Development of hyaluronic acid-based edible film for alleviating dry mouth

2023-01-21DongKeonKweonJungAhHn

Dong-Keon Kweon,Jung-Ah Hn

a Jinwoo Bio Co.,Ltd.,Yongin 17111,Korea

b Department of Food and Nutrition,Sangmyung University,Seoul 03016,Korea

Keywords:Edible film Hyaluronic acid Saliva stimulating Tensile strength Thickness

ABSTRACT For alleviating dry mouth symptoms,edible films based on hyaluronic acid (HA) with 3 different mw (800,1 200 and 2 300 kDa) were prepared (800F,1200F and 2300F,respectively),and the properties as well as effectiveness were compared.The concentration of each HA dispersion for film forming was set as 3.0%,1.5% or 1.0%,for the mw 800,1 200 and 2 300 kDa,respectively,based on the solubility.The 800F showed the highest thickness,tensile strength,and water vapor transparency,whereas obtained the lowest transparency and elongation at break among samples.All of the HA films showed safety against microorganism during 28 storage day at 40 °C with 60% humidity.The optimum site for f ilm attachment in mouth was the palate,and 800F was the most effective for stimulating saliva secretion,eliciting a 38% increase compared to control(without film),tested by the elderly over 65 years old.By the sensory test,800F was also the most acceptable.Based on above results,the edible films effectively stimulating saliva secretion could be produced with HA,and the physical,sensory characteristics as well as disintegration times of the film could be controlled by mw and the dissolution concentration of HA.

1.Introduction

Hyposalivation defined as an unstimulated salivary flow rate <0.1 mL/min [1],and this was originally proposed by Ericsson and Hardwick [2].That is a condition that primarily affects older adults and can have a signif icant negative effect on one’s quality of life [3].In elderly people,both aging and the long-term use of medications are regarded as major causes of hyposalivation [4].Polypharmacy in adults could also increases oral dryness as a side effect [5].Saliva,a complex mixture of proteins,glycoproteins,mucins,and ions,helps prevent dental caries,promotes remineralization of early carious lesions,buffers acids generated by oral bacteria,and prevents other types of oral infections [6],so dry mouth due to hyposalivation in elderly people is known to cause dental problems and changes in chewing,swallowing,digestion,and taste [7].Therefore,natural salivary substitutes such as water [7],milk [8],or vegetable oils [9]as well as synthetic substitutes may provide symptomatic benefits of short duration for xerostomia patients.Pharmacological agents designed to increase salivary flow (secretagogues),including bromhexine,anetholtrithion,pilocarpine,and cevimeline,have been tested in patients with dry mouth [10].Although they have been shown to transiently increase salivary output,side effects such as perspiration or mineral loss associated with these agents also limit their use [11,12].

Hyaluronic acid (HA),a natural polyanionic polysaccharide,is distributed widely in the extracellular matrix and throughout the connective tissue,eyes,intestines,and lungs.It is a nontoxic,biocompatible and biodegradable mucoadhesive polysaccharide bearing negative charge,and so it was approved for injections by the Food and Drug Administration (FDA) [13].Unmodified HA itself has been applied for many important applications in drug delivery and surgery.Among the product types made of HA,films [14]for wound dressing or drug delivery [15],sponge sheets [16],or nanofibers [17]were reported.Recently,oral HA administration was reported by preventing reduction amount in body,increasing the moisturizing power of the skin and eyes [18],and relieving joint pain and skin wrinkle [19],so various shapes for oral HA administration need to be developed.

Edible films have been used for extending shelf life of food products through food packaging [20],or for potential carriers for flavors or nutritional additives [21].An edible film was first developed in the late 1970s as alternatives to tablets,capsules,and syrups for pediatric and geriatric patients who experience difficulties swallowing traditional oral solid dosage forms [22],which is known to be a novel dosage form for taking active pharmaceutical ingredients,vitamins and ingredients for food supplements.Edible film also requires only a small amount of saliva to dissolve within a few minutes and water is not necessary for administration.The advantage is the improvement of acceptance and patient compliance with no risk of choking,associated with better safety and efficacy in comparison with conventional dosage forms [23].

