Real-time energy optimization of HEVs under-connected environment:a benchmark problem and receding horizon-based solution

2022-07-06FuguoXuHirokiTsunogawaJunichiKakoXiaosongHuShengboEbenLiTielongShenLarsErikssonCarlosGuardiola

Fuguo Xu·Hiroki Tsunogawa·Junichi Kako·Xiaosong Hu·Shengbo Eben Li·Tielong Shen·Lars Eriksson·Carlos Guardiola

Abstract In this paper, we propose a benchmark problem for the challengers aiming to energy efficiency control of hybrid electric vehicles (HEVs) on a road with slope. Moreover, it is assumed that the targeted HEVs are in the connected environment with the obtainment of real-time information of vehicle-to-everything(V2X),including geographic information,vehicle-toinfrastructure(V2I)information and vehicle-to-vehicle(V2V)information.The provided simulator consists of an industriallevel HEV model and a traffic scenario database obtained through a commercial traffic simulator,where the running route is generated based on real-world data with slope and intersection position.The benchmark problem to be solved is the HEVs powertrain control using traffic information to fulfill fuel economy improvement while satisfying the constraints of driving safety and travel time.To show the HEV powertrain characteristics,a case study is given with the speed planning and energy management strategy.

Keywords Powertrain control·Connected and automated vehicles·Hybrid electric vehicles·Vehicle-to-everything

1 Introduction

Maximizing energy efficiency by on-board management of the engine and the electric machines is a primordial issue for hybrid electric vehicles (HEV), since the innovative hybrid electric powertrain technology was motivated for the potential in saving energy consumption by managing the power sources with different characteristics,and it has been accepted widely during the last two decades [1-3]. Hence,energy optimization for HEVs is not a new topic even in the system control field. Since the first mass production HEV was launched into the automotive market at 1997,developing energy optimization method has been a long-run hot challenging issue [4]. However, most researches on this issue focused on the minimization of energy consumption for a given targeted driving route.It means that to implement the minimization, the driving power or the profile of vehicle speed along the targeted route must be previously known before starting the trip.Benefit from this unfeasible assumption,the optimization methods with the constraint of dynamic equations,usually a model of the battery,the vehicle dynamics or the energy conversation devices,have been exploited to develop the optimization algorithms,see the next subsection of the short review.However,from the view of practice requiring the power demand of the whole route previously is the bottleneck for application of optimal control algorithm due to the power demand delivered by the human driver or an autonomous driving controller is real-timely decided on the rout according to the variable environment.Without the adaptability to the real-time changes on the route the previously solved optimal solution will be no more meaningful in optimization.However,very few literatures,up to the authors knowledge,addressed the issue of real-time energy optimization for HEVs,even a common concept or evaluation method is not formulation for real-time optimization of HEVs.This paper will address this challenging issue by proposing a realtime optimization problem formulation with evaluating.

1.1 Literature review

During the last two decades, a large number of researches have been reported to explore the potential of HEVs in energy saving and emission reduction. From the view of powertrain control and management technology, the key issue is the energy management strategy(EMS)that is implemented in the onboard control unit and delivers the commands to the power sources of powertrain according to the state of the powertrain and the power demand of the driver [5]. There are mainly two categories in the implementation of EMS:rule-based strategy and optimization-based strategy.

Due to the simplicity of rule-based EMS, it was widely employed in the onboard application of HEVs, especially in the hybrid electric bus with a fixed route. Moreover, the threshold values of rule-based EMS can be determined to improve the fuel economy through the intelligent algorithms,such as genetic algorithm and particle swarm optimization[6,7].However,there is limitation of this EMS since it does not focus on the optimization. When the optimal control theory is employed in the EMS, the demand torque from the driver is seen as the disturbance.The dynamic programming(DP)and Pontryagin’s maximum principle(PMP)are two branches for solving the optimal control problem(OCP)to derive global solutions during the optimization horizon.They have been widely researched into the EMS under the assumption that the power demand profile of the driver under the whole driving route is previously known[8,9].Usually,a numerical optimization problem is transformed from the original OCP and it is time-consuming to obtain the solution when the number of the interval of the driving route is large so it is unrealistic to apply these algorithms to the onboard control[10].

Focusing on the optimal energy efficiency problem, the real-time optimization has also been employed. Equivalent consumption minimization strategy (ECMS) was proposed to convert the fuel consumption and electricity consumption intooneidenticalconsumptionbyintroducingaweightfactor[11].It has been concluded that when there is the only state of charge(SOC),which indicates the energy used in battery and is treated as the state variable in the OCP,the same optimal solution can be derived from PMP and ECMS with specialized weight factor [11,12]. Under this conclusion, adaptive ECMSs are developed to optimized the weight factor for the fuel consumption reduction with knowledge of the driving cycles [13,14]. Another alternative approach for real-time EMS is the model predictive control (MPC), which is also called as the receding horizon control.Based on the principle that an open-loop optimization in the predictive horizon and only current optimal solution used as input for controlled system,the computation burden of MPC is low,which makes it widely researched in application of EMS for HEVs[15].

Although real-time optimization has been focused many attentions that challenge the energy consumption optimization problem without complete pre-information, there still exists a gap between the onboard optimization technology and used in mass production HEVs.A bottleneck to fill this gapis thevarietyandtheuncertaintyindrivers power demand in the future period of a driving trip or in the prediction horizon for MPC, however, that is necessary to be previously known when one solve the energy consumption minimization problem. Therefore, further challenging in real-time optimization of energy consumption is still an open issue in powertrain control community[16,17].A new milestone is greatly anticipated by breaking the bottleneck not only from automotive industry but also the academic community of energy system and optimization. Previously, the driver demand power or the demand vehicle speed that can also be used to calculate the demand power through the longitudinal vehicle dynamics equation, are predicted with the data of standard driving cycles or the actual driving cycles by using Markov-chain model and neural network model[18-21]. However, these approaches can not be applied to the real-world traffic because there are surrounding participants that play virtual role in the driver demand power.

Fortunately,theconnectivityprogressedveryrecentlyprovided a big opportunity in developing innovative technology of onboard optimization of energy consumption. With the technology development of the high speed communication with everything(V2X),including vehicle-to-vehicle(V2V)and vehicle-to-infrastructure (V2I), the real-time information of the surrounding participants in the traffic scenario is available to the ego vehicle[22,23].The real-time traffic information ahead of the ego vehicle is beneficial to the prediction of the future driver demand power in the prediction horizon for receding horizon-based energy management by Gaussianprocessandextremelearningmachine,respectively[24,25]; or the vehicle speed prediction through chaining neural network and deep fuzzy predictor, respectively[26,27].Moreover,it can also be used to derive the optimal speed planning strategy and sequentially to calculate driver demand power for EMSs by a two-level optimal controller[28-33].Since the driver that connects the outside traffic scenario and the inside powertrain dynamics influences the total fuel economy of HEV.The further fuel consumption reduction can only be achieved by the co-optimization of vehicle dynamics and the powertrain operation synchronously.The advanced technologies of connectivity and automated driving make it possible to jointly optimize the powertrain operation and vehicle dynamics for HEVs,which have been very recently researched[34-36].

