Establishment and Application of Food Traceability System Based on SWOT Analysis

2022-04-28LIWanyaQUGeMaryWongYANGFangqiong

LI Wanya, QU Ge, Mary Wong*, YANG Fangqiong

(1.Faculty of Science, University of Hong Kong, Hong Kong 999077, China)(2.College of Mechanical and Electrical Engineering, South Central University, Changsha 410000, China)

Abstract: Food traceability system refers to the ability to track and trace the process covering all links in the food industry chain, which plays an important role in food safety. Although China has promulgated various regulations to strengthen food safety, some gaps in the implementation process may reduce the effectiveness of the law. Based on the current situation a mixed method of data collection was adopted to achieve two objectives: to explore factors affecting the adoption of food traceability systems in China and to construct a food traceability system for a medium-sized restaurant in Hong Kong. In particular, a quantitative method involving a structured questionnaire analyzed the factors affecting food traceability systems, while a case study approach was applied to conduct a thorough SWOT analysis of the proposed food traceability system. The results indicate that consumers’ psychographic characteristics, socio-demographic profiles, and consumer cognition of food safety affect food traceability systems. The SWOT framework revealed that, despite the internal weaknesses and external threats to the proposed system, organizations can take advantage of the strengths and existing opportunities of the system to operate the tool. Literature reference, questionnaire survey and field investigation are used as methods respectively in project, then a traceability system for Wing's Catering was designed and this system was analyzed by SWOT analysis. As a result, the system is simple to operate within low cost, and it is suitable for similar specification like Wing's to apply food traceability.

Key words: food traceability; tracking and tracing; food safety; batch number; QR code

The growing trend of globalization has resulted in consolidation across various food categories and in food supply chains, posing a threat to food safety. With the dramatic changes in information technology, both developing and developed countries have adopted food traceability systems to reduce buyer uncertainties during the purchasing process to enhance quality and safety[1].Food traceability refers to the logistics (movement)management process that captures, stores, and transmits details about food systems across the supply chain to enable quality assurance, upward tracing, and downward tracing. Traceability plays a critical role in the food market, which involves tracing and tracking activities. As early as the 1990s, many countries with a high rate of agricultural exports began to study the food traceability system[2]. In 2002, the European Union established the EU Food Safety Authority and subsequently implemented a traceability system for food, feed, and raw materials to address safety and quality issues in processing, storage, and distribution in the entire food chains. In 2013, the United States established the Global Traceability Center to support multidisciplinary activities by integrating enterprises, governments, foundations,consumers, and experts to enhance traceability in global food chain systems. In 2016, the China Food and Drug Administration initiated a national project to create a prototype for a food traceability system in China[3].

Since the outbreak of the bovine spongiform encephalopathy (BSE) virus in 1986 in England,governments have established stringent public health measures to reduce health risks. BSE is a disease that affects the spinal cord and the brain in human beings and animals[4]. Following the BSE outbreak, organizations and governments address food safety, quality, and assurance concerns using a tracking system[5], for example, China’s new laws on the food industry, which were launched on June 1, 2009, require organizations to use traceability systems[6]. Despite the enactment of the law, one of the greatest challenges regards the laxity in the implementation of a framework of inspecting and certifying the tracking system for traceable foods in order to reestablish confidence in the food system due to the vague responsibilities of food safety regulators[7].

The implementation of Good Manufacturing Practice (GMP), ISO 9000 and Hazard Analysis Critical Control Point (HACCP) systems can effectively control the microbiological, chemical and physical hazards in the processing process to some extent. Although these systems play a great role in quality control, they are not adequate to ensure the safety management of the entire food chain[8]. In addition, the government and other stakeholders in the market do not apply strict measures to ensure adherence to the rules and regulations, resulting in food fraud and food safety problems due to economic opportunism. This situation has become increasingly severe with the rapid globalization of the food supply chain[9].

Moreover, due to the widespread existence of small workshops and the ineffective traceability systems of some enterprises in China, a significant number of products in the food market lack proper labels and abbreviations such that it is difficult to trace their origins[10]. In addition, China has experienced various food safety incidents, such as, the Jinhua ham dichlorvos incident, in which producers added highly toxic pesticide,resulting in major economic losses[11]. Research shows that a reliable food traceability system is a technological and scientific contribution that will promote agricultural sustainability[12]; thus, reliable and confirmable food authentication and traceability system have become essential[13]. However, under the perspective of food supply chain, a gap in literature exists, particularly on issues related to the hazardous elements, information transfer, traceability chain construction, and the whole construction process of the system from farm to desk[14].Therefore, a way is provided to establish food traceability system for a specific catering organization and then the system is evaluated its advantages and disadvantages through SWOT analysis.

