Physicochemical properties of silver carp (Hypophthalmichthys molitrix)mince sausages as influenced by washing and frozen storage

2023-10-19KvehRhmnifrhJoeRegensteinMehdiNikoo

Kveh Rhmnifrh, Joe M.Regenstein, Mehdi Nikoo

a Department of Pathobiology and Quality Control, Artemia and Aquaculture Research Institute, Urmia University, Urmia, West Azerbaijan, 57179-44514, Iran

b Department of Food Science, Cornell University, Ithaca, NY, 14853-7201, USA

Keywords:Frozen storage Emulsion-type sausages Hypophthalmichthys molitrix Minced fish

ABSTRACT Frozen storage of emulsion-type sausages may be one approach to avoid or reduce the use of sodium nitrite,which is associated with health risks.Silver carp (Hypophthalmichthys molitrix) mince (M0) was washed for 1 (M1)or 3 (M3) times and the impact of washing on the properties frozen storage (- 18 ◦C) during 4 months were determined and results were compared to those of conventional silver carp sausages (Mt).Lipid oxidation, as evidenced by changes in thiobarbituric acid reactive substances and FFAs, took place during storage in the order of M0 > M1 = M3 = Mt with M0 being highly oxidized (P ≤0.05).Total volatile base nitrogen formed during storage and the ranking for the quality loss was as follows M0 > M1 > M3 = Mt.Washing (M1 = M3) led to less hardness (P ≤0.05).Mt had better redness, while M1 and M3 led to higher expressible moisture, water release and lightness (P ≤0.05).Results indicated the lower sensory and consumer-liking properties of frozen M1 and M3 sausages.Therefore, washing and frozen storage influenced silver carp mince sausages.

1.Introduction

Among various emulsion meat products, sausages are desired by consumers due to their desirable sensory properties (Abbasi et al., 2019;Chattopadhyay, Xavier, Balange, Layana, & Nayak, 2019).Consumer demand has been increasing for fish sausages (Chaijan & Panpipat,2020; Chattopadhyay, Xavier, Balange, et al., 2019; Feng et al., 2020;Liu, Ji, Zhang, Xue, & Xue, 2019; Rahmanifarah, Shabanpour, & Shabani, 2015; Surasani, Raju, Shafiq, Chandra, & Lakshmisha, 2020).Fish sausages are usually healthier and nutritionally better than conventional mammalian and avian meat sausages because of its greater polyunsaturated fatty acids (PUFA) (Feng et al., 2020).However, fish sausages might rapidly develop oxidative rancidity during storage, resulting in safety and quality issues.The fish meat also has iron, haemoglobin and other soluble components involved in oxidative reactions (Nikoo,Regenstein, & Ahmadi Gavlighi, 2018) making fish products highly susceptible to lipid and protein oxidation (Eymard, Baron, & Jacobsen,2009; Medina & Pazos, 2010).

In cured meat products, nitrite is added to enhance color and flavor,for microbial inhibition, and as an antioxidant (Kurt & Zorba, 2010).However, there is a potential toxicity issue with nitrite salts and their carcinogenicity resulting from the reactions with biogenic amines and the formation of N-nitrosamines (Kur´cubi´c et al., 2014), which in part has driven the interest for fresh or minimally processed foods with“clean” labels that are microbiologically safe, nutritious and healthy(Tsironi, Houhoula, & Taoukis, 2020).

Silver carp (Hypophthalmichthys molitrix) is a major commercially aquacultured carp species.The global production of silver carp has expanded steadily, rising from 3.8 million tonnes in 2006 to 5.3 million tonnes in 2016 (FAO FishStat).Production of sausages with less fishy and muddy flavor from silver carp might increase its value and profitability (Nie, Lin, & Zhang, 2014; Nie, Zhang, & Lin, 2014; Pourashouri,Shabanpour, Kordjazi, & Jamshidi, 2020; Rahmanifarah et al., 2015; Xu,Xia, Yang, & Nie, 2010).During fish mince preparation, hemopigments may be incorporated into the product, causing it to darken in color (de Oliveira Filho, Viegas, Kamimura, & Trindade, 2012).This issue can be addressed by washing the mince with water, removing pigments as well as deteriorative bacteria, soluble proteins, enzymes, ammoniacal components, flavorings, lipids, and blood (Medina et al., 2012; Park & Lin,2005).Despite possible changes of the proximate composition, this may improve the sensory quality and increase the shelf life of the product (de Oliveira Filho et al., 2012).On the other hand, production of emulsion sausages needs the use of nitrite to maintain the quality and safety of the product during refrigerated storage.Production of frozen fish sausages might be one way to reduce the need for nitrite.However, no information is available on the effect of frozen storage on the quality of silver carp emulsion sausages, particularly from washed mince.Therefore, this study aimed to investigate the effects of washing silver carp mince on the quality of sausages during frozen storage.