1.2 Motivation and innovation

Firstly, currently the real-world connectiv ity environment providing real-time information such as preceding vehicle speed,traffic light’s phase and timing,and the history data of them are not always realistic for most researchers.To verify the traffic scenario anticipation-EMSs,the ideal approach is to test them on the HEVs running on a real-world traffic.Usually, this is time-consuming and expensive that would increase the design cost.Even worse,since the test version of theproposedoptimizationstrategymaybeinadequateconsiderationinsafetyprotectionforreal-worldtrafficcondition,it may cause vehicles in a dangerous situation.Secondly,the optimal solution derived from EMSs are the command signals in the upper level, such as engine demand torque and motor demand torque.However,in the validation process of the lower level, the high-fidelity powertrain model should be used to simulate the powertrain dynamics.For example,the engine response should not be ignored since there are the physical delays of the throttle and during the combustion process. Except for the physical limitation of electric motors, the physical limitation of batteries also can not be ignored.Finally,in communities of control,optimization and computing science,there are large-scale advanced theories.However,the application of these advanced theories is limited because of lack of the application background. On the other hand,in the automotive field,there are actual physical parameters and models of powertrain and vehicle,and a mass of data-based traffic information.It is concluded that the gap between theory communities and application areas is large.To break through this situation, formulating a benchmark problem of real-time energy management with academic and industrial consensus is a beneficial task for promoting the researches on this challenging issue.

The aim of this paper is to propose a real-time energy optimizationproblemforHEVsundertheconnectedenvironment.To evaluate the solution of the problem,a simulation platformisdevelopedwithahybridelectricpowertrainmodel which is constructed under an automotive industrial background and the functions for eliminating real-time traffic environment and V2X information.A real-time energy optimization strategy is constructed to solve the benchmark problem, and the evaluated results with the proposed evaluating standard is demonstrated.

The contributions of this article are summarized as follows: A benchmark problem of developing real-time optimization algorithm for HEVs is firstly proposed which provides a common concept of a real-time optimization with V2X and its evaluating standard. A simulation platform is developed that provides a virtual testing system for HEV energy management strategy with a powertrain model and a randomly generated traffic scenario on a real-world driving route. A receding horizon optimization-based real-time energy management strategy is proposed to solve the benchmark problem.

1.3 Organization

The rest of this paper is organized as follows.Section 2 formulates the problem focusing on the minimization of fuel consumption on a route of fixed initial and terminal points with the satisfaction of serval constraints. The detail introduction of a provided simulator,and the model description of powertrain and the available data of V2X are given in Sect.3.Then the explanation of benchmark tasking and evaluation are given in Sect.4.A case study of the powertrain control for the targeted HEV is conducted to show the characteristics of HEV powertrain in Sect.5.Finally,the conclusion of the benchmark is conducted in Sect.6.

2 Problem formulation

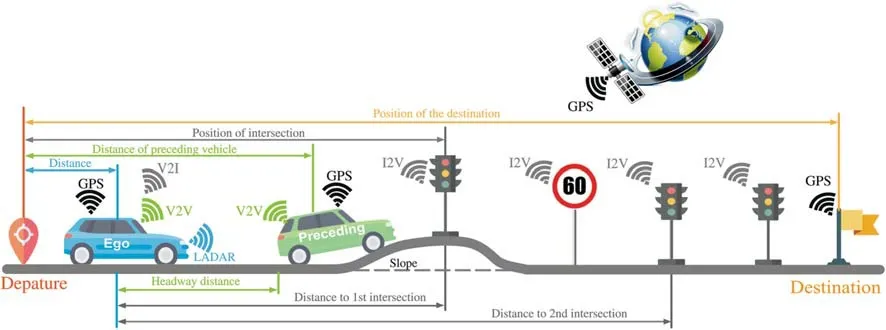

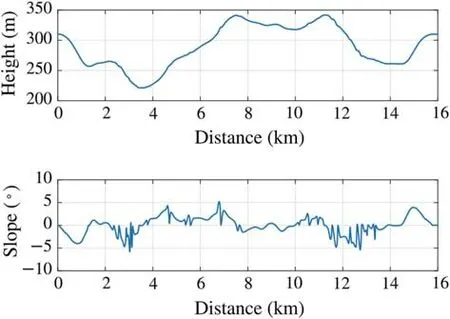

The framework of vehicles in the connected environment is sketched in Fig.1 where the connected vehicles are enabled to communicate with GPS,V2V and V2I during the trip.For example,the V2I information,such as traffic light phase and timing,the distance to the next intersection can be obtained for ego vehicle.The distance headway between ego vehicle and the preceding vehicle should be considered for driving safety and it is available to ego vehicle equipping the distance detecting sensor.The preceding vehicle information,such as distance, speed and acceleration, is transmitted to the ego vehicle through the V2V.On the road,the maximum speed limit based on traffic rule is also considered. The targeted road for this benchmarking is shown in Fig.2, which is a montanic town area and the running route is highlighted by a white line.The data of height and slope along the route is obtained by automotive road tests and the profiles are shown in Fig. 3. When the departure and destination points in the road for ego vehicle are determined, the slope and position of the intersection along the road can be pre-known through GPS information.

Fig.1 Framework of the vehicle in connected environment

Fig.2 Map showing the location of the road in the benchmark problem obtained from Google Maps