The following objectives are aimed to achieve:

-To explore factors affecting the adoption of food traceability systems in China

-To construct a food traceability system a medium-sized restaurant in mainland China

2 Methodology

2.1 Research Design

The researcher adopted a mixed research approach to collect data about food traceability systems. Firstly, the research applied a quantitative method by administering questionnaires to the respondents. Secondly, the researcher used a case study method to create a traceability system for Wing’s Catering. The author explores Wing’s Catering’s new traceability system using SWOT analysis. In order to evaluate Chinese consumers'cognition of traceable food, satisfaction with traceable food, and the purchase intention of this kind of food, a structured questionnaire based on primary survey was conducted using a convenience sampling method. The questionnaire had a total of 15 related questions based on previous experience[15]and the current food safety situation. Considering the average age distribution of the respondents, online and offline methods was adopted to issue questionnaires. In total 325 participants completed the questionnaire, yielding 100% response rate. The respondents came from 24 different provinces and cities,covering more than half of China.

2.2 Survey Instrument

As indicated, the structured questionnaire evaluates consumers’ cognition of food traceability and factors influencing their intentions to purchase. In addition, the questionnaire comprises information about the socio-demographic profiles of the participants. In order to measure factors associated with traceability systems, for example, satisfaction levels and buyers’ intentions to purchase; a 5-point Likert scale was designed with the following measures: 5 (highly satisfied), 4(very satisfied),3 (satisfied), 2 (somewhat satisfied, 1(not satisfied). To measure the psychological antecedents or the perceptions of the buyers, a ranking method was used that comprise of the following items: 1). Risk value (high risk, low risk).2). Food properties (shelf life, taste). 3). Food production line (raw materials). The reliability of the scale was evaluated through a pilot survey of 20 respondents, which enabled to make the necessary adjustments.

3 Results and Discussion

3.1 Satisfaction with Food Traceability Systems

Based on the results, a large percentage of the respondents expressed their dissatisfaction with food traceability systems in China (Fig.1). The reasonable levels are that consumers do not often effectively monitor food safety issues, such as food-borne diseases due to the lack of traceability systems. In reference to the concept of Traceable Resource Unit (TRU), the internal and the external nature of the food item is important to consider.Thus, the internal batches and other commodities traded in the external supply chain could be valuable to the organization and its customers. The TRU identification number, data of production, and the raw materials used are some of the main aspects of a commodity that are important to a consumer. The majority of the respondents(about 76%) expressed their dissatisfaction with the current food safety situation, which indicates that China should improve on food safety supervision. At present,China exhibits insufficient food safety supply chain management due to ineffective tracking of food supply chain problems, poor foresight, inaccurate prediction and inadequate planning of food supply chain problems,making it more difficult to achieve the dual optimization goals of food safety and corporate profitability. Therefore,the government should fully assume its responsibility by increasing publicity efforts and guaranteeing food safety to enhance consumer’s confidence. In recent years, the relevant authorities in China have issued a series of guiding documents on promoting the construction of food traceability system, and relevant departments are actively exploring the construction of food traceability system[16-27].

3.2 Psychological Antecedents and Food Traceability

Our survey indicates that about 76.92% of customers are willing to pay a premium price for a product with traceable information. Therefore, the respondents demonstrated a strong preference for food traceability. Based on the ranking scale, the respondents generally believed that meat products are the most prone to safety accidents followed by dairy products. Although past research indicates that many consumers prefer ready-made frozen food, for example, white and red meat supplied through original equipment manufacturers(OEMs) technique, because of the perception that it is healthier and safer than traditional foods, the results indicate that consumers seem attribute the highest percentage of safety accidents to meat products.Regarding food properties, the respondents demonstrated greater concern for a product’s shelf life followed by taste.Therefore, organizations should invest in appropriate food labels to present the expiration time and storage condition to ensure actual shelf life. Finally, the respondents emphasized the need for accurate information about raw materials and processing information in that order in the whole foods production line.

