Rice Drying, Storage and Processing: Effects of Post-Harvest Operations on Grain Quality

2022-01-20AmandallerMarcelaTrojahnNunesVanessaMaldanerPauloCarteriCoradiRosanaSantosdeMoraesSamuelMartensAndressaFernandesLealVladisonFogliatoPereiraCristiellenigMarin

Amanda Müller, Marcela Trojahn Nunes, Vanessa Maldaner, Paulo Carteri Coradi,, Rosana Santos de Moraes, Samuel Martens, Andressa Fernandes Leal,Vladison Fogliato Pereira, Cristielle König Marin

Review

Rice Drying, Storage and Processing: Effects of Post-Harvest Operations on Grain Quality

Amanda Müller1, Marcela Trojahn Nunes1, Vanessa Maldaner1, Paulo Carteri Coradi1,2, Rosana Santos de Moraes1, Samuel Martens1, Andressa Fernandes Leal1,Vladison Fogliato Pereira1, Cristielle König Marin1

(Post-Graduation Program in Agricultural Engineering, Rural Sciences Center, Federal University of Santa Maria, Camobi 97105-900, Santa Maria, Rio Grande do Sul, Brazil; Department of Agricultural Engineering, Campus Cachoeira do Sul, Federal University of Santa Maria, Highway Taufik Germano, 3013 - Passo D’Areia 96503-205, Cachoeira do Sul, Rio Grande do Sul, Brazil)

Various post-harvest processes of rice are commonly employed, especially during the off-season, to ensure its consumption feasibility,which often affect the grainquality. Different forms of drying, storage and processing of rice are evaluated to identify their effects on grain quality. Microwave drying has emerged as an alternative to the widely-used intermittent-drying and fixed-bed-dryer methods of drying paddy rice. Control of drying-air temperatures (between 40 ºC and 60 ºC) according to the rice variety can improve quality, especially for exotic varieties. Keeping stored grain in hygroscopic balance, with water content between 11% to 15%, at temperatures between 16 ºC and 20 ºC and with intergranular relative humidity near 60%, allows 12 months of storage in a controlled environment without significant deterioration. Other innovations, notably the application of artificial refrigeration to grain stored in bulk in vertical cylindrical silos and the use of impermeable packaging for storage, ensure the conservation of grain mass. The different stages and equipments used to obtain polished, brown and parboiled rice result in significant changes in the nutritional value of rice because of the removal of the outermost layers of the grains. Polishing reduces the nutritional value and physical homogeneity of rice. Brown rice retains more bioactive compounds and nutrients because it does not lose the outer layer of the grains in the polishing processes. Parboiled rice, although less nutritious than brown rice, has better grain integrity and milling yield and less loss of nutrients than white rice.

agricultural engineering; post-harvest rice engineering; quality in rice pre-processing; rice process industry

Rice (L.) is part of the daily diet for millions of people worldwide, providing energy, vitamins and minerals. Factors such as varieties, climatic conditions, pre-harvest operations and technical managements affect grain quality. However, post-harvest processes are equally essential.Because of the seasonality of the rice crop, it is necessary to ensure the preservation and availability of the product for a long period (Elert, 2014).

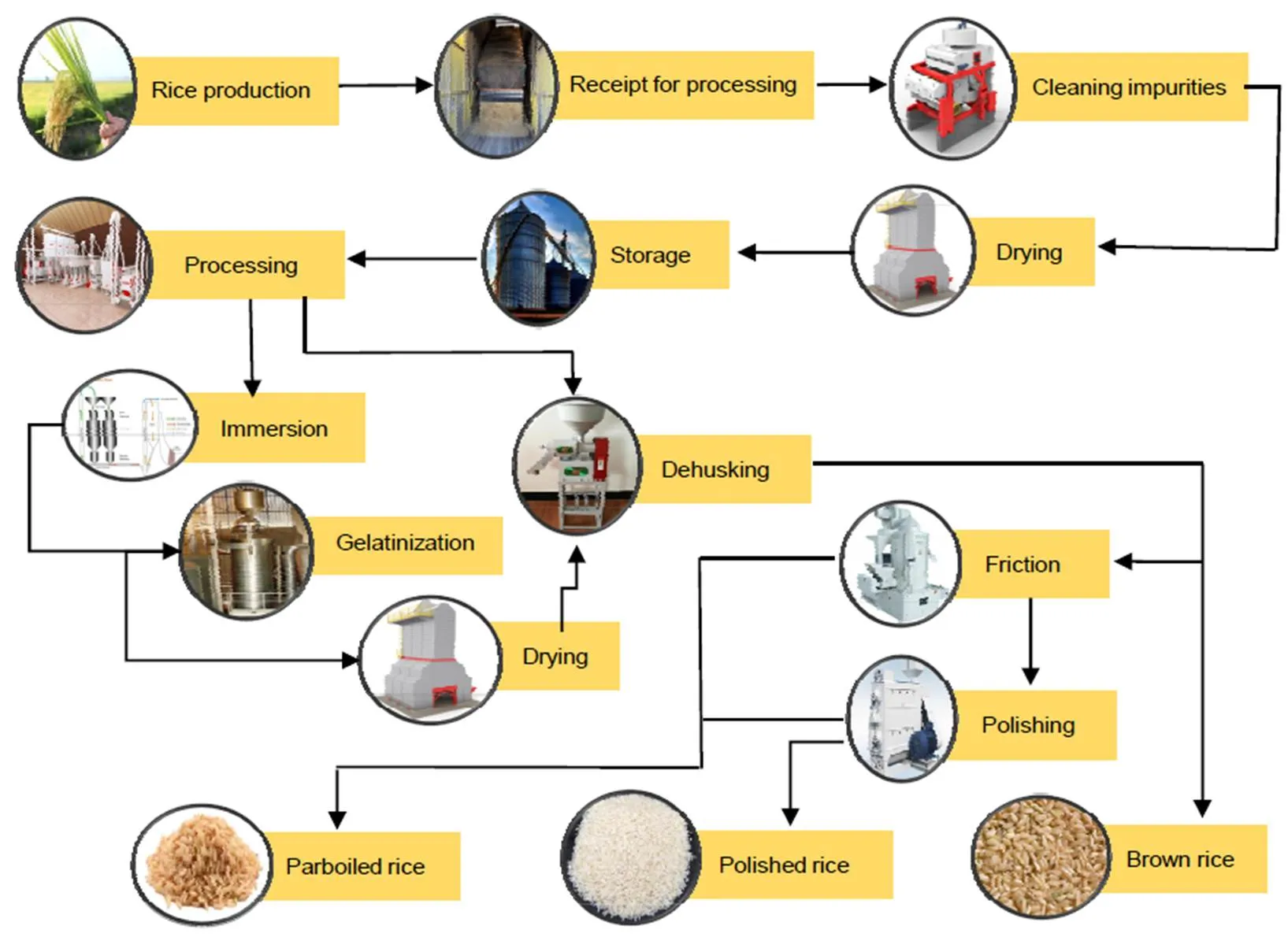

The main post-harvest objectives are maintaining grain quality, avoiding physical damages and changes in the chemical compositions, and preventing contamination by insects or fungi (Coradi et al, 2016). Therefore, the choice of procedures adopted in post-harvest operations such as drying, storage and processing can strongly influence the rice quality (Fig. 1) (Shad and Atungulu, 2019; Olorunfemi and Kayode, 2021). To ensure quality and minimize physical and chemical damage to the rice grains, it is imperative to adopt modern technologies and proper equipments. The review work considers the effects of drying, storage and processing stages on the quality of rice grains.

Fig. 1. Flowchart of post-harvest drying, storage and processing of rice grains.

Production and rice harvest

Rice is grown in an area of approximately 160 million hectares worldwide. Increase in productivity and improvement of rice grain quality have occurred in recent years as a result of technological advances in genetics and the implementation of good agricultural practices at many levels, from the field to the industry.

Both cultivar and pre-harvest factors (such as cultural practices and environmental conditions) affect post-harvest quality of rice. To classify irrigated rice cultivars, the crop cycle, production potential, plant morphology, and tolerance of biotic and abiotic stresses are considered (Bao, 2019; Barnaby et al, 2019).The production separation of culture in cycles helps the producer make the farm management (Barnaby et al, 2019). Management of application times, split or non-split, from nitrogen sources can considerably increase the effectiveness of nitrogen fertilizers and thus the productivity and yield of processed grains (Fryer et al, 2019). Air temperature is another factor having a direct relation to thegrain quality. High night air temperature during grain filling stage drastically affects the quality of rice milling, in terms of the processed-rice yield, color and functional characteristics, including viscosity profile and gelatinizationtemperature (de Guzman et al, 2017).

