大气等离子喷涂FeCoCrNiAl高熵合金涂层的高温摩擦磨损性能

2023-11-06王跃明李晨龙韩旭航黄杰朱建勇解路刘秀波

王跃明,李晨龙,韩旭航,黄杰,朱建勇,解路,刘秀波

大气等离子喷涂FeCoCrNiAl高熵合金涂层的高温摩擦磨损性能

王跃明1,李晨龙1,韩旭航1,黄杰1,朱建勇2,解路3,刘秀波4

(1.湖南科技大学 材料科学与工程学院,湖南 湘潭 411201;2.湖南省冶金材料研究院有限公司粉末冶金与金属陶瓷研究所,长沙 410129;3.江苏城乡建设职业学院 管理工程学院,江苏 常州 213147;4.中南林业科技大学 材料表界面科学与技术湖南省重点实验室,长沙 410004)

研究环境温度对FeCoCrNiAl高熵合金涂层摩擦磨损性能的影响,探讨将其应用于高温及富氧环境中的可行性。采用大气等离子喷涂制备FeCoCrNiAl高熵合金涂层,考察喷涂功率对涂层微观组织的影响;测试涂层的纳米力学性能,分析其对涂层摩擦磨损性能的影响;基于涂层及对偶磨球磨损表面形貌、元素分布及含量、物相组成,讨论涂层在室温及高温环境中的摩擦磨损特性与机制。涂层中形成了白色、浅灰色、深灰色及黑色4种区域,区域颜色随O元素含量增加而加深,涂层纳米力学性能逐渐增加,进而将对其摩擦磨损性能造成影响。20 kW喷涂功率制备涂层的室温摩擦因数、磨损率及磨痕深度均达最佳值,分别为(0.70±0.02)、(9.22±0.01)×10‒5mm3/(N∙m)及(130±10) μm。室温环境下,磨粒磨损、疲劳磨损及塑性变形为涂层的主要磨损机制。20 kW功率制备涂层的摩擦因数、磨损率、磨痕深度等均随摩擦环境温度的升高先增加而后降低,经600 ℃摩擦试验后分别低至(0.58±0.01)、(6.14±0.01)×10‒5mm3/(N∙m)及(104±8) μm;涂层磨损表面的氧化程度随环境温度的升高而加剧,经600 ℃摩擦试验后氧含量高达31.62%(质量分数)。当摩擦环境温度≥400 ℃时,涂层以氧化磨损为主,以磨粒磨损、粘着磨损和疲劳磨损为辅。由于磨损表面形成连续氧化膜的保护和固体润滑作用,高熵合金涂层在高温环境中的耐磨性明显提高,可广泛应用于高温及富氧环境中。

大气等离子喷涂;FeCoCrNiAl高熵合金;涂层;微观组织;摩擦磨损性能

高熵合金[1-2]因其特殊的相结构而具备远超传统合金的高强度、高硬度、高耐磨、高耐蚀等优异性能,可广泛应用于航空航天、生物医学、新能源、核工业等尖端领域。自叶均蔚[3-4]首次提出高熵合金的概念以来,高熵合金的制备及性能研究已成为全球材料科学工作者们的研究热点。目前,高熵合金块体主要通过电弧熔炼[5-6]、放电等离子烧结[7-8]等方法制备。然而,上述方法所制备高熵合金块体尺寸有限、成本高昂,不利于其实际推广应用。近年来,以高熵合金理论为基础、结合表面工程技术所开发的高熵合金涂层,即可大幅降低制备成本,又可获得与其块体相似的性能[9]。因此,在实际应用中可以根据不同的工况需求,制备相应的高熵合金涂层以取代高熵合金块体材料。

等离子喷涂[10]热源温度高达10 000 ℃以上,对基体热影响极小,易于控制、成本较低,适用于大规模生产,工业应用潜力巨大。近年来,大气等离子喷涂(APS)已成为高熵合金涂层常见制备技术之一。Hsu等[11]详细对比了APS制备NiCo0.6Fe0.2Cr1.5SiAlTi0.2涂层与其块体性能的差异。Ang等[12]系统研究了AlCoCrFeNi 和MnCoCrFeNi两种纳米级高熵合金涂层微观形貌和显微硬度随APS过程中粒子速度、温度及粒径的变化规律。Anupam等[13]延续了Ang等[12]的研究思路,并深入研究了APS制备AlCoCrFeNi涂层过程中飞行颗粒的氧化行为,利用DPV2000设备监测喷涂过程中不同速度、温度、粒径大小的飞行粒子特征,最后综合对比了不同粒径、温度条件下所制备的涂层性能。Lin等[14]分别对APS制备FeCoCrNiAl涂层进行热处理和激光重熔,以改善其性能。Wang等[15]利用APS制备了CoCrFeMnNi涂层,并深入研究了激光重熔后涂层的相演变与凝固开裂机理的相关性。Cheng等[16]分别采用真空气体雾化及APS制备了AlCoCrFeNi粉体及其涂层。研究发现,高熵合金粉体粒径影响AlCoCrFeNi涂层的物相组成,粗粉(60~90 μm)可抑制涂层中FCC相的形成,而AlCoCrFeNi涂层孔隙率、硬度、饱和磁化强度等物理性能可通过其物相组成来调整。Xiao等[17]研究了H2流量对APS制备FeCoNiCrMn涂层微观组织及性能的影响,并对比分析了喷涂态涂层及经800 ℃、2 h退火处理的涂层的摩擦磨损性能。Hsu等[18]分别采用APS及超音速火焰喷涂(High Velocity Oxy Fuel Spray,HVOF)制备了Ni0.2Co0.6Fe0.2CrSi0.2AlTi0.2涂层。研究结果表明,HEA涂层的硬度约为800Hv,其耐磨性几乎是SUJ2轴承钢的2倍,且HEA涂层相对于MCrAlY涂层而言具备更加优良的耐高温氧化性能。Jin等[19]采用APS和激光重熔工艺制备了6种不同硅含量的FeCoCrNiAl0.5Si涂层。研究结果表明,随着Si含量的增加,涂层硬度及体心立方相的体积分数均增加,而磨损系数、磨痕轮廓深度和质量损失均有所降低,耐磨性有所提高。Shi等[20]研究发现,在APS制备的AlCoCrFeNi涂层中添加Ag和BaF2/CaF2共晶自润滑相后,复合涂层室温磨损率降低达10倍。在高温摩擦环境中,添加润滑剂改变了高熵合金涂层氧化产物组成,抑制了氧化层的分层,可减轻涂层磨损行为,显著降低磨损率。Xiao等[21]采用APS制备了铝含量(物质的量分数)分别为0.5%、1.0%和1.5%的FeCoNiCrSiAl涂层,并研究了FeCoNiCrSiAl涂层在干态和水润滑条件下的摩擦磨损性能。Wang等[22]系统研究了退火处理对APS制备AlCoCrFeNi涂层组织及性能的影响。Meghwal等[23]在多尺度水平上建立了APS制备AlCoCrFeNi涂层微观组织与硬度及磨损性能之间的联系,还评估了涂层整体残余应力分布及其在海水环境中的电化学性能。

