Differences of Physicochemical Properties Between Chalky and Translucent Parts of Rice Grains

2022-10-25WangCuiliGuoWenHuPeisongWeiXiangjinTangShaoqingJiaoGuiai

Wang Cuili, Guo Wen, Hu Peisong, Wei Xiangjin, Tang Shaoqing, Jiao Guiai

Research Paper

Differences of Physicochemical Properties Between Chalky and Translucent Parts of Rice Grains

Wang Cuili#, Guo Wen#, Hu Peisong, Wei Xiangjin, Tang Shaoqing, Jiao Guiai

()

Ricegrain chalkiness is an important characteristic, but the difference between chalky and translucent parts in grains is still unclear. Here, we investigated the differences of flour made from the chalky or translucent part of rice grains in threeand threerice varieties. The chalky flour had significantly lower amylose and protein contents and looser starch granule morphology, and starches in the chalky flour had higher relative crystallinity, higher short chain content but lower long chain content than those in the translucent flour. The water states, determined with nuclear magnetic resonance, differed between the chalky and translucent flour after soaking, cooking and retrograding, and the chalky flour had more bound and free water but less constructural water than the translucent flour. Mostly, the chalky flour had lower viscosity and shorter gel consistency, but higher onset temperature and gelatinization enthalpy than the translucent flour. The results indicated that starch granule morphology would be more indicative than other attributions on pasting and gelatinization properties of chalky and translucent parts of rice grains.

chalkiness; starch structure; water state; pasting property; gelatinization characteristic

Chalkiness is an important factor for rice quality. It not only affects appearance, but also leads to a higher rate of grain breakage due to weaker bonds among the starch granules (Lisle et al, 2000). Chalkiness is especially common in southern China. A study of 5 879 rice samples from 17 major rice-producing provinces in China from 2016 to 2020 found the lowest head rice rates and the highest chalkiness percentages in rice from the Yangtze River Basin and southeast coastal areas, respectively (Zhang et al, 2021). Therefore, chalkiness is deemed to the main factor limiting rice quality improvement in southern China.

A few studies have investigated the effect of chalkiness on physicochemical properties, however, most of these studies focused on the correlation analysis between chalkiness and cooking quality by using several rice varieties with different chalkiness degrees, and their conclusions are inconsistent. For example, several studies found that chalkiness reduces cooking and eating quality (Shi et al, 2016; Tu et al, 2017), whereas others found that chalkiness has no significant effect on rice taste (Tang et al, 2003; Zhang et al, 2006), or even that rice varieties with higher chalkiness degree have a better cooking quality (Li et al, 2015). Even fewer studies have investigated the mechanism by which chalkiness affects cooking quality.Therefore, it is very important to identify the differences between chalky and translucent parts of rice grains from more perspectives.

Although previous research revealed that chalky rice grains differ from translucent grains in starch granule morphology, chemical composition and starch structure, and these differences are coupled with variations in gelatinization and pasting characteristics, these results are inconsistent. Some reseachers found starches from chalky grains contain less amylose and more short branch-chain amylopectin (Patindol and Wang, 2003; Singh et al, 2003). In contrast, others revealed that chalkiness does not affect the amylose and protein contents and starch structure of rice grains (Lisle et al, 2000). Their inconsistent results probably due to using chalky and translucent whole grains located on different positions of panicles, which can notreflect the differences between chalky and translucent parts of grains. In this study, threeand threerice varieties with different chalkiness degrees were investigated. The chalky and translucent parts of rice grains were separated and processed into flour. Then, we assayed their differences in compositions, starch granule morphologies, starch fine structures, crystal structures, pasting properties and thermal characteristics of the flour.

Most notably, rice gelatinization occurs due to interactions between rice endosperm components and water molecules under heat. However, the effects of chalkiness on water molecular migration and the interactions during soaking, cooking and retrogradation have not yet been investigated. Nuclear magnetic resonance (NMR) technology measures the transverse relaxation time of hydrogen protons, producing a spectrum that reflects the distribution and state of water molecules in a sample. The transverse relaxation time represents the tightness of the combination of water molecules with starch, protein and other molecules in a sample. A shorter transverse relaxation time indicates a lower water mobility and a tighter water holding capacity of sample, while a longer relaxation time indicates a weaker combination degree of water (Hou et al, 2001; Horigane et al, 2006; Yu et al, 2010). Here, we measured the differences of water states in soaked rice flour, cooked paste and retrograded rice gels with an NMR spectroscopy. The results will provide more perspectives and comprehensive infor- mation regarding the effect of chalkiness on rice cooking quality.

RESULTS

Compositions of chalky and translucent flour

Chalky rice rates and chalkiness degrees of six varieties are shown in Table 1. The threerice [Zhongjiazao 17 (ZJZ17), Zhongzao 39 (ZZ39) and Zaojian 177 (ZJ177)] showed much higher chalky rice rates and chalkiness degrees than the threerice [Zhonghua 11 (ZH11), Nangeng 46 (NG46) and Qiutianxiaoding (QTXD)]. The total starch content between the chalky and translucent flour in each tested rice variety was similar. However, there were significantly lower amylose and protein contents in the chalky flour compared with the translucent flour. The chalky flour had a higher fat content than the translucent flour, but the differences were not significant in ZJZ17, ZJ177 and NG46.

Scanning electron microscopy (SEM) images of chalky and translucent flour

SEM images of rice flour passed through 0.15 mm screen revealed that the majority of the starch granules clustered together to form different sizes or even large aggregates instead of single, in both chalky and translucent flour. ZH11 was taken as an example here, showed in Fig. S1-A, and the situations for the other five varieties were very similar. When focused on the fracture surfaces of the large aggregates (Fig. S1-B to -G), roughly equal shape starch granules were found to be bind tightly with no obvious gaps in the translucentflour. However, quite a number of different sizes, individual and ellipsoidal particles existed in the chalky flour, and larger voids presented between adjacent starch granules.

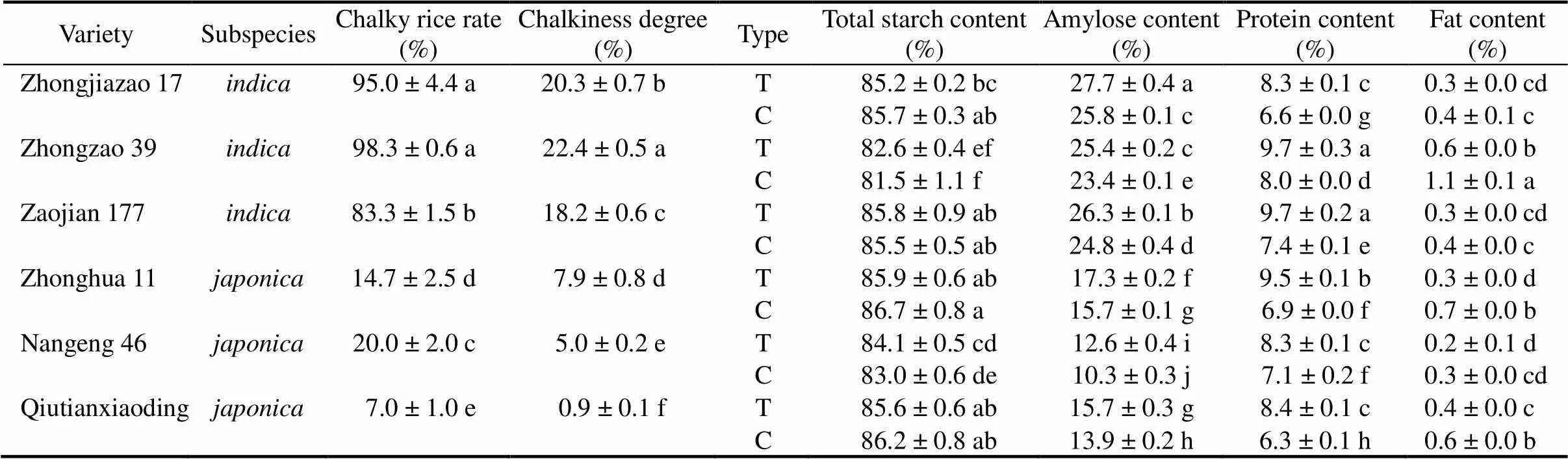

Table 1. Physicochemical properties of translucent (T) and chalky (C) flour from six rice varieties.

