Towards high degree of c-axis orientation in MgB2 bulks

2022-10-25GrigoroscutAldicBurduselSnduKuncserPsukIonescuSuzukiVsylkivBdic

M.A.Grigoroscut ,G.V.Aldic ,M.Burdusel ,V.Sndu ,A.Kuncser ,I.Psuk ,A.M.Ionescu,T.S.Suzuki,O.Vsylkiv,P.Bdic,∗

a National Institute of Materials Physics,405A Street Atomistilor,Magurele 077125,Romania

b National Institute for Materials Science,1-2-1 Sengen,Ibaraki,Tsukuba 305-0047,Japan

Abstract The paper presents fabrication and characterization of spark plasma sintered textured (001) MgB2 with a record degree of orientation of about 40% and 16% by high-energy ultra-sonication and slip casting in high magnetic field (12 T) and 0 T magnetic field,respectively.Structural characterization was performed by X-ray diffraction,and electron microscopy.The analysis revealed unexpected preferred orientation also in the MgO secondary phase due to the epitaxial growth of (111) MgO on (001) MgB2.The influence of oriented microstructure on the superconducting characteristics expressed by critical current density (Jc),irreversibility field (Hirr),and on the pinning properties were assessed.High anisotropy versus sample orientation in applied magnetic field, H,was observed for Jc, Hirr,pinning activation energy (U∗)extracted from relaxation measurements.The zero-field critical current, Jc0 and Fp,max are weakly or not dependent on the direction of H,while the other indicated parameters are significantly influenced.Results enable control of superconducting parameters by further optimization of microstructure through MgB2 texturing as a novel and viable strategy for development of bulk MgB2 with enhanced properties when taking advantage of its anisotropy.

Keywords: Textured MgB2 bulk;Slip casting;Spark plasma sintering;Critical current density;Pinning force;Pinning activation energy.∗Corresponding author.

1.Introduction

MgB2occupies a special niche among practical superconductors.It has a convenient critical temperatureTcof 39 K,about two times higher than for the low temperature metallic superconductors (e.g.18 K for Nb3Sn).Therefore,this enables the use of MgB2in the temperature range of 15-30 K.Liquid hydrogen (20 K) can be used as a cooling agent and technologies based on it are recognized to show enormous potential for development of the future green economy.MgB2is a lightweight material.Its bulk density of 2.63 g/cm3is a few times lower than for other practical superconductors including high temperature superconductors (e.g.6.3 g/cm3for YBa2Cu3O7).Hence,MgB2is a valuable superconductor especially for portable applications,in space,transportation,medicine,energy and others.However,to take advantage of the presented features,the improvement of the critical current density,Jc,and of the irreversibility field,Hirr,is required.Since the coherence length is relatively large in MgB2,about 10-40 nm [1],introduction of size-comparable defects can promote vortex pinning and enhancement ofJcandHirr.Literature indicates a few routes such as use of additives and of different processing technologies.In the first case,precipitates of secondary phases and defects associated with them(interfaces,strain at interfaces,local non-stoichiometry,modification of the grain boundaries) or direct substitution of a component element into the crystal lattice of MgB2(e.g.,carbon for boron [2-4]) can generate effective pinning centers.Modification of the microstructure (e.g.nano-structuring for a high density of grain boundaries as pinning centers) and enhancement of the bulk density are induced by specific technological procedures [5-23],popular being high-energy ball milling and pressure-assisted techniques.Heat treatments in reactive atmospheres are also effective for pinning centers insertion.Spark plasma sintering in N2atmosphere generated nano-precipitates of the MgB9N phase enhancing the critical current density at high magnetic fields [24].

A novel strategy is to obtain (001) textured MgB2bulks with enhanced transport properties for a preferential direction [19,25].Samples were fabricated by magnetic field slip casting (MFSP) followed by spark plasma sintering (SPS).Textured powder-in-tube tapes obtained by mechanical deformation and annealing were also reported [26,27].The MgB2has a hexagonal,anisotropic crystal structure with (ab)-planes of boron and Mg stacked in thec-axis direction.Despite the feeble magnetic properties at room temperature of MgB2,its anisotropy promotes orientation in MFSP [28,29] which can be further enhanced by spark plasma sintering.In the partially oriented samples with an orientation degree of 21%,JcandHirrwere pushed to higher values in the favorable direction,while in the disadvantageous one,JcandHirrhad a small suppression when compared to a randomly oriented sample[19].These samples have also shown a complex behavior of the volume pinning force,Fp.

This work reports fabrication and properties of(001)MgB2textured bulk samples with a higher degree of orientation than in the previous attempts [19,25].Orientation enhancement is induced by high-energy ultra-sonication for de-agglomeration and homogenization [30] of the colloidal solution of MgB2in ethyl alcohol during slip casting processing.A record orientation degree of about 40% is obtained after spark plasma sintering (SPS) in vacuum or nitrogen if a high magnetic field is applied during slip casting,compared to 16% obtained in zero-field slip casting.The influence of oriented microstructure on superconducting characteristicsJcandHirrand on pinning properties is assessed.

2.Material and methods

Sample processing is presented in Fig.1.A colloidal solution of powder MgB2(99.5% purity,metal basis,LTS Research Laboratories Inc.US) in ethanol was prepared under high energy ultrasound sonication (600 W) (Fig.1a,b).The as-prepared solution was slip casted (SC) and the resulting compact was spark plasma sintered (SPS) (sample M1,Table 1).Slip casting experiments were also performed under a magnetic field,H0,of 12 T (Fig.1c).The as-resulting casted compacts were spark plasma sintered in vacuum(30 Pa)(sample M2,Table 1)or in a N2atmosphere(91 kPa)(sample M3,Table 1,Fig.1d,e).Spark plasma sintering was performed at 1150 °C for 30 min,using a FCT Systeme GmbH-HP D 5 (Germany) sintering furnace,with graphite die systems.The heating rate was 150 °C/min and the maximum uniaxial pressure applied on the disk-shaped samples(20 mm diameter and 3 mm thickness) was 95 MPa.Noteworthy is that different from our previous works [19,25],no dispersing agent was introduced in the colloidal solution.Instead,as already mentioned,the colloidal solution was sonicated at high energy.

