A comprehensive review of the 3D printing of sp2 carbons: Materials,properties and applications

2022-12-13SatendraKumarManojGoswamiNetrapalSinghSathishNatarajanSurenderKumar

Satendra Kumar, Manoj Goswami, Netrapal Singh, Sathish Natarajan, Surender Kumar,*

(1.Academy of Scientific and Innovative Research (AcSIR), Ghaziabad 201002, India;2.CSIR - Advanced Materials and Processes Research Institute (AMPRI), Bhopal 462026, India)

Abstract: Three dimensional (3D) printing is a modern technology that has the possibility to transform existing production methods.It offers a novel production method of layered manufacturing and layer-by-layer stacking, which radically simplifies the manufacturing process and enables large-scale customizable production.However, there are still numerous problems with this new technology.Except for pure graphene, sp2 carbons can be 3D printed with little difficulty because of their hydrophilicity.The hydrophobic nature of pure graphene makes it difficult to print and process in water-based media, but advances in capillary inks allow for the 3D printing of pure graphene.This review focuses on the most recent developments in the 3D printing of sp2 carbons.A concise overview of 3D printing technologies is presented, followed by a summary of 3D printed sp2 carbons and their diverse applications.Finally, prospects and opportunities for this new field are discussed.

Key words: 3D printing technologies;sp2 carbons;Carbon-based composites;Applications

1 Introduction

Additive manufacturing (AM) is a rapid manufacturing process based on the technique of printing material layer-by-layer in a 2-Dimensional space through the help of a computer-based design[1,2].The on-demand production of materials makes AM different from the conventional manufacturing methods and a promising one, too[3].David E.H.Jones first introduced the idea of 3D printing in 1974.Chuck Hall filed his patent titled "apparatus for production of three-dimensional objects by stereolithography" in 1984[4].AM has advanced through the years and has become flexible with complex shapes and materials,applied in construction, medical science, aerospace,fashion design, and so on[5].Cost, product complexity,material usage and material property requirements,time, energy consumption, sustainability, and other factors all play a role in the choice of a fabrication technique.Compared to traditional manufacturing processes, AM has the advantages of freedom of design, requires less skilled workers, quality assurance, fast prototyping, and less energy consumption with almost zero pollution[6].In the upcoming years, it is anticipated that the consumption of 3D printing equipment, materials, software, and associated difficulties will increase by 22.3 per cent annually.

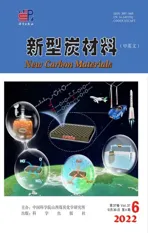

Carbon-derived materials are prospective because carbon atoms have a great tendency to link up with other atoms through strong covalent bonds.They have their characteristic properties like excellent physical, thermal, mechanical, and chemical properties.For example, major sp2carbons that are 3D printed to date are graphite, graphene oxide (GO), carbon dots(CDs), reduced graphene oxide (rGO), graphene, carbon nanotubes (CNTs), carbon fibers, carbon black(CB)[7–9].The large surface area and high porosity of 3D graphene fibers and rGO have been utilized unprecedentedly for various purposes like building supercapacitors and solar cells[10,11].The sp2carbons manufactured through 3D printing can produce complex shape materials and overcome shortcomings such as excessive cost, poor efficiency, and intricate procedures[12–15].A polymer-graphene composite 3D printed with 5.6% graphene loading had a thermal expansion coefficient of 7.5×10−6°C−1.The electronic structure of the sp2carbons is tuned with the doping of heteroatoms, which alters their electron and charge transfer mobility[16].Manufacturing of transparent electrodes can be done efficiently with these materials as they have high conductivity (550 S cm−1)[17], stable electrochemical property, and electrocatalytic activity with a conversion efficiency of 8.13% in solar cells[18–20].3D printing of sp2carbons and their applications are schematically shown in Fig.1.

Fig.1 Schematic representation of 3D printed sp2 carbons and their possible applications

Possessing high specific surface area, the carbon derivatives (graphene: 2 630 m2g−1) are used in the field of biomedical as they act as a medium for the swift diffusion of drugs and direct them to specific sites[21].3D printed functionalized-GO (5% loading)/resin composite showed 108higher electrical conductivity than bare resin[22].3D printed graphene scaffolds are used in electronics (800 S cm−1) and biomedical applications[23].CDs have an excellent fluorescent property with size and medium (an emission wavelength of 460 and 550 nm in acidic and basic medium, respectively) dependent on tunable emission[24].CDs are resistant to photobleaching, which makes them an excellent material for bio-imaging applications[25].Furthermore, the materials mentioned above remove toxicity, which comes with metallic quantum dots.These materials have exceptional optical properties such as tunability and wavelength selectivity,which gives their use as LEDs and bolometers (conductivity of 12.0 W m−1K−1@ 45% graphene loading)[26,27].As a carbon catalyst for water purification over other expensive metal catalysts has a flux of~60 L m−2h−1MPa−1[28].Carbon black and active carbon having high surface area acts as deposition supporters of transition metals through adsorption[29].

Utilization of sp2carbons as a photocatalyst has the advantage of low rate of recombination ((1.8 ±0.7)×10−10cm3s−1) of electron-hole pair[30]and numerous active sites contribute to the efficiency as a photocatalyst.By the same property, CO2is reduced photo catalytically[31].The catalytic activity of a printed graphene composite aerogel electrode is studied,which has an electrochemically active surface area greater than 1 700 m2g−1[32].The application of 3D printed sp2carbons electrodes is extensively explored in energy storage/conversion, fuel cells, and solar cells.Ultrathin (0.4 mm) rGO framework decorated with Ni nanoparticles (~5 nm) is 3D printed for Li-CO2battery application[33].The Ni/rGO framework delivered an areal capacity of ~15 mA h cm−1@0.10 A g−1.Renet.al3D printed flexible Zn//CNT@MnO2electrode with a capacity of 63 μAh cm−2@400 μA cm−2[34].Another group has reported 3D printed CNT/graphene electrodes for light-reharvesting of solar cells with a transmittance of 30% and conversion efficiency of 7.7%[35].The graphene/CNT composite is 3D printed for high-performing flexible strain sensors[36].A strain sensor with a ratio of CNTs to graphene of 3∶1 presented a high sensitivity of 136 327 (gauge factor) at 250% strain and was stable up to 3 000 cycles.Overall, the integration of sp2carbons with 3D printing technology is able to give freedom of electrode design, intricate shape fabrication,low-cost manufacturing, etc.