Fig.3 Height and slope information of the road

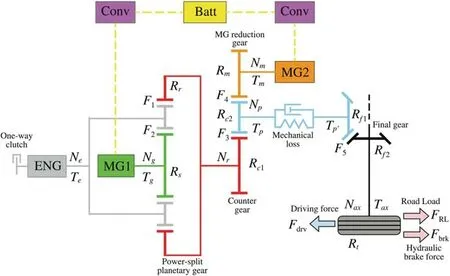

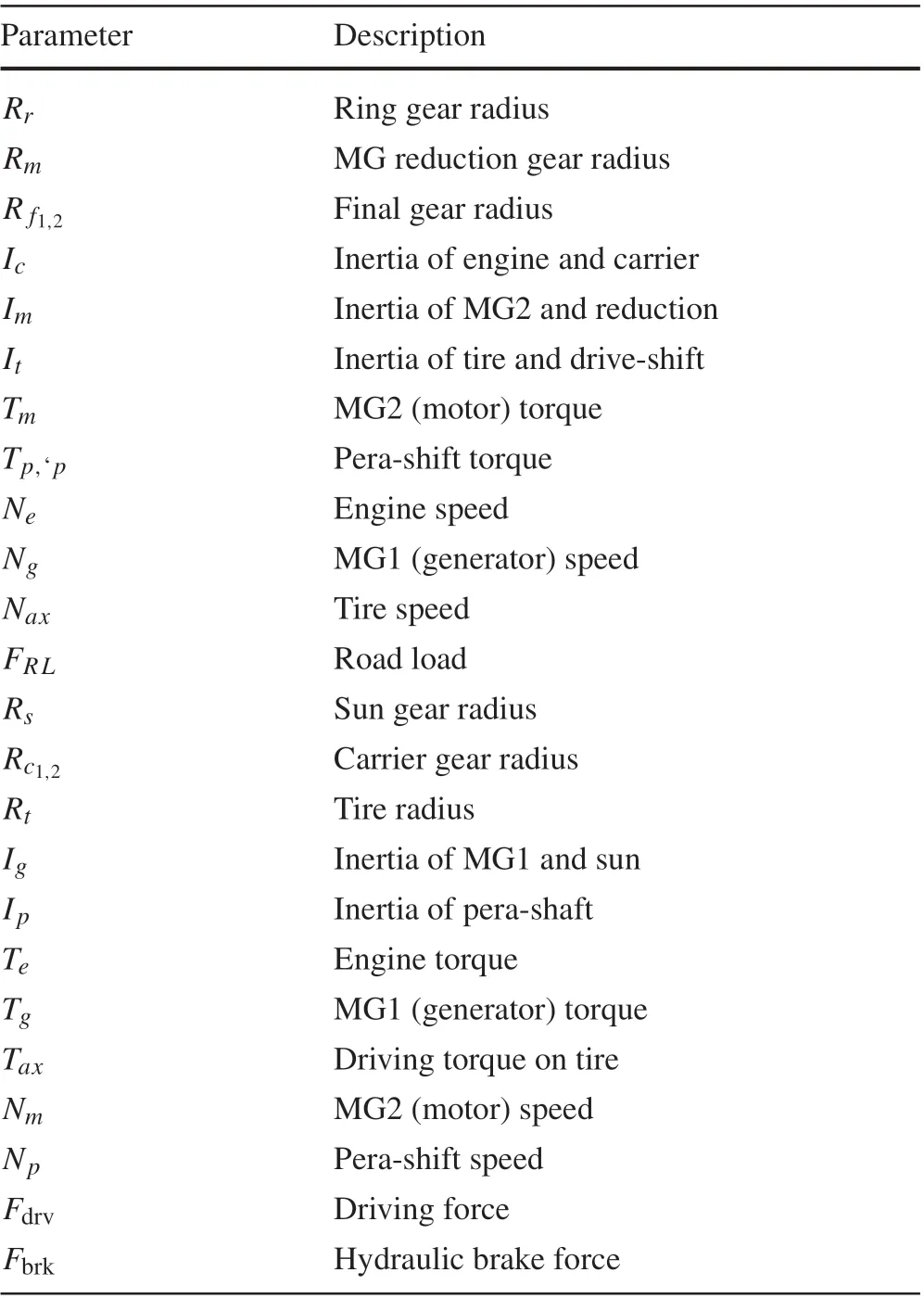

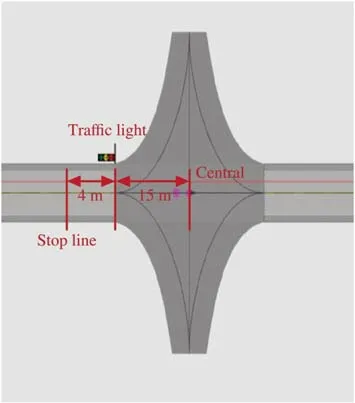

The targeted vehicle is a passenger hybrid electric vehicle with power-split hybrid system and produced by Toyota Motor Corporation.The structure of power-split powertrain system consisting of engine,motor,generator and planetary gear is shown in Fig.4,where ENG,MG1 and MG2 denote the engine, generator and motor, respectively. An engine,a generator and a motor are mechanically connected to the carrier gear, sun gear and ring gear of the planetary gear,respectively. Both MG1 and MG2 are also connected to the battery electrically,where there are converters between battery and MG1 and MG2,respectively.Moreover,the driveline of the powertrain is not rigid in this simulator so that the mechanical loss of the driveline is also considered,seen in Fig.4.The control inputs of the powertrain are torques of engine,motor and generator,and a mechanical braking force is used to compensate for the insufficient generative force by the motors.The detail meanings of the parameters in Fig. 4 is described in Table 1 and the values of these parameters are listed in Table 2.

The goal of the benchmark problem is to develop an onboard optimal energy management strategy for the targeted HEV that minimizes the total fuel consumption when the vehicle finishes the trip along the given route but randomly generated traffic environment.The control scheme proposed by the challengers should drive the vehicle and manage the fuel consumption at the same time, but it is not permitted to overtaking the preceding vehicle.The detailed constraints and competition rules will be presented in the following sections.

3 Proposed simulation system

3.1 Component model and physical parameter

In this subsection,the detailed models of powertrain and battery,and physical parameter of ego vehicle sensor and V2X are briefly explained,respectively.

Fig.4 Structure of power-split HEV

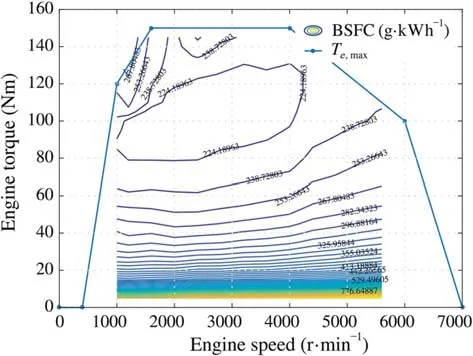

Table 1 Meaning of parameters

3.1.1 Powertrain model

(a)Engine model

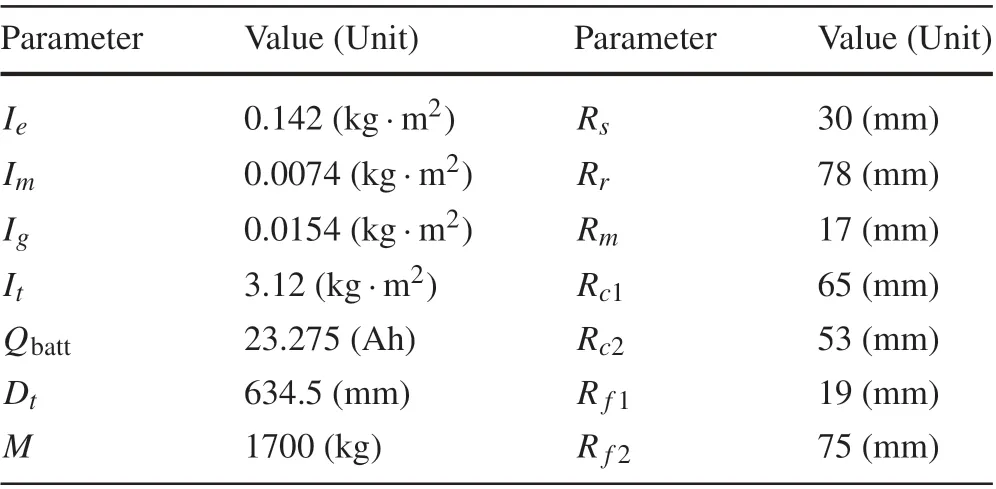

Table 2 Values of parameters

The fuel consumption rate of engine ˙m fis dependent on the engine speedNer/min and engine torqueτe, which is described as a map form, shown in Fig.5. Moreover, the minimum and maximum of speed and torque for engine are forced. The maximum engine torque is dependent on the engine speed.A negative torque is considered when engine is not ignited.All about information is given in the simulator,where the challengers can obtain it.