The typical composition of edible film is water soluble polymer(40% −50%) and plasticizers (0% −20%).Starch,modified starch,or pullulan have been primarily employed [24],and sugars and gums [25],glycerol [26],or chitosan [27]have been used as plasticizers.Recently,there are many attempts to release the drug by putting the ingredient in HA as a medium.However,since HA itself has a large amount of moisture,this study focused to find out the optimal addition ratio and its effect for improving dry mouth symptoms.In this study,we developed edible film based on HA,which is not just carrier of functional material but functional material stimulating saliva secretion and retention in mouth based on both the excellent water sorption ability and water retention power.For the prepared HA film with differentmw,the saliva stimulating effects in the mouth were compared,especially for elderly people,to suggest a new method for dry mouth treatment.The preference as well as physical and microbiological properties of the film were also characterized.

2.Material and methods

2.1 Materials

HA (fromStreptococcus equisub.) of three different molecular weights (mw,800,1 200,2 300 kDa) was provided by JinWoo Bio Corp.(Seoul,Korea).HA dispersions were prepared by dissolving each polymer in ultrapure water (Milli-Q®system) containing 10% ethanol.With several pretests,the concentration of each HA for film forming dispersion was set as 3.0%,1.5% or 1.0% with 800,1 200 and 2 300 kDa,respectively,based on the solubility.

2.2 Viscosity measurement of HA dispersion

The apparent viscosity of each film forming dispersion was determined using a viscometer (RVDV-II+Pro,Brookfield Inc.,Middleboro,MA,USA) with spindle 7 at 50 r/min.

2.3 Film preparation

Each HA dispersion (120 g) with differentmwwas stored at room temperature for 24 h to remove air bubbles,and then was cast into films by a film applicator (COAD 411,Ocean Sci.,Uiwang,South Korea).The prepared films were then dried at 40 °C and relative humidity (RH) of 60% for 6 h,and then stored in sealed plastic bags prior to analyses.In this experiment,it was confirmed that unmodified HA itself could sufficiently form film without plasticizer.The prepared film was designated as 800F,1200F or 2300F according to itsmw,respectively.

2.4 Physical properties of film with different mw

Tensile strength and elongation break of the films were determined by using a texture analyzer (TAXT2i Stable Micro System,Surrey,UK) by reference to the ASTM D882-02 guidelines [28].Each film was cut into strips (10 mm × 50 mm) and then measured during the strip extension up to breakage at 1.0 mm/s with an initial grip separation of 40 mm,and then calculated by dividing the maximum force at break by the cross-sectional area of the film.The final values were recorded at least five times.Percent elongation at break was calculated on the basis of length extended as compared to the original length of the film.

The thickness of each film was measured by a micrometer caliper (Mitutoyo Manufacturing Co.Ltd.,Kawasaki,Japan).Seven different positions on the film were used to take measurements for each film,and the average value was reported.For transparency measurement,the film was cut into a rectangular shape (4 mm ×10 mm) and placed inside a spectrophotometer cell,and then the percent light transmittance of the film was analyzed at 600 nm by using a UV spectrophotometer (model UV-2100,Beijing Purkinje General Instrument Co.Ltd.,Beijing,China).The transparency was calculated by the following equation:

whereT(%) was the light transmittance at 600 nm andbwas the thickness of film (mm).

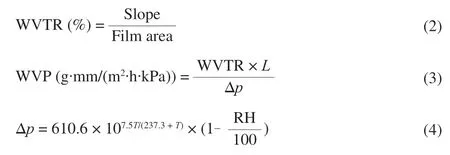

Water vapor permeability (WVP) was measured performed according to the ASTM E96–05Standard Test Methods for Water Vapor Transmission of Materials.Films (3 cm × 3 cm) were used to cover the opening of vials containing 18 mL of distilled water.The vials were then kept in a thermo-hygrostat (at 25 °C and RH of 50%,TH-PE-065,Jeio Tech Co.,Daejeon,Korea) for 8 h and weighed at 1 h intervals.WVP was calculated as following equation:

where slope is mass loss of vial by time,Lis the average thickness of film (μm),Δpis the difference of partial water vapor pressure across the film,Tis temperature (°C) and RH is the relative humidity (%).

2.5 Microstructure of the film

The microstructures of HA films with differentmwwere obtainedby environmental scanning electron microscopy (E-SEM,Regulus 8230,Hitachi,Tokyo,Japan).The surface and cross-section of each film were observed.

2.6 Microbiological analysis of film with different mw

Generally,edible films are placed in an aluminum packaging bag and kept in a vacuum state,but in this study,the stability to microorganisms was measured in a short time under the following harsh condition.The produced HA film (20 mm × 30 mm) placed on a glass plate was stored in the air for 28 days without packaging under constant temperature and humidity (40 °C,and 60%,respectively).

