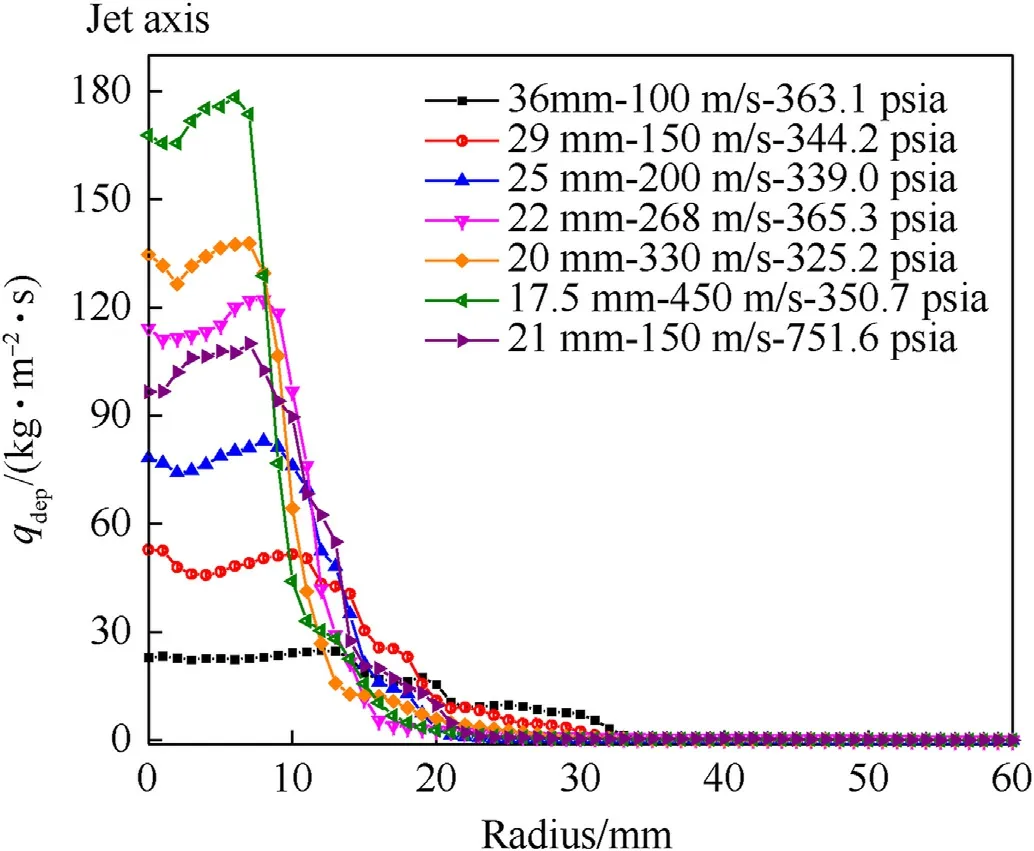

For a quantitative analysis of the ablation of the test sample in relation to alumina deposition,a local distribution of the droplet deposition mass flux,qdep,on the sample is required for each jet velocity.However,the raw deposition mass flux showed vibratory behavior owing to the discrete nature of the Euler-Lagrange approach based on finite streams of particles.Therefore,a radial distribution ofqdepfor eachVjetwas obtained by averaging a radial strip with a width of 1 mm for each radius (i.e.,the value atr=2.0 mm was average of values from 1.5 to 2.5 mm) for a smoother distribution,and shown in Fig.6.For a lowVjet(e.g.,100 m/s),droplets are spread out over a large area that extends to a radius of 30 mm owing to the largeDjetand low momentum of the droplets.However,the jet is concentrated at the center,andqdepincreases rapidly whenVjetincreases.For everyVjet,the size of the plateau in theqdepdistribution is larger than 0.8Djet,and this is the main area of interest for this research.For validation purposes,the mass of deposited alumina on the copper sample of test #15 was calculated by integratingqdepover the entire sample surface and multiplying it byteffof test#15.The predicted mass of alumina was 12.4 g,which is in good agreement with the experimental result of 12.6 g gathered from the surface of the copper sample after test#15.