Fig.1.Processing steps: (a) Colloidal solution preparation;(b) high-energy ultrasonication;(c) slip casting under 12 T;(d) dried casted compact;(e)spark plasma sintering.

XRD patterns were obtained with a Bruker-AXS D8 ADVANCE diffractometer (CuKαradiation).From Rietveld analysis (software MAUD 2.31 [31]) the weight fractions and the crystallite size of the detected phases,aandclattice parameters of MgB2,and the microstrain for MgB2and MgO were determined.In order to obtain a good fit by Rietveld refinement,the preferred orientation of MgB2and MgO had to be taken into account,and the March-Dollase orientation parameterr[32],was extracted.We further used this parameter for the calculation of the degree of preferred orientation parameterη,and the characteristic angleφ[33]:

The degree of preferred orientationηmeans the excess volume fraction of crystallites having the preferred orientation axis (which is [001] for MgB2and [111] for MgO,as shown below) within the surface normal and the angleφ,compared with a random sample.φis the angle from the surface normal for which the orientation probability in a textured sample equals the orientation probability in a random sample.(For a random sample:r=1,η=0,φis undefined).We expressed the orientation degree of MgB2also in terms of the Lotgering factor,LF[34],which is commonly used in the literature.

The apparent densitiesof the SPSed pellets were measured by Archimedes method (in toluene media).The relative densitiesRSPS(%) were calculated as100.The theoretical densitiesρSPStof the composites were determined by the procedure described in Ref.[35].The phases used in calculation of the theoretical density were MgB2(2.63 g/cm2),MgO (3.58 g/cm2),and MgB4(2.49 g/cm3).

SEM Lyra3XMU and TEM JEM 2100 microscopes were employed to observe the microstructure of the samples.For SEM,bulk MgB2samples were polished and etched for 70 s in Royal water (aqua regia).

Magnetization measurements as a function of the applied fieldm(H) at different temperaturesTand as a function of temperaturem(T) at 0.01 T,as well as the relaxation of the magnetizationm(t) were performed with a MPMS-SQUID 7T(Quantum Design,US) magnetometer.The samples for magnetic measurements were cut from the center of the sintered disks and have approximately a cuboidal shape (~L×l×g=1.1 × 1.05 × 1 mm3).To determine the critical current densityJc,the Bean formula for a plate-like geometry[36] was used:

wherem↓andm↑are the magnetic moments in emu for ascending and descending magnetic field,respectively,in them(H) loops,Vis the sample volume in cm3,andL,l,are in cm.Flux jumps were observed in them(H) loops on the ascending branch(one jump at~1.45 T)at temperatures below 10 K,5 K and 15 K for samples M1,M2 and M3,respectively.They were not taken in consideration in our analysis.The pinning force isFp=μ0HJc.To avoid the complications with macro flux jumps and with estimation of |m↑-m↓|in the classic Bean model,the self-field,Jc0(in A/cm2),was estimated from a modified Bean relation,considering the descending branch of the hysteresis loop [37]:

The irreversibility field,Hirr,is the field for whichJc=100 A/cm2.The pinning activation energy was determined from relaxation measurements.Samples were zero field cooled to different temperatures,a magnetic field was applied,and the decay of the magnetic moment in timem(t)was recorded for a time windowtwof 50 min.In the range where ln(|m|) versus ln(t) is linear,the normalized vortexcreep activation energy is:

averaged overtw.[38,39].ForU∗(T) an external field of 3 T was applied andU∗(H) was measured at 10,15 and 20 K.