At 28 storage day,each film was used to monitor the changes in microbiological test by mixing with 5 mL of saline.For an aerobic plate count (APC),1 mL of each prepared suspension was mixed with 20 mL of plate count agar (PCA).Plates were rotated and several times crosswise for equal distribution of the media.After solidification of the media,the plates were inverted and placed in incubator to incubate at 37 °C for 18 h by the pour plate method.For coliforms andListeriameasurement,1 mL of each suspension was dropped of Coliforms PetrifilmTM(6410,3MTMHealth Care Ltd,UK) and Listera PetrifilmTM(6447,3M™Health Care Ltd.,UK) and incubated 35 °C for 48 h.All analyses were performed in triplicate.

2.7 Site and overall preferences of the films in mouth

Both site and overall preference of the film in mouth were tested by 30 elderly subjects who were over 65 years old (18 women and 12 men) with 800F (20 mm × 30 mm).For site preference,three different sites: palate (mouth ceiling),tongue,and buccal mucosa were selected,and the saliva amount secreted during 10 min as well as the feeling of comfort were compared using the 7-point hedonic scale (1=very uncomfortable;7=very comfortable).For overall preference,each HA films (20 mm × 30 mm) with differentmwwere served to the panelists in plastic dishes coded with random threedigit numbers,and the research subjects were asked to evaluate the appearance,taste,moistness,feeling of comfort during attachment,and overall preference.Sensory assessment was analyzed using a seven-point hedonic scale (1 indicates “extremely dislike” and 7 indicates “extremely like”).

2.8 Degree of both saliva secretion stimulation and disintegration of film with different mw

Both the saliva amount secreted by the film (20 mm × 30 mm)which were attached at the palate and film disintegration in mouth were measured by the same panels performed above the preferences test.For saliva gathering,the initial amount of saliva in the mouth before film attachment was totally swallowed,the newly secreted saliva after film attachment was gathered into a 50 mL falcon tube for 10 min,and the amounts were compared.All of the tests were conducted in comfortable conditions,and water was provided to panelists to rinse their mouths between samples.The panelists were required to wait for 30 min before testing the next sample.The saliva gathered without film was used as a control.The disintegration time(DTs) of each film with differentmwwas acquired by measuring the time for complete dissolution after attaching the film at the palate of the mouth.Sufficient time between each sample was allowed.After three repetitions,the average time was calculated.

All of the tests performed by the panelists were conducted in accordance with the ethical principles as approved by the Research Ethics Committee of University (BE2018-07).

2.9 Statistical analysis

The data were analyzed using the statistical analysis system (ver.23.0,IBM Corp.,Armonk,NY,USA) package software for analysis of variance (ANOVA).Duncan’s multiple range tests were used to detect the significance of differences atP<0.05.All experiments were performed in triplicate.Correlation among variables was also analyzed.

3.Results and discussion

3.1 Viscosity of film forming dispersion and appearance of film

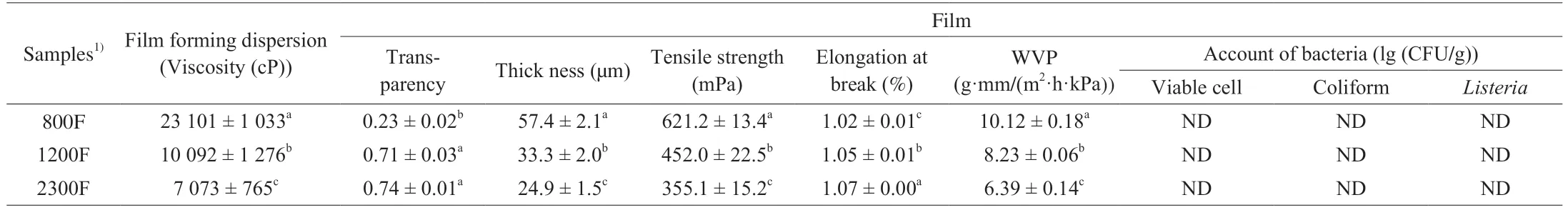

The viscosity of each film forming dispersion is presented in Table 1.Each concentration of 800,1 200 and 2 300 kDa HA based on solubility was 3.0%,1.5% and 1.0%,respectively,and the viscosity of each dispersion was 23 101,10 092 and 7 073 cP,respectively.The viscosity increased with concentration rather thanmwof HA.

Table 1 Physical and microbial properties of both film forming dispersion and HA film with different mw.

