Study on the Effect of Solid Particles on Jet Flow and Base Thermal Environment for Solid-Liquid Bundled Rocket

2022-10-29ZHANGLiangYANLiSUNPeijieYANGFanWANGHepingRENJie

ZHANG Liang ,YAN Li ,SUN Peijie ,YANG Fan ,WANG Heping ,REN Jie

1 Aerospace System Engineering Shanghai,Shanghai 201108

2 Shanghai Academy of Spaceflight Technology,Shanghai 201108

3 Nanjing University of Science and Technology,Nanjing 210094

Abstract: Compared with using liquid rocket engines,there are a lot of high-temperature solid particles in the solid-liquid bundled rocket,which make the rocket base thermal environment worse.In order to study the influence of high-temperature solid particles on the base thermal environment,firstly,the effect of particle diameter on the jet distribution and the thermal environment in a single solid motor jet was analyzed using a numerical simulation method,and the results were compared with those of a ground test.Further,the effects of high-temperature solid particles on the jet and the thermal environment of the solid-liquid bundled rocket were analyzed and compared with flight data.The results show that high-temperature solid particles can increase the jet temperature and reduce the jet velocity.The larger the particle diameter,the greater the impact on the jet core temperature.The role of high-temperature solid particles cannot be ignored in the study of the base thermal environment.

Key words: solid rocket motor,thermal environment,two-phase flow,solid-liquid bundled rocket

1 INTRODUCTION

With the development of solid rocket technology,the solid rocket reliability is improved and cost is reduced,with the advantages such as easy ground handling,simple maintenance,and good performance compared with the liquid rocket,which already has the basic conditions as a launch vehicle.However,the hot high-speed gas flow discharged by the solid rocket motor contains a large number of AlOsolid particles.This not only greatly increases the thermal radiation at the bottom of the rocket,but also affects the flow field distribution of the gas flow at the bottom of the rocket.The motor jet interaction makes the high-temperature gas with high-temperature solid particles backflow which impact the bottom or nozzle structure of the rocket in the cluster rocket or bundled rocket,resulting in serious additional heat transfer.Therefore,it is necessary to study the effects of particles on the jet and the thermal environment at the bottom of the jet in the solid-liquid bundled rocket.

The development of the solid propellant rocket,as used for the power source of launch vehicles,is now mature overseas.Examples include the Delta series rocket,Titan rocket and Space Shuttles in the United States,Ariane 3 and 5 series rockets in Europe,and M series,N series and H series rockets in Japan.The law and mechanism of the jet and base thermal environment have been studied considerably through a large number of engineering calculations,numerical analysis,ground testsand flight measurement.Federico et al.calculated the two-phase jet with Euler-Euler method and Euler-Lagrange method respectively,the results show that the particles increase the momentum of the jet by about 19-22% and the thrust by about 7.5%.Hideyo et al.used Euler-Lagrange method and discrete coordinate method to calculate the rocket two-phase jet and heat radiation during the complete flight.It has been proved that jet radiation is the main factor in the bottom thermal environment compared with flight measurement data.Burt et al.studied the effect of particle’s size in a jet on space radiation intensity by computational fluid dynamics/direct simulation of Monte Carlo (CFD/DSMC) method,the results indicated that soot particles have less effect on radiation and AlOparticles have greater effect.

The jet flow field and base thermal environment distribution of a solid rocket motor and a solid-liquid bundled rocket were calculated,where the continuous phase model was used to simulate the gas phase,the discrete phase model (DPM) was used to simulate the solid particle phase,and the discrete ordinates model (DOM) was used to simulate the medium radiation containing solid particles.The influence of solid particles on the flow field of the motor was analyzed,and comparing with the measured results of the ground test and flight test,the accuracy of the simulation model of the jet and bottom thermal environment of a solid-liquid bundled rocket was verified,thus laying a foundation for the systematic study of the base thermal environment of the solid-liquid bundled rocket.

2 NUMERICAL METHOD

The simulation process can be divided into three steps.First,the gas-phase jet field is calculated,then the solid-phase particle phase is added to calculate the gas-solid two-phase jet,and finally,the thermal radiation model is added to calculate the heat flux distribution at the bottom of the rocket.The calculation methods used in each step are as follows.

2.1 Continuous Phase Model

Continuity equation:

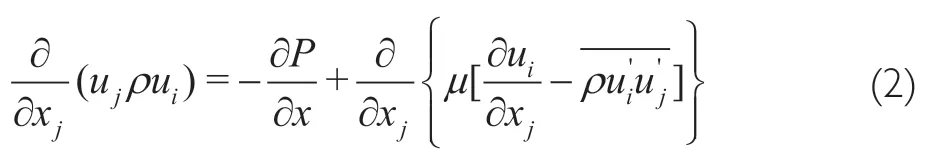

Momentum equation:

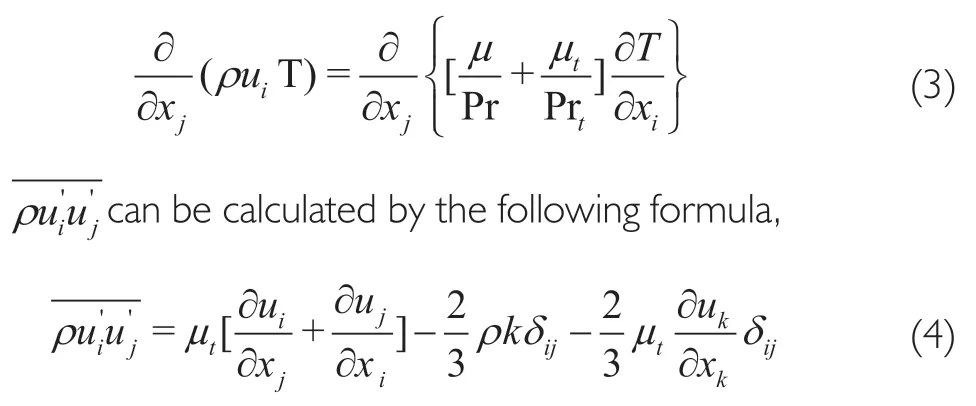

Energy equation:

Turbulence model use standardtwo equation models.The governing equation is as follows:

where constant coefficientσ=0.09;=1.44,=1.92.