3.Results and discussion

3.1.Structure and microstructure of the investigated samples

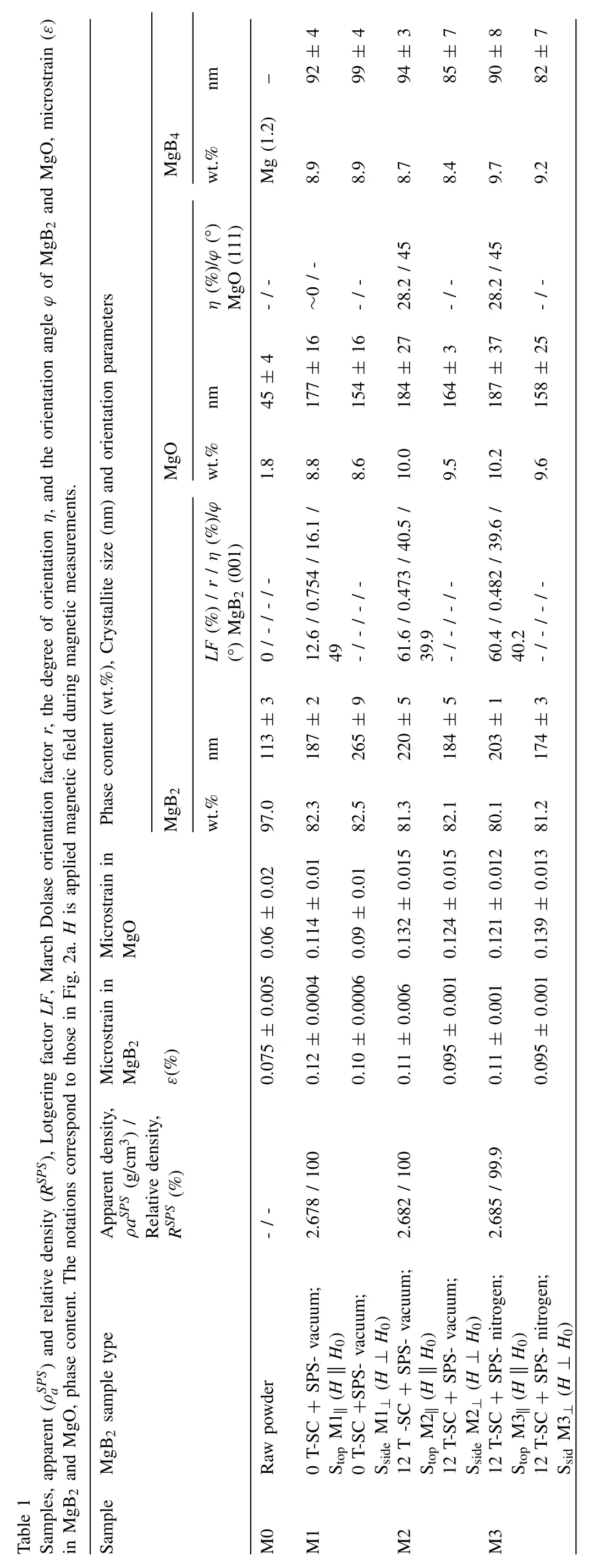

Two X-ray diffraction patterns were obtained for each bulk sample,one on the surface Stopin which case the scattering vector is parallel with the SPS uniaxial pressing forceFSPSand the processing magnetic field during slip castingH0and the other on Sside,with the scattering vector perpendicular toFSPSandH0(Fig.2a).The patterns measured on Stopare presented in Fig.2b.The qualitative analysis shows the presence of the major phase MgB2,and of MgO and MgB4as the secondary phases.To highlight the [001] texturing of MgB2,the intensities were represented being divided by the intensity of the (101) line,which is the most intense for a randomly oriented sample.Slip casting and SPS decreases the amount of MgB2(Table 1) from 97 wt.% in the raw powder (sample M0) to 80.1-82.5 wt.% in the sintered bulks (M1,M2,and M3),while the amounts of MgB4and MgO increase from 1.8 and 1.2 wt.% to 8.8-10.2 and 8.4-9.7 wt.%,respectively.

Although the amount of the secondary phases is limiting the connectivity within the samples,if properly engineered,these phases can be effective pinning centers[40,41].Sintered samples show (001) MgB2preferred orientation with the (ab)plane parallel to Stop.A texture with a degree of orientationηof 16.1% (LF=12.6%) occurs in the sintered sample M1(Table 1) even in the absence of the magnetic field during slip casting.

We explain this result by the effect of the high energy ultrasonication which breaks the agglomerates of MgB2[42].It is recognized that agglomeration is one of the main limiting factors for mouldability and sintering and cannot be improved in dry powders [43].The plate-like MgB2grains will organize during slip casting in a partially textured green compact and will enhance their texture during subsequent SPS.Enhancement of texture during SPS of a green compact with a low orientation was addressed in an earlier work [19].For the samples processed by slip casting under a magnetic field of 12 T and SPSed in vacuum or in N2atmosphere,a relatively high orientation is achieved withηof 40.5 (LF=61.6%) and 39.6% (LF=60.4%),andφof 39.9 and 40.2°,respectively.Therefore,the preferred orientation of MgB2is considerably increased in the samples obtained in a magnetic field.

Another interesting aspect is that for a good Rietveld fitting of the measured XRD patterns of the highly oriented samples M2 and M3,it was necessary to consider a preferred orientation also for MgO,with the (111) plane parallel to Stop.In both samples M2 and M3,an excess of about 28% of the MgO crystallites is oriented with the<111>axes within about 45° from the surface normal (direction ofH0).Considering the texturing mode of MgB2and MgO,it results that the (111) crystal planes of MgO are oriented preferentially parallel to the (001) plane of MgB2.The orientation degree of MgO is a bit worse than that of MgB2(η=28%compared to about 40%).A closer look at the atomic structures of the(111) MgO and (001) MgB2planes shows excellent theoretical lattice matching that favors the epitaxial growth of MgO on MgB2crystallites (Fig.3d) during SPS.The epitaxial mismatch is (3.0860-2.9797)∗100/3.086=3.4%.It is expected that the epitaxial stress causes a compression strain in the(ab)-plane of MgB2at the interface with MgO,and a slight increase of the average MgO lattice parameter.The epitaxial growth of (001) MgB2thin films on (111) Si single crystal substrates with a MgO seed layer was reported in Ref.[44].Fig.3a and Fig.3b show an average decrease of the MgB2lattice parameters parallel to the SPS pressing force (FSPS,Fig.2a),which generates an expansion of the unit cell in the perpendicular direction (macrostrain).This behavior is valid for bothaandcconstants of MgB2because,the samples are only partially textured,and the crystallites could have different orientations to the pressing force.The effect of compression and expansion is more directly transferred to theaandclattice constants when the unit cells (crystallites) are oriented in the two extreme positions depicted in the inset of Fig.3b.As the orientation degree increases,the probability that the unit cell is orientated withcparallel to the compression force increases,hence,the effect upon the values ofaandcis higher.In the same key,one can comment on the decrease of the microstrain with the enhancement of texturing (Fig.3c).Microstrain measures the dispersion of the interplanar spacings,which may originate from many sources,e.g.,local lattice strain (caused,for instance,by point defects or dislocations),or structure changes near the crystallite or grain boundary,or different lattice strain in different crystallites.This last cause is probably preponderant for our partially textured and uni-axially-stressed bulk samples.The dispersion of the interplanar spacing decreases with orientation enhancement,and this is the case when measured both for Stopor Ssidearrangements.In isotropic and macrostrain-free MgB2samples,the change in thea-lattice parameter of MgB2is considered an indicator of the degree of substitution of B by C [45-49].Substitution of C for B leads to the creation of strain and distortion in the matrix because C-B bond is shorter than the B-B one.The dependence reported in the above-mentioned reports [45-49] works well for randomly oriented samples.In the case of highlyc-axis oriented samples,the uniaxial pressure generated an enhancement of the anisotropic distribution of the strains and makes the model questionable.Therefore,additional investigations are required for a correct evaluation of the relationship between the doping level and lattice changes in highly textured MgB2samples.For our samples,it is reasonable to consider that some small amount of carbon intake,e.g.,from the graphite die system occurs during SPS processing in the textured samples as in the randomly oriented ones [46].

Fig.3.Structural parameters for samples M1,M2,and M3 extracted from XRD data measured on Stop (//) and Sside (⊥),respectively: (a) lattice parameter a of MgB2;(b) lattice parameter c of MgB2.The inset in (b) explains intuitively the different values of the lattice constants obtained by XRD on the two perpendicular faces of the sample: the lattice shrinks in the SPS direction (//) and expands in the perpendicular directions (⊥).(c) Microstrain ε (%) of MgB2;(d) Lattice matching relationship between (001) MgB2 and (111) MgO.The distance between two neighboring Mg or B atoms in the (001) MgB2 plane is 3.086 ◦A,while the distance between two oxygen or Mg atoms in the (111) MgO plane is 2.9797 ◦A The two crystal planes also have compatible rotational symmetry,namely of 6th order for (001) MgB2 and 3rd order for (111) MgO;(e) comparison of MgB2 and MgO crystallite sizes (in nanometers) of the textured samples.