All contents are on dry base. Data are Mean ± SD (= 3). Data followed by different lowercase letters in a column differ significantly(< 0.05).

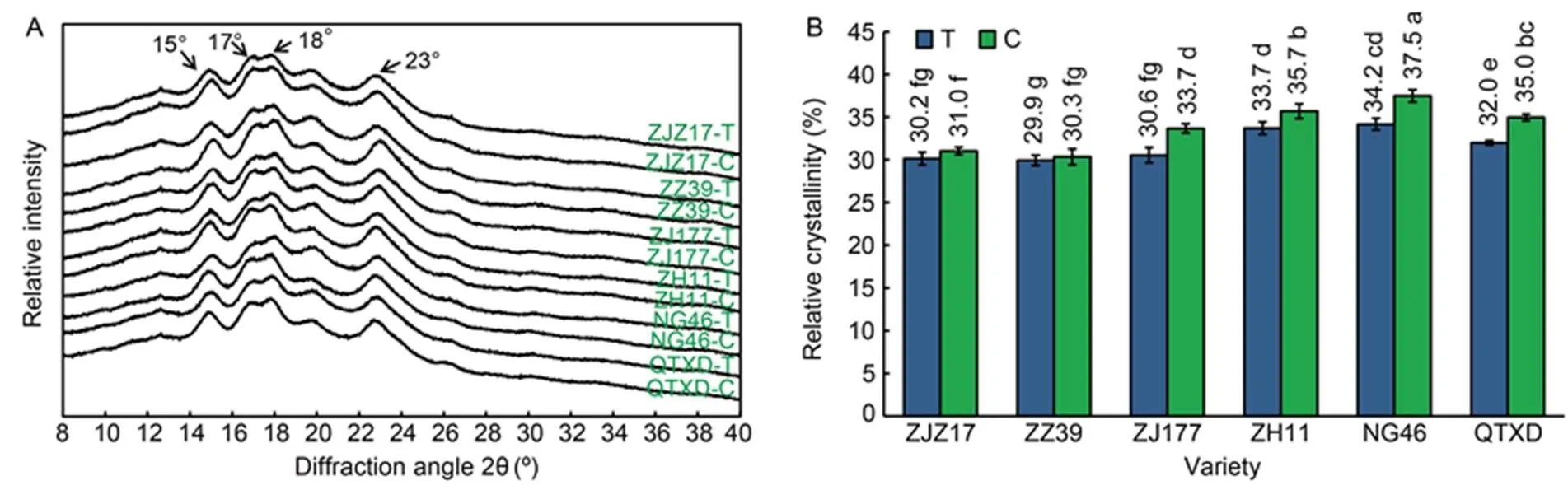

Fig. 1. X-ray diffraction patterns and relative crystallinities of starch granules in translucent (T) and chalky (C) flour from six rice varieties.

A, X-ray diffraction patterns of starch granules in T and C flour from six rice varieties..

B, Relative crystallinity of starch granules. Data are Mean ± SD (= 3). Different lowercase letters behind the mean values indicate significant difference at< 0.05.

ZJZ17, Zhongjiazao 17; ZZ39, Zhongzao 39; ZJ177, Zaojian 177; ZH11, Zhonghua 11; NG46, Nangeng 46; QTXD, Qiutianxiaoding.

X-ray diffraction patterns and relative crystallinity of starch in the chalky and translucent flour

All starch samples isolated from the chalky and translucent flour of the six rice varieties showed a typical A-type X-ray diffraction pattern (Fig. 1-A). There were strong diffraction peaks at 2θ = 15º, 17º, 18º and 23º, with the diffraction peaks at 17º and 18º being double. The relative crystallinity ranged from 29.9% to 37.5%, which was similar to previous reports on rice starch crystallinity (Qin, 2011; Cai et al, 2015). The crystallinity of the chalky flour was higher than that of the translucent flour for all the varieties (Fig. 1-B). Additionally, the crystallinities of ZJ177, ZH11, NG46 and QTXD were significantly higher in the chalky flour than in the translucent flour. Moreover, the starch crystallinity of therice varieties seemed higher than that of thevarieties.

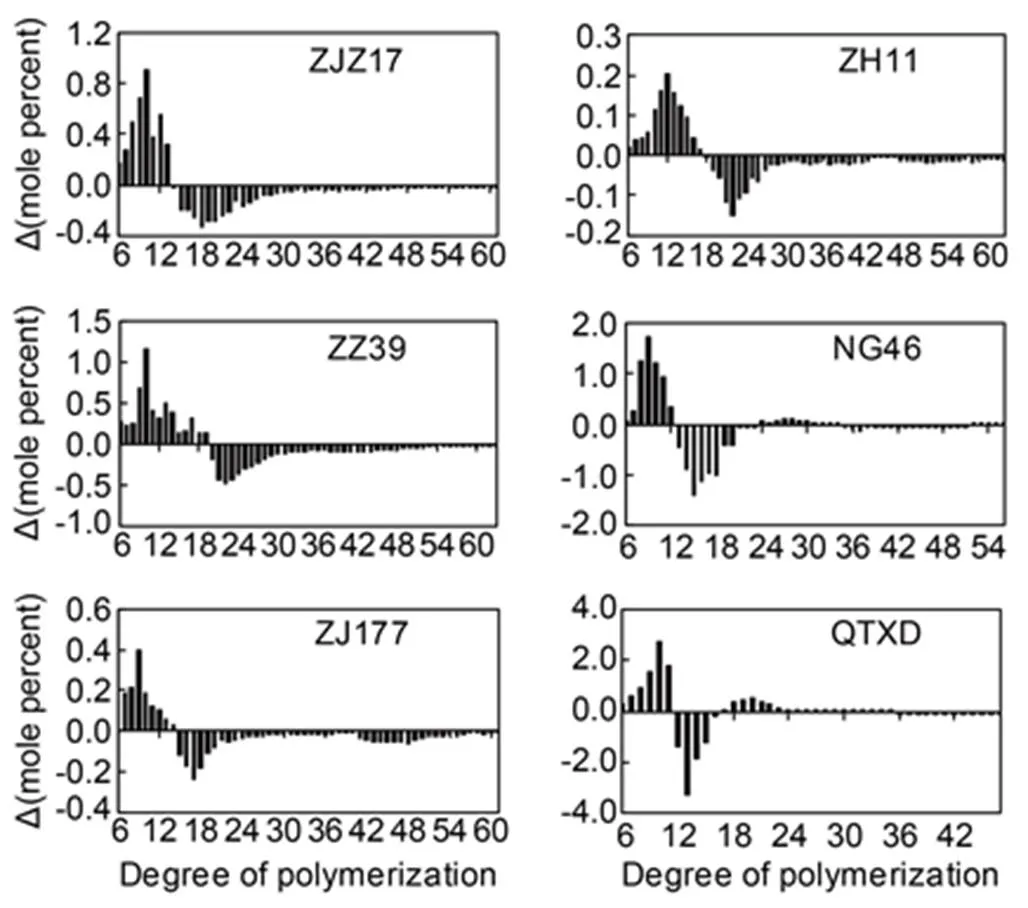

Starch chain length distribution of chalky and translucent flour

Starch chain structure is closely related to rice quality, and starch branched cluster and chain arrangement affect crystal structure and ultimately the functional properties of starch (Cai et al, 2015; Jaiswal and Chibbar, 2017). The chalky and translucent flour differed in their starch chain length distributions (Fig. 2). For all the tested varieties, there were more A chains [degree of polymerization (DP) = 6–12] in the chalky flour than in the translucent flour, especially for ZJZ17, NG46 and QTXD. However, the distributionsfor B1 chains (DP = 13–18) varied among the varieties. The chalky flour of ZJZ17, ZJ177, NG46, and QTXD had fewer B1 chains, whereas the chalky flour of ZZ39 and ZH11 had more B1 chains compared with the corresponding translucent flour. In general, there were fewer long chains (DP > 36) in the chalky flour than in the translucent flour.