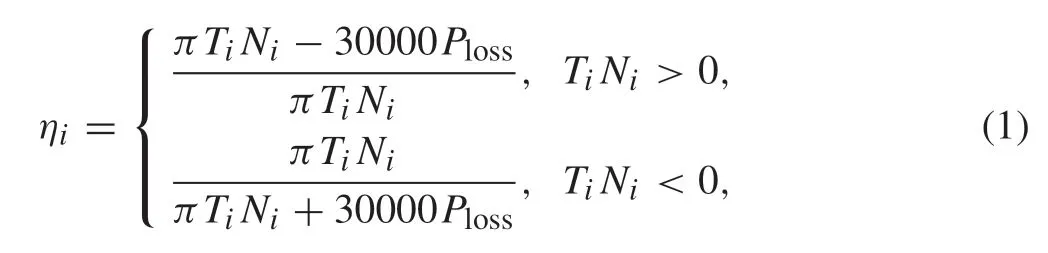

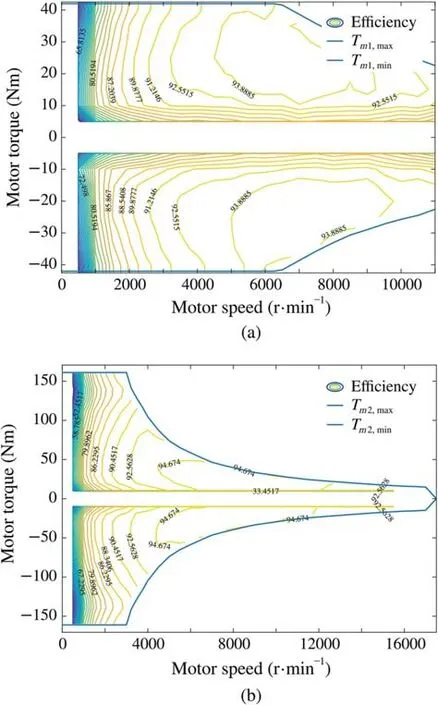

(b)Motors model

As shown in Fig.4, there are two motors in this plenary gear structure,which are MG1 and MG2 treated as generator and motor,respectively.The electric powersPi,i∈[m,g]for motor and generator are related to torqueτiand speedωi.The electric machines modeling are represented as efficiency maps, shown in (a) and (b) of Fig.6. The limitation of speed and torque for motors are also forced.Similarly,the maximum and minimum torques of motor and generator are dependent on the speed.For more information,please see the simulator package. Actually, the power loss is given in the simulator and the relationship between the power loss and efficiencies of the generator and motor can be described as follows:

Fig.5 Map of fuel consumption

wherePlossis the power loss(kW)in motors,which is seen as the mechanical power loss during rotation.It is noted that power loss is not constant and it is dependent on torqueTand speedNof motor and generator.For the reader,please find the map information in the simulator package.

(c)Battery model

For the goal of controller diversity,this benchmark does not provide any detail expression of the battery dynamics.However,inner signals of the battery,including battery current, battery voltage and open-circuit voltage, are available in the simulator.Based on these real-time signals,the challenger can build the SOC model of battery by yourselves.

3.2 V2X

In the real-world traffic scenario with the ability of advanced communication technology, the traffic information is available for the ego vehicle,which mainly consists of geographical information and traffic participants.In the following part of this section, the information obtained from ego vehicle sensor,geographical equipment and other traffic participants will be introduced,respectively.

3.2.1 Ego vehicle sensor

Fig.6 The maps of efficiencies of MG1 and MG2

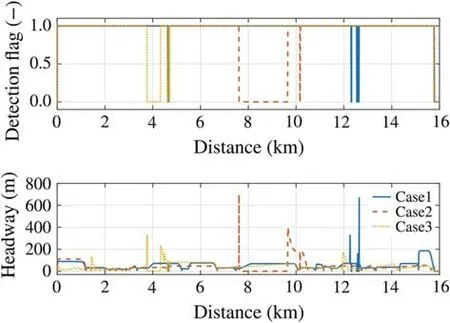

For ego vehicle equipped with sensor,it is possible to detect the inter distance between ego vehicle and preceding vehicle.The real-time signals of the detection flag and distance headway are provided in the simulator.The detection flag signal 1 and 0 denote detectable and undetectable,respectively.If the flag signal is 1,the real-time distance headway is available;otherwise,the value of distance headway is given as 0.The profiles of ego sensor’s information in three traffic scenarios running in the route of Fig.2 are shown in Fig.7.

3.2.2 Geographical information

Although the route shown in Fig.2 is full of turns, it is assumed that the road in this benchmark is a straight one withoutanyturn,butwithintersectionsinthereal-worldpositions and there are traffic lights in these intersections.Thus,the lateral dynamics of the ego vehicle is not considered in this research.The geographical information,including road length, intersections’ location and route slope, is assumed to be available for ego vehicle through GPS.In this benchmark, there are 26 intersections along the road; moreover,it is assumed that the vehicles ahead of the ego vehicle will be disappeared after the 26th intersection and only ego vehicle runs on the link after 26th intersection,whose length is 195m.Above geographical information can also be obtained in the simulator.

Fig.7 Ego vehicle’sensor information of three traffic cases

3.2.3 Traffic participants

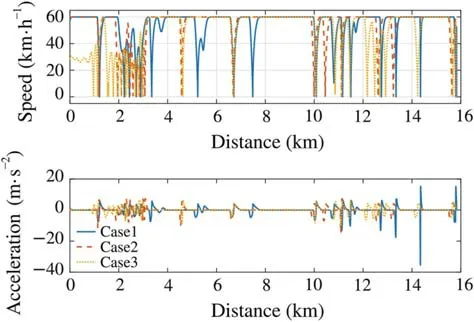

(1) For vehicle running in the real-world traffic scenario,the other traffic participants in the same scenario should also be considered,consisting of traffic lights and vehicles ahead of the ego vehicle. The real-time position,speed and acceleration of preceding vehicle are available to ego vehicle through V2V communication. The profiles of speed and acceleration of the preceding vehicle in three cases are shown in Fig.8.It is noted that the vehicles ahead the ego vehicle are disappeared after the 26th intersection and only ego vehicle runs to the destination.

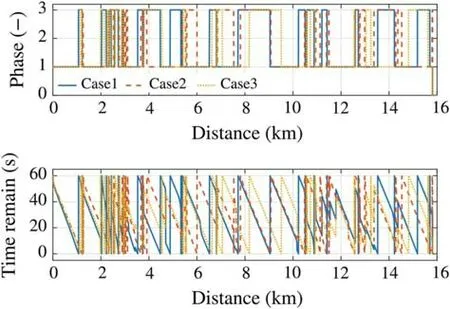

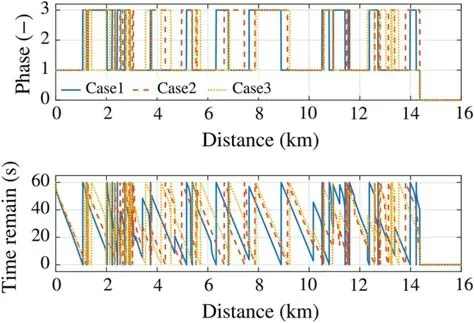

(2) The ego vehicle should follow the rule of the traffic light.It is noted that only red and green signals for the traffic light so that it follows the rule that vehicle runs and stops when facing with the green and red signals at the intersection,respectively.There is a traffic light at each intersection and the distance to the intersection (traffic light)is available to the ego vehicle.Moreover,it is noted that the traffic light phase at each intersection is not identical.In this benchmark,the total traffic light information of 10 data is provided in the simulator. But in the simulator,only on-board traffic lights’s information of next 2 intersections are available for real-time controller.The phases and remaining timings of upcoming 2 traffic lights in three cases are shown in Fig.9 and Fig.10, respectively.In Fig.9 and Fig.10,the phase denotes the traffic light information, where 1 and 3 denote the green light and the red light,respectively.

