非平衡磁控溅射CrTiAlN涂层的制备及空蚀性能研究

2023-11-06刘铭悦黄志全张习羽AnnZammitJosephBuhagiarGlennCassar王建明陈坚

刘铭悦,黄志全,张习羽,Ann Zammit,Joseph Buhagiar,Glenn Cassar,王建明,陈坚*

非平衡磁控溅射CrTiAlN涂层的制备及空蚀性能研究

刘铭悦1,黄志全1,张习羽1,Ann Zammit2,Joseph Buhagiar2,Glenn Cassar2,王建明1,陈坚1*

(1.东南大学 材料科学与工程学院,南京 211189;2.Department of Metallurgy and Materials Engineering, University of Malta, Msida 2080, Malta)

为缓解动力系统金属表面发生的空泡失效问题,提高水下装备推进系统在复杂多变环境中的综合服役性能,将涂层技术用于金属材料的表面防护。基于正交实验设计,采用非平衡磁控溅射技术在AISI 316不锈钢基体上制备CrTiAlN涂层。采用XRD、SEM、EDS和AFM等测试手段对涂层的物相、形貌、成分和表面粗糙度进行表征;采用维氏硬度计、划痕仪和洛氏硬度计对涂层的显微硬度和膜基结合力进行测试与评估;通过球–盘磨损实验、电化学测试和空蚀实验,分别评价涂层的耐干摩擦磨损、耐腐蚀和抗空蚀性能。实验结果表明,利用正交试验设计调控Cr、Ti和Al靶电流,基于涂层硬度得到最佳靶电流分别为4、8、8 A,此时涂层显微硬度达到1 242HV0.01,纳米硬度为(17.00±0.99) GPa,远高于316不锈钢;涂层的摩擦因数和磨损率远低于316不锈钢;在质量分数为3.5%的NaCl溶液中,涂层的腐蚀电位较高,腐蚀电流较小,具有较好的耐腐蚀性能,采用涂层保护后316不锈钢的寿命得到显著提高;在空蚀实验后,316不锈钢的粗糙度从4.5 nm增至112.0 nm,并出现空蚀坑,而CrTiAlN涂层只出现了褶皱,其粗糙度从4.8 nm增至10.0 nm,仅在涂层缺陷处发生了零星剥落现象。可见,CrTiAlN涂层有效缓解了空蚀的冲击作用,提高了316不锈钢的抗空蚀性能。可将CrTiAlN涂层作为防护涂层,并应用于水利工程装备关键部件。

磁控溅射;CrTiAlN涂层;摩擦磨损;腐蚀;空蚀

空蚀是普遍发生在水下运动材料表面的一种破坏现象,如水下动力系统螺旋桨叶片表面。空蚀是由高速流动液体中夹杂的微小气泡产生的冲击所致[1]。由于气泡的压力可达到200~1 000 MPa[2],因此会缩短材料的使用寿命。目前,制备无人水下航行器(Unmanned Underwater Vehicle)的材料多采用316不锈钢、TC4钛合金和铝合金等,以Tecnadyne公司生产的商用UUV为例,其螺旋桨的直径约为100~500 mm,产生的推力最高可达到11 N,急速水流产生的空泡会对螺旋桨表面产生巨大的冲击力。随着舰船、无人水下航行器等水下装备不断向远程和智能化方向的发展,它面临的水文环境也越来越复杂,这对材料的抗空蚀性能提出了更高的要求[3]。

为了减小空蚀的危害,当前主要采用优化机械设计、研发新材料和应用表面工程技术等方案[4],其中采用表面工程技术具有经济、性能提升效果显著等特点,已成为最广泛的选择[5-9]。Man等[6]利用激光合金化在铝合金表面制备了陶瓷相增强的金属基复合材料,使其抗空蚀性能提高了3~4倍。Huang等[7]在S48C钢表面渗氮,增加了表面硬度,降低了材料在淡水中的空化率和质量损失。Liu等[8]利用热喷涂技术制备的WC-10Co4Cr涂层也表现出良好的抗冲蚀性能。近年来,研究者利用气相沉积技术提高了材料的抗空蚀性能,延长了零件的服役寿命[10-12]。其中,磁控溅射法作为常用的物理气相沉积技术之一,所制备涂层均匀致密、缺陷少、结合强度高[13],而且具有易于控制和无环境污染等优势,得到了越来越多的关注。

CrTiAlN涂层是一种典型的以CrN为基础的四元体系涂层,具有较高的硬度(30~38 GPa),表现出良好的抗磨损性和耐腐蚀性能[14-16]。其中,Cr元素起着提高涂层硬度和抗氧化性等作用[17],少量的Ti元素可改善涂层的力学性能和耐磨性[18],同时添加Al元素可降低涂层的摩擦因数[19]。Wang等[20]采用非平衡磁控溅射法在Si片基体上制备了CrTiAlN涂层,其力学性能和抗裂性明显优于CrN、CrTiN、CrAlN涂层。Fernandes等[17]研究了WC片基体上的TiAlCrN涂层在实际钻井试验中的高温摩擦学性能和切削性能,在室温和650 ℃高温下TiAlCrN涂层均具有较低的磨损率,且有效延长了钻头的切削性能。Fuentes等[21]利用阴极电弧沉积法在H13钢上制备了CrTiAlN涂层,通过研究涂层的金属元素原子比和硬度,探讨了涂层的强化机理。目前针对CrTiAlN涂层的研究主要集中于切削、高温等应用领域,对它在水下环境中的抗空蚀性能研究较匮乏。

本文首次报道了CrTiAlN涂层的抗空蚀性能,采用非平衡磁控溅射法在316不锈钢和Si片基体上制备CrTiAlN涂层,利用Cr、Ti和Al 3种元素的电流进行正交试验设计,根据涂层的硬度对工艺参数进行优化,评价了优化后涂层试样的摩擦磨损性能、耐腐蚀性能和抗空蚀性能,并对其空蚀失效机制进行探讨。

1 实验

1.1 涂层制备

实验采用英国Teer公司生产的UDP800闭合磁场非平衡磁控溅射离子镀膜设备在316不锈钢(20 mm× 30 mm×2 mm)和Si片上制备CrTiAlN涂层,使用2个Cr靶(纯度为99.99%)、1个Ti靶(纯度为99.99%)和1个Al靶(纯度为99.99%)。在实验前,将基体放入无水乙醇中超声清洗15 min,然后烘干后放入腔体内,抽至真空度为4×10–6MPa后开始镀膜。在沉积过程中,靶基距为11.5 cm,氩气流量(sccm)为40 cm3/min,氮气流量由OEM(Optical emission monitor)控制,试样架的转速为4 r/min。沉积工艺:首先在−400 V高偏压下对样品表面进行离子清洗,然后保持偏压为−70 V,沉积5 min的Cr打底层,然后通过OEM逐步增加N2流量,制备CrN过渡层,最后OEM参数值为65%,稳定沉积90 min的CrTiAlN层。