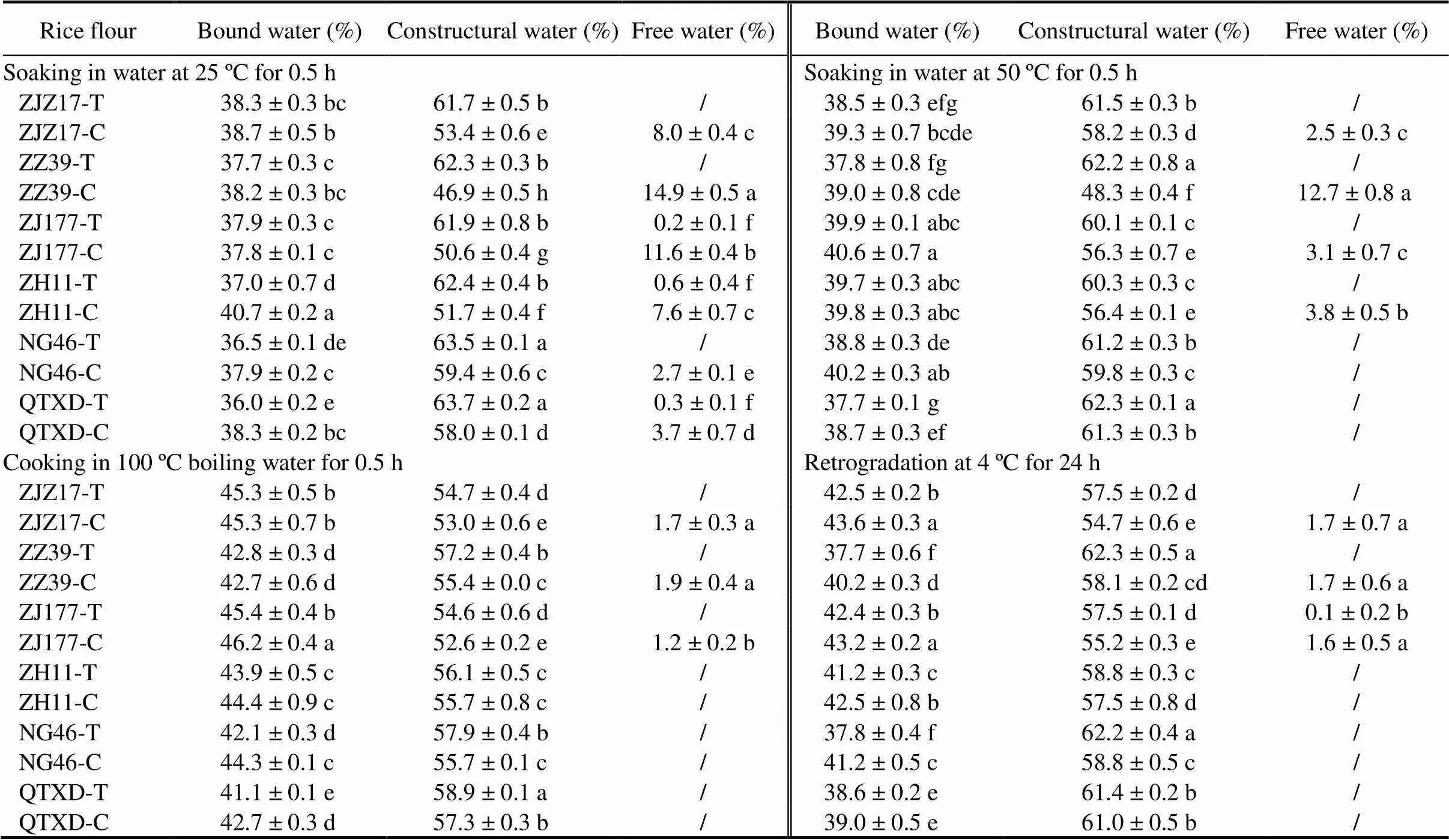

Water states of chalky and translucent flour

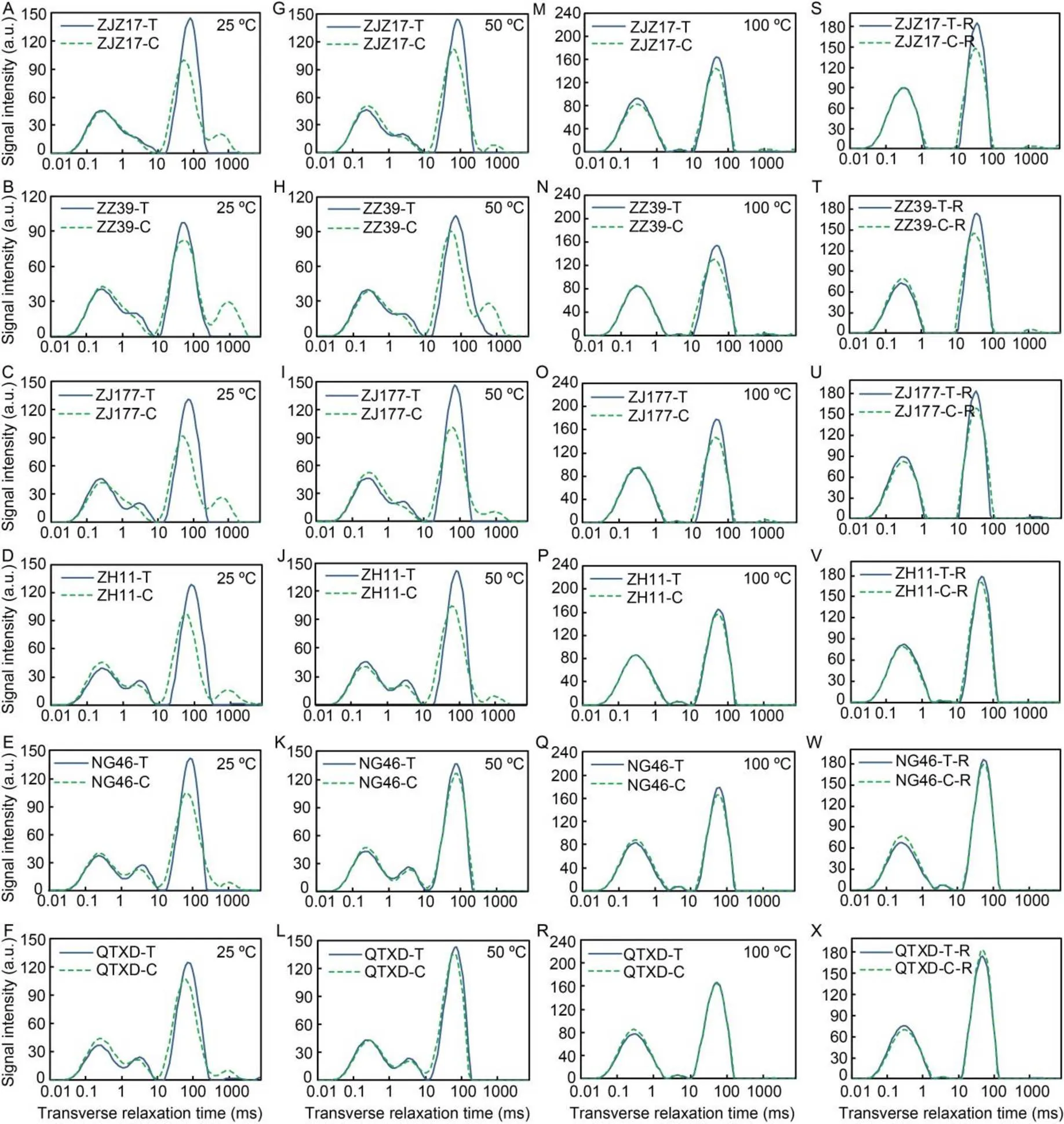

Water states were determined for soaked chalky and translucent rice flour, cooked rice paste and retrograded rice gel. The results for rice flour soaked at 25 ºC and 50 ºC are shown in Fig. 3-A to -L and Table 2. The water in most soaked chalky rice flour is divided into three parts: transverse relaxation time of 0.01–10, 10– 400 and 400–6 000 ms, which represent bound water, constructural water and free water, respectively. However, water in the soaked translucent rice flour was mainly consisted of two parts: bound water and constructural water. Whether it was chalky or translucent flour, the bound water in the soaked flour contained a double peak, which indicated bound water in the soaked flour consisted of two parts: stronger bound water and weaker bound water. When flour was soaked at 25 ºC, the proportions of bound water were 36.0%–38.3% in the translucent flour and 37.8%–40.7% in the chalky flour. The chalky flour showed a much lower proportion of constructural water and a remarkable higher proportion of free water than the translucent flour, regardless of variety (Table 2). For the chalky flour of ZZ39 and ZJ177, the proportions of free water were 14.9% and 11.6%, respectively. By contrast, there was less than 1.0% free water in the translucent flour (Table 2). For flour soaked at 50 ºC, free water tended to be transformed to constructural water, therefore, there was less free water and more constructural water compared with flour soaked at 25 ºC. Even so, there were still a significant lower proportion of constructural water and a remarkable higher proportion of free water in the chalky flour compared with the translucent flour of most varieties soaked at 50 ºC.