Rice harvesting can contribute to post-harvest grain quality. The ideal range of the harvest water content is 19% to 22% for long rice grains and 22% to 24% for medium rice grains (Siebenmorgen et al,2007). Low water content reduces the yield and results in cracks by moisture adsorption and breakage of rice grains during milling. The harvesting of grains when the water content is between 18% and 23% facilitates the logistics and the flow of the grain mass in the post-harvest stages, especially the receiving and drying operations. Lang et al (2020) indicated that grains with a longer drying delay at 25 ºC suffer from greater degradation of phenolic compounds and reduced protein solubility.

Thus, the defects acquired during the various phenological stages of development and vegetative growth, harvesting, transportation and pre-storage operations, especially drying, do not disappear during storage, but tend to increase incrementally, adversely impacting the grain quality (Mutungi et al, 2019).

Drying rice

Objectives and mechanism of drying process

The drying process involves heat and mass transfer between grains and drying air. For drying to occur, the water vapor pressure of the grains should be greater than that of the drying air. If the water vapor pressure of the grains is lower, the product will moisten, and if the pressures are equal, a hygroscopic equilibrium will occur between the product and the environment in which it is to be stored (Fig. 2) (Silva et al, 2008). However, reducing the water content of the vegetable material causes chemical and physical changes in the product(Inprasit and Noomhorm, 2001). When water is lost, the grain size decreases because the external compression increases. With heating, the internal pressure increases and the central layers of the grain expand. The mechanical stress suffered by the grain in this process is very high and can cause fissures, cracks or even breakage, because the grain surface does not have the plasticity or elasticity to support them. Such phenomena are described by the mathematical models (Table 1) used in drying analysis and the development and optimization of dryers (Coradi et al, 2018; Coradi and Lemes, 2019).

Fig. 2. Drying process in rice grains.

A, Start drying in rice plant. B, Need to immediately subject the rice grains to drying. C, Intermittent dryer. The intermittent dryer consists of two chambers, one for drying and the other for equalization. D, Procedure in the equalization chamber. E, Procedure in the drying chamber. Pg, Grain vapor pressure; Par, Air vapor pressure; T1, Exhaust air temperature; T2, Inlet air temperature; UR1, Exhaust air relative humidity; UR2, Inlet air relative humidity.

Drying methods and effects of drying parameters on grain quality

Drying can occur naturally (i.e., on the plant itself) or be artificially induced. The heat supply can be continuous or intermittent, and the movement of grain mass can be stationary or continuous.

The use of heated air is an obvious way to dry grains. Heated air has a high evaporative capacity, and its exchange energy is increased by increasing its enthalpy. When heating occurs in the grains, evaporation and internal pressures increase (de Menezes et al, 2012; Donlao and Ogawa, 2018). The main advantages of drying with heated air are the high drying capacity and the reduction of time, and the disadvantages include the energy cost required to heat the air and the damage that can be caused to the grains because of the rise in temperature (Mussi et al, 2015).

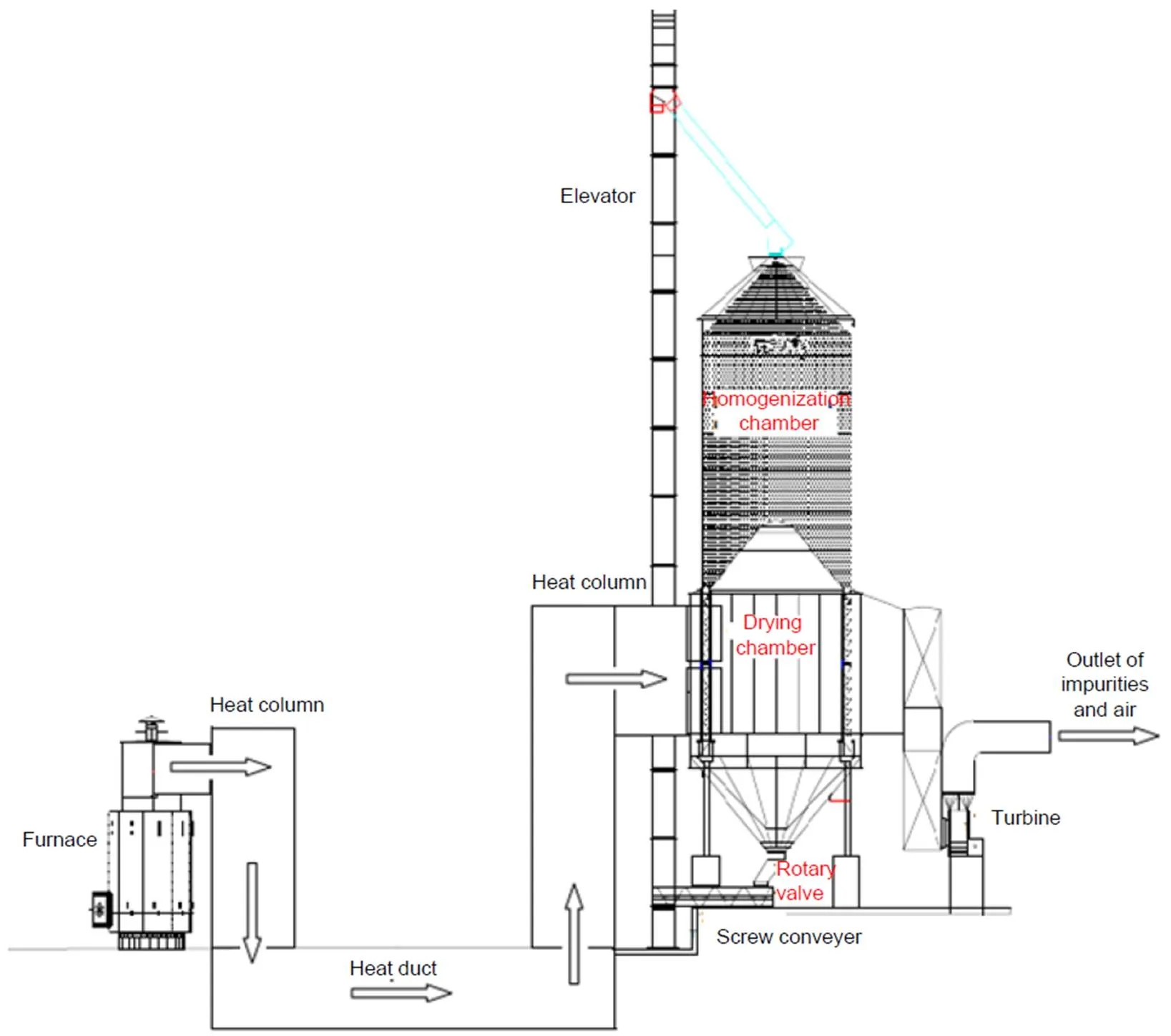

Intermittent drying is the most commonly recommended and widely used method for drying paddy rice (Fig. 3). The equipment comprises two chambers: one for drying and the other for moisture equalization in the grain (where the grains have no contact with the drying air). In an intermittent dryer, heated air passes through the moving grain mass, promoted by the product’s recirculation in the dryer. In the rest chamber, water diffuses from the center to the periphery of the grains, and the surface water evaporates from the grains in a more balanced. The process is accompanied by the movement of the drying air and the grains; however, this can result in mechanical damage to the grains (Wiset et al, 2005;Wang et al, 2017; Coradi et al, 2020a).

Table 1. Equations for description of drying rice grains and determining equilibrium moisture content.

,Moisture ratio (dimensionless);,Drying time (h);, k,k,Drying constant (h-1);, Number of terms in the equation. X, Equilibrium moisture content (dry basis); D, Diffusivity;, Temperature;, Relative humidity of the air;,,, Coefficients of the model for caculatingand adjustment parameters adapted to each method for caculatingX.

The number of drying cycles and the different treatments of the grains in the equalization chamber influence the number of fissured grains and consequently the yield. Aquerreta et al (2007) verified that the rest chamber in high temperature conditions (60 ºC) results in higher water removal and reduces the drying time by up to 38%. According to Oyoh and Menkiti (2013), the ideal temperature for producing high-quality rice seeds is around 40 ºC.