Fig.8 Speed and acceleration of preceding vehicle of three traffic cases

Fig. 9 1st upcoming traffic light’s remain timing and phase of three traffic cases

Fig.10 2nd upcoming traffic light’s remain timing and phase of three traffic cases

4 Challenging and evaluating

4.1 Challenging issue

The task of the benchmark is to design a controller that achieving the minimization of fuel consumption on the route shown in Fig.1. The real-time dynamic information of powertrain, battery and vehicle are available to the controller.Meanwhile,the real-time traffic scenario information,including ego vehicle sensor, GPS, V2I and V2V, are also provided to the controller. The challengers can be selective to use above real-time information.Moreover,the safety constraints, including vehicle speed and distance headway between ego vehicle and preceding vehicle should be satisfied.On the one hand,the physical constraints of powertrain,battery and vehicle should be satisfied. On the other hand,the stop constraint when facing a red traffic light at the intersection should be considered.Next,the four tasks above will be introduced in detail.

4.1.1 Fuel consumption

The main goal is to improve the fuel economy of HEVs in the connected environment under the constraint of travel time.With set of initial and terminal SOC,the goal can be seen as the minimization of fuel consumption of engine. Since the start point and terminal point are fixed,the goal of this benchmark is also to reduce the travel timet fin this road.However,overtaking behavior is not allowed in the traffic scenario.To minimize the total fuel consumption is the main objective of this benchmark problem.However,the electricity consumption calculated by the difference between the initial and the terminal SOC will be taken into account by the total fuel consumption mass(see the following section for details).

4.1.2 Physical constraints

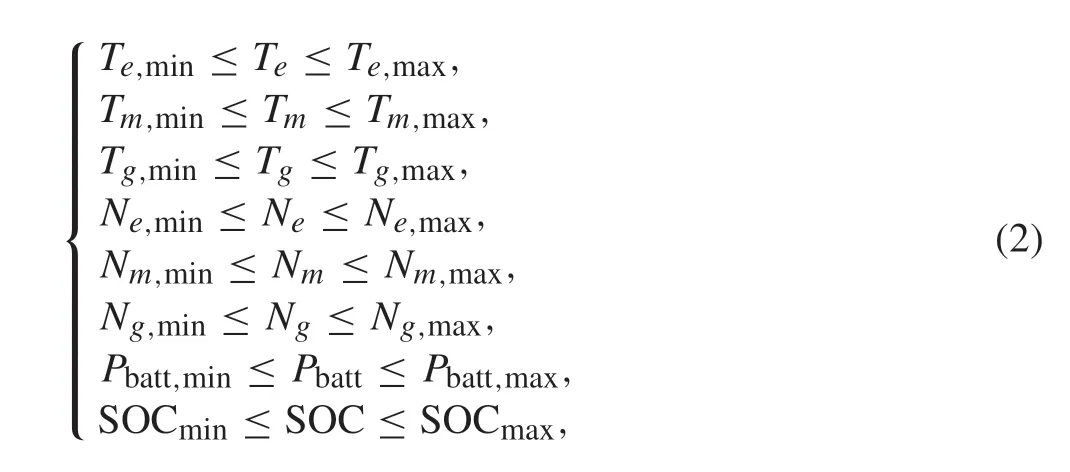

The physical limitations of powertrain, including engine,motor and generator,and the battery that the vehicle has to follow are written as follows:

where the minimum and maximum torque of engine,motor and generator are also dependent on corresponding speeds,respectively. And the detail values of other parameters are listed in Table 3.

Table 3 Values of minimum and maximum parameters

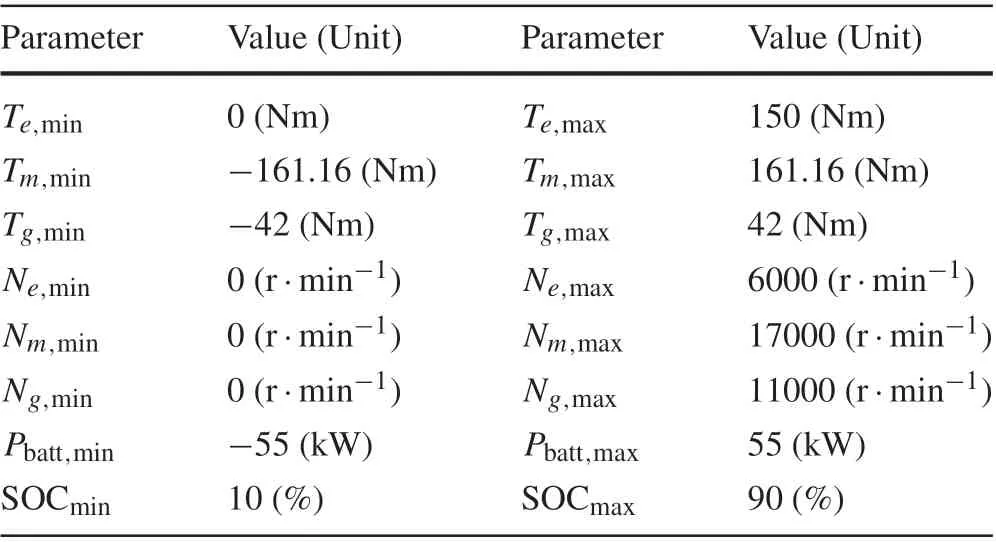

On the other hand, the initial conditions of powertrain,vehicle and battery are also determined:

wherexdenotes the traveling distance of ego vehicle.

4.1.3 Boundary constraints

(1) The headway distancesbetween ego vehicle and preceding vehicle for driving safety should be considered,which is shown as follows:

wheresminis the minimum allowed distance headway andhdenotes the driver reaction time.

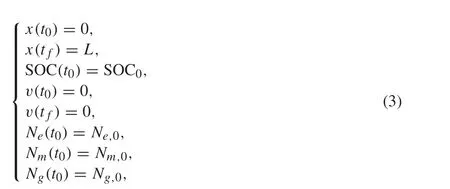

(2) Since there are traffic lights at the intersection along the route,the vehicle should stop before the stop line when thetrafficlightisinred.Inthisroute,thedistanceoftraffic light to the central of intersection is set as 15m and the distance of stop line to the traffic light is set as 4m, as shown in Fig.11.When the traffic light is red,the vehicle has to stop before 19m to the central of intersection. It is noted that the central of intersection is the end of the previous link and the start of the new link. If the ego vehicle does not stop before the stop line when facing the red light,a punishment time will be added to the actual travel time.

Fig.11 The distances of stop line and the traffic light to the central of intersection

4.2 Evaluating

The performances of submitted controllers are evaluated in other 3 random traffic scenarios,where the road and slope are the same as the sample data that have been provided in the public simulator.Mainly,the traffic densities on the links and initial phase and timing of traffic lights in the 3 random traffic scenarios are different from these in the sample data. The championship evaluating processes are conducted through the following items.