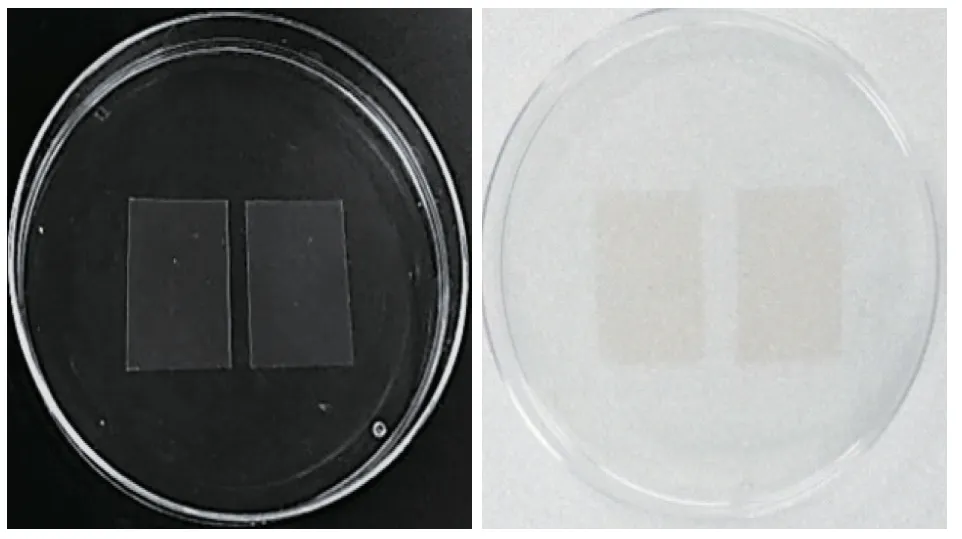

The appearance of HA films withmw800 kDa was shown in Fig.1,and there was no difference in appearance among samples with differentmw.The transparency and thickness of each film were also shown in Table 1.Xu et al.[14]prepared HA film with chitosan for wound dressing,and a good transmittance is desirable for the purpose of direct observation.For the HA film in this study,although it was difficult to differentiate transparency among films by eye,the transparency of the 800F was the lowest (0.23),while that of 2300F was the highest (0.74).

Fig.1 The appearance of the HA film with mw 800 kDa.

3.2 Physical properties of film

Thickness of the films is an important parameter for WVP and barrier properties.The thickness of HA films with differentmwranged from 24−57 μm.The value was proportional to the concentration of HA,so 800F exhibited the highest thickness.In literatures,the thickness range of the pullulan film was 29−75 μm [29],and that of the soy protein edible film was 33−78 μm [30],demonstrating similar ranges to our results.In this experiment,the concentration of the HA dispersion,rather than themwof HA,was found to have a more direct effect on the thickness of the film.A similar result was reported by Kim et al.[29],indicating that the higher solid content of the pullulan film (20%) resulted in significantly enhanced thickness when compared to films containing starch (5%)which has much highermwthan pullulan.Mali et al.[31]also reported that the films became thicker as the solid concentration in the film forming dispersion increased,an effect which was simply due to the increased total residual mass in the film,regardless of the type of polysaccharide used.Kim et al.[29]reported that there is a significant negative correlation between the thickness and transparency of the films,suggesting that the thinner films were simply more transparent.With same tendency,the 800F prepared in this experiment with the highest solid concentration showed the highest thickness and the lowest transparency.

The mechanical properties including tensile strength of the films are highly related with film composition,plasticizer and its concentration [32].Regarding the tensile strength of films in the literature,the starch film exhibited values up to 40−50 mPa [33],and those of pullulan film were 60−85 mPa [29].Because of its poor tensile strength of starch-based materials [34],the improvement of mechanical properties is an ongoing challenge.To enhance the tensile strength,several additives were tested;the value of gelatin film was slightly increased through the addition of grapefruit seed extract [35],and the stiffness of chitosan film could be increased (from 65.5 to 104 MPa) when neutralized with higher NaOH concentration.The isolated soy protein film showed a value of 8.8 mPa,which increased up to 10.7 mPa when phenolic compound was added [30]due to cross-linking between protein and polyphenols.When compared to the literature values,the tensile strength of the HA film prepared in this experiment was much higher within the range from 355.1 to 621.2 mPa.The value was proportional to the concentration of HA,so the increase of HA content resulted in increasing tensile strength of the films.If tensile strength means a measure of film strength,elongation at break means a measure of film stretch ability prior to breakage [36].The elongation at break value of HA film was from 1.02% to 1.07%,and significant increase was observed bymwincrease.For elongation at break in literatures,alginate film ranged 2.73% −4.84% ;gellan based film ranged 3.52% −5.71% [37],and gelatin-starch based film ranged 2.1% −11.0% [38].When compared the literature values,HA itself could serve as an inflexible and strong edible film without any additives,and the strength could be varied by controllingmwor the concentration of HA.