Fig. 2. Starch chain length distribution in chalky and translucent flour from six rice varieties indicated by mole percent of chalky flour minus mole percent of translucent flour [Δ(mole percent)].

ZJZ17, Zhongjiazao 17; ZZ39, Zhongzao 39; ZJ177, Zaojian 177; ZH11, Zhonghua 11; NG46, Nangeng 46; QTXD, Qiutianxiaoding.

Fig. 3. Water states in translucent (T) and chalky (C) flour determined by nuclear magnetic resonance.

A‒F, Water states in translucent and chalky flour after soaking in water at 25 ºC for 0.5 h.

G‒L, Water states in translucent and chalky flour after soaking in water at 50 ºC for 0.5 h.

M‒R, Water states in translucent and chalky flour after cooking at 100 ºC in a water bath for 0.5 h.

S‒X, Water states in translucent and chalky flour after retrogradation at 4 ºC in a refrigerator for 24 h.

Transverse relaxation time of 0.01‒10, 10‒400 and 400‒6 000 ms represents bound water, constructural water and free water, respectively. ZJZ17, Zhongjiazao 17; ZZ39, Zhongzao 39; ZJ177, Zaojian 177; ZH11, Zhonghua 11; NG46, Nangeng 46; QTXD, Qiutianxiaoding.

Table 2. Proportions of different water states in translucent (T) and chalky (C) flour from six rice varieties after four treatments.

/, Not detected. ZJZ17, Zhongjiazao 17; ZZ39, Zhongzao 39; ZJ177, Zaojian 177; ZH11, Zhonghua 11; NG46, Nangeng 46; QTXD, Qiutianxiaoding.

All data are Mean ± SD (= 3). Data followed by different lowercase letters in a column with the same treatment differ significantly (< 0.05).

The NMR spectra of cooked pastes and retrograded gels are shown in Fig. 3-M to -X. The spectral patterns of the cooked pastes and retrograded gels differed from those of the soaked flour samples: double peak of bound water ranged of 0.01‒10 ms almost disappeared in the cooked pastes and retrograded gels, and instead by one main peak with a shorten range of 0.01‒3 ms, which indicated that bound water was more tightly binding in the cooked pastes and retrograded gels. The proportions of bound water increased and those of constructural water and free water decreased in the cooked pastes compared with the soaked flour, regardless of the variety (Table 2). Bound water proportion increased meant that free water and a part of constructural water were transformed into bound water after gelatinization. The shorter transverse relaxation time and higher bound water proportion indicated the lower water mobility and better holding water capacity in the cooked pastes compared with the soaked flour. For the cooked pastes, the differences between the chalky and translucent samples were smaller than the corresponding soaked flour. However, for ZJ177, NG46 and QTXD, the chalky cooked pastes had a significantly higher proportion of bound water and a lower proportion of constructural water compared with the translucent cooked pastes. Moreover, for the threerice, the chalky cooked pastes contained free water while the translucent cooked pastes did not (Table 2).

After retrogradation at 4 ºC for 24 h, the proportion of bound water decreased and that of constructural water increased, indicating that a part of bound water had turned into constructural water during retrogradation. For most varieties, the proportion of bound water was significantly higher and the proportion of constructural water was remarkable lower in the chalky retrograded gels than in the translucent retrograded gels (Table 2). This indicated that the chalky gels can retain more bound water molecules than the translucent gels. However, some chalky retrograded gels still remained free water, implying that water state in the chalky retrograded gels was more uneven than that in the transparent retrograded gels.

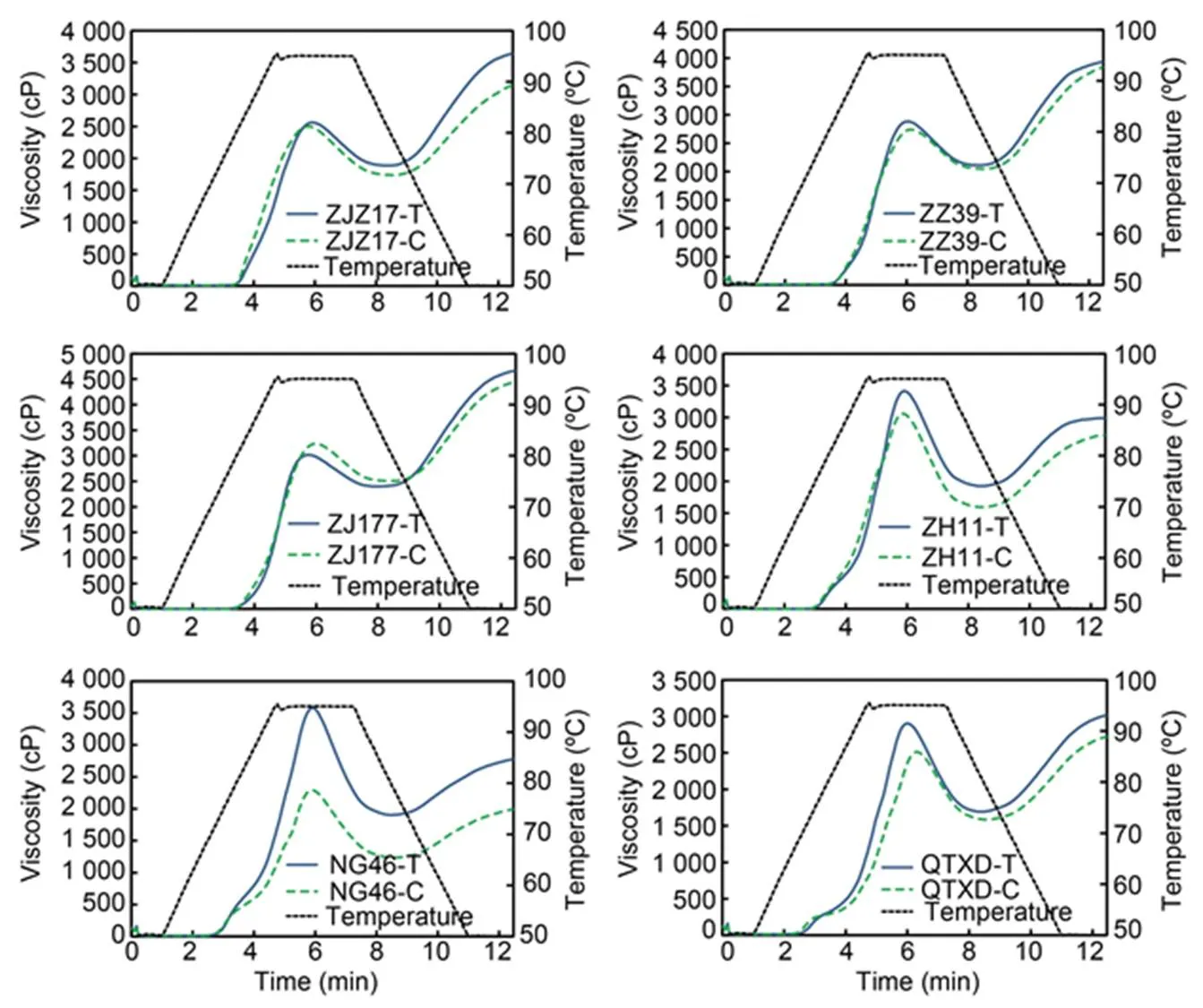

Pasting properties and gel consistency of chalky and translucent flour

The pasting characteristics of the chalky and translucent flour of the six rice varieties are shown in Fig. 4. For all the varieties except ZJ177, the chalky flour showed lower peak, hot paste, breakdown and final viscosities than the translucent flour, especially for the threerice. In contrast, for therice ZJ177, the chalky flour showed higher peak, hot paste and breakdown viscosities compared with the translucent flour, but the differences were not significant. There were differences among varieties for the effect of chalkiness on pasting properties. However, at the beginning of gelatinization, the chalky flour uniformly showed a higher viscosity than the translucent flour for all the tested varieties, as shown in Fig. S2.

