TA15钛合金高温摩擦磨损性能研究

2023-11-06刘彬李晟毛玉刚李鹏飞李亮亮孟宪凯王赛兰吴嘉诚

刘彬,李晟,毛玉刚,李鹏飞*,李亮亮,孟宪凯,王赛兰,吴嘉诚

TA15钛合金高温摩擦磨损性能研究

刘彬1,李晟1,毛玉刚1,李鹏飞1*,李亮亮2,3,孟宪凯1,王赛兰1,吴嘉诚1

(1.江苏大学 机械工程学院,江苏 镇江 212013;2.吉林大学 机械与航空航天工程学院,长春 130025;3.沈阳飞机工业(集团)有限公司 创新研究院,沈阳 110000)

为探究TA15钛合金高温耐磨性能的潜力,研究了TA15钛合金在室温~800 ℃下的摩擦磨损性能。利用Rtec摩擦磨损试验机(Rtec,San Jose,USA)进行TA15钛合金的摩擦磨损性能测试,通过激光共聚焦显微镜、JSM-7800F扫描电镜(SEM)、能谱仪(EDS)、X射线衍射仪(XRD)等手段,分析了TA15钛合金在不同温度下的磨痕形貌、成分变化以及磨损机理。在不同试验温度下,微观组织没有出现明显变化,主要为等轴α相和β相;不同温度下的摩擦因数波动不大,从室温的0.279下降到600 ℃的0.224,而在800 ℃时,表面严重氧化导致摩擦因数增大到0.309;在室温~400 ℃时,试样表面磨痕不断变窄变浅,犁沟和磨屑不断减少,而到400 ℃以上时磨痕逐渐变宽,比磨损率也大幅增大,且在600 ℃时的磨损量最大;在600 ℃时,以氧化磨损为主,并伴随着磨粒磨损和黏着磨损,且表面磨痕形貌和宽度比较均匀;在800 ℃时磨损表面以黏着磨损和氧化磨损为主,并伴随着高温焊接的发生。TA15合金表面的O元素含量随温度的升高而逐渐升高,并且氧化反应主要发生在β相内。随着试验温度的升高,TA15钛合金磨损表面的氧化磨损现象也更加明显。

TA15钛合金;高温性能;磨损机理;氧化磨损;摩擦因数

TA15(Ti-6Al-2Zr-1Mo-1V)合金是典型的近α型中强度钛合金,具有高比强度、良好的热稳定性、较好的耐腐蚀性及焊接性能等优点,广泛应用于航空航天、船舶等领域[1],因其优异的综合力学性能,成为承载复杂载荷结构件的重要材料之一,也是燃气轮机压气机叶片和压气机盘的重要材料[2-3]。由于TA15合金具有良好的高温力学性能,它广泛应用在一些高温场合[4-7]。因此,研究TA15钛合金在不同温度下的力学性能具有重要意义。

Wang等[8]在800~900 ℃下进行了高温拉伸试验,研究了激光焊接TA15接头的热变形机制,研究发现,在900 ℃、应变速率为0.001 s−1时,最大延伸率为292%。Vo等[9]在975、1 000、1 025、1 060、1 100 ℃的温度和0.1、1 s−1的应变率下,模拟了TA15钛合金压缩试验中的流动应力。Yang等[10]在温度为750~850 ℃(以25 ℃为间隔)以及应变率为0.001、0.01、0.1 s−1条件下进行了拉伸试验,研究了TA15的热拉伸性能,金相结果表明,初生α相变为等轴晶,次生α相和层状β相弯曲直至破碎。Hao等[11]在温度为−60~900 ℃和应变率为0.001s−1条件下进行了TA15钛合金的拉伸试验,利用电子背散射衍射(EBSD)分析了不同温度下微观组织的演变和变形机制。研究表明,在相对较低的温度(60、23、400 ℃)下,位错滑移机制主导了变形,在高温(600 ℃和800 ℃)下α板条的球化和动态再结晶(DRX)占主导地位,导致了流动软化。Zhao等[12-13]研究了TA15钛合金板材在退火和800 ℃高温拉伸过程中的再结晶行为,并分析了热拉伸过程中TA15钛合金板材在750 ℃时沿轧制方向的变形不均匀性和滑移模式。Zhao等[14]通过等温拉伸试验研究了双态组织TA15合金的热变形行为与断裂特征,结果表明,材料的流动软化主要由双态组织动态球化引起。Li等[15]通过指数型Zener-Hollomon方程研究了应变和温度对热变形的影响,在温度为800~1 000 ℃,应变速率为10、1、0.1、0.01和0.001 s−1以及应变为0.9的条件下进行了等温压缩试验,验证了所提出本构方程的有效性。Feng等[16-17]研究了400~700 ℃温度范围内TiB晶须增强TA15钛基复合材料(TiBw/TA15)的拉伸性能和断裂机理,并尝试通过添加TiBw提高TA15钛合金的高温塑性变形能力。Li等[18]揭示了钛合金在温度为910~970 ℃、应变速率为0.01~0.1 s−1的单轴热拉伸试验中的流动软化和塑性损伤机制。Zhao等[19]通过试验和晶体塑性仿真的方式,研究了TA15板材在750 ℃的拉伸试验中沿轧制方向的织构演变规律。Liu等[20]探究了750 ℃高温下变形的TA15钛合金的值与应变的相关性。

虽然有学者系统研究了TA15合金在高温下的拉伸性能和组织演变机理,但是国内对其摩擦磨损性能的研究却很少。因此,本文以TA15钛合金为研究对象,进行了5组不同温度下的摩擦磨损性能测试,分析了TA15钛合金从室温(RT)到800 ℃的磨损性能及微观组织的变化规律,进而探究其高温条件下的磨损机理。

1 试验

1.1 材料及微观结构表征

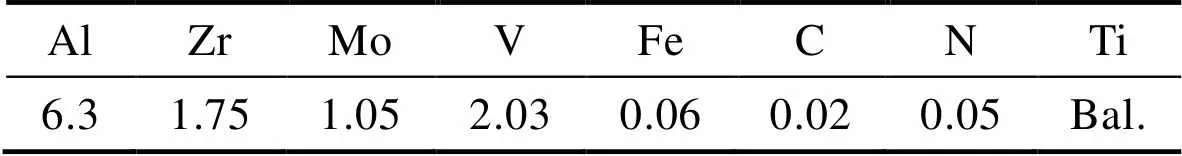

所用材料为锻造TA15钛合金,其化学成分如表1所示。通过不同温度下的摩擦磨损试验,获得需要观察的微观组织区域。通过制备金相试样和标准的检验方法对试样进行研磨和抛光。使用HF+HCl+HNO3+水(体积分数分别为1%、1.5%、2.5%、95%)化学腐蚀25 s,采用SEM观察试样微观组织。

采用精度为0.1 mg的电子天平称量磨损试验前后的质量损失,利用激光共聚焦显微镜观察磨损形貌并测量磨痕的宽度和深度。用X射线衍射仪(XRD)测定其物相组成,用扫描电镜分析磨痕表面宏观和微观形貌,并使用其配备的能谱仪(EDS)分析磨痕的化学成分,计算比磨损率,并探究磨损机理。