The WVP is an important factor that can change the quality of the film itself or the food packaged with the film by evaporating moisture from the film or conversely,by attracting moisture from the surrounding environment [26].So the films with high water barrier properties or low WVP can prevent packed foods from spoilages caused by moisture absorption.The WVP of the HA film developed in this study was the highest for 800F at 10.12 g·mm/(m2·h·kPa),8.23 g·mm/(m2·h·kPa) for 1200F and 6.39 g·mm/(m2·h·kPa) for 2300F,respectively.This tendency is consistent with the prior results that the WVP increases as the thickness of hydrophilicity materialbased film increases [39].

The WVP of a film made of a hydrophilic polymer material such as chitosan [40]or cellulose [41]increased depending on the moisture content of the film.There is a report that the moisture content and WVP could decrease by the density increased due to cross-linking of additives [42].Sharma et al.[43]reported that the quality of the edible film can be improved by decreasing WVP.The WVP of the HA film developed in this study ranges from 6.39 to 10.12 g·mm/(m2·h·kPa),which is similar or slightly higher values than casein-based edible films(7.91 g·mm/(m2·h·kPa)) reported by Chick and Ustunol [44],apple peel film (4.20−7.56 g·mm/(m2·h·kPa)) reported by Sablani et al.[45],or potato peel film (2.99−5.30 g·mm/(m2·h·kPa)) reported by Kang and Min [46].For long term storage,high WVP film needs to be vacuum-sealing preserved.

