Time-sequenced damage behavior of reactive projectile impacting double-layer plates

2023-10-09YingYuanYiqiangCaiHuanguoGuoPengwanChenRuiLiuHaifuWang

Ying Yuan,Yi-qiang Cai,Huan-guo Guo,Peng-wan Chen,Rui Liu,Hai-fu Wang

Beijing Institute of Technology,Beijing,100081,China

Keywords:Reactive projectile Damage behaviors Impact Double-layer plates

ABSTRACT The time-sequenced damage behavior of the reactive projectile impacting double-layer plates is discussed.The analytical model considering the combined effect of kinetic and chemical energy is developed to reveal the damage mechanism.The influences of impact velocity and reactive projectile chemical characteristics on the damage effect are decoupled analyzed based on this model.These analyses indicate that the high energy releasing efficiency and fast reaction propagation velocity of the reactive projectile are conducive to enhancing the damage effect.The experiments with various reactive projectiles impact velocity increasing from 702 to 1385 m/s were conducted to verify this model.The experimental results presented that,the damage hole radius of the rear-plate increases with the increase of impact velocity.At the impact velocity of 1350 m/s,the radius of damage hole formed by PTFE/Al/Bi2O3,PTFE/Al/MoO3,PTFE/Al/Fe2O3 projectile on the rear-plate become smaller in sequence.These results are consistent with the analytical model prediction,demonstrating that this model can predict the damage effect quantitatively.This work is of constructive significance to the application of reactive projectiles.

1.Introduction

Reactive projectiles,different from the conventional inert projectiles,could release a lot of chemical energy when subjected to strong load plates [1,2].When the conventional inert projectile impacts multi-layer plates at high velocity,the damage mode of plates is mainly mechanical penetration.When conventional inert projectiles impact multi-layer plates at high velocity,the damage mode of the plate presents multi-perforation or petaling tearing because of debris cloud [3-5].Single kinetic energy damage mechanism limits the damage effect of projectiles on multi-layer structures.However,reactive projectile shows great application potential in enhancing damage effect by using kinetic energy and chemical energy.Reactive projectile/plate interaction is a complex problem covering mechanics,chemicals,and thermodynamics.It is still a grand challenge to comprehensively understand this issue,attracting the attention of researchers [6].

As the basic properties of reactive materials,many scholars have carried out many studies on mechanical properties [7-9] and energy release properties [10].By now,the damage effects of reactive projectiles were mainly studied by ballistic impact experiments.And the relationships between damage effects and various considerations were indicated based on those experimental results.Song Zhang conducted the ballistic impact experiments about reactive projectiles (PTFE/Al/W and PTFE/Al/Mg/W) impacting multi-plates,indicating that the damage effect of the reactive projectile is improved by additional Mg[11].The experiments also suggested that increasing the chemical energy of reactive projectiles can further improve the damage ability of reactive projectiles.Jia Lan investigated the damage performance of PTFE-Al-XmOyagainst the aluminum plate by ballistic impact experiments.The results showed that damage performances of PTFE/Al/Bi2O3,PTFE/Al/MoO3,and PTFE/Al/Fe2O3projectile decreases in sequence[12].Army Research Laboratory also studied the terminal ballistics of encased reactive projectiles against urban,light-armor,and heavy-armor targets.The experimental results demonstrated that enhanced PTFE/Al projectiles increase the pressure inside the chamber [13].In addition,the experimental results show that the reactive projectile is more likely to ignite the fuel tank and enhance the structural damage to the fuel tank [14,15].

A handful of theoretical studies have been conducted to analyze the damage patterns and the impact-initiated reaction behaviors.Researchers from Beijing Institute of Technology developed an analytical model about reactive projectiles damaging single-layer aluminum plates to predict the extent of the petal bulge and the perforation hole sizes qualitatively [16].In addition,the analytical model about damaging double-layer plates was developed based on the debris cloud theory without considering the enhancement effect of chemical energy,to qualitatively analyze the damage hole radius,which was affected by the impact velocity and thickness of rear plates [17].Despite these substantial experiments of reactive projectiles damaging the plates,the damage behavior is not well understood.There are no comprehensive analytical models on damage behaviors accepted,which is considering the combination effect of kinetic and chemical energy.

This research aims to develop a model considering the combination of kinetic and chemical energy effect to predict the timesequenced damage behavior of the reactive projectile impacting double-layer plates.The shock wave and fetal failure of plates were considered in the theoretical analysis.The ballistic impact experiments with impact velocity ranging from 702 -1385 m/s were conducted to verify the reliability of this model.Furthermore,the relationship between the damage effect and consideration,including impact velocities and chemical characteristics of reactive projectiles,are discussed.

2.Experimental materials and procedures

2.1.Reactive projectile preparation

A series of experiments,which reactive projectiles damage double-layer plates,were conducted to verify the analytical model.In addition,inert projectile (φ10 mm × 10 mm) damage experiments also were carried out to compare the effects of chemical energy.Three similar PTFE/Al/oxide reactive projectiles composed of PTFE,Al,and oxide were designed and fabricated.Raw power:Al(2.78 g/cm3,24±3 μm),PTFE(2.20 g/cm3,~12 μm),Bi2O3(8.90 g/cm3,<45 μm),Fe2O3(5.24 g/cm3,<45 μm),and MoO3(4.69 g/cm3,<45 μm).Al,as the fuel,can have violent redox reactions with PTFE and oxide (YmOn),respectively,releasing a large amount of heat rapidly.The chemical reaction can be expressed as follows

whereQ1andQ2are heat of specific chemical reaction,respectively.