Fig.3e summarizes the average crystallite (coherence domain) sizes in vertical and lateral directions.One can notice that the MgO lateral size is always smaller than that of MgB2,which could be an argument in favor of MgO epitaxy on MgB2.The column-shaped MgB2crystallites are the constituents of the micron-size plate-shaped grains revealed in the SEM images presented below (Fig.4).

When measured on Stopand Sside,the crystallite size of MgB4(83-98 nm,Table 1) shows differences and the tendencies for a certain measurement arrangement with the orientation degree are similar to those for MgB2although for this phase texturing was not found.Lack of correlations and explanations for the crystallite size dependencies have the origin in the complexity of the processes during processing,involving chemical reactions,solid,liquid,and gas phases,and also in the limitations in evaluation by Rietveld method of the crystallite size for the anisotropic crystals with a model that is suitable for spherical ones.A careful assessment and further studies are required.

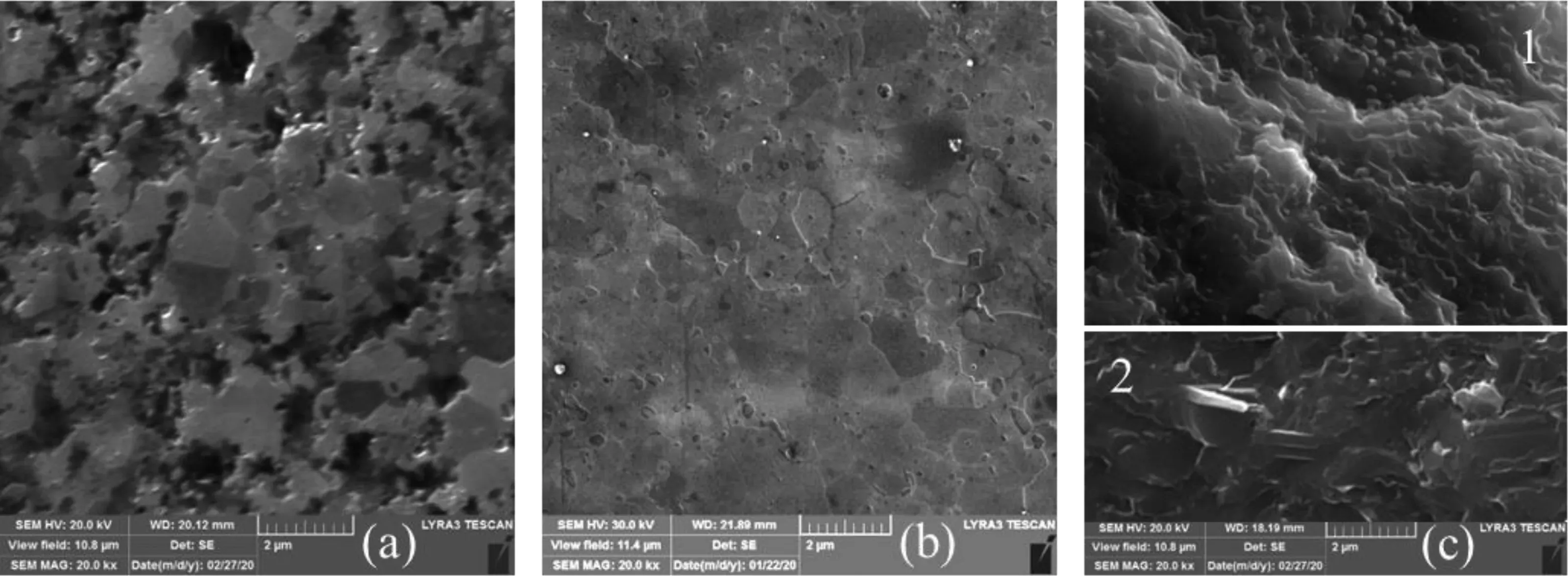

The relative density of the samples is high,close to the theoretical value(Table 1).This is confirmed by the SEM images obtained on the highly oriented samples M2 and M3 (Fig.4b and c2) showing few pores.Few closed pores are visible also in sample M1 (Fig.4a) with a lower degree of orientation,but they can be the result of chemical etching.The platelike hexagonal grains,which were ascribed to MgB2phase,are visible in the SEM images of highly oriented samples M2 and M3 (Fig.4b,c1 and c2).The in-plane size of the platelets is about 1 μm.These micrographs confirm thec-axis texturing of MgB2.We also note that samples with a higher level of orientation (e.g.M2,Fig.4b) are more corrosion resistant than sample M1 (Fig.4a).The anisotropic corrosion resistance is easy to understand from the crystal chemistry of MgB2.The weak chemical bonding of Van der Waals type between the alternating Mg and B (ab)-planes favors a lower corrosion resistance than in the plane where the bonds are strong.

Fig.4.SEM images taken on etched samples: (a) Stop of 0T-SC+SPS vacuum;(b) Stop of 12T-SC+SPS vacuum;(c) Sside of 12T-SC+SPS nitrogen (1 -fractured surface and 2 -polished surface).