2.Materials and methods

2.1. Raw material and mince processing

Fresh post-rigor aquacultured silver carp (H.molitrix) (1200–1500 g)were purchased from a local fish store (Shirin, Kermanshah, Iran) estimated to be one year old and caught/harvested from earthen ponds and transported in ice to the laboratory (Danesh Salamat Khorak Yaran,Mahisa Co., Hamedan, Iran) within 20 min.At the Mahisa laboratory,the fish were beheaded, gutted, and deboned using a 3 mm hole plate fish separator (Baader 696, Bone Separator, Germany).Minces were washed in cold distilled water (2◦C) at a ratio 1:3 (w/v) for 5 min with slow stirring for 30 s every 1 min and then allowed to settle for 6 min.Total time spent at each washing step was 10 min (Rahmanifarah et al.(2015)).Following each washing, the minces were dewatered using two layers of cheese cloth.Different minces obtained during processing were: silver carp mince obtained after the mincing (M0), mince after the first washing (M1), and mince after the third washing (M3).Immediately after processing, mince products (2 kg each) were used for sausage preparation.

2.2. Preparation of fish sausages

Sausages were prepared according to Rahmanifarah et al.(2015).by mixing washed or unwashed mince (700 g/kg) with crushed ice (100 g/kg), vegetable oil (100 g/kg), filler and binders (wheat starch,carrageenan, and sodium caseinate) (76 g/kg), salt (11 g/kg), sodium tripolyphosphate (3 g/kg), and spice mix (10 g/kg).Control sausages(Mt) were prepared using unwashed mince (M0) and 120 ppm sodium nitrite.The mixtures were mixed in a mini cutter for 10 min and manually stuffed in 5 layers’ polyamide casings (25 mm diameter; Arta,Tabriz, Iran) using a stainless-steel sausage stuffer.The stuffed sausages were cooked at 90◦C for 85 min in a temperature-controlled water bath.Cooked sausages were then cooled in a water bath and stored frozen(- 20◦C) for 0, 30, 60, 90, and 120 days and at each time point, three samples from each treatment were randomly taken for analysis.

2.3. Compositional analysis

Total protein (crude protein, N ×6.25) content of mince samples and sausages were determined using the Kjeldahl method according to standard AOAC methods (1998).Total moisture content of samples was determined by the AOAC (Horwitz, 2010).The ash content was determined by mineralization at 550◦C according to standard AOAC methods(1998).

2.4. Determination of fatty acid composition

A gas chromatography (GC) system (Agilent Technologies 7890A,Santa Clara, CA, USA) equipped with a flame ionization detector (FID)and a 30 m × 0.25 mm DB225MS column was used to measure the composition of fatty acids (Miquel, 1992) in oils from rainbow trout by-products subjected to FT or GIT processes for different times.The content of each fatty acids was expressed as % of the total of the peaks obtained, assuring that the results add up to ~100%.

2.5. Expressible moisture (EM)

EM was determined by centrifugation of 5 g of sausages at 1000×gfor 15 min at 4◦C.The liquid loss was determined and EM was the percentage of weight loss divided by the total sample weight (Jin et al.,2007).

2.6. Released water (WR)

For measuring WR, sausages were first weighed (A) and the casings were removed.The water released on the surface after 60 min storage at room temperature (24 ± 1◦C) was removed using a filter paper(Whatman No.4) and samples were reweighed (B).The weight of the empty casing was also obtained (C).WR was calculated using the following equation WR (%) =(A- (B +C)/(A- C) ×100 (Rahmanifarah et al., 2015).

2.7. Texture profile analysis (TPA)

TPA was done using a Texture Analyzer (LFRA 4500, Brookfield Engineering, Middleboro, MA, USA) according to a previous method(Pereira et al., 2011).For textural analysis, sausages after removing the casing were left at room temperature for 1 h, then cut into 15 mm long cylinders.Nine samples (1.5 × 2.5 cm)/treatment were compressed to 30% of their original height in a double cycle compression as described by Bourne (1978) at a constant rate of 1 mm/s using a 50 mm flat probe(TA1000).Hardness (N) and springiness (cm) were obtained from the software with the instrument.