2.2 Discrete Phase Model

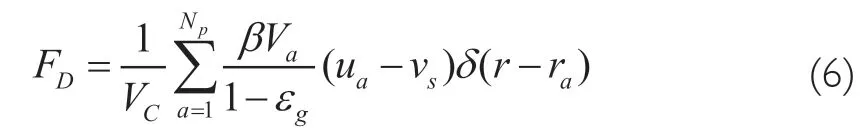

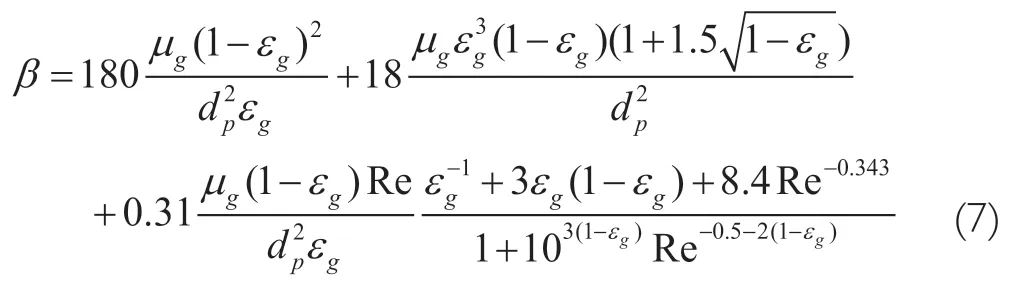

According to the jet characteristics of the solid motor,the mass fraction of AlOparticles is about 32%,but the volume fraction is less than 10%.Therefore,the Lagrange discrete phase model was used to consider the interaction between the particle phase and the continuous phase.The first is the drag force between two phases acting on the particles,as shown in the following formula:

whereVis the calculated mesh volume andis the drag force coefficient,which is determined by the following formulas:

The collision force between particles is obtained by the following formulas:

Gas phase stress is obtained by the following formula:

2.3 Thermal Radiation Model

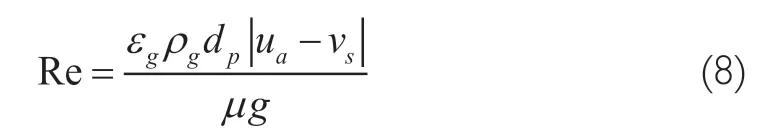

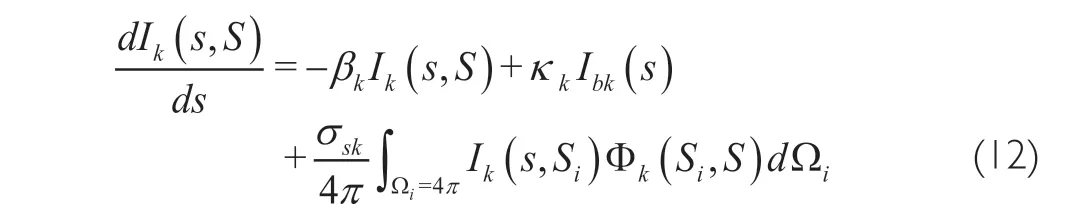

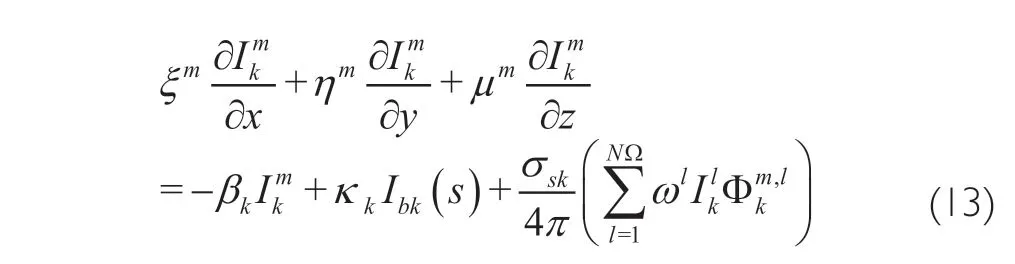

The discrete coordinate method was used to calculate the radiation effect of the jet.DOM is based on discretizing the direction change of radiation intensity.The solution of the problem was obtained by solving a series of radiative transfer equations in discrete directions covering the whole solid angle of 4 π space.It can calculate the radiation problems of all optical thicknesses,and the calculation range covers various radiation problems,including surface radiation,translucent medium radiation and interpenetrating radiation in combustion problems.The expression of radiative transfer equation in absorption,emission and scattering media based on spectral band model is:

whererepresents the spectral band modelarea;I(,)represents the radiation intensity of spatial position,transmission directioninspectral band.κ,σ,βare the spectral band absorption,spectral band scattering and spectral band attenuation coefficients of the medium.Φ(S,) is the radiation phase function.In the three-dimensional rectangular coordinate system (,,),the discrete coordinate method was adopted.The integral term at the right end of the above formula is approximately replaced by a numerical integral,and the radiative transfer equation was solved in the discrete direction.

The absorption coefficient used the grid based weighted summation model,the scattering phase function selects isotropy,and the scattering absorption assumes a constant.