3.3 Consumer Cognition, Information Seeking Behavior, and Food Traceability

The results do not confirm our hypothesis that socio-demographic factors, such as, the education level have a positive relationship with food traceability.Notwithstanding their high educational levels, some respondents demonstrated limited awareness about food traceability. However, only the educational component of the socio-demographic characteristics indicated a negative relationship with food traceability, which could be attributed to the weaknesses of the convenience sampling method applied in research.

The results confirm our hypothesis that consumers’information-seeking behaviors or cognition has a direct positive influence on food traceability. When buyers inquire about the information related to traceability, they utilize the QR code and the official website to confirm the details. With the rapid development of information technology, people are more inclined to scan the QR code due to its large capacity, good confidentiality, high damage resistance, good error correction, and high rate of effectiveness[28].

Currently, although governments and some enterprises have developed and promoted many traceable network platforms their utilization is still low because of low efficiency. What is more, many Chinese organizations have not implemented traceability systems in their infrastructure. The lack of interoperability and coordination between the government and business enterprises lead to the low utilization rate of information regarding traceable system network platforms.

Nearly 97% of the respondents believed that food-testing reports should be included in the traceability information. Although only an insignificant percentage of the respondents noted that they would check the inspection reports carefully, availing inspection reports to the public can improve consumers’ general satisfaction levels about food safety traceability information. In addition, this approach encourages the masses to supervise the product quality of their suppliers. Because the majority of the consumers believe that meat products are the most prone to safety accidents, mainland China was chosen as the business pilot and a series of feasibility analysis was conducted based on the current national conditions and the operating conditions of the restaurant.

3.4 Establishing a Food Traceability System for Wing’s Catering

Wing's producing line is similar to McDonalds’because both of them follow the original equipment manufacturer (OEM) concept, in which a company produces parts and equipment that may be marketed by another manufacturer. (Fig.1) Therefore, Wing’s Catering does not have a central kitchen in all its franchises.