This article reviews current advances in the 3D printing of novel devices with various sp2carbonbased applications, such as energy storage, electronic circuits, sensors, and thermal/mechanical applications.Supercapacitors containing sp2carbons and 3D printed batteries are examined for energy storage.In addition to offering different methods of creating micro devices, 3D printing technology also enhances functionality of numerous devices.This is reviewed and talked about.3D printed sp2carbon-based flexible circuits, sensors, and composites in electrical circuits are reviewed.A conclusion and forecast are provided at the end of the paper, outlining potential future designs and advancements of 3D printing technology for various applications.

2 3D printing technologies

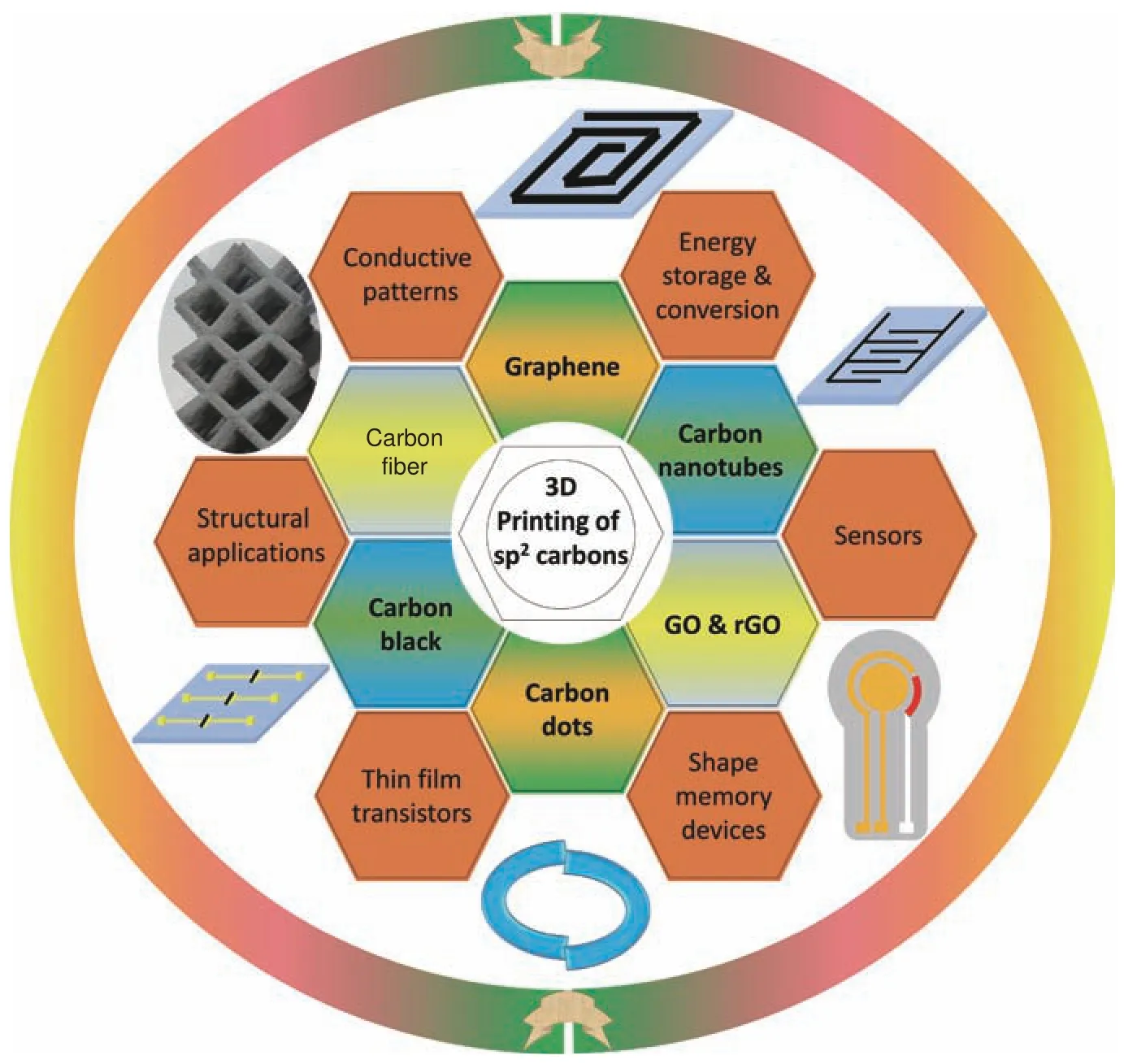

In the era of modern technology, 3D printing can replace an entire manufacturing unit.3D printing is highly flexible and quick, accelerating modernization,reducing energy usage, minimizing material waste,and compressing the supply chain[37].The material is managed by 3D layers according to the design[38].3D printing is helpful in various sectors, for instance,manufacturing, industrial design, footwear, architecture, medical, and many more[39].It creates new possibilities and offers hope for numerous possibilities to improve manufacturing efficiency[40].The layer from the finished product can be printed using various methods.Some of the major 3D printing methods that are primarily used these days are fused deposition modelling (FDM)[41], direct ink writing (DIW)[42], stereolithography (SLA)[43], and selective laser sintering(SLS)[44].According to the ASTM standard, there are 7 different types of AM processes: material-extrusion,vat photopolymerization, powder bed-fusion, binderjetting, directed energy-deposition, sheet-lamination,and material jetting[45].Depending on the many input materials, 3D printing techniques can be classified as solid, liquid, or powder.For solids, 3D items can be fabricated in FDM and laminated object manufacturing (LOM) using layers of adhesive paper, metal laminates, and plastic wire material.The typical basic material for liquid-based technologies is photosensitive resin.Metal, ceramic, and polymer powder are the three categories in powder-based materials.Fig.2 displays the classification.

Fig.2 Technical classification of 3D printing techniques.PolyJet: photopolymer jetting, SLM: selective laser melting, HSS: high-speed sintering, BJ: binder jetting, EBM: electron beam melting.Adopted from Ref.[45] with little modifications

The use of 3D printing technologies might alter society.The way we make goods and generate commodities globally may change and improve dramatically due to advancements in 3D printing technology[46].Applications for 3D printing are quite diversified, ranging from manufacturing simple electronic circuits, moulds, and fixtures to intricate realworld applications, including human 3D organs, 3D vehicles, and nutritious food products[47].3D printing includes approximately hundreds of materials nowadays, and research is going on to increase the range of materials used in this technique[48].Hopefully, it can be said that the precipitous development of 3D printing technologies will play a vital role in modern economy.