3 RESULTS

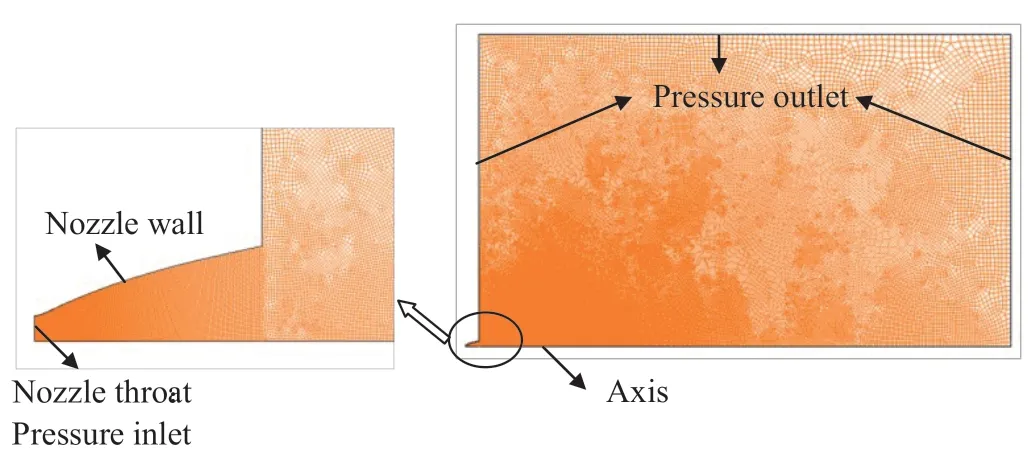

3.1 Flow Simulation of Single Solid Rocket

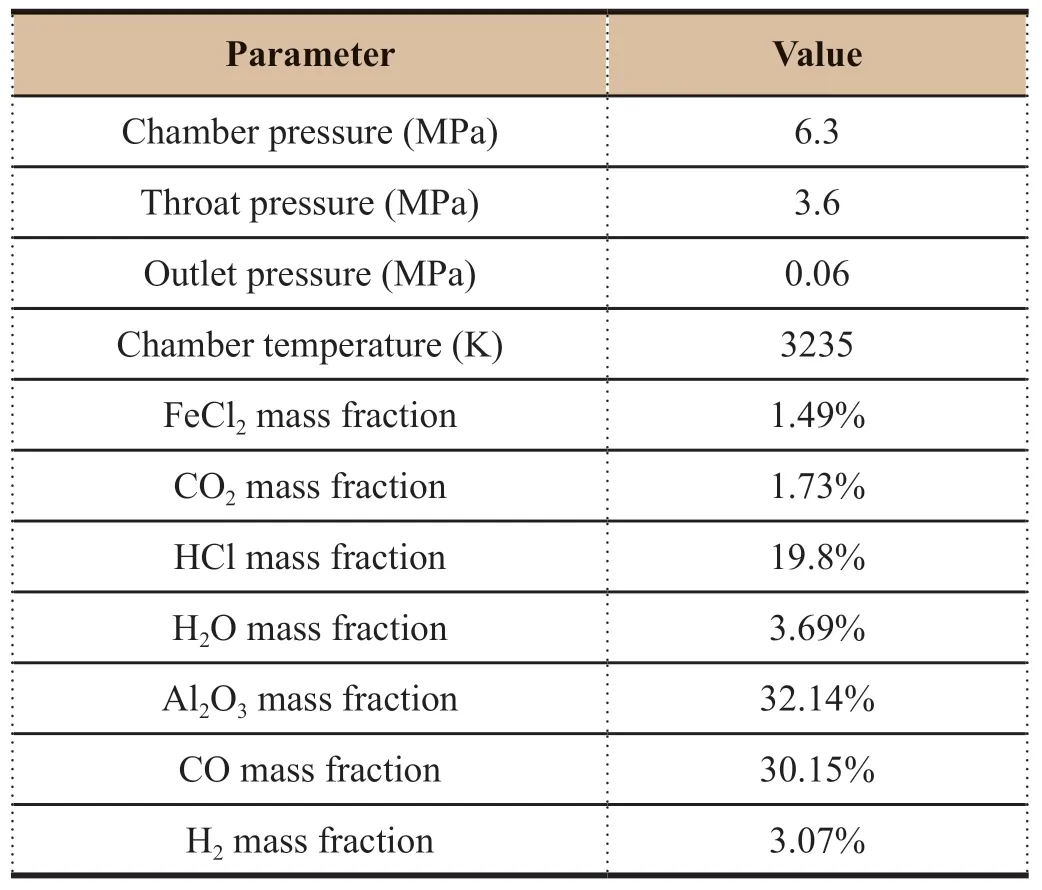

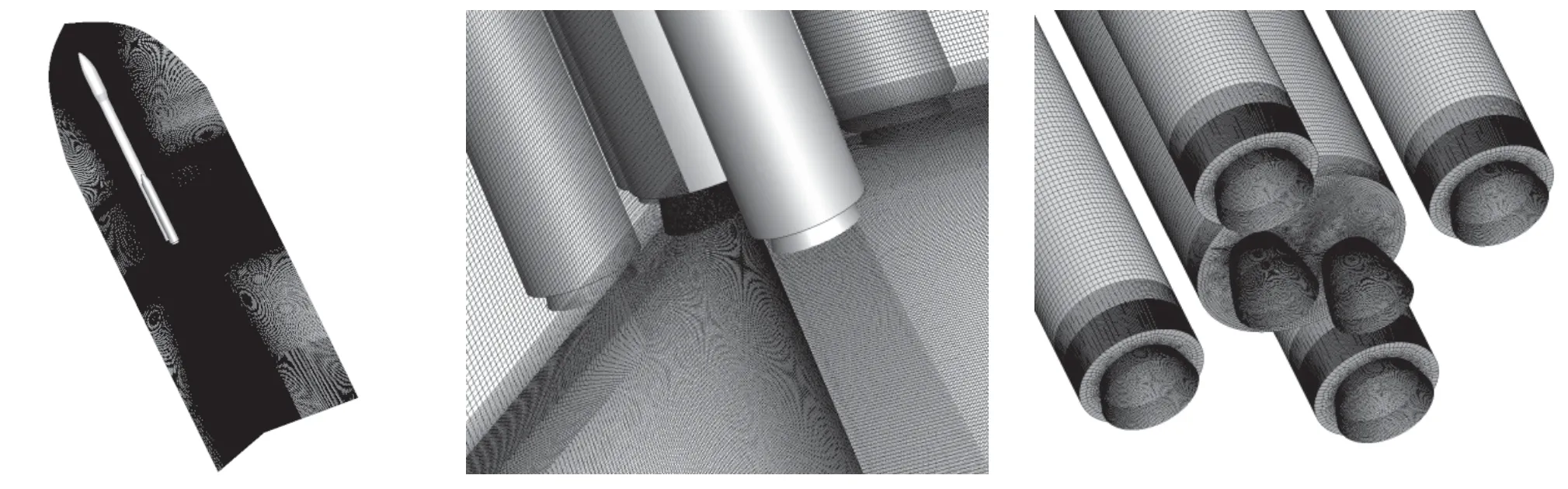

Firstly,the effect of high-temperature particles with different diameters on the jet flow in a single solid rocket motor was simulated.The calculation area and grid are shown in Figure 1.The nozzle throat was the flow inlet with total pressure of 6.3 MPa,static pressure of 3.6 Mpa,and total temperature of 3236 K.It was set as a pressure outlet at the far field of the nozzle.The ground atmospheric environment was set as 1atm,the temperature is 300 K,and the nozzle wall was set as a 300 K constant temperature boundary.The incident temperature and velocity of solid particles are 2300 K and 1243 m/s respectively.Thermodynamic parameter of solid rocket is shown in Table 1.

Table 1 Thermodynamic parameter of solid rocket

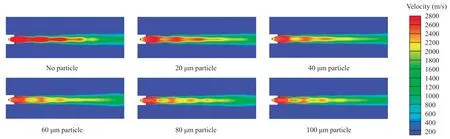

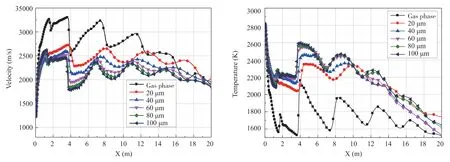

Numerical simulation of the effect of particles with diameter of 20 μm,40 μm,60 μm,80 μm,100 μm in the temperature field and velocity field in the two-phase flow field are shown in Figure 2 and Figure 3.It can be seen that there are four obvious barrel shaped mach disks in the pure gas phase flow field.With the increase of the particle diameter in the jet,the boundary of the barrel shaped mach disk and the shock reflection point in the core area of the nozzle outlet become blurred.In addition,with the increase of the particle diameter,the jet velocity decreases and the temperature increases.This is because the gas in the supersonic flow has strong expansibility,when the gas ejected from the high-pressure combustion chamber,the internal energy of the gas can be quickly converted into kinetic energy,and the