迄今为止,关于APS工艺参数(喷涂功率、喷涂距离等)对高熵合金涂层微观组织及摩擦磨损性能的影响的研究报道较少。为此,本文选用真空气雾化FeCoCrNiAl类球形粉体,采用APS制备涂层,对比分析了喷涂功率对该型涂层显微组织及摩擦磨损性能的影响,并系统分析了该型涂层的室温及高温摩擦磨损特性与机制。

1 试验

1.1 大气等离子喷涂

由图1a可以看出,采用气体雾化法制备的粉末具有良好的球形度。由单个粉体截面EDS面扫元素分布图1c~g表明,Fe、Co、Cr、Ni、Al元素均匀分布在粉末截面中,说明经气雾化技术所制备粉末具有良好的成分均匀性。经测定,该型粉体的平均粒度为40 μm,其粒径分布范围为10~90 μm,其霍尔流速及松装密度分别为24.3 s/50 g及3.52 g/cm3。

图1 APS用粉末SEM形貌及EDS面扫元素分布图

为提高粉末流动性,喷涂前需将其置于100 ℃干燥箱中处理1 h。为改善涂层与基材界面结合效果,需用丙酮清除304不锈钢基材(尺寸为140 mm× 30 mm×5 mm)表面油污,然后在0.2 MPa压力下用120#(0.125 mm)棕刚玉砂对其表面作喷砂粗化处 理[24]。采用DH-1080型等离子喷涂设备制备高熵合金涂层,1号样品(S1)、2号样品(S2)及3号样品(S3)的具体喷涂工艺参数见表1。

1.2 性能检测

采用Tescan Mira4型扫描电镜观察粉末、APS涂层、磨屑、摩擦试验后涂层及Si3N4磨球磨痕表面形貌,能谱面扫描测量样品元素分布。采用Bruker D8 Advance型XRD衍射仪分析粉末及涂层相组成,选用Cu靶Kα射线(=1.540 56 Å),电压、电流、扫描速度及步长分别设定为40 kV、40 mA、2 (°)/min及0.02°,扫描范围0°~100°[24]。采用LA-950型激光粒度分析仪测试粉末粒度。采用纳米压痕仪(G200,Agilent Technologies)及Berkovich金刚石压头测定高熵合金涂层的纳米硬度和约化弹性模量[25],加载载荷、加载速率、卸载速率及保载时间分别设定为10 mN、20 mN/min、20 mN/min和 10 s。每种压痕都在相同颜色区域打 10个点,并取其平均值。高熵合金涂层室温及高温摩擦磨损试验在GF-I型高温摩擦磨损试验机上进行,载荷为60 N,转速为600 r/min,时间为30 min,对磨球为直径6 mm的Si3N4球,磨球往复长度5 mm,温度分别设定为室温、200、400、600 ℃。试验过程中摩擦因数由计算机记录,并取相同试验条件下3次摩擦试验的算术平均值;采用MT-500型探针式材料表面磨痕测量仪分析磨痕截面形貌、计算磨损体积,探针运行长度为3 mm[24]。

2 结果与分析

2.1 APS涂层形貌及物相分析

由图2a可见,S1涂层截面为明显的层状结构,涂层孔隙较少,涂层厚度较均匀,为(780±10) μm。图2b为图2a中白色方框区域放大照片,涂层中可观察到白色、浅灰色、深灰色和黑色4种不同颜色区域,还可观察到较多未熔颗粒。S2涂层仍保留了明显的层片结构特征,其厚度为(880±10) μm,见图2c。图2d为图2c局部区域放大照片,图中大部分颗粒得以充分熔化铺展,仍存在一定数量未熔颗粒。喷涂功率增大至25 kW时,S3涂层厚度为(490±10) μm,见图2e。白色方框区域局部放大图2f中几乎观察不到未熔颗粒存在。