表1 TA15钛合金化学成分

Tab.1 Chemical composition of TA15 titanium alloy wt.%

1.2 摩擦磨损性能测试

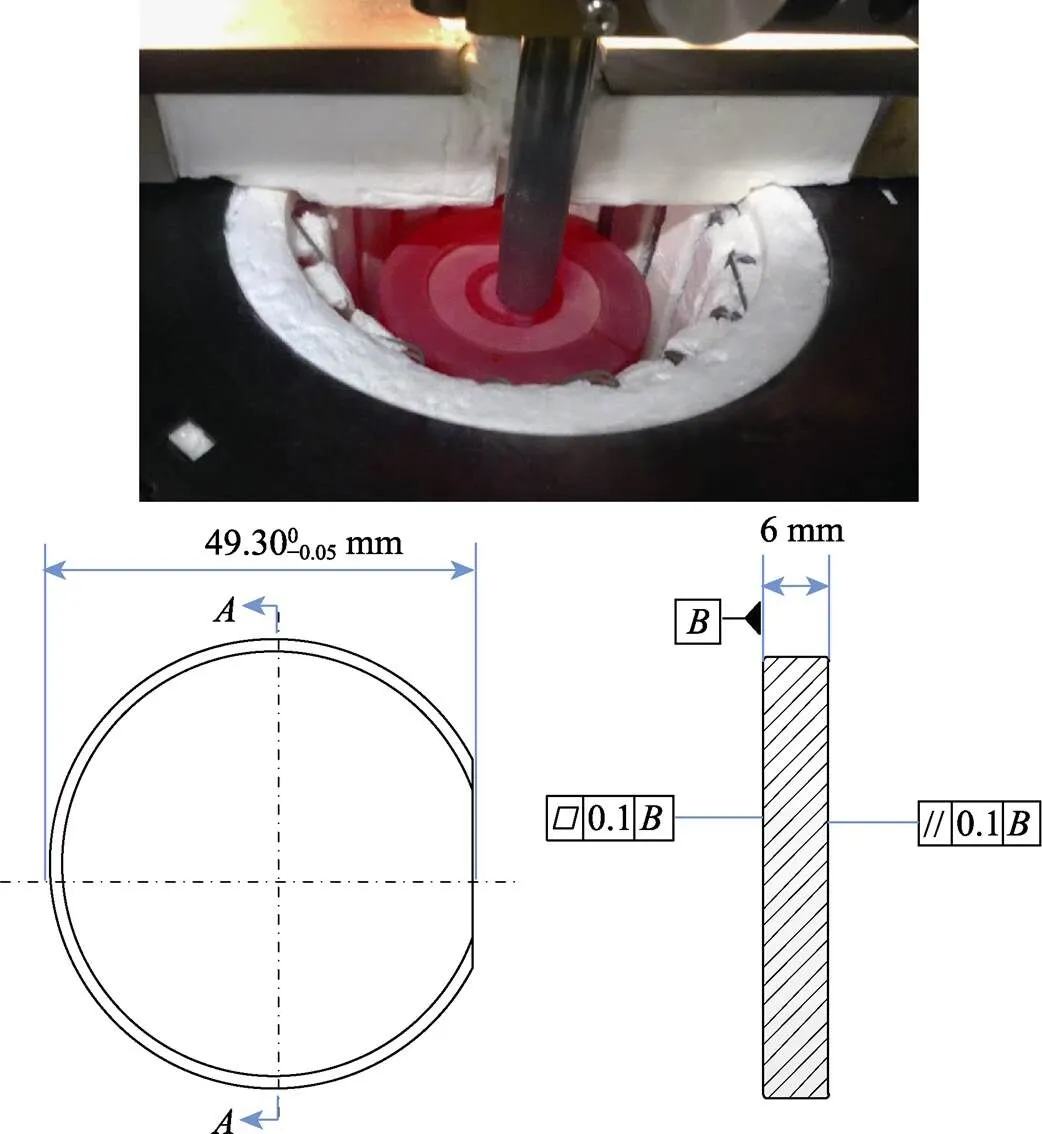

使用Rtec摩擦磨损试验机进行高温摩擦学和磨损试验,该设备配有高温炉,加热速度为100 ℃/min,摩擦磨损测试后炉温冷却。试验设备和试样尺寸如图1所示。摩擦磨损试验在室温(RT)、200 ℃、400 ℃、600 ℃和800 ℃下进行,在每个温度下均进行2次测试,取测试结果的平均值,每次测试都在一个新的抛光试样表面上进行,以保证所有测试的起始条件相同。使用直径为9.525 mm、硬度为1 500HV的氮化硅球,在球对盘装置中进行试验。为保证在磨损试验中出现明显划痕且不使基体产生严重的塑性变形,采用摩擦载荷为10 N、滑动速度为50 mm/s、滑动持续时间为1 200 s、磨损轨迹半径为8 mm[21]。