Fig.6.Radial distribution of droplet deposition mass flux with different jet velocity and pressure.

2.3.3.Wall jet speed and shear stress

In this work,the velocity of the deposited alumina film on the sample surface is one of the key parameters,as it affects the residence time of the film and the Al2O3-C reactions.In a two-phase flow simulation,the velocity of the liquid film on a sample surface can be obtained as part of the Stanton-Rutland wall film model.However,the film model was not calibrated for a high-temperature alumina film in an SRM,especially considering the thermal--chemical interactions between the film and surface.In this study,the average wall shear stress exerted by the gas flow on a certain area were used instead of the speed of the wall film itself to characterize the film behavior.This was based on the assumption that the radial film movement on the surface is solely driven by the shear stress from the flow over the film.

Because the wall jet is generated by the flow turning at the stagnation point,the shear stress of the jet is zero at the jet axis.It then increases with a radius to the outer section owing to acceleration and thinning of the wall jet.Although the velocity of the incoming jet and developing wall jet are determined by the jet geometry and gas properties,the wall shear stress can become different even for tests with sameVjetdue to the variation of the flow density and Reynolds number resulting from different pressure.Therefore,wall shear stress for each test were directly calculated from the simulation with correspondingPeff.And the average velocity of the wall jet was taken at the surface 0.5 mm away from the thickest point of the boundary layer as a supplementary value to characterize the film movement.

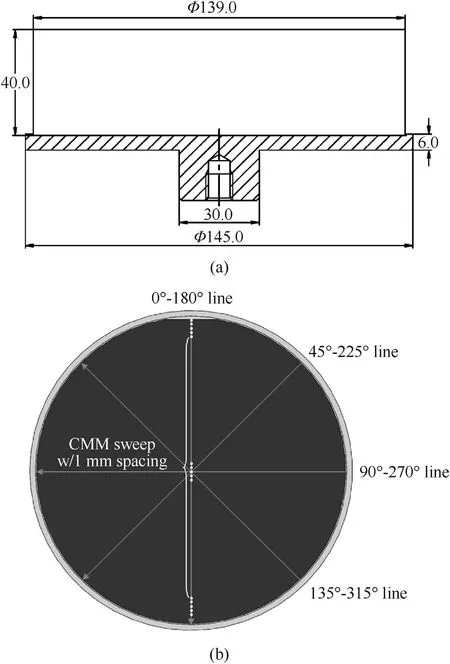

2.4. Test sample and measurement of ablation

Fourteen cylindrical test samples made of Kevlar fiberreinforced EPDM were identically manufactured with a diameter of 139 mm and a height of 40 mm.The composition of the material is the same as that used by Kang et al.[11],which includes 30 phr.of silica sphere and 8 phr.of chopped Kevlar short fiber without directionality.Fire retardant was not present in the material.The initial material was made into a square plate by stacking rubber sheets,and the stacked plate was cured in an autoclave.The cured plate was then machined into a cylindrical test sample.The finished test sample was bonded to a stainless-steel sample holder using Araldite AW 106 adhesive,as shown in Fig.7(a),and fastened to the aft casing of each test SRM using a bolt.For test#15,a copper test sample of the same size as that of the Kevlar/EPDM test sample was clamped to the sample holder using four bolts.Copper was used to maintain the surface temperature of the sample to be as low as possible with its high thermal mass and thermal diffusivity to solidify the alumina film deposited on the sample.

Fig.7.Design of test sample and measurement locations:(a)Design of test sample and sample holder;(b) Lines of CMM measurement sweep on sample surface.