3.3 Microstructure of HA films with different mw

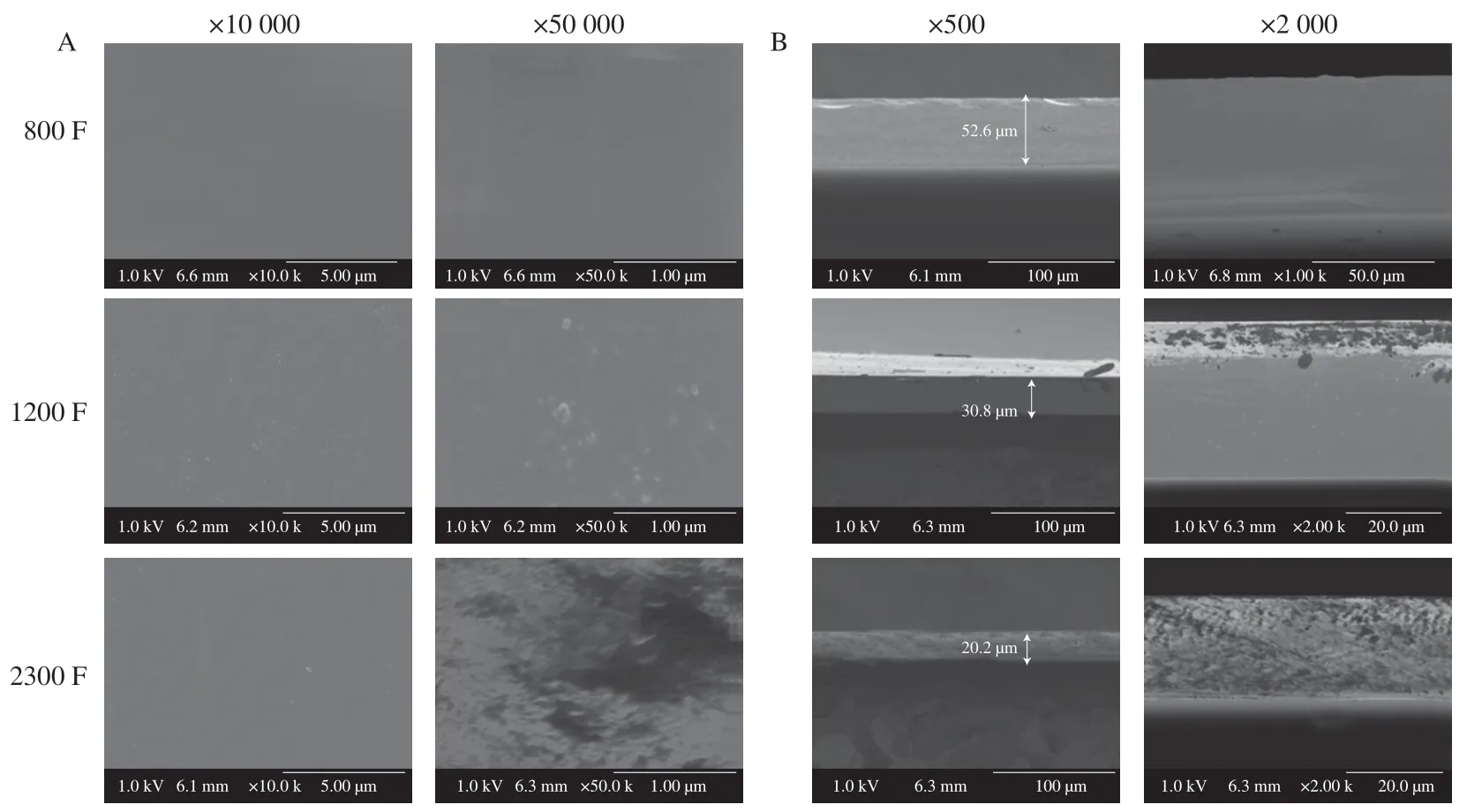

The surfaces,cross sections,and thicknesses of the HA films with differentmwwere observed by SEM,and the results are shown in Fig.2.The surface of each film showed a relatively uniform shape without any difference even with enlarging ×10 000,as well as with eye.With magnification of ×50 000 for the surface and ×2 000 for the cross section,a slightly roughened surface was observed withmwincrease.This might be due to the uneven dispersion of highmwHA.An accurate determination of the thickness of the film is important,because it serves as a basis for calculation of several functional properties of the films,and is critical for the analysis of manufacturing reproducibility [47].The thickness values upon enlarging the cross section by ×500 were measured as 52.6,30.8,and 20.2 μm in the order of 800F,1200F,and 2300F,and these results were similar to the values measured by calipers (Table 1),which show approximately 10% difference.

Fig.2 Microstructure of HA film (A) surface and (B) cross section.

3.4 Microbiological safety of film with different mw

The microorganism safety of film was shown in Table 1.The APC is one of the most common tests applied to indicate the microbiological quality of food,so monitoring the value is an important factor in determining the maintenance period of product quality.According to the Korean Food and Drug Administration,although the number of APC is not particularly limited in general foods including dried foods,however 5 (lg(CFU/mL)) in storage of food are regarded as spoilage in general [48].Fortunately,no APC was detected in the film until 28-day storage.The presence ofE.coliin products is undesirable because it indicates poor hygienic conditions which have led to contamination.Listeria monocytogenesis widespread in the environment and can be isolated from a wide variety of foods [49].Both ofE.coliandListeriawere not also detected in films,until 28-day storage.According to Pirnazar et al.[50],concerning the antimicrobial activity,HA has shown varied bacteriostatic dose-dependent effects on different microorganisms.They investigated the potential bacteriostatic effect of HA,and the results showed that HA solutions with differentmwexerted varied bacteriostatic effects on all the bacterial strains.Ardizzoni et al.[51]also showed that different microbial species and sometimes,different strains belonging to the same species displayed a HA dose-dependent growth inhibition.Besides gels or sponges type of HA also have been reported to reduce bacterial contamination during surgical therapy [50],the film type HA in this experiment also showed microorganism safety in this experiment.

3.5 Site preference and saliva amount secreted

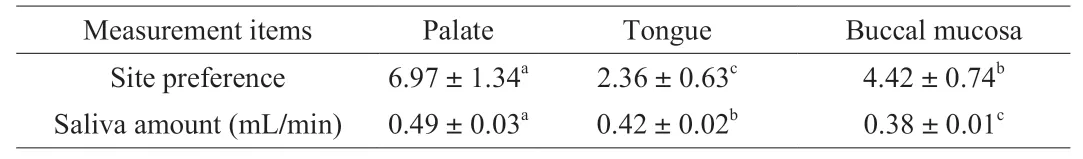

The site preference and saliva amount secreted by film at different sites were compared in Table 2.The site preference on film attachment were resulted that the palate was the best,while the front part of the tongue was the worst.The amount of saliva secreted was significantly different according to the film attachment site;the most(0.49 mL/min) occurred when adhering the film to the palate,and the least (0.38 mL/min) was obtained when adhering on the buccal mucosa.Therefore,in this experiment,the best site for HA film attachment for the purpose of stimulating saliva flow was the palate.

Table 2 Preference and saliva amount secreted depending on film attachment position.