4.2.1 Disqualification

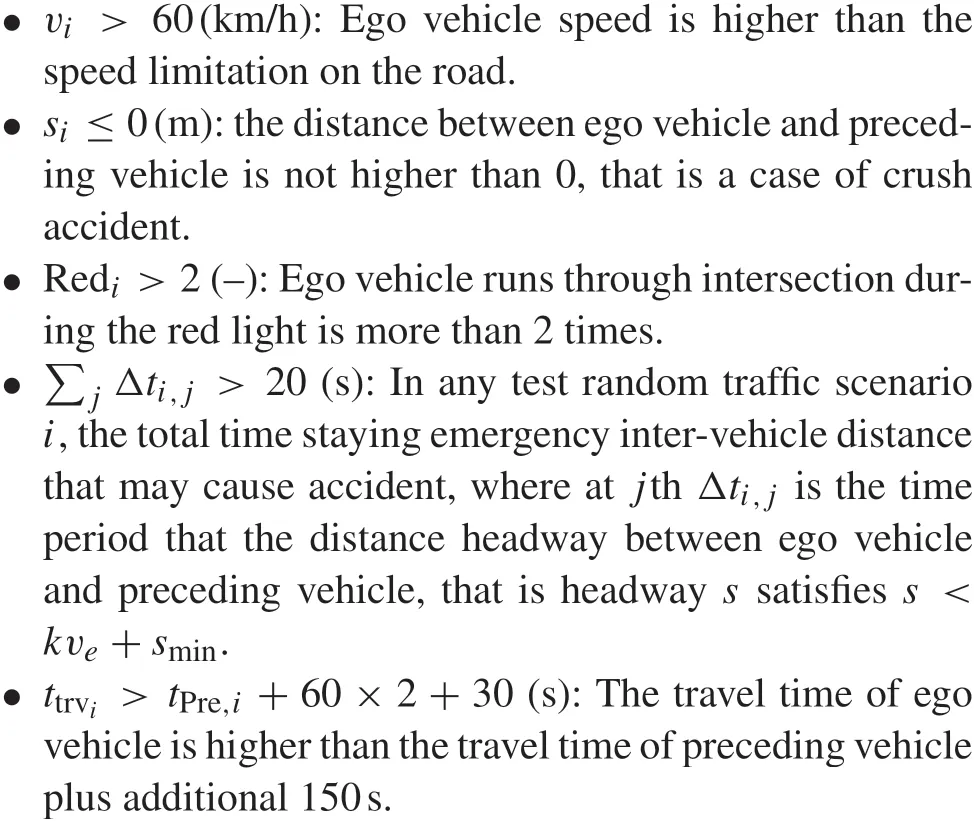

The challenger will be disqualified if one of the following rules is broken by the challenger:

4.2.2 Scoring

The total fuel consumptions in the 3 testing traffic scenarios are used to obtain the score for each challenger.The fuel consumption and the arriving time will be evaluated individually with the following methods:

(1) Total fuel consumption

wherem f iandt f iare the total fuel consumption mass and arriving timing, respectively. When SOC0-SOC(t f i) <0,there is electric energy saved in the battery;SOC0-SOC(t f i)>0 denotes more electric energy is used for propelling the vehicle. To calculate the fuel consumption accurately, SOC0- SOC(t f i)should be transformed to fuel consumption by using the equivalent factorγ >0.iindicates the index of testing scenario.Based on the energy consumption of patterns of pure engine and pure motor,the equivalent factorγis set as 25.

(2) Travel time

where the second term is the penalty for red light crossing,which means each time of red light crossing would plus additional 60s.With satisfaction of the physical and boundary constraints that are shown in subsections of Sect. 5 and removing the disqualified challengers, the championship goes to the one challenger with the least total fuel consumption in the rest challengers.

5 MPC-based optimal control scheme

5.1 Proposed control scheme

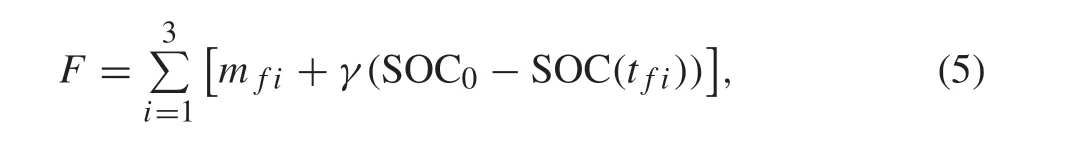

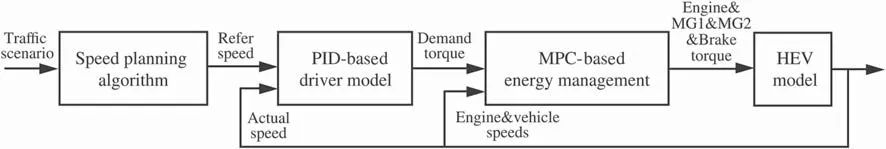

The block diagram of the control scheme for this case study is shown in Fig.12.Based on the traffic scenario,a speed planning algorithm is used to obtain the optimal reference speed.This algorithm is achieved by the IPG CarMaker,where the flowchart of this algorithm is shown in Fig.13. The reader can obtain more detail information on this speed planning algorithm in the User Manual Version 7.1.1 IPGDriver.

Withthedifferencebetweenreferencespeedandtheactual speed,a PID-based driver model is used to derive the demand torque.In the MPC-based energy management strategy,the predictive horizon is set as 8 steps and the sampling time is 0.1s.It is noted that without prediction of demand torque,the further torques in the prediction horizon are set as same as

Fig.12 Block diagram of the control scheme in case study

Fig.13 Flowchart of the vehicle speed planning

the current one.The state variables for energy management strategy are vehicle speed and engine speed with consideration of the powertrain motion.The control inputs are set as engine torque and generator torque. Then the motor torque can be calculated under determination of demand torque,engine torque and generator torque. Moreover, the braking mechanical force is determined through a rule-based controller.

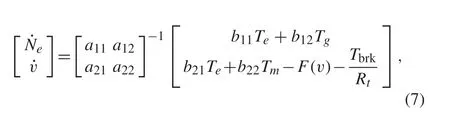

The dynamic model that describes the HEV powertrain system is employed based on the mathematical model written in Eq.(15)in[5],which is shown as follows:

whereai jandbi j(i=1,2;j=1,2)are the parameters that are determined based on physical rules.

The designed energy management strategy consists of driving mode decision and MPC-based controller. In the driving mode decision,the modes between EV(energy generation in the braking scenario) and HEV are determined through the demand torque from driverTdr, shown as follows:

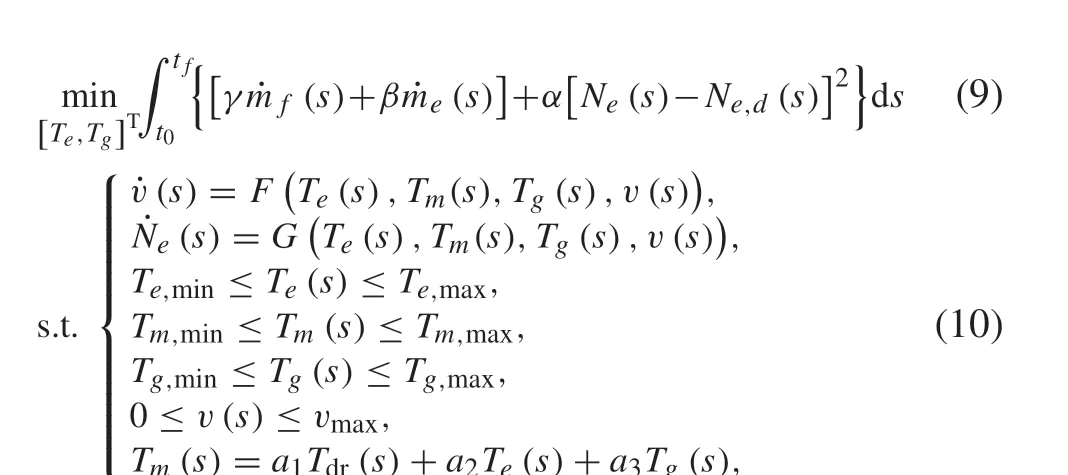

In the HEV mode,to reduce the computation burden,the MPC-based controller is only activated when the demand acceleration reaches a specific value, which is seen as the driver demand torque reaches a specific value.For the MPCbased controller,the goal is to minimize the energy consumption in a monetary sense, including the fuel consumption and electricity consumption. Meanwhile, the tracking performance is considered between the actual engine speed and theoptimalenginespeedNe,dthatisderivedthroughtheoptimal line of engine torque and engine speed.The constrained optimal control problem is formulated as follows:

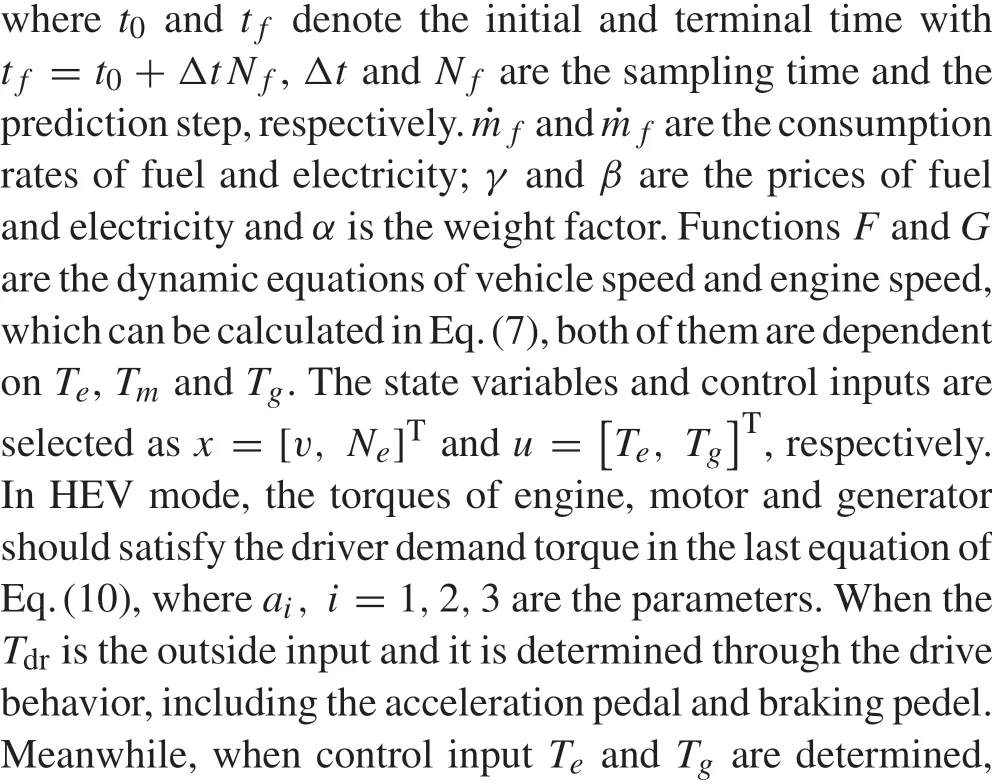

Fig. 14 Flowchart of model predictive control algorithm with SQPbased optimization solution

The constrained nonlinear optimal control problem is discreted firstly and solved by the sequential quadratic programming (SQP) approach to derive the optimalTeandTgin the HEV mode.The flowchart of model predictive control algorithm with SQP-based optimization solution to solve the receding horizon optimal control problem in Eqs.(9)and(10)is given in Fig.14.It is shown in the flowchart that the initial parameters,such as minimum and maximum constraints of state variables and control inputs,the prices of gasoline and electricity and the weight factor,should be given.The initial optimal control problem is converted into a nonlinear programming problem and it can be solved by SQP.For detailed information on sequential quadratic programming approach shown in Fig.14,please refer[37].