The thickness of each Kevlar/EPDM sample before and after the static fire test was measured on every 45°line with a radial spacing of 1 mm,as shown in Fig.7(b).A hexagonal Croma 686 CMM was used with a measuring error of less than 1.3 μm in the thickness direction.Pre-test measurements showed that the maximum standard deviation of thickness for the 14 samples was 0.15 mm,and the average thickness of the samples was 40.3 mm.After the static fire test,thickness of the char residue was negligible,usually less than 0.2 mm due to a fast ablation rate.Thus,char residue was removed from the sample surface using a steel brush before a measurement to prevent contamination of the measurement probe.The ablation thickness,δabl,was obtained by comparing the measured thicknesses at each point before and after the static fire test.The ablation rate Vablwas derived by dividing δablat each point by the teffof each test.Finally,the volumetric rate of ablation per unit mass of alumina,Qabl,was defined as the division of Vablby qdepat each point to compare the rate of ablation between the cases with different Vjetand qdep.As Vablis related to the speed of char consumption by the Al2O3-C reaction and qdepis related to the supply of alumina mass to the surface,Qablindicates the completeness Al2O3-C reactions on the surface with a moving alumina film.When Qablis multiplied by a density of char layer,it indicates a mass ratio of consumed carbon and alumina and would be around 0.2 for stationary Al2O3-C reaction as reported by Gubertov et al.[28].

3.Results

3.1. Basic characteristics of ablation

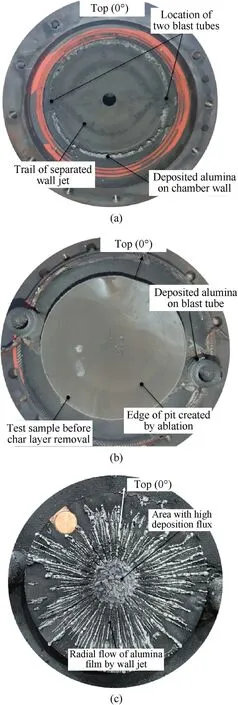

The rear view of the disassembled test SRM after test #5 is shown in Fig.8(a),and the aft casing of the SRM with a test sample and two blast tubes is shown in Fig.8(b).A trail of the separated wall jet that circled around the test sample and discharged through the blast tube is visible at the bottom of the jet nozzle.In particular,the black marks on the bottom of the jet nozzle show a reattachment point of the separated flow where the wall shear is low;thus,smoke particles are not washed away.On the contrary,the alumina film on the sample surface is washed away by the wall jet and alumina residue is found around the sides of the test chamber.At the 90°and 270°sections of the chamber where the blast tubes are located,the sediment is found at the side of the blast tube instead of the chamber because the wall jet impinges on the blast tube at these sections.In addition,there is hardly any alumina deposited inside the blast tubes and nozzles owing to flow turning at the entrance of the blast tubes,as intended by the SRM design.

Fig.8.Condition of the test SRM and test sample after static fire test: (a) Bottom side of the jet nozzle after test#5(Vjet=200 m/s);(b)Aft-casing and test sample after test #5 (Vjet=200 m/s);(c) Deposited alumina film on the copper test sample after test#15 (Vjet=100 m/s).

The ablation of the K/EPDM sample can be more clearly understood by referring to the shape of the alumina film deposited on the copper sample.As shown in Fig.8(c),the alumina droplets from the incoming jet are mainly deposited at the center of the test sample.The flow of the deposited film in the radial direction induced by the wall jet is clearly visible in the outer region of the sample.More importantly,the region around the jet is fully covered with the alumina film,even in the test with the lowestVjetandqdep,either by direct deposition from the jet or radial flow of the film.Because the sample surface is not exposed to the combustion gas,the chemical and mechanical ablation of the K/EPDM sample by the gas flow can be neglected.Thus,the ablation of the sample shown as a pit at the center of the sample in Fig.8(b) can be solely attributed to alumina-induced ablation.A small amount of alumina is visible at the center of the test sample,as most of the alumina film is either consumed by the Al2O3-C reaction or washed away by the wall jet.Further,almost no char layer is left on the surface owing to fierce ablation.