3 Printing sp2 carbons

The sp2carbons are extensively employed in 3D printing owing to their superior chemical resistance,mechanical, thermal, electrical, and electrochemical properties, and diverse nanostructures[49].The advancement in 3D printing techniques has offered tremendous variations in the applications of sp2carbons.3D printed sp2carbon-based nanomaterials have various uses, including counting sensors, catalysis, charge storage, electronics, composites, microfluidics, and biomedical application[50,51].3D printing has opened up the area of the fabrication of complex structures of sp2carbons, which are very difficult with conventional methods.These structures have various potential applications, especially in energy storage systems[46].Carbon black (CB), nanotubes, fibers, graphene, CDs,and GO are the different sp2carbons used for 3D printing and are discussed in this section.

3.1 Carbon black

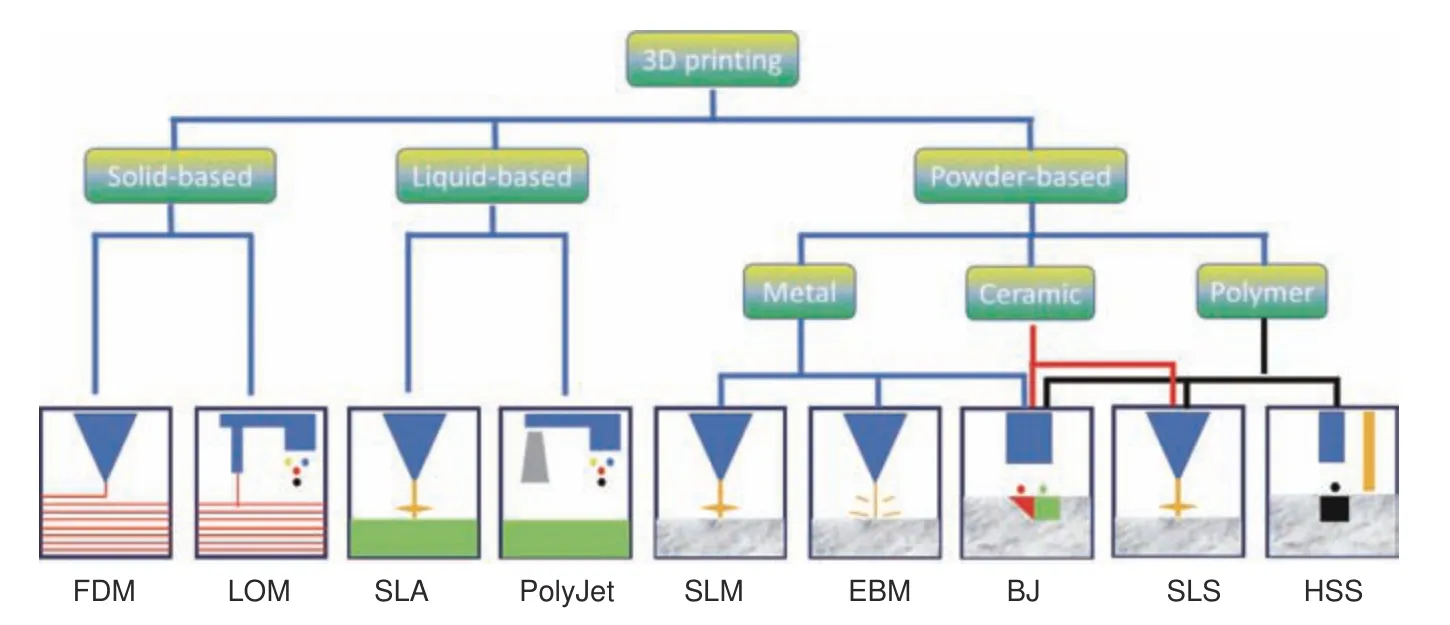

CB, one of the carbon forms, has been broadly used as a nano additive in polymer matrices to improve properties like tensile strength, fracture toughness (2.22 MPa m1/2at 5% loading)), and electrical(~100 S cm−1) and thermal conductivities[52,53].Such properties have made CB one of most widely employed carbon nanomaterials in AM.The main reason of including CB in the manuscript is only that it has some part of sp2carbon content.CB consists of not purely sp2carbon.The percentage of sp2carbon in CB depends on the degree of oxidation, which varies from 10% to 90%[54,55].Most CB-based AM is based on its nanocomposites with thermoplastics, such as polylactic acid (PLA)[56].The CB-based composites have various applications in electronics, medical, electrochemical sensing, etc.[55,56,58].A group demonstrated a 3D printed electrochemical device of conductive CB(CCB)-based PVA composite for electroanalysis of biofuel antioxidants[59].They 3D printed the PLA/CCB composite onto the 3D printed acrylic templates using a 3D pen.The structures were further used to sense the most common biofuel antioxidants,such as tert-butylhydroquinone (TBHQ) and butyl hydroxyanisole (BHA) (Fig.3a-d).The 3D printed solvent sensors were reported by Sathieset al.[60],which were fabricated from PVA-CB.The sensor with 40% infill density and 0.4×2 mm2dimension showed a high sensitivity.The 3D printed sensor of PVA-CB was capable of sensing dichloromethane, chloroform,etc.3D printing of a composite of polyamide-12 with CB was reported by Alejandroet al.and its electrical and thermal properties were studied[61].CB was loaded up to 10%, and printing was done by SLS.Beyond 1.5% CB loading, mechanical strength was reduced,and modulus was increased beyond 1.5% loadings.Leiet al.3D printed the composites of CB with polypropylene (CB/PP composites)[57].These composites had different loading of CB up to 10% and were utilized as microwave absorbers with a reflection loss of approx.−39 dB (maximum) at ~15 GHz (Fig.3eh).3D printed CB composites have also shown potential applications as joule heating devices and shape memory devices[56,62].All these studies have reflected the versatility of 3D printed CB structures and their potential uses.

Fig.3 Cyclic voltammetric (CV) of (a) TBHQ, (b) BHA, (c) differential pulse voltammetry responses of TBHQ and BHA, and (d) corresponding calibration curves.Reproduced from Ref.[59] with permission from Springer.(e) Calculated reflection loss curves, (g) corresponding 3D plot, (f) layer thickness matching ,and (h) effective absorption bandwidth.Reproduced from Ref.[57] with permission from the Elsevier

CB has various sp2content and can be used for various applications in composites with tuneable properties.3D printed CB/polymer composites have been used for multiple applications such as sensors.The properties of 3D printed CB can be modified by tuning the sp2content.