2.8. Color measurements

Instrumental color parameters were measured in triplicate using a colorimeter (Lovibond, CAM-System 500, England) at room temperature.The values of L*, a* and b* indicating lightness, redness/greenness and yellowness/blueness, respectively, were obtained.

2.9. pH measurements

Two g of chopped sausages was homogenized with distilled water (8 mL) (Heidolph DIAX900, Heidolph Instruments GmbH, Schwabach,Germany) for 1 min and pH was read using a pH meter (Metrohm 713 pH meter, Herisau, Switzerland) (Feng et al., 2020).

2.10.Total volatile base nitrogen(TVBN)

TVB-N were determined using the method of Watabe, Kamal, and Hashimoto (1991).TVB-N content was expressed as mg/100g of sample.

2.11.Thiobarbituric acid-reactive substances(TBARS)

TBARS were determined using the method of Buege and Aust (1978).TBARS were expressed as mg malonaldehyde/kg sample using a standard curve of 1,1,3,3-tetramethoxypropane (0–6 mg/kg).

2.12.Free fatty acid(FFA)

FAA was measured according to the method described by Egan et al.on the lipids extracted according to Bligh and Dyer (1959) method.Lipids was dissolved in 25 mL of ethanol:NaOH and titrated using thymolphthalene as indicator.Results were expressed as the percentage of oleic acid.2.13.Statistical analysis

Data were subjected to analysis of variance (ANOVA) (the Statistical Package for the Social Sciences, ver 16.0, SPSS Inc, Chicago, IL, USA)and differences among means were determined using Duncan’s multiple range tests atP< 0.05.All data were expressed as Mean ± Standard deviation (SD) (n = 3).

3.Results and discussion

3.1. Proximate composition of raw washed minces

Different washing process changed proximate composition in silver carp meat (Table 1).M0had higher content of protein and lower moisture than M1and M3(P≤0.05).During washing some substances include blood, pigments, odors, enzymes, mucus, and some watersoluble proteins effectively removed.Washing of mince also increases binding agents and subsequently percentage of moisture in the product increased compared to M0.The highest moisture content was observed in M3 (83.2%) because of further exposure to water as compared to M1(82.6%) and M0 (78.7%).Overall, protein and moisture analysis results were similar to that reported by Wiles, Green, and Bryant (2004) for catfish mince.Additionally the moisture content of M3 and M1 in this study was higher than commercial surimi (Eymard et al., 2009) and this could be explained by hand dehydration.Ash content in M0was higher than M1 and M3 (P≤0.05) but significant differences between M1and M3not observed (P≤0.05).Decrease in ash content in M1and M3may be due to removal of water-soluble mineral constituents.Lipid content regularly decreased during washing processes.It altered from 2.9% in unwashed mince to 1.5% in M3.M1had intermediate fat content (2.1%).

3.2. Fatty acid composition of raw fish minces

Results of fatty acid composition analysis in M0, M1and M3are summarized in Table 1.Fatty acids were 23.2%–27.6% saturated (SFA),32.9%–37.7% monounsaturated (MUFA), and 25.8%–35.9% polyunsaturated (PUFA) of the total fatty acids for all minces.Palmitic acid(C16:0) was the most important fatty acid within saturated fraction.Oleic acid C18:1 was the major monounsaturated fatty acid.MUFA proportions were highest in M0and lowest in M3(P≤0.05).AmongPUFA, eicosapentaenoic (C20:5n3) (EPA) and docosahexaenoic(C22:6n3) (DHA) were prominent in M1(17.4% and 12.9% respectively)and significantly less in M0(12.6% and 7.6% respectively) (P≤0.05).Total PUFA, n-3, n-6, ratio of PUFA/SFA and sum of EPA and DHA were important in M1and significantly less important in M0(P≤0.05).Fatty acid profiles in this work were near to those found in washed sardine mince (Selmi, Batista, Sadok, Bandarra, & Nunes, 2010).The higher proportion of EPA and DHA in M1and M3can be related to the easier deletion of the neutral lipids than of the polar lipids during washing.Due to interactions of polar lipids with proteins, phospholipids rich in omega-3 fatty acids were hardly removed during processing and proportions of PUFA including EPA and DHA increased in M1and M3(Eymard et al., 2009).The decrease in lipid content of M1occurred by changes in fatty acid content.During washing lipids are floated at the surface and subsequently removed (Rahmanifarah et al., 2015).

Table 2 Moisture content of silver carp mince sausages during frozen storage (- 20 ◦C).

