济宁二号煤矿通风系统优化改造

2023-04-29掌奕然陶维国郭传清陈修杰苗德俊

掌奕然 陶维国 郭传清 陈修杰 苗德俊

摘要:針对目前对矿井工作面通风系统风量调节及矿井降阻等方面研究较少的问题,以济宁二号煤矿10303工作面和33下02工作面为工程背景,对这2处原有的通风系统在风量调节及矿井降阻等方面进行优化改造。将工作面通风系统图导入Ventism软件中,生成实体巷道并迭代计算,构建矿井通风网络解算模型。将现场实测的主要参数输入到该模型中进行风流计算,得到的巷道内流速、温度及风量等相关数据与现场测定数据误差在标准范围内。由矿井通风阻力测定结果可知,原有通风系统存在如下问题:南翼石门调节风墙设置不合理;33下02工作面实际供风量小于理想需风量;南翼?740水平轨道大巷通风路线长,受辅助运输巷并联进风的影响,南翼回风大巷阻力大。针对上述问题,提出3条改造措施:①在南翼回风石门和北翼带式输送机巷交汇处设置1个封闭风门,并将南翼带式输送机大巷与回风石门原有的风窗面积调整为2.9 m2;②在三采区轨道下山延伸与33下02轨道联络巷处设置1个面积为0.1 m2的调节风窗;③在十一采区管子道和南翼?740水平轨道大巷接口处,将0.9 m2的调节风窗改为2.4 m2,减少南翼?740水平轨道大巷风量,增加辅助运输巷的并联风量。改造后的通风系统模拟结果表明:南翼?740水平轨道大巷阻力降低了32.7%,33下02工作面风量提升了19.8%,矿井通风路线总阻力降低了6.4%。改造后的通风系统现场实测结果表明:实测风量和数值模拟结果平均相对误差为1.28%,实测阻力和数值模拟结果平均相对误差为2.52%,模拟结果与现场实测结果基本吻合。通风系统改造后,进风井风量和阻力变化不大;回风井监测点处的风量减少,阻力降低;33下02轨道联络巷及工作面监测点处实测风量分别增加了25.3%和21.4%,阻力增大了57.4%和41.1%;南翼?740水平轨道大巷监测点处实测风量降低了20.3%,实测阻力减小了36.6%。工作面风量和矿井总阻力达到预期优化效果。

关键词:煤矿通风系统;风量调节;矿井通风网络解算;Ventsim软件;通风阻力

中图分类号: TD724 文献标志码: A

Optimization and transformation of ventilation system in Jining No.2 Coal Mine

ZHANG Yiran1, TAO Weiguo2, GUO Chuanqing2, CHEN Xiujie1, MIAO Dejun1

(1. College of Safety and Environmental Engineering, Shandong University of Science and Technology,Qingdao 266590, China;2. Jining No.2 Coal Mine, YankuangEnery Group Co., Ltd., Jining 272000, China)

Abstract: Currently, there's a lack of research on air volume regulation and mine resistance reduction of ventilation system in mine working face. In order to solve the above problem, taking 10303 working face and 33low 02 working face of Jining No.2 Coal Mine as the engineering background, the original ventilation systems in these two areas are optimized and transformed in terms of air volume regulation and mine resistance reduction. The ventilation system diagram of the working face is imported into Ventism software, generating a solid roadway and iterating the calculation to construct a mine ventilation network solution model. The main parameters measured on-site are input into the model for airflow calculation. The errors between calculated relevant data suchas flow velocity, temperature, and air volume in the roadway obtained and the on-site measurement data are within the standard range. From the measurement results of mine ventilation resistance, it can be seen that the original ventilation system has the following problems. The setting of the regulating air wall at the south wing stone gate is unreasonable. The actual air supply volume of 33low02 working face is less than the ideal air volume. The ventilation route of the south wing -740 horizontal track main roadway is long. It is affected by the parallel intake of auxiliary transportation roadways, resulting in high resistance in the south wing return air main roadway. In order to solve the above problems, three renovation measures are proposed.① A closed air door is installed at the intersection of the south wing return air stone gate and the north wing belt conveyor roadway. The original air window area of the south wing belt conveyor roadway and return air stone gate is adjusted to 2.9 m2.② A 0.1 m2 adjustable wind window is installed at the intersection of the extension of the third mining area's track downhill and the 33low02 connecting roadway.③ The 0.9 m2 adjustable air window at the interface between the pipe duct in the 11th mining area and the south wing -740 horizontal track roadwayhas been changed to 2.4 m2,so as to reduce the air volume of the south wing -740 horizontal track roadway and increase the parallel air volume of the auxiliary transportation roadway. The simulation results of the modified ventilation system show that the resistance of the southern wing -740 horizontal track main roadway has been reduced by 32.7%. The air volume of the 33low02 working face has been increased by 19.8%. The total resistance of the mine ventilation route has been reduced by 6.4%. The on-site measurement results of the modified ventilation system show that the average relative error between the measured air volume and numerical simulation results is 1.28%. The average relative error between the measured resistance and numerical simulation results is 2.52%. The optimized simulation results are basically consistent with the on-site test results. The range of changes in air volume and resistance of the intake shaft before and after the entilation system adjustment is not significant. The air volume at the measuring point of the return air shaft decreases, and resistance decreased. The optimized measured air volume at the 33low02 track connecting roadway and the measuring points of the working face increase by 25.3% and 21.4%, respectively, and the resistances increase by 57.4% and 41.1%. The optimized measured air volume at the south wing -740 horizontal track roadway decreases by 20.3%, and resistance decreases by 36.6%. After the renovation, the air volume of the working face and the total resistance of the mine have achieved the expected results.