Gel consistency is an important factor for evaluating the cooking and eating qualities of rice. Rice flour is gelatinized in 0.2 mol/L KOH and cooled at 25 ºC to produce rice gel. The extension length of rice gel is correlated with the softness of cooked rice and the tendency to retrograde. In this study, the gel consistency of the chalky flour was significantly shorter than the translucent flour, regardless of the variety (Fig. S3). This indicated that chalkiness results in harder texture for cooked rice, which is easier to retrograde.

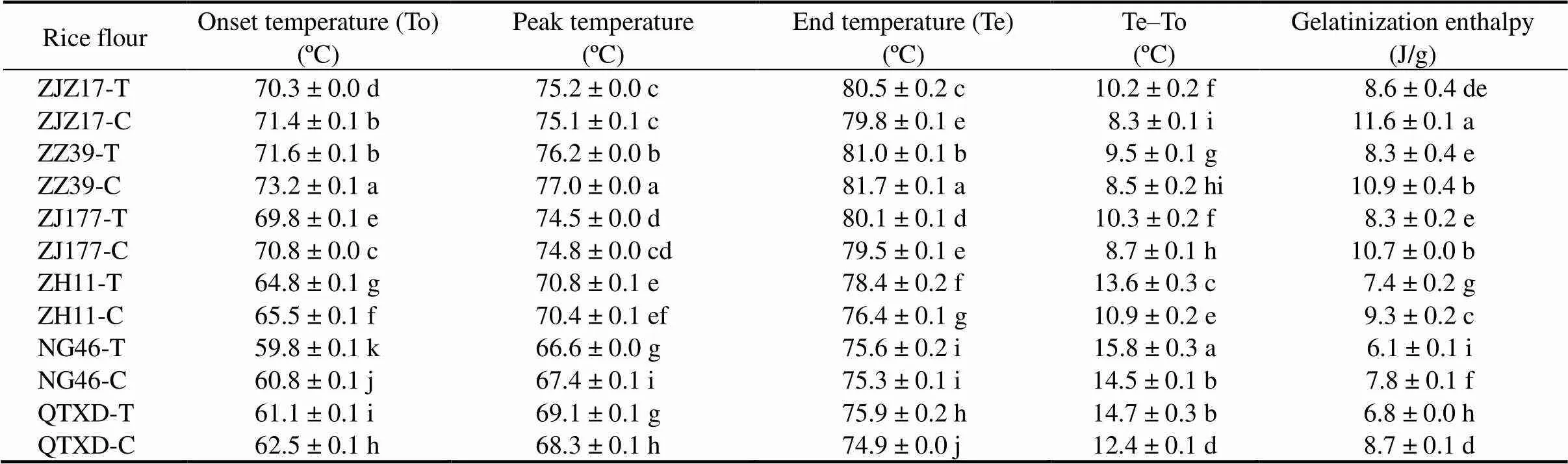

Gelatinization characteristics of chalky and translucent flour

Gelatinization characteristics are shown in Table 3. For all the varieties, the chalky flour had a significantly higher gelatinization onset temperature (To) than the translucent flour. However, the gelatinization peak temperature (Tp) and the gelatinization end temperature (Te) varied among the varieties. The chalky flour showed significantly higher Tp in ZZ39 and NG46, but significantly lower Tp in QTXD than the translucent flour. For ZJZ17, ZJ177 and ZH11, the Tp of the chalky and translucent flour was similar. The Te was lower in the chalky flour than in the translucent flour for all the varieties except ZZ39. For all the varieties, the chalky flour had a significant higher gelati- nization enthalpy (∆H) and a remarkable shorter gelatinization process (Te‒To) than the translucent flour.

Fig. 4. Rapid Visco Analyser profiles of translucent (T) and chalky (C) flour from six rice varieties.

ZJZ17, Zhongjiazao 17; ZZ39, Zhongzao 39; ZJ177, Zaojian 177; ZH11, Zhonghua 11; NG46, Nangeng 46; QTXD, Qiutianxiaoding.

DISCUSSION

Chalkiness is associated with lower amylose and protein contents

In this study, chalkiness was found to be associated with lower amylose and protein contents, which was consistent with some previous studies (Patindol and Wang, 2003; Singh et al, 2003; Shi et al, 2016), but opposite to others which indicated that chalkiness is positively related to amylose content (Zhou et al, 2002; Huang et al, 2006; Li et al, 2015). To clarify the reasons for the differences, we compared the methods of previous studies and found that there were three approaches used in the determination of the effect of chalkiness on rice composition content by far. The first one is correlation analysis between chalkiness and rice composition content by using rice varieties with different levels of chalkiness (Zhou et al, 2002; Li et al, 2015). However, these correlation analyses can not rule out the effects of the variety itself on these traits. The second one is direct comparison of composition contents between chalky and translucent rice grains. In these studies, rice grains with opaque white portions are categorized as chalky and those without or with only small opaque white portions are sorted as translucent grains (Lisle et al, 2000; Patindol and Wang, 2003). However, chalkiness is also related to the positions where rice grain located. Grains on lower spikelets show higher chalkiness than those on higher spikelets, grains on the primary branches appear lower chalkiness than those on the secondary branches, and dominant grains present lower chalkiness than inferior grains (Dong et al, 2006; Chen, 2014; Luo et al, 2021). Meanwhile, grain location affects filling rate andbiosynthesis in rice endosperm. Therefore, when the whole rice grains of chalky and translucent are assayed directly, their own grain filling states might be quite different, which can explain the inconsistent results among studies. The third process is manually separated the chalky and translucent parts of individual rice grains, and then the chalky parts from multiple rice grains are pooled and compared with the pooled translucent parts from the same grains (Cheng et al, 2002, 2005). This process allows the analysis of chalkiness in different varieties independent of grain location, which is considered to be more reliable.

Table 3. Gelatinization properties of transparent (T) and chalky (C) flour from six rice varieties.

ZJZ17, Zhongjiazao 17; ZZ39, Zhongzao 39; ZJ177, Zaojian 177; ZH11, Zhonghua 11; NG46, Nangeng 46; QTXD, Qiutianxiaoding.

Data are Mean ± SD (= 3). Data followed by different lowercase letters in a column differ significantly (< 0.05).

Differences of starch structure between chalky and translucent parts

Starch granules are assembled by alternating crystalline and amorphous lamellae. Crystalline lamellae are composed of A chains and adjacent B chains of amylopectin, which form a double helix structure. Amorphous lamellae mainly consist of loose branching points and amylose. Jenkins and Donald (1995) found that amylose can not form crystals in itself but interlard into amylopectin helical structure, suggesting that amylose disrupts the structure of amylopectin crystallites. Such a disrupted array would be less dense than a more tightly packed array of amylopectin chains. Therefore, it is likely that increased amylose content might lead to reduction in crystalline lamellar density. Kuang et al (2021) found a significant negative correlation between amylose content and relative crystallinity in rice. Cheetham and Tao (1998) found that the degree of starch crystallinity in maize decreases with the increasing amylose content and average chain length in amylopectin, and crystallinity appears to be directly proportional to the mole percent of the short-chain fraction of DP 10‒13. Similarly, the short-chain fraction is positively correlated with crystallinity in rice starch (Vandeputte and Delcour, 2004; Liu et al, 2010). To sum up, lower amylose content and higher short amylopectin chains are associated with higher level of starch crystallinity. Here, the chalky rice flour showed lower amylose content, higher percentage of A chains and higher degree of crystallinity than the translucent flour. The result was in contrast to what we expected. We took it for granted that starch chains would be arranged more orderly and form a higher degree of crystallinity in the translucent rice grains. The threerice showed higher crystallinity levels than the threerice might be due to their relatively lower amylose content.

Patindol and Wang (2003) found that starches from chalky grains contain more A + B1 chains and fewer B3 chains (DP > 36) compared with those from translucent grains, and inferred that starch synthesis in chalky grains may slightly favor glucan chain branching over chain elongation, which were consistent with the results of this study. We found there were more short A chains and fewer long chains in the chalky flour than in the translucent flour, regardless of the variety. Yang (2015) observed that rice chalkiness is associated with a higher proportion of amylopectin long chains and a lower amylose molecular weight by using Wuyujing 3 and Wuyujing 13 mutants with different chalkiness degrees. However, in recent studies from our laboratory with some chalky mutants, we found that all chalky mutants assayed had more short chains (either A chains, B1 chains or A + B1 chains) than the wild type (Li et al, 2017; Wei et al, 2017; Cai et al, 2018; Chao et al, 2019; Wang et al, 2020; Liu et al, 2021; Monsur et al, 2021). In general, we consider chalkiness is related to the formation of more short chains due to the retardation of starch chain elongation.