1.2 材料表征

采用德国Bruker公司的X射线衍射仪(D8 Discover型)分析CrTiAlN涂层的物相结构,采用Cu Kα(λ= 1.541 8),测试电压为40 kV,电流为30 mA,扫描角度2为10º~90º,扫描速度为0.15 (º)/min。采用场发射扫描电子显微镜(Sirion)和其附带的能谱仪分析样品的形貌和成分。采用球坑仪测量涂层的膜厚。利用载荷10 g的显微维氏硬度计测定涂层的硬度。采用装有Berkovich压头的纳米压痕仪(Micro Materials)测试样品的硬度,控制压入的最大深度为200 nm,每个样品重复测量6个点。采用洛氏硬度计并结合光学显微镜评价涂层的结合力。

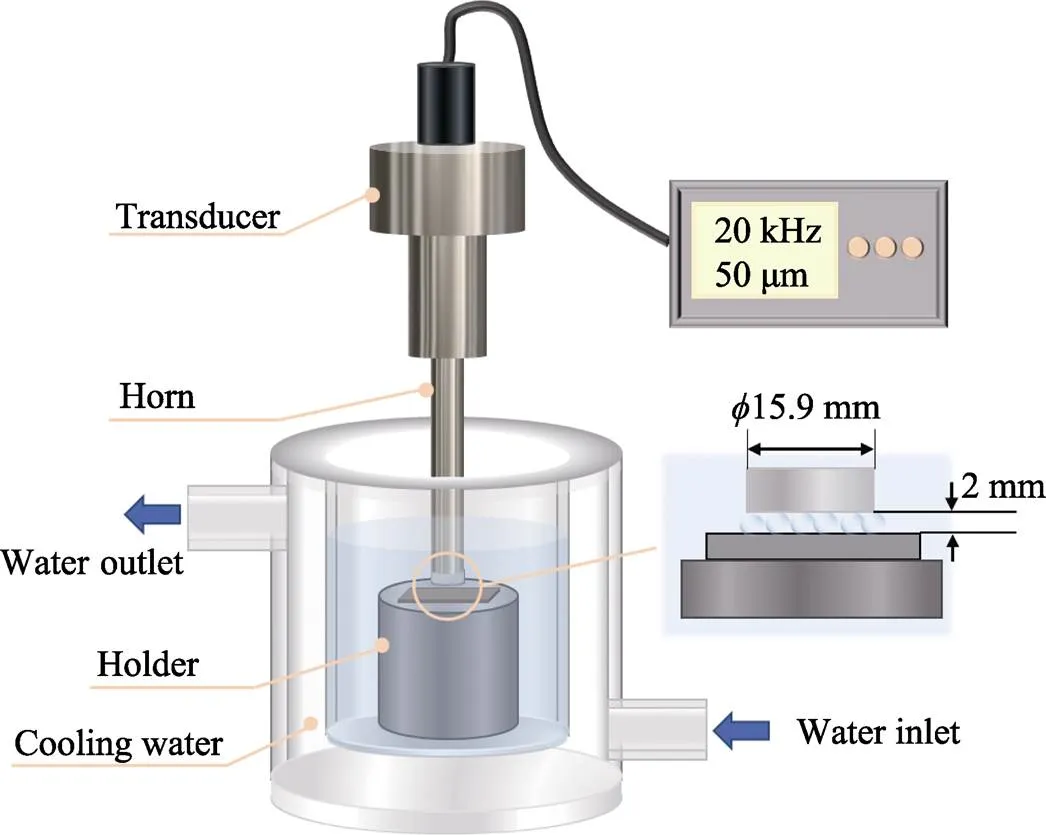

采用电化学工作站(chi660e)测定涂层的电化学性能。涂层摩擦磨损试验采用球–盘摩擦磨损试验机,摩擦副为WC球,直径为6.35 mm,测试时间为1 800 s,温度为25 ℃(室温),采用10 N的恒定负载和38 r/min的转速,并连续记录测试过程中的摩擦因数。采用轮廓仪(DEKTAK 150)和扫描电镜分析获得涂层的磨痕深度和形貌。采用振动空蚀实验装置(ASTM G32-10)测定涂层的抗空蚀性能。与其他空蚀实验装置相比,振动空蚀实验装置具有设计简单、便于快速操作等特点,它是测试与评价材料抗空蚀性能的首选方法[22]。将(20±0.5)kHz的超声传感器安装在变幅杆上,高频振动的液体会产生空泡,作用在距变幅杆下端2 mm的试样表面,振幅为(50±2.5)μm,实验装置如图1所示[8,11,23]。空蚀试验在20 ℃(室温)下进行,采用去离子水溶液,每隔10 min对试样进行称量和光镜观察,并采用AFM原子力显微镜(Dimension ICON)测试空蚀前后的表面粗糙度。

图1 空蚀实验装置示意图

2 结果与讨论

2.1 正交参数设计与分析

首先通过调研确定了3种靶材的常用电流范围,Cr靶电流取值为4、5、6 A,Ti靶和Al靶电流取值为6、7、8 A,然后采用正交实验方法进行系统优化[15,20,24]。在此基础上,根据涂层的显微硬度结果进一步优化工艺参数[25-26]。