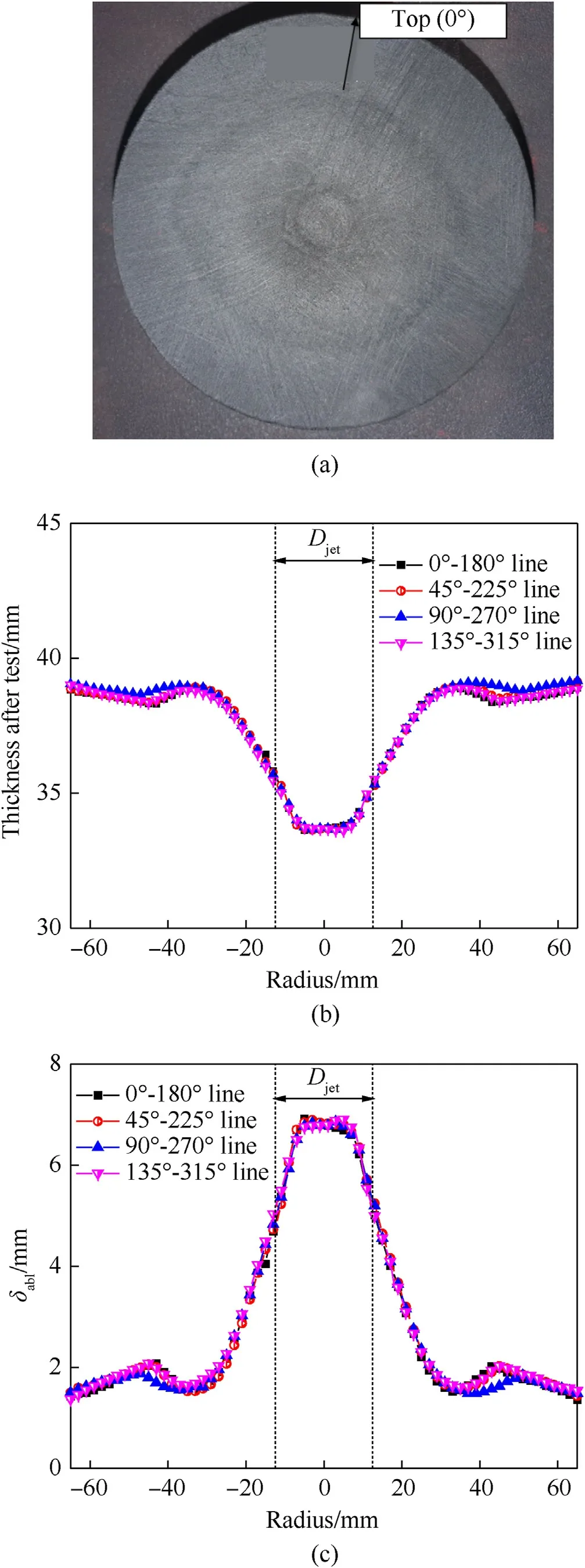

Fig.9 shows a test sample after removing the char layer and the measured residual and ablation thicknesses for test #5.Before measurement by CMM,the surface of the sample was brushed to a decomposition zone that is noticeable by the gluey melted silica in this layer.This was done to reduce the contamination of a CMM probe during measurement and the difference in the measured thickness due to a char layer is negligible (less than 0.2 mm compared to a measured ablation thickness of approximately 6.8 mm for test#5).The measured sample shape showed a flat area at the center within a radius of approximately 6 mm.Then,the residual thickness increases linearly with the radius to a point of approximately 30 mm.At this point,the shear stress of the wall jet reaches its maximum and then starts to decrease.Therefore,the residual thickness after that point slightly decreases owing to the increased residence time of the alumina film,along with a drop in the wall jet shear stress.

Fig.9.Sample shape after removal of char layer and distribution of residual/ablation thickness after test#5(Vjet=200 m/s):(a)Test sample after removal of char layer;(b) Measured sample thickness on CMM sweep lines after test;(c) Measured ablation thickness on CMM sweep lines.

As shown in Fig.9(c),the maximum δablof test #5 is 6.92 mm near the center of the jet.The average δablvalue of the flat surface with a diameter of 12 mm was 6.81 mm and the standard deviation of δablin this region is only 0.06 mm.δabllinearly drops away from this region and becomes 1.5 mm at a radius of 34 mm,and increases slightly to 2.08 mm at a radius of 45 mm in connection with the film movement.The δablat the edge of the test sample is approximately 1.5 mm.