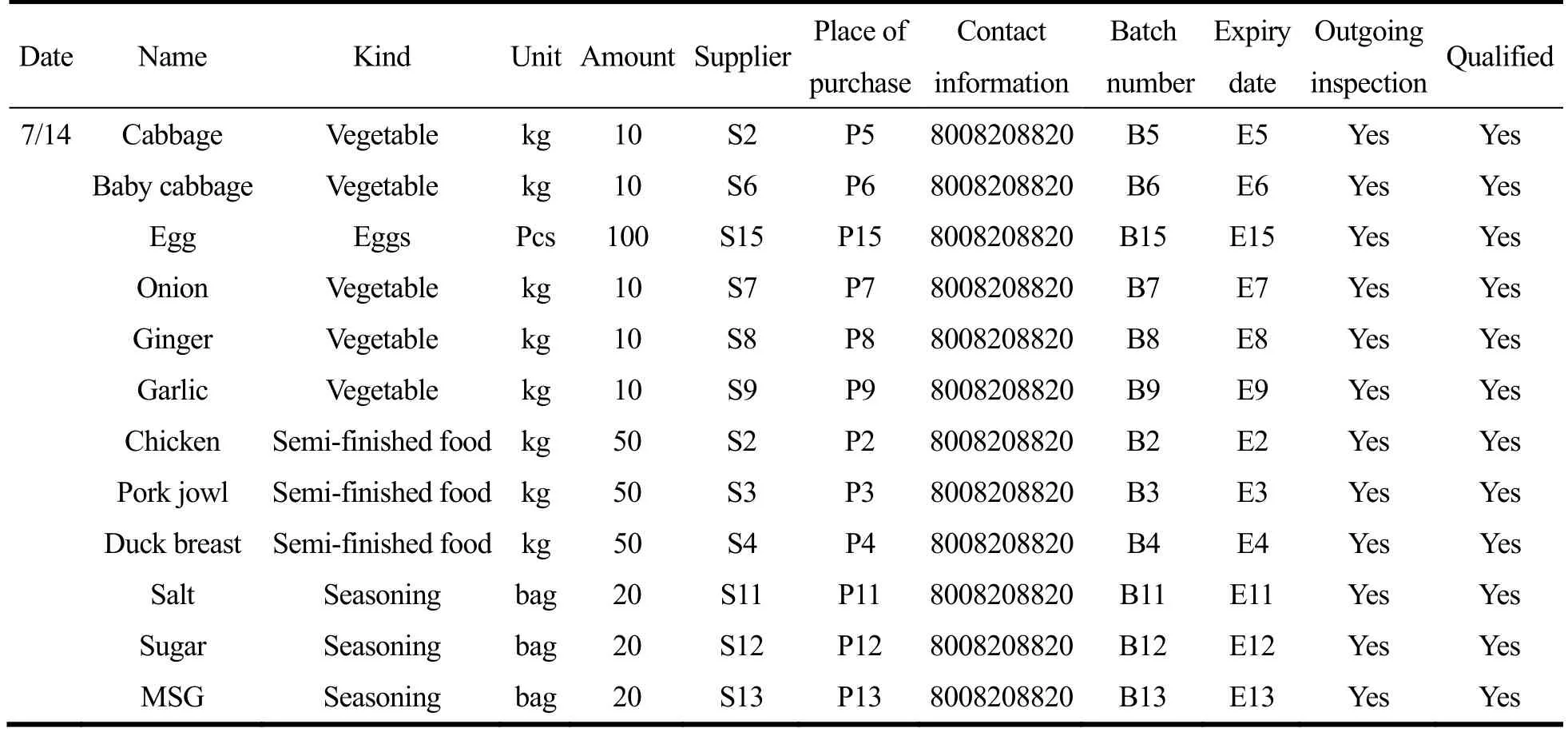

Wing’s Catering’s raw chicken and pork can be tracked from Shandong, China. At present, the organization vacuum seals the marinated chicken steak and uses a transparent plastic bag for packaging. Once they are properly packed, the firm adds a simple label with the product’s name, shelf life (limited to one month),storage temperature, and weight. However, some of the other commodities do not have detailed records. In order to improve the process of inventory management, in particular, purchasing and storage records of the restaurant, excel was used to maintain records for traceability purposes (Table 1).

Table 1 Example of filling purchasing information

When filling in the information, the content should be completed, the abbreviation or abbreviation of the name of the unit should be unified, and the corresponding table with the full name of the unit should be provided. In addition, any numeric and alphanumeric data, including signatures, should be clear, legible, and not easily erased.An amendment to the data should involve corresponding signatures or seals for verification purposes. Information records should be filled in or collected during the shift,and should not be amended after the event to ensure accuracy. The auditor and the person filling the record should double-check the information and sign it to confirm the clarity and completeness of the record. The signature requirements of electronic recording shall comply with GB/T 25064. Additionally, all records should be properly maintained for at least 2 years.

This traceability system is hinged on the theoretical construct of Object-Oriented Programming (OOP), which is a programming concept that involves data and methods to achieve an objective. In this system, each TRU represents an object with several attributes, for instance,batch number, production date, and product type among others. The golden rule in traceability systems is that each transaction must have a supporting documentation. In fact, scholars argue that traceability systems are non-discriminatory and generic, in such a way that they record information in the entire production process.

Regarding electronic data processing, the most important aspect is to design an appropriate batch number to trace the relative information easily. Batch number is an identification number assigned to a particular quantity or lot of material from a single manufacturer. Batch numbers, which are typically found on the surface of the packaging material, enable the tracing of the constituent parts or ingredients and labor and equipment records involved in the manufacturing of a product. This enables manufacturers and other entities to perform quality control checks, calculate expiration dates, and issue corrections or recall information to subsets of their production output. Moreover, batch numbers allow consumers to locate the identifier that they can use in contacting the manufacturer and researching the production process involved in making the goods received. For example, consumers can trace the origin of fish or meat, in case of a public health problem. Some batch numbers are generated with the use of date and time stamps to help identify a specific lot.

The license plate principle was adopted, which is also known as person number principle, in assigning TRUs and TRUs identifiers. This approach emphasizes the importance of using a unique internal identifier for each commodity. The internal production batch number was chosen as the main identifier because it is the most common TRU in the food industry. Although some organizations use multiple TRUs on several food items,this method could diminish the effectiveness of the traceability system in the long-term view, especially when the operator intends to make new transformations[29]. Transformations occur when the operator join and split TRUs or when new TRUs are created based on existing ones. The transformation types in a traceability system may include join, mix, and split transformations.

There are two steps to setting up lot and serial attributes. First, the lot and serial contexts must be defined. Contexts are supported by descriptive flex-fields,so the setup is identical to the setup for descriptive flex-fields. Second, the default context must be assigned to item categories and, if appropriate, items. The reason for this step is that standard descriptive flex-field functionality requires the reference field for the context to be on the Transaction form. The Item Category field is not on the Transactions forms. Therefore, this additional piece of functionality was built to drive the context of the item category[30].