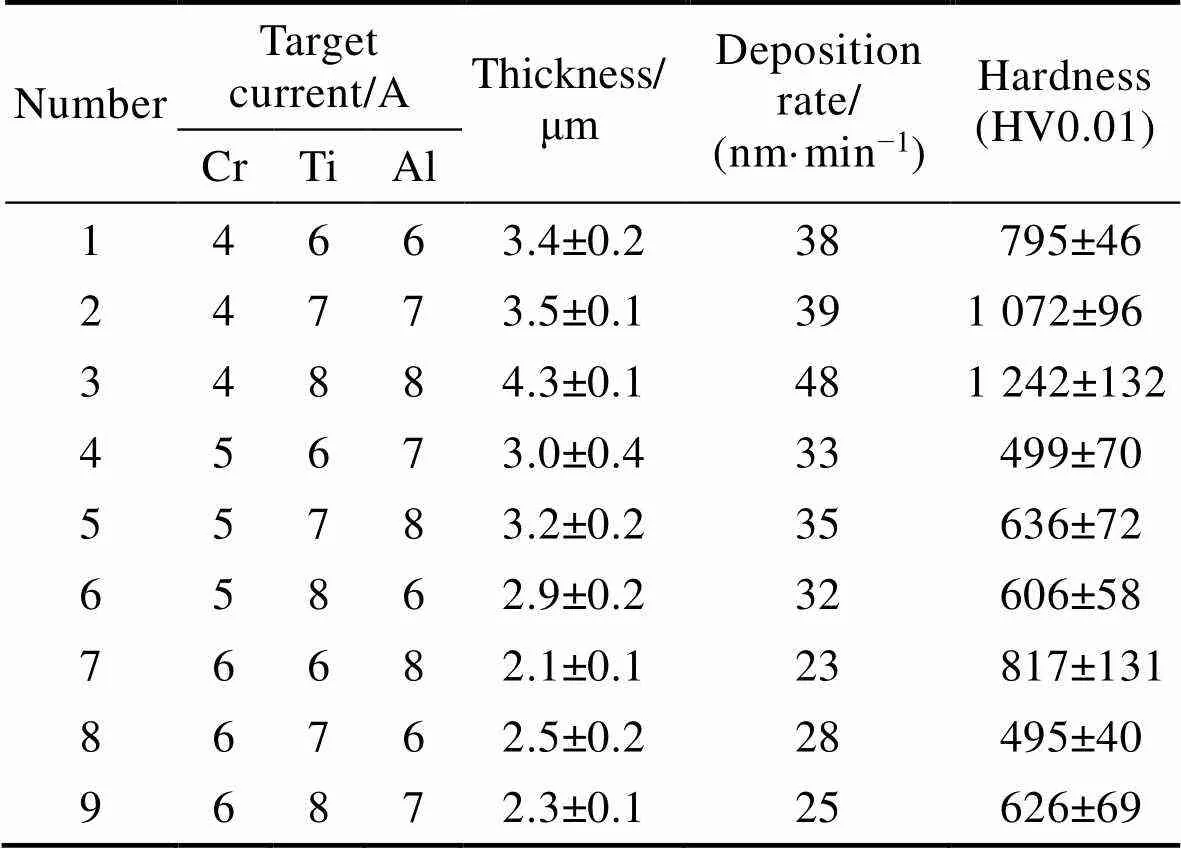

9组CrTiAlN涂层的膜厚、沉积速率和显微硬度结果如表1所示。总体而言,涂层的厚度随着靶电流的增加呈现上升趋势。在反应溅射时,由于N原子会对靶表面造成污染,常称为“靶中毒”,导致沉积速率下降。在每次实验前,均会对靶表面进行打磨处理,防止表面的杂质影响涂层的沉积。由于实验过程中无法避免地会出现一定程度的“中毒”现象,且Cr、Ti、Al靶表面的“靶中毒”行为不一致,因此靶电流与厚度之间形成了复杂的关系。当Cr、Ti和Al靶电流分别为4、8、8 A时,涂层的厚度达到最大值(4.33 μm),对应的沉积速率为48 nm/min,并且此时涂层的显微硬度也达到了最大值(1 242HV0.01)。这是由于压入形变区域尺寸超过了涂层的厚度,硬度结果能够反映膜基体系的综合力学性能,因此膜厚对硬度起到了重要作用。为了避免基体和厚度对涂层的硬度产生影响,依次对316不锈钢及Cr、Ti、Al靶电流分别为4、8、8 A的涂层进行了纳米压痕测试,316不锈钢的硬度为(5.08±0.22)GPa,CrTiAlN涂层的硬度为(17.00±0.99)GPa,可见CrTiAlN涂层的硬度远大于316不锈钢的硬度。与文献[14-16]相比,此次实验制备的CrTiAlN涂层的硬度较低的原因可能是涂层以非晶态存在。

表1 正交实验9组试样的CrTiAlN膜厚、沉积速率和显微硬度

Tab.1 Thickness, deposition rate and microhardness of CrTiAlN coatings for 9 groups of samples in orthogonal test

依据涂层的硬度进行正交设计极差分析,计算同一水平各因素下涂层硬度的平均值,结果如图2所示。因为涂层硬度的提高可以有效改善材料的抗空蚀性能[27-29],所以根据正交实验结果,确定了硬度最高的涂层实验参数:Cr靶4 A、Ti靶8 A、Al靶8 A,并对采用此实验参数制备的涂层进行性能的综合评价。