3.2 Carbon nanotubes

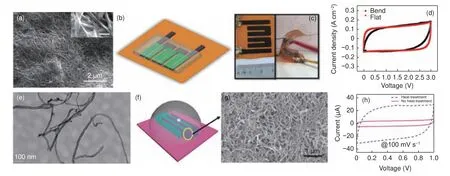

CNTs, one-dimensional sp2carbon nanomaterials with matchless mechanical (100 GPa), electrical(106S cm−1), optical, and thermal (3 000 W m−1K−1)properties can be used to fabricate a wide range of devices[63,64].Moreover, the biocompatibility of CNTs[65]makes them very appealing for implantable and wearable applications[66].3D printing has added new applications of CNTs such as electronics[67], robotics[68]and optoelectronics[69].Photoelectrochemical hydrogen generation using 3D printed vertical arrays of g-C3N4/CNT was up to ~4.4 cm−2h−1[70].3D printing of pure CNTs is well documented in the literature using techniques such as vat-polymerization, aerosol and inkjet printing[71].Chenet al.printed flexible supercapacitor electrodes with single-walled CNTs[72].The electrodes were printed with aqueous CNT ink under surfactant presence.Following that, on top of the electrodes, the PVA-based thin layer electrolyte was also printed.They demonstrated a wide range of electrode patterns with widths of 0.15-0.25 cm2, a length of 2 cm and gap of 1, 2 and 4 mm between electrodes, as shown in Fig.4a-d.The electrochemical test results demonstrated a high specific capacitance of ~16 F cm−3with an energy density of >1.0 mWh cm−3and a power density of ~12.0 W cm−3.Similar to this work, Yuet al.fabricated a CNT-based micro-supercapacitor[73], as shown in Fig.4e-h.They used CNT inks with 6%, 7% and 8% material loadings.The 3D printed multi-layered CNT structures as interdigitated microelectrodes using PVA-H3PO4gel as electrolytes were used to fabricate the micro-supercapacitor (~2.5 F cm−2@ 20 μA cm−2).

Fig.4 (a) SEM image of 3D printed CNTs.(b) Schematic of fabricated device.(c) Real-time digital image of the device.(d) CV profile of 3D printed CNT device.Reproduced from Ref.[72] with permission from the American Chemical Society.(e) TEM image of CNTs.(f) Schematic of the device in which polymer gel electrolyte is cast.(g) SEM image of the electrode material.(h) CV profile of packaged device.Reproduced from Ref.[73] with permission from the American Chemical Society

The electrical properties of CNTs are well known and highly dependent on their alignment.Gohet al.[74]used a high-precision aerosol-jet printing technique in combination with an evaporation-driven self-assembly method to get preferentially aligned CNT traces of widths of 30-80 μm on a flexible substrate.The resistance of printed CNT traces can easily be tuned by controlling the printing speed and number of printing passes.Luet al.fabricated CNT-based thinfilm transistors with the aerosol jet printing method by printing temperature control[75].They found that the printing temperature had significantly impacts on the CNT-TFT homogeneity and printing stability.A low bath temperature of 8 °C improved the device steadiness during short-term and long-term printing.A conductive channel of the PLA/CNT nanocomposite was 3D printed by a local enrichment strategy, and the results were verified by simulations by Shi and the team[76].The as-printed structure showed ~ 108times higher electrical conductivity.The conductivities of printed PLA/CNT and CNT/high-density polyethylene composites were studied experimentally and verified by simulations[77].Besides 3D printing CNT/polymer composites, rGO/CNT aerogel was also 3D printed for a dendrite-free sodium metal anode[78].The 3D printed anode from rGO/CNT aerogel presented a capacity of ~1.0 mAh cm−2under 2 mA cm−2.The results were also verified by simulations, and a full battery was also assembled, which showed a capacity of~68 mAh g−1at 0.10 A g−1after hundred cycles.

Little did she know that, over the years, the husband have been trying all ways to please her, little did she know that drumsticks was the husband s favorite.

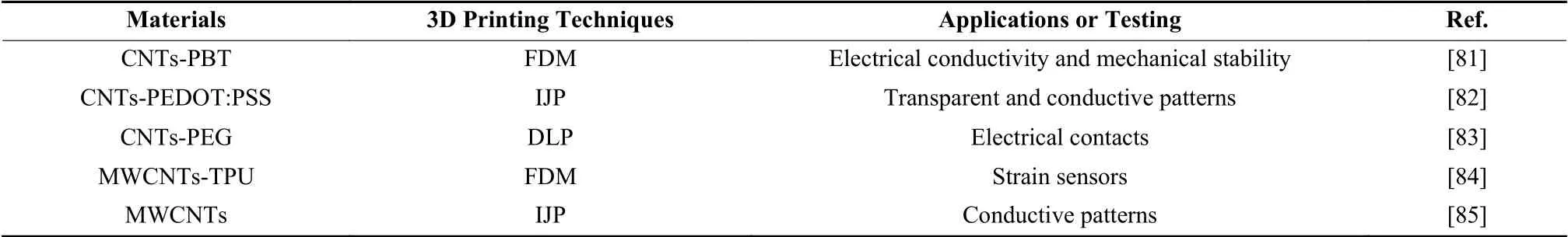

The 3D printed CNTs are also used in non-conventional applications such as the detection of pyocyanin[79]and fabrication of terahertz detectors[80], which show the versatility of 3D printed CNT structures and their potential applications.Other applications of 3D printed polymer-CNTs are tabulated in Table 1.Hence, sp2hybridized CNT/polymer composites can easily be 3D printed for various applications with improved electrical and mechanical properties.

Table 1 3D printed CNT-polymer structures

3.3 Carbon fibers

The carbon fiber reinforced polymer matrix composites are widely employed in the defence, automotive, aerospace, and sport-related sectors as structural elements[86–89].These materials are lightweight and stiff with high tensile strength (3.5 GPa).The fiber component provides the appropriate specific strength to the fabricated objects.The 3D printing machinery is used to make fiber-reinforced polymers in industry sectors[90].Huet al.investigated the printing procedure for continuous carbon fiber composites and the flexural characteristics[91].They achieved the flexural strength of printed items up to 610 MPa with flexural modulus up to 40 GPa by modulating the thickness of the layer, printing speed and printing temperature.A similar work was done by another group and achieves a tensile strength of 103 MPa[92].Carbon fibers were also used as reinforcement fillers in nylon and 3D printed by Calignano and the team[93].Compared to samples built in the XZ plane (49.7 N mm−2), those produced in the XY plane were harder (53.6 N mm−2).Similar hardness values were obtained for the samples constructed in the XZ plane with 80% and 100%fillings.The samples built in the XZ plane displayed a substantially lower hardness than those made in the XY plane at a filling percentage of 100.