表1 大气等离子喷涂工艺参数

Tab.1 APS parameters

图2 APS涂层SEM照片

图3为S2的EDS元素面扫分布图。由图3b、c、e可见,Fe、Co和Ni元素主要分布在白色区域;Cr元素则均匀分布在APS涂层中,见图3d。而Al元素则偏聚在涂层的浅灰色、深灰色和黑色区域,且区域颜色越深,Al元素含量越高,见图3f。值得引起注意的是,涂层中Al元素分布与O元素(图3g)几乎完全一致。分析表明,等离子喷涂过程中,HEA粉体中Al元素与大气环境中O元素优先反应生成氧化物,而Fe、Co、Cr、Ni元素与O元素之间的反应则相对较弱。

由表2中EDS面扫数据可见,气雾化所制备FeCoCrNiAl高熵合金粉末属于等原子配比粉体,而APS高熵合金涂层中氧含量高达28.56%(原子数分数),这是由于APS过程中高熵合金粉体与大气环境中的氧剧烈反应造成的。

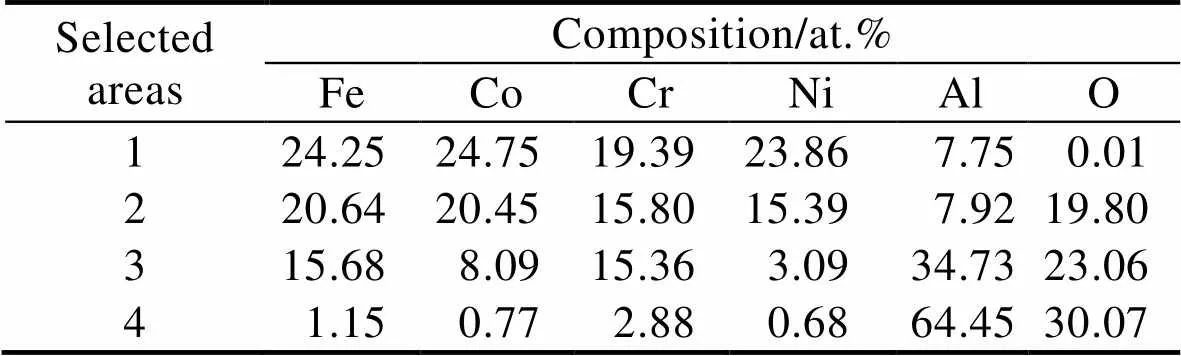

选定图3a中的白色(Area 1)、浅灰色(Area 2)、深灰色(Area 3)、黑色(Area 4)4个区域分别做EDS分析,表3为其各不同颜色区域元素成分表。由表3可见,S2涂层随着区域逐渐由白色过渡至浅灰色、深灰色及黑色,Fe、Co、Cr、Ni元素含量依次降低,而Al元素及O元素含量显著增大,进而再次印证了APS过程中HEA粉体中Al元素优先与大气环境中氧气发生反应而形成氧化物。

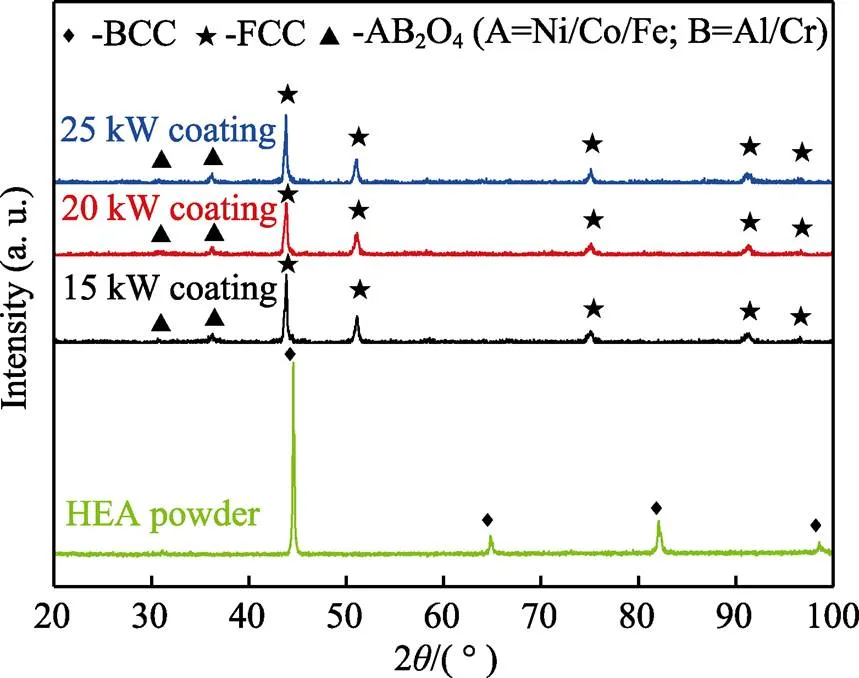

由图4可见,HEA粉末出现了对应于BCC单相固溶体(110)、(200)、(211)、(220)的衍射峰,APS涂层中可观察到分别对应于FCC相的(111)、(200)、(220)、(311)和(222)晶面的衍射峰,Shi等[20]也发现了类似现象。图4中还可观察到位于30.61°及36.26°处的对应于AB2O4(A=Ni/Co/Fe,B=Cr/Al)型混合氧化物的弱衍射峰,Ang等[12]、Anupam等[13]及Meghwal等[23]也观察到了类似的现象。分析表明,Al是一种已知的BCC相稳定元素,由于APS过程中HEA粉末颗粒的氧化现象使得Al元素被消耗殆尽,导致高熵合金涂层仅可观察到以FCC相为主、AB2O4相为辅的衍射峰,而无明显BCC相衍射峰存在。