Fig.1.Expressible moisture (EM) and water release (WR) of silver carp sausages during 120 days of storage (- 20 ◦C).Bars represent standard deviations(n = 3).Different small and capital superscript letters indicate significant differences among storage times and treatments, respectively (P ≤0.05).

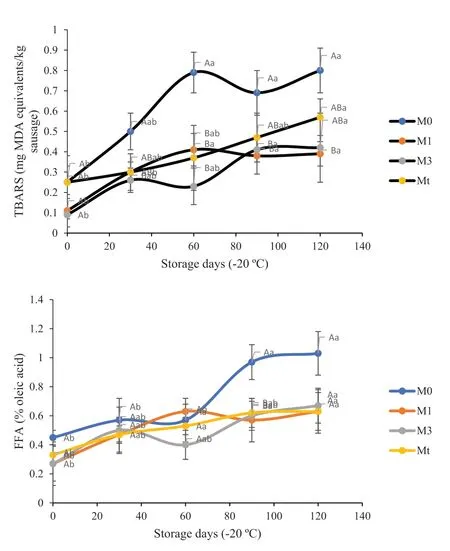

Fig.2.TBARS and free fatty acids (FFA) of silver carp sausages during 120 days of storge (- 20 ◦C).Bars represent standard deviations (n = 3).Different small and capital superscript letters indicate significant differences among storage times and treatments, respectively (P ≤0.05).

3.3. Moisture, expressible moisture (EM) and water release (WR)

Changes of moisture, EM and WR of silver carp washed or unwashed mince sausages during 120 days are shown in Table 2 and Fig.1.At day 1, moisture content of sausages was between 66 and 70% and M1and M3sausages showed higher moisture than M0and Mt which were not different between the two samples (Table 1) (P≤0.05).In all sausages,moisture did not change during frozen storage (P≥0.05).However,after 120 days of storage at - 20◦C, M0and Mt had significantly lower moisture (P≤0.05).Increases in moisture content after washing have been observed in washed mince of Nile tilapia (de Oliveira Filho et al.,2012) and horse mackerel (Eymard et al., 2009).EM was increased in all treatments after 30 days frozen storage (Fig.1A) (P≤0.05) but did not change with increasing frozen storage time (P≥0.05).Different sausages had similar EM up to 30 days of storage (P≥0.05).At day 60, EM in M1and M3was significantly higher than M0and Mt and this pattern continued until 120 days (P≤0.05).However, M0and Mt sausages were not different in their EM at the end of frozen storage (P≥0.05).WR increased from 0.2 to 0.5% in fresh sausages to 0.7%–1.1% at day 30 (P≤0.05).However, differences among different sausages were not significant (P≥0.05).WR was significantly higher in M1and M3from day 60 up to 120 than M0and Mt (P≤0.05) while M0and Mt showed similar values (Fig.1B) (P≥0.05).WR refers to water that was retained in the casing and on the surface of the product.Sausages with high WR might have proteins with lower ability to retain water (Riebroy, Benjakul,Visessanguan, & Tanaka, 2005).However, the higher WR in M1and M3might be due to the higher moisture in these sausages compared to sausages prepared from unwashed mince (M0and Mt).Rahmanifarah et al.(2015) found the higher WR in silver carp sausages prepared from surimi during the 40 days of refrigerated storage (4◦C).