2.2 形貌、成分与物相分析

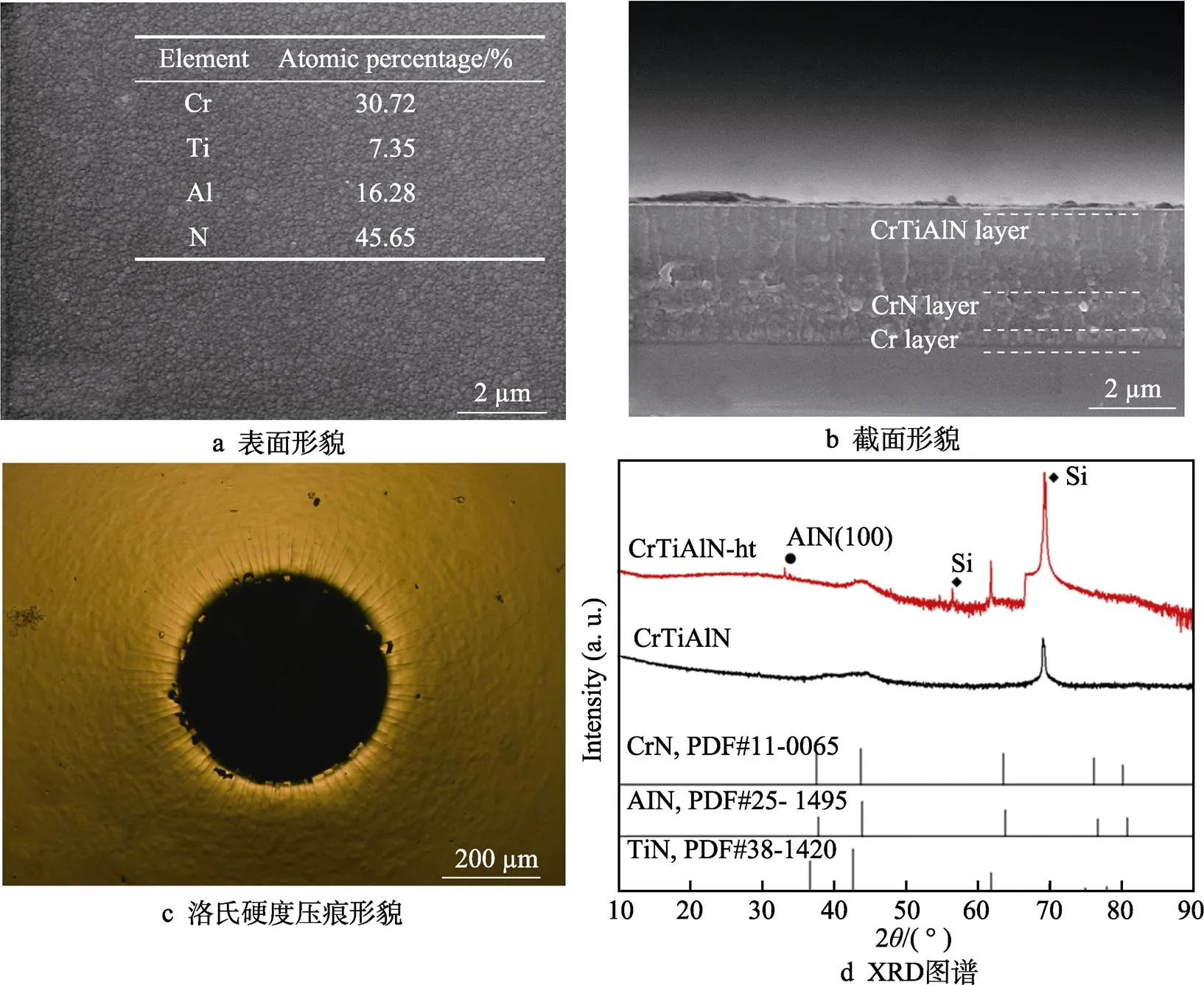

CrTiAlN涂层的表面形貌如图3a所示,涂层表面存在密集的圆状颗粒,且颗粒大小均匀。涂层由Cr(原子数分数为30.72%)、Ti(原子数分数为7.35%)、Al(原子数分数为16.28%)、N(原子数分数为45.65%)组成。涂层的截面形貌如图3b所示,可以观察到, CrTiAlN涂层分为Cr打底层、CrN过渡层和CrTiAlN顶层,且涂层整体未出现明显的空隙和缺陷[30]。CrTiAlN涂层的洛氏硬度压痕形貌如图3c所示,压痕周围出现了明显的径向裂纹和零星剥落现象,根据DIN 4856:2018-02可知涂层的结合强度等级为HF3。涂层的X射线衍射图谱如图3d所示,分别为原始涂层样品和500 ℃热处理后涂层样品的XRD物相结果。原始涂层样品只出现了较为明显的Si片基底的衍射峰,涂层经过热处理后出现了CrN、AlN和TiN的衍射峰,其中CrN的衍射晶面分别为(111)、(200)和(220),AlN的衍射晶面分别为(111)、(200)、(220)和(100),TiN的衍射晶面分别为(200)和(220)。说明因制备温度较低,原始涂层状态为非晶态。未经热处理的涂层表现出较为致密的结构,无空隙和缺陷,且膜基结合力较高,因此采用未处理的涂层试样进行性能评价。

2.3 耐磨损性能

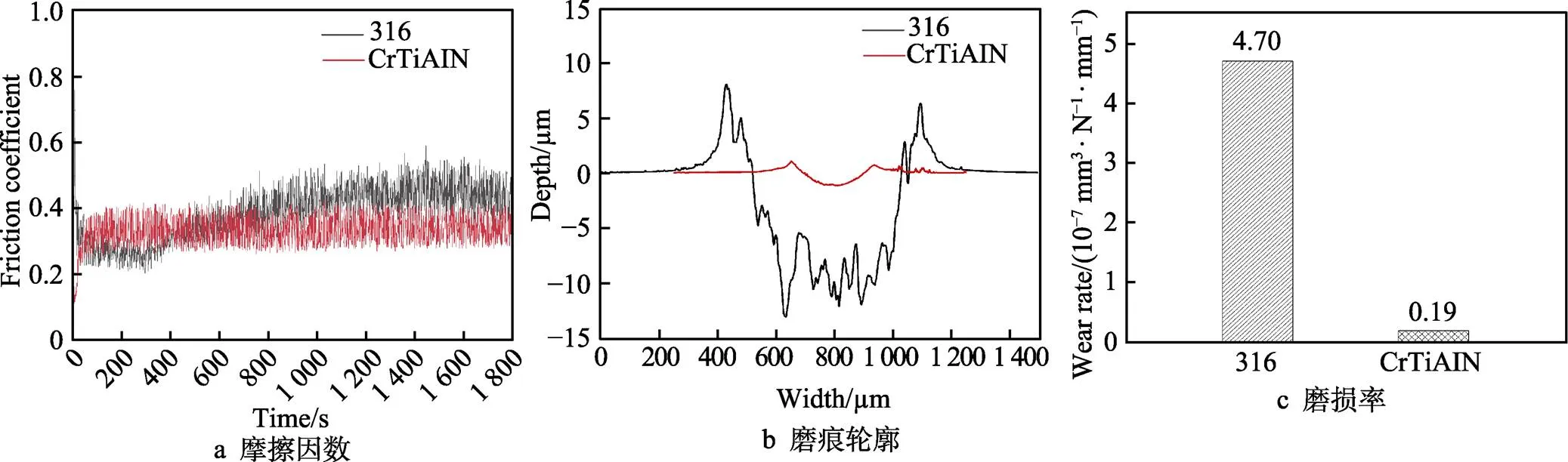

316不锈钢和CrTiAlN涂层试样的摩擦因数变化曲线如图4a所示,可以看出,316不锈钢的摩擦因数随着时间的延长呈现先降低后增加的趋势,CrTiAlN涂层试样的摩擦因数较稳定,二者在稳定阶段的摩擦因数分别为0.45和0.34。316不锈钢和CrTiAlN涂层的磨痕轮廓如图4b所示,反映了2组试样的磨损特性。从图4b中可以看出,CrTiAlN涂层试样的磨痕深度较小,最大深度为1.13 μm,且磨痕宽度较窄(仅为286 μm)。316不锈钢磨痕的最大深度为12.14 μm,磨痕宽度为665 μm。316不锈钢和CrTiAlN涂层的磨损率如图4c所示,分别为4.70×10−7、0.19×10−7mm3/(N·mm),CrTiAlN涂层的磨损率远低于316不锈钢的磨损率,具有优异的耐磨损性能。