speed is increased and the temperature is decreased.However,the high-speed solid particles do not have expansibility,and can only be accelerated through the gas viscosity force.The solid particle has obvious hysteresis effect to jet flow.Compared with the particles with different diameters,the small diameter particles are more affected in the gas-phase viscous force and have better fluidity,while the large diameter particles are less affected by the gas-phase force and flow freely through the core area,which has a greater impact on the flow field in the core area of the jet.

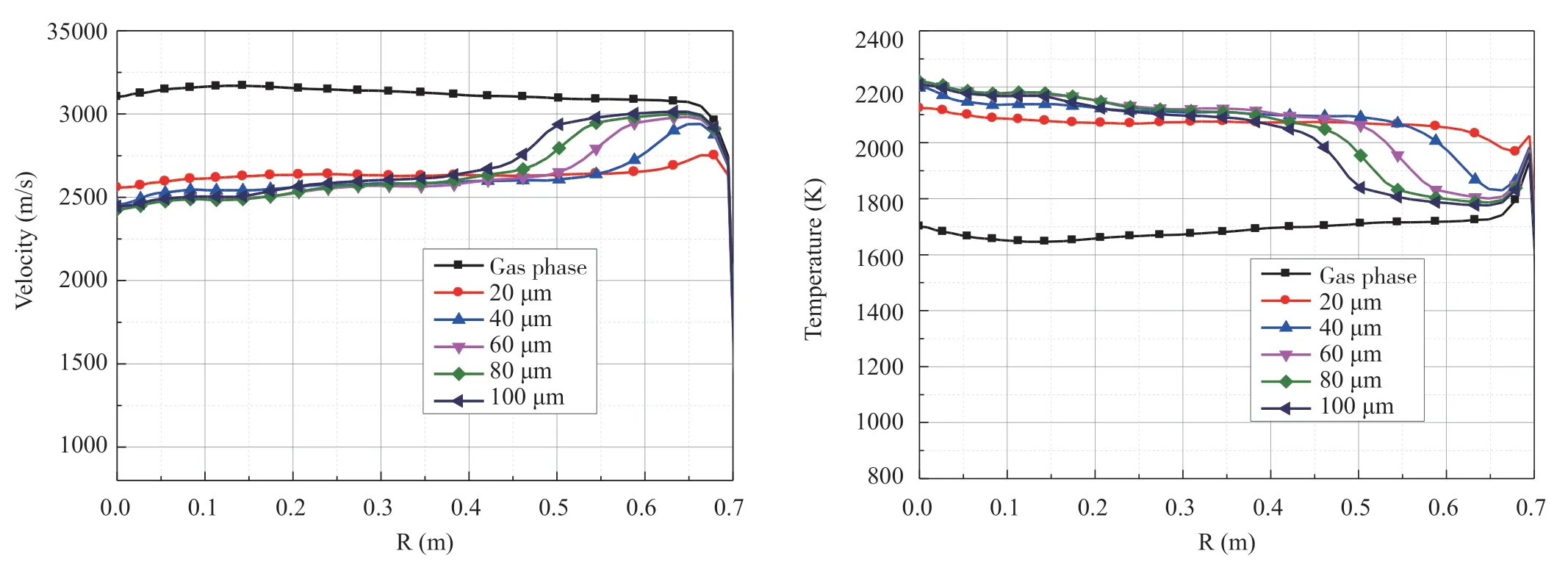

Figure 1 Calculation zone and mesh of solid rocket

Figure 4 shows the radial variation curve of the temperature and velocity at the nozzle outlet of the engine in the jet flow field.It can be seen that the nozzle outlet velocity decreases and the temperature rises in gas-solid two-phase flow.In two phase flow field with small diameter particle,the radial distribution of the flow field is uniform,and the variation trend is close to the gas phase distribution.With the increase of particle diameter,the radial variation gradient of the flow field parameters becomes larger,and the radial distance where the parameter changes is smaller.This is consistent with the particle characteristics where the smaller the particle diameter has better fluidity,the solid particles are distributed more evenly in the radial direction of the nozzle outlet.With the increase of the particle diameter,the particles tend to distribute in the core area of the nozzle,which affects the flow field parameters of the core area.However,the flow field parameters are close to the gas phase in the radial direction,close to the nozzle wall,which results in obvious parameter changes in the radial direction.