Thermal control in the drying process is important to avoid exaggerated elevations in the temperature, which can cause starch breakdown and changes in composition or color. Donlao and Ogawa (2017) and Donlao et al (2018)investigated the effects of drying in the sun and with hot air at 40 ºC, 65 ºC, 90 ºC and 115 ºC on the total starch content.They concluded that increasing the drying temperature increases the concentration of starch in the grains, which can be explained by the partial gelatinization and retrogradation of amylose.

For rice, continuous flow drying should only be applied with air temperatures below 70 ºC. Ramos et al (2019) found that the relative crystallinity of rice starch decreases from 21.97% to 20.35% with an increase in temperature from 40 ºC to 100 ºC,which is attributed to the decrease in amylopectin chains.

The dry-aeration, although slower than stationary drying methods, allows rapid and homogeneous drying. The dry-aeration method increases the operational speed of the dryers, reduces costs in the application of thermal energy, and improves the use of facilities. The grains come out of the dryer heated and partially dry; so they are directed to a silo-dryer, where they remain at rest. As the internal energy of the grains at the outlet of the dryer is high, the water migrates to the periphery, and it is removed through forced ventilation with unheated air (Elias et al, 2007).

Fixed-bed, stationary, or fixed-layer dryers have a bottom composed of perforated plates, through which the drying air passes,and the product is at rest on the perforated plates of the bottom of the dryer. This method is used in successive layers: when the first layer reaches hygroscopic equilibrium with the drying air, the second layer begins to dry, while the third remains moist because it is ahead of the drying front (de Menezes et al, 2012).

Fig. 3. Intermittent dryer.

Studies have been conducted to develop new dryers and improve the existing ones, with the aim of improving the process yield and maintaining the quality of agricultural products. The main factors involved in these improvements are temperature and air flow controls, speed and pressure of the heated air, and movement and uniformity of the water content of the product. For example, Coradi et al (2021) have achieved high operational and quality performance for rice with a new fixed-layer silo-dryer-aerator that employs high and low temperatures of the drying air.

Norkaew et al (2017) observed that drying in the sun preserves anthocyanins and γ-orianols in black rice better than drying in hot air. Junka et al (2018) evaluated the influence of three drying temperatures (100 ºC, 130 ºC and 150 ºC) on the preservation of anthocyanins and found that the higher temperature reduces 18% of anthocyanin content. In a fixed-bed dryer, Lang et al (2019) evaluated changes in color and content of anthocyanins in blackrice grains dried at 20 ºC, 40 ºC, 60 ºC, 80 ºC and 100 ºC. The increase in the drying temperature promotes reduction in the total anthocyanin content, with drying temperatures below 60 ºC being more appropriate for maintaining the anthocyanin levels. In addition, luminosityincreased as the drying temperature rose, indicating a lightening of the grain surface(Rattanamechaiskul et al, 2016).

In the composition of germinated brownrice grains, Parnsakhorn and Langkapin (2018) found that lipid content and totalγ-aminobutyric acid (GABA) content decrease with increasing drying temperatures. Srisang et al (2011) compared drying the grains only in a fluidized bed dryer to combine the fluidized bed dryer with superheated steam.Even after using high temperatures (130 ºC and 150 ºC) in both types of drying, neither the method nor the temperature influences the GABA content.

Patindol et al (2003) carried out drying in a thin layer at 20 ºC, 40 ºC and 60 ºC, and found that neither group observes significant variations in the percentage of whiteness. Chen et al (2014) carried out freeze-drying at 20 ºC, drying in an oven with air convection at 90 ºC, and drying in an oven with air convection (90 ºC) combined with a microwave. The whiteness in drying with lyophilization is significantly higher than that of freshly cooked rice grains, probably because the freezing treatment causes starch retrogradation. For oven drying with air convection, the drying temperature has a negative effect on color.In combined drying, the whiteness shows no any significant difference when compared with the freshly cooked rice sample.

Microwave drying is an expanding method. In this technique, heat is generated inside the grains as the electromagnetic radiation heats the water molecules.Moisture evaporates and is transported towards the surface of the material. A common problem with microwave drying is non-uniform heat generation, which leads to uneven drying (Li et al, 2011). However, the method is fast and requires low energy expenditure.

Optimum drying conditions

In the drying process, the dryer settings must be adjusted constantly according to the water content of the grains at the inlet and outlet. This primarily involves monitoring the air temperature through sensors, thermometers and furnace records. It is also necessary to control feed regulation, grain level in the dryer and drying-air speed. The use of sensors allows the measurement of temperature and relative humidity of the grain mass. The data are transmitted to a controller that regulates the operations of the fan and the furnace. The sensors can be applied to both drying and storage of grains (Olatunde and Atungulu, 2017).

Rice-storage structure and effects of storage conditions on rice grain quality

A grain-storage facility is defined as a system that is designed, structured and equipped to receive, clean, dry, store and dispatch grains and/or seeds (Kudra, 1996). Storage in silos or warehouses equipped with thermometry, aeration and other resources helps maintain grain quality.

Bulk warehouses (also known as horizontal silos) are different from vertical silos in their height-to-length ratios. Horizontal silos can reach up to 180 m in length. To compensate for the lack of storage capacity in Brazil, horizontal silos (silos bags) have been widely constructed and exploited. They are classified by their floor profiles: V-bottom, semi-V and flat. Horizontal silos are generally flat-bottomed and may or may not have aeration (Khatchatourian et al, 2016).

The storage conditions of the grains can infer on the time that it can remain stored with quality. Rice is often stored for short periods, usually a few months, although (as mentioned earlier) there is no universally accepted maximum storage period (Singh et al, 2006). Studies have shown that inadequate rice storage conditions are not only a sanitary problem, but also affect rice yield and cooking (Sodhi et al, 2003).

According to Kumar and Kalita (2017), storage loss can be classified as direct (i.e., physical loss) or indirect (loss of quality and nutrition). Indirect loss can occur because of biotic factors (insects, pests, rodents and fungi) or abiotic ones (temperature, moisture and rain) (Bernaola et al, 2018). Thus, monitoring the temperature, relative humidity and water content of the rice grains is imperative for maintaining quality throughout storage.Rice quality cannot be improved during storage, but a temperature- and relative-humidity-controlled environment allows the grains to be preserved until the appropriate period for sowing, with no reduction in quality.

Equilibrium moisture content is related to the balance between the water vapor pressures in the material and in the environment, and it can be used to determine the minimum moisture value that the material can reach in a certain condition. This is of fundamental importance in modeling the drying process storage. The principal equations used to estimate the equilibrium moisture of cereals are grouped in Table 1. Teles Junior and Vilela (2020) have developed a computational tool to assist in calculating the equilibrium moisture of different agricultural products from the Chung-Pfost equation (Table 1). Ways are being sought for the software to communicate with the data acquisition system through temperature and relative-humidity sensors in real time.

The reduction of grain metabolism can mitigate the loss of grain quality. Grain deterioration is related to the respiration of the grain mass and the accompanying microorganisms. The relative air humidity, the temperature and storage time influence the O2and CO2contents, thereby affecting the rice rheology. A high water content or grain-mass temperature can alter the product’s metabolic activity and respiration, depending on the storage ecosystem (Zhang et al, 2014;Singh and Fielke, 2017).

The decomposition of 1 g dry matter during aerobic respiration requires 1.07 g O2and releases 1.47 g CO2, 0.6 g water, and 15.4 kJ heat. Thus, models of CO2production are used to predict the loss of dry matter during storage, as well as to determine the diffusivity of CO2in the grain mass based on Fick’s second law (Huang et al, 2013). Huang et al (2013) found that the effective CO2diffusion coefficient in bulk grains increases as the temperature goes from 10 ºC to 30 ºC and decreases as the water content of the grains goes from 14.0% to 18.8%. Thus, the transfer of heat and moisture between the grains and the intergranular air causes deterioration of the grain mass, increasing the levels of CO2concentration.