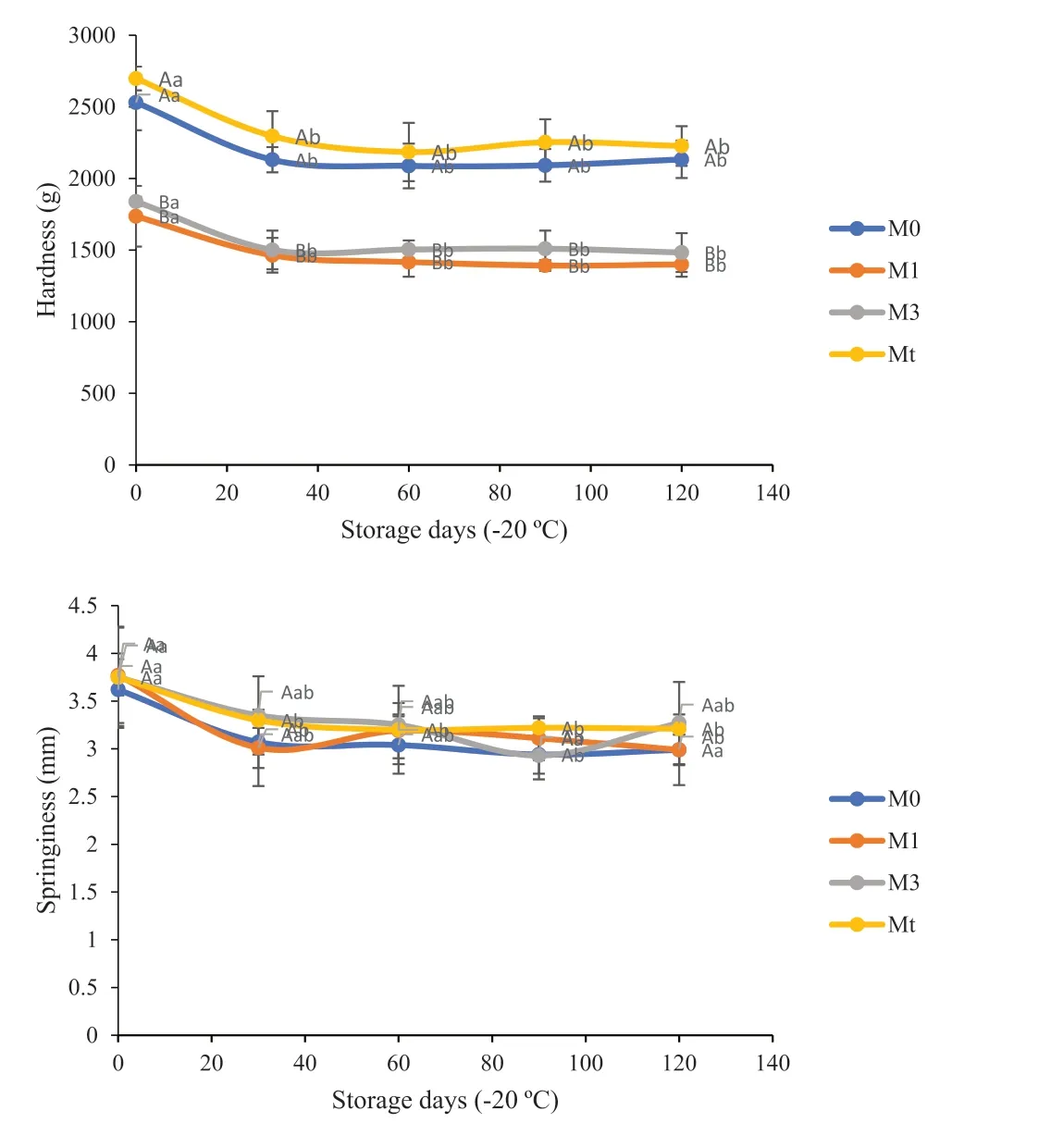

Fig.3.Hardness and springiness of silver carp sausages during 120 days of storge (- 20 ◦C).Bars represent standard deviations (n =3).Different small and capital superscript letters indicate significant differences among storage times and treatments, respectively (P ≤0.05).

3.4. Lipid oxidation

Lipid oxidation in fish sausage samples during 120 days of frozen storage in shown in Fig.2.TBARS values of all sausages increased with increasing the frozen storage time (Fig.2A).Mince M0sausages had higher TBARS compared to other sausages, especially after 30 days (P≤0.05).The TBARS value of lipids from M1and M0showed the lowest values at 1 day (P≤0.05).However, the increase was found with further increase of time.Nevertheless, no differences in TBARS were noticeable at 90 and 120 days of frozen storage (P≥0.05).With Mt, the TBARS value was generally higher than that of M1and M3at a similar time (P≤0.05) and showed a slight increase with increasing frozen storage time(P≥0.05).M0at 120 day showed a higher rate of lipid oxidation compared to Mt, M1and M3(P≤0.05).Marine lipids are rich in PUFA,which are prone to oxidation (Nikoo, Regenstein, Noori, & Gheshlaghi,2021; Sarteshnizi et al., 2021).The enhanced oxidation occurred when M0was used for sausage production, and was more pronounced when frozen storage time increased.This might be due to the higher fat and unsaturated fatty acids and pigments in M0that may make the sausages more susceptible to lipid oxidation.Washing fish mince will creates an imbalance in the prooxidant-antioxidant equilibrium in the muscle tissue and contributes to the differences in the oxidative status of mince and unwashed mince.In horse mackerel, lipid oxidation developed faster in mince (M0) during refrigerated storage compared to washed minces with the ranking of M0>M1>M2>M3(Eymard et al., 2009).Washing silver carp mince might lower the pro-oxidants and undesirable oxidative substrates from mince, leading to the decrease in lipid oxidation, as evidenced by the lower TBARS in M1and M3in frozen sausages compared to M0.With Mt, the lower TBARS was observed compared to M0, which might be due to the antioxidative activity of nitrite (Jo, Ahn, Son, Lee, & Byun, 2003).