图1 高温磨损设备及尺寸

2 结果与分析

2.1 微观组织

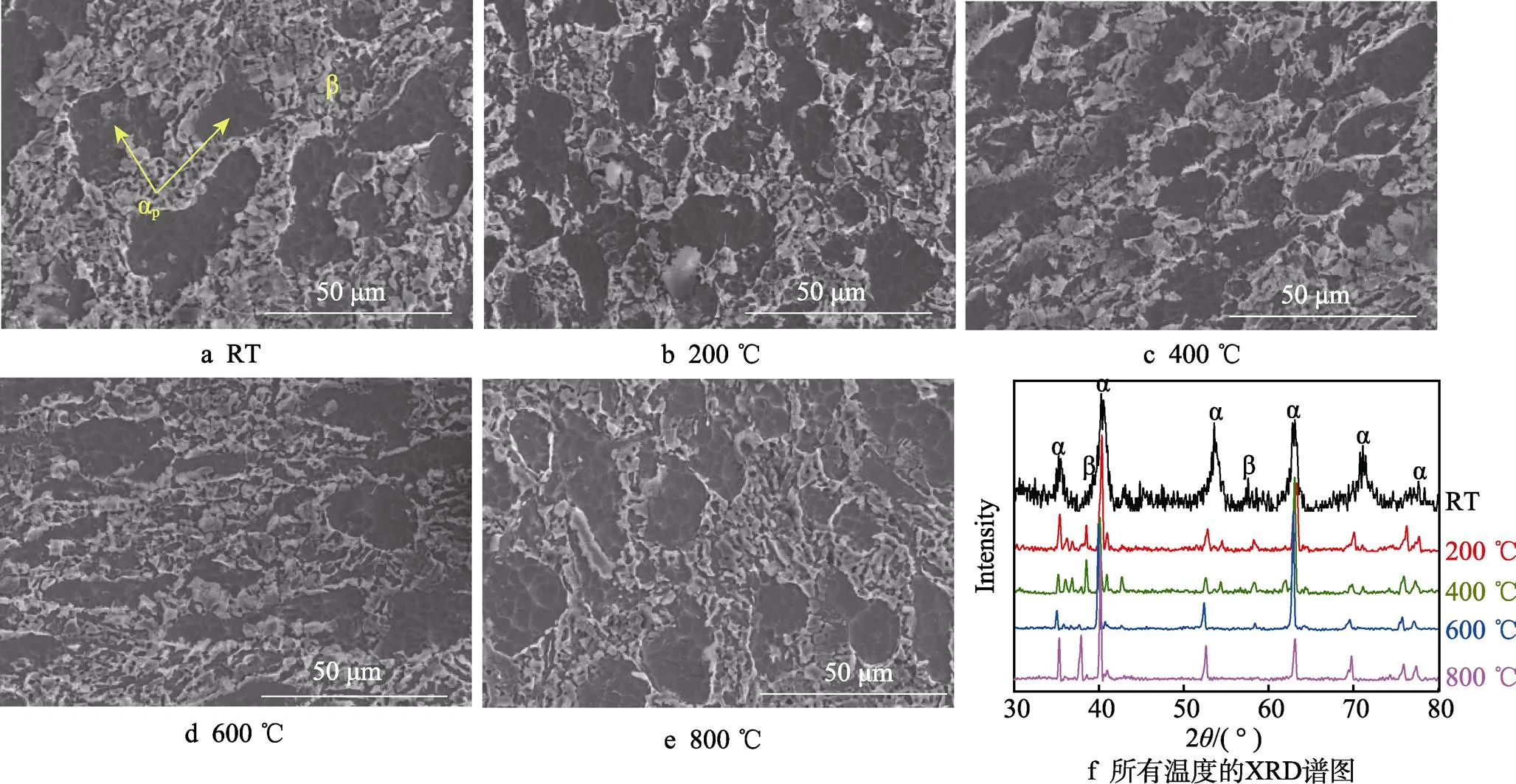

测试温度从RT到800 ℃时TA15钛合金的微观组织形貌和XRD谱图如图2所示。可以看出,在β相基体中存在大量等轴初生α相,并且不同试样的微观组织差异不明显,这说明高温测试时间过短,对TA15合金的微观组织影响不大。

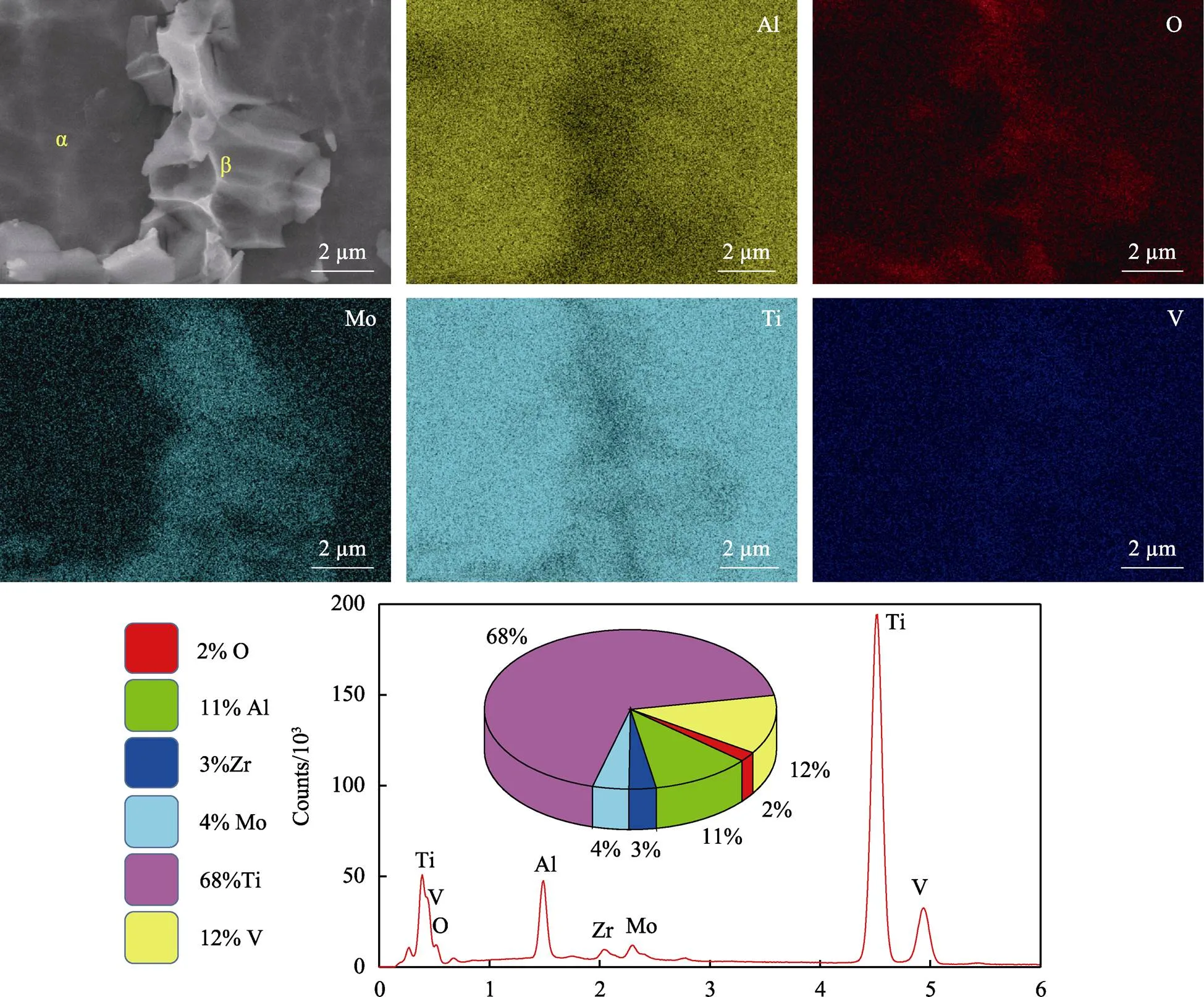

为了进一步明确TA15合金中α相与β相含量的差异,在600 ℃下对试样的微观结构进行EDS扫描分析,结果如图3所示。结合表1可以看出,Ti仍是TA15合金的主要元素,而V和O元素的含量明显增加,这表明试样磨损表面发生氧化。EDS谱图结果表明,Ti和Al元素主要分布在α相中,Mo、V和O元素主要分布在β相中。