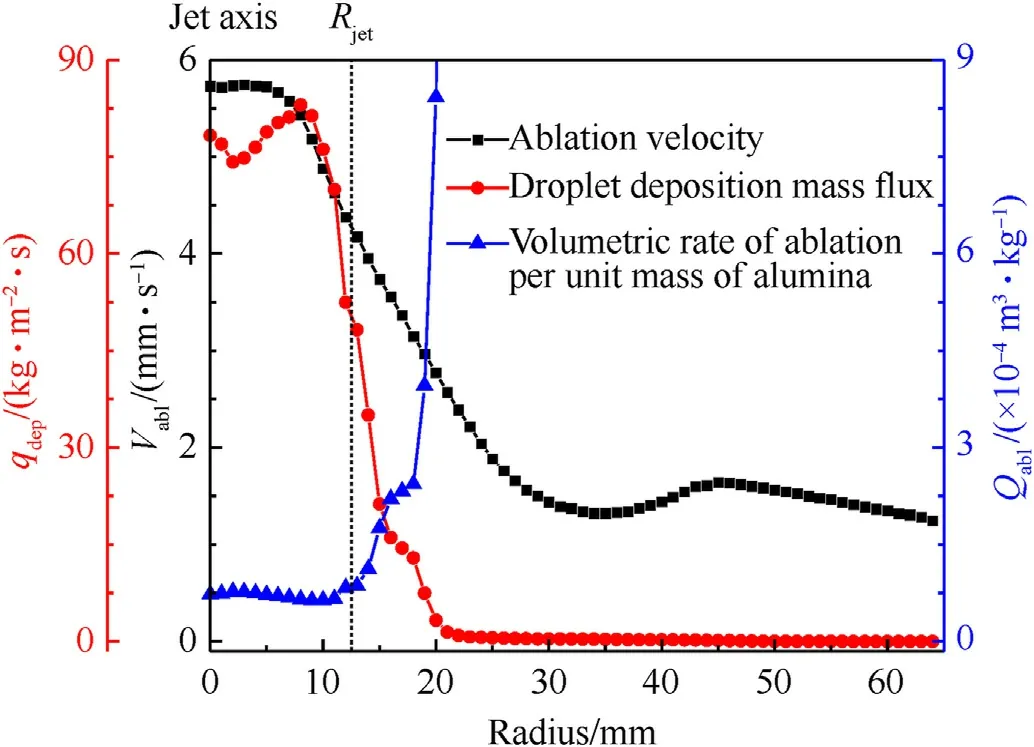

Fig.10 shows the radial distributions of ablation rate,droplet deposition mass flux,and volumetric rate of ablation per unit mass of alumina for test#5.Vablwithin 6 mm radius is almost flat with an average value of 5.72 mm/s,and it is significantly higher than the maximum ablation rate around 1.0 mm/s reported in previous works [23,26,31].From the measured chemical kinetics of the reaction[31],a reactant conversion(from 0 to 1),a,can be expressed with first-order reaction model and Arrhenius equation with preexponential factor,A=5.8×109min-1,and activation energy,Ea439.5 kJ/mol,as equation below.

Fig.10.Distribution of ablation rate,droplet deposition mass flux and volumetric rate of ablation per unit mass of alumina for test #5 (Vjet=200 m/s).

wheretis time in min,Ris 8.314 J/mol·K andTis absolute temperature.Time required for a conversion of 90% of reactant are calculated as 298.5 s at 2000°C and 19.5 s at 2300°C.And it corresponds to the ablation rate of 0.52 mm/s and 8.03 mm/s,respectively.Therefore,the reason for the higher reaction rate is the active Al2O3-C reaction on the surface with a continuous supply of high-temperature alumina into the deposited film in this research.

qdepdeduced from the simulation varies from 74.2 to 83.0 kg/m2s on a plateau area within 9 mm radius and sharply drops to nearly zero at a radius of 22 mm.As the rate of the reaction decreases by a faster wall jet,lowerqdepand temperature drop of film caused by the endothermic heat at the outer region,Vabldecreases to 1.32 mm/s at a radius of 34 mm.At this point,almost no alumina droplets are deposited from the incoming jet,and the alumina reacting with the char layer is provided by a radial flow of the film.