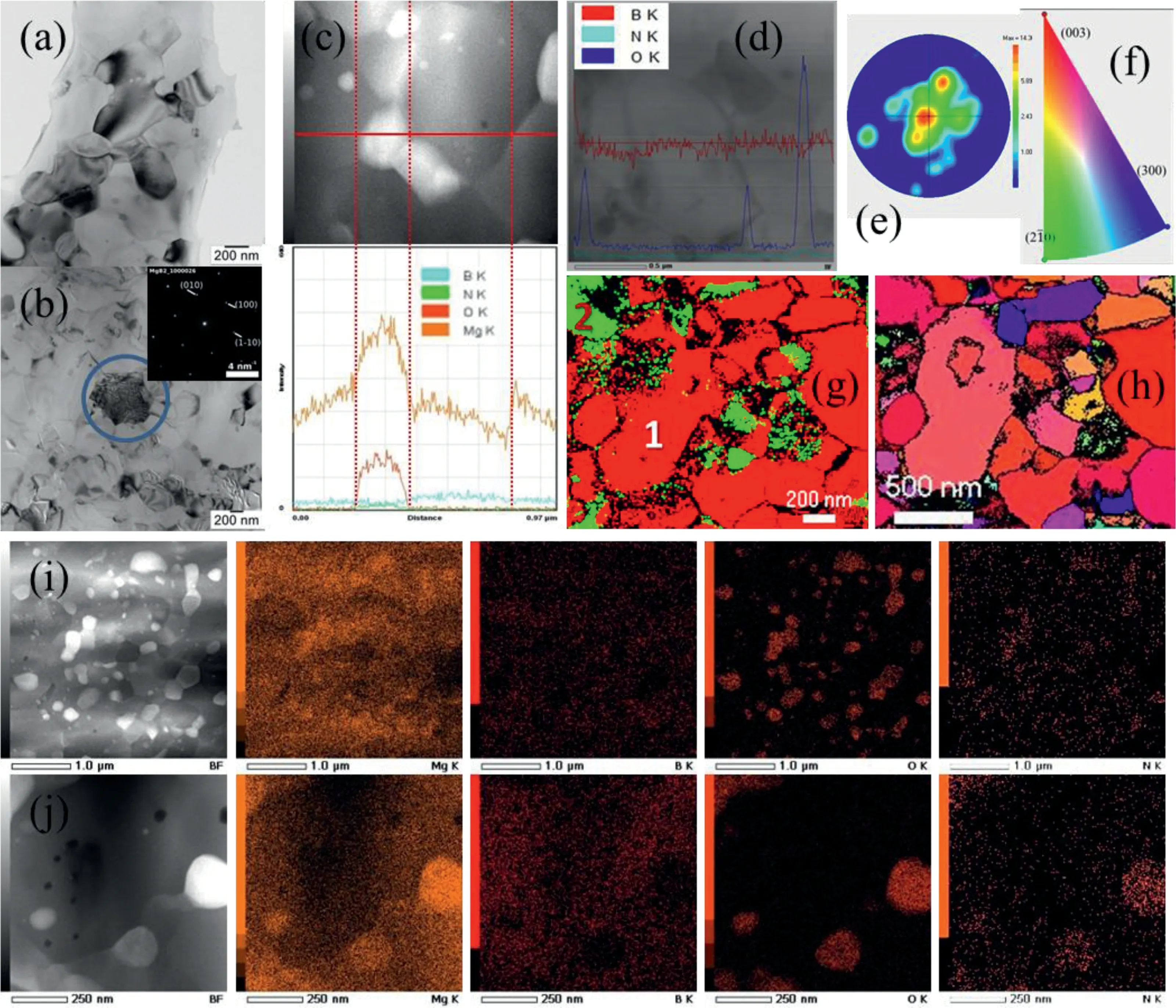

The general TEM image on sample M3 shows grains with flat hexagonal surfaces (Fig.5a).These grains (Fig.5b) have the crystal structure of MgB2with thecaxis perpendicular to the surface,as determined by selected area electron diffraction (SAED) (inset to Fig.5b).Other grains with a bulky appearance are ascribed to MgO (Fig.5c).Oxygen was also found at the grain boundaries,between MgB2grains(Fig.5d).Distribution of MgO and MgB2grains can be also observed by using SAED mapping (Fig.5g).By neglecting the MgO grains,the orientation map for MgB2is presented in Fig.5h.The color and intensity code map from (Fig.5f),which are based on the orientation map from Fig.5h,indicates that most grains are (00l) textured (red color is dominant) but there are angular deviations from a perfect orientation.Indeed,the pole Fig.5e for (00l) MgB2confirms that most grains of MgB2arec-axis oriented since the highest intensity is for the center of the pole figure.Horizontalc-axis orientation is also present(blue color,in Fig.5f).Apparently,in the pole Fig.5e there are present extra peaks with orientation at about 25-40°(from the vertical) that corresponds quite well toφof about 39° determined by XRD.Nevertheless,this result might be just a statistical artefact since the number of measured grains is limited.The MgB2domain sizes of about 200 nm,highlighted in Fig.5g,are close to the average lateral extent of the coherence domains of the MgB2resulted from XRD.

The EDS maps from Fig.5i,and Fig.5j show the distribution of elements.In some cases,nitrogen seems to accompany Mg and O from relatively large regions (Fig.5j).There is also nitrogen in smaller nano areas not following the O distribution.As reported in Ref.[24],in randomly oriented samples fabricated by SPS in nitrogen,these nano grains were ascribed to phase MgB9N.The amount and size of this phase are small and due to this it cannot be clearly observed in XRD patterns(Fig.2b).In Ref.[24]the nano size of MgB9N was determined to be comparable with the coherence length of MgB2(10-20 nm),and,thus,the precipitates of this phase can play the role of effective pinning centers.Confirmation of the presence of the MgB9N phase in the samples from this work requires additional observations by electron microscopy.

3.2.Superconductivity aspects from magnetic measurements of the investigated samples

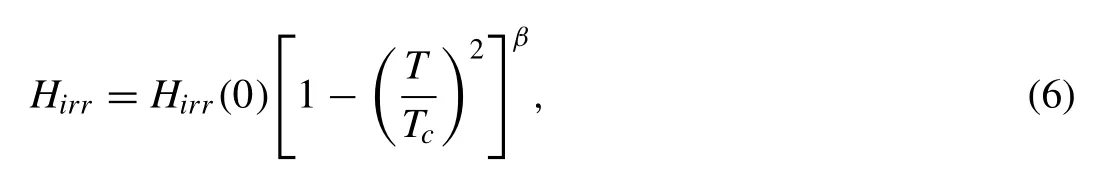

Fig.6a shows magnetization curves with temperature.The critical temperaturesTcareTc=37.5 K,38.4 K,and 38.3 K for the samples M1,M2,and M3,respectively.The slightly higher critical temperature of the samples M2 and M3 with a better texture is probably due to the slightly lower level of the microstrain [50] noticed in these samples (Fig.3c).