In Wing’s catering, unique TRUs and TRU identifies was developed for each batch number and commodity.For example, a lot code was created for each drink and food item. While it is possible to create transformations,for example, by merging or adding new lot codes to a particular batch number of identifiers, each lot code was ensured to be unique. Products with universal batch numbers, for instance sugar, salt, soy sauce were easier to classify than those that required the development of a new identifier. Several factors were considered, such as,receiving data, shelf life, product category, and serial number to assign the relevant batch number. Because the standard category of OEM food is 01 due to its semi-finished elements, particular standard was adhered to enhance electronic interchange (IED) and supply chain traceability.

The following is an example of setting batch numbers for the materials without the original lot number(Table 2).

Table 2 Example of the batch number

For purchasing information consolidation, a database using Access was created, in which the storage record information follows a similar approach. A list was designed as the information record of purchase part through a website (https://www.wjx.cn/newwjx/manage/myquestionnaires.aspx). Employees can use their mobile phones to fill in relevant information by clicking on the website or scanning the special QR code. Upon submitting the list, the staff can check the submission time and relevant content from the Internet. If any abnormal conditions occur while the employee is filling in the blanks, they should click the "abnormal" button and a new filling box will appear to input the details.

Throughout the food supply chain, labeling plays an extremely important role in traceability. The information of each link in the food chain should be marked during production and transportation. Besides, information about the previous link (suppliers) should be collected to foster chain traceability. At present, the available identification codes mainly include read-only bar code, QR code,electronic tag code (RFID). This system includes a quick response code that enables customers to track the traceability process and make healthy choices. The developed menu data to be used in code generation using a website (https://cli.im/). In the future, the Internet of Things (IoT) was intended to leverage on, which is the interconnection of physical devices and software to enhance the exchange of information. The system will rely on sensors, actuators, electronics, and network connectivity to improve the performance of the QR code.The system will also leverage on transformations and new technologies to ensure automatic duplication of the code on the consumers’ package for convenience purposes (Fig.2). Therefore, the system will enable the consumer to scan the code to understand product attributes, supply chain traceability, and internal traceability using the given batch number.

Experts prefer traceability systems with high levels of granularity to increase the accuracy of the results.Although a system with high granularity has a sizeable number of TRUs, particularly in businesses with potentially high product recalls, this method could be effective in Wing’s Catering. Business with coarse granularity may recall unnecessary commodities in the event of a mistake. By incorporating TRU identifiers, for example, numeric and alphanumeric codes and utilizing proper reference standards could limit the chances of error. In addition, TRU identifiers should emphasize internal uniqueness using a coding scheme.

By providing the batch number, the detailed information of the product, such as purchasing time,supplier, expiry date, quantity and personnel involved,can be accurately located through the internal database of the enterprise (Table 3).

Table 3 Searching traceability information using a batch number

Consumer complaints are important sources of traceability information. If a complaint occurs, employees can record the traceability information including the name of the complainant and the time of the complaint.In addition, they may indicate the low-quality meals and beverages on the website using the mobile phone. For example, if the complaint involves a sanitation or disinfection problem, consumers or government personnel can also check the environmental record of the day through external inquiry.

In case of rejected commodities, the name of the customer involved, the name of the product, specification,production date or batch number, quantity, cause of nonconformity, handling measures, treatment results, and other contents of nonconforming products shall be recorded. The merchant should record the name and contact information of the buyer of the complaint, the name of the product purchased, the date of production or batch number, the cause of the complaint and the resolution.

At the same time, a special inquiry website and QR code was provided for external auditing. The consumer can check the relevant complaint information by entering his/her name or other conditions. Figure 3 indicates Wing’s traceability system.

This traceability system fosters internal traceability because it emphasizes on the accurate recording of each transaction, including all transformations that may take place, for example, merging sales receipts for a particular customer. Internal traceability is the most important activity in the traceability system because it focuses on the relationships between production batches, incoming trade items, outgoing trade items. While internal traceability is the responsibility and domain of Wing’s Catering, it is an effective predictor of supply chain traceability. Chain traceability entails gaining visibility into the links and operations of other organizations in the industry, primarily through electronic data interchange(EDI). In order to achieve chain traceability, Wing’s Catering must engage in consultations with other firms to establish standards, structure, content, and identifiers.