As a factor considering both the deposition and reaction of alumina,Qablis 7.32×10-5m3/kg at the center of the jet,and the deviation is only 6.6% in the region withinDjet.Notably,the area with uniformQablis larger than that with uniformVabl.In this region,the incoming alumina mass and removal of intermediate species of the reaction by the film movement are balanced,and the rate of the Al2O3-C reaction is maintained even with a decreasingqdepat the edge of the jet.Outside ofDjet,Qablrapidly increases to 8.42×10-4m3/kg at a radius of 20 mm.However,Qablin this region does not have a physical meaning because most of the reacting alumina is supplied by the radial flow of the film.In this region,the mass flow rate of the alumina film in the radial direction should be used forQablinstead ofqdep.However,a model of the thermal and chemical interactions between the char layer and alumina film is required,which is extremely complex and currently not available.Therefore,the ablation of samples with different wall jet shear stress was analyzed only in the region withinDjet,where the definition ofQablwithqdepis valid.

3.2. Effect of film movement

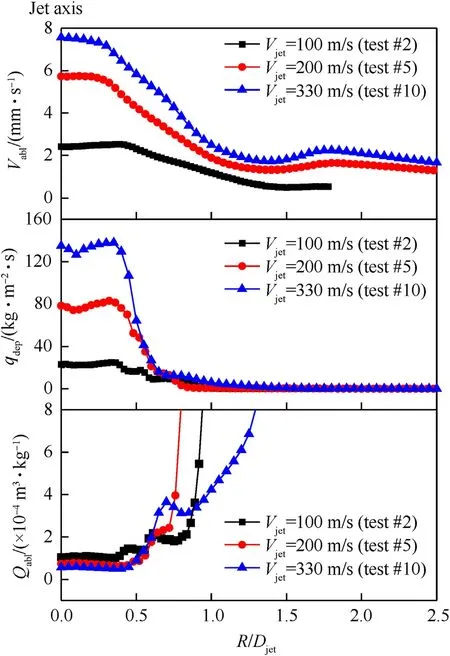

Fig.11 shows the radial distributions of ablation rate,droplet deposition mass flux,and volumetric rate of ablation per unit mass of alumina with different jet velocities.In order to compare the results with different jet sizes,each distribution is illustrated withR/Djet,normalized radius withDjetof each test.First,Vablat the center of the jet changes from 2.41 to 7.57 mm/s whenVjetincreases from 100 to 330 m/s.The area with uniformVablextends toR/Djetaround 0.4 forVjet=100 m/s,and reduces slightly with increasingVjet.Like the increase inVablwithVjet,qdepat the center also increases rapidly,from 23.0 to 134.8 kg/m2·s,as the jet is concentrated on a smallerDjet.The plateaus ofqdepfor differentVjetvalues have a similar size compared toDjetof each case-around 0.8Djetfor all cases.The averageqdepvalues in this area are 23.3 kg/m2·s,78.3 kg/m2·s,and 133.4 kg/m2·s,respectively.Further,maximum deviation ofqdepwithin this area is 3.7% for test #2.Normalized distributions ofVablandqdepfor differentVjetsuggest that a similarity of the jet structure is maintained in each test,as intended in the design of the test SRM.

Fig.11.Distribution of ablation rate,droplet deposition mass flux and volumetric rate of ablation per unit mass of alumina with different Vjet.

Although bothVablandqdepincrease withVjet,Qablthat related to a completeness of Al2O3-C reaction of incoming alumina mass exhibits a different trend.As shown in the lowest part of Fig.11,Qablat the jet axis is 1.05×10-4m3/kg forVjet=100 m/s and decreases to 0.56×10-4m3/kg forVjet=330 m/s.If we assumed that the ablation is mainly caused by the mechanical erosion from the particle,the ablation rate divided by the incoming particle mass flux,Qablshould increase with the impact velocity,as the higher momentum of the particle induce more deformation and fracture of the char layer based on the Hertzian theory of impact [52-55].Therefore,it is likely to be caused by a reduced residence time of the film and incompleteness of the Al2O3-C reactions,as stated in this research.To determine the relationship betweenQabland the residence time of the film,a region within 0.8Djet,whereQablis uniform for all cases,was chosen for further analysis.The values averaged in this region areVabl,avg,qdep,avg,Qabl,avg,τwall,avg,and Wwalljet,avgwhere each denotes the average ablation rate,average droplet deposition mass flux,average volumetric rate of ablation per unit mass of alumina,average wall shear stress and average wall jet velocity,respectively.