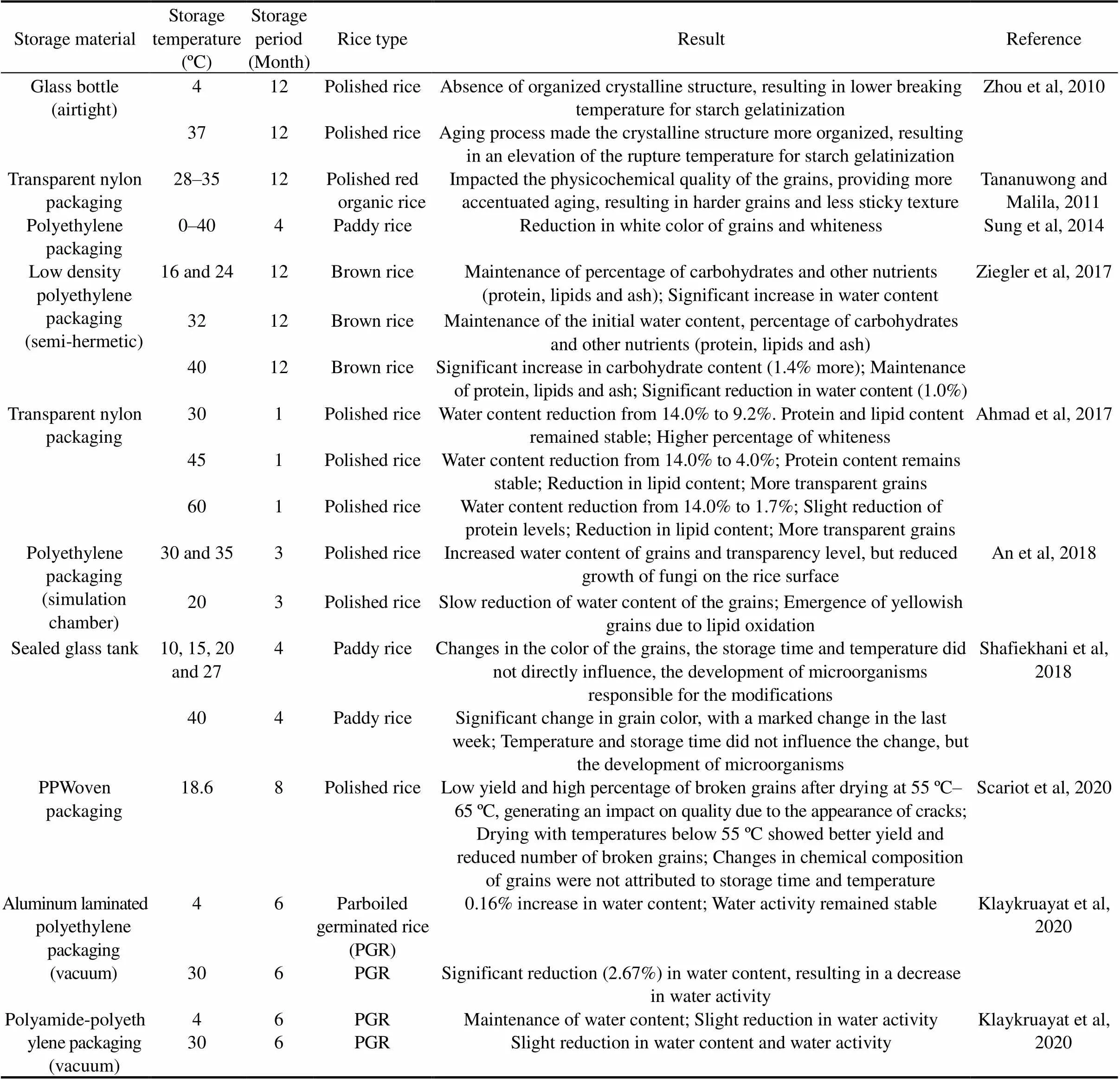

Table 2. Influence of storage temperature over time on physical-chemical quality and color of rice grains.

Experimental results concerning the effect of storage temperature over time on grain quality are listed in Table 2. Higher temperatures cause an excessive reduction in the water content of rice grains, which affects the protein, lipid and ash contents. Above 35 ºC, the grains become more transparent because of the water content. The increase in the water content and temperature of the grain mass induces a more intense respiratory process, and consequently accelerates the grain metabolism, causing greater consumption of dry matter and reducing the starch content (An et al, 2018).

Sung et al (2014) and Klaykruayat et al (2020) reported that, temperatures below 4 ºC allow the initial characteristics of the grains to be maintained with only small changes in water content, water activity and grain color (whiteness level). However, Shafiekhani et al (2018) reported that the change in grain color is influenced by the development of microorganisms. Zhou et al (2010) observed a change in the rupture temperature for starch gelatinization caused by the absence of an organized crystalline structure in polished rice stored for 12 months at 4 ºC.

Thermometry and aeration are essential to avoid grain loss, improve storage conditions and maintain the quality of stored grains (Khatchatourian et al, 2017). Aeration comprises the movement of ambient air through the mass of grains with adequate temperature and moisture (Binelo et al, 2019). Thermometry is the means used to measure the temperature through a network of sensors strategically placed in the grain mass. Currently, two types of sensors are most commonly used: the thermocouple and the thermistor (Neto andde Carvalho Lopes, 2015).

According to Neto and de Carvalho Lopes (2015), it is possible, with the aid of automatic thermometric equipment, to automate the process of activating the fans and making decisions regarding the entire aeration system of the storage unit. Factors that alter the distribution of aeration air flow include the filling method, compaction,grain sphericity, moisture, porosity and the presence of insects or fungi. Grain storage in bulk warehouses significantly affects the air-flow field,which leads to anisotropy due to the variable area and in homogeneity of the grain mass, making air distribution more complex (Faoro et al, 2018). Khatchatourian et al (2016) showed positive results in the implementation of mathematical models and the development of software capable of improving and optimizing the distribution of airflow in horizontal storage silos equipped with an aeration system. However, there are still few studies that evaluate bulk warehouses in relation to rice quality.

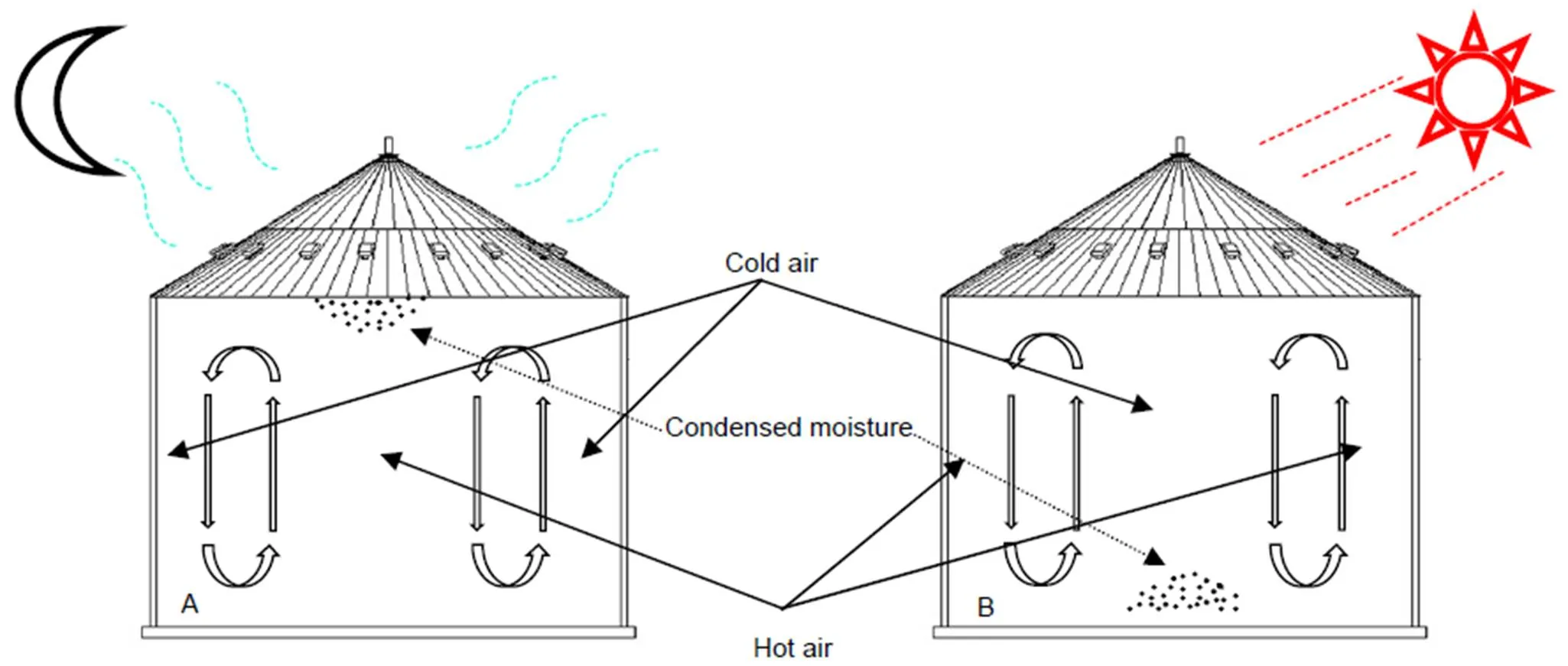

A frequent problem in metal silos is the condensation of moisture on the surface of the grain mass, which occurs because of temperature variation due to solar irradiation of the metal walls; this, of course, varies from day to night (Fig. 4). Because grains are not good thermal conductors, the air near the silo walls heats up and becomes less dense than that in the central part when the external temperature is high. This forms upward convective currents that eventually cause moisture to condense at the bottom center of the grain mass (Yamamoto and Kato, 1999).