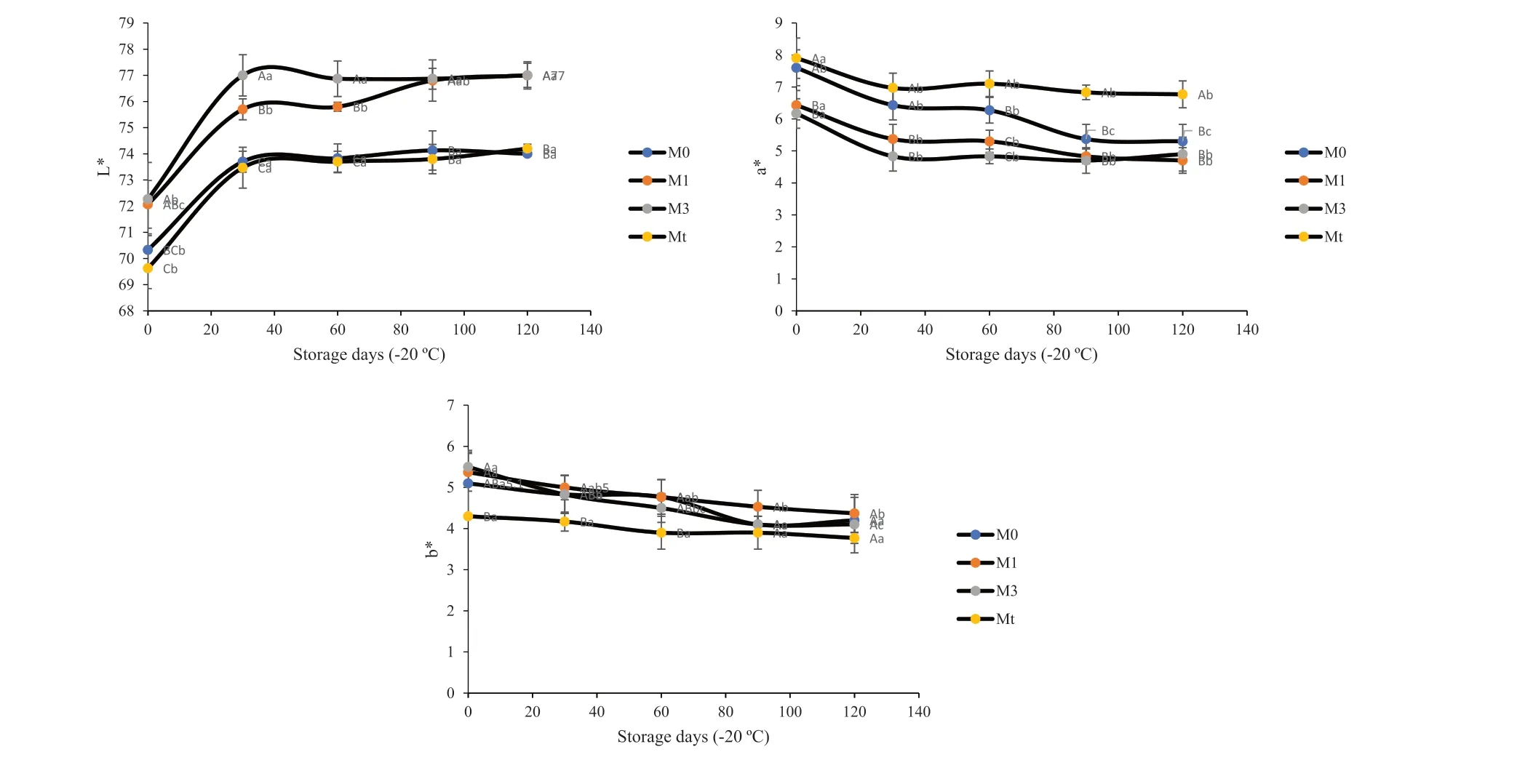

Fig.4.Color parameters of silver carp sausages during 120 days of storge (- 20 ◦C).Bars represent standard deviations (n = 3).Different small and capital superscript letters indicate significant differences among storage times and treatments, respectively (P ≤0.05).(For interpretation of the references to color in this figure legend, the reader is referred to the Web version of this article.)