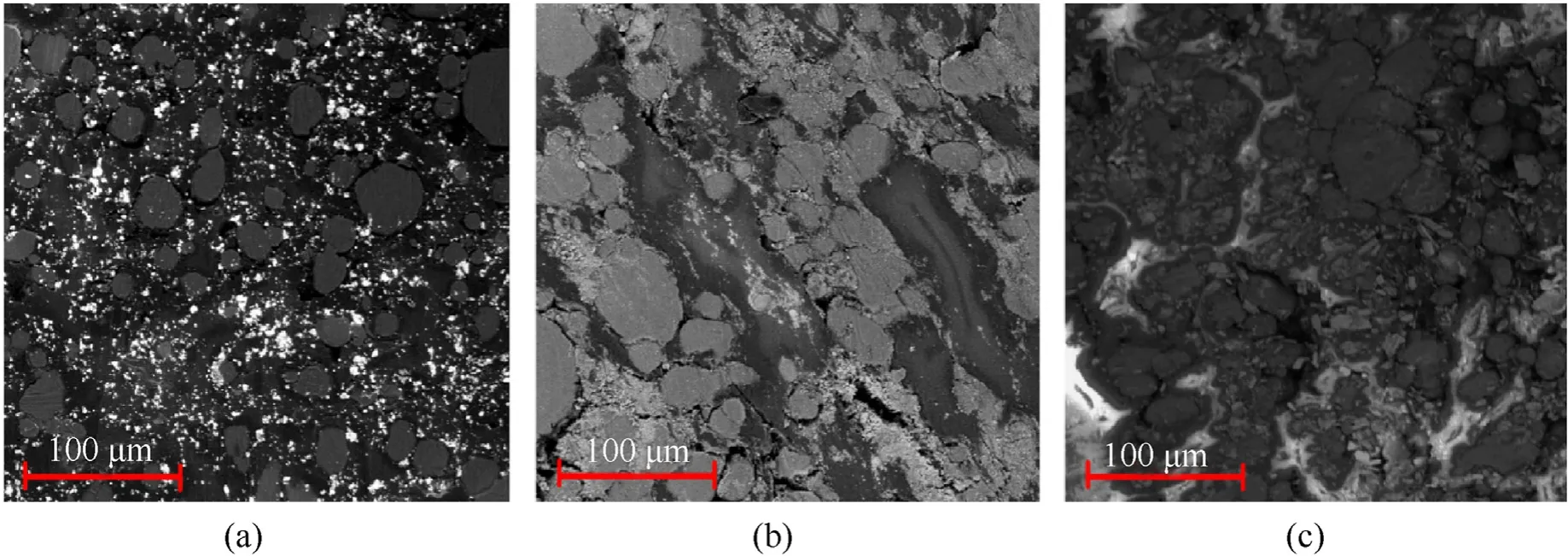

The content of each reactive material follows the stoichiometric ratio.The specific information of the reactive projectile is listed in Table 1.The raw powers were mixed,cold isostatic pressed at a pressure of 250 MPa and sintered to fabricate the reactive projectiles with a size of φ10 mm×10 mm.The sintering temperature rose to 370 ℃ at a rate of 60 ℃/h,then held at 370 ℃ for 4.5 h,and cooled to room temperature naturally.The microstructure of the sample is shown in Fig.1,from which it can be seen that Al and oxide particles were tightly wrapped in PTFE matrix [18,19].

Fig.1.Microstructure of the sample: (a) PTFE/Al/Bi2O3;(b) PTFE/Al/MoO3;(c) PTFE/Al/Fe2O3.

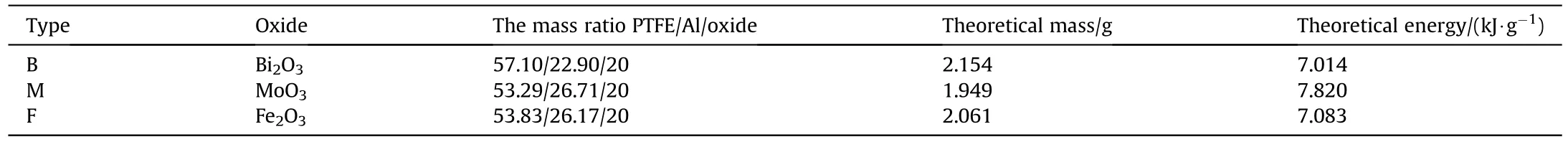

Table 1 Specific information of the reactive projectiles.