2.2 摩擦磨损性能

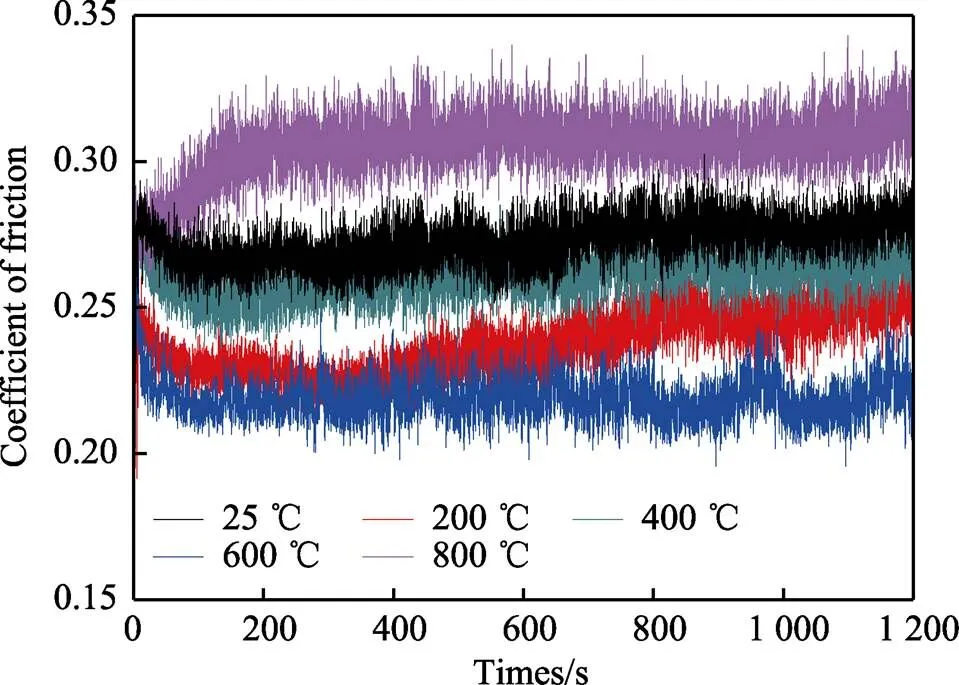

摩擦因数是衡量材料摩擦磨损性能的重要指标之一。不同温度下TA15合金磨损试样在10 N载荷下的摩擦因数随滑动时间的变化情况如图4所示。可见,RT、200 ℃、400 ℃、600 ℃、800 ℃温度下的平均摩擦因数分别为0.279、0.247、0.266、0.224、0.309。随着试验温度的升高,在600 ℃时摩擦因数最小,这是因为随着摩擦磨损表面的温度逐渐升高,合金发生高温软化,导致工件表面硬度降低,对塑性变形的抗力下降,磨削球可以更容易压入磨损表面,此时磨损产生的磨屑也会充当润滑作用,因此摩擦因数不断降低。但由于在800 ℃时TA15合金表面存在更厚的氧化层,导致摩擦阻力变大,使摩擦因数突然增大。