图3 S2面扫区域SEM形貌照片及EDS元素面分布图

表2 FeCoCrNiAl粉末及APS涂层EDS面扫数据表

Tab.2 EDS map results of FeCoCrNiAl powder and APS coating

表3 图3a中4个不同颜色区域EDS数据表

Tab.3 EDS results of four different color areas in Fig.3a

图4 粉末喂料及APS涂层XRD图谱

2.2 APS涂层的力学性能分析

2.2.1 纳米力学性能分析

由S2中各区域的载荷-位移曲线图5可见,随着O含量的增加,白色、浅灰色、深灰色及黑色区域的最大位移max逐渐降低,分别为324、251、176及171 nm,表明这些区域的硬度逐渐增加。Pharr[26]经研究指出,热喷涂层和基材的纳米硬度和弹性模量可以经载荷与位移曲线计算得出。计算结果表明,白色、浅灰色、深灰色及黑色区域的纳米硬度()及弹性模量(r)是单调增加的,详见表4。纳米硬度和弹性模量的比值(/r)为抗塑性指数,它是说明高熵合金涂层变形机制的有效手段,也是预测其抗耐磨性的重要指标之一。经计算,S2中白色、浅灰色、深灰色及黑色区域的抗塑性指数均小于0.1,说明该型涂层主要发生塑性变形[27]。S2中白色、浅灰色、深灰色及黑色区域的另一比值3/r2随着O含量的增加而增大,其值越大则表明材料抵抗塑性变形的能力越强[28]。

由图5计算得到S2中白色、浅灰色、深灰色及黑色区域在加载过程中的总变形能随O含量的增加而降低。而该样品白色、浅灰色、深灰色及黑色区域在卸载过程中的弹性变性能elastic分别为0.22、0.36、0.38、0.35。此外,值表示拉伸试验过程中材料韧性的弹性比率[29]。表4中的涂层的纳米力学性能(包括、r、/r3/r2、total、elastic及等参数)均为APS涂层摩擦磨损性能的重要影响因素[29],随着涂层中氧化物含量增加,其纳米力学性能提高,耐摩擦磨损性能随之而增大。

图5 S2中白色、浅灰色、深灰色及黑色区域的载荷-位移曲线

Fig.5 Load-displacement curves of white, light grey, dark grey and black phases of S2

2.2.2 摩擦磨损性能分析

室温摩擦试验结果表明,S1、S2、S3的平均室温摩擦因数分别为0.77±0.03、0.70±0.01及0.77±0.02,磨痕深度分别为(153±10)、(130±6)、(137±8) μm,平均体积磨损率为(12.25±0.03)×10‒5、(9.22±0.01)×10‒5、(9.34±0.02)×10‒5mm3/(N∙m)。分析表明,摩擦因数、磨痕深度及平均磨损率随样品制备功率的变化趋势是一致的。通常情况下,摩擦因数、磨痕深度及磨损率越低,则耐磨性越优异。因此,3组涂层样品中,S2的耐磨性是最佳的。

因其具备最佳室温摩擦性能,本文选择S2开展高温摩擦试验。由图6可见,该样品在室温、200、400、600 ℃下的平均摩擦因数分别为0.70±0.03、0.81±0.04、0.67±0.02及0.58±0.01[24]。随着摩擦环境温度逐渐升高,摩擦因数先增大,而后有所降低。

此外,S2在室温、200、400、600 ℃下的磨痕轮廓深度分别为(130±10)、(143±12)、(117±9)、(104±8) μm,相同条件下的平均体积磨损率分别为(9.22±0.03)×10‒5、(10.33±0.04)×10‒5、(7.77±0.02)×10‒5及(6.14±0.01)× 10‒5mm3/(N∙m)。当摩擦环境温度由室温升高至200 ℃时,由于热软化效应,磨痕轮廓深度及平均体积磨损率稍有增大,耐磨性有所降低。而经400、600 ℃高温摩擦试验后,磨痕轮廓深度反而逐渐降低,Löbel 等[30]也报道了类似的研究成果。

表4 S2中白色、浅灰色、深灰色及黑色区域的纳米力学性能

Tab.4 Nano-mechanical properties of white, light grey, dark grey and black phases of S2

图6 S2摩擦因数-时间曲线图

图7为S2的磨损表面形貌图。由图7a可见,S2经室温摩擦30 min后的磨痕宽度约为2 166.3 μm,其局部放大形貌图中还可分别观察到剥落坑、平行于磨球运动方向的摩擦沟槽及垂直于磨球运动方向的微裂纹。当摩擦环境温度升高至200 ℃时,S2的磨痕宽度增大至2 261.0 μm,见图7b。当摩擦温度进一步升高至400 ℃及600 ℃后,S2的磨痕宽度分别缩小至2 059.9 μm(见图7c)及1 876.1 μm(见图7d)。此外,S2磨痕局部放大图7b及图7d中可观察到磨屑、摩擦沟槽及剥落坑。图7c中还可观察到磨痕表面存在大量纳米颗粒,这是由于磨痕表面形成了大量氧化物所致。仅从磨损表面形貌可见,室温摩擦过程中S2主要为磨粒磨损、疲劳磨损及塑性变形,而高温摩擦过程中则发生了磨粒磨损、粘着磨损及塑性变形等多种磨损机制。