2.2.Experimental setup

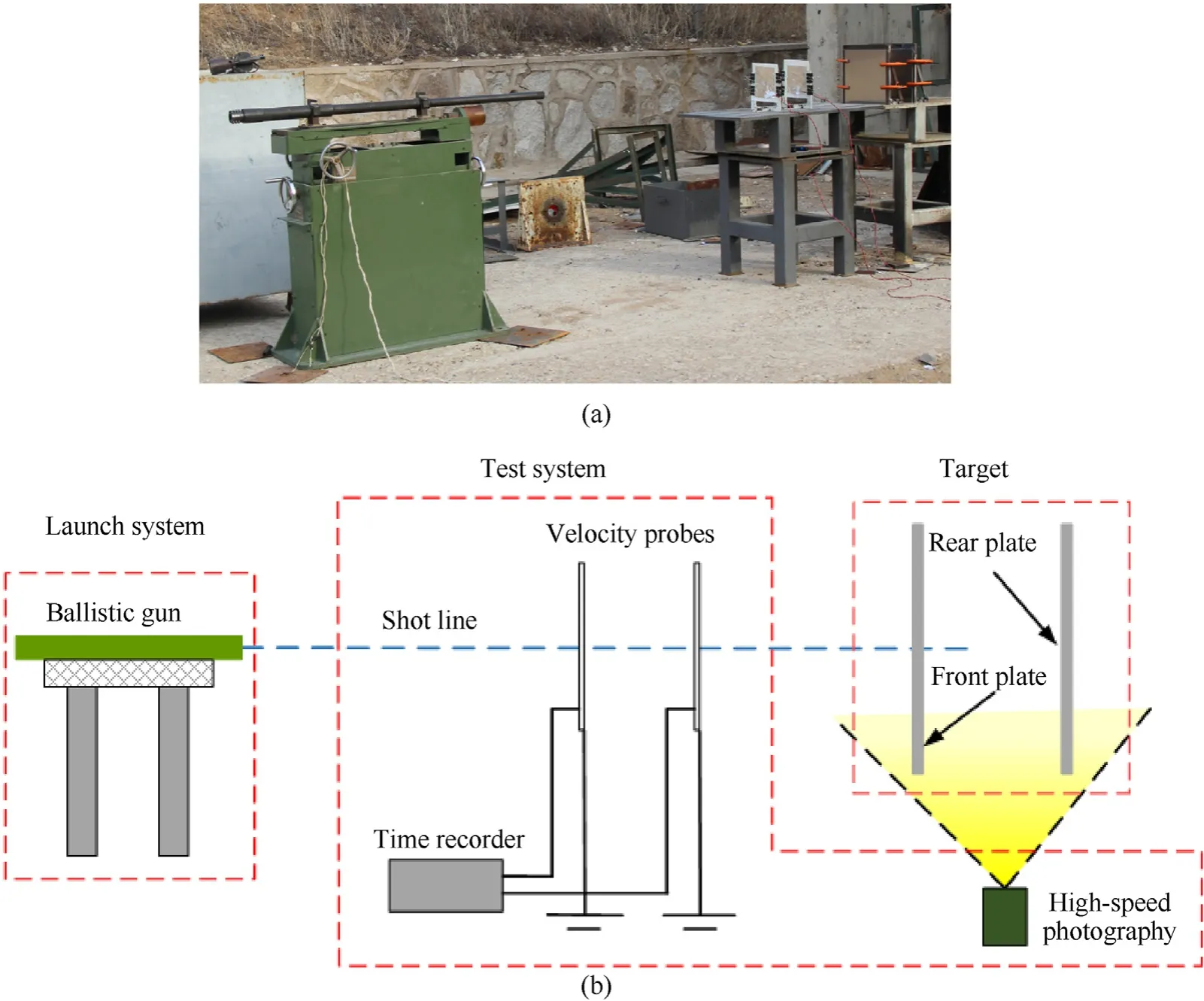

The experimental site layout and schematic of the experimental setup are shown in Fig.2.As shown in Fig.2,the ballistic impact experimental system mainly includes the launch part (ballistic gun),test part (velocity probes,time recorder,and high-speed photography),and target (double-layer plates).The reactive projectiles encapsulated in a nylon sabot were launched from the ballistic gun with a diameter of 12.7 mm at the velocities ranging from 702 to 1385 m/s.Velocity probes and time recorders were adopted to measure the impact velocity of reactive projectiles.The Phantom V710 high-speed photography (Vision Research,Inc.,Wayne,NJ,USA)was used to record the impact damage behaviors,with a frame rate of 10,000 fps and a resolution of 640×480 pixels.The targets were double-layer aluminum plates (2024-T3 aluminum,300×300 mm2)with a thickness of 3 mm/3 mm and a distance of 200 mm.

Fig.2.Experimental setup: (a) Physical diagram;(b) Schematic.

3.Theoretical analysis of reactive projectiles against the double-layer plates

3.1.Problem description

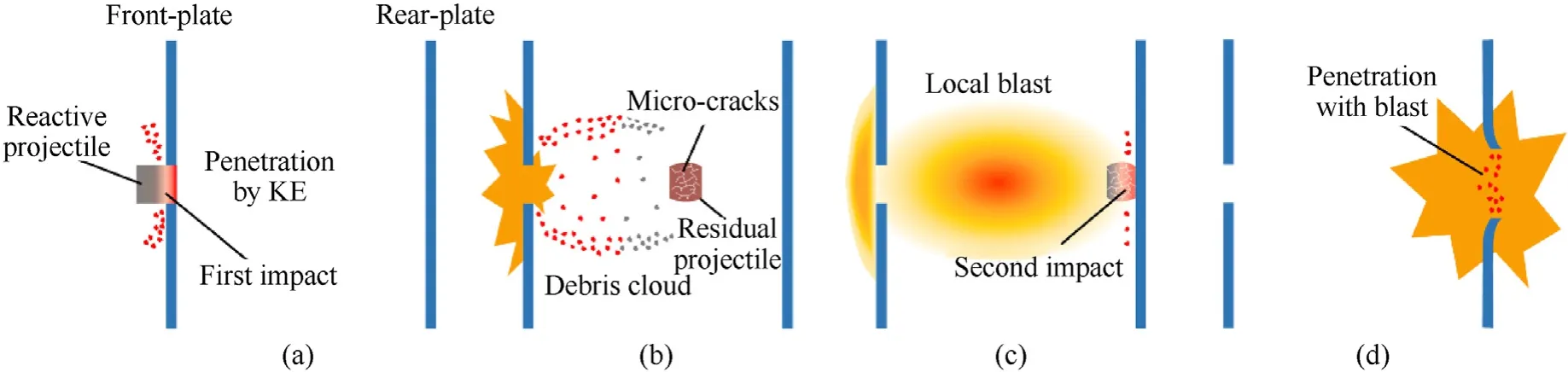

As the reactive projectile impact the double-layer plates,the plates were seriously damaged by the combination of kinetic and chemical energy.This damage behavior is complex with the coupling of penetration and blast,and is significantly different from that of the traditional inert metal projectile.This special terminal ballistic behavior can be divided into four main phases,as shown in Fig.3.

Fig.3.Damage behavior of the reactive projectile impacting double-layer plates: (a) Penetration by kinetic energy;(b) Formation of debris cloud;(c) Local blast;(d) Structural failure by combined kinetic energy and chemical energy.

The first phase is the impact of reactive projectile with the frontplate and penetration within several microseconds,as shown in Fig.3(a).In this phase,the front-plate is perforated,presenting the typical kinetic energy perforation damage pattern.On the other hand,the shock wave is generated by the impact and propagates from the impact interface to the projectile tail,resulting in partial fragmentation of the reactive projectile and resputtering of debris in front of the front-plate.

The second phase is the formation of reactive debris cloud between two plates,and the movement of residual reactive projectile towards the rear-plate,as shown in Fig.3(b).In this phase,the resputtering reactive debris reacts around the front-plate.Meanwhile,numerous micro-cracks are formed in the residual reactive projectile because of the first impact,improving the reaction sensitivity and shortening the reaction delay time of the predamage reactive projectile.

The third phase is the local blast of reactive debris and the impact of residual reactive projectile with the rear-plate,as shown in Fig.3(c).In this phase,reactive debris deflagrates after a certain delay time and induces local overpressure around the plates.However,it is noted that the local overpressure is unlikely to cause structural damage to the intact rear-plate.

At the last phase,the rear-plate is damaged by the impact of reactive projectiles,as shown in Fig.3(d).On the one hand,the reactive material debris impacts the rear-plate and deflagrates instantly[20].However,the overpressure induced by the dispersed reactive debris reaction is difficult to cause serious structural damage to the intact rear-plate.On the other hand,the residual reactive projectile penetrates the rear-plate with reaction,leading to serious structural failure of rear-plate by the coupled effect of the penetration and blast.

The final phase presents significant distinction of the reactive projectile damaging the double-layer plate,in which kinetic energy and chemical energy are imposed on plates.The tearing failure of plate mainly occurs in the last stage because the overpressure in open space tends to cause cracks or tears only when the plate has perforation formed by the projectile.This indicates that the damage behavior of reactive projectiles against double-layer plates presents significant time-sequenced characteristic.The rear-plate present serious structural damage only when the chemical energy effect lags behind the kinetic energy penetration.

3.2.Metal-like penetration behavior

An analytical model is developed based on the problem description above to discuss the damage effect on double-layer plates.In this analysis model,the metal-like penetration behavior and plate failure effect are mainly considered.