图2 不同温度下的微观组织和XRD谱图

图3 600 ℃磨损试验后TA15微观组织的EDS图谱和元素含量分析

图4 不同温度下TA15合金的摩擦因数

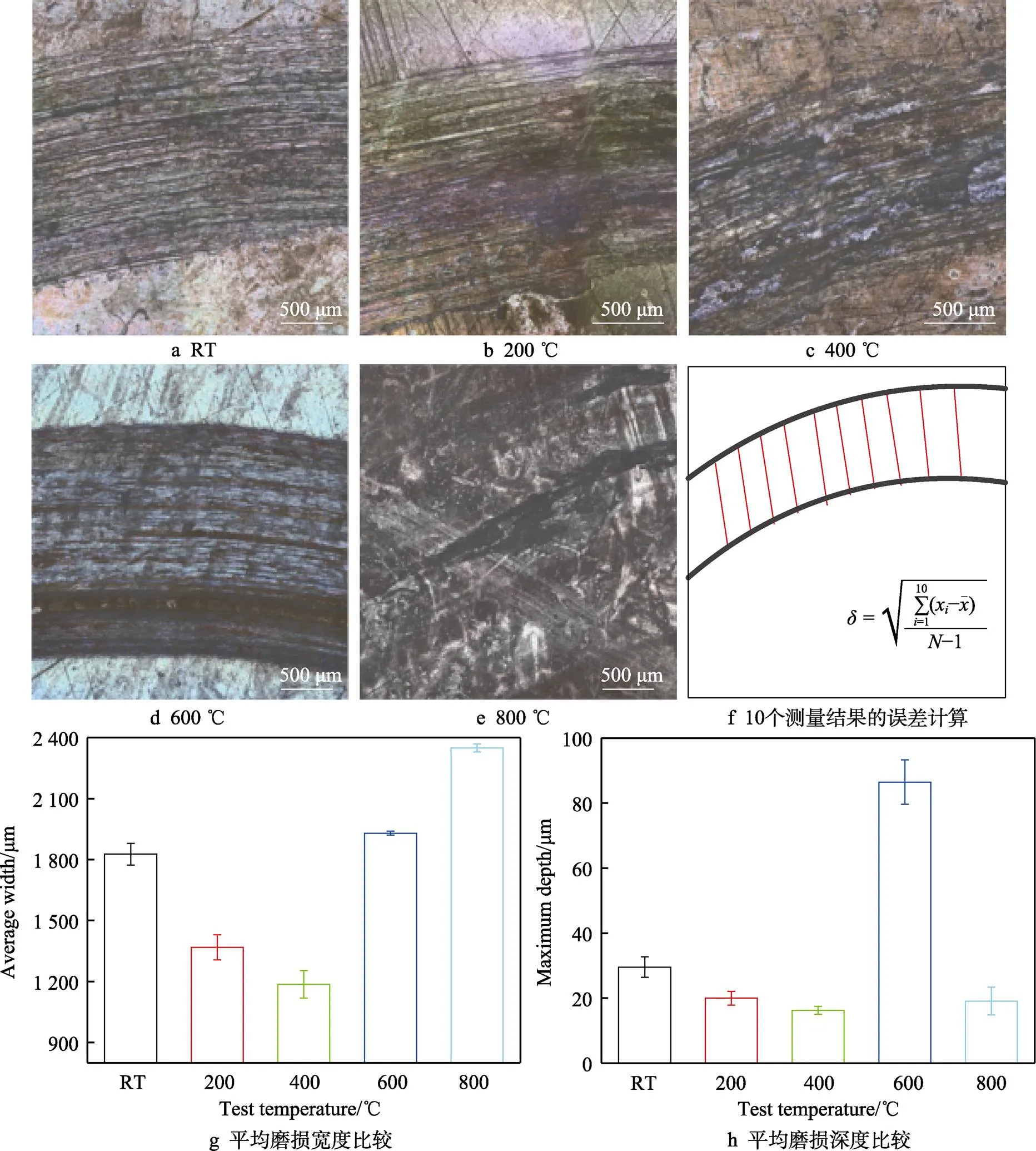

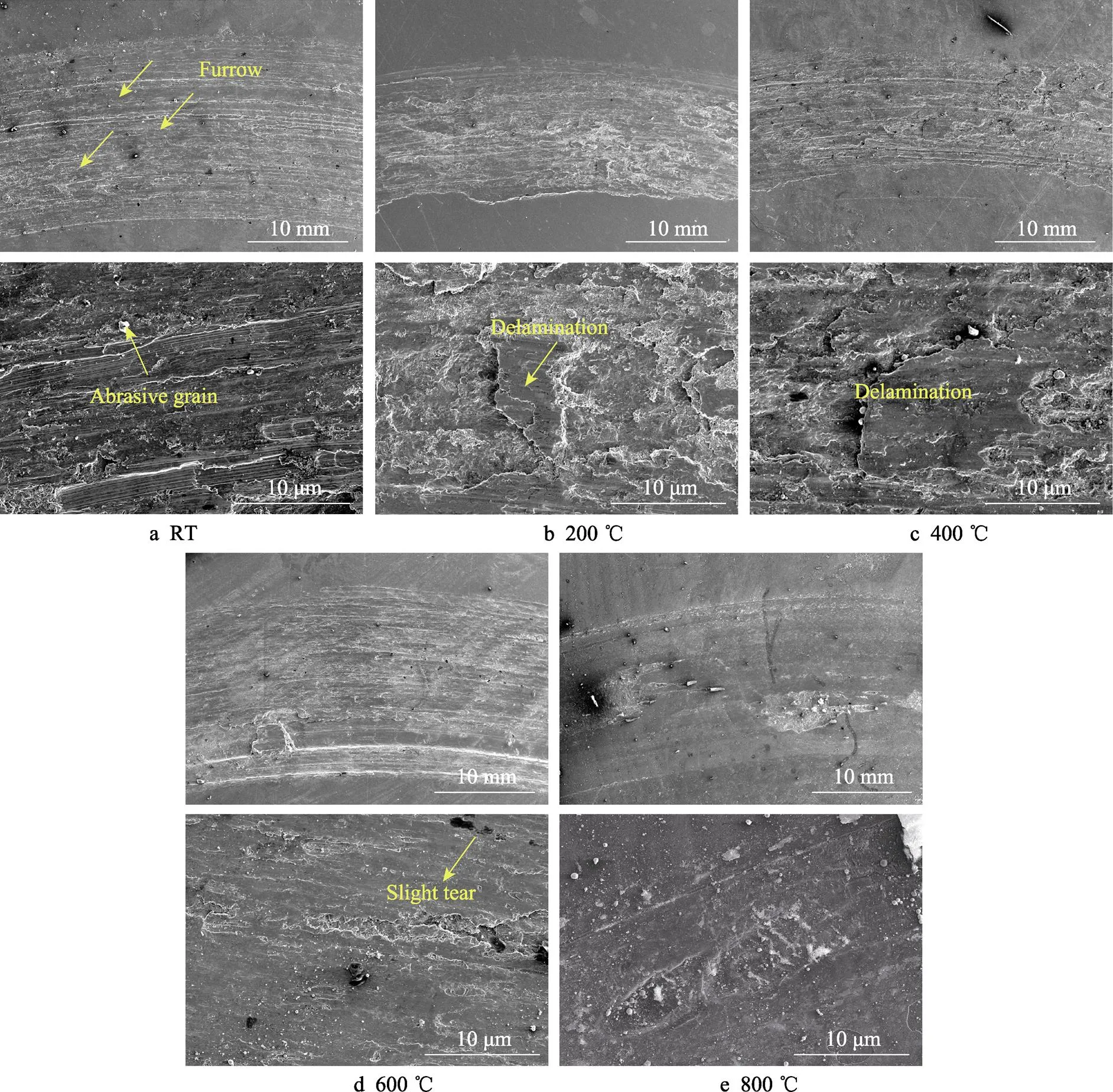

不同温度下TA15合金的磨损形貌如图5所示。在室温时,磨痕比较宽,犁沟细而密,并且深度较大。在200 ℃和400 ℃时,磨损宽度发生明显变化,结合各个试样的平均宽度(见图5g)和平均深度(图5h)可以看出,随着试验温度的升高,表面磨痕平均宽度和深度不断减小,在400 ℃时达到最低。但当试验温度超过400 ℃后,磨痕的宽度和深度都大幅增大,这说明TA15钛合金的磨损程度随温度的升高而降低,而超过400 ℃后表面磨损程度反而增大。在600 ℃时磨损宽度误差最小,但磨损深度误差最大,这主要是因为在高温软化作用下发生了磨粒磨损,从而导致试样表面划痕偏深。当试验温度为800 ℃时,试样被挤压变形,磨损宽度显著增大。此外,试样表面磨痕深度因受高硬度氧化层的影响而大幅下降。

图5 用激光共聚焦显微镜观察磨损形貌

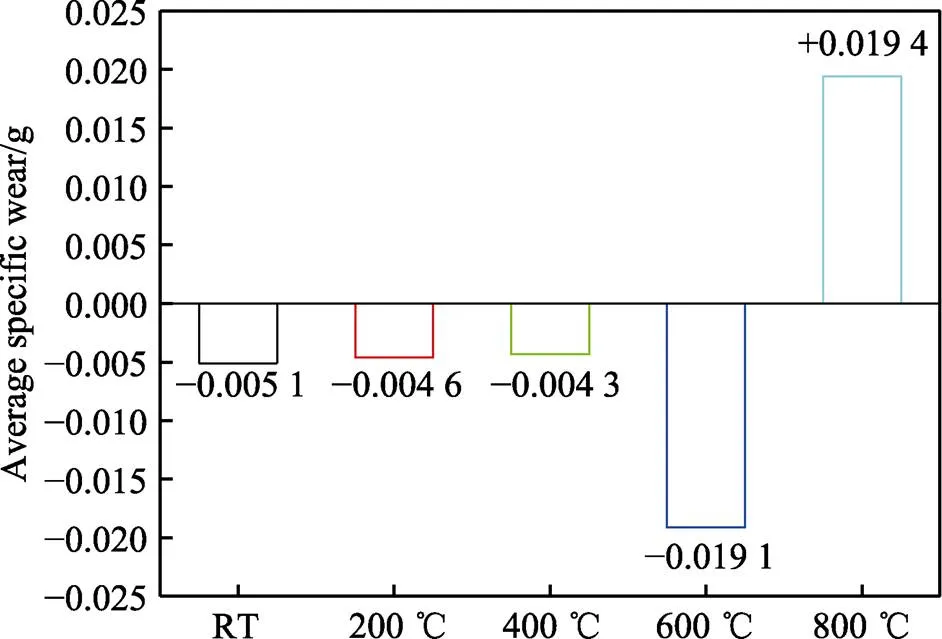

不同试验温度下TA15合金的磨损量如图6所示。可以看出,当试验温度低于600 ℃时,随温度的升高,磨损量减小,从0.005 1 g下降到0.004 3 g,然而在600 ℃时,磨损量突然增大到0.019 1 g,这主要是因为在600 ℃时,高温软化起主导作用,导致试样的塑性非常好。由此可见,高温显微硬度也会影响磨损量和磨损机理。结合图5g、图5h和图6可以得出,在600 ℃时,硬度下降,塑性有所提升,从而使磨损量大大增大。但当试验温度为800 ℃时,总质量意外增大0.019 4 g,这主要是由于TA15钛合金在高温软化后发生了明显的高温焊接。