TheJc(H) curves at 5-35 K (see,e.g.,curves for 5 and 20 K in Fig.6b and Fig.6c) of all samples are pushed to higher applied fieldsHwhen the measurement is performed in parallel geometry,i.e.,H||H0,than whenH⊥H0but converge to the same value at zero field.Nevertheless,a small anisotropy of zero-field critical current densityJc0(Jc0,||>Jc0,⊥) at any investigated temperature can be visualized in Fig.6d.Samples M2 and M3 with a higher level of orientation (η=40.5 and 39.6%) have a higher difference betweenJc||andJc⊥when compared with sample M1 (η=16.1%).At low temperatures (e.g.,at 5 K,Fig.6c),this difference is perhaps further expanded by the presence of nitrogen in sample M3.The influence of orientation can be understood based on the following observation.In a parallel field,the Lorentz force would try to move the vortices across the grain boundaries which provide a strong pinning.Hence,a highJc||occurs.In the direction perpendicular to the surface,the MgB2platelets are defined as a high/dominant number of stacked interfaces parallel to the Stopsurface.When the measuring field is applied in a perpendicular geometry,i.e.parallel to the (001)planes,the Lorentz force drives the vortices along the grain boundaries to positions that make the field gradient smaller and,consequently,theJc⊥is smaller than in the previous case.However,this scenario should take into account also other factors such as the inhomogeneity of the lattice parameters due to doping or stoichiometry variations,inhomogeneity and anisotropy of the microstrain due to orientation and to the presence of precipitates and defects.For example,in sample M3 introduction of nitrogen modifies the grain boundaries due to the occurrence of MgB9N nano precipitates.

Fig.5.TEM/EDS images on bulk sample ‘M3’: (a) general TEM image;(b) detail showing the hexagonal surface of a MgB2 grain as identified by SAED(inset);(c) TEM image and line scan showing that white grains are MgO;(d) TEM image and EDS line scan showing grain boundaries containing oxygen;(g) SAED map that identifies the crystal structures of 1 -MgB2 (red) and 2 -MgO (green);(h)=SAED map showing the degree of orientation of MgB2 that corresponds to pole figure for (00l) from (e) and orientation color code from (f);(i) and (j) TEM images at two different magnifications and EDS maps for Mg,B,O,and N.

The indicated factors influence the coherence length size and pinning,thus,impacting superconducting parameters.

The temperature dependence of the irreversibility field(Fig.6e) follows the law:

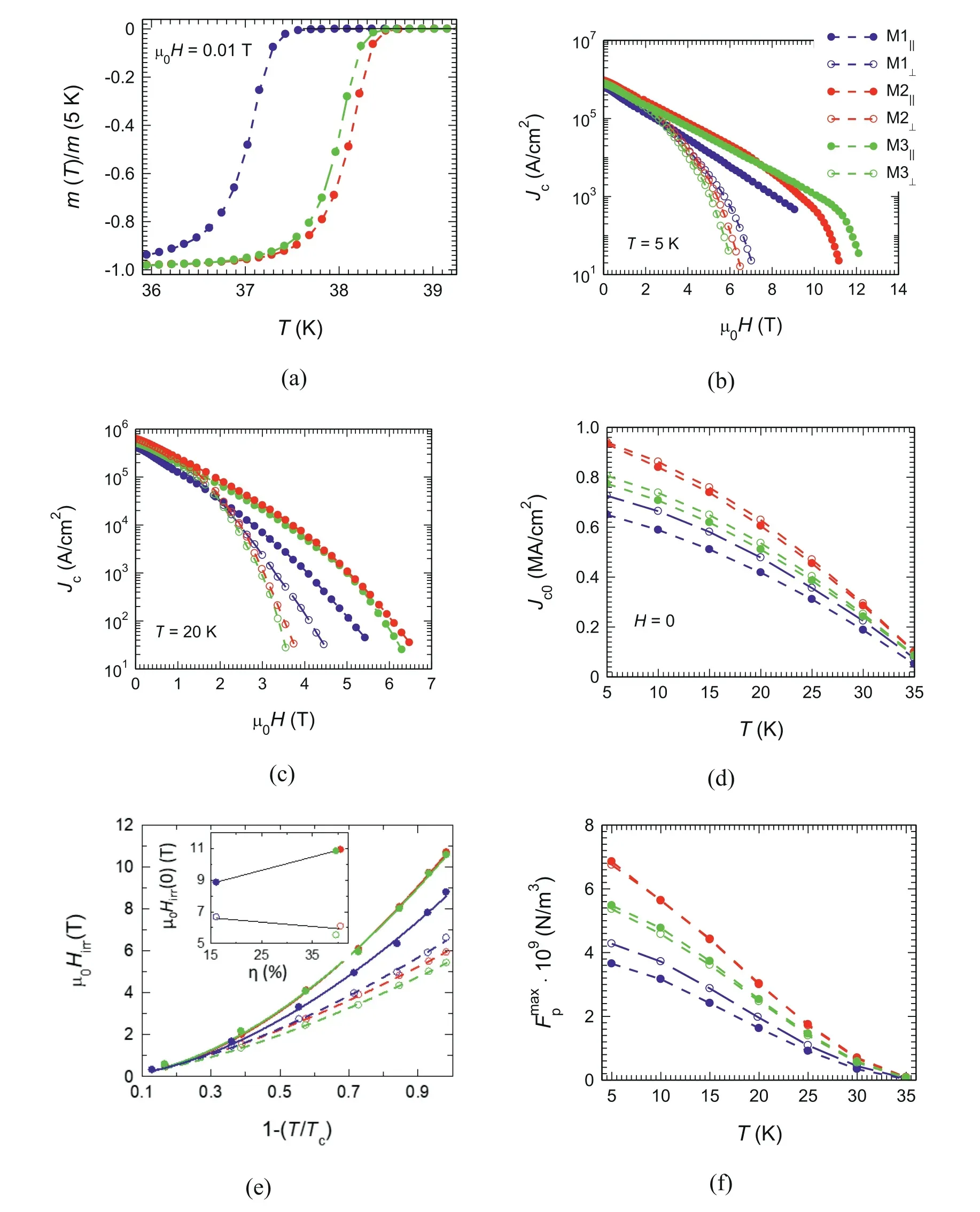

BothHirr(0) andβare strongly dependent on the orientation (Table 2).The values ofβare grouped around two different values within the error of measurement: whenH||H0,the exponent is rather highβ||≥1.7,whereas forH⊥H0,β⊥has an average value≈1.5,which is close to the classical value of 1.5[51,52].For an increasing orientation degreeη,Hirr,||(0) increases andHirr,⊥(0) decreases (Table 2,inset to Fig.6e).It is noteworthy that the increase ofHirr(0) with orientationηforH||H0(‘M1||’,‘M2||’,‘M3||’) is more pronounced than decrease forH⊥H0(‘M1⊥’,‘M2⊥’,‘M3⊥’)(see inset to Fig.6e).This result is important for practical applications and motivates the use of textured MgB2bulks.A linear fit of theη-dependence of the zero-temperature irreversibilityHirr(0) forH||H0andH⊥H0provides close values for a random orientation (η=0):Hirr,|||η=0=7.50± 0.02 andHirr,⊥|η=0=7.02 ± 1.90.A consequence of the existence of different irreversibility fields is the divergence of the current anisotropy,γJ=Jc,||/Jc,⊥atHirr,⊥.The dependence at 20 K ofγJon the reduced fieldh||=H/Hirr,||for our samples is presented in Fig.7a.A second consequence is that there is a temperature dependence of the anisotropy of theHirr,γH=described by:

Fig.6.(a) Reduced magnetization curves vs.temperature;(b) and (c) curves of critical current density Jc(μ0H) at 5 K and 20 K,respectively;(d) zero-field critical current density Jc0 with temperature;(e) temperature dependence of the irreversibility field Hirr of MgB2 samples in the parallel and perpendicular geometries of measurements.Lines are fits with Eq.(6).Inset shows the dependence of the irreversibility fields on the degree of (001) orientation η.The lines are linear fits.All the fit parameters are shown in the Table 2;(f) volume maximum pinning force with temperature.

Table 2.Fit parameters with Eq.(6) of the irreversibility curves vs.temperature (Fig.6e).

Fig.7.(a) Current anisotropy γJ as a function of the applied field relative to the irreversibility field for parallel direction h||= H/Hirr,|| at 20 K;(b) temperature dependence of the anisotropy of the irreversibility field γH in samples M1||,M2|| and M3||.Continuous lines are fits with Eq.(7).

withδ=β||-β⊥.The temperature dependence ofγHis shown in Fig.7b and the values ofβare gathered in Table 2.

One observes that also the maximum pinning forceFp,maxis slightly larger in samples with a higher level of orientation(Fig.6f).