This traceability system follows the Trace Food conceptual framework established by other researchers.In particular, the components of the system include the principle for unique identification, generic guidelines of implementation, principle for documentation of transformations, sector-specific language, sector-specific guidelines, and generic language for electronic interchange. Regarding the generic language for electronic interchange, this system requires users to use two additional websites to retrieve and display data,which plays a key role in electronic data interchange(EDI). Although this system is comprehensive, some of the recommended changes in the future include the development of an accurate and systematic approach to documenting and implementing transformations.Additionally, researchers should focus on creating traceability systems that identify biochemical properties in each TRU item. With the development of Internet of Things (IoT) and new technologies for Automatic Identification and Data Capture (AIDC), this system could serve Wing’s Catering effectively.

4 SWOT Analysis

Through SWOT analysis, which is also known as the tried-and-true tool of strategic analysis[31]. Despite the drawbacks of the SWOT analysis framework, the tool is useful in exploring possibilities, performing first-level evaluations of both the internal and external environments, and making essential decisions. The synthesis of SWOT could provide valuable insights regarding the elements of the traceability system developed for Wing’s Catering. By focusing on the four quadrants of the SWOT framework through content mapping, the strengths, weaknesses, opportunities, and threats of the system can be established. The SWOT framework has been applied in strategy building,matching and converting, corporate planning and marketing of enterprises and products. The SWOT framework can promote informed decision-making processes by helping an organization to set objective and obtainable goals and steps to further social change or promote community development[32]. The tool analyzes four aspects, which include Strengths (S), Weaknesses(W), Opportunities (O), and Threats (T). Through these comprehensive considerations, stakeholders forward rational and pragmatic strategic ideas for each item and provide strategic suggestions for the future management and development.

During the project, the research object is the traceability system for Wing’s Catering. The research entails conducting a case evaluation of the firm’s traceability system using the SWOT framework. The internal advantages and disadvantages of this system will be reasonably considered, the opportunities and threats faced by the external environment will be analyzed and then suggestions for future management of Wing’s will be applied.

4.1 Strengths

4.1.1 Simple structure and ease of operation

Wing’s Catering replicates the business models of well-known fast- food restaurants, such as KFC. They use semi-products supplied by OEM factories instead of relying on the central kitchen. After a customer orders a meal, the employees directly use the prepared food for further cooking, thus, saving time and maintaining the freshness of the meals. In addition, this approach reduces Wing’s inventory levels, enabling it to focus on its core business. In this way, the business method enhances convenience and incentivizes the employees to maintain accurate records.

The proposed food traceability system is divided into two parts. The first one involves recording,purchasing, and warehousing information using computer software, for example, Microsoft Office and Access. At the same time, the system generates a QR code though a website (https://cli.im/). The second part entails using Internet technology to record processing steps,environmental conditions, complaint-handling process,and abnormal conditions using a website(https://www.wjx.cn/).

At present, Wing's is relatively small in scale and lacks technical talents and robust financial capacity.Irrespective of these challenges, the application of this system only requires employees to be familiar with Microsoft office software. The workers can quickly grasp the contents of the system with moderate training in later stages of implementation. Besides, Wing’s has a simple management structure characterized by large scope of authority. When food safety issues occur, workers can use the system to trace the relevant information quickly and find the corresponding person in charge. Overall, the system is easy to manage and operationalize, especially in regards to tracing sources of error. Therefore, the system can be adopted in Wing’s branches.

4.1.2 Low cost with high-cost performance

This traceability system should be installed in a computer that supports Internet connectivity. The application software to operationalize the system include Microsoft office, QR code generation website and other websites which can input information and store the records. Except for the Microsoft software, the other two websites, the QR code generation page, and the recording information page do not charge extra fees in the long-term perspective. Therefore, the system can still support its information storage function and help Wing’s Catering to trace and track food-related information.

Moreover, the system has a user-friendly interface,making it simple to use at Wing’s Catering, particularly for employees with basic knowledge about the Internet and Microsoft Office software. As indicated previously,the application of this system does not require specialized computer technical skills nor does it compel the organization to hire specialized high-tech personnel.Therefore, the company can control the training and labor costs and ensure they are within a desirable range. Since Wing's has operated for more than 20 years as a tea restaurant, it’s reasonable to believe that they have adequate economic capacity to implement the establishment of the traceability system.