3.6 Overall preference

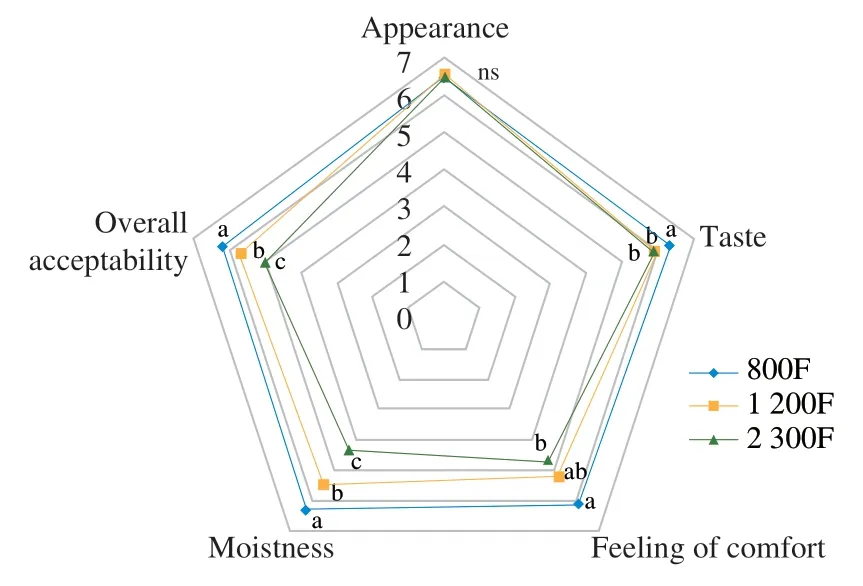

The results of sensory test of HA films with differentmwwere shown in Fig.3.For appearance,no differences were observed among the samples.However,there were significant differences in feelings of comfort,moistness and taste;the taste was best for 800F;however,there was no significant difference between 1200F and 2300F.For the feeling of comfort,800F was also regarded as the most,whereas 2300F was evaluated as the worst.According to the explanation of panels,the feeling of comfort primarily arose from thickness: the thinner the film was,the less favorable.Moistness ascended in the order of 800F,1200F,and 2300F.Overall,the preference of HA film was significantly distinguished in the order of 800F,1200F and 2300F.

Fig.3 Sensory properties of HA film with different mw.a−c mean significant difference at the P <0.05 level.