Factors such as the height and flow of the grain mass, temperature and relative humidity of the drying and storage air, temperature of the grain mass, and type of drying process need to be addressed to ensure operational efficiency and grain quality in a dryer silo (Coradi et al, 2020b). For example, the increase in the height of rice mass causes drying in the upper layers to remain incomplete, which results in low drying efficiency and poor rice grain quality.

Fig. 4. Heat and water transfers and convective currents and in metallic silos.

A, Moisture condensation on top in the night. B, Moisture condensation at the bottom in the daytime.

The silo-bag was adapted to store dry grains as a practical, low-cost solution to the lack of storage capacity in rural properties. This technique comprises storing dry grains in airtight plastic bags. Respiration by the various biological agents of the grain ecosystem (grains, insects, mites and microorganisms) involves the consumption of O2and generation of CO2. Airtight storage can result in gas concentrations that promote an adequate environment for the conservation of grains (Barreto et al, 2017).

According to Hidalgo et al (2013), rice with a water content of 16% can be stored in a silo-bag for up to 4 months. With a water content of 20%, it is still possible to store the rice for 40 d without affecting grain quality, as long as the silo-bag is controlled. Hermetic storage is a method that creates a modified atmosphere with a high concentration of CO2using structures/materials that allow hermeticity, such as sealed bags (Coradi et al, 2020c). In this type of storage, insects and aerobic microorganisms in the grains create a self-inhibitory atmosphere over time, increasing the concentration of CO2and consequently decreasing that of O2, because of the respiratory metabolism (Abalone et al, 2011). Other studies indicate that the capacity to produce aflatoxin fromis reduced under high concentrations of CO2(Tefera et al, 2011).

Processing of white rice

In white rice, the outer bran layers of brown rice, composed of aleurone and surrounding the endosperm, are removed with a mill comprised of abrasive stones (Runge et al, 2019). The whitening process is divided into abrasion and friction. The fine adjustment of the equipment’s settings based on the characteristics of the grain is important to achieve high performance.

The friction between the grain particles during milling causes unevenness in size, shape and roughness. This reduces the milling quality and increases grain breakage and unevenness in the removal of bran (Zeng et al, 2018). Ahmad et al (2017) relate the intensity of milling to the texture of cooked rice. As rice milling increases (from brown rice to white rice), the cooked grains absorb more water, thereby becoming softer and exhibiting progressively faster gelatinization rates than brown rice (Buggenhout et al, 2013).

The choice of the milling degree determines the percentage of rice-bran removal, which directly influences grain yield and physical-chemical and textural properties. Rodríguez-Arzuaga et al (2016) studied the influence of the milling degree, quantified by the lipid content on the grain surface, on the appearance of the grains and found better color uniformity and increased brightness and whiteness for higher degrees of milling.

Water content of 12% during the milling helps obtain the highest whiteness for both parboiled and non-parboiled grains (Nasirahmadi et al, 2014). After milling the grains, homogenization or polishing is conducted by spraying water and air, and the rice bran that still adheres to the grain is then separated. At this stage, the mill yield is defined, based on the number of whole grains obtained at the end of the process (Kale et al, 2015; Müller et al, 2020).

The physical and mechanical properties of rice are important in determining the response of the grain to beneficiation. Unfortunately, research that correlates these parameters with the dynamics of beneficiation processes is lacking because of the difficulty in performing the experiments: the friction between the grain particles during milling changes their properties (Buggenhout et al, 2013).

Zeng et al (2018) evaluated the effects of friction in rice milling in a horizontal mill, analyzing the particle movement with different coefficients of static friction between the sieve wall and the particle, and between particles. The results indicated that the friction between the sieve walls affect the axial movement of the particle, whereas the friction between the particles influences the circular movement. The residence time is influenced by the axial movement, whereas the collision energy of the particles is influenced by the circular movement. The best uniformity of the axial movement is 0.3, and the best uniformity of circular movement can be obtained when panicle was greater than 0.1.

Brown rice processing

Brownrice processing initially follows the same steps as whiterice processing, but stops with the separation of the grains after husking. Accordingly, brown rice is highly recommended by nutritionists and has great demand potential, attracting interest from scientists, governments and consumers globally.

Because brown rice does not lose the outer layer of the grain, it has a higher content of bioactive compounds such as phenolic acids, flavonoids, aminobutyric acid, α-tocopherol and γ-tocotrienol (Gong et al, 2017). Kaur et al (2020) found that, in some cases, brown rice may have about 15% protein, 85% fat, 90% calcium, 75% phosphorus, 80% thiamine, 70% riboflavin, 90% pyridoxine, 60% iron and 68% niacin. These levels can change according to variables such as processing, handling, grain production, varieties and edaphoclimatic conditions.

Growing demand for brown rice has necessitated safe long-term storage with retention of quality. Compared to storing rice grains, storing brown rice saves significant space and is more convenient for emergency use (Thomas et al, 2015). However, because of the absence of rice husks, the quality of brown rice can easily deteriorate when the bran layer is exposed to the external environment, and this can reduce its shelf life.

Lipids, play an important role in stored-rice quality.Increase of enzyme activity can acceleratethe degradation of lipid and reduce the sensory quality of the product during storage (Ding et al, 2018).An innovative strategy for obtaining brown rice consists of the use of high-pressure processing (HPP), which is a non-thermal technology used for the preservation of food with few changes in nutritional quality and sensory aspects. HPP aims to reduce the degradation of lipids and control enzymatic reactions (Norton and Sun, 2008). Wang et al (2018) analyzed the use of HPP to contain the hydrolytic and oxidative rancidity of brown rice during storage. However, the mechanism of rancidityinfluencing the composition of fatty acids, especially the roles of lipase and lipoxygenase, is still unclear.

Parboiled rice processing

Processing parboiled rice has three main steps: immersion, gelatinization and drying (Demont et al, 2012; Venkatachalapathy and Udhayakumar, 2013). These three stages differ from those for polished and whole rice. Initially, the husked rice is immersed in water in a cylindrical body tank with a cone-shaped bottom at a temperature below the gelatinization threshold of the starch. The hydration is positively correlated with the temperature of the immersion water (Bello et al, 2007). Thus, the main factor that controls the hydration of rice is temperature (Oli et al, 2014). After drainage, the husked rice is heated to gelatinize starch by applying hot vapors (100 ºC to 120 ºC) over 5–30 min,which results in water content of approximately 35% in the grains (Sarangapani et al, 2016).

Investigating the impacts of parboiling conditions, immersion temperature (65 ºC, 70 ºC and 75 ºC), application in steam at 112 ºC, and immersion time (10, 15 and 20 min), on rice quality, Leethanapanich et al (2016) found that the maximum brownrice yield is obtained when the immersion temperature is 75 ºC. Higher immersion temperatures can accelerate hydration rates, as well as reduce fissures, as a result of swelling and rearrangement of starch granules, increasing the grain’s resistance to breakage. Deformed grains are observed as the steam-cooking duration increases, and itis related to a possible annealing process.

Gelatinization is performed in an autoclave or by rotating a cylindrical greenhouse, which causes the grains to join and fix the vitamins after immersion,resulting in the chemical changes (linked to nutritional improvements) in parboiling. Analysis of the nutritional composition of rice grains after the hydrothermal process indicated that parboiled rice has higher mineral content (18%) than that of polished rice(Heinemann et al, 2005). Further, parboiling enables the transfer of vitamins distributed in the bran to the inner layers of the caryopsis (Taghinezhad et al, 2016; Villanova et al, 2017), due to water-soluble vitamins are spread to the rice, which degrade thiamine to some extent during the heating stage and allow micronutrients to be transported to the starch endosperm from the aleurona and germ (Atungulu and Pan, 2014).

Quality control of rice grains

Traditional chemical methods are difficult, but new technologies for the physicochemical analysis of grains can assist in the characterization of quality and decision-making in post-harvest processes, minimizing the effects on grain quality while maximizing efficiency (de Medeiros et al, 2020).