Figure 2 Particle effect on velocity distribution

Figure 3 Particle effect on temperature distribution

Figure 4 Velocity and temperature curves along the nozzle outlet radiation direction

Figure 5 shows the temperature and velocity curves in the axial direction of the motor outlet in the jet flow field.In the solid-gas two-phase flow,the speed decreases and the temperature increases in the nozzle axis direction,which is consistent with the previous flow field analysis.In the gas phase flow field,it can be seen temperature and velocity fluctuations with four barrel shaped shock waves.There are also temperature and velocity fluctuations in the gas-solid two-phase flow,but the amplitude of the fluctuations decreases.Additionally,with the increase of solid particle diameter,the fluctuation distance gradually decreases.This is because the increase of particle diameter increases the impact on the Mach disk parameters in the core region,which suppresses the expansion and compression shock waves in the gas phase flow field.

Figure 5 Velocity and temperature curves along the nozzle axis direction

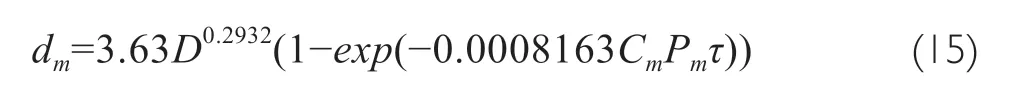

The effect of particles with different diameters on the flow field has been analyzed above.In fact,the propellant combustion process in the solid rocket is complex,and there are many influencing factors.The particle diameter is distributed between several microns and hundreds of microns.In order to comprehensively consider the influence of particles with different diameters on the jet,the Rosin-Rammler (R-R) distribution was used to describe the distribution of high-temperature particles.The R-R distribution refers to the functional relationship:

whereYis the mass fraction of the particles which diameter is greater than,dis the mean particle diameter,is the propagation coefficient.The mean particle diameter uses mass mean diameter,which is shown as follows:

whereis the diameter of nozzle outlet,Cis the particle mass fraction,Pis the chamber pressure,is the dwell time of particle in chamber.