The behavior of reactive projectile penetrating the front-plate is similar to that of metal projectile penetrating the plate.On the one hand,the projectile perforates the front-plate with the velocity attenuating,and the projectile partially fragments and forms numerous micro-cracks in the interior.On the other hand,the shock wave is generated in the reactive projectile and ignites the reactive material.The shock wave induced by impact the frontplate controls the response behaviors of reactive projectiles subsequent,affecting the damage effect on the rear-plates.

Based on the one-dimensional shock wave theory,considering the conservation of mass and momentum at the impact interface,the initial shock wave induced by impact within reactive projectile can be expressed as Refs.[21,22].

whereP0is the initial impact shock pressure,v0is the impact velocity of the reactive projectile,Uis the shock wave velocity,and ρ0is the initial density of the reactive projectile,respectively.Subscripts p and t represent parameters of reactive projectile and plate,respectively.The relationship between shock wave velocity and particle velocity can be expressed as

whereCis the sound velocity of the material,Sis the Hugoniot parameter,uis the particle velocity.Reactive projectile as a typical composite material,the sound velocity and Hugoniot parameter can be estimated by following Eq.[23].

whereiis a specific component,nis the number of components.The shock pressure in reactive projectile is attenuated in exponent with distance,which can be expressed as follow[24].

whereP(l)is the shock pressure in reactive projectile at a distance ofl,δ is an attenuation coefficient determined by material properties,δ=0.038 mm-1[17].When the shock pressure reaches its fracture limit (Yc),the reactive projectile will crack into debris clouds[25].The lengthLrand the massmrof the residual reactive projectile can be expressed as

whereLandmare the length and mass of reactive projectile,α is the radius expansion coefficient determined by mechanical properties of the reactive projectile,respectively.

The penetration behavior of reactive projectiles against the front-plate is similar to that of inert projectiles.According to E.Martel theory[26],during the penetration,the motion of projectile is mainly affected by shear yield stress σsbetween the plunger,whose diameter is assumed to be the same as the reactive projectile diameter.Assuming that the common velocityof reactive projectiles and the plunger reaches the moment of impact,it can be expressed as

wheremtis the mass of plunger,mt=>.The penetration behavior of the reactive projectile against the plates can be expressed as

wherehtis the thickness of plate,xsis the penetration depth,Among them,dv/dt=dv2/2dx.And Eq.(9)can be further expressed as

Combined with Eq.(8) and Eq.(10),whenxs=ht,the residual velocityvrof the reactive projectile can be expressed as

The ballistic limiting velocityv50can be expressed as

3.3.Fetal failure of plates

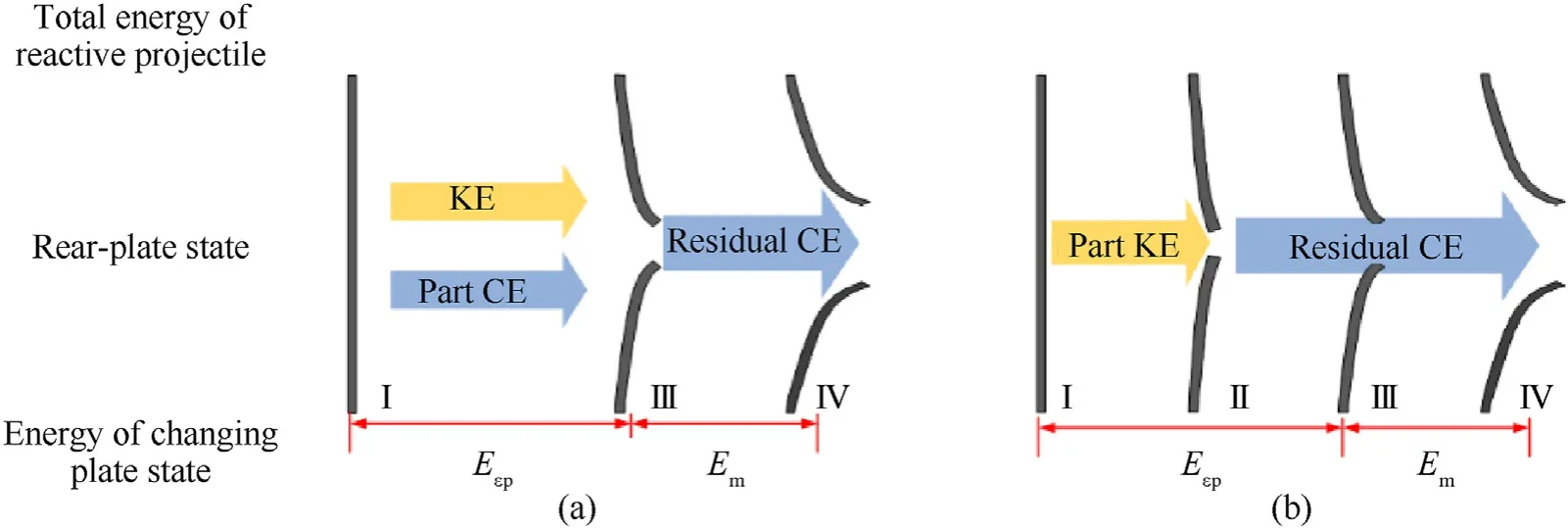

The damage behavior of the reactive projectile against the rearplate can be divided into two typical types according to the performance of the reactive projectile.Fig.4 shows the damage mode of the rear-plate varies with the energy applied by the reactive projectile.Eεpand Emare the plastic deformation energy of rear-plate from initial to crack and the plate tearing failure energy,respectively.The damage behavior of the rear-plate presents a significant time-sequenced characteristic,which means that the chemical energy releasing time of reactive projectile has a significant influence on the damage effect of rear-plate.Rather,the chemical energy of reactive projectiles can enhance the damage effect only when the release of chemical energy lags behind the kinetic energy perforation.

Fig.4.Energy impartion and rear-plate state during impact process.

As shown in Fig.4(a),when reactive projectile impacts plates at low velocity,the velocity declines as it penetrates through the front-plate,resulting in the difficulty for the residual reactive projectile to perforate the rear-plate only by kinetic energy.The state of the rear-plate change from plastic deformation to cracking(State III) due to the overall kinetic energy and part of chemical energy.With the compression of subsequent chemical energy,the cracks in the rear-plate propagate from the crevasse,increasing the damage area (State Ⅳ).As shown in Fig.4(b),when the reactive projectile impacts plates at high velocity,the residual reactive projectile damages the rear-plate with kinetic energy(State II),and the chemical energy released by the reactive projectile causes plastic deformation on the rear-plate until the plate reaches the critical state of cracking (State III).The release of chemical energy induces crack propagation (State Ⅳ).