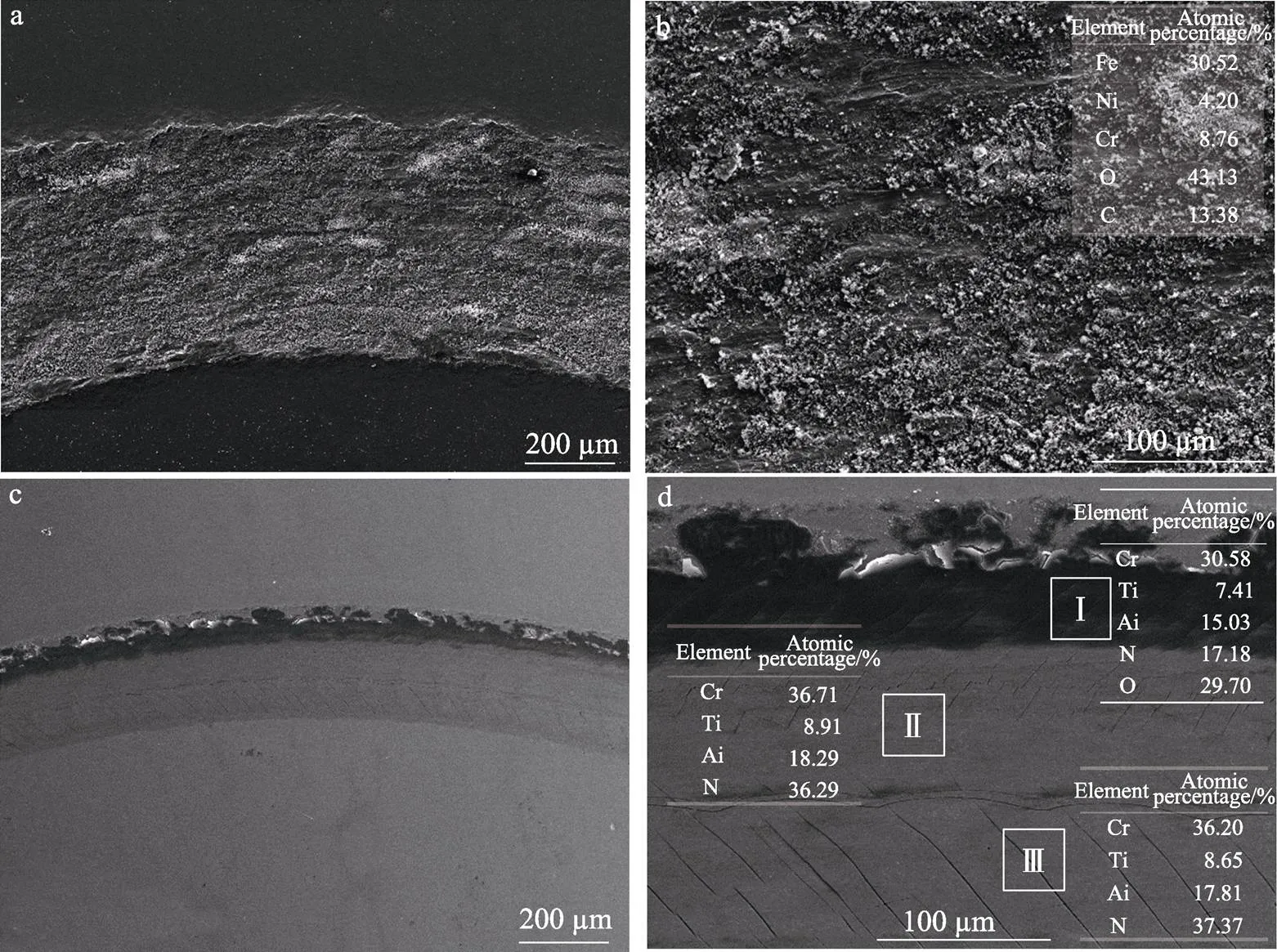

316和CrTiAlN涂层的SEM磨痕形貌及2组试样EDS成分组成结果如图5所示。316不锈钢的磨痕形貌如图5a~b所示,磨痕表面出现了明显的犁沟状形貌,说明316在磨损过程中主要发生了磨粒磨损[31]。此外,316试样的磨痕表面出现了大量的氧元素,其原子数分数达到43.13%,说明存在氧化磨损现象[32]。CrTiAlN涂层的磨痕形貌如图5c~d所示,在磨痕内侧出现了裂纹,为典型的疲劳磨损特征。磨痕外侧有大量磨屑堆积,外侧(Ⅰ)区域的EDS能谱分析显示,除了含有Cr、Ti、Al、N 4种元素外,其表面还发现大量的氧元素(原子数分数为29.70%),说明涂层在摩擦过程中也存在氧化磨损。同时,选取了CrTiAlN涂层磨痕的中间(Ⅱ)和内侧(Ⅲ)2个区域进行EDS能谱分析,从元素组成来看,Cr、Ti、Al和N 4种元素的原子百分比相似,且均未发现Fe元素,说明涂层并未被磨穿。可见,CrTiAlN涂层有效改善了金属材料表面的耐摩擦磨损性能。