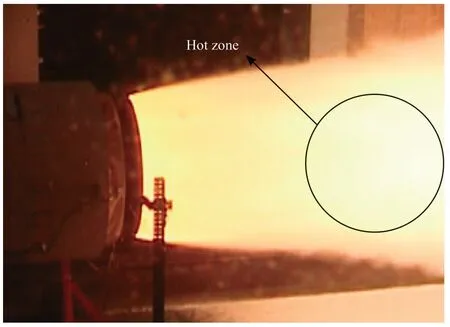

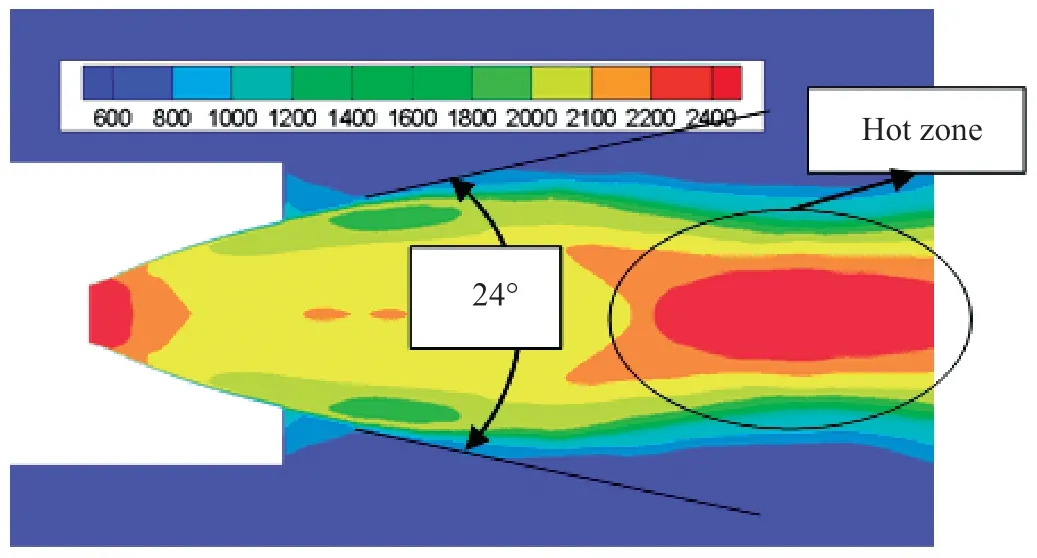

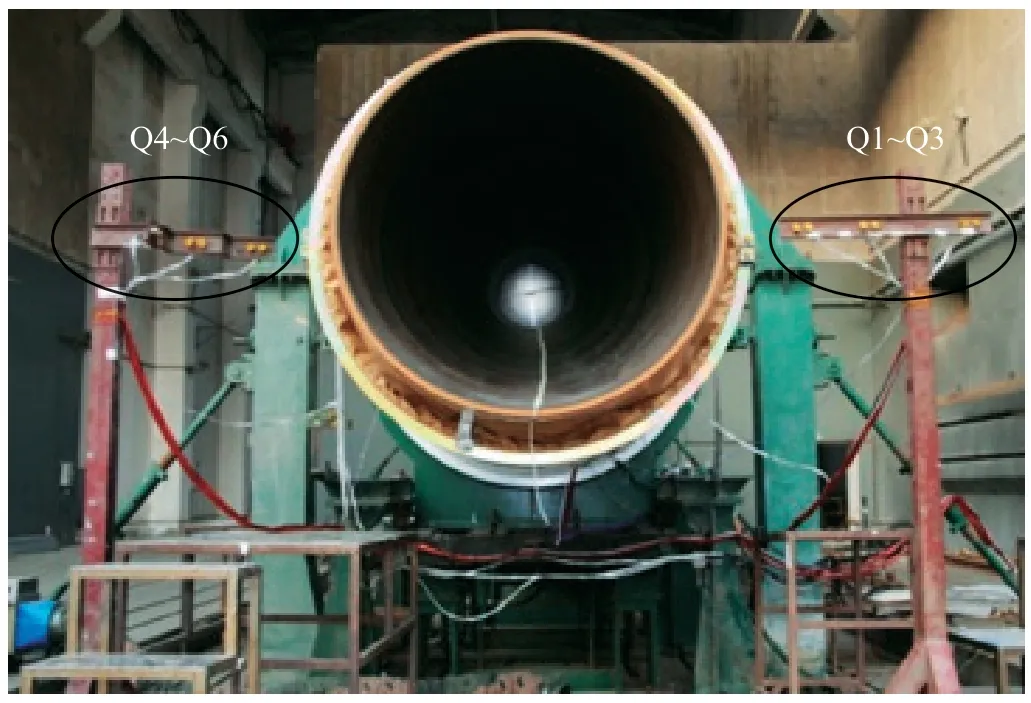

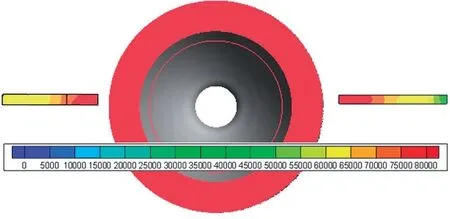

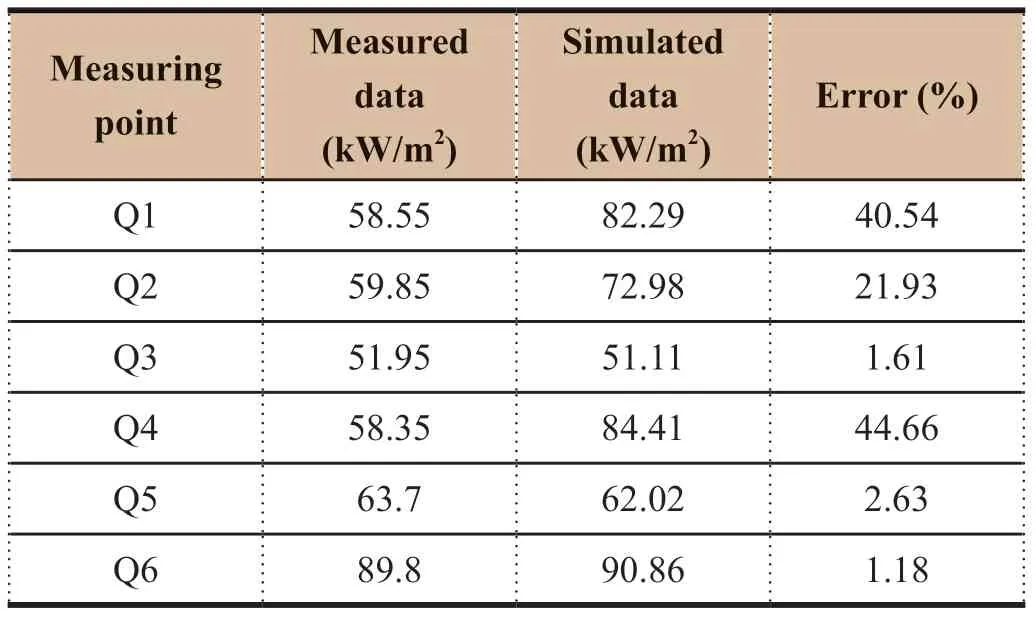

Figure 7 shows the distribution of temperature field under the test condition with R-R distribution particles.It can be seen that the high temperature zone is formed after the compression wave near the nozzle meets.The jet expansion angle is 24°,which is consistent with the ground test measurement results.The heat flux at the measuring point was extracted and compared with the test results,as shown in Table 2.The calculated heat flux of measuring points Q1-Q6 are in good agreement with the test results,and the variation trend was consistent.The numerical mean error is 17%,which verified the accuracy of the simulation model.

Figure 6 Picture of rocket engine test

Figure 7 Temperature of simulated flow

Figure 8 Position of measuring point

Figure 9 Calculated heat flux

Table 2 Comparison of heat flux for measured and simulated data

3.2 Jet Flow and Thermal Environment of Solid-liquid Bundled Rocket

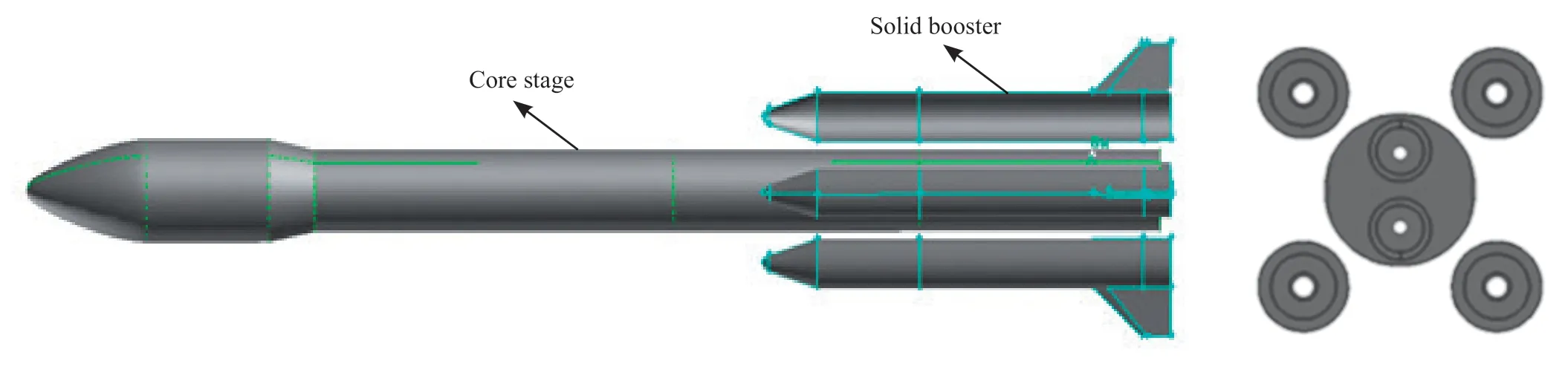

The solid-liquid bundled rocket has two LOX/Kerosene engines in core stage and four solid boosters,as shown in Figure 10.Calculation zone contains a quarter core stage and one solid booster,because of the symmetry of rocket.The calculation model use 12 million hexahedral meshes.To reduce the calculated resource and improve accuracy,different size grids are used for different area.The meshes in nozzle and near nozzle areas are refined.