3.4 Graphene oxide and reduced graphene oxide

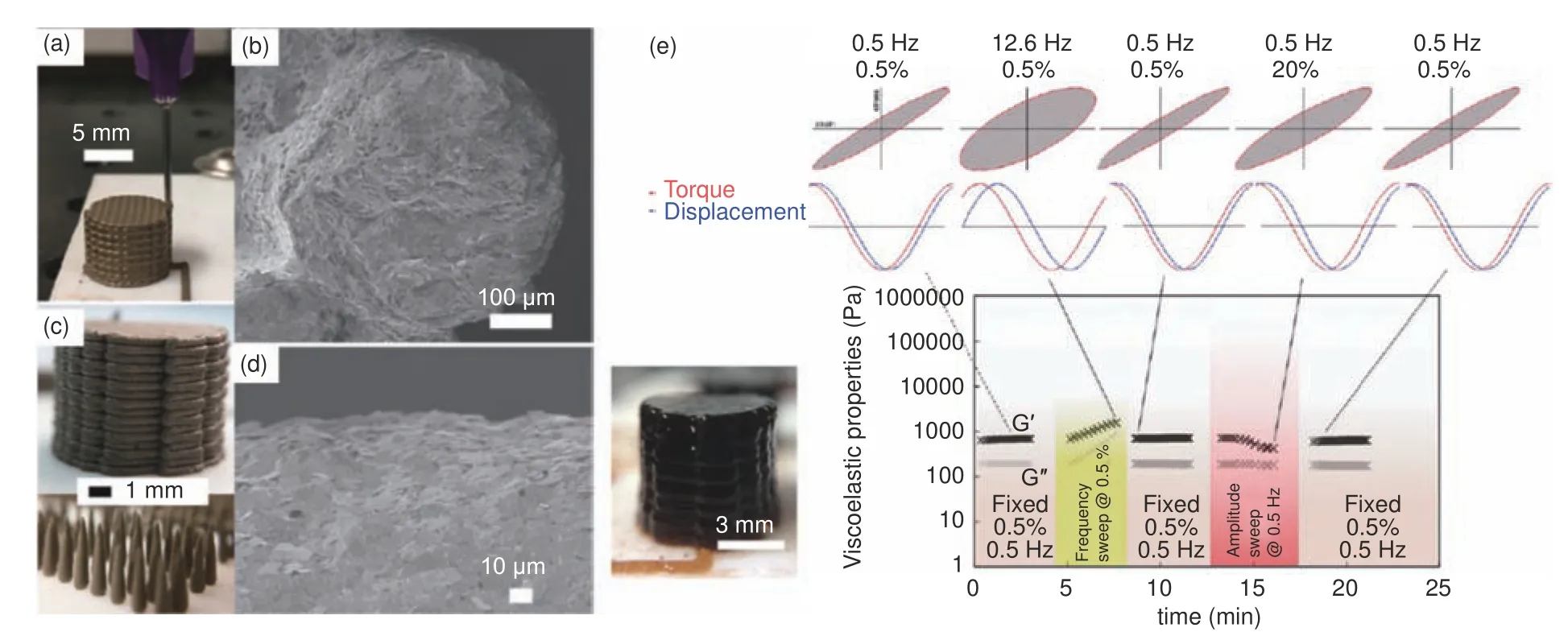

Due to its excellent ink-formation capabilities in aqueous media due to abundant functional groups[94,95],GO-based ink is frequently employed for 3D printing[96].Jianget al.presented the direct printing of GO aerogel micro-lattices (GOAMs) using GO ink through a simple ion-induced gelation process[97].The aqueous dispersion of GO transformed to printable gel ink with the addition of a trace amount of Ca2+.Selfsupportive 3D shapes with customizable micro-lattices were directly 3D printed in air.The 3D printed GOAMs were further utilized as supercapacitor electrodes and showed excellent capacitance and rate performance and better cycle performance for at least 50 000 cycles.A related study of aerogel printing was performed by Zhanget al.[98].They utilized a multinozzle-based drop-on-demand inkjet 3D printing to print aerogels using a suspension of GO ink.These printed aerogel structures showed ultralight densities(500 μg cm−3), high conductivity (~16 S m−1), and great squeezability and had potential applications in creating thermal insulating materials with anisotropy.A team showed the 3D printing of polymers, ceramics, steel, and additive-free GO structures based on the concept[99], as shown in Fig.5a-e.GO acted as a dispersion, viscosifier and adhesive due to its amphiphilic nature and 2D structure.

Fig.5 (a) and (c) Printed structures.(b) and (d) FESEM images.(e) Viscoelastic fingerprints of 3D printed PVA-GO ink with 0.3% GO loading.Reproduced from Ref.[99] with permission from the American Chemical Society