图2 正交设计极差分析结果

图3 CrTiAlN涂层

图4 316不锈钢和CrTiAlN涂层的耐磨损性

2.4 耐腐蚀性能

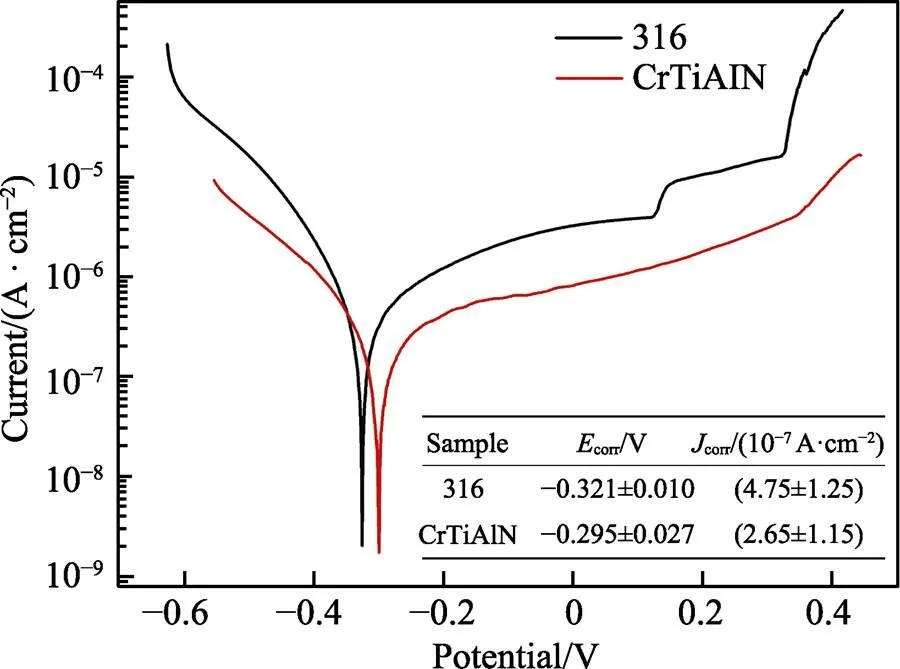

在室温条件下,在质量分数为3.5%的NaCl溶液中,通过极化曲线研究了316不锈钢基体表面沉积的CrTiAlN涂层的耐腐蚀性能,如图6所示。电化学实验采用三电极体系,以饱和甘汞电极为参比电极,以铂电极为辅助电极,把试样置于质量分数为3.5%的NaCl溶液中,测得涂层的腐蚀极化曲线,通过极化曲线外推法计算试样的腐蚀电流和腐蚀电位,评价涂层的耐腐蚀性能。电化学实验结果表明,316不锈钢和CrTiAlN涂层的腐蚀电位分别为−0.321、−0.295 V。CrTiAlN涂层具有更高的腐蚀电位,表明镀有CrTiAlN涂层的316不锈钢的耐腐蚀性得到显著提高。CrTiAlN涂层的腐蚀电流为2.651×10−7A/cm2,小于316不锈钢的腐蚀电流(4.752×10−7A/cm2),说明CrTiAlN涂层的腐蚀速度更低,拥有更好的耐腐蚀性能[33]。

图5 在磨损实验后316不锈钢(a、b)和CrTiAlN涂层(c、d)的磨痕形貌及EDS成分组成

图6 316不锈钢和CrTiAlN涂层的电化学实验结果

2.5 抗空蚀性能

在空蚀时间为3 h时,316不锈钢和CrTiAlN涂层的失重曲线如图7a所示,可以看出,随着空蚀时间的延长,二者均出现了失重现象。经过3 h的空蚀实验,316不锈钢的质量损失达到2.8 mg,明显高于CrTiAlN涂层。为了探究二者在空蚀初期的损伤过程,研究了316不锈钢和CrTiAlN涂层在空蚀30 min内的失重和形貌变化情况,如图7b所示。经过30 min的空蚀实验,在316不锈钢和CrTiAlN涂层的空蚀失重曲线中均未表现出明显的失重现象;从二者的表面宏观照片来看(图7c),在空蚀10 min后原始光滑的316不锈钢表面出现了明显起伏,且随着时间的延长,其表面粗糙化程度不断增大。由于空蚀由空泡溃灭过程中产生的冲击引起,这种反复的冲击作用会使材料表面发生塑性变形和疲劳破坏等,在宏观上表现为材料的表面粗糙度增加,并逐渐形成空蚀坑[22]。相较而言,CrTiAlN涂层的空蚀表面仍较光滑,粗糙度无明显变化,随着时间的延长会出现零星剥落现象。空蚀的破坏过程分为孕育、上升、稳定和衰减等4个阶段。在空蚀孕育期,材料未失重或失重很少,但其表面会发生塑性变形[34]。由此可见,316不锈钢和CrTiAlN涂层在30 min的空蚀时间内失重不明显,二者均处于空蚀孕育期。

为了进一步探究316不锈钢和CrTiAlN涂层形貌和成分的变化情况,对2组试样进行了SEM、AFM形貌分析和EDS能谱分析,如图8所示。在30 min空蚀实验后,316不锈钢表面出现了褶皱状形貌,粗糙度明显增大,表面成分无变化。从图8d可以发现,CrTiAlN涂层从底层剥落,裸露出316不锈钢基体。可以推断,当空泡冲击试样表面时,由于涂层的硬度较高,所以在空蚀初期可有效抵挡空泡的冲击作用。随着空蚀时间的延长,涂层表面缺陷处发生了较小面积剥落现象[35],剥落直径约为170 μm。空蚀产生的气泡直径最大可达到1.7 mm[2],说明CrTiAlN涂层可有效提高金属表面的抗空蚀能力。从图8d可以看出,涂层剥落周围具有明显的分层现象,试样逐层剥落,说明多层涂层不仅可以提高膜基结合强度,还可有效抵抗空蚀破坏。此外,如图8b、c、e、f所示,316不锈钢与CrTiAlN涂层在空蚀前的粗糙度分别为4.5、4.8 nm。在30 min空蚀实验后,两者的粗糙度变为112.0、10.6 nm,CrTiAlN涂层的粗糙度变化幅度远小于316不锈钢。综上可知,CrTiAlN涂层的抗空蚀性能相较于316不锈钢得到明显提升。

图7 空蚀时间分别为3 h(a)和30 min(b)的316不锈钢和CrTiAlN涂层的失重曲线和光镜形貌(c)

3 结论

利用非平衡磁控溅射法在316不锈钢基体上制备CrTiAlN涂层,通过正交实验方法,改变Cr、Ti、Al 3种靶材电流来调控涂层的成分,根据涂层的硬度得出了Cr、Ti、Al靶电流分别为4、8、8 A的最佳实验工艺参数。涂层的显微硬度为1 242HV0.01,纳米硬度为(17.00±0.99) GPa。CrTiAlN涂层表面呈圆颗粒状,截面的致密度较高。涂层具有CrN、AlN、TiN衍射峰,结合力等级为HF3。CrTiAlN涂层的磨损率远小于316不锈钢的磨损率,具有优异的耐摩擦性能。与316不锈钢相比,CrTiAlN涂层的腐蚀电流更小、腐蚀电位更大,具有更好的抗腐蚀性能。在空蚀实验前后,316不锈钢的粗糙度从4.5 nm增至112.0 nm,CrTiAlN涂层试样的粗糙度从4.8 nm增至10.0 nm,CrTiAlN涂层的粗糙度变化较小。这是由于涂层的硬度较高,在空蚀初期可以起到缓冲作用。随着时间的延长,涂层会在表面缺陷处出现较小面积的剥落现象,并呈现逐层剥落趋势。这说明多层涂层可以有效抵抗空蚀的破坏,提高金属表面的抗空蚀性能,因此CrTiAlN涂层可作为防护涂层应用于水利工程装备关键部件。

[1] 李雪寒, 李家乐, 秦真波, 等. 耐空蚀涂层及其研究进展[J]. 表面技术, 2022, 51(1): 1-15. LI Xue-han, LI Jia-le, QIN Zhen-bo, et al. Research Progress of Cavitation Corrosion Resistant Coatings[J]. Surface Technology, 2022, 51(1): 1-15.

[2] BRUJAN E A, IKEDA T, MATSUMOTO Y. On the Pressure of Cavitation Bubbles[J]. Experimental Thermal and Fluid Science, 2008, 32(5): 1188-1191.