At day 0, the FFA was not different among different samples(Fig.2B).It increased with increasing frozen storage times (P≤0.05).However, the differences between 30 and 60 days and between 90 and 120 days were not significant (P≥0.05).With M3sausages, the FFA increase was not significantly different from 30 to 90 days (P≥0.05),and with further storage to 120 days, it increased significantly (P≤0.05).M1and M3sausages showed the similar FFA during frozen storage and had no significant difference with Mt (P≥0.05).FFA levels indicating lipid hydrolysis showed an increasing trend during frozen storage at - 20◦C and reached the highest level for M0after 120 day.The increase in FFA during frozen storage of fish was possibly due to some enzymatic activity (Baron, KjÆrsgård, Jessen, & Jacobsen, 2007).Results indicated the higher susceptibility of M0sausages to lipid oxidation during frozen storage.However, TBARS of all sausages were below the threshold value (1.0 mg MDA equivalent/kg) for detection of rancid flavors (Chaijan & Panpipat, 2020; Seo, Yum, Kim, Jeong, & Yang,2016).

3.5. Textural properties

TPA parameters of silver carp washed or unwashed mince sausages are shown in Fig.3.At day 1, hardness was significantly lower in M1and M3compared to M0and Mt (Fig.3A) (P≤0.05), however no differences were observed between M1and M3or M0and Mt (P≥0.05).Hardness in all sausage samples decreased during frozen storage.However, the changes from 30 to 120 days were not significant for all sausages (P≤0.05).Washing silver cap mince led to lower sausage hardness, as evidenced by lower values (1400 and 1480 g for M1and M3, respectively)compared to M0(2130 g) and Mt (2230 g) after 120 days of storage at- 20◦C (P≤0.05).The lower hardness of M1and M3sausages was consistent with higher moisture and lower fat in these samples.de Oliveira Filho et al.(2012) found that sausages produced with washed tilapia mince had lower texture.They suggested that the lower hardness may be due to the higher content of moisture in sausages after washing than that of the original raw material, resulting in a reduced protein concentration and a softer product.A decrease in hardness of seafood products after washing was also observed for products from catfish(Wiles et al., 2004) and surimi in sausages (Murphy, Gilroy, Kerry,Buckley, & Kerry, 2004).Therefore, TPA tests showed that washing decreased silver carp frozen sausage texture.While washing produced the greatest decrease in the hardness of sausages, it did not change springiness considerably (Fig.3B) which means that the elasticity of the sausages is not decreased.However, it showed a slight decrease with increasing frozen storage (P≤0.05).

3.6. Color

Effect of washing and thermal treatments on color of silver carp sausages was determined (.Fig.4).There were significant differences among experimental treatments forL*,a*,b* values during the storage period (P≤0.05).After sausage preparation, lightness in M0, M1, M3and Mt were 70.3, 72.1, 72.3 and 69.6, respectively.Lightness of sausages increased with storage time increased and M1and M3had higher lightness than M0and Mt at the end of the frozen storage (P≤0.05).On the other hand, Mt showed higher redness and lower yellowness after 120 days (P≤0.05).The results indicated that washing of silver carp mince led to an increase in lightness and yellowness of sausage samples while it decreased redness.Discoloration of fish sausages during the storage might be related to the storage time, lipid oxidation, and oxidation of pigments, heme and sarcoplasmic proteins.Blood and heme pigments such as myoglobin and hemoglobin are removed by washing fish mince (Medina et al., 2012; Sadeghinejad, Sarteshnizi, Gavlighi, &Barzegar, 2019; Wiles et al., 2004).Higher lightness of washed mince might be due to the higher moisture content (Rahmanifarah et al.(2015)).M3had significantly higher lightness than M1especially after 30 and 60 days of frozen storage.The number of washing cycles might influence color of fish mince (Baxter & Skonberg, 2008).Therefore,color of frozen silver carp emulsion sausages was influenced by washing.