Fig.7 Panorama and local magnification SEM image of worn surfaces of S2after wear test at different temperature: a) wear test at RT; b) wear test at 200 ℃; c) wear test at 400 ℃; d) wear test at 600 ℃

经室温摩擦试验后,S2磨痕表面图8a中可观察到浅灰色及深灰色物相存在。EDS面扫描分析表明,深灰色区域O元素集中分布,为磨痕表面的氧化物;浅灰色区域Cr元素含量高,为合金涂层区;为了简化起见,Fe、Co、Ni、Al元素能谱面分布图并未放入本文中。随摩擦温度升高至200 ℃,涂层磨痕表面浅灰色区域减少,深灰色区域有所增加,见图8b。而当温度升高至400及600 ℃后,磨痕表面基本被深灰色相所覆盖,即高温摩擦试验后涂层磨痕表面形成了连续的氧化物层,详见图8c及图8d。能谱检测结果表明,经室温摩擦试验后S2磨损表面氧含量约为16.02%(质量分数)。当摩擦环境温度升高至200、400及600 ℃后,涂层磨损表面氧含量分别增大至20.20%、26.53%、31.62%(质量分数),氧化磨损随摩擦温度升高加剧。在400及600 ℃高温下,氧化磨损已成为高熵合金涂层的主要磨损机制。

Meghwal等[23]对APS制备AlCoCrFeNi涂层磨损表面开展了XPS分析,发现其磨损表面氧化物膜是由Al2O3、Cr2O3、Fe2O3、CoO及Co3O4等金属氧化物组成的。Liu等[31]也报道了类似的试验现象。本文研究表明,当摩擦环境温度≤200 ℃时,高熵合金涂层磨痕表面未形成连续氧化膜,对磨损表面的保护和固体润滑作用有限。相对于室温而言,当摩擦温度升高至200 ℃时,摩擦因数、磨痕轮廓深度和宽度以及磨损率都会由于材料热软化而有所增加。在更高的摩擦环境温度下(≥400 ℃),涂层磨损表面上形成光滑、连续的氧化膜,氧化物膜的纳米力学性能高于APS涂层,在稳定氧化膜的保护和固体润滑作用下,涂层磨粒磨损、粘着磨损作用减弱,S2涂层的摩擦因数、磨痕轮廓深度和宽度以及磨损率均有所降低。

由图9a可见,经室温摩擦30 min后,Si3N4对偶磨球表面形成了直径约2 107.6 μm的磨痕。当摩擦温度升高至200 ℃后,Si3N4磨球表面磨痕直径增大至约2 192.2 μm,见图9b。而经400及600 ℃摩擦30 min后,Si3N4磨球表面磨痕直径降低至约2 036.7 μm及1 887.7 μm,分别见图9c及图9d。值得引起注意的是,Si3N4磨球表面磨痕直径的变化趋势与涂层样品表面磨痕宽度(见图7)的变化趋势是一致的。由EDS面扫元素分布图9a及图9b可见,当摩擦环境温度≤200 ℃时,磨球表面所形成的氧化物较少;而当摩擦环境温度≥400 ℃时,磨球磨痕中的氧化物急剧增加,并形成光滑连续的氧化物膜,分别见图9c及图9d。分析表明,由于对偶磨球及涂层的磨痕表面均形成了连续稳定氧化膜,在纳米力学性能优异的氧化膜的保护及固体润滑作用下,涂层磨粒磨损、粘着磨损作用减弱,高温下涂层的摩擦因数、磨痕轮廓深度及宽度、体积磨损率等均明显降低。

图9 Si3N4磨球经不同温度摩擦试验后的磨痕表面SEM形貌照片及O、Cr元素面分布

Fig.9 SEM images and O and Cr element map distribution of wear scars of Si3N4balls after test at different temperature: a) wear test at RT; b) wear test at 200 ℃; c) wear test at 400 ℃; d) wear test at 600 ℃

图10为S2经不同温度摩擦试验后所收集的磨屑SEM形貌照片。由图10a可见,S2经室温摩擦试验后所收集的磨屑大多为细颗粒。经200 ℃摩擦试验后,所收集的磨屑颗粒变粗,还可观察到片状颗粒,见图10b。随着摩擦温度升高至400及600 ℃,磨屑的粒度逐渐增大,且片状磨屑增多,分别见图10c和图10d。此外,图10d中的片状磨屑上还可观察到复杂微裂纹。分析表明,摩擦环境温度升高后,涂层磨损表面所形成的氧化物增多。随着摩擦试验继续进行,氧化物变形成薄膜覆盖在涂层磨损表面上,且疲劳磨损导致这些氧化物薄层最终出现开裂和剥落。因此,摩擦环境温度升高后可收集到更多片状磨屑。

图10 S2经不同温度摩擦试验后所收集磨屑SEM形貌照片

总之,APS高熵合金涂层在高温(≥ 400 ℃)下的磨损机制以氧化磨损为主,磨粒磨损、粘着磨损和疲劳磨损为辅。此外,高熵合金涂层及Si3N4对偶磨球磨痕表面连续氧化膜的保护及固体润滑作用对APS涂层的高温摩擦磨损性能起着重要作用。据报道[17,31-32],其他HEAs涂层体系在高温摩擦试验过程中磨损表面原位形成氧化物对其耐磨性也有着重要影响,从而进一步印证了本文研究结论。