Key words: coal mine ventilation system; air volume regulation; mine ventilation network calculation; Ventsim software; ventilation resistance

0 引言

矿井通风的作用是供给井下足够的新鲜空气,稀释并排除井下有毒有害气体,调节井下气候,保证正常生产[1-2]。为了设计和模拟井下工作環境,研究人员开发应用Ventsim三维矿井通风仿真系统,其不仅适用于通风设计与网络解算,也可对风流、污染物及火灾进行实时模拟与监测,确保工人和设备处在一个良好的工作环境中[3-5]。

目前,Ventsim软件已广泛应用到煤矿和非煤矿山的通风系统优化中[6]。卢辉等[7]使用Ventsim软件对工作面优化后的通风系统和风压分布状态进行模拟。辛嵩等[8]运用Ventsim软件对煤矿单翼通风系统进行优化处理,得到通风总阻力、巷道测点风速等优化结果。陈浩等[9]利用Ventsim软件优化通风系统,有效降低了矿井通风阻力,减少了能耗。耿守锋[10]采用Ventsim软件对通风网络进行计算,有效解决了矿井风机联合运行不稳定的问题。肖梦辉等[11]使用Ventsim软件对金属矿山进行3种不同工况下的火灾数值模拟,研究当有火源产生时,井下风压变化及烟气的扩散规律。任浩[12]采用增大巷道断面面积、提升主要通风机性能、改变通风方式等方法对通风网络进行优化,通过Ventsim软件进行风路优化网络解算,达到矿井通风系统预期风量优化目标。上述学者借助Ventsim软件对矿井通风系统预警与稳定性进行了分析,但缺乏对工作面风量调节及矿井降阻等方面的研究[13-14]。

本文以兖矿能源集团股份有限公司济宁二号煤矿10303工作面和33下02工作面为工程背景,采用Ventsim软件建立三维通风网络模型,基于该模型,针对这2处通风系统存在通风路线长、阻力大、南北两翼通风结构不均衡等问题,对原有的通风系统进行优化改造。

1 矿井概况及通风系统分析

1.1 矿井概况

济宁二号煤矿位于山东省济宁市高新区,隶属兖矿能源集团股份有限公司。该矿主要以长壁开采法采煤,矿井生产能力为5 Mt/a,核定通风能力为 6 Mt/a,配套建设一座入洗能力为4 Mt/a 的现代化大型造煤厂,井田面积为90 km2,地质储量为8.55亿 t,可采储量为3.47亿 t。矿井地质条件复杂,煤层赋存变化大,埋藏深,矿井采用立井多水平开拓方式,第一水平标高为?555 m,第二水平标高为?740 m,开采深度为?450~?1000 m。

1.2 通风系统分析

矿井通风系统为中央并列通风,通风方式为抽出式,主井和副井进风,回风井回风。其中南翼轨道大巷、南翼公路大巷、南翼?740水平轨道大巷、十采区进风巷为进风,西翼通风巷、北翼回风巷、南翼回风大巷为回风。地面主要通风机机房安装2台 GAF33.5?17?1GZ 型轴流式通风机,配备 TD1600?8/1430同步电动机,电动机额定功率为1600 kW,额定转速为750 r/min,额定流量为342.8 m3/s。