The automatic inspection and evaluation of grain quality combines image analysis and machine-learning techniques such as machine vision (Kuo et al, 2016). For rice, image processing is applied for identification, quality control and germination assessment (Lurstwut and Pornpanomchai, 2017). Superficial changes can be easily detected as unlike internal damage, minor damage or micro-damage, which require detailed examinations for detection.

Interest in using image-analysis techniques to assess the internal morphology of grains and seeds has been growing in recent years. X-ray imaging can provide a quick and efficient assessment of the parts of the seeds in most species (Gomes Junior, 2010), and can identify cracks within a rice grain. Kumar and Bal (2007) clearly demonstrated internal details including cracks and air spaces between the hull and the grain.

X-ray diffraction technique can detect regular ordered repetitions of the amylopectin helices organized inside starch granules, which reflect the three-dimensional order of the starch crystals. Thus, by identifying the crystalline zones, it is possible to classify the starches through the X-ray diffraction peaks (Wang and Copeland, 2013). Zhong et al (2005) evaluated the effects of drying at ideal and high temperatures using X-ray diffraction.

Near infrared spectroscopy is an efficient method for chemical characterization and screening of agricultural crops, and it is emerging as an alternative to traditional methods (Bazoni et al, 2017). Infrared radiation is passed through a sample of the material inside a device called a spectrometer, and sensors capture the unique spectral signature of the molecular vibrations of the chemical components (Baldin et al, 2018).

Magnetic resonance imaging is a noninvasive technique involving the interaction of certain sample nuclei with an external magnetic field. The spatial coding of the precession frequencies of these nuclei permits internal structure to be visualized with high resolution and contrast. However, a detailed magnetic-resonance-imaging study of the internal morphology of seeds and grains is lacking (Köckenberger, 2001).

Occupational hazards at grain-storage units

The size of grain-storage units and the complexity of their operations make grain-handling facilities a hazardous work environment posing constant risk of severe or life-threatening injury. Occupational noise, mainly from machinery and equipment, is present at post-harvest operations. The reception and unloading of grains, the operation of dryers, the transport and handling of equipment and the expedition operation all result in occupational noise (Ramaswamy and Mosher, 2017). Dust is generated in the receiving, cleaning, handling and shipping of grains. The dust is produced by mechanical solid rupture and its composition varies according to the grain type and the methodsof harvesting, storage and processing (Rodriguez-Zamora et al, 2017).

In the grain storage unit, there are many confined spaces, including tunnels, hoppers, elevator bases and silos. The evaporation, fermentation or decomposition of grains may cause the atmosphere in these spaces to be modified by the presence of toxic gases and/or inadequate oxygen levels, and the asphyxiation is the most frequent cause of death from accidents in these conditions (Selman et al, 2019).

Grain entrapment, causing engulfment, is the hazard most associated with working in storage units. It is occurs when characterized by a worker is totally or partially covered by the mass of stored grains, either in the hopper, the silo or the grain warehouse. This kind of accident occurs when a worker is present above or under the grain mass, often attempting to combat the formation of compacted grain walls, grain crusting on the side walls of the storage structure, or the formation of air pockets under the top layer of grain (Kingman and Field, 2005).

Future research priorities

The definitions of cultivars, environment and fertilizers, and the use of harvesting strategies must be aligned with the post-harvest and rice processing stages, according to the final quality. Monitoring post-harvest changes in the physico-chemical properties of rice grains will make possible better decision-making about rice management.The drying of rice in intermittent or fixed-layer processes associated with freeze-drying technologies; drying in an oven with air convection; and microwave drying with controlled air temperatures up to 60 ºC should be further investigated. These techniques have strong possibilities of real-world industrial-scale application.Artificial refrigeration and modified environments are promising directions for storage.New technologies using sensors and software should be developed to monitor the occupational hazards and risks that occur in grain storage and processing units in real time.

ACKNOWLEDGEMENTS

The authors thank CAPES (Coordination for the Improvement of Higher Education Personnel) (Financial Code 001), CNPq (National Council for Scientific Technological Development), FAPERGS-RS (Research Support Foundation of the State of Rio Grande do Sul), UFSM (Federal University of Santa Maria)-Research Group at Postharvest Innovation: Technology, Quality and Sustainability, for their financial contributions.

Abalone R, Gáston A, Bartosik R, Cardoso L, Rodríguez J. 2011. Gas concentration in the interstitial atmosphere of a wheat silo-bag. Part II: Model sensitivity and effect of grain storage conditions., 47(4): 276‒283.

Ahmad U, Alfaro L, Yeboah-Awudzi M, Kyereh E, Dzandu B, Bonilla F, Chouljenko A, Sathivel S. 2017. Influence of milling intensity and storage temperature on the quality ofrice (L.)., 75: 386‒392.

An Y X, Zhou X Q, Zhang Y R. 2018. Changes in physicochemical, cooking and sensory characteristics of rice shifted from low-temperature storage., 1(1): 8‒14.

Aquerreta J, Iguaz A, Arroqui C, Vírseda P. 2007. Effect of high temperature intermittent drying and tempering on rough rice quality., 80(2): 611‒618.

Atungulu G G, Pan Z L. 2014. Rice industrial processing worldwide and impact on macro- and micronutrient content, stability, and retention., 1324(1): 15‒28.

Baldin T, Marchiori J N C, dos Santos G A, Gallo R, dos Santos O, Valente B M R T, Hein P R G. 2018. Evaluation of alternative sample preparation methods for development of NIR models to assess chemical properties of wood., 13(3): 5394‒5407.

Bao J S. 2019. Postharvest technology: Rice storage and cooling conservation.: Atungulu G G, Kolb R E, Karcher J, Shad Z M. Rice: Chemistry and Technology. 4th edn. St. Paul, USA: American Association of Cereal Chemists Press: 517‒555.

Barnaby J Y, Rohila J S, Henry C G, Sicher R C, Reddy V R, McClung A M. 2019. Physiological and metabolic responses of rice to reduced soil moisture: Relationship of water stress tolerance and grain production.,20(8): 1846.

Barreto A A, Abalone R, Gastón A, Ochandio D, Cardoso L, Bartosik R. 2017. Validation of a heat, moisture and gas concentration transfer model for soybean () grains stored in plastic bags (silo bags)., 158: 23‒37.

Bazoni C H V, Ida E I, Barbin D F, Kurozawa L E. 2017. Near-infrared spectroscopy as a rapid method for evaluation physicochemical changes of stored soybeans., 73: 1‒6.

Bello M O, Tolaba M P, Suarez C. 2007. Water absorption and starch gelatinization in whole rice grain during soaking., 40(2): 313‒318.

Bernaola L, Cange G, Way M O, Gore J, Hardke J, Stout M. 2018. Natural colonization of rice by arbuscular mycorrhizal fungi in different production areas., 25(3): 169‒174.

Binelo M O, Faoro V, Kathatourian O A, Ziganshin B. 2019. Airflow simulation and inlet pressure profile optimization of a grain storage bin aeration system., 164: 104923.

Buggenhout J, Brijs K, Celus I, Delcour J A. 2013. The breakage susceptibility of raw and parboiled rice: A review., 117(3): 304‒315.

Chen X, Qian P, Zhang X J, Liu F N, Lu R R. 2014. Improving instant rice quality by novel combined drying., 32(12): 1448‒1456.

Coradi P C, Fernandes C H P, Helmich J C. 2016. Adjustment of mathematical models and quality of soybean grains in the drying with high temperatures., 20(4): 385‒392.

Coradi P C, Lemes A F C, Steinhaus J I, Müller A, Alves C Z. 2018. Mathematical modeling of drying in a new concept of silo-dryer-aerator and the quality of soybean seeds ((L.) Merrill)., 8: 483‒498.

Coradi P C, Lemes  F C. 2019. Experimental prototype of silo-dryer-aerator of grains using computational fluid dynamics (CFD) system., 41(1): e36949.

Coradi P C, Müller A, Souza G A C, Steinhaus J I, Wagner R. 2020a. Quality of soybean cultivars in the drying and storage processes in real scale and experimental., 43: e13418.

Coradi P C, Nunes M T, Dutra A P, de Souza G A C, Carneiro L O, Steinhaus J I. 2020b. Evaluation of the operating system of a storage unit for drying silos and the quality of rice grains,9(9): e235997073.