Differences of water states between chalky and translucent flour

Rice cooking quality evaluation studies often focus on rice grain composition over a long time. However, few studies have investigated changes in water inside rice grains while cooking. Gelatinization of rice is a process in which water molecules enter the interior of rice grains through starch granule gaps and combine with starch, protein and other macromolecules. However, water migration and interaction during cooking are still not well understood (Yu et al, 2010; Bi, 2020). In this study, the water states inside flour made from the chalky and translucent parts of rice grains were identified in soaked flour, cooked pastes and retrograded rice gels.

Rice is often soaked before cooking, and the soaking conditions influence the rice cooking quality. Though whole grains would be a better representation for the real situation of rice cooking, flour made from the chalky and translucent parts of rice grains was used to determine the effect of chalkiness in this study, which made water penetrate into starch more easily. The soaked chalky flour contained bound water, constructural water and free water, whereas the soaked translucent flour contained bound water and constructural water, with no or very little free water. Overall, the soaked chalky flour showed significantly lower constructural water content and higher free water content compared with the soaked translucent flour. When rice flour is immersed in water at a temperature lower than the gelatinization temperature, water molecules enter the amorphous layer of starch granules through the gaps between starch granules, but the crystal structure does not change (Hou et al, 2001). Chalky flour with looser starch granules, allowing water to penetrate more easily, can explain its higher free water content. However, its smaller amorphous regions resulted in less constructural water in chalky flour during soaking.

During the cooking process, water molecules enter the starch crystalline structure and disrupt the associationsbetween starch molecules, thus destroying the amylose double helices. Water diffuses into starch granules and interacts with the chemical bonds of starches, proteins and lipids, resulting in bound water, which can explain the higher proportion of bound water in the cooked rice flour compared with the soaked rice flour (Fig. 3 and Table 2). However, Bi (2020) found that the free water in rice grains gradually transforms to constructural water during cooking. The different results might be due to rice flour used in this study and intact rice grains used by Bi (2020). Rice grain with compacted structure makes water permeate interior gradually, starch granules in the surface layer gelatinized earlier which turn into a barrier for water molecules entering during cooking, thus, free water molecules can not migrate more deeply and tightly bind further, thus, only a transition to constructural water was found in rice grain study. In contrast, rice flour has a looser starch granule structure and much smaller particles, allowing water molecules to penetrate more easily and bind tightly. Therefore, transitions from free and constructural water to bound water occur during rice flour gelatinization in this study.

After retrogradation at 4 ºC for 24 h, the chalky gel samples showed a higher proportion of bound water than the translucent gel samples, suggesting that the chalky gels can hold more bound water during retrogradation. The difference in water states between gelatinization and retrogradation indicated that, during the gelatinization process, water molecules entered the starch crystalline structure and some of the constructural and free water changed to bound water. However, during retrogradation, some of the bound water was released mainly due to the re-formed of double helix of amylose and transformed into constructural water. The chalky flour with lower amylose contentwas more crystalline before gelatinization, retained more bound water during retrogradation. In summary, the chalky and translucent flour differed in terms of their water states when soaked, cooked and retrograded, suggesting that water state is a non-negligible factor leading to different cooking properties. In particular, the effects of chalkiness in rice grains on cooking and retrogradation need further investigation.

Differences of pasting properties and gel consistency between chalky and translucent flour

Lisle et al (2000) reported that chalky grains have lower peak and final viscosities. Patindol and Wang (2003) found that chalky grains have higher peak and breakdown viscosities than the translucent grains from the rice variety IR65, whereas the variations in pasting properties between the chalky and translucent grains are less pronounced in the other five varieties. Cheng et al (2002) found that rice variety Zhou 903 has higher peak and final viscosities, whereas the other four varieties have lower peak and final viscosities in the chalky flour. Other Rapid Visco Analyser (RVA) characteristics, including hot paste viscosity and setback values, vary among the varieties. These results were consistent with ours. In this study, five varieties showed lower peak, hot paste, breakdown and final viscosities in the chalky flour. However, for ZJ177, the chalky flour showed higher peak, hot paste and breakdown viscosities compared with the translucent flour. Even though the chalky and transparent flour of all the tested varieties showed the same or similar trends for composition, crystallinity and starch fine structure, their RVA curves differed. This indicated that the RVA curves reflected various factors and there were differences among varieties on the effect of chalkiness on pasting properties. Nonetheless, at the beginning of gelatinization, the chalky flour had a higher viscosity than the translucent flour regardless ofvariety. This indicated that the weaker binding capacity and more voids of starch granules in the chalky flour led to starch granules swelling more easily at the beginning of the expansion stage (Fig. S2). This has also been detected in rice flour after removing water soluble fractions with looser starch granules, which influence pasting viscosity (Jiao et al, 2014).

Gel consistency can reflect amylose content and interactions among amylose, amylopectin, protein and other macromolecules. Using rice varieties with different levels of chalkiness, negative correlations were found between chalkiness and gel consistency (Zhao et al, 2001; Huang et al, 2006), which was consistent with our results. However, few studies have compared the chalky and translucent parts of rice grains. Amylose and protein contents negatively affect gel extension length (Wang et al, 2005). However, in our study, the chalky flour had lower amylose and protein contents but a shorter gel consistency. This indicated that amylose and protein contents are not the overwhelming determinants of gel consistency. It is possible that looser starch granules and larger gaps between starch granules decreased the adhesive degree between starch granules after gelatinization, resulting in shorter gel consistency and lower viscosity.

她吃完饭之后,按铃请服务生过来买单,过了几分钟就悄悄地走了。敦礼听到她轻微的脚步声,很想转过头看看。可是万一她也在朝这边看呢,就算正往外面走,也许无意中回过头来看一眼,那也不是不可能的。还有,如果她把什么东西落在座位上了呢。被一个陌生人盯着看,她会怎么想呢?又会怎么看我呢?敦礼到底还是打消了这个突然冒出来的念头。他给那个素不相识的女子取了一个名字:月光。

Differences of gelatinization characteristics between chalky and translucent flour

Cheng et al (2002, 2005) found that the To, Tp, Te, and ∆H of chalky flour are generally higher than those of translucent flour. Singh et al (2003) found that chalky grains show higher Te and ∆H than translucent grains. Patindol and Wang (2003) found that the To and Tp of chalky grain starches are statistically similar to those of translucent grain starches, and the ∆H of chalky grain starches is higher than that of translucent grain starches. In this study, the chalky flour had significantly higher To and ∆H compared with the translucent flour for all the varieties. Additionally, the gelatinization process (Te‒To) was shorter for the chalky flour. According to previous studies, To, Tp and ∆H are negatively correlated with short A chain content and positively correlated with amylose and protein contents (Jane et al, 1999; Varavinit et al, 2003; Liu et al, 2013). If the very short A chains (DP 6‒8) cannot form double helices with B1 chains and properly associate into crystalline lamellae, the thickness and density of the crystalline lamellae are reduced and the lamellar structure of starch granules is unstable, resulting in a poor crystallization sequence and lower gelatinization temperature (Jane et al, 1999). Protein acts as a natural barrier to protect starch granules and inhibits gelatinization and associated granule expansion. Therefore, higher protein content leads to higher To and ∆H. Amylose has higher initial gelatinization temperature than amylopectin, and starch endogenous lipids tend to form complexes with amylose, resulting in increased gelatinization temperature and increased energy required for melting. In this study, the chalky flour had lower amylose and protein contents and more short A chains. Theoretically, the chalky flour should have lower To and ∆H, but we found the opposite. This indicated that the composition and molecular structure of rice flour cannot fully explain its thermal properties. We found that the starch granule morphology and bonding degree are more indicative of the gelatinization process. The chalky flour had looser starch granules, which allowed water and heat to infiltrate more easily, resulting in granules expanding more easily at the first step of gelatinization, as shown in Fig. S2. However, the looser starch granules also resulted in more space for starch granules expanding, which meant that granules expanded more and broken down more slowly. Therefore, granules may need more energy to swell and breakdown, which can explain the higher To and ∆H.