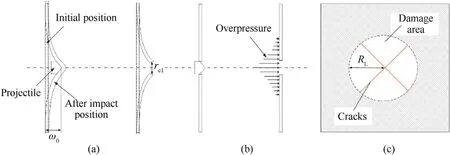

The typical damage behaviors of residual projectiles to rearplate with different velocities are illustrated in Fig.5.This behavior of the reactive projectile damaging the rear-plate is analyzed based on energy conservation.The deformation energy of the projectile and thermal energy is ignored to simplify the analysis.

Fig.5.Typical damage behaviors of residual projectile to rear-plate: (a) Low-velocity impact;(b) High-velocity impact;(c) Petal-tear damage schematic.

When residual reactive projectile impacts the rear-plate with a low-velocity,the energy conservation can be expressed as

whereErkis the residual kinetic energy,Ecη is the chemical energy of released by the residual reactive projectile.Ecηcan be expressed as

whereEcris the theoretical residual chemical energy,Ecr=EcLr/L,η(v)is the energy release efficiency of the reactive projectile,which is determined by impact velocity.According to Ref.[16],the energy release efficiency η of the reactive projectile is approximately an Sshaped curve with the impact velocity,which can be expressed as

wherevmidandrsare parameters related to the reaction characteristics of the reactive projectile.According to previous research results,vmidandrsare 5.968 and 0.006371,respectively [27,28].When the plate fails,the strain of the plate and its plastic deformation energyEεcan be expressed as Ref.[26].

where Γ is deformation area of plate.The deformation energy of the plateEεcan be expressed as

where ω is the deflection of the plate center,γ is the Poisson’s ratio of plate,which is 0.33 for aluminum plates,Epis the plastic hardening modulus of plate,which is 777 MPa,σYis the tensile yield stress,which is 345 MPa[29].When the plastic deformation of the plate reaches the critical state of crack,the Eεpcan be expressed as

where ω0is the maximum deflection of the plate center only without cracking,which can be expressed by the ballistic limit velocity v50as follow

With the release of chemical energy,the damage pattern of plate changes to petal-tear failure.The crack length,which represents the damage hole radius,can be expressed as Ref.[30].

whereRLis the damage hole radius,rc1is the perforation radius of the plate before the circumferential crack occurs,rc1=rc+rcεf,the failure strain εfis 0.3 for aluminum plates,θ is the central angle of the petal,usually π/4,b is the expansion factor of bending moment,b=Combining Eq.(13),Eq.(14),Eq.(18),Eq.(20),the damage effect of the reactive projectile on the rear-plate with low-velocity can be analyzed.

The rear-plate presents plug failure when the reactive projectile impacts at a high-velocity,and the slight deformation is ignored.Assuming that the reactive projectile release chemical energy at a constant rate,the energy conservation during damage behavior of the reactive projectile against rear-plate can be expressed as

whereEk-debrisis the debris cloud kinetic energy,depending on the debris cloud velocity and mass,andEceffis the effective chemical energy,which is determined by the penetration duration of the residual reactive projectile against the rear-plate and the energy release efficiency.It can be expressed as

wheretdis penetration duration against the rear-plate,ωr0is the maximum deflection of the rear-plate,vrris residual velocity of residual reactive projectile penetrating the rear-plate,it can be calculated by Eq.(11).The et(t) is the energy release efficiency of the reactive material at the specific time t.The damage effect of the reactive projectile on rear-plate with high-velocity can be analyzed by combining Eq.(20) -Eq.(22).

4.Results

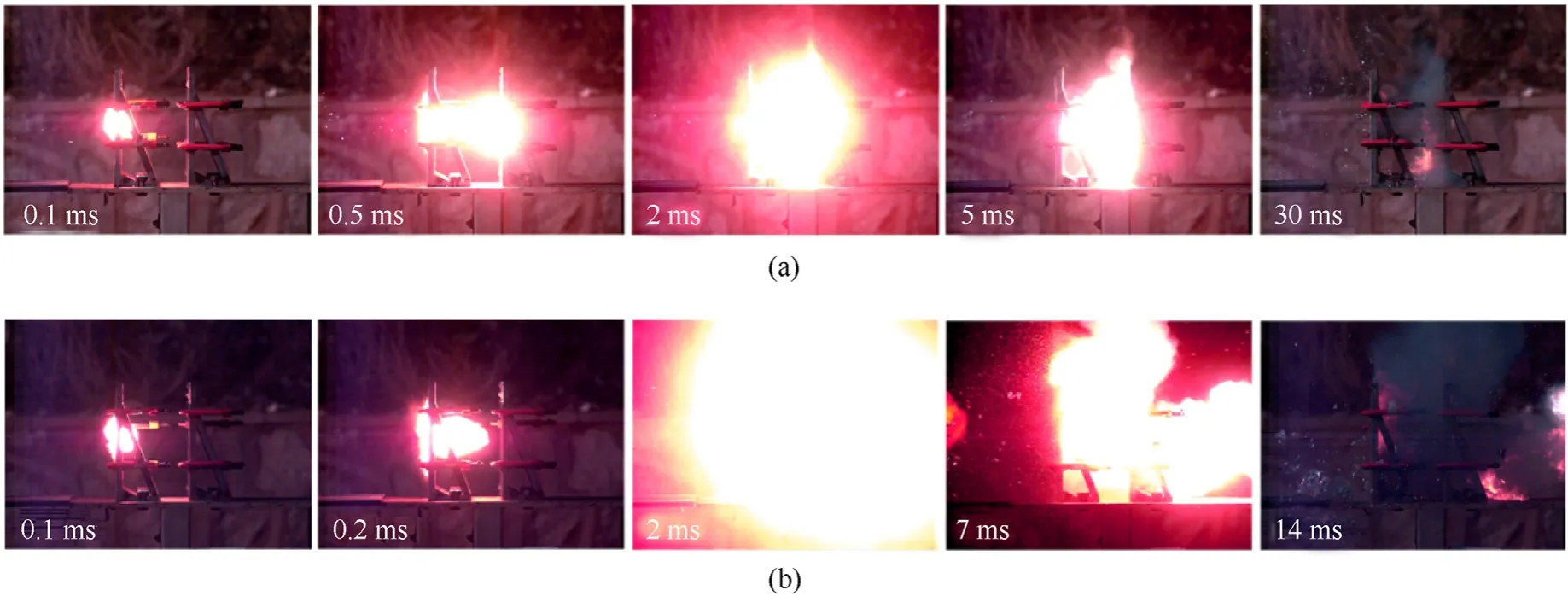

Fig.6 presents the typical damage behavior of the reactive projectile impacting double-layer plates.As shown in Fig.6(a),the reactive projectile impacted the front-plate and reacted around the impact point.After perforation,the reactive projectile continued on to the rear-plate with reaction.Subsequently,the reactive projectile impacted the rear-plate with a more violent reaction.This phenomenon indicates that the chemical energy is released mainly after the secondary impact.The flame mainly concentrated between two plates and presented approximately spherical.It lasted for tens of milliseconds and then gradually died out.