图6 不同试验温度下TA15合金的磨损量比较

为了更加准确地比较试样在不同温度下的磨损量,可用磨损体积来计算磨损率。球体积磨损的计算如式(1)所示。

式中:为试样磨损体积,mm3;为磨痕宽度,mm;为磨损球半径,mm。

目前,常用比磨损率作为衡量材料摩擦磨损性能的重要指标。比磨损率定义公式如式(2)所示。

式中:为比磨损率,mm3/(N·m);为法向载荷,N;为滑动距离,m。

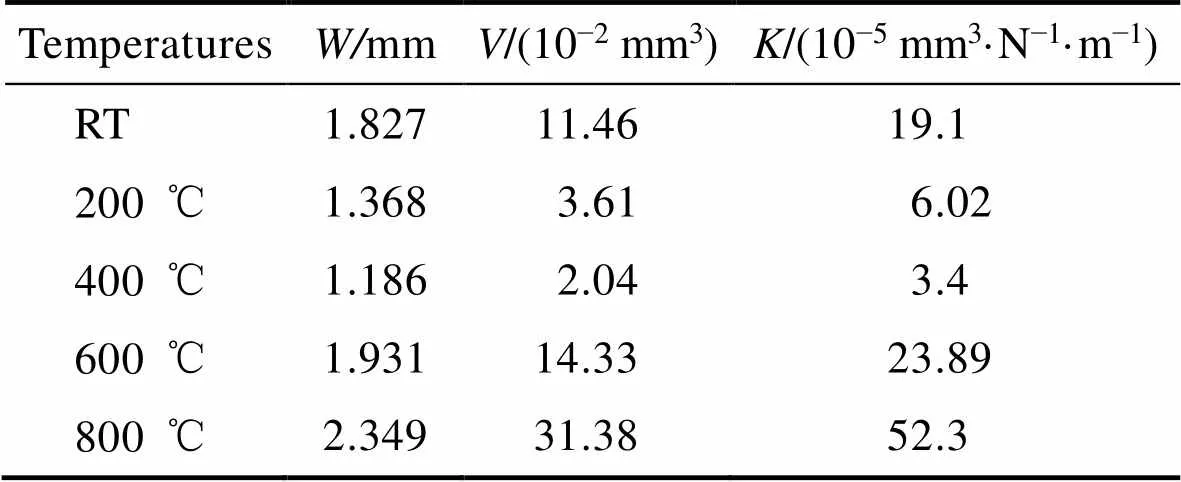

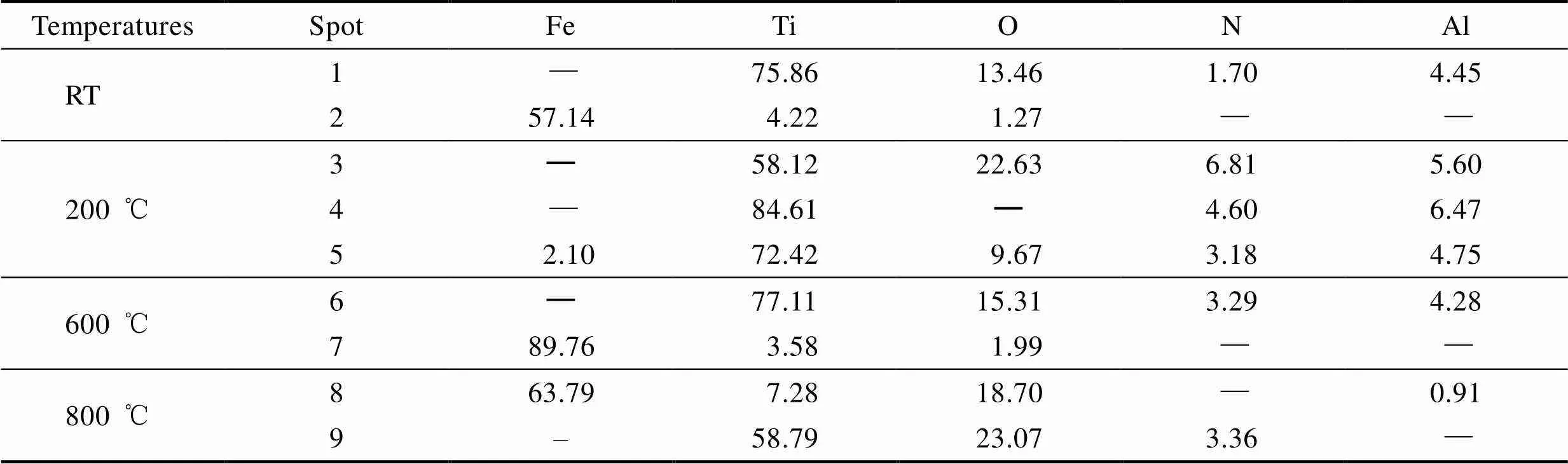

经计算,不同温度下TA15钛合金试样的比磨损率如表2所示。可以明显看出,当温度低于600 ℃时,随着温度的升高,TA15钛合金的比磨损率不断降低,在400 ℃时,试样的比磨损率不足RT时的1/5,降幅达83.2%,表明此时TA15钛合金具有最佳的耐磨损性能。但是,600 ℃时的比磨损率为23.89× 10−5mm3/(N·m),此时试样的比磨损率高于RT时的,并随温度的升高而升高,而且800 ℃时的比磨损率远高于RT时的,涨幅为64.1%。

表2 不同温度下TA15钛合金的磨损体积和比磨损率

Tab.2 Wear volume and specific wear rate of TA15 titanium alloy at different temperatures

为了研究不同温度下的摩擦磨损机理,采用扫描电镜分析表面磨痕形貌,如图7所示。从图7a可以看出,磨粒磨损是RT下的主要磨损形式,磨痕表面黏附着大量磨屑,机械犁耕现象明显。从图7b和图7c可以看出,200 ℃和400 ℃时的磨损机理相似,主要以黏着磨损为主,而且均出现了明显的分层和撕裂痕迹,并伴有少量的磨屑。此外,磨痕边缘的不均匀可能与分层密切相关。600 ℃时磨损宽度和形貌比较均匀,如图7d所示,表面看到明显的氧化磨损和黏着磨损特征,磨削球与工件之间的高温摩擦导致表面出现轻微黏着撕裂的现象。800 ℃时试样的摩擦磨损形貌如图7e所示,可以看到明显的挤压变形,磨痕较浅,犁沟基本消失,未发现撕裂的现象,这主要是表面高硬度氧化层和基体高温软化共同作用的结果。根据图7d、图7e和表2可以看出,磨损试样表面磨损的挤压变形明显,这主要是由于TA15钛合金的过度软化使磨痕宽度大幅增大,从而导致比磨损率大幅增大。