Figure 10 Geometric model for solid bundled rocket

Figure 11 Calculated meshes for solid bundled rocket

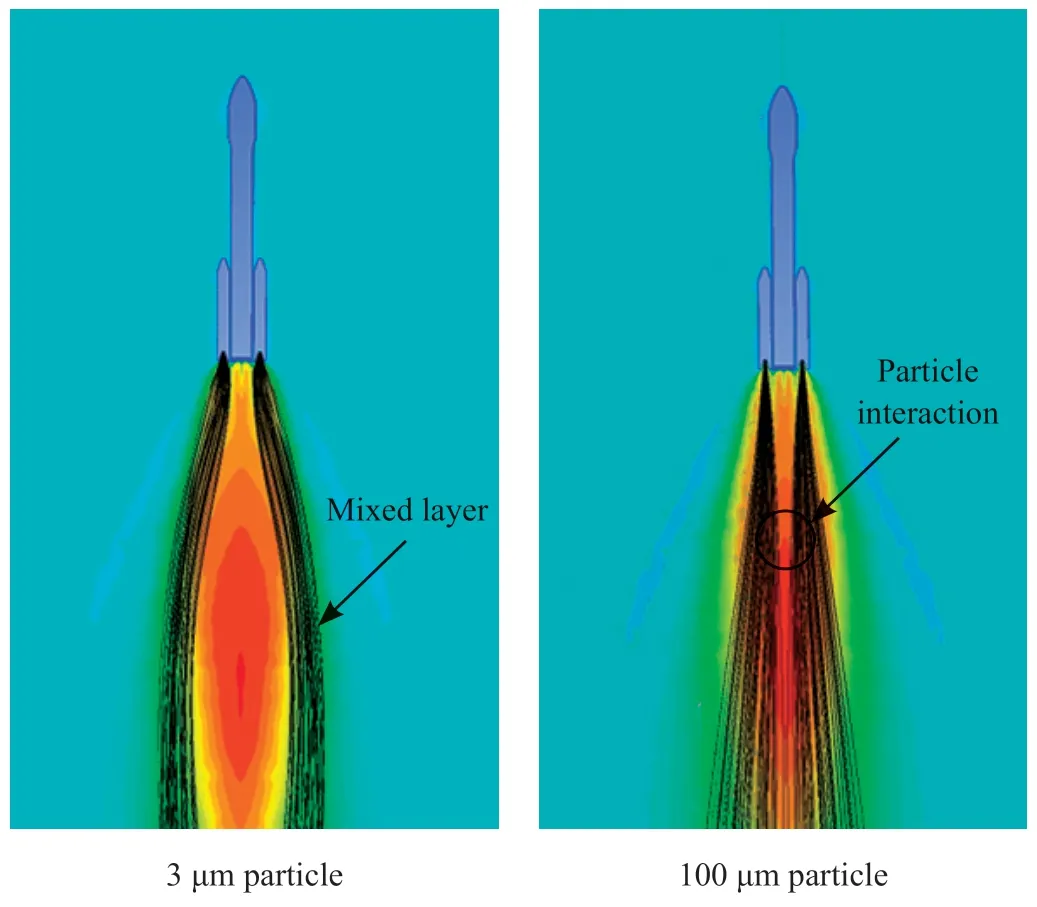

The effect of particles of small diameter (3 μm) and large diameter (100 μm) on the gas-solid two-phase flow field of solid bundled rocket was numerically simulated and analyzed.The numerical simulation results are shown in Figure 12.It can be seen from the figure that the 3 μm particles are distributed in the boundary mixed layer of the jet due to small particles’ good fluidity,which are distributed in the expansion area.The large particle in contrast has poor fluidity and is less affected by the gas expansion wave.After being ejected from the nozzle,it flows in a free expansion state,thus has a large impact on the core area of the interactive flow field and directly affects the distribution of the bottom thermal environment.However,there is no solid particle backflow in the interactive two-phase flow field,which is essentially different from the gas backflow in the interactive flow field.

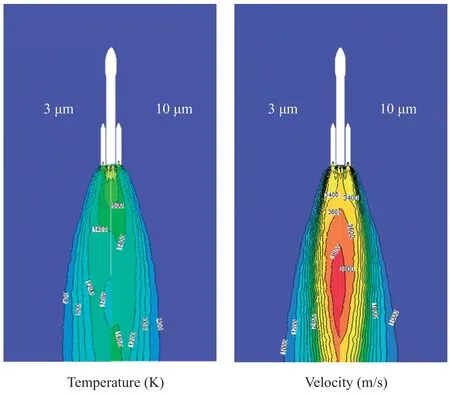

Figure 13 shows the comparison results of the temperature field and velocity field of the particles with two diameters.As shown in the figure,the expansion wave dimensions of the two jet flow fields with different diameters are similar,and the solid particle size has little effect on the expansion degree of the jet flow field.However,the temperature and velocity parameter distribution in the core area are different.The temperature in the core region with 100 μm particles decay behind the 3 μm particles,and the velocity is less than the flow with 3 μm particles,which is due to the large solid particles being ejected by the four solid boosters interacting in the middle zone of the jet flow field,hence has a great impact on the flow field in the core area.