[3] 钟宏伟. 国外无人水下航行器装备与技术现状及展望[J]. 水下无人系统学报, 2017, 25(4): 215-225. ZHONG Hong-wei. Review and Prospect of Equipment and Techniques for Unmanned Undersea Vehicle in Foreign Countries[J]. Journal of Unmanned Undersea Systems, 2017, 25(4): 215-225.

[4] 张桃, 刘海霞, 康灿, 等. 铅黄铜合金在不同液体介质中的超声空蚀行为及机理[J]. 表面技术, 2018, 47(1): 109-115. ZHANG Tao, LIU Hai-xia, KANG Can, et al. Ultrasonic Cavitation Erosion Behavior and Mechanism of Pb-Brass Alloy in Different Liquids[J]. Surface Technology, 2018, 47(1): 109-115.

[5] SINGH R, TIWARI S K, MISHRA S K. Cavitation Erosion in Hydraulic Turbine Components and Mitigation by Coatings: Current Status and Future Needs[J]. Journal of Materials Engineering and Performance, 2012, 21(7): 1539-1551.

[6] MAN H C, KWOK C T, YUE T M. Cavitation Erosion and Corrosion Behaviour of Laser Surface Alloyed MMC of SiC and Si3N4on Al Alloy AA6061[J]. Surface and Coatings Technology, 2000, 132(1): 11-20.

[7] HUANG W H, CHEN K C, HE J L. A Study on the Cavitation Resistance of Ion-Nitrided Steel[J]. Wear, 2002, 252(5/6): 459-466.

[8] LIU Xiao-bin, KANG Jia-jie, YUE Wen, et al. Cavitation Erosion Behavior of HVOF Sprayed WC-10Co4Cr Cermet Coatings in Simulated Sea Water[J]. Ocean Engineering, 2019, 190(10): 106449.

[9] LIN C J, HE J L. Cavitation Erosion Behavior of Electroless Nickel-Plating on AISI 1045 Steel[J]. Wear, 2005, 259(1): 154-159.

[10] KRELLA A. Cavitation Erosion of TiN and CrN Coatings Deposited on Different Substrates[J]. Wear, 2013, 297(1/2): 992-997.

[11] MOMENI S, TILLMANN W, POHL M. Composite Cavitation Resistant PVD Coatings Based on NiTi Thin Films[J]. Materials & Design, 2016, 110: 830-838.

[12] KRELLA A K, CZYZNIEWSKI A, GILEWICZ A, et al. Experimental Study of the Influence of Deposition of Multilayer CrN/CrCN PVD Coating on Austenitic Steel on Resistance to Cavitation Erosion[J]. Coatings, 2020, 10(5): 487.

[13] YANG Q, ZHAO L R, CAI F, et al. Wear, Erosion and Corrosion Resistance of CrTiAlN Coating Deposited by Magnetron Sputtering[J]. Surface and Coatings Technology, 2008, 202(16): 3886-3892.

[14] LU Li, WANG Qi-min, CHEN Bing-zhou, et al. Microstructure and Cutting Performance of CrTiAlN Coating for High-Speed Dry Milling[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(6): 1800-1806.

[15] TAM P L, ZHOU Z F, SHUM P W, et al. Structural, Mechanical, and Tribological Studies of Cr-Ti-Al-N Coating with Different Chemical Compositions[J]. Thin Solid Films, 2008, 516(16): 5725-5731.

[16] 李潇, 施雯, 张健, 等. 非平衡磁控溅射CrTiAlN涂层的耐腐蚀性能[J]. 中国表面工程, 2010, 23(3): 33-37. LI Xiao, SHI Wen, ZHANG Jian, et al. The Corrosion Resistance Properties of CrTiAlN Coating by Unbalanced Magnetron Sputtering[J]. China Surface Engineering, 2010, 23(3): 33-37.

[17] FERNANDES F, DANEK M, POLCAR T, et al. Tribological and Cutting Performance of TiAlCrN Films with Different Cr Contents Deposited with Multilayered Structure[J]. Tribology International, 2018, 119: 345-353.

[18] LIN Jian-liang, ZHANG Xu-hai, OU Yi-xiang, et al. The Structure, Oxidation Resistance, Mechanical and Tribological Properties of CrTiAlN Coatings[J]. Surface and Coatings Technology, 2015, 277: 58-66.

[19] HAN Liang, HE Liang, LIU de lian. The Effect of Chromium, Titanium and Aluminum on the Friction Coefficient and Wear Property in the Nitride Coatings[J]. Key Engineering Materials, 2012, 531/532: 49-53.

[20] WANG Qian-zhi, ZHOU Fei, YAN Ji-wang. Evaluating Mechanical Properties and Crack Resistance of CRN, CrTiN, CrAlN and CrTiAlN Coatings by Nanoindentation and Scratch Tests[J]. Surface and Coatings Technology, 2016, 285: 203-213.

[21] FUENTES G G, PÉREZ-GANDARILLA L, MEDRANO A, et al. Microstructure and Indentation Hardness Study of CAE-PVD (Cr, Ti, Al)N Solid Solution Coatings Deposited Using a Combinatorial Multitarget Approach [J]. Surface and Coatings Technology, 2021, 420: 127326.

[22] SREEDHAR B K, ALBERT S K, PANDIT A B. Cavitation Damage: Theory and Measurements-a Review[J]. Wear, 2017, 372/373: 177-196.

[23] WANG Zhen-hua, ZHANG Bing. In-Situ Study on Cavitation Erosion Behavior of Super Ferritic Stainless Steel[J]. Wear, 2021, 482-483: 203986.

[24] TAM P L, ZHOU zhi feng, SHUM P W, et al. Oxidation Resistance of Multicomponent CrTiAlN Hard Coatings at Elevated Temperatures[J]. Advanced Materials Research, 2009, 75: 37-42.

[25] 钟厉, 龙永杰, 韩西. 刀具表面磁控溅射CrN涂层及其耐磨性能研究[J]. 表面技术, 2018, 47(10): 151-156. ZHONG Li, LONG Yong-jie, HAN Xi. Preparation and Wear Resistance Properties of CrN Coating by Magnetron Sputtering on Tool Surface[J]. Surface Technology, 2018, 47(10): 151-156.

[26] SHI Yong-jing, LONG Si-yuan, YANG Shi-cai, et al. Deposition of Nano-Scaled CrTiAlN Multilayer Coatings with Different Negative Bias Voltage on Mg Alloy by Unbalanced Magnetron Sputtering[J]. Vacuum, 2010, 84(7): 962-968.

[27] KRELLA A. Resistance of PVD Coatings to Erosive and Wear Processes: A Review[J]. Coatings, 2020, 10(10): 921.