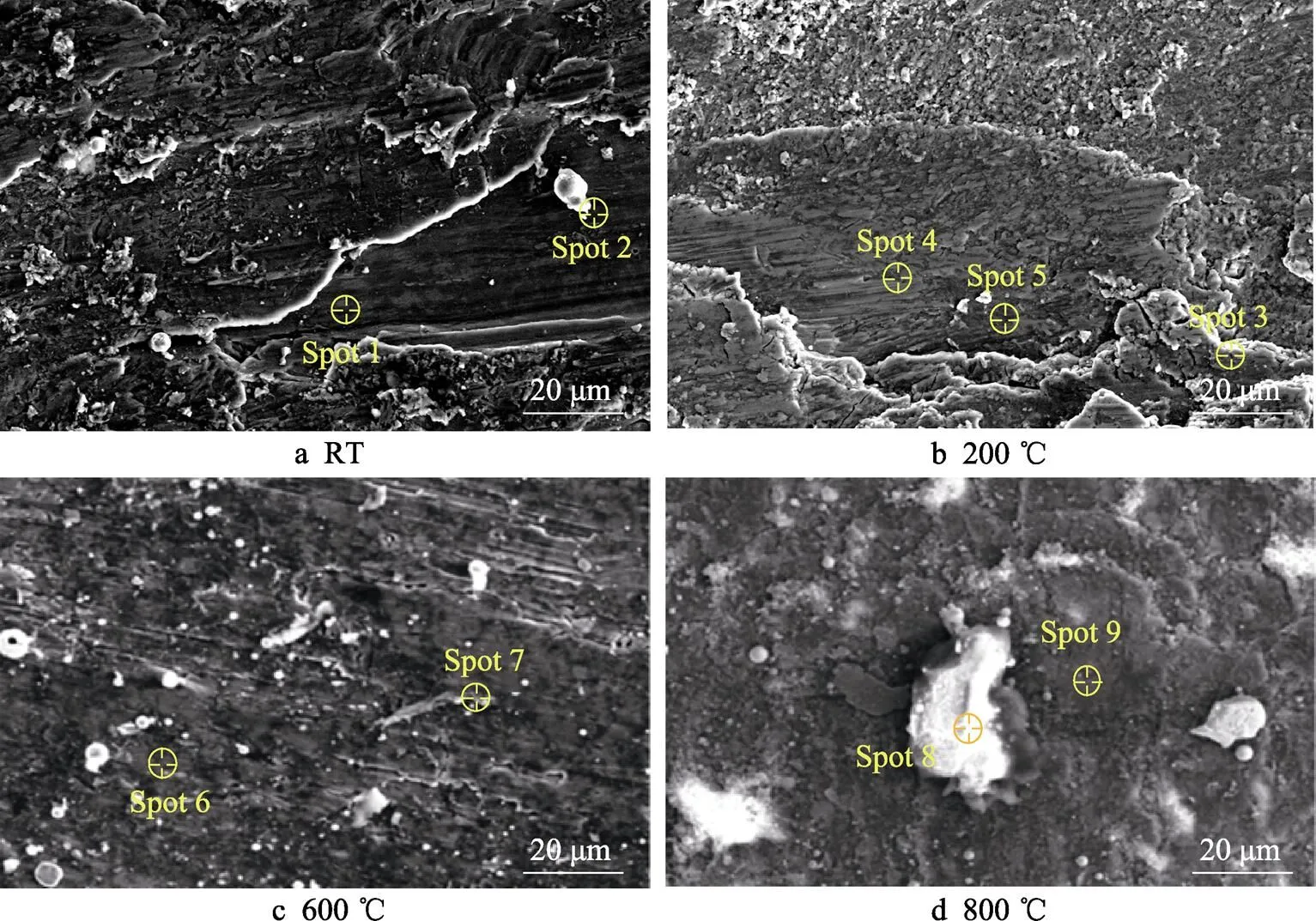

对TA15合金摩擦磨损形貌进行EDS分析,测点位置如图8所示,EDS结果如表3所示。从图8可以看出,表面分布有许多不同形状的颗粒。所有试样(点4、点6和点9)的主要元素都是Ti,但在这些点都检测到N元素,这说明无论测试温度是多少,磨削球颗粒都嵌入在基体中。O元素含量随着试验温度的升高而增加,再加上Ti具有较高的化学活性,氧化现象不可避免。这进一步证实了高温条件下试样表面的Ti元素容易氧化形成高硬度、高脆性的氧化物薄膜,并易在挤压作用下脱落,裸露的表面又继续生成新的氧化物薄膜而继续发生氧化磨损,同时剥落的磨屑不及时排出会导致磨粒磨损。

图7 不同工作温度下磨损形貌的SEM图像

图8 TA15合金磨损形貌的EDS测点位置

表3 图8中EDS分析的元素组成

Tab.3 Elemental composition of EDS analysis in Fig.8 wt.%

3 讨论

TA15合金具有较高的比强度和高温强度,能服役于较高的温度环境。高温软化和表面氧化是影响TA15合金高温摩擦磨损性能的主要因素。在本试验中,600 ℃的高温软化效果普遍好于表面氧化引起的硬化效果,这导致了磨损量突然大幅升高。

不同的磨损温度会导致不同的磨损质量和磨损机理,如图9所示。从RT到400 ℃,磨损机理以磨粒磨损和黏着磨损为主。随着磨损温度的升高,TA15合金轻微软化导致分层,出现少量分布不均匀的颗粒。当试验温度为600 ℃时,磨损试样材质较软,摩擦磨损比较均匀,少数大颗粒导致磨损深度显著增大。800 ℃的过度软化虽然提高了塑性,增大了磨痕的宽度,但表面氧化层使硬度有所提升,导致试样的磨痕深度大大降低。此外,磨削球与磨损试样发生了明显的高温焊接和黏着磨损,并由于黏附,总质量略有增大。

图9 高温磨损机理示意图

4 结论

通过不同温度的摩擦磨损试验,分析了TA15钛合金的摩擦磨损性能。可以得出以下结论:

1)随着试验温度的升高,在RT~400 ℃下,TA15合金表面磨痕不断变窄变浅,摩擦因数从0.279下降到0.224,磨损量有所减小,在400 ℃时,磨损量和比磨损率均降到最低,表现出较高的耐磨损特性,而在600 ℃时,试样的比磨损率开始增大,磨损量此时达到最大。

2)通过对比分析不同试样的磨痕微观形貌,发现TA15合金在常温环境下的磨损形式以磨粒磨损和黏着磨损为主,而在高温磨损环境下除了磨粒磨损和黏着磨损外,伴随着明显的氧化磨损。

3)600 ℃是TA15合金摩擦磨损性能的分界线。在600 ℃以下,磨损表面存在大量磨屑,磨痕不均匀,并伴有明显的黏着撕裂特征。而在600 ℃时,高温软化作用明显,因此,磨痕宽度和形貌比较均匀。当试验温度为800 ℃时,由于黏附和高温焊接的作用,TA15合金的总质量有所增大。

[1] SUN Q J, XIE X. Microstructure and Mechanical Properties of TA15 Alloy after Thermo-mechanical Processing[J]. Materials Science and Engineering A, 2018, 724: 493-501.

[2] ZHAO Jie, LYU Liang-xing, WANG Ke-huan, et al. Effects of Strain State and Slip Mode on the Texture Evolution of a Near-α TA15 Titanium Alloy during Hot Deformation Based on Crystal Plasticity Method[J]. Journal of Materials Science and Technology, 2020, 38: 125-134.

[3] WU Hui-li, SUN Zhi-chao, CAO Jing, et al. Formation and Evolution of Tri-modal Microstructure during Dual Heat Treatment for TA15 Ti-alloy[J]. Journal of Alloys and Compounds, 2019, 786: 894-905.

[4] LI Yan-xi, GAO Peng-fei, YU Jing-yue, et al. Mesoscale Deformation Mechanisms in Relation with Slip and Grain Boundary Sliding in TA15 Titanium Alloy during Tensile Deformation[J]. Journal of Materials Science and Technology, 2022, 98: 72-86.

[5] JIANG X Q, FAN X G, ZHAN M, et al. Microstructure Dependent Strain Localization during Primary Hot Working of TA15 Titanium Alloy: Behavior and Mechanism[J]. Materials and Design, 2021, 203: 109589.

[6] XU Ye-lin, LIU Er-liang, WEI Shi-liang. Investigation on Tensile Fracture Properties of TA15 Specimen Formed by Selective Electron Beam Melting[J]. Materials Science and Engineering A, 2020, 773: 138826.

[7] JIANG Jun-jie, REN Zhi-chao, MA Zhi-bo, et al. Mechanical Properties and Microstructural Evolution of TA15 Ti Alloy Processed by Selective Laser Melting before and after Annealing[J]. Materials Science and Engineering A, 2020, 772: 138742.

[8] WANG Ke-huan, LIU Gang, TAO Wang, et al. Study on the Mixed Dynamic Recrystallization Mechanism during the Globularization Process of Laser-welded TA15 Ti- alloy Joint under Hot Tensile Deformation[J]. Materials Characterization, 2017, 126: 57-63.

[9] VO P, JAHAZI M, YUE S, et al. Flow Stress Prediction during Hot Working of Near-α Titanium Alloys[J]. Materials Science and Engineering A, 2007, 447(1/2): 99-110.

[10] YANG Lei, WANG Bao-yu, LIU Gang, et al. Hot Tensile Behavior and Self-consistent Constitutive Modeling of TA15 Titanium Alloy Sheets[J]. Journal of Materials Engineering and Performance, 2015, 24(12): 4647-4655.

[11] HAO Fang, XIAO Jun-feng, FENG Yong, et al. Tensile Deformation Behavior of a Near-Titanium Alloy Ti-6Al- 2Zr-1Mo-1V under a Wide Temperature Range[J]. Journal of Materials Research and Technology, 2020, 9(3): 2818-2831.

[12] ZHAO Jie, WANG Ke-huan, HUANG Ke, et al. Recrystallization Behavior during Hot Tensile Deformation of TA15 Titanium Alloy Sheet with Substantial Prior Deformed Substructures[J]. Materials Characterization, 2019, 151: 429-435.