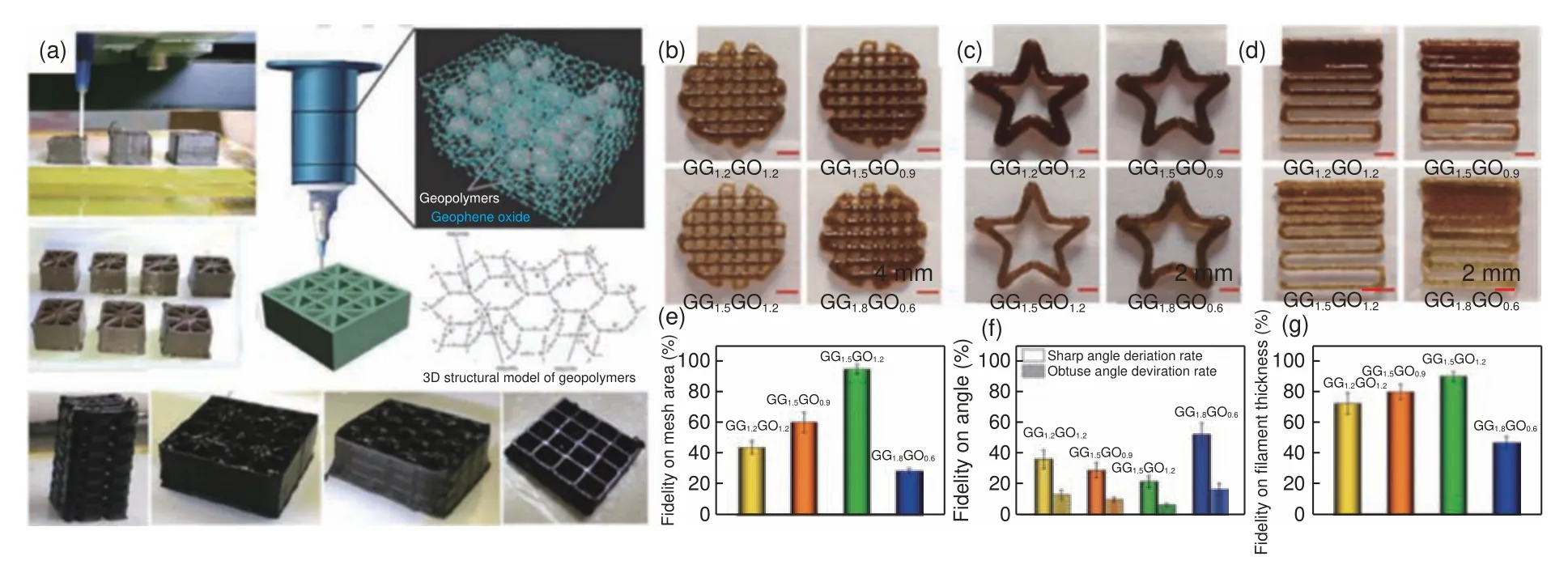

Qiaoet al.and Laceyet al.demonstrated highperformance Li-ion-based batteries using GO ink to 3D print the required electrode structures[33,100].Another group demonstrated that highly concentrated GO inks could provide suitable rheological properties for printing GO-based electrodes for charge storage applications[101].Their findings further illustrated that the scaling of linear capacitance was highly dependent onthe thickness in the z-direction and had a positive relationship with the increment in the thickness of the electrode.The study provided new and effective strategies for fabricating excellent 3D printed electrodes for supercapacitor devices that have potential significance for future energy demands.The un-printable geopolymer can be 3D printed with the incorporation of GO sheets.A high mechanical strength(Young's modulus: 700 MPa) and highly conductive(100 S m−1) GO/geopolymer nanocomposite were 3D printed[102](Fig.6a).The applications of printed GO devices are not limited to energy storage devices but have potential use in the area of bone repair, tumour therapy and printed electronics[103,104](Fig.6b-g).

Fig.6 (a) Graphical representation of printing process and different structures printed with GO/geopolymer nanocomposite.(b) Printability of GG/GO bioinks.Digital images of (c) the printed matrix pentagram, (d) gradient spacing grids and ( e, f, g) printing fidelity for GO bio-inks.Reproduced from Ref.[102] and [92] with permission from the Elsevier

rGO can be obtained by reducing GO by thermal or chemical means.Like other sp2carbon nanomaterials, rGO has also been extensively used in 3D printing for numerous applications.3D printing of rGO is by DIW in which the slurry of rGO is used to print the desired structures[105].Thunget al.3D printed rGO/CuCo2S4nanocomposites for supercapacitor devices[106].They used a simple one-step hydrothermal approach to prepare rGO/CuCo2S4nanocomposites.Electrochemical studies showed that 3D printed electrodes had a capacitance of 1 123 F g−1.Kimet al.[107]sed a novel meniscus-guided approach to 3D print the freestanding rGO nanowires.The desired 3D structures can be printed using a computer-controlled micropipette meniscus in this approach.They used these nanowires as stretchable interconnects and 3D transducers in CO2sensing as proof of concept.

Zhanget al.demonstrated a similar application of 3D printed rGO electrodes for flexible electronics[108].They used inkjet printing to construct desired silver/rGO composite 3D structures, which were further used to fabricate flexible electronic circuits.The electrical conductivity was increased 50-fold when printing cycles were increased from 1 to 10.The 3D printed rGO/PLA nanocomposite can be used for biosensing applications.As proofs-of-concept, the rGO/PLA electrodes were used to assess serotonin in artificial urine with a threshold limit of 0.032 mol L−1[109].A tyrosinase biosensor was developed with a threshold limit of 0.26 mol L−1for catechol in natural water.The poly (ε-caprolactone)-rGO conductive scaffolds were 3D printed to repair peripheral nerve injury[110].

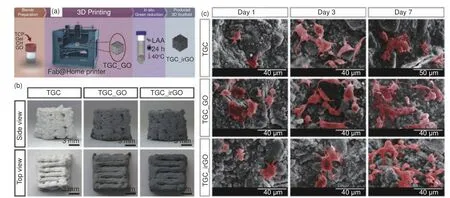

3D printed ultralight biomimetic hierarchical material and its applications for 3D printed rGO functionalized scaffolds for bone tissue regeneration were described in the literature[111,112], as shown in Figs.7 and 8.The flexibility of using 3D printing methods for rGO can be understood from the above discussion.Moreover, the advancement in 3D printing techniques will further promote the progress in rGO-based additive manufacturing with significant potential applications.

The sp2hybridized GO and rGO have been extensively 3D printed for various applications such as energy storage, sensing and bio scaffolds.The hydrophilic nature makes them bind with other materials to form composites.

3.5 Graphene

Fig.7 (a) Schematic of 3D rGO scaffold preparation.(b) Macroscopic images of prepared scaffolds (side and top views).(c) Biological properties.Reproduced from Ref.[100] with permission from the Elsevier

Fig.8 (a) Schematic of temperature treatment setup for rGO.(b) Digital image of Al-rGO thin film.I vs V profile of Al-rGO film (c) before and (d) after heat treatment.(e) Al-rGO thin film under Joule heating.(f) Emission spectra of thin-film.(g) Temperature monitored at different powers.(h) Raman spectra with and without heat treatment.Reproduced from Ref.[101] with permission from Nature