3 结论

1)采用气雾化FeCoCrNiAl高熵合金球形粉体,APS制备了高熵合金涂层。随着喷涂功率由15 kW逐渐提高至20及25 kW,高熵合金粉体在等离子弧焰流中受热更加充分,涂层中未熔颗粒减少。随着涂层截面中四个区域逐渐由白色过渡至浅灰色、深灰色及黑色,区域中Fe、Co、Cr、Ni元素含量依次降低,而Al元素及O元素含量显著增大。高熵合金粉体XRD图谱以BCC相衍射峰为主,而涂层XRD图谱中仅可观察到以FCC相为主、AB2O4相为辅的衍射峰。

2)相对于S1及S3而言,S2室温摩擦因数、体积磨损率及磨痕深度均为最小值,分别为(0.70±0.01)、(9.22±0.01)×10‒5mm3/(N∙m)及(130±6) μm。室温环境下,磨粒磨损、疲劳磨损及塑性变形为FeCoCrNiAl高熵合金涂层的主要磨损机制。

3)随着摩擦环境温度升高,S2的摩擦因数、磨痕深度与宽度、体积磨损率等首先增加,而后有所降低。涂层磨损表面的氧化程度随试验温度的升高而加剧,当摩擦环境温度≥400 ℃时,高熵合金涂层以氧化磨损为主,以磨粒磨损、粘着磨损及疲劳磨损为辅。涂层及对偶磨球磨损表面连续氧化膜的纳米力学性能优异,氧化膜的保护及固体润滑作用对涂层的高温摩擦磨损行为有着显著影响。摩擦环境温度越高,HEA涂层的耐磨性越好。

[1] GLUDOVATZ B, HOHENWARTER A, CATOOR D, et al. A Fracture-Resistant High-Entropy Alloy for Cryogenic Applications[J]. Science, 2014, 345(6201): 1153-1158.

[2] HE J Y, WANG H, HUANG H L, et al. A Precipitation- Hardened High-Entropy Alloy with Outstanding Tensile Properties[J]. Acta Materialia, 2016, 102: 187-196.

[3] TSAI M H, YEH J W. High-Entropy Alloys: A Critical Review[J]. Materials Research Letters, 2014, 2(3): 107-123.

[4] YEH J W. Physical Metallurgy of High-Entropy Alloys[J]. JOM, 2015, 67(10): 2254-2261.

[5] CHEN Yong-xing, ZHU Sheng, WANG Xiao-ming, et al. Microstructure Evolution and Strengthening Mechanism of Al0.4CoCu0.6NiSi(=0-0.2) High Entropy Alloys Prepared by Vacuum Arc Melting and Copper Injection Fast Solidification[J]. Vacuum, 2018, 150: 84-95.

[6] MASEMOLA K, POPOOLA P, MALATJI N. The Effect of Annealing Temperature on the Microstructure, Mechanical and Electrochemical Properties of Arc-Melted AlCrFeMnNi Equi-Atomic High Entropy Alloy[J]. Journal of Materials Research and Technology, 2020, 9(3): 5241-5251.

[7] SINGH N, SHADANGI Y, SHIVAM V, et al. MgAlSiCrFeNi Low-Density High Entropy Alloy Processed by Mechanical Alloying and Spark Plasma Sintering: Effect on Phase Evolution and Thermal Stability[J]. Journal of Alloys and Compounds, 2021, 875: 159923.

[8] MOAZZEN P, TOROGHINEJAD M R, CAVALIERE P. Effect of Iron Content on the Microstructure Evolution, Mechanical Properties and Wear Resistance of FeCoCrNi High-Entropy Alloy system Produced via MA-SPS[J]. Journal of Alloys and Compounds, 2021, 870: 159410.

[9] 黄灿, 杜翠薇, 代春朵, 等. 高熵合金涂层的研究进展[J]. 表面技术, 2019, 48(11): 15-22, 35.HUANG Can, DU Cui-wei, DAI Chun-duo, et al. Research Progress of High-Entropy Alloy Coatings[J]. Surface Technology, 2019, 48(11): 15-22, 35.

[10] 辛蔚, 王玉江, 魏世丞, 等. 热喷涂制备高熵合金涂层的研究现状与展望[J]. 工程科学学报, 2021, 43(2): 170-178.XIN Wei, WANG Yu-jiang, WEI Shi-cheng, et al. Research Progress of the Preparation of High Entropy Alloy Coatings by Spraying[J]. Chinese Journal of Engineering, 2021, 43(2): 170-178.

[11] HSU W L, YANG Ya-chu, CHEN C Y, et al. Thermal Sprayed High-Entropy NiCo0.6Fe0.2Cr1.5SiAlTi0.2Coating with Improved Mechanical Properties and Oxidation Resistance[J]. Intermetallics, 2017, 89: 105-110.

[12] ANG A S M, BERNDT C C, SESSO M L, et al. Plasma-Sprayed High Entropy Alloys: Microstructure and Properties of AlCoCrFeNi and MnCoCrFeNi[J]. Metallurgical and Materials Transactions A, 2015, 46(2): 791-800.

