Cold Plasma: A Potential Alternative for Rice Grain Postharvest Treatment Management in Malaysia

2022-01-20MohdFadthulIkmalMisnalNorizahRedzuanMuhamadNorFirdausZainalNorhayatiAhmadRajaKamarulzamanRajaIbrahimLindaAgun

Mohd Fadthul Ikmal Misnal, Norizah Redzuan, Muhamad Nor Firdaus Zainal, Norhayati Ahmad, Raja Kamarulzaman Raja Ibrahim, Linda Agun

Review

Cold Plasma: A Potential Alternative for Rice Grain Postharvest Treatment Management in Malaysia

Mohd Fadthul Ikmal Misnal1, Norizah Redzuan1, Muhamad Nor Firdaus Zainal1, Norhayati Ahmad1, Raja Kamarulzaman Raja Ibrahim2, Linda Agun1

(Department of Physics, Faculty of Science, Universiti Teknologi Malaysia, Johor Bahru)

Use of pesticides, herbicides and fertilizers is among the techniques to control insect pests and fungal pathogens. However, the technique is the major contributor to severe environmental implications in terms of air, water and soil pollution. Besides, variable inconsistency becomes an important issue in the implementation of inclined bed dryers, leading to significant rice grain loss. Cold plasma technology has been widely proposed as a potential alternative for rice grain postharvest treatment management due to the presence of generated ionised gas that eventually produces reactive oxygen species or reactive nitrogen species. These species are used to decontaminate foodborne pathogens, mycotoxins and bacterial diseases. This review explores the current literature regarding cold plasma treatment technology, focusing on its efficiency as the microbial decontamination medium and insect pest mortality medium, and on the enhancement functional, nutritional and cooking properties, especially in rice grains. Previous studies have successfully demonstrated the ability of cold plasma treatment to significantly reduce the microbial count of foodborne pathogens, detoxify mycotoxins, and control seedborne rice seedling bacterial diseases. Previous studies have also proved that the implementation of cold plasma technology in postharvest management should be seriously considered for improving rice grain quantity and quality in Malaysia.

rice grain; postharvest management; cold plasma; microbial decontamination; bacterial control

With the global population increment, the future demand for staple food, especially rice, is estimated to increase. In fact, 80% of global rice is consumed by Asian people. In Malaysia, approximately 30%–40% of rice is imported to fulfil the annual domestic rice demand (Omar et al, 2019). The increase of domestic rice demand is consistent with the steady increment of Malaysia’s population, which was estimated from 32.5 million in 2019 to 32.7 million in 2020 (DOSM, 2020a). However, the rice production security and sovereignty in Malaysia are at stake due to the significant reduction of paddy production by 11% from 2.64× 106t in 2018 to 2.35× 106t in 2019 (DOSM, 2020a). The decrease of paddy production eventually leads to a worrying self-sufficiency ratio of rice at 69% in 2018, which is sufficient to make all local food technology scientists aware about the importance of research and development to ensure future rice sustainability with improved quality (DOSM, 2020b). Globally, the trend of paddy production decrement has been recorded in main rice producerssuch as Thailand (Amnuaylojaroen et al, 2021), Vietnam (Trinh et al, 2021), Indonesia (Agus et al, 2021), China, India and Myanmar (Wu et al, 2021).

Based on the 2019 Annual Report by the Department of Meteorology Malaysia, the average temperature shows an increase of 0.66 ºC–0.71 ºC compared to the normal temperature, which is contributed by the climate change and El-Nino Southern Oscillation cycle, leading to various extreme weather conditions, such as strong winds, heavy rains, heat waves and dry weather conditions (MetMalaysia, 2019). Under the current climate circumstances, a temperature increment of 1 ºC may affect the rice grain yield by 9.6%–10.0% (Peng et al, 2004). Moreover, rice production might drop by 9%–10% when the night temperature increases and exceeds 25 ºC. The concern arises as rice production is predicted to decrease significantly due to natural phenomena related to climate changes, such as dry spell due to 15% decrease of rainfall and flood due to 15% increase of rainfall. Based on recorded observation data, the temperature increment delayed the heading date, which led to delayed rice production. Recent mathematical model developed has projected the decrease of mean rice production by5%–7%, due to temperature increase during grain-filling period (Ahn et al, 2021). The change in temperature eventually affects the growth of rice in terms of nutrient and water absorption, photosynthesis as well as respiration processes (Hong et al, 2018).