4.2 Weaknesses

4.2.1 High dependence on external websites

The system relies greatly on the ability of an employee to utilize the Internet because most of the information, except for records related to purchasing and warehousing, is processed by two websites. For example,the generation of a QR code requires the user to upload relevant information on the special website. In addition,vital records, such as, customers’ complaints should be recorded and submitted online. In the event of a malicious attack on the website or exposure to a technical error, the usefulness of the traceability system could decrease dramatically.

4.2.2 Limited functions

Currently, this traceability system can be integrated with a website at no extra cost; however, extra service packages is intended to add to enhance functionality in the future. Different service packages can be customized to achieve better user experience, such as, increased storage space, intelligent query, periodic evaluation of products, and QR code watermarking. The development of the new features and extensions require the company to purchase service packages, which has a financial implication on the business.

4.3 Opportunities

4.3.1 Electronic information is easy to keep and manage

In addition to the necessary paper records, the proposed traceability system converts information into electronic records and then uploads them to the computer or Internet for storage, thereby enhancing convenience in accessing and tracing food-related information. Using cloud storage solutions allows the company to periodically update and review electronic information.Furthermore, because the conditions in the kitchen area could lead to the deterioration of the quality of the records, the restaurant could prefer to use electronic records because they are less vulnerable to destruction than physical documents.

As outlined in the previous sections, the system enables easy management and access of electronic information. Users can retrieve vital information, such as,a batch number, including purchase date, purchasing personnel, daily usage, daily storage, complaints by consumers, and the name of the attendant. This system simplifies the process of retrieving information without performing complex calculations and double-checking many paper records.

4.3.2 Convenient sharing of information

Because the proposed traceability system mostly uses the Internet, it allows users to share and transfer information in electronic format conveniently.Importantly, the system allows remote access of the electronic records using a computer or a mobile phone.With the advent of the era of big data, the upgrading frequency of science and technology-related concepts is accelerating rapidly due to the proliferation of the Internet.It’s obvious that he promotion of these digital technologies can provide better technical support for the food traceability system more or less in the future.

4.3.3 National support

In terms of the social environment, the vigorous implementation of China's reform and growing adoption of globalization present an opportunity for Chinese users to learn and share a lot of information about food traceability systems and resources from other advanced countries. In this way, technologies and management methods can be absorbed better to further improve the traceability system that have been established. At present,the establishment of many food regulations in China is based on or close to the European standard, and the whole system of food law is increasingly becoming reference subject of discussion. Whether in in Hong Kong or in mainland China, the governments can provide sufficient and complete regulation support for the implementation of this system.

4.4 Threats

4.4.1 Limited functions versus system competitiveness

A good traceability system should not only effectively foster communication and relationships between the company’s upstream and downstream stakeholders, such as, government organizations, but also facilitate the sharing of all kinds of related information with third parties. The proposed traceability system does not make a specific distinction between the government and consumers. Instead, this system mainly adopts different ways to information search and traceability for internal and external purposes, which is contrary to other systems adopted by large enterprises, in which they establish a special internal ERP system to perform multiple tasks. The function and users of our current traceability system are not comparable with the ERP system.

4.4.2 Challenges during initial promotion

Expanding businesses and installing new systems is a capital-intensive activity, which could be extremely challenging for a medium-size entity. Wing's is a small and medium-sized catering enterprise at and lacks a complete management system. In addition, it has a simple management structure is simple with limited standardized management model.

Moreover, the company lacks highly talented employees and adequate knowledge about food traceability systems. Although the leader is aware about food traceability systems and their importance in the food industry, there is no widespread or specialized training for the majority of the employees. These factors pose a challenge to the successful implementation of the system.

4.4.3 The system requires more time and sustained investment

Ideally, the traceability system can foster the management of Wing's products and enhance the utilization rate of resources in each branch. Additionally,it does not only allow consumers to eat healthy and safe foods but also improve Wing’s competitive strength by offering higher confidence for food safety, which is a win-win situation for the business and consumers.However, as a chain catering enterprise, Wing's does not have a strict management training system or special food certification, such as GMP and ISO. The organization requires financial and technical support to apply the traceability system, such as securing certification and training. These processes may involve lengthy discussions with the relevant authorities and employees,indicating that the benefits of the proposed system are only achievable in the long-term view.