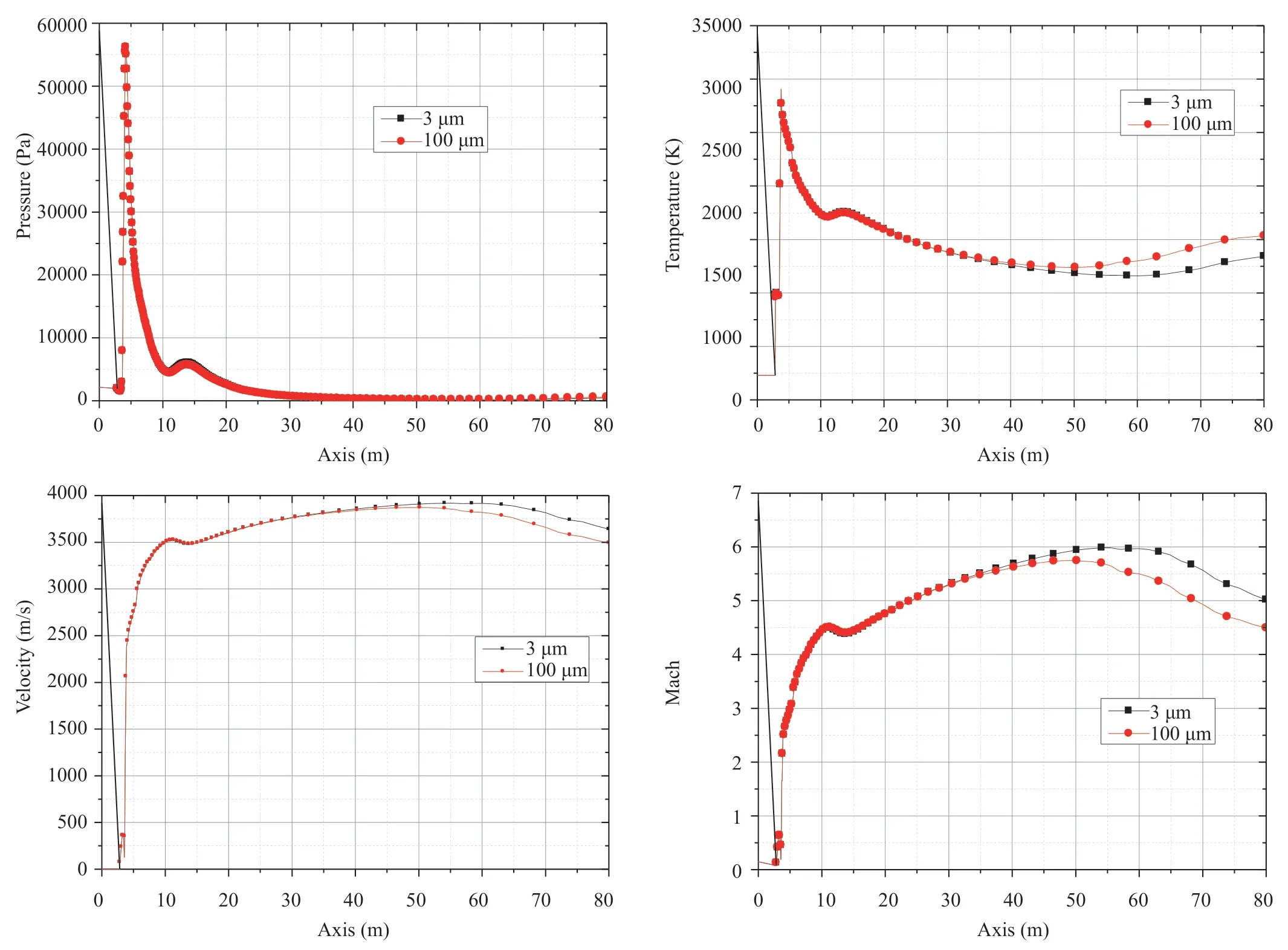

Figure 14 shows the parameter distribution on the axis of the flow field.According to the pressure change curve,flow field parameters with 3 μm particle and 100 μm are in good agreement,which is consistent with the results obtained from the previous two-dimensional flow field analysis.The effect of the solid particles on the pressure of the flow field can be ignored.According to the temperature curve,the temperature of flow field with 100 μm particles is higher than that with 3 μm particle,which is mainly due to the interaction between the solid particles of the four solid boosters.According to the axial curve of velocity and Mach number,when the axial distance exceeds 40 m,the velocity of flow field with 3 μm is less than that with 100 μm,which is consistent with the change law of temperature field.

Figure 12 Particle distribution in two-phase flow

Figure 13 Temperature and velocity distributions in twophase flow

Figure 14 Parameter curves along the axis of nozzle

4 CONCLUSIONS

The influence of solid particles in the jet of a solid-liquid bundled rocket was analyzed by numerical simulation and compared with the ground test and flight results,the following conclusions are obtained:

1) The high-temperature particles in solid rocket motor increase the jet temperature and decrease the jet velocity.The larger the particle diameter,the greater the impact on the core area.The smaller the particle diameter,the greater impact on the jet edge area.

2) The simulation results were compared with the heat flux measurement results of the solid motor hot test,and the mean error was 17%.The accuracy of numerical calculation of thermal environment was verified,which provides guidance for rocket thermal protection design.

3) Small particles are distributed in the boundary mixed layer and the large particles have a great impact on the core area for solid-liquid bundled rocket.

4) In the analysis of the jet and thermal environment of a solid bundled rocket,the influence of solid particles cannot be ignored,and the bottom heat flux is increased.

杂志排行

Aerospace China的其它文章

- Research on Unattended Loading Technologies of the New Generation Launch Vehicles

- Adaptive Reconfiguration for Launch Vehicle Under Servo Mechanism Fault

- Application and Research of High-Power Electric Servo System on Launch Vehicle

- Research and Application of High-Voltage Power Supply and Distribution on Launch Vehicle

- Research on Key Technologies of Segmented Solid Rocket Booster

- Research on Modal Test Technology of LM-6A Solid-Liquid Strap-On Launch Vehicle