Fig.6.Typical damage behavior of the reactive projectile: (a) PTFE/Al/MoO3,706 m/s;(b) PTFE/Al/Bi2O3,1319 m/s.

There are some differences between damage behaviors when reactive projectiles impact double-layer plates at different velocities.One difference is that when the reactive projectile impacts the front-plate at a high-velocity,the flame distribution in front of the front-plate is wider (as shown in the sequence at 0.1 ms).This is because there are more backsplash debris distribute over a wider area in front of the front-plate under a higher impact velocity.Another difference is that compared with impacting at a lowvelocity,the flame is brighter and the distribution between the plates is broader(as shown in the sequence at 2 ms).This is because as the impact velocity increases,more reactive materials are involved in the chemical reaction with a more violent reaction.The last difference is that after the reactive projectile with higher velocity penetrating through the rear-plate,the bright flame extends to the back of the rear-plate (as shown in the sequence at 7 ms).This phenomenon indicates that after the penetration,the residual reactive projectile continues on moving away from the rear-plate with the energy released unceasingly.

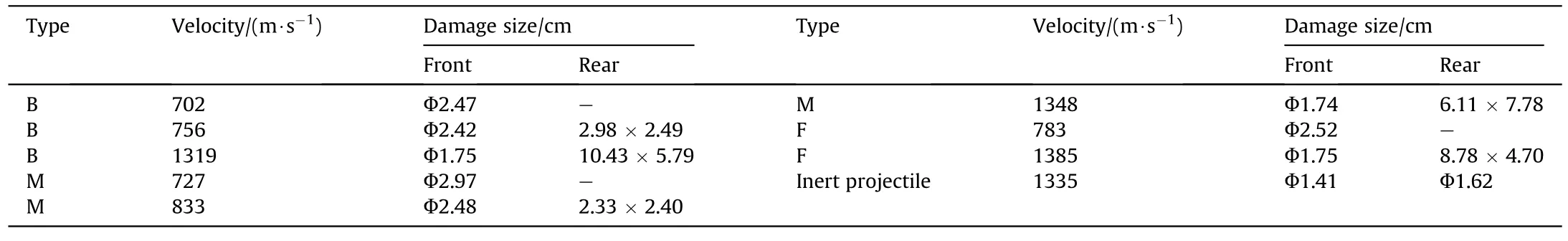

The plates show different failure modes under the impact of the reactive projectile The front-plate usually presents the regular circular perforation,while the rear-plate usually presents serious petal-tearing.When the reactive projectile impacts with highvelocity,the rear-plate presents irregular perforation and bulge deformation.The results of the damage hole sizes of the doublelayer plates are listed in Table 2.The perforation equivalent diameter and a rectangular zone are adopted to describe the damage size of front-plate and rear-plate respectively,as shown in Fig.7(a).

Fig.7.Damage effects: (a) Reactive projectile;(b) Inert projectile.

Table 2 Experimental results.

Fig.7(b)shows the damage effect of inert projectiles on doublelayer plates.It can be seen from the figure that when inert projectiles impact double-layer plates at 1335 m/s,both the front and rear plates present a typical plug failure mode and the perforation is regular round,which is completely different from the damage mode of the rear plate damaged by reactive projectiles.This is mainly because the load characteristics of the plate are significantly different when different projectiles impact plates.Under the projectile/plate interaction condition discussed in this paper,when the inert projectile impacts the double-layer plate,the load on the rear plate is concentrated and fast,and the adiabatic shear is formed in the direct impact area,so the rear plate shows mechanical perforation failure.In contrast,when the reactive projectile impact double-layer plate,the rear plate is not only subjected to the kinetic energy penetration of the residue projectile,but also subjected to the chemical energy compression.The compression load induced by chemical energy has the characteristics of longer time,wider influencing range and lower load peak,making the rear plate show a petaling tearing failure mode.

As listed in Table 2,as the velocity increased,the damage effect of the rear-plate was enhanced in experiments.As the impact velocity increased from 727 m/s to 1348 m/s,the reactive projectile damage the rear-plate gradually changed from bulge without perforation to the petal-tearing failure.

5.Discussion

5.1.The effect of impact velocity on damage hole radius

Subjected by the coupling effect of multiple considerations,the damages of reactive projectile on double-layer plates is a complex problem.The decoupling analysis of the individual consideration is conducted based on the analytical model.Compared with the damage effect of inert projectile,that of the reactive projectile is more affected by velocity.This is because the impact velocity not only affects the kinetic energy but also determines the chemical energy released.