Coradi P C, Padia C L, Jaques L B A, de Souza G A C, Lima R E, Müller A, Teodoro P E, Steinhaus J I, Carneiro L O. 2020c. Adaptation of technological packaging for conservation of soybean seeds in storage units as an alternative to modified atmospheres., 15(11): e0241787.

Coradi P C, Lemes A F C, Müller A, Jaques L B A, Dubal I T P, dos Santos Bilhalva N, Teodoro P E, Steinhaus J I, Maier D E. 2021. Silo-dryer-aerator in fixed and thick layer conceptualized for high quality of grains applied in different social scales post-harvest: Modeling and validation., 1: 1‒26.

de Guzman C, Esguerra M, Linscombe S, Berger G, Sha X Y, Oard J. 2017. Genetic analysis of photoperiod/thermosensitive male sterility in rice under US environments.,57(4): 1957‒1965.

de Medeiros A D, da Silva L J, da Silva J M, dos Santos Dias D C F, Pereira M D. 2020. IJCropSeed: An open-access tool for high-throughput analysis of crop seed radiographs., 175: 105555.

de Menezes N L, Pasqualli L L, Barbieri A P P, Vidal M D, Conceição G M. 2012. Drying temperatures on physical integrity, physiological quality and chemical composition of rice seeds., 42(4): 430‒436.

Demont M, Zossou E, Rutsaert P, Ndour M, van Mele P, Verbeke W. 2012. Consumer valuation of improved rice parboiling technologies in Benin., 23(1): 63‒70.

Ding C, Khir R, Pan Z L, Wood D F, Venkitasamy C, Tu K, El-Mashad H, Berrios J. 2018. Influence of infrared drying on storage characteristics of brown rice., 264: 149‒156.

Donlao N, Ogawa Y. 2017. Impact of postharvest drying conditions onstarch digestibility and estimated glycemic index of cooked non-waxy long-grain rice (L.)., 97(3): 896‒901.

Donlao N, Ogawa Y. 2018. Impacts of processing conditions on digestive recovery of polyphenolic compounds and stability of the antioxidant activity of green tea infusion duringgastrointestinal digestion., 89: 648‒656.

Donlao N, Matsushita Y, Ogawa Y. 2018. Influence of postharvest drying conditions on resistant starch content and quality of non-waxy long-grain rice(L.)., 36(8): 952‒964.

Elert E. 2014. Rice by the numbers: A good grain., 514: S50‒S51.

Elias M C, Lopes V, Gutkoski L C, Oliveira M, Mazzutt S, Dias A R G. 2007. Grain pre-storage, storage and conservation operations.: Elias M C, Oliveira M, Elias S A A, Dias A R G, Antunes P L. Post-harvest Rice: Drying, Storage and Quality. Pelotas:UFPel: 147‒244.

Faoro V, Khatchatourian O A, Binelo M O. 2018. Airflow performance analysis in bulk warehouses., 6(1): 0100221‒0100222.

Fryer M S, Slaton N A, Roberts T L, Hardke J T, Norman R J. 2019. Validation of soil-test-based phosphorus and potassium fertilizer recommendations for flood-irrigated rice.,111(5): 2523‒2535.

Gomes Junior F G. 2010. Application of image analysis to evaluate internal seed morphology., 20(3): 33‒50.

Gong E S, Luo S J, Li T, Liu C M, Zhang G W, Chen J, Zeng Z C, Liu R H. 2017. Phytochemical profiles and antioxidant activity of processed brown rice products., 232: 67‒78.

Heinemann R J B, Fagundes P L, Pinto E A, Penteado M V C, Lanfer-Marquez U M. 2005. Comparative study of nutrient composition of commercial brown, parboiled and milled rice from Brazil., 18(4): 287‒296.

Hidalgo R, Pozzolo O, Domínguez F, Serafini E, Botta G. 2013. Studies of different factors affecting the quality of rice preserved in plastic bags., 20: 23‒29.

Huang H B, Danao M G C, Rausch K D, Singh V. 2013. Diffusion and production of carbondioxide in bulk corn at various temperatures and moisture contents., 55: 21‒26.

Inprasit C, Noomhorm A. 2001. Effect of drying air temperature and grain temperature of different types of dryer and operation on rice quality., 19(2): 389‒404.

Junka N, Wongs-Aree C, Rattanamechaiskul C. 2018. Optimal drying and storage conditions for purple rice based on expected high quality., 42(2):e13502.

Kale S J, Jha S K, Jha G K, Sinha J P, Lal S B. 2015. Soaking induced changes in chemical composition, glycemic index andstarch characteristics of basmati rice., 22(5): 227‒236.

Kaur A, Bhise S, Kaur M. 2020. Hydrothermal treatments for paddy to improve physicochemical quality of brown rice., 9(5): 913‒926.

Khatchatourian O A, Binelo M O, Faoro V, Toniazzo N A. 2016. Three-dimensional simulation and performance evaluation of air distribution in horizontal storage bins., 142: 42‒52.

Khatchatourian O A, Binelo M O, Neutzling R, Faoro V. 2017. Models to predict the thermal state of rice stored in aerated vertical silos., 161: 14‒23.

Kingman D M, Field W E. 2005. Using fault tree analysis to identify contributing factors to engulfment in flowing grain in on-farm grain bins.,11(4): 395‒405.

Klaykruayat S, Mahayothee B, Khuwijitjaru P, Nagle M, Müller J. 2020. Influence of packaging materials, oxygen and storage temperature on quality of germinated parboiled rice., 121: 108926.

Köckenberger W. 2001. Functional imaging of plants by magnetic resonance experiments., 6(7): 286‒292.

Kudra T. 1996. On-farm drying and storage systems., 14(2): 477‒478.

Kumar D, Kalita P. 2017. Reducing postharvest losses during storage of grain crops to strengthen food security in developing countries., 6(1): 8.

Kumar P A, Bal S. 2007. Automatic unhulled rice grain crack detection by X-ray imaging., 50(5): 1907‒1911.

Kuo T Y, Chung C L, Chen S Y, Lin H A, Kuo Y F. 2016. Identifying rice grains using image analysis and sparse-representation-based classification., 127: 716‒725.

Lang G H, Lindemann I S, Ferreira C D, Hoffmann J F, Vanier N L, de Oliveira M. 2019. Effects of drying temperature and long-term storage conditions on black rice phenolic compounds., 287: 197‒204.

Lang G H, Lindemann I S, Goebel J T, Ferreira C D, Acunha T S, de Oliveira M. 2020. Fluidized-bed drying of black rice grains: Impact on cooking properties,starch digestibility, and bioaccessibility of phenolic compounds.,85(6): 1717‒1724.

Leethanapanich K, Mauromoustakos A, Wang Y J. 2016. Impacts of parboiling conditions on quality characteristics of parboiled commingled rice., 69: 283‒289.

Li Z Y, Wang R F, Kudra T. 2011. Uniformity issue in microwave drying., 29(6): 652‒660.

Lurstwut B, Pornpanomchai C. 2017. Image analysis based on color, shape and texture for rice seed (L.) germination evaluation., 51(5): 383‒389.

Müller A, Coradi P C, Steinhaus J I, de Souza G A C, Carneiro L O, Jaques L B A, Grohs M. 2020. Physical quality of grains benefited from rice cultivars produced at different levels of fertilization., 42: e29.

Mussi L P, Guimarães A O, Ferreira K S, Pereira N R. 2015. Spouted bed drying of jambolão () residue: Drying kinetics and effect on the antioxidant activity, anthocyanins and nutrients contents., 61(1): 80‒88.

Mutungi C, Muthoni F, Bekunda M, Gaspar A, Kabula E, Abass A. 2019. Physical quality of maize grain harvested and stored by smallholder farmers in the northern highlands of Tanzania: Effects of harvesting and pre-storage handling practices in two marginally contrasting agro-locations., 84: 101517.

Nasirahmadi A, Emadi B, Abbaspour-fard M H, Aghagolzade H. 2014. Influence of moisture content, variety and parboiling on milling quality of rice grains., 21(2): 116‒122.

Neto A J S, de Carvalho Lopes D. 2015. Thermistor based system for grain aeration monitoring and control., 116: 45‒54.

Norkaew O, Boontakham P, Dumri K, Noenplab A N L, Sookwong P, Mahatheeranont S. 2017. Effect of post-harvest treatment on bioactive phytochemicals of Thai black rice., 217: 98‒105.

Norton T, Sun D W. 2008. Recent advances in the use of high pressure as an effective processing technique in the food industry., 1: 2‒34.