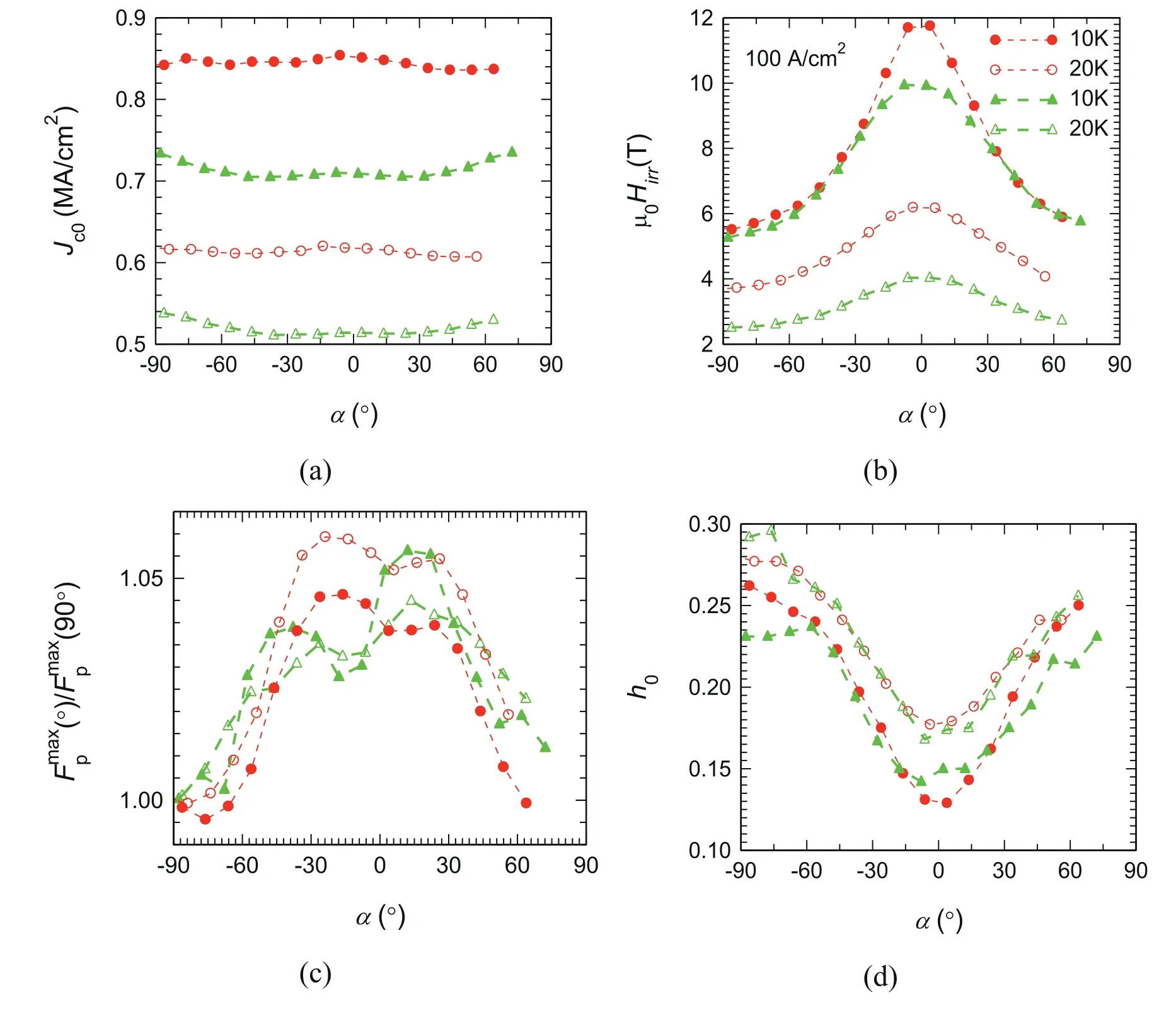

Next,we present the results of the angular (α) dependence of superconducting parameters determined from magnetization loopsm(H) measured at 10 and 20 K.The weak angular dependence ofJc0(Fig.8a) confirms the low field convergence ofJc||andJc⊥mentioned above.However,for sample M2,close toα=90° the curveJc0(α) is approximately constant,while for sample M3 there is a slow increase.The reason for this effect is missing.As expected,Hirrdisplays a high angular variation(Fig.8b).The normalized pinning forceFpmax/Fpmax(90°) displays a split of the main peak into two peaks positioned atαpeak=± 25-38° (Fig.8c).The values of |αpeak| ≤φ(Table 1).They likely correspond also with results of the pole figure from TEM measurements (Fig.5e,see also text in Section 3.1):in pole figures there is a main central peak accompanied by satellite peaks.The intensity of the two better resolved satellite peaks in the pole figure is not equal and this might be the reason for different intensities of theFpmax/Fpmax(90°) whenαis positive or negative,but more research is needed.Overall,the peak ofFpmax/Fpmax(90°) without considering its split is broad and this might be convenient for applications.Following this idea,the result may suggest that from a practical viewpoint,a partially textured but optimized (00l) MgB2material might be more valuable than a perfectly textured one.More research is needed to demonstrate this idea.Finally,we observe that the reduced field of the pinning forceh0=H(Fp,max)/Hirras a function ofαhas a minimum atα=0° (H||H0).The minimum values ofh0(Fig.8d) are in the range 0.12-0.16 (α~0°).These values are smaller than the lowest theoretical valueh0=0.2 corresponding to the pinning on the grain boundaries [53] which remain the dominant pinning mechanism in MgB2[54]).As already introduced before,the favorable direction for superconductivity in (001) oriented MgB2is whenH||H0(H||c-axis) and one can take advantage of a better connectivity and of an effective use of grain boundaries for pinning.To further observe this effect in terms of the pinning behavior for differentTandH,we assessed as an example the pinning activation energyU∗from relaxation measurements for sample M3 and we compare the curves with those for a reference randomly oriented sample prepared by SPS without the slip casting step (Fig.9).

The activation energyU∗increases with temperature in the collective (elastic) vortex-creep regime where the vortex phase is ordered [55] and decreases for plastic (dislocation mediated) creep where the vortex phase is disordered [56].Curves for studied samples show this trend as one can observe in Fig.9a.The crossover at about 9 K can be understood in terms of an energy balance relation,where the thermal energy can be neglected for strongly pinned samples whenTis much lower thanTc.Therefore,at lowT,the relaxation is smaller leading to aJcloser toJc,the effective pinning is weak and the inter-vortex interactions play an important role,giving rise to collective pinning.At highTthe energy balance changes,becauseJrelaxes faster andU∗increases.In these conditions,in the vortex system,dislocations occur due to vortex pinning and the creep becomes plastic.Roughly,this dynamic crossover appears when the effective depth of the pinning potential well equals the vortex deformation energy[57].No crossover was observed inU∗(H)andU∗decreases with increasing field,which is characteristic for plastic creep(Fig.9b).

Fig.8.Curves of: (a) zero-field critical current density Jc0;(b) irreversibility field μ0Hirr;(c) normalized pinning force Fpmax/Fpmax(90°);(d) h0 as a function of applied field orientation angle α (0° denotes the H || H0 position) at 10 and 20 K for highly textured sample M2 in red and sample M3 in green.

Fig.9.The pinning activation energy as a function of temperature (for an applied magnetic field of 3 T) (a) and applied magnetic field (b).Sample denoted reference is a randomly oriented sample made from the same raw material and by SPS,but without slip casting.

CurvesU∗(H)andU∗(T)measured on the oriented sample M3 for the applied magnetic field in the parallel and perpendicular directions indicate on the anisotropy ofU∗.The pinning activation energyU∗of the sample M3 measured in parallel geometry (H||H0) is higher than for the reference sample,whereas the measurement in perpendicular geometry provides a lowerSimilar to the irreversibility feild,this behavior is related to different density of barriers,namely to grain boundaries that a vortex encounters when its orientation is parallel to the plate or perpendicular on it.The values and curves shape ofU∗are comparable with data reported in literature for pristine,added or proton irradiated MgB2bulks[58-61].

4.Conclusion

The approach from this work demonstrates new possibilities for further improvements of the MgB2superconductor and its processing technology.

We have shown that de-agglomeration and homogenization of the colloidal solution by high energy ultra-sonication during slip casting promotes (00l)orientation of the MgB2grains in the spark-plasma-sintered bulks.When during slip casting a magnetic field is not applied,the degree of orientation in the sintered sample attains~16%.The degree of orientation is further enhanced towards high values (~40%),if during slip casting a high magnetic field of 12 T is applied.Some orientation was detected also for the grains of the secondary MgO phase.

Anisotropy of structural,microstructural and superconducting parameters of MgB2is analyzed and corroborated.The efficiency of grain boundaries on vortex pinning depends on orientation.The peak ofFpmax/Fpmax(90°) was found to be broad in the highly oriented samples from this work suggesting that for practical applications a partially textured,but optimized (00l) MgB2bulk might be more suitable than a material with perfect 100% (00l) texture.This result and the pinning activation energy behavior provide the first elements necessary for design,fabrication and control of textured MgB2bulks (Eqs.(1)-(5)).

Declarations of Competing Interest

None.

Acknowledgments

Authors gratefully acknowledge financial support from MCI-UEFISCDI Romania,the projects PN030101(21 N/2019),5PTE/2020 -BIOTEHKER,and POC 37_697 no.28/01.09.2016 REBMAT.

杂志排行

Journal of Magnesium and Alloys的其它文章

- Improving the Young’s modulus of Mg via alloying and compositing -A short review

- Surface modifciation of magnesium alloys using thermal and solid-state cold spray processes: Challenges and latest progresses

- Preparation,structure and properties of Mg/Al laminated metal composites fabricated by roll-bonding,a review

- A review on recent advancements in biodegradable Mg-Ca alloys

- Analysis of element loss,densification,and defects in laser-based powder-bed fusion of magnesium alloy WE43

- Pore structure of porous Mg-1Mn-xZn alloy fabricated by metal-gas eutectic unidirectional solidification✩