METHODS

Rice sample collection and preparation

Threerice (ZJZ17, ZZ39 and ZJ177) and threerice (ZH11, NG46 and QTXD) with varying levels of chalkiness were investigated. The threerice and onerice ZH11 were harvested from the Fuyang experimentalfield of the China Rice Research Institute in 2019. Additionally, tworice NG46 and QTXD were harvested from the Jiangsu Academy of Agricultural Sciences and Jilin Academy of Agricultural Sciences, China, respectively. All samples were stored at room temperature under the same conditions for more than three months after harvest. The grains were dehulled using a rice machine (Satake, Tokyo, Japan) and then polished (ZM100 grain polisher, Xinfeng company, Taizhou, China). Milled chalky grains were selected, and the chalky white parts and the translucent parts were separated manually with a sharp blade one by one. The chalky parts and the translucent parts from different rice grains were pooled as described by Cheng et al (2002, 2005) and ground with a mill (Cyclotec 1093 sample mill, Foss, Höganäs, Sweden) to obtain chalky flour and translucent flour, respectively. The flour was then sieved through a 0.15-mm screen.

Flour composition attributes

The chalky rice rate, chalkiness degree and gel consistency were determined according to NY/T 83‒2017 (The Ministry of Agriculture of the People’s Republic of China, 2017). Amylose content was determined using the spectrophotometric method (NY/T 2639‒2014, The Ministry of Agriculture of the People’s Republic of China, 2014). The total starch content was determined with a kit supplied by Megazyme International (Bray, Ireland). The protein content was determined with the Kjeldahl method (GB 5009.5‒2016, State Food and Drug Administration et al, 2016), and 5.95 was used as the protein conversion factor. Fat content was measured using a total fat analyzer (VELP SER148/3, Italy) following extraction with petroleum ether (60 ºC–90 ºC) according to the Soxhlet extractor method. Each sample was assayed in triplicate.

Rice flour physicochemical analysis

Rice flour samples were prepared according to the filtration and precipitation by anhydrous ethanol method (Qin, 2011). SEM images of rice flour were obtained by viewing with a SEM 435 VP device (LEO Electron Microscopy, Cambridge, UK) after sputter coating with gold particles according to Jiao et al (2014). X-ray diffraction patterns of starch were obtained with a Bruker D8 analytical diffractometer according to Qin (2011). Starch chain length distributions were measured using a PA800 plus pharmaceutical analysis system (carbohydrate labeling and analysis, Beckman Coulter, USA, http://www.beckmancoulter. com/). Pasting properties were measured using a Rapid Visco Analyser (Techmaster, Newport Scientific, Narrabeen, Australia) according to the AACC International Approved Method 61-02.01 (AACC International Approved Methods of Analysis, 1997). The To, Tp, Te and ∆H of rice flour were measured using a differential scanning calorimeter (DSC 1, Mettler-Toledo, Switzerland) according to Jiao et al (2014).

NMR analysis of soaked rice flour, cooked paste, and retrograded gel

Chalky and translucent rice flour (50.0 ± 0.1 mg) was independently weighed into 2-mL centrifuge tubes, and 100 µL distilled water was added. Samples were subjected to four treatments, with three replicates for each treatment. The treatments were as follows: soaking at 25 ºC for 0.5 h, soaking at 50 ºC for 0.5 h, cooking at 100 ºC in a water bath steamer for 0.5 h, and refrigeration at 4 ºC for 24 h for retrogradation after cooking. After treatment, all samples were measured using an NMR spectrometer (NMI20-015V-I, Suzhou Niumag Analytical Instruments Corperation, China) operating at a1H resonance frequency of 20 MHz. Treated samples were placed in the center of the NMR coil position at a constant temperature of 32 ºC. The relaxation time and amplitude of the signal were measured using the Carr-Purcell-Meiboom-Gill (CPMG) pulse sequences. The parameters set for the CPMG experiment were as follows: spectral width, 250 kHz; repeated sampling waiting time, 1 500 ms; the number of echoes, 10 000; echo time, 0.15 ms; and the number of repeated sampling, 16. Each sample was measured in triplicate.

Statistical analysis

Statistical analyses were performed with Microsoft Office Excel 2007, and data were presented as Mean ± SD. Analysis of variance (ANOVA) and the significance of differences among samples were analyzed with the ANOVA procedure (SAS version 9.2, SAS Institute, Cary, NC, USA) followed by the Duncan’s multiple range test, applying a significance threshold of< 0.05.

ACKNOWLEDGEMENTS

This study was supported by the National Natural Science Foundation of China (Grant Nos. 32172080 and 31971925) and China Agriculture Research System (Grant No. CARS-01-16).

SUPPLEMENTAL DATA

The following materials are available in the online version of this article at http://www.sciencedirect.com/journal/rice-science; http://www.ricescience.org.

Fig. S1. Scanning electron microscopy graph of chalky and translucent flour from six rice varieties.

Fig. S2.Rapid visco analyser profiles of chalky and translucent flour at beginning of gelatinization.

Fig. S3. Gel consistency of chalky and translucent flour.

AACC International Approved Methods of Analysis. 1997. Determination of the pasting properties of rice with the Rapid Visco Analyser: Method 61-02.01.St. Paul, MN, USA: AACC International [2021-11-20]. http://dx.doi.org/10.1094/AACCInt Method-61-02.01.

Bi S L. 2020. Research and analyses on influence of heating rate and soaking temperature on qualities of rice. Wuxi, China: Jiangnan University. (in Chinese with English abstract)

Cai J W, Man J M, Huang J, Liu Q Q, Wei W X, Wei C X. 2015. Relationship between structure and functional properties of normal rice starches with different amylose contents., 125: 35–44.

Cai Y C, Li S F, Jiao G A, Sheng Z H, Wu Y W, Shao G N, Xie L H, Peng C, Xu J F, Tang S Q, Wei X J, Hu P S. 2018.encodes a plastidic pyruvate kinase involved in rice endosperm starch synthesis, compound granule formation and grain filling., 16(11): 1878–1891.

Chao S F, Cai Y C, Feng B B, Jiao G A, Sheng Z H, Luo J, Tang S Q, Wang J L, Hu P S, Wei X J. 2019. Editing of rice isoamylase geneprovides insights into its function in starch formation., 26(2): 77–87.

Cheetham N W H, Tao L P. 1998. Variation in crystalline type with amylose content in maize starch granules: An X-ray powder diffraction study., 36(4): 277–284.

Chen S Q. 2014. Relationship between chalky characters, shapes of grains and the quality at different grain positions ofrice., 29(5): 161–167. (in Chinese with English abstract)

Cheng F M, Zhong L J, Shu Q Y, Huang H H, Shi C H, Wu P. 2002. Studies on the cooking and eating quality properties in chalky milled grains of earlyrice., 28(3): 363–368. (in Chinese with English abstract)

Cheng F M, Zhong L J, Wang F, Zhang G P. 2005. Differences in cooking and eating properties between chalky and translucent parts in rice grains., 90(1/2): 39–46.

Dong M H, Sang D Z, Wang P, Zhang W J, Yang J C. 2006. Difference in chalky characters of grains at different positions within a rice panicle., 32(1): 103–111. (in Chinese with English abstract)

Horigane A K, Takahashi H, Maruyama S, Ohtsubo K, Yoshida M. 2006. Water penetration into rice grains during soaking observed by gradient echo magnetic resonance imaging., 44(3): 307–316.

Hou C Y, Seiichi O, Yasuhisa S, Yoshinori K. 2001. State of moisture in rice kernel during cooking process by1H-NMR measurement., 17(2): 126–131. (in Chinese with English abstract)

Huang Q L, Ma J, Cai G Z. 2006. Progress of correlation study between rice quality and chalkiness inandrice.,22(1): 81–84. (in Chinese with English abstract)

Jaiswal S, Chibbar R N. 2017. Amylopectin small chain glucans form structure fingerprint that determines botanical origin of starch., 158: 112–123.

Jane J, Chen Y Y, Lee L F, McPherson A E, Wong K S, Radosavljevic M, Kasemsuwan T. 1999. Effects of amylopectin branch chain length and amylose content on the gelatinization and pasting properties of starch., 76(5): 629–637.