[28] HATTORI S, ISHIKURA R, ZHANG Qing-liang. Construction of Database on Cavitation Erosion and Analyses of Carbon Steel Data[J]. Wear, 2004, 257(9/10): 1022- 1029.

[29] 刘志强, 张智嘉, 魏浩. 材料表面抗空蚀涂层的研究进展[J]. 功能材料, 2021, 52(4): 4038-4045. LIU Zhi-qiang, ZHANG Zhi-jia, WEI Hao. Research Progress on Cavitation Erosion Resistance Coatings of Material Surfaces[J]. Journal of Functional Materials, 2021, 52(4): 4038-4045.

[30] 贠柯, 蒋百灵, 白力静. Ti靶电流对CrTiAlN镀层组织结构及硬度的影响[J]. 材料热处理学报, 2009, 30(6): 149-153. YUN Ke, JIANG Bai-ling, BAI Li-jing. Influence of Ti Target Current on Microstructure and Hardness of CrTiAlN Coatings Prepared by Magnetron Sputtering[J]. Transactions of Materials and Heat Treatment, 2009, 30(6): 149-153.

[31] ZHANG Peng, SHAN Lei, SU Xiao-lei, et al. Microstructure and Tribological Performance of CrTiSiCN Coatings on 316L and TC4 in Seawater[J]. Tribology International, 2021, 156: 106832.

[32] WANG Tao, ZHANG Guo-jun, JIANG Bai-ling. Comparison in Mechanical and Tribological Properties of CrTiAlMoN and CrTiAlN Nano-Multilayer Coatings Deposited by Magnetron Sputtering[J]. Applied Surface Science, 2016, 363: 217-224.

[33] 李淑钰, 刘应瑞, 郭鹏, 等. 海洋环境下物理气相沉积氮/碳基抗磨蚀涂层的研究进展[J]. 表面技术, 2021, 50(7): 44-56. LI Shu-yu, LIU Ying-rui, GUO Peng, et al. Research Progress of Nitrogen/Carbon-Based Anti-Tribocorrosion Coatings by Physical Vapor Deposition for Marine Applications[J]. Surface Technology, 2021, 50(7): 44-56.

[34] HATTORI S, NAKAO E. Cavitation Erosion Mechanisms and Quantitative Evaluation Based on Erosion Particles[J]. Wear, 2001, 249(10/11): 839-845.

[35] KRELLA A, CZYŻNIEWSKI A. Cavitation Resistance of Cr-N Coatings Deposited on Austenitic Stainless Steel at Various Temperatures[J]. Wear, 2009, 266(7/8): 800-809.

Preparation and Cavitation Erosion Resistance of CrTiAlN Coatings by Unbalanced Magnetron Sputtering

1,1,1,2,2,2,1,1*

(1. School of Materials Science and Engineering, Southeast University, Nanjing 211189, China; 2. Department of Metallurgy and Materials Engineering, University of Malta, Msida 2080, Malta)

In order to improve the service performance of underwater propulsion systemsin complex and variable marine environment, surface modification technology has been widely used for the protection of the metal surface. To alleviate the problem of cavitation failure on the metallic surface of the power systems, CrTiAlN coating was prepared on AISI 316 stainless steel (316 SS) substrates by unbalanced magnetron sputtering technology. Through an orthogonal experimental design, the optimal target current of Cr, Ti, Al was obtained based upon the coating hardness. The phase, morphology, composition and surface roughness of the coating were characterized by XRD, SEM, EDS and AFM. Vickers and Rockwell hardness testing and scratch testing were used to evaluate the microhardness and the adhesion of the coating. The dry friction and wear resistance, corrosion resistance and cavitation erosion resistance of the coating were evaluated by Ball-disk wear, electrochemical test and cavitation erosion test, respectively. The results showed that the optimal target current of Cr, Ti and Al was 4 A, 8 A and 8 A respectively. The coating possessed 49.95% Cr, 11.99% Ti, 24.41% Al and 13.65% N; and the thickness and adhesion grade were 4.33 μm and HF3, respectively. Dense uniform round particles could be clearly observed on the coating surface, and the cross-sectional morphology showed that there were Cr bonding layer, CrN transition layer and CrTiAlN top layer with no obvious voids and defects. The nano-hardness of coating was (17.00±0.99)GPa much higher than that of 316 SS. During the ball-disk wear test,the friction coefficients of 316 SS and CrTiAlN coating were 0.45 and 0.34 respectively, and the maximum depth and width of wear scar of the coating were 1.13 μm and 286 μm, much less than those of 316 SS (12.14 μm and 665 μm), indicating the superior wear resistance. According to the surface morphology and composition analysis, the 316 SS suffers severe abrasive wear and oxidation wear, while the CrTiAlN coating undergoes mild oxidation wear and fatigue wear. In 3.5% NaCl solution, the CrTiAlN coating has the higher value of the corrosion potential and the lower value of the corrosion current than 316 SS. Thus, the coated material exhibits better corrosion resistance than bare 316 SS, which can significantly extend the service life. During the cavitation erosion tests for 30 min, no obvious weight loss has been identified, but the surface roughness (a) of 316 SS significantly increases from an average of 4.5 nm to 112.0 nm with the appearance of appreciable wrinkle patterns, and a large amount of cavitation pits can be observed. In contrast, the surface of the CrTiAlN coating becomes slightly rough, and thea increases from 4.8 nm to 10.0 nm. In addition, only sporadic peeling occurs at coating defects. It reveals that the CrTiAlN coating can effectively mitigate the impact of cavitation erosion and improve cavitation resistance of 316 SS. Therefore, CrTiAlN coating can be potentially used as a protective coating for key components of engineering equipment in the marine environment.

magnetron sputtering; CrTiAlN coating; friction and wear; corrosion; cavitation erosion

2022-12-18;

2023-05-06

TB33

A

1001-3660(2023)10-0367-09

10.16490/j.cnki.issn.1001-3660.2023.10.032

2022-12-18;

2023-05-06

国家重点研发计划(2019YFE0191500);中马合作项目

Ministry of Science and Technology of the People's Republic of China (2019YFE0191500); Malta Council for Science and Technology through the Sino-Malta Fund 2019 Call (Science and Technology Cooperation)

刘铭悦, 黄志全, 张习羽, 等.非平衡磁控溅射CrTiAlN涂层的制备及空蚀性能研究[J]. 表面技术, 2023, 52(10): 367-375.

LIU Ming-yue, HUANG Zhi-quan, ZHANG Xi-yu, et al. Preparation and Cavitation Erosion Resistance of CrTiAlN Coatings by Unbalanced Magnetron Sputtering[J]. Surface Technology, 2023, 52(10): 367-375.

通信作者(Corresponding author)

责任编辑:彭颋