3.7 Degree of stimulating saliva amount and DTs

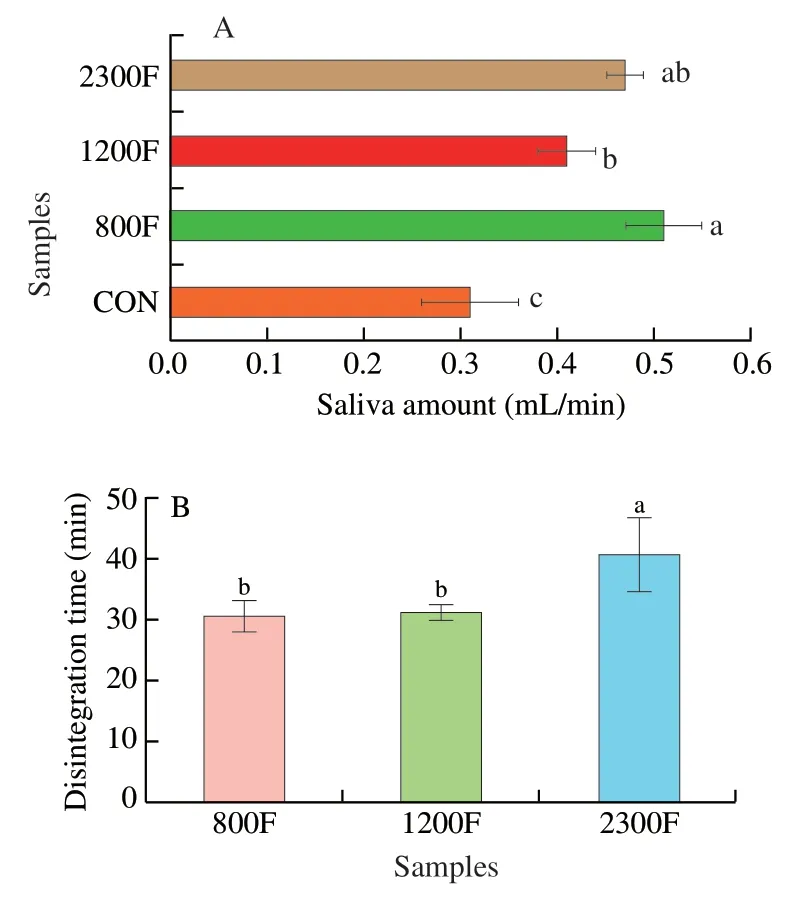

Generally,dry mouth symptoms were evaluated by subjective or objective finding.Subjective symptoms were evaluated by 5 questions based on the work of Fox et al.[52],however the question“Does your mouth usually feel dry?” is used as a strong indicator of subjective oral dryness [53].To prove the symptom relief on dry mouth,we compared the salivary amount secreted before and after film attachment,and the result was shown in Fig.4A.The average saliva amount in the elderly group without film (control) was 0.31 mL/min,and the amount significantly increased after attaching the HA film;with 800F,the saliva amount secreted was 0.50 mL/min:this value was the highest,representing an approximate 38% increase when compared with control.By attaching 1200F,the amount was increased by 20%,exhibiting 0.41 mL/min,and with 2300F,the amount increased up to 34%,at 0.47 mL/min.Here,attaching HA films was effective on dry mouth,and especially 800F attached on the palate is the most effective for stimulating saliva secretion.

Fig.4 (A) Saliva secretion rate by HA film with different mw and (B)disintegration time of HA film in mouth.a−c mean significant difference at the P <0.05 level.

The time for the HA films produced with differentmwto be completely disintegrated in the mouth were measured and compared in Fig.4B.The times were 30.38 and 31.02 min for 800 and 1200F,respectively,without significant difference;however,2300F required the longest time (40.46 min) with significance.This difference could be attributed to themw,that is,with highermw,more time was required for complete dissolution.A similar result,that the disintegration rate of the polymers is decreased by increasing themwof polymer film bases,was reported by Arya et al.[54].

DTs of films could be varied and controlled by film materials.For example,rapid DTs (18 s) of pullulan based film was reported by Sharma et al.[43].DTs of starch based film was to be (10.3 ± 0.8) s,whereas that of gelatin based film increased up to (20.4 ± 0.8) s [38].The addition of the ascorbic acid could lead to an enhanced production of saliva and reduced the DTs [55].The DTs of the HA film in this experiment was uniquely higher when compared with those in the literatures above.Higher DTs could be superior,since continuing saliva secretion causing by film attaching could relieve the symptoms of dry mouth for longer.Takeuchi et al.[56]measured of DTs of edible film by several methods and reported that in any test methods,the DTs clearly correlates with the thickness of films because the immersion of water into the film was likely to depend on the film thickness.

4.Conclusions

In this work,edible films based on HA were prepared with differentmw,and the effects of relieving the symptom of dry mouth were compared.The HA films were transparent,strong and inflexible when compared starch,pullulan or gelatin based films,and has microorganism safety.All the produced HA film promoted saliva flow rate,and the most effect was observed in 800F.The saliva flow rate showed a significant difference depending on the film application site.The fastest flow rate was observed when attaching the film to the palate,which was almost 30% higher than when attaching to the buccal mucosa.For the DTs of film,with highermw,more time was required for complete dissolution,which might come from the low solubility due tomw.Therefore,it seems possible to manufacture various films by controlling themw,concentration or thickness according to the specific purpose.Based on this research,it could be expected that the edible films stimulating saliva flow without side effects could be produced with HA.Furthermore,various films can be developed by adding several functional materials or pharmaceutical compounds to the HA solution,which will be a good formulation with ease and convenient consumption,especially for those who have difficulty swallowing oral solid forms

Conflict of interest

The authors declare that they have no conflict of interest.

Acknowledgments

This work was supported by the Korea Institute of Planning and Evaluation for Technology in Food and Agriculture and Forestry (IPET) through the High Value-Added Food Technology Development Program funded by the Ministry of Agriculture,Food and Rural Affairs (MAFRA) (117071-02-1-HD020) and by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science,ICT&Future Planning (NRF-2019R1A2C1002782).

杂志排行

食品科学与人类健康(英文)的其它文章

- Colloidal nanoparticles prepared from zein and casein:interactions,characterizations and emerging food applications

- Biological factors controlling starch digestibility in human digestive system

- Preparation methods,biological activities,and potential applications of marine algae oligosaccharides: a review

- Mushroom β-glucan and polyphenol formulations as natural immunity boosters and balancers: nature of the application

- Preparation of multicore millimeter-sized spherical alginate capsules to specifically and sustainedly release fish oil

- Structural characteristics,anticoagulant and antithrombotic mechanism of a novel polysaccharide from Rosa Chinensis Flos