Jenkins P J, Donald A M. 1995. The influence of amylose on starch granule structure., 17(6): 315–321.

Jiao G A, Wei X J, Shao G N, Xie L H, Sheng Z H, Tang S Q, Hu P S. 2014. Impact of rice flour cold-water-soluble fraction removal on gelatinization and pasting properties., 91(5): 473–481.

Kuang N, Zhou W, Zhang X, Zheng H B, Tang Q Y. 2021. The research of ratoon rice on cooking and eating quality and the paste property and starch crystal structure., 36(1): 21–26. (in Chinese with English abstract)

Li D D, Zheng G P, Zheng Y, Cai Y S, Zhao Y, Pan S J, Huang C L, Wang L, Jiang Y W, Zhong W J, Song Z, Zhou J, Yin D W. 2015. Relationship between chalkiness index and other quality traits inrice., 43(6): 70–72. (in Chinese with English abstract)

Li S F, Wei X J, Ren Y L, Qiu J H, Jiao G A, Guo X P, Tang S Q, Wan J M, Hu P S. 2017.encodes an ADP-glucose transporter involved in starch synthesis and compound granule formation in rice endosperm., 7: 40124.

Lisle A J, Martin M, Fitzgerald M A. 2000. Chalky and translucent rice grains differ in starch composition and structure and cooking properties., 77(5): 627–632.

Liu S, Shao G N, Jiao G A, Zhu M D, Wu J M, Cao R J, Chen Y J, Xie L H, Sheng Z H, Tang S Q. 2021. Editing of rice endosperm plastidial phosphorylase geneadvances its function in starch synthesis., 28(3): 209–211.

Liu T Y, Liu C M, Fu G M, Luo S J, Liu W. 2013. Influence of rice protein in rice flour on pasting properties., 34(2): 97–99; 103. (in Chinese)

Liu X L, Guo T, Wan X Y, Wang H Y, Zhu M Z, Li A L, Su N, Shen Y Y, Mao B G, Zhai H Q, Mao L, Wan J M. 2010. Transcriptome analysis of grain-filling caryopses reveals involvement of multiple regulatory pathways in chalky grain formation in rice., 11: 730.

Luo Y H, Li B, Sun Y J, Guo C C, Xin M W, Li F J, Liu F Y, Yang Z Y, Xu F X, Ma J. 2021. Effects of postponing nitrogen topdressing on yield, chalkiness in different grain positions and tasting quality of hybridrice., 27(5): 54–58. (in Chinese with English abstract)

Monsur M B, Cao N, Wei X J, Xie L H, Jiao G A, Tang S Q, Sreenivasulu N, Shao G N, Hu P S. 2021. Improved eating and cooking quality ofrice cultivar YK17 via adenine base editing ofWxallele of granule-bound starch synthase I (GBSS I)., 28(5): 427‒430.

Patindol J, Wang Y J. 2003. Fine structures and physicochemical properties of starches from chalky and translucent rice kernels., 51(9): 2777–2784.

Qin F L. 2011. Structural properties and development of starch granule in high-amylose rice endosperm. Yangzhou, China: Yangzhou University. (in Chinese with English abstract)

Shi L L, Zhang X, Ding D L, Wang S W, Cui J. 2016. Study on the relationship between chalky rice content and rice quality., 41(9): 177–180. (in Chinese with English abstract)

Singh N, Sodhi N S, Kaur M, Saxena S K. 2003. Physico-chemical, morphological, thermal, cooking and textural properties of chalky and translucent rice kernels., 82(3): 433–439.

State Food and Drug Administration, National Health and Family Planning Commission of the People’s Republic of China. 2016. National standard for food safety: Determination of protein content in foods: GB 5009.5‒2016 [2021-11-20]. http://down.foodmate. net/wap/index.php?moduleid=23&itemid=50381. (in Chinese)

Tang S Z, Shun Y, Jiang Y F, Han X D, Mao B H, Gu M H. 2003. Effect of chalkiness on cooking and eating quality ofrice., 4: 4–5. (in Chinese)

The Ministry of Agriculture of the People’s Republic of China. 2014. Determination of amylose content in rice: Spectrophotometric method: NY/T 2639‒2014. Beijing: The Ministry of Agriculture of the People’s Republic of China. (in Chinese)

The Ministry of Agriculture of the People’s Republic of China. 2017. Method for determination of rice quality: NY/T 83‒2017[2021-11-20]. http://www.eshian.com/standards/40834.html. (in Chinese)

Tu X L, Li J, Pan S Y, Wang L F. 2017. Correlation study on rice chalkiness degree and steamed rice cooking quality., 33(12): 210–215. (in Chinese with English abstract)

Vandeputte G E, Delcour J A. 2004. From sucrose to starch granule to starch physical behaviour: A focus on rice starch., 58(3): 245–266.

Varavinit S, Shobsngob S, Varanyanond W, Chinachoti P, NaivikulO. 2003. Effect of amylose content on gelatinization, retrogradation and pasting properties of flour from different cultivars of Thai rice., 55(9): 410–415.

Wang D Y, Zhang X F, Zhu Z W, Chen N, Min J, Yao Q, Yan J L, Liao X Y. 2005. Correlation analysis of rice grain quality characteristics., 31(8): 1086–1091. (in Chinese with English abstract)

Wang W, Wei X J, Jiao G A, Chen W Q, Wu Y W, Sheng Z H, Hu S K, Xie L H, Wang J Y, Tang S Q, Hu P S. 2020., encoding a CBM48 domain-containing protein, affects rice quality and yield., 62(7): 948–966.

Wei X J, Jiao G A, Lin H Y, Sheng Z H, Shao G N, Xie L H, Tang S Q, Xu Q G, Hu P S. 2017.regulates grain filling and starch synthesis during rice caryopsis development., 59(2): 134–153.

Yang X Y. 2015. Physicochemical analysis of rice grain quality from perspective of starch structure. Nanjing, China: Nanjing Agricultural University. (in Chinese with English abstract)

Yu R X, Gu Z Y, Han J Z. 2010. Research on the change of moisture state in rice during soaking process by LF-NMR., 1: 12–15. (in Chinese with English abstract)

Zhang W X, Ma C Y, Yuan Y W, Hu X Q, Chen M X, Zhu Z W. 2021. Current situation and regional difference of rice grain quality in three rice-production superiority areas of China., 27(5): 12–18. (in Chinese with English abstract)

Zhang Y D, Zhu Z, Zhao L, Wang C L. 2006. Correlation analysis of chalkiness character and food taste value in rice., 2: 25–26. (in Chinese)

Zhao Y L, Zhang Y J, Wang J X, Zhang S H, Zhang L M, Li D L, Lv B, Shan L L. 2001. Factor analysis on earlyrice quality in North China., 27(4): 538–540. (in Chinese with English abstract)

Zhou S C, Li H, Wang J S, Huang D Q, Xie Z W, Lu D C. 2002. Correlation among eating quality and cooking, apparent and milling qualities of South-Chinarice in the early-cropping season., 28(3): 397–400. (in Chinese with English abstract)

10 December 2021;

2 March 2022

Copyright © 2022, China National Rice Research Institute. Hosting by Elsevier B V

This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/)

Peer review under responsibility of China National Rice Research Institute

http://dx.doi.org/10.1016/j.rsci.2022.03.002

Jiao Guiai (jiaoguiai@caas.cn); Tang Shaoqing (sqtang@126.com)

(Managing Editor: Wu Yawen)

杂志排行

Rice Science的其它文章

- Transcriptome Analysis Provides Novel Insights into Salt Stress Response in Two Egyptian Rice Varieties with Different Tolerance Levels

- QTL Mapping for Plant Height Using Introgression Lines Derived from Zhonghui 8015 and Wild Rice (Oryza rufipogon)

- Genetic Dissection of Quantitative Trait Loci for Panicle Traits and Heat Tolerance by High-Density Bin Map in Rice

- Improvement of Rice Production under Drought Conditions in West Africa:Application of QTLs in Breeding for Drought Resistance

- Characterization of a Novel Weak Allele of RGA1/D1 and Its Potential Application in Rice Breeding

- CRISPR/Cas9-Targeted Knockout of Rice Susceptibility Genes OsDjA2 and OsERF104 Reveals Alternative Sources of Resistance to Pyricularia oryzae