Olatunde G A, Atungulu G G. 2017. Potential of turbulence interference in rough rice bin drying and storage systems fitted with cabling technology., 163: 1‒14.

Oli P, Ward R, Adhikari B, Torley P. 2014. Parboiled rice: Understanding from a materials science approach., 124(9): 173‒183.

Olorunfemi B J, Kayode S E. 2021. Post-harvest loss and grain storage technology:A review., 9(1): 75‒83.

Oyoh K B, Menkiti M C. 2013. Optimum safe drying temperature for seed grains., 3(3): 190‒192.

Parnsakhorn S, Langkapin J. 2018. Effects of drying temperatures on physicochemical properties of germinated brown rice., 40(1): 127‒134.

Patindol J, Wang Y J, Jane J I. 2003. Structure functionality changes in starch following rough rice storage., 57(5): 197‒207.

Ramaswamy S K, Mosher G A. 2017. Using workers’ compensation claims data to characterize occupational injuries in the commercial grain elevator industry.,23(3): 203‒217.

Ramos A H, Rockenbach B A, Ferreira C D, Gutkoski L C, de Oliveira M. 2019. Characteristics of flour and starch isolated from red rice subjected to different drying conditions., 71: 1800257.

Rattanamechaiskul C, Junka N, Wongs-Aree C, Prachayawarakorn S, Soponronnarit S. 2016. Influence of hot air fluidized bed drying on quality changes of purple rice., 34(12):1462‒1470.

Rodríguez-Arzuaga M, Cho S, Billiris M A, Siebenmorgen T, Seo H S. 2016. Impacts of degree of milling on the appearance and aroma characteristics of raw rice, 96(9): 3017‒3022.

Rodriguez-Zamora M G, Medina-Escobar L, Mora G, Zock J P, de Joode B V W, Mora A M. 2017. Dust exposure in workers from grain storage facilities in Costa Rica.,220(6): 1039‒1045.

Runge J, Heringer O A, Ribeiro J S, Biazati L B. 2019. Multi-element rice grains analysis by ICP OES and classification by processing types., 271: 419‒424.

Sarangapani C, Thirumdas R, Devi Y, Trimukhe A, Deshmukh R R, Annapure U S2016. Effect of low-pressure plasma on physico-chemical and functional properties of parboiled rice flour., 69(2): 482‒489.

Scariot M A, Karlinski L, Dionello R G, Radünz A L, Radünz L L. 2020. Effect of drying air temperature and storage on industrial and chemical quality of rice grains., 89: 101717.

Selman J, Spickett J, Jansz J, Mullins B. 2019. Confined space rescue: A proposed procedure to reduce the risks.,113: 78‒90.

Shad Z M, Atungulu G G. 2019. Post-harvest kernel discoloration and fungi activity in long-grain hybrid, pureline and medium-grain rice cultivars as influenced by storage environment and antifungal treatment., 81: 91‒99.

Shafiekhani S, Wilson S A, Atungulu G G. 2018. Impacts of storage temperature and rice moisture content on color characteristics of rice from fields with different disease management practices., 78: 89‒97.

Siebenmorgen T J, Bautista R C, Counce P A. 2007. Optimal harvest moisture contents for maximizing milling quality of long- and medium-grain rice cultivars., 23(4): 517‒527.

Silva J S. 2008. Drying and storage of agricultural products., (2): 560.

Singh C B, Fielke J M. 2017. Recent developments in stored grain sensors, monitoring and management technology., 20(3): 32‒55.

Singh N, Kaur L, Sandhu K S, Kaur J, Nishinari K. 2006. Relationships between physicochemical, morphological, thermal, rheological properties of rice starches., 20(4): 532‒542.

Sodhi N S, Singh N, Arora M, Singh J. 2003. Changes in physico-chemical, thermal, cooking and textural properties of rice during aging., 27(5): 387‒400.

Srisang N, Varanyanond W, Soponronnarit S, Prachayawarakorn S. 2011. Effects of heating media and operating conditions on drying kinetics and quality of germinated brown rice., 107: 385‒392.

Sung J, Kim B K, Kim B S, Kim Y. 2014. Mass spectrometry-based electric nose system for assessing rice quality during storage at different temperatures., 59: 204‒208.

Taghinezhad E, Khoshtaghaza M H, Minaei S, Suzuki T, Brenner T. 2016. Relationship between degree of starch gelatinization and quality attributes of parboiled rice during steaming., 23(6):339‒344.

Tananuwong K, Malila Y. 2011. Changes in physicochemical properties of organic hulled rice during storage under different conditions.,125(1): 179‒185.

Tefera T, Kanampiu F, de Groote H, Hellin J, Mugo S, Kimenju S, Beyene Y, Boddupalli P M, Shiferaw B, Banziger M. 2011. The metal silo: An effective grain storage technology for reducing post-harvest insect and pathogen losses in maize while improving smallholder farmers’ food security in developing countries., 30(3): 240‒245.

Teles Junior C G S, Vilela M O. 2020. Computer program for determining the equilibrium moisture content of agricultural products., 14(1): 1‒7.

Thomas R, Bhat R, Kuang Y T. 2015. Composition of amino acids, fatty acids, minerals and dietary fiber in some of the local and import rice varieties of Malaysia., 22(3): 1148‒1155.

Venkatachalapathy N, Udhayakumar R. 2013. Effects of continuous steaming on milling characteristics of tworice varieties., 20(4): 309‒312.

Villanova F A, Vanier N L, deAvila Madruga N, Pesek J, Matyska-Pesek M, Elias M C, de Oliveira M. 2017. Improvement of the quality of parboiled rice by using anti-browning agents during parboiling process., 235(5): 51‒57.

Wang H, Zhu S M, Ramaswamy H S, Hu F F, Yu Y. 2018. Effect of high pressure processing on rancidity of brown rice during storage., 93: 405‒411.

Wang S J, Copeland L. 2013. Molecular disassembly of starch granules during gelatinization and its effect on starch digestibility: A review., 4(11): 1564‒1580.

Wang T X, Khir R, Pan Z L, Yuan Q P. 2017. Simultaneous rough rice drying and rice bran stabilization using infrared radiation heating., 78: 281‒288.

Wiset L, Srzednicki G, Wootton M, Driscoll R H, Blakeney A B. 2005. Effects of high-temperature drying on physicochemical properties of various cultivars of rice., 23: 2227‒2237.

Yamamoto S, Kato K. 1999. A basic study on moisture movement and prevention of uneven moisture distribution in grain silo: Possibility of dew condensation to the silo in wall., 30: 257‒265.

Zeng Y, Jia F G, Meng X Y, Han Y L, Xiao Y W. 2018. The effects of friction characteristic of particle on milling process in a horizontal rice mill., 29(5): 1280‒1291.

Zhang S B, Zhai H C, Huang S X, Cai J P. 2014. A site-directed CO2detection method for monitoring the spoilage of stored grains by insects and fungi in Chinese horizontal warehouses., 59: 146‒151.

Zhong L J, Cheng F M, Wen X, Sun Z X, Zhang G P. 2005. The deterioration of eating and cooking quality caused by high temperature during grain filling in early-seasonrice cultivars., 191(3): 218‒225.

Zhou Z K, Robards K, Helliwell S, Blanchard C. 2010. Effect of storage temperature on rice thermal properties., 43(3): 709‒715.

Ziegler V, Ferreira C D, Tonieto L, da Silva J G, de Oliveira M, Elias M C. 2017. Storage temperature effects of brown, black and red pericarp brown rice grains on the physicochemical and paste properties., 20: e2016051.

18 February 2021;

15 July 2021

Paulo Carteri Coradi (paulo.coradi@ufsm.br)

Copyright © 2022, China National Rice Research Institute. Hosting by Elsevier B V

This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/)

Peer review under responsibility of China National Rice Research Institute

http://dx.doi.org/10.1016/j.rsci.2021.12.002

(Managing Editor: Li Guan)

杂志排行

Rice Science的其它文章

- UvWhi2 Is Required for Stress Response and Pathogenicity in Ustilaginoidea virens

- Fine Mapping of QTLs for Stigma Exsertion Rate from Oryza glaberrima by Chromosome Segment Substitution

- Simple Bioassay for PAMP-Triggered Immunity in Rice Seedlings Based on Lateral Root Growth Inhibition

- Ionomic Profiling of Rice Genotypes and Identification of Varieties with Elemental Covariation Effects

- Cold Plasma: A Potential Alternative for Rice Grain Postharvest Treatment Management in Malaysia

- Diversity of Sodium Transporter HKT1;5 in Genus Oryza