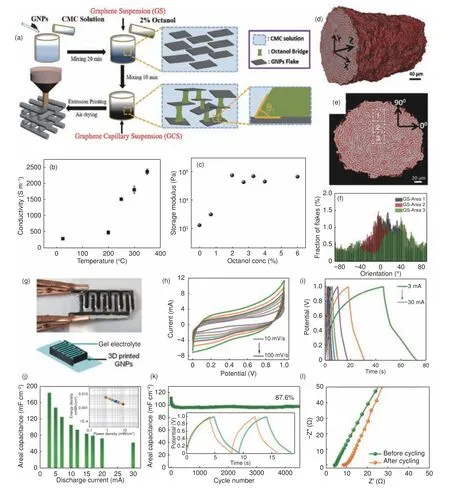

3D printing of graphene has mainly been reported using ink-based additive manufacturing processes.Creating printable inks with high graphene loading is typically challenging, especially in water-based systems[113].Processability is hampered by the hydrophobic nature of pristine graphene, resulting in its instability in aqueous dispersions[114].Therefore, the use of GO and rGO in place of pristine graphene has dominated the DIW of graphene electrodes.Due to its hydrophilic moiety, GO can be easily dispersed in aqueous media at high doses (up to 100 mg mL−1)[100].Capillary inks, a revolutionary class of inks for extrusion techniques, have recently come into existence and provide the benefit of eliminating or drastically decreasing the postprocessing of printed structures[115].They work by using a secondary liquid that is selected to construct a capillary bridge network between the material particles by matching the surface tension.The bridges serve as reversible linkages that can be bent and split during an AM process and subsequently reconstruct when the substance is at rest to offer a shear thinning behavior[116].Implementing this method to produce aqueous graphene inks has made it possible to create aqueous graphene inks from pure graphene with no use of GO.Dinget al.reported 3D printed aqueous graphene ink structures using capillary suspensions[117](Fig.9a-f).Graphene capillary suspension of 17% in aqueous media was prepared with~4% of carboxymethyl cellulose as a stabilizer and a minor amount of the immiscible liquid octanol.The printed structure, which was resistant in handling, had a porosity of 81%, a compressive strength of 1.3 MPa and an electrical conductivity 250 S m−1.Conductivity was increased to 2 370 S m−1after heat treatment at 350 °C, while strength was just 0.4 MPa.Inspired by the above work, Tagliaferri team prepared aqueous pristine graphene ink for 3D printing micro-supercapacitors[118]( Fig.9g-l).The micro-supercapacitors showed a capacitance of 1.50 F cm−2at 2.0 mA cm−2,which retained above 72.0% of the initial capacitance after holding tests at multiple voltages.They featured logically designed topologies and an innate conductivity of ~1 370.0 S m−1.Both the power density(~1 mW cm−2) and energy density (~51 Wh cm−2)beat that of previously published carbon supercapacitors that have either been inkjet or 3D manufactured.Satendraet al.also employed the graphene ink-based 3D printing technique to 3D print interdigitated electrodes (IDE) for a flexible supercapacitor.The fabricated device showed a good capacitance of ~138 F g−1at 0.50 A g−1with an energy density up to ~12.0 Wh kg−1[119].

Fig.9 (a) Graphical representation of ink formulation and printing.(b) Conductivity of 3D printed aqueous graphene ink.(c) Storage modulus vs octanol amount.X-ray tomography analysis: (d) 3D image, (e) cross-section view and (f) histogram of graphene flake orientation.Reproduced from Ref.[117] with permission from the Royal Society of Chemistry.(g) Digital image and schematic of 3D printed device.(h) CV profile, (i) GCD profile, (j) histogram of areal capacitance, (k) cycle test profile and (l) Nyquist plot ofthe 3D printed flexible supercapacitor.Reproduced from Ref.[118] with permission from the American Chemical Society

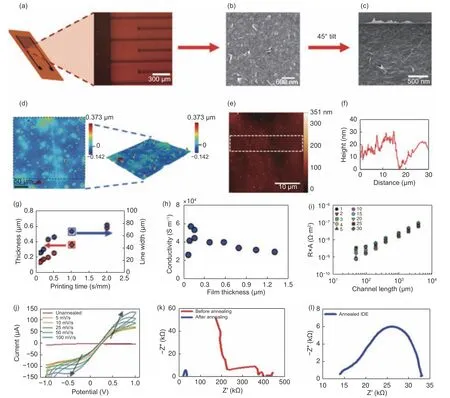

Parateet al.[120]stated that the use of a printed flexible graphene-based immunosensor can monitor two different cytokines: (1) interleukin 10 (IL-10) and(2) interferon-gamma (IFN-γ).IDEs with a finger widths of 40 μm were 3D printed through aerosol-jetprinting on a polyimide substrate using graphene-nitrocellulose ink, as shown in Fig.10.Thus, fabricated immunosensors had wide sensing ranges (0.15%ng mL−1for IFN-γ and 0.12% ng mL−1for IL-10) and low threshold limit (25.0 pg mL−1for IFN-γ and 46.0 pg mL−1for IL-10) with high selectivity.In a similar process, Shaet al.stated the use of a powerbed-based automated 3D printing technique to print graphene foams (GFs)[121].Sucrose served as a catalyst and the template for the GF was sintered Ni metal.The printed GF had a high porosity of 99%, a density of 15.0 mg cm−3, a conductivity of ~9 S cm−1, an impressive storage modulus (11 kPa), and an excellent damping ability (~ 0.06).

Fig.10 (a) Schematic and optical micrographs of the graphene electrode.(b) and (c) The morphology of printed graphene electrode.(d) 2D and 3D images for surface roughness study.(e) and (f) AFM image and height profile of the electrode.(g) The electrode thickness vs printing speed.(h) Conductivity vs electrode thickness.(i) Resistance vs electrode length.(j) CV profile, (k) Nyquist plot and (l) magnified Nyquist plot for the annealed electrode.Reproduced from Ref.[120] with permission from the American Chemical Society