Table 4 summarizesVabl,avg,qdep,avg,Qabl,avg,τwall,avg,and Wwall-jet,avgfor every test conducted with the Kevlar/EPDM sample.Because Peffrelated to the total mass flow rate through the test SRM is varied intentionally by the amount of propellant or unintentionally by the longer tail-off pressure,qdep,avgalso varied from test to test,even for the tests with same Vjet.The largest variation of qdep,avgis 21.7% between tests #1 and #2 with Vjetof 100 m/s.Similar variation was also observed in τwall,avgas it was affected by the Reynolds number.On the contrary,Wwalljet,avgof the 0.8Djetarea barely changes when Vjetis the same because Vjetand the velocity around the jet nozzle are mainly determined by the geometric ratio Djet/Dnoz,effand exhaust gas properties.As a result,two tests for each Vjetwere performed with different qdep,avg,τwall,avgand similar Wwalljet,avg.For test#13 and#14,Wwalljet,avgand momentum of the incoming droplet were similar to those of test#3 and#4 with same Vjet,although τwall,avgof these tests were higher than those of test with Vjetof 268 m/s at 2.5 MPa due to higher pressure.

Table 4 Summary of test results of alumina induced ablation.

By comparing the results from test #1 to test #12,the effect of the wall jet velocity increase from 30.5 to 136.0 m/s can be observed.It is important to note that a variation inQabl,avgfor sameVjetis less than 5.1% whenVjetis below 200 m/s.However,the scatter ofQabl,avgincreases with the scatter of τwall,avgat a higher Vjet.Maximum variation of Qabl,avgis 43.2% between tests #9 and#10 with Vjetof 330 m/s.The reason for this is the large change in the jet geometry during test #9,especially Hjet/Djet,caused by the long exposure to high qdep,avg.In fact,δablin test #9 is larger than 20 mm and Hjet/Djetis increased from 0.9 to 1.97 for this case.This change alters the actual value of qdep,avgand τwall,avgin the test SRM over time and cannot be predicted by the simulation.The increase in the variation of Qabl,avgcan also be explained by this phenomenon,which is the reason why the target test duration is shorter for a test with a higher Vjet.Except for a large scatter in test #9,Qabl,avgdecreased constantly from 1.07×10-4to 0.49×10-4m3/kg with increasing Wwalljet,avgfrom 30.5 to 136.0 m/s.

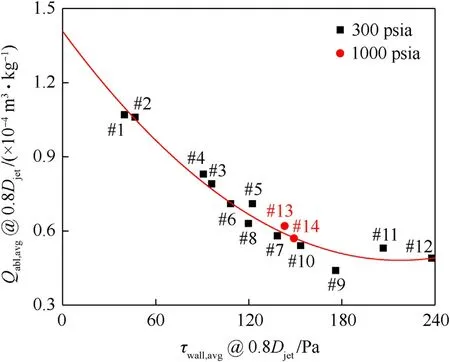

However,Qabl,avgof test #13 and #14 with higherPeffare significantly lower than the value of test#3 and#4 with similarVjetandWwalljet,avg.Instead,they are comparable with the value of test#7 and#8 with similar τwall,avg.A scatter plot of the average Qabl,avgand τwall,avgshown in Fig.12 confirms that τwall,avgis the major factor related to the film movement and resulting change of Al2O3-C reactions.And it also indicates that the momentum of the incoming droplet is not the main factor of the ablation in this study.As shown in Fig.12,Qabl,avgdecreases with increasing τwall,avgand converges to a certain value at higher τwall,avgas the slope decreases.A polynomial curve fit shows good agreement with the experimental results including test #13,#14 and converges to a Qabl,avgvalue around 0.49×10-4m3/kg.And This convergence of Qabl,avgcan be explained by the intermediate reactions involved in the Al2O3-C reaction.