Applied techniques, such as pesticides, herbicides and fertilizers, have led to severe environmental implications, especially in terms of air, water and soil pollution (Habibi et al, 2019; Harun et al, 2021). Moreover, those techniques significantly contribute to greenhouse gas emissions, which is one of the main factors of global warming and climate change (Yodkhum et al, 2017; Jeong et al, 2018; Zhao et al, 2019). In Malaysia, the agricultural sector is just a small contributor of greenhouse gases with 4% from the nation’s total emission, but 33% of the agricultural emission is from synthetic fertilizers. It was projected that in 2020, the rice cultivation sub-sector would contribute approximately 19.4% of the total agricultural sector emission (MESTECC, 2018).

For the sake of food security, a great emphasis on maintaining the quality of stored rice grain has been taken into consideration. However, it has become a real challenge to maintain a good quality of stored rice grain for an extended period due to Malaysia’s tropical climate. Consequently, the national rice grain storage might be jeopardised due to the decrease of rice grain quality in terms of rice grain discolouration and odour, as well as loss due to presence of mould, fungi and unwanted stored pests (Rukunudin, 2009). Apart from rice grain storage, improper or non-uniform rice grain drying eventually reduces the rice grain quantity and quality (head rice yield) by the presence of microbial organisms and agricultural pests (Jittanit et al, 2010). For industrial scale, the use of inclined bed dryers has been implemented, but certain limitations still exist especially in terms of operational parameter optimization such as efficient ventilation systems, impurity percentage prior to drying, paddy bed optimum thickness, drying air temperature, drying period and air flowrate (Nordin Ibrahim et al, 2014; Sahari et al, 2018).

In recent years, cold plasma has become one of the prospective alternatives, especially for postharvest treatment management purposes. This technology is feasible for large-volume applications without any harmful residues and additional chemicals, and it can inactivate or decontaminate pathogens without causing thermal damage (Ochi et al, 2017; Ten Bosch et al, 2017; Amnuaysin et al, 2018; Lee et al, 2018; Penado et al, 2018; Poonsawat et al, 2018). Attention has recently been focused on the emerging cold plasma treatment technology on rice grain, which is reflected in the perspective of rice grain postharvest management in Malaysia. Therefore, this review highlights the fundamentals and potential of cold plasma as a microbial decontamination medium and an insect pest mortality medium, enhancement of rice grain quality through cold plasma, and influence of treatment parameters (i.e., voltage and power, gas type and treatment time).

Fundamentals of cold plasma technology

Cold plasma is commonly referred to as the fourth state of matter with special characteristics. Cold plasma is an ionised gas composed of excited species of atoms, molecules and ions coexisting with the reactive species of electrons, negative and positive ions, free radicals, atoms and molecules in the excited or ground state. Due to its non-equilibrium status, the gas persists at low temperatures due to the cooling of ions and uncharged molecules rather than electron energy transfer (Bourke et al, 2018). Through the application of thermal energy (heating) or electromagnetic fields (electric fields or high energy light), the given gas can be ionised. The application of an electrical field is the most well-known method for technical applications of plasma at room temperature under atmospheric pressure conditions. The word ‘cold’ is often debatable within the context of cold plasma technology. In this context, cold is neither applied to sub-zero temperatures nor the convention concerning a temperature range. It is informally considered that plasma sources operating at near ambient temperatures below 60 ºC may be recognised as cold plasmas (Misra et al, 2019a, b).

Technically, cold plasma discharge is regulated by the Townsend-based ionisation avalanche mechanism. As a high voltage current is applied, free electrons are accelerated and aggressively collide with neutral gas atoms. Consequently, the collision leads to the gas ionisation phase. As the process continues, electron and ion avalanches are present in the gas gap where ion avalanches are accelerated to the cathode (i.e., ground electrode), while electron avalanches are accelerated to the anode (i.e., high voltage electrode). The high intensity of the avalanches allows the ion avalanches to release electrons from the ground electrode, igniting the release of self-sustaining gas as the phase approaches the breakdown voltage (Wagner et al, 2003).

Reactive oxygen species (ROS) and reactive nitrogen species (RNS) have been identified as the most active plasma components that can induce oxidation, and these species are highly responsible for the