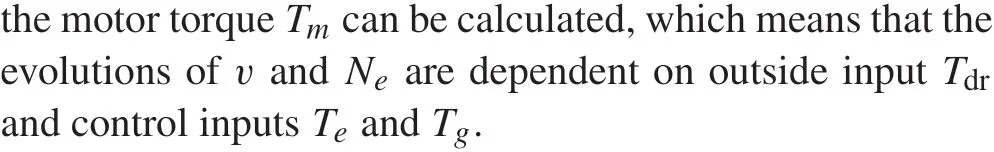

Fig.15 Vehicle speed in case 1

5.2 Simulation validation

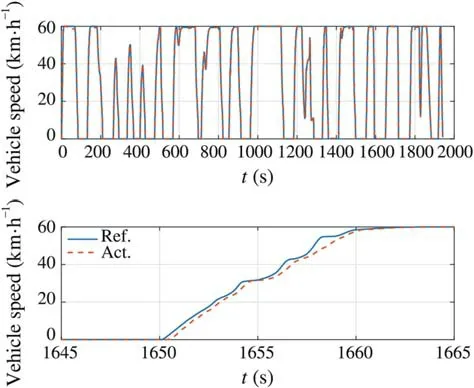

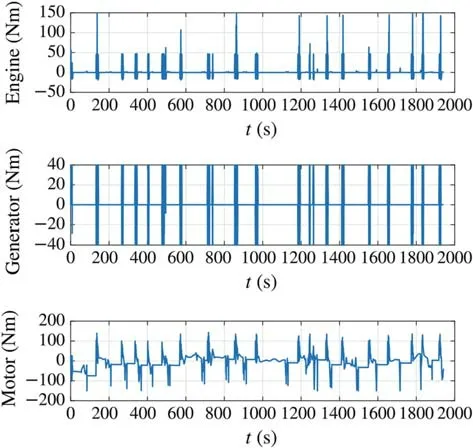

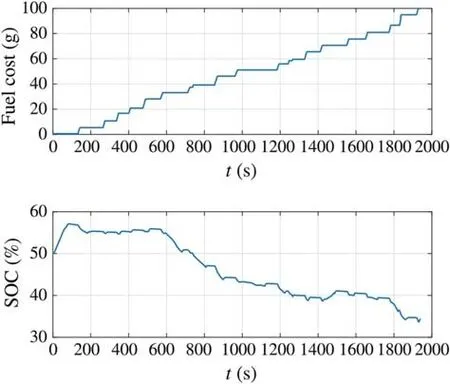

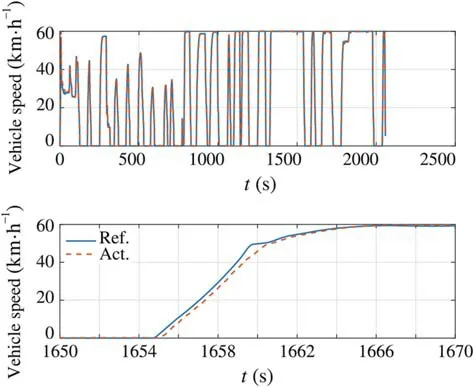

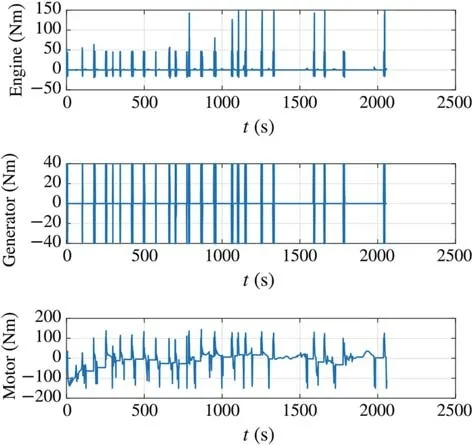

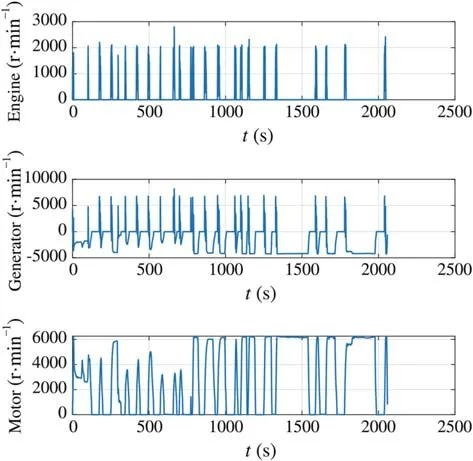

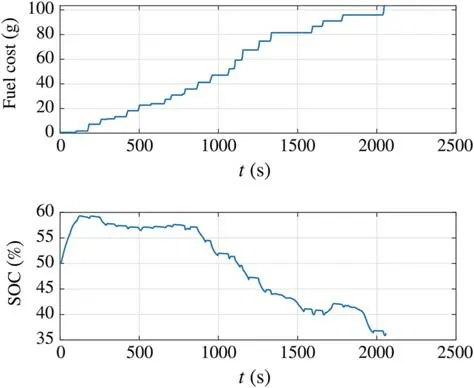

The simulation results in case 1 are shown in Fig.15-Fig.18.In Fig.15, it is shown that the actual speed can track the demand speed well;however when there is high acceleration demand at the high vehicle speed,the tracking performance is not that good because of the powertrain performance limitation. Fig.16 and Fig.17 show the torques and speeds of engine, generator and motor, it can be concluded that the torque and speed can satisfy the powertrain physical constraints. Moreover, the negative motor torque denotes that HEV is in regenerative mode and kinetic energy is converted into electric energy by motor.The fuel consumption in engine and electricity consumption in battery (SOC) in case 1 are also shown in Fig.18.Since the SOC dynamics in the energy management strategy proposed in this paper is not considered in the optimal control problem,the terminal SOC is relatively low.

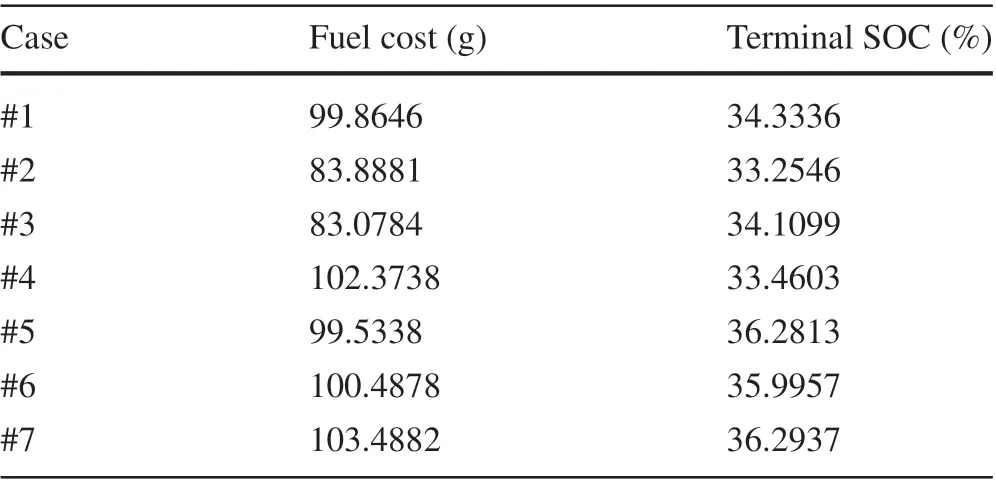

Moreover,the simulation results in case 2 are also shown in Fig.19-Fig.22 and the similar conclusions can be obtained through these results. The performance comparison under different cases are given in Table 4,including fuel consumption,terminal SOC and total travel time.It is noted that the SOC at the initial time is the same in different cases,which is set as 50%.

5.3 Discussion

Fig.16 Torques of engine,generator and motor in case 1

Fig.17 Speeds of engine,generator and motor in case 1

(1) It is seen that the control scheme in this case study includes two layers.In the first layer the vehicle dynamics is optimized and the powertrain operation is controlled in the second layer.However,the planning vehicle speed in the first layer does not consider the physical limitation of powertrain. When the vehicle speed is high,the high acceleration demand can not be achieved even though both engine and motor work in maximum torque states, shown in the lower curve of Fig.15 and Fig.19.Therefore, the optimization of vehicle dynamics and powertrain operation jointly is very important or in the planning of vehicle speed, the powertrain constraints,such as maximum engine torque (dependent on engine speed),should be taken into account.It is noted that the control scheme in the case study is only used to show the problem of the benchmark.The designed control scheme by the challengers can actually be any form.

Fig.18 Curve of SOC in case 1

Fig.19 Vehicle speed in case 2

(2) In the optimal control problem of the case study, the SOC dynamics and the terminal SOC are not considered so that the terminal SOC is free and it is lower than the initial SOC in this case study. Therefore, there are electric energy from the battery is used to propel the vehicle. The additional electricity consumption should be transformed into fuel consumption based on theγ.

(3) In this MPC-based energy management strategy for HEV powertrain,SQP approach is employed to solve this nonlinear programming problem that is converted from the original optimization problem.In the simulation process,the SQP toolbox named as “fmincon” in MATLAB is used to derive the optimal solution.The computation time in each step is dependent on the predictive step of the MPC problem and the SQP toolbox to solve this problem is fast.On the other hand,the on-board control and practical application of proposed algorithm is also dependent on the predictive step, which can be archived by the improvement of computation ability of the electronic control unit(ECU).

Fig.20 Torques of engine,generator and motor in case 2

Fig.21 Speeds of engine,generator and motor in case 2

Fig.22 Curve of SOC in case 2

(4) The proposed energy efficiency optimization algorithm of HEVs for this benchmark problem mainly consists of speed planning algorithm and energy management strategy.In the benchmark,it is assumed that the ego vehicle in the traffic scenario only with a single lane and without overtaking behavior. Whereas, in the real-world traffic condition,there may be vehicle on the other lane inserting in or out of current line.In this case,the speed planningalgorithm in Fig.13 should be modified with the new consideration of inserting vehicle and moving out vehicle.

Table 4 Performance comparison under different cases

6 Conclusions

In this paper, a benchmark problem for optimal powertrain control of power-split HEVs using V2X information is proposed.A simulator of HEV in connected environment is provided and built in the MATLAB/Simulink platform,which consists of V2X information communication and HEV model.Thetaskof thebenchmarkis todesignanoptimal controller on a fixed road with slope to improve the performances of the fuel economy; meanwhile several criteria have to be fulfilled,suchasthetravelsafetyandtraveltime.Acasestudy is given to show the characterisers of the powertrain and it is also shown the necessity of optimal powertrain control with consideration of V2X information.Finally,it should be noted that the benchmark problem addressed here is also open to challengers from academic and industrial community.

杂志排行

Control Theory and Technology的其它文章

- Stochastic model predictive braking control for heavy-duty commercial vehicles during uncertain brake pressure and road profile conditions

- Characterizing human driver characteristics using an artificial neural network and a theoretical model

- On-board torque management approach to the E-COSM benchmark problem with a prediction-based engine assignment

- Speed planning and energy management strategy of hybrid electric vehicles in a car-following scenario

- Torque control strategy with V2X information for HEVs to minimize fuel consumption

- Optimization of fuel consumption and NOx emission for mild HEV via hierarchical model predictive control