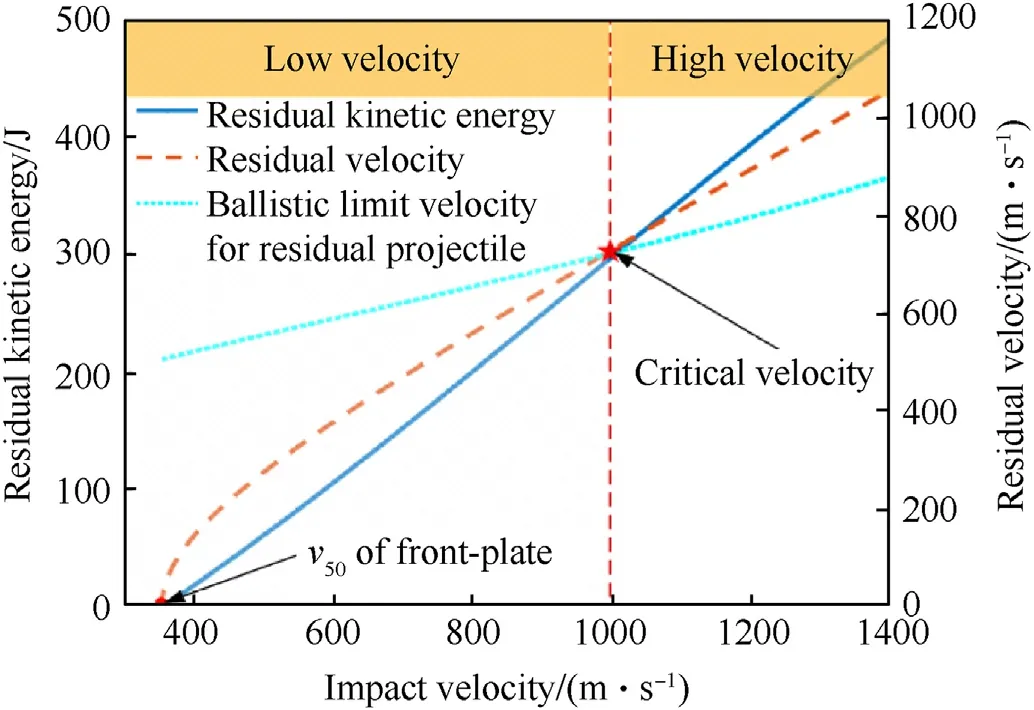

Fig.8 depicts the residual velocity and the residual kinetic energy varying with initial impact velocity.As shown in Fig.8,with the impact velocity increasing,the residual velocity and residual kinetic energy both increases,despite the mass of residual reactive projectile reduces.The ballistic limiting velocity of the residual reactive projectile penetrating the rear-plate increases as the impact velocity increases.With the increase of impact velocity,the shock pressure in the reactive projectile is enhanced,resulting in more serious deformation and fragmentation of the reactive projectile.This will lead to less residual reactive projectile mass and the worse projectile penetration performance.As shown in Fig.8,when the residual velocity of the projectile is higher than the ballistic limit velocity of the rear-plate,the reactive projectile can penetrate the rear-plate only by kinetic energy.This velocity is defined as the critical velocity and is the distinction between high and low velocity in the analysis model above.

Fig.8.Residual kinetic energy and velocity of reactive projectile.

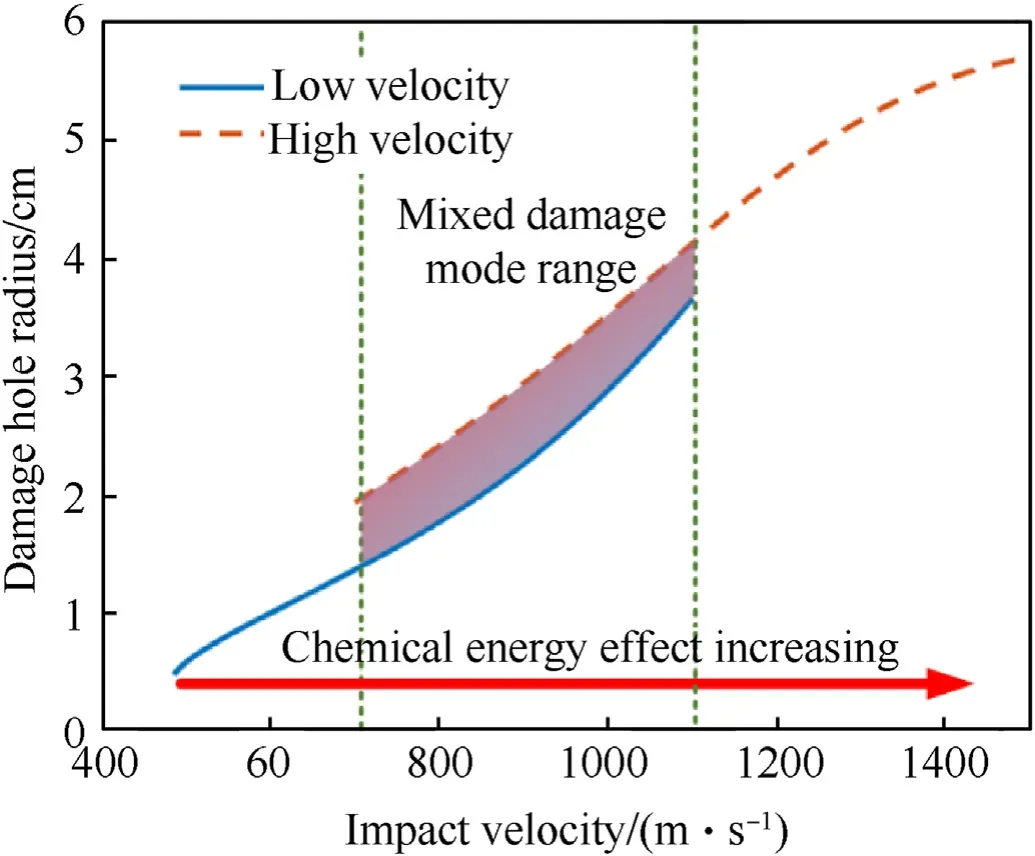

Fig.9 describes the damage hole radius of the rear-plate varies with the increasing of impact velocity,according to the analytical model including two damage modes.As shown in Fig.9,overall,as impact velocity increases,the damage hole radius of the rear-plate increases.When reactive projectile impacts with a low velocity,a more accurate prediction about damage hole radius varying with impact velocity is presented by blue line in Fig.9.On the other hand,when reactive projectile impacts with a low velocity,a more accurate prediction about damage hole radius varying with impact velocity is presented by red line in Fig.9.In addition,there is a mixed damage mode range near the critical velocity,which is also the reason why the two predictions do not coincide completely at the same velocity.As the impact velocity increases,both the chemical energy released and the kinetic energy of the debris cloud increase,resulting in the rear-plate showing significant petaltearing failure.

Fig.9.Damage hole radius of rear-plate vs.impact velocity.

However,it is worth noting that when the impact velocity increases to very velocity (usually >1500 m/s,vηc),the damage hole radius does not change with the impact velocity.This abnormal result is explained by the failure mechanism that the damage hole radius of the rear-plate is mainly determined by the Eeff,which depends on combination of the penetration duration and the chemical energy released per unit time during penetration.On the one hand,the increase of collision velocity leads to the shortening of penetration time,which is not conducive to the expansion of damage hole radius of rear-plate.On the other hand,the increase of impact velocity leads to the increase of chemical energy released per unit time,which is conducive to the expansion of the damage hole radius of rear-plate.Therefore,this abnormal result is caused by the combination of these two considerations.