3.6 Carbon dots

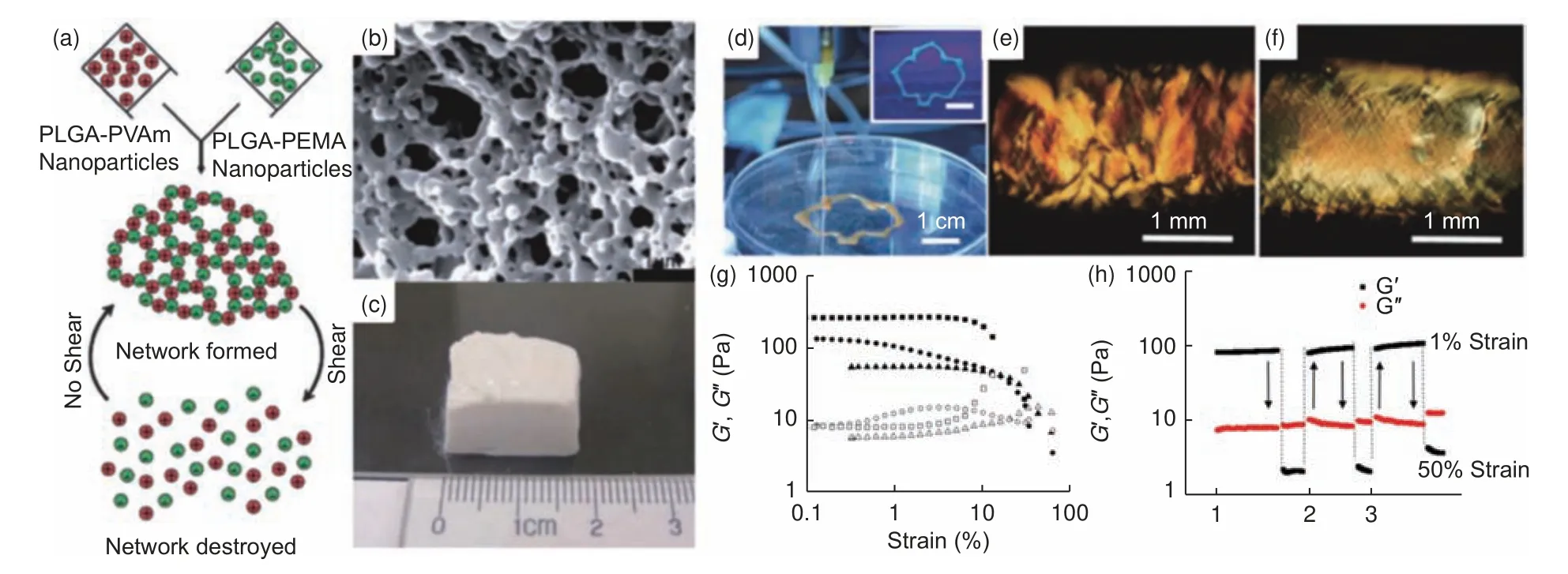

Recently, there has been a lot of debate about graphene quantum dots (GQDs) in materials research.Their uses in catalysis, theranostics, photovoltaics, energy storage, and organic LEDs have all been investigated[122–126].3D printed white LEDs with colour rendering index >90 were fabricated from CDs prepared from chitosan[124].Physically crosslinked hydrogels can be utilized as injectable materials for printing and tissue engineering thanks to their shear-thinning feature[125–131](Fig.11a-c).Khabibullinet al.prepared injectable shear-thinning GQDs and 3D printed fluorescent structures[127].Printable ink was prepared(Fig.11d-h) with carboxymethyl cellulose (modified with amino groups) of concentrations of 10-50 mg mL−1and GQDs concentrations from 1-10 mg mL−1.The prepared three recipes of printable GQDs hydrogels displayed a linear viscoelastic behavior at a strain of <10%.Bioactive scaffolds were 3D printed from CDs for bone regeneration bearing.The concentration of CDs varied from 0.5-2 g in 40 g of PLA[132].Zhou et al.embedded orange-CDs (~2 nm)in superabsorbent polymers and 3D printed them for additive manufacturing applications[133].

Fig.11 (a) Schematic mechanism of self-healing and shear-thinning behavior of colloidal gel.(b) SEM and (c) digital image of a colloidal gel.Reproduced from Ref.[122] with permission from the Royal Society of Chemistry.(d) 3D printed GQDs structure.(e) and (f) Fluorescence images at 365 nm excitation.(g) Storage (solid) and loss (empty) modulus curves of GQD-hydrogel.(h) Effect of cycling on storage and loss modulus.Reproduced from Ref.[127] with permission from the American Chemical Society

Apart from the above-discussed sp2carbons, 3D printing has been employed for other forms of carbon nanomaterials such as carbon aerogels, porous carbons, and monolithic carbons (Table 2).Geet al.3D printed the carbon aerogel micro-lattices using a solgel ink of resorcinol-formaldehyde (RF) by the direct ink writing method.These carbon aerogels are nontoxic and have potential applications for cell supports[134].Steldinger and co-workers showed a novel approach to prepare tuneable hierarchically structured porous carbon structures using SLA 3D printing[135].On the other hand, Yang and his team used the DLP technique with UV curable resin to 3D print the porous carbonaceous anodes for microbial fuel cells.After the 3D printing process, a controllable carbonization process, which led to excellent conductivity and good biocompatibility of the anode materials, was employed[136].Shaoet al.presented the practicability of 3D printing for constructing mechanically resistant and electrically conductive monolithic carbon structures.These monolithic 3D printed structures are potential electrode materials for charge storage[137].3D pyrolytic carbon electrodes, cellular carbon microstructures, carbon nanoelectrodes, etc., are other types of 3D printed carbon nanomaterials with excellent potential applications[138–140].

Table 2 3D printed sp2 carbons and their applications

4 Conclusions and outlook

The most significant recent advancements in sp2carbons for 3D printing are addressed in this review.Here, we detail the many kinds of materials, their manufacture, and how sp2carbons structures are printed.Printing of sp2carbons can be viewed as a method for improving the mechanical, electrical and optical properties.But there are still a lot of difficulties with this new technology.Except pristine graphene,sp2carbons are easily 3D printed due to their hydrophilic nature.Apart from printability, sp2carbons are prepared in several steps to 3D print.The hydrophobic nature of pristine graphene hinders the printability and processability in water media.The development of capillary inks has made pristine graphene 3D printing possible.Therefore, it appears that sp2carbons are better suited for little devices than large ones when printed in 3D, but as technology develops, perhaps printing the large ones turns out to be true.3D printing needs to be optimized based on the knowledge of the material and process characteristics because as it is a relatively new technique when sp2carbons are used.Therefore, it is safe to state that 3D printing methods used with sp2carbons are very encouraging and will continue to be a popular option.

Because of the structural manipulation and quick prototype capabilities of 3D printing, it, as an emerging technology, has been proven essential in the design of micro- and macrostructures.The technique of 3D printing is not without its difficulties.First, only a few materials can be used directly for 3D printing,necessitating the need for rheological properties with high viscosity and sheer thinning tendency.Second,after the solvent is removed, 3D printed structures are porous, resulting in poor mechanical properties and less active material loading level.Because of their poor mechanical properties, 3D printed structures are frequently unstable and challenging to handle.There is still a need to pay attention to the design of raw materials and structural finish for 3D printing technology.

Declaration of interest

There are no conflicts to declare.

Acknowledgements

Dr.Surender Kumar thanks the DST's SYST scheme (SP/YO/2019/1554) for financial assistance.Dr.N.Sathish thanks CSIR (NMILTI scheme, TLP-001) for the support, and Mr.Satendra Kumar thanks the CSIR-JRF/SRF: File No.31/041(0078)/2019-EMR-I for the fellowship.Additionally, we are grateful for the facilities provided by the director of CSIRAMPRI, Bhopal.

杂志排行

新型炭材料的其它文章

- Coal-based graphene as a promoter of TiO2 catalytic activity for the photocatalytic degradation of organic dyes

- 咖啡渣成型制备生物质炭及其CH4/N2分离性能

- A flexible hard carbon microsphere/MXene film as a high-performance anode for sodium-ion storage

- Preparation and lithium storage of anthracite-based graphite anode materials

- Oxygen-incorporated carbon nitride porous nanosheets for highly efficient photoelectrocatalytic CO2 reduction to formate

- 炭纸衬底上化学气相沉积直立型二维过渡金属硫化物及其电催化产氢性能