[13] ANUPAM A, KOTTADA R S, KASHYAP S, et al. Understanding the Microstructural Evolution of High Entropy Alloy Coatings Manufactured by Atmospheric Plasma Spray Processing[J]. Applied Surface Science, 2020, 505: 144117.

[14] LIN Dan-yang, ZHANG Nan-nan, HE Bin, et al. Influence of Laser re-Melting and Vacuum Heat Treatment on Plasma-Sprayed FeCoCrNiAl Alloy Coatings[J]. Journal of Iron and Steel Research, International, 2017, 24(12): 1199-1205.

[15] WANG Cai-mei, YU Jian-xing, ZHANG Yu, et al. Phase Evolution and Solidification Cracking Sensibility in Laser Remelting Treatment of the Plasma-Sprayed CrMnFeCoNi High Entropy Alloy Coating[J]. Materials & Design, 2019, 182: 108040.

[16] CHENG K C, CHEN Jing-han, STADLER S, et al. Properties of Atomized AlCoCrFeNi High-Entropy Alloy Powders and Their Phase-Adjustable Coatings Prepared via Plasma Spray Process[J]. Applied Surface Science, 2019, 478: 478-486.

[17] XIAO Jin-kun, TAN Hong, WU Yu-qing, et al. Microstructure and Wear Behavior of FeCoNiCrMn High Entropy Alloy Coating Deposited by Plasma Spraying[J]. Surface and Coatings Technology, 2020, 385: 125430.

[18] HSU W L, MURAKAMI H, YEH J W, et al. On the Study of Thermal-Sprayed Ni0.2Co0.6Fe0.2CrSi0.2AlTi0.2HEA Overlay Coating[J]. Surface and Coatings Technology, 2017, 316: 71-74.

[19] JIN Bing-qian, ZHANG Nan-nan, GUAN Sheng, et al. Microstructure and Properties of Laser re-Melting FeCoCrNiAl0.5SiHigh-Entropy Alloy Coatings[J]. Surface and Coatings Technology, 2018, 349: 867-873.

[20] SHI Pei-ying, YU Yuan, XIONG Ni-na, et al. Microstructure and Tribological Behavior of a Novel Atmospheric Plasma Sprayed AlCoCrFeNi High Entropy Alloy Matrix Self-Lubricating Composite Coatings[J]. Tribology International, 2020, 151: 106470.

[21] XIAO Jin-kun, WU Yu-qing, CHEN Juan, et al. Microstructure and Tribological Properties of Plasma Sprayed FeCoNiCrSiAlHigh Entropy Alloy Coatings[J]. Wear, 2020, 448-449: 203209.

[22] WANG Liang-quan, ZHANG Fan-yong, YAN Shu, et al. Microstructure Evolution and Mechanical Properties of Atmosphere Plasma Sprayed AlCoCrFeNi High-Entropy Alloy Coatings under Post-Annealing[J]. Journal of Alloys and Compounds, 2021, 872: 159607.

[23] MEGHWAL A, ANUPAM A, LUZIN V, et al. Multiscale Mechanical Performance and Corrosion Behaviour of Plasma Sprayed AlCoCrFeNi High-Entropy Alloy Coatings[J]. Journal of Alloys and Compounds, 2021, 854: 157140.

[24] 王跃明, 唐求豪, 夏运朝, 等. 超音速火焰喷涂TiB2-50Ni复合涂层的高温摩擦磨损性能[J]. 表面技术, 2020, 49(10): 89-98. WANG Yue-ming, TANG Qiu-hao, XIA Yun-zhao, et al. Friction and Wear Properties of TiB2-50Ni Composite Coating Fabricated by High Velocity Oxygen Flame Spraying at High Temperature[J]. Surface Technology, 2020, 49(10): 89-98.

[25] 欧阳晟, 储志强, 唐求豪, 等. 爆炸喷涂铁基非晶涂层的微观结构和纳米压痕行为[J]. 粉末冶金材料科学与工程, 2020, 25(6): 480-485. OUYANG Sheng, CHU Zhi-qiang, TANG Qiu-hao, et al. Microstructure and Nano-Indentation Behavior of Detonation Sprayed Iron-Based Amorphous Coating[J]. Materials Science and Engineering of Powder Metallurgy, 2020, 25(6): 480-485.

[26] PHARR G M. Measurement of Mechanical Properties by Ultra-Low Load Indentation[J]. Materials Science and Engineering: A, 1998, 253(1-2): 151-159.

[27] 汪利斌, 秦黎, 闻寄勤, 等. 纳米压痕法测定NiTi形状记忆合金表面氧化膜纳米硬度和弹性模量[J]. 热加工工艺, 2019, 48(6): 182-187.WANG Li-bin, QIN Li, WEN Ji-qin, et al. Measurement of Nano Hardness and Elastic Modulus of Surface Oxidation Film on NiTi Shape Memory Alloy by Nano- Indentation[J]. Hot Working Technology, 2019, 48(6): 182- 187.

[28] MUSIL J, JIROUT M. Toughness of Hard Nanostructured Ceramic Thin Films[J]. Surface and Coatings Technology, 2007, 201(9-11): 5148-5152.

[29] CHENG J B, LIANG X B, XU B S. Devitrification of Arc-Sprayed FeBSiNb Amorphous Coatings: Effects on Wear Resistance and Mechanical Behavior[J]. Surface and Coatings Technology, 2013, 235: 720-726.

[30] LÖBEL M, LINDNER T, LAMPKE T. High-Temperature Wear Behaviour of AlCoCrFeNiTi0.5Coatings Produced by HVOF[J]. Surface and Coatings Technology, 2020, 403: 126379.