[13] ZHAO Hui-jun, WANG Bao-yu, JU Dong-ying, et al. Hot Tensile Deformation Behavior and Globularization Mechanism of Bimodal Microstructured Ti-6Al-2Zr-1Mo- 1V Alloy[J]. Transactions of Nonferrous Metals Society of China (English Edition), 2018, 28(12): 2449-2459.

[14] ZHAO Jie, LYU Liang-xing, LIU Gang, et al. Analysis of Deformation Inhomogeneity and Slip Mode of TA15 Titanium Alloy Sheets during the Hot Tensile Process Based on Crystal Plasticity Model[J]. Materials Science and Engineering A, 2017, 707: 30-39.

[15] LI Jiang, LI Fu-guo, CAI Jun. Constitutive Model Prediction and Flow Behavior Considering Strain Response in the Thermal Processing for the TA15 Titanium Alloy[J]. Materials, 2018, 11(10): 1985.

[16] FENG Yang-ju, CUI Guo-rong, ZHANG Wen-cong, et al. High Temperature Tensile Fracture Characteristics of the Oriented TiB Whisker Reinforced TA15 Matrix Composites Fabricated by Pre-sintering and Canned Extrusion[J]. Journal of Alloys and Compounds, 2018, 738: 164-172.

[17] FENG Yang-ju, ZHANG Wen-cong, ZENG Li, et al. Room- temperature and High-temperature Tensile Mechanical Properties of TA15 Titanium Alloy and TiB Whisker- reinforced TA15 Matrix Composites Fabricated by Vacuum Hot-pressing Sintering[J]. Materials, 2017, 10(4): 1-14.

[18] LI Jun-ling, WANG Bao-yu, HUANG He, et al. Behaviour and Constitutive Modelling of Ductile Damage of Ti-6Al-1.5Cr-2.5Mo-0.5Fe-0.3Si Alloy under Hot Tensile Deformation[J]. Journal of Alloys and Compounds, 2019, 780: 284-292.

[19] ZHAO Jie, LYU Liang-xing, LIU Gang. Experimental and Simulated Analysis of Texture Evolution of TA15 Titanium Alloy Sheet during Hot Tensile Deformation at 750 ℃[J]. Procedia Engineering, 2017, 207: 2179-2184.

[20] LIU Gang, WANG Ke-huan, HE Bin-bin, et al. Mechanism of Saturated Flow Stress during Hot Tensile Deformation of a TA15 Ti Alloy[J]. Materials and Design, 2015, 86: 146-151.

[21] LU Hai-feng, MIAO Qiang, LIANG Wen-ping, et al. High-temperature Tribological Behaviors of a Cr-Si Co-alloyed Layer on TA15 Alloy[J]. Chinese Journal of Aeronautics, 2017, 30(2): 846-855.

Tribological Properties of TA15 Titanium Alloy at Different High Temperatures

1,1,1,1*2,3,1,1,1

(1. School of Mechanical Engineering, Jiangsu University, Jiangsu Zhenjiang 212013, China; 2. School of Mechanical and Aerospace Engineering, Jilin University, Changchun 130025, China; 3. Innovation Research Institute, Shenyang Aircraft Corporation, Shenyang 110000, China)

To investigate the high-temperature wear resistance potential of the TA15 titanium alloy, its tribological properties were studied at various temperatures, ranging from room temperature to 800 ℃. The Rtec Universal Tribometer (Rtec, San Jose, USA) equipped with a high-temperature furnace capable of reaching 1 000 ℃, with a heating rate of 100 ℃/min, was used to conduct friction and wear property tests on the TA15 titanium alloy. The impact of temperature on the friction coefficient and wear rate was analyzed. The wear morphology, composition changes, and wear mechanism of the TA15 titanium alloy at different temperatures were analyzed with a laser confocal microscope, a JSM-7800F scanning electron microscope (SEM), energy dispersive spectrum (EDS), and X-ray diffraction (XRD). The study showed that there were no significant changes in the microstructure at different test temperatures, and the microstructure was primarily composed of equiaxed α and β phases. As the test temperature increased, the O element content on the surface of the TA15 titanium alloy continuously increased, and the oxidation wear phenomenon on the wear surface became more apparent. The wear width varied significantly at 200 ℃ and 400 ℃, owing to the small average width and depth at these temperatures. Although the wear width error was the smallest at 600 ℃, the wear depth error was the highest due to too deep partial scratches, indicating that abrasive wear was the primary factor. At 800 ℃, the specimen was extruded and deformed, resulting in a significantly increased wear width (about 2 300 μm). Furthermore, increased adhesive wear caused noticeable local tearing. At temperatures below the service temperature of 500 ℃, wear losses only slightly varied from 0.005 1 g to 0.004 3 g. However, at 600 ℃, the wear loss abruptly increased to 0.019 1 g, which was mainly due to TA15's excellent plasticity at that temperature. Additionally, the high temperature microhardness affected the wear loss and mechanism. Unexpectedly, at a test temperature of 800 ℃, the total mass increased by 0.019 4 g due to the softened TA15's compaction and obvious adhesive wear. The wear mechanism of TA15 at room temperature was primarily abrasive wear. At 200 ℃ and 400 ℃, the wear was mainly stripping wear and adhesive wear, accompanied by minor abrasive wear and oxidation wear. At 600 ℃, the wear was primarily oxidized, accompanied by abrasive wear and adhesive wear, with uniform surface wear morphology and width. At 800 ℃, the wear surface was mainly affected by adhesive wear and oxidation wear, accompanied by high temperature welding. At high temperatures, TA15's surface wear is mainly influenced by high temperature softening and surface oxidation. Worn surfaces are distributed with various particles of different morphologies, with Ti as the main element and N element detected at various spots, indicating that grinding ball particles are embedded in the substrate regardless of test temperature. Owing to Ti's high chemical activity, oxidation is inevitable, and the content of O element increases gradually with the rise in test temperature.

TA15 titanium alloy; high-temperature properties; wear mechanism; oxidation wear; friction coefficient

2022-09-15;

2023-03-31

TG147

A

1001-3660(2023)10-0151-09

10.16490/j.cnki.issn.1001-3660.2023.10.011

2022-09-15;

2023-03-31

国家科技重大专项(2017ZX04001001);江苏省自然科学基金青年基金(BK20210758);中国博士后科学基金面上一等资助项目(2022M710060);航空动力装备振动及控制教育部重点实验室开放基金(VCAME202208);江苏省研究生实践创新计划(SJCX22_1849,KYCX22_3626)

National Science and Technology Major Project (2017ZX04001001); Natural Science Foundation of Jiangsu Province (BK20210758); China Postdoctoral Science Foundation Funded Project (2022M710060); Open Fund for the Key Laboratory of Vibration and Control of Aviation Power Equipment, Ministry of Education (VCAME202208); Postgraduate Research & Practice Innovation Program of Jiangsu Province (SJCX22_1849, KYCX22_3626)

刘彬, 李晟, 毛玉刚, 等. TA15钛合金高温摩擦磨损性能研究[J]. 表面技术, 2023, 52(10): 151-159.

LIU Bin, LI Sheng, MAO Yu-gang, et al. Tribological Properties of TA15 Titanium Alloy at Different High Temperatures[J]. Surface Technology, 2023, 52(10): 151-159.

通信作者(Corresponding author)

责任编辑:蒋红晨