5 Literature Review

5.1 Hypotheses

The researcher had three major hypotheses for the study:

1) The socio-demographic profile of the consumer has a positive correlation with the development of a food traceability system;

2) Consumers’ psychographic characteristics influence their preferences in food traceability systems;

3) Buyers’ information-seeking behaviors have a direct influence on food traceability;

4) Brand image has a mediating effect between consumers’ psychographic qualities and food traceability.

5.2 Socio-Demographic Profile and Food Traceability

The socio-demographic characteristics of the buyers may have a direct positive impact on food traceability systems. Factors, such as, household income, age of the family members, and the level of education, may compel buyers to pay premium prices for traceable foods[33].Demographic characteristics in urban areas contribute to consumers’ preferences about food traceability. For example, health-conscious buyers may willingly accept to pay premium prices for products sourced from known producers and markets. In addition, socio-demographic factors significantly influence purchase decisions.

5.3 Psychological Antecedents and Food Traceability

Current research indicates that consumers are shifting from traditional diets to ready-made frozen food(RMFF) because of the perception that the latter is healthier, tastier, and safer than the former. The most notable attribute increasing the demand for RMFF is the perception that it is safe and of high quality[34]. In addition, consumers cite proper packaging and labeling as some of the main factors motivating them to consumer RMFF.

5.4 Consumer Cognition (Information-Seeking Behavior) and Food Traceability

Considering the growing body of supply chain risk management (SCRM), organizations in the food industry have been compelled to respond to the information-seeking behaviors of their customers.Information-management processes that emphasize compliance to food traceability regulations, quality control, and vertical integration of logistics may foster information sharing about risks in the supply chain[35]. In the era of tech-savvy consumers, organizations must assume the perspective of transparency in the management of reports about food components. With the aim of fostering traceability, companies must ensure interoperability between their information management systems, especially by ensuring that customers receive up-to-date information about the products through proper labeling and abbreviations. In a study investigating consumers’ perspectives about food traceability, the majority of the respondents indicated that information about the “slaughtering date” and “history of illness” in the product label influenced their purchase decisions[36].In addition, consumers prefer traceable details, such as,processing information, environmental information, and traceable tag certification information, indicating a growing trend of information-seeking behaviors among buyers.

5.5 Brand Image and Food Traceability

Researchers have established a positive relationship between brand image and consumers’ purchase intentions[33-36]. Brand image refers to consumers’ emotional response to a particular company or product, enabling them to differentiate between alternative products.However, it appears that there is limited scholarship evaluating the relationship between brand image and food traceability. Constant advertising campaigns,sponsorships, and consumer direct experience are some of the aspects of brand promotion that determine purchase intentions. In this case, brand image plays a mediating role in the relationship between consumer psychographic characteristics, for instance, attitude, and traceability. In other words, buyers tend to view the restaurant as the broker between them and producers, in which the former seeks to protect his or her corporate brand.

5.6 SWOT Analysis of a Traceability System

SWOT analysis is a tool for analyzing the internal and external environments of a business to determine the effectiveness of the current strategies[37]. SWOT denotes strengths, weaknesses, opportunities, and threats.Strengths and weaknesses represent the internal factors that can either facilitate or inhibit the implementation of food traceability systems. For example, an organization with a strong brand name may leverage on this quality to adopt a new system. Opportunities and threats refer to the factors in the external environment that are beyond the control of a firm, for example, new laws and intense rivalry. Figure 4 indicates a conceptual framework indicating food traceability systems and the components of the SWOT framework.

6 Conclusion

6.1 The results of the study indicate that many Chinese consumers have limited cognition about food traceability.However, with the growing adoption of the Internet,buyers demonstrate a growing concern for food traceability systems for safety reasons. In fact, some consumers are likely to pay a premium price to purchase traceable foods. Brand image plays a mediating role between food traceability systems and users’psychographic factors. If Wing’s Catering adopts a traceability system, it may promote its brand image and attract health-conscious buyers. In addition to the necessary paper records, the proposed traceability system enhances convenience by covering information into electronic records accessible through a computer or a mobile phone. Big data and informatics present an opportunity for Wing’s to operationalize a traceability system and foster efficiency in its processes.

6.2 Currently, stakeholders in the food industry, such as,manufacturers and restaurant operators, face various competitive pressures. To improve the performance of their businesses, the organizations should employ new techniques to food management. It is imperative for firms to strengthen communication and information sharing in the food supply chain to understand the operating conditions. Therefore, establishing food traceability system could be a critical investment for the future.