[31] LIU Hao, LIU Jian, CHEN Pei-jian, et al. Microstructure and High Temperature Wear Behaviour of In-Situ TiC Reinforced AlCoCrFeNi-Based High-Entropy Alloy Composite Coatings Fabricated by Laser Cladding[J]. Optics & Laser Technology, 2019, 118: 140-150.

[32] TIAN Li-hui, FENG Zong-kang, XIONG Wei. Microstructure, Microhardness, and Wear Resistance of AlCoCrFeNiTi/ Ni60 Coating by Plasma Spraying[J]. Coatings, 2018, 8(3): 8030112.

Friction and Wear Properties of FeCoCrNiAl High Entropy Alloy Coatings Prepared by Atmospheric Plasma Spraying at High Temperature

1,1,1,1,2,3,4

(1. School of Materials Science and Engineering, Hunan University of Science and Technology, Hunan Xiangtan 411201, China; 2. Powder Metallurgy and Cermet Institute, Hunan Metallurgy Material Institute Co., Ltd., Changsha 410129, China; 3. School of Management Engineering, Jiangsu Urban and Rural Construction Vocational College, Jiangsu Changzhou 213147, China; 4. Hunan Province Key Laboratory of Materials Surface & Interface Science and Technology, Central South University of Forestry and Technology, Changsha 410004, China)

Highentropy alloys (HEAs) can be widely used in aerospace, biomedicine, new energy, nuclear industry, etc. for their high strength and hardness, superior wear resistance and corrosion resistance. However, the cost of HEAs is expensive due to the high price of each principal component. HEA coatings developed based on HEA theory and modern surface technology can not only reduce preparation cost, but also obtain superior properties. The work aims to prepare FeCoCrNiAl HEA coatings under a power of 15, 20 and 25 kW by atmospheric plasma spraying (APS) and investigate the effects of temperature on microstructure and wear resistance of HEA coatings.

Microstructure, element map distribution and phase structure of feedstock, APS coatings, worn surfaces of coatings and grinding balls were characterized by scanning electron microscope (SEM), energy dispersive spectroscopy (EDS) and X-ray diffractometer (XRD), respectively. The nano-mechanical properties of APS coatings were investigated by a NanoTest Berkovich diamond nano-indenter. Tribological properties of APS coatings were analyzed with a ball-on-disc high speed reciprocating wear tester. The Si3N4balls with a diameter of 6 mm were selected as counterparts. The cross-sectional morphology of wear marks and wear volume loss of HEA coatings were measured by Probe-type material surface wear mark measuring instrument.

The results indicated that white, light gray, dark gray and black phases formed in the APS coatings. The higher the oxygen content was, the darker the color of the phases was. Values of nano-mechanical properties including nano-indentation hardness (), Young's modulus (r), ratio of hardness to elastic modulus (/r) gradually increased as color of the phase region transformed from white to light gray, dark gray and black. The HEA powder melted more completely with the increase of spray power. The XRD patterns of HEA powder were dominated by diffraction peaks of BCC phase, while those of APS coatings were dominated by FCC phase and supplemented by AB2O4phase. The room temperature (RT) wear resistance of HEA coating sprayed under 20 kW power was the best of the three under the optimum coefficient of friction (COF), wear rate and wear track depth of (0.70±0.02) (9.22±0.01)×10‒5mm3/(N∙m) and (130±10) μm, respectively. Abrasive wear, adhesive wear, fatigue wear, and plastic deformation were the main wear mechanisms of APS coatings at RT. COF, wear track depth and width, wear rate of APS coating prepared under 20 kW power all initially increased and then decreased with the rise of test temperature. Most of wear debris collected from RT wear test were fine particles. Particle size of wear debris increased with more and more plate-like debris being formed during wear test at higher temperature. Oxidation degree of worn surfaces of HEA coatings increased with test temperature rising. Main oxidation wear and supplemented abrasive wear, adhesive wear and fatigue wear occurred during high temperature wear test. The wear resistance of HEA coatings was obviously improved at high temperature due to protection and solid lubrication from a continuous oxide film formed on the worn surface. APS HEA coatings may be widely used in high temperature and oxygen enriched environments in the near future.

atmospheric plasma spraying; FeCoCrNiAl high entropy alloy; coating; microstructure; friction and wear properties

2022-08-05;

2023-04-14

TG174.442

A

1001-3660(2023)10-0160-11

10.16490/j.cnki.issn.1001-3660.2023.10.012

2022-08-05;

2023-04-14

湖南省自然科学基金(2021JJ50025);湖南省重点研发计划项目(2022GK2030);益阳市科技创新计划项目(2022061)

Supported by Natural Science Foundation of Hunan Province (2021JJ50025); Key R&D Plan Project of Hunan Province (2022GK2030); Yiyang Science and Technology Innovative Program Project (2022061)

王跃明, 李晨龙, 韩旭航, 等. 大气等离子喷涂FeCoCrNiAl高熵合金涂层的高温摩擦磨损性能[J]. 表面技术, 2023, 52(10): 160-170.

WANG Yue-ming, LI Chen-long, HAN Xu-hang, et al. Friction and Wear Properties of FeCoCrNiAl High Entropy Alloy Coatings Prepared by Atmospheric Plasma Spraying at High Temperature[J]. Surface Technology, 2023, 52(10): 160-170.

责任编辑:万长清