3.7. TVB-N and pH

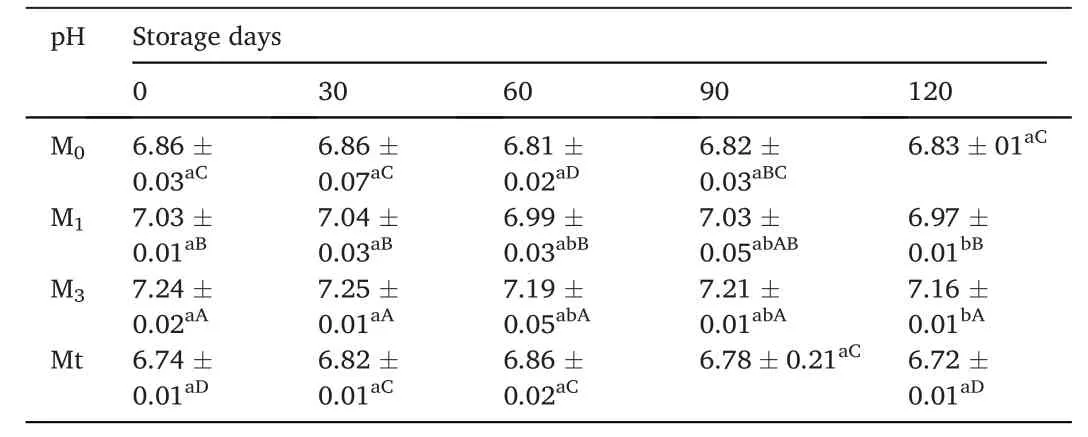

The change in pH and TVB-N of silver carp sausages during frozen

4.Conclusion

Fig.5.TVB-N (mg/100 g) (A) and pH (B) of silver carp sausages during 120 days of storge (- 20 ◦C).Bars represent standard deviations (n = 3).Different small and capital superscript letters indicate significant differences among storage times and treatments, respectively (P ≤0.05).

Table 3 pH of silver carp mince sausages during frozen storage (- 20 ◦C).

Washing caused a reduction in sensory properties compared to unwashed mince.However, sausages from washed minces showed lower TVB-N and lipid oxidation compared to sausages from unwashed mince.Color properties were negatively influenced as washed mince sausages were lighter and had lower hardness.In addition, washed mince sausages had higher moisture content and EM.Those properties were influenced by frozen storage.A lower sensory and properties of frozen M1and M3sausages were observed.Washing and frozen storage influenced silver carp mince sausages.storage was determined.Initial TVB-N of M1and M3sausages was lower than M0and Mt at day 1 (Fig.5) (P≤0.05) while the differences between the two samples and between M0and Mt were not significant (P≥0.05).In M0, TVB-N increased from 10.2 to 28.9 mg N/100 g after 120 days of frozen storage (P≤0.05).M1and M3sausages showed the increase in TVB-N during storage, however it was not changed significantly from day 60–120 days in these samples (P≥0.05).After 120 days, TVB-N of M3 and Mt was similar to each other (P≥0.05) and reached 14.5 mg N/100 g in both samples.Total volatile nitrogen (TVN)is a quality assessment parameter and includes ammonia, TMA, and DMA at different proportions.For different seafood products and fresh fish, a critical limit of 25–35 mg TVN/100 g has been suggested(Oehlenschl¨ager, 2014).Among all samples, M0 showed the highest TVB-N (28.9 mg TVN/100 g) after 4 months of frozen storage which exceeded the critical limit.M3however showed an acceptable TVB-N at the end of storage.During mince washing, free amino acids, sarcoplasmic protein, and N-containing compounds of non-protein nature will be removed, resulting in lower decomposition of nitrogenous compounds.Regarding pH, M3followed by M1sausages had the higher pH after 120 days of storage (Table 3) (P≤0.05).The lowest pH was measured for Mt during the whole storage time (P≤0.05).The increase of sausages pH with washing cycles of fish mince might have occurred due to leaching of fatty acids, amino acids, and other compounds (Wiles et al., 2004) and was observed in sardine (Montero, Pardo,Gomez-Guillen, & Borderias, 1999) and Nile tilapia (de Oliveira Filho et al., 2012) sausages made with washed mince.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgement

Authors are grateful to Mahisa Danesh Salamat Khorak Yaran Co.(Hamedan, Iran) for their assistance in sausage production and laboratory analysis.

杂志排行

Aquaculture and Fisheries的其它文章

- A framework for risk analysis of the shellfish aquaculture: The case of the Mediterranean mussel farming in Greece

- Slurry ice as an alternative cooling medium for fish harvesting and transportation: Study of the effect on seabass flesh quality and shelf life

- Application of hurdle technology for the shelf life extension of European eel(Anguilla anguilla) fillets

- Bacterial community in response to packaging conditions in farmed gilthead seabream

- Effective algorithmic operational framework for fish texture evaluation in industry: Achieving maturity

- Seasonal variation in the biochemical composition, condition index, and meat yield of the non-indigenous pearl oyster Pinctada imbricata radiata(Leach, 1814) from the West of the Aegean Sea, Greece