Fig.12.Change in averaged volumetric rate of ablation per unit mass of alumina with averaged shear stress on 0.8Djet area.

Guan et al.[26]compared three reactions between Al2O3and C,which generate pure Al,Al2OC,and Al4C3,respectively.The reaction that produces Al4C3was speculated to be the fastest under SRM conditions because it had the lowest Gibbs free energy at an elevated temperature.From this point of view,Qabl,avgin this study can be understood as a combined effect of fast and slow reactions between Al2O3and C.Because a fast reaction has a much smaller characteristic reaction time,the reduction in residence time due to the movement of the film would have a more pronounced effect on slow reactions.A drop in the reaction rate only for slow reactions would yield a decayingQabl,avgwith increasing τwall,avg.However,further research is needed to truly correlate the species,momentum and energy conservations of the film with the heterogeneous Al2O3-C reaction.At the current stage,deduced relationship between Qabl,avgand τwall,avgcan be used to predict the ablation rate in the area where a liquid alumina formed with incoming droplet mass flux,qdep,is under movement by the shear stress τwall,avglike aft dome of the rocket motor and inlet section of the nozzle.

4.Conclusions

In the present study,the alumina film-induced ablation of Kevlar/EPDM with different lateral film speeds was investigated in a test SRM with an impinging jet configuration.Unlike previous studies,a jet with a high alumina droplet flux was located close to the sample to ensure the formation of an alumina film on the surface and encourage the lateral movement of the film by a strong wall jet.The lateral speed of the deposited alumina film was governed by the velocity of the wall jet and was indirectly changed using six different design jet velocities (Vjet=100 m/s,150 m/s,200 m/s,268 m/s,330 m/s,and 450 m/s).Fifteen static fire tests were conducted,including one with a copper sample,to visualize the alumina film.A two-phase flow simulation was used to analyze the conditions on the sample surface.

The ablation rate was considerably higher than the previously reported value due to a continuous supply of high temperature alumina to the surface by the jet.The ablation rate increased with the jet velocity,as a smaller jet diameter resulted in an increased droplet deposition mass flux.However,Qabl,avgthat indicates fraction of Al2O3reacted with char layer initially decreased with increasing average wall shear stress (τwall,avg) and converged at a higher τwall,avg.This phenomenon indicates that the consumption of alumina in Al2O3-C reactions became less efficient at higher τwall,avgbecause of the reduced residence time of the film.The influence of the residence time was found to be more pronounced for slow reactions among the several intermediate reactions involved in the Al2O3-C reactions.In addition,the fast reactions were less affected by the residence time,resulting in the convergence of Qabl,avgwith τwall,avg.We expect the result from this research will contribute to extend the knowledge of the reaction mechanism between alumina and carbonaceous char layer and it will become further useful with further analysis of species/momentum/energy of the alumina film.At the moment,the relationship between Qabl,avgand τwall,avgobtained from the test SRM can be directly used for full-scale SRMs to predict the ablation of an insulator exposed to a droplet deposition and high-speed lateral flow (i.e.,at the aftcylinder or aft dome of a case).The alumina-induced ablation on a submerged nozzle can also be predicted from the experimental results if the difference in the carbonaceous char density between different materials is properly considered.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

杂志排行

Defence Technology的其它文章

- Investigation on the ballistic performance of the aluminum matrix composite armor with ceramic balls reinforcement under high velocity impact

- Dynamic analysis of buried pipeline with and without barrier system subjected to underground detonation

- Influence of liquid bridge force on physical stability during fuel storage and transportation

- Adaptive fuze-warhead coordination method based on BP artificial neural network

- Cooperative multi-target hunting by unmanned surface vehicles based on multi-agent reinforcement learning

- High-Velocity Projectile Impact Behaviour of Friction Stir Welded AA7075 Thick Plates