In the analysis above,PTFE/Al is selected as an example to the discussion,ignoring the radial expansion of the reactive projectile.This assumption only slightly affects the quantitative value of the analytical model predictions,but does not affect the research results in this section.

5.2.The effect of chemical characteristics on damage hole radius

Chemical reaction characteristics,the most unique characteristics of the reactive projectile,dominate the damage effect to the rear-plate.Energy release efficiency and the reaction propagation velocity,which represent the total amount of chemical energy released and the release velocity of chemical energy respectively,are adopted to study the influence of chemical reaction characteristics on damage effect.

Fig.10 depicts the effect of energy release efficiencies on the damage hole radii.The figure on the lower right shows energy release efficiencies of two kinds of reactive projectiles,representing high energy release efficiency reactive materials (HERM) and low energy release efficiency reactive materials (LERM),respectively.PTFE/Al/Bi2O3and PTFE/Al are adopted to represent the HERM and LERM,respectively [27].In general,HERM is more beneficial to increase the damage hole radius of the rear-plate.When impact at a low-velocity,the HERM releases more chemical energy,increasing the effective chemical energy.It is worth noting that thevηc of HERM is lower than that of LERM.This will lead to larger damage hole radius on the rear-plate caused by LERM,when projectile impact velocity is higher than hypervelocity(>vηc).This is because when the energy release efficiency of HERM approaches 1,the impact velocity is lower.Rather,HERM will release chemical energy in a shorter time with higher impact velocity.

Fig.10.The effect of energy release efficiency on damage hole radius.

Reaction propagation velocity determines the chemical energy releasing rate during the penetration.When the reactive projectile impacts the plate at a low-velocity,all chemical energy is imparted to the rear-plate,so the damage of the rear-plate is slightly related to the energy releasing velocity.On the contrary,when the reactive projectile impacts the plate at a high-velocity,only part of chemical energy is applied to rear-plate,causing structural damage.The reaction propagation velocity has a significant effect on the energy released during the penetration.Fig.11 depicts the effective chemical energy and damage hole radius varying with reaction propagation velocity.As shown in Fig.11,as the reaction propagation velocity increases,the effective chemical energy and damage hole radius both increases.This is because with the increase of reaction propagation velocity,the reaction duration shortens,resulting in more chemical energy released during penetration and applied to the plate for the crack propagation.

In the analysis above,parameters of PTFE/Al,which were not discussed in this model,are adopted to analyze the damage effect,and the assumed impact velocity is 1300 m/s.These assumptions little affect the patterns obtained in the analysis.

5.3.Comparison of experimental and theoretical results

When various reactive projectiles impact the double-layer plates with similar high-velocity,the damage hole radiuses of the rear-plate present differences.The radius of damage hole formed by PTFE/Al/Bi2O3,PTFE/Al/MoO3,and PTFE/Al/Fe2O3projectile on rearplates become smaller in sequence.The energy release efficiencies of PTFE/Al/Bi2O3,PTFE/Al/MoO3,and PTFE/Al/Fe2O3projectiles mentioned above becomes lower in sequence with the same external load [12].The predictions of the analytical model on damage hole radii of different material follow the same sequence.The analytical model indicates that high energy release efficiency and fast reaction propagation velocity are beneficial to enhance the damage effect of the rear-plate.According to the reaction propagation velocity of corresponding thermite in PTFE/Al/oxide reactive material [31,32],it is recognized that the reaction propagation velocities of various PTFE/Al/oxide from fast to slow are PTFE/Al/Bi2O3,PTFE/Al/MoO3,and PTFE/Al/Fe2O3.The predictions of the analysis model are consistent with the experimental results,which indicates that the theoretical model can well predict the damage performance of different kinds of reactive materials with the same impact velocity.

It is worth noting that the rear-plates were not perforated by reactive projectiles with low-velocity (PTFE/Al/Bi2O3,702 m/s;PTFE/Al/MoO3,727 m/s;PTFE/Al/Fe2O3,783 m/s).However,the prediction of the analytical model about damage hole radius,which is about 1.2 cm,is larger than that of experimental results.The main reason is that the partial chemical energy released by the reactive projectile is imparted to the surroundings,such as gas and plates,resulting in less effective chemical energy,which weakens the damage effect of the rear-plate.

Although the characteristics of the reactive projectile are provisionally sketchy,the analytical model quantitatively predicts the damage hole radius of the reactive projectile to the rear-plate.Once the reactive materials’ performance parameters involved in analytical model are calibrated by relevant experiments,the analytical model can predict the damage hole radius of the rearplate more accurately.

6.Conclusions

The current study developed an analytical model for the timesequenced damage behavior of reactive projectile impacting double-layer plates considering the shock wave effect and petaltearing failure by combination of kinetic and chemical energy.Furthermore,the damage mechanism is revealed by the analytical model.The main conclusion can be drawn as follows.

(1) The analytical model indicates that,the damage hole radius of the rear-plate increases while the growth rate diminishes with the increase of impact velocity.When the impact velocity is higher thanvηc,the damage hole radius of the rearplate decreases with increasing of the impact velocity.This unique damage behavior is dominated by the combination of chemical energy release rate and duration on the rear-plate.

(2) The decoupling analysis based on the analytical model shows that,both the high release efficiency and the fast reaction propagation velocity of the reactive projectile is beneficial to enhance damage effect of the reactive projectile on rearplate.

(3) The experiments showed that,increasing the reactive projectile impact velocity from 702 m/s to 1385 m/s,the damage mode of the rear-plate gradually changed from bulge without perforation to serious structure failure.When the impact velocity was 1350 m/s,the radius of damage hole caused by PTFE/Al/Bi2O3,PTFE/Al/MoO3,and PTFE/Al/Fe2O3projectiles became smaller in sequence.

(4) The analytical model predictions show a good agreement with experiments.The validity of the analytical model will be improved by calibrating the parameters of reactive projectiles.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work was supported by the State Key Program of National Natural Science Foundation of China (Grant No.12132003),and State Key Laboratory of Explosion Science and Technology (Grant No.QNKT20-07).

杂志排行

Defence Technology的其它文章

- An energetic nano-fiber composite based on polystyrene and 1,3,5-trinitro-1,3,5-triazinane fabricated via electrospinning technique

- Dynamic response of UHMWPE plates under combined shock and fragment loading

- Aerial multi-spectral AI-based detection system for unexploded ordnance

- Model-based deep learning for fiber bundle infrared image restoration

- Robust design and analysis for opto-mechanical two array laser warning system

- Combustion behavior and mechanism of molecular perovskite energetic material DAP-4-based composites with metal fuel Al