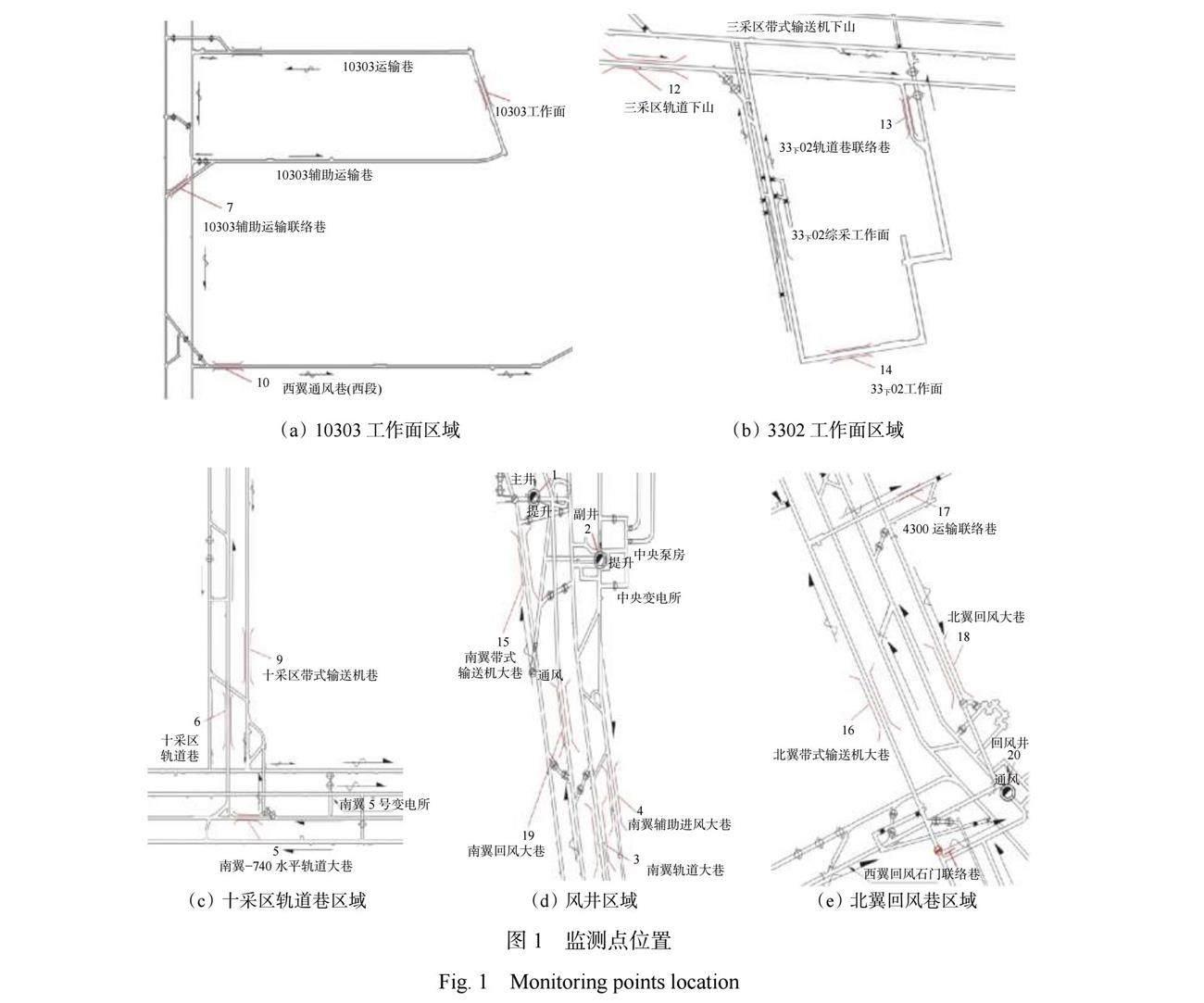

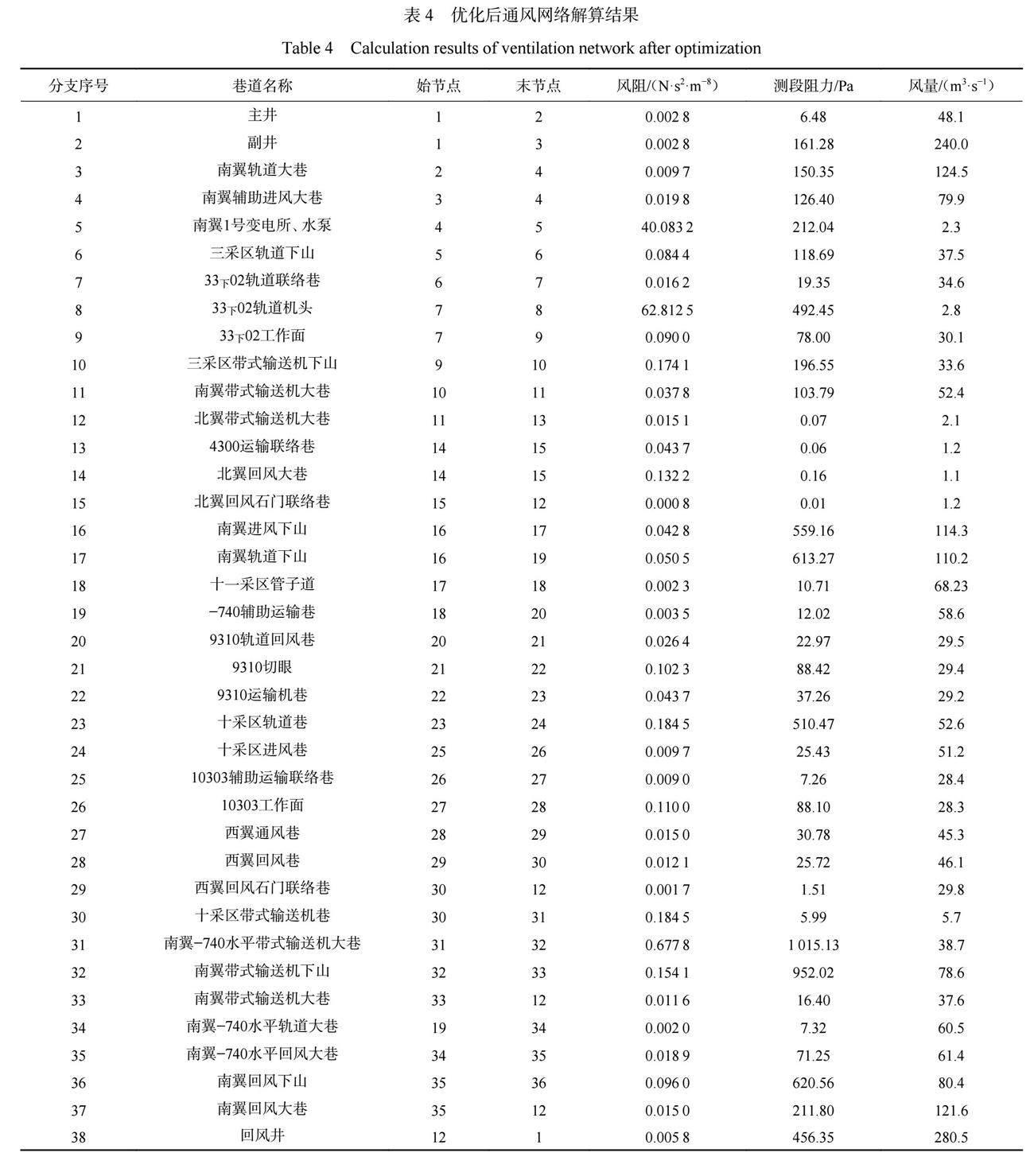

结合矿井的生产布局和现有的通风系统状况,在通风路线及用风地点设置20个监测点,如图1所示,通风路线阻力测定数据见表1。

2 通风系统三维模型建立及可靠性验证

2.1 三维模型建立

由于济宁二号煤矿通风网络结构复杂,为了确保模拟的准确性,对不受2条通风系统路线影响的其他巷道及部分密闭的巷道采取不建模解算,模型中只保留主要通风大巷及部分联络巷。在不影响、破坏整个通风系统分析的前提下,对济宁二号煤矿通风模型进行简化。利用 CAD 绘图软件绘制通风路线的巷道中心线并标出 z 轴坐标,图纸以 DXF 格式保存并导出。将绘制完成的通风系统图以单线格式导入Ventism[15]软件中,构建矿井通风网络拓扑关系[16],对通风系统进行数字化、可视化处理,录入巷道尺寸、风阻参数、风机数据等解算相关数据,生成实体巷道并迭代计算。最终对比实测数据进行校准和检测[17-18],构建矿井通风网络解算模型,如图2所示。

2.2 模型可靠性验证

为检验模拟结果的可靠性,对通风系统三维模型进行网络模拟解算。将现场实测的巷道断面尺寸、障碍物面积、摩擦因数等主要参数输入模型中,进行风流计算并得到巷道内的流速、温度及风量等相关数据[19-20]。将模拟结果与现场实测数据进行对比验证,通过二者误差结果判定模型及相关参数的可靠性,确保该模型能够应用到优化改造措施中,比结果如图3所示。

由图3可看出,测点2副井处实际风量与模拟风量的误差最大,误差值为3.2%;测点9十采区带式输送机巷误差最小,其误差值为1.3%。根据上述结果可得,误差区间在标准范围(±20%)之内,模拟结果符合实际情况。因此,本文构建的三维模型真实有效,模型参数可在后续通风系统的改造中使用。

3 改造措施的建立及模拟分析

3.1 改造措施的建立

根据矿井通风阻力测定结果可知,济宁二号煤矿通风系统存在通风路线长、阻力大、南北两翼通风结构不均衡等问题。南北两翼带式输送机大巷贯穿整个矿井的南北采区,南翼石门调节风墙设置不合理,南翼带式输送机大巷阻力为175 Pa;33下02 工作面受到三采区轨道下山分风的影响,实际供风量为24.8 m3/s,小于理想需风量;南翼?740水平轨道大巷通风路线长,受到辅助运输巷并联进风的影响,南翼回风大巷阻力达227.45 Pa。为了满足矿井正常生产,本文提出3条改造措施,如图4—图6所示。

改造措施1:回风风流从南翼带式输送机大巷到北翼带式输送机大巷再到北翼回风巷,其路程长,摩擦阻力大。在南翼回风石门和北翼带式输送机大巷交汇处设置1个封闭风门,并将南翼带式输送机大巷与回风石门原有的风窗面积调整为2.9 m2。通过增大南翼回风石门的回风量,降低北翼带式输送机大巷阻力。

改造措施2:33下02工作面风量仅为24.8 m3/s,实际供风量远小于理想需风量。由于三采区轨道下山延伸后的巷道不参与通风回路解算,在三采区轨道下山延伸与33下02轨道联络巷处设置1个调节风窗,风窗面积为0.1 m2,增大了33下02轨道联络巷和33下02工作面的供风量。

改造措施3:进风风流从南翼进风、轨道下山并联进入?740水平轨道巷和辅助运输巷,由南翼进风下山贯穿十一采区管子道通向南翼?740水平轨道大巷,在十一采区管子道和南翼?740水平轨道大巷接口处有1个0.9 m2的调节风窗,将其面积改为2.4 m2,减少南翼?740水平轨道大巷风量,增加辅助运输巷的并联风量。

3.2 改造后模拟结果分析

对北翼回风巷、33下02工作面及?740水平轨道大巷3处用风地点进行优化改造,通过设置风门、改变调节风窗面积、并联通风降阻等措施,解决了矿井通风系统阻力大、路线长及局部地点风量较小等问题,对改造后的通风系统进行风流模拟,结果见表2。

根据图7表2可得,20个巷道监测点优化后的总阻力为2081.31 Pa,较优化前降低了6.4%。分析南北两翼回风大巷、南翼?740水平轨道大巷、33下02 工作面4个监测点优化前后的风量和阻力,以此探究3处用风地点的优化效果。南翼回风大巷优化后的风量为123.0 m3/s,较优化前增加了2.4 m3/s;北翼回风大巷优化后的风量仅为1.2 m3/s,阻力为0.19 Pa,阻力较优化前降低了103.45 Pa。南翼?740水平轨道大巷优化后的风量为62 m3/s,阻力为7.69 Pa,阻力较优化前降低了32.7%。33下02工作面优化后的风量为29.7 m3/s,较优化前增加了19.8%。通过增加南翼回风大巷的回风量,降低了北翼回风大巷阻力;通过增大调节风窗面积,降低了南翼?740水平轨道大巷阻力;在33下02轨道联络巷设置调节风窗,33下02工作面的风量得到了提升。矿井的总阻力降低,各测点优化后的风量及阻力都符合标准。

3.3 改造后实测效果分析

在三采区轨道下山延伸与33下02轨道联络巷处设置风窗,33下02轨道联络巷和33下02工作面设置监测点;主井、副井及回风井各设置监测点;南翼?740水平轨道大巷1号联络巷设置1个监测点。监测点需要放置在风流稳定、巷道规整的地点,然后使用 CFZZ5通风阻力测试仪,风表、秒表等工具监测几处测点的风量、阻力变化情况,如图7所示,将优化前后测定的数据与数值模拟结果对比见,表3。

由表3可看出,各监测点优化前实测风量和模拟风量误差在1%之内,优化后二者最大误差为2.4%,这是由于优化后南翼?740水平轨道大巷内风量减小,解算的参数不变,導致二者误差变大,但在可接受范围之内。优化后实测风量和模拟风量平均相对误差为1.28%,优化后实测阻力和模拟阻力平均相对误差为2.52%,模拟结果与现场实测结果基本吻合。通风系统优化后,进风井风量和阻力变化不大;回风井监测点处的风量减少,阻力降低;33下02 轨道联络巷及工作面监测点处实测风量分别增加了25.3%和21.4%,阻力增大了57.4%和41.1%;南翼 ?740水平轨道大巷监测点处实测风量降低了20.3%,实测阻力减小了36.6%。工作面风量和矿井总阻力达到预期优化效果。

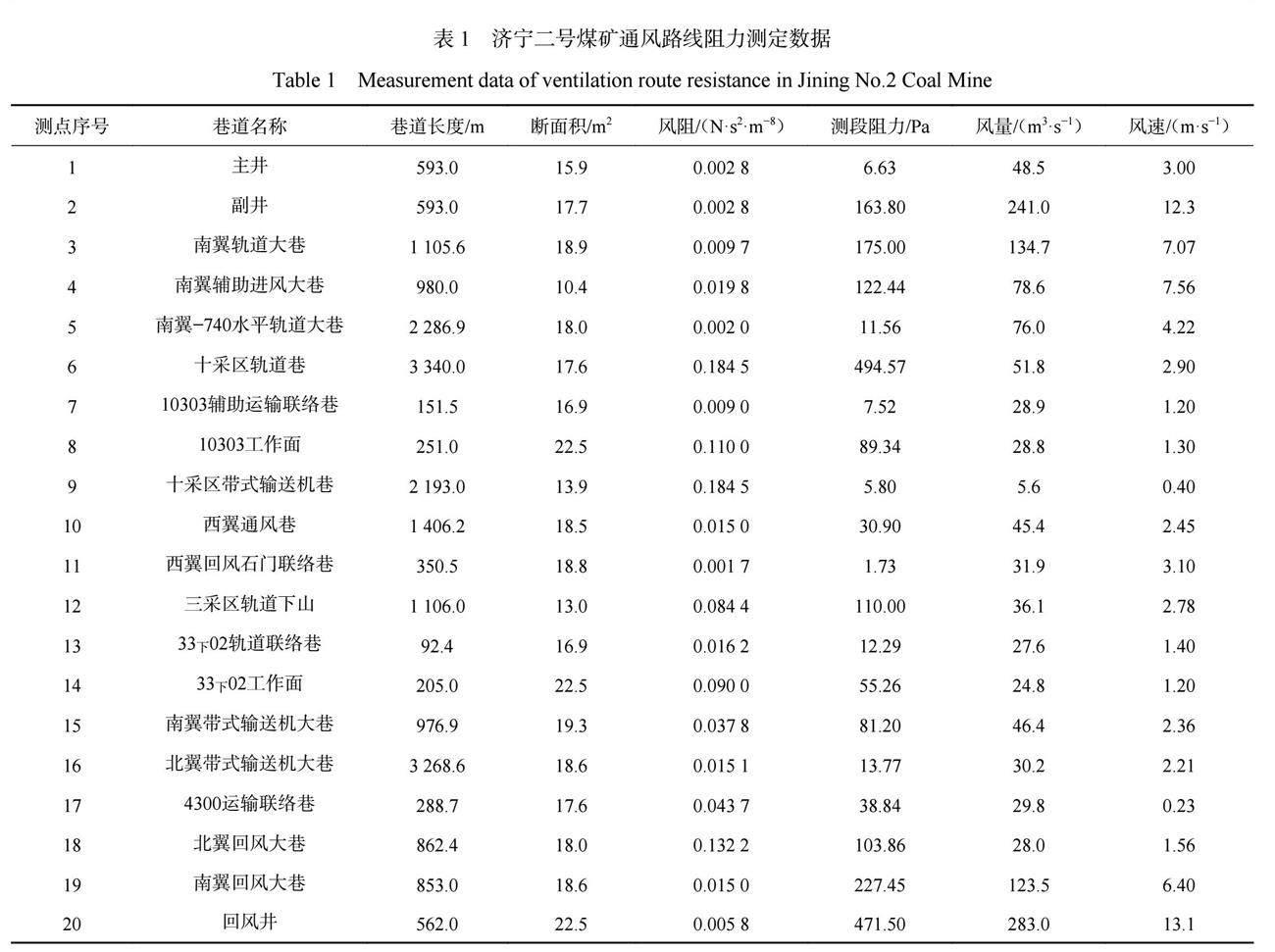

4 优化后通风系统安全校验及网络解算

为确保优化后的通风系统既能够完成部分区域的风量调节目标,又不影响矿井其他分支的风量输送,对整个矿井进行通风网络安全校验。根据优化后的通风系统得到风网阻力参数,在原有网络结构上添加分支,并结合现有的巷道参数对分支进行赋值,最终对优化后的通风系统进行网络解算。优化后矿井通风网络解算结果见表4。可看出进风总风量为288.1 m3/s,回风总风量为280.5 m3/s,风量损失较少,约为2.6%;33下02工作面风量达到30.1 m3/s,较优化前提升了21.4%,南翼?740水平轨道大巷阻力降低,且风量为60.5 m3/s,减少了20.3%,由此判定整个通风系统是合理的。

5 结论

1)针对33下02工作面受到三采区轨道下山分风导致风量较小的问题,通过在三采区轨道下山延伸处设置1个0.1 m2的调节风窗,将三采区轨道下山的风量大部分引入工作面。改造后工作面的实测风量达30.1 m3/s,较之前提高了21.4%。

2)风流从南翼进风下山流向南翼?740辅助运输巷和南翼?740水平轨道大巷,将十一采区管子道和南翼?740水平轨道大巷接口0.9 m2的调节风窗改为2.4 m2,增加辅助运输巷的并联风量,改造后南翼?740水平轨道大巷的实测风量为60.5 m3/s,减少了20.3%;通过在北翼运输巷设置风门,改变联络巷的风窗面积,封闭了北翼回风巷,减少了风量的沿程损失,总阻力明显降低。

3)将改造措施应用到济宁二号煤矿的通风系统优化中,现场实测风量和数值模拟结果平均相对误差为1.28%,实测阻力和数值模拟结果平均相对误差为2.52%,优化后的模拟结果与现实测结果基本吻合。

参考文献(References):

[1] 李兴旺.优化矿井通风与安全生产的关系研究[J].矿业装备,2021(6):164-165.

LI Xingwang. Study on the relationship between optimizing mine ventilation and safety production[J]. Mining Equipment,2021(6):164-165.

[2] 袁明昌,支学艺,吴亚军.武山铜矿通风系统优化研究[J].矿业研究与开发,2019,39(6):118-121.

YUAN Mingchang,ZHI Xueyi,WU Yajun. Study on optimization of ventilation system in Wushan Copper Mine[J]. Mining Research and Development,2019,39(6):118-121.

[3] 闫岩.基于Ventsim模型矿井通风优化研究[J].煤炭与化工,2021,44(6):115-117.

YAN Yan. Study on mine ventilation optimization based on Ventsim model[J]. Coal and Chemical Industry,2021,44(6):115-117.

[4] 郝海清,蒋曙光,王凯,等.基于Ventsim的矿井运输巷火灾风烟流应急调控技术[J].煤矿安全,2022,53(9):38-46.

HAO Haiqing,JIANG Shuguang,WANG Kai,et al. Emergency control technology of air and smoke flow in mine belt roadway fire based on Ventsim software[J]. Safety in Coal Mines,2022,53(9):38-46.

[5] 石银斌.五虎山矿井通风量数值模拟优化研究[J].工矿自动化,2021,47(增刊1):75-77.

SHI Yinbin. Research on numerical simulation and optimization of ventilation rate in Wuhushan Coal Mine[J]. Industry and Mine Automation,2021,47(S1):75-77.

[6] 何敏,武福生,成燕玲.基于三维模型的通风系统优化调控模拟分析[J].工矿自动化,2016,42(11):41-44.

HE Min,WU Fusheng,CHENG Yanling. Simulation analysis of optimal regulation and control of ventilation system based on 3D model[J]. Industry and Mine Automation,2016,42(11):41-44.

[7] 卢辉,袁树杰,马瑞峰,等.基于Ventsim的南山煤矿孤岛工作面均压通风方案研究[J].中国安全生产科学技术,2020,16(8):125-130.

LU Hui,YUAN Shujie,MA Ruifeng,et al. Study on scheme of pressure equalizing ventilation in isolated island working face of Nanshan coal mine based on Ventsim[J]. Journal of Safety Science and Technology,2020,16(8):125-130.

[8] 辛嵩,侯傳彬,金晓娜,等.基于Ventsim模型的矿井单翼通风系统优化研究[J].矿业安全与环保,2019,46(6):84-88.

XIN Song, HOU Chuanbin, JIN Xiaona, et al. Optimization of mine single-wing ventilation system based on ventsim[J]. Mining Safety & Environmental Protection,2019,46(6):84-88.

[9] 陈浩,陈宜华,胡秀林,等.基于Ventsim的深井金属矿山通风系统优化[J].工业安全与环保,2018,44(4):30-33.

CHEN Hao,CHEN Yihua,HU Xiulin,et al. Ventilation system optimization of deep well metal mine based on ventsim[J]. Industrial Safety and Environmental Protection,2018,44(4):30-33.

[10] 耿守锋.矿井通风系统三维模型构建与优化设计[J].煤矿现代化,2022,31(1):77-79.

GENG Shoufeng. Three-dimensional model construction and optimal design of mine ventilation system[J]. Coal Mine Modernization,2022,31(1):77-79.

[11] 肖梦辉,于涛,常宝孟,等.基于Ventsim的复杂矿井火灾数值模拟研究[J].矿业研究与开发,2021,41(12):129-134.

XIAO Menghui,YU Tao,CHANG Baomeng,et al. Numerical simulation study on complex mine fire based on ventsim[J]. Mining Research and Development,2021,41(12):129-134.

[12] 任浩.新发煤业通风系统优化研究[D].包头:内蒙古科技大学,2020.

REN Hao. Study on optimization of ventilation system in XinfaCoal Mine[D]. Baotou: Inner Mongolia University of Science & Technology,2020

[13] 曹怀轩.基于Ventsim的复杂通风系统优化及监测预警研究[D].青岛:山东科技大学,2020.

CAO Huaixuan. Research on optimization and monitoring early warning of complex ventilation system based on Ventsim[D]. Qingdao:Shandong University of Science and Technology,2020.

[14] 朱旭东.基于Ventsim的漳村矿通风系统优化研究[D].焦作:河南理工大学,2020.

ZHU Xudong. Study on optimization of ventilation system of Zhangcun Mine based on Ventsim[D]. Jiaozuo:Henan Polytechnic University,2020.

[15] 陈艳丽.基于Ventsim的矿井通风系统稳定性分析[D].长沙:中南大学,2014.

CHEN Yanli. The stability analysis of mine ventilation system on Ventsim software[D]. Changsha:Central South University,2014.

[16] 陶維国,姜希印,王连涛,等.济宁二号煤矿通风系统优化研究与实施[J].煤矿现代化,2016(4):130-133.

TAO Weiguo,JIANG Xiyin,WANG Liantao,et al. The optimize researches and implement on ventilation system of Jining NO.2 Coal Mine[J]. Coal Mine Modernization,2016(4):130-133.

[17] 王绪友,王连涛,陶维国,等.济宁二号煤矿沿空留巷工作面通风系统优化研究[J].矿业安全与环保,2016,43(1):77-80.

WANG Xuyou,WANG Liantao,TAO Weiguo,et al. Study on ventilation system optimization of working face with gob-side entry retaining in Jining No.2 Coal Mine[J]. Mining Safety & Environmental Protection,2016,43(1):77-80.

[18] 郭鹏阁.基于VSE软件的矿井通风系统优化研究[J].山东煤炭科技,2021,39(3):103-106.

GUO Pengge. Research on optimization of mine ventilation system based on VSE software[J]. Shandong Coal Science and Technology,2021,39(3):103-106.

[19] 谢中朋.复杂矿井通风系统稳定性研究[D].北京:中国矿业大学(北京),2015.

XIE Zhongpeng. Research on stability of complicated mine ventilation system[D]. Beijing:China University of Mining and Technology-Beijing,2015.

[20] 孙利阳.鲁奎山铁矿通风系统优化方案研究[D].昆明:昆明理工大学,2021.

SUN Liyang. Study on the optimization scheme of ventilation system in Rukui Mountain Iron Mine[D]. Kunming: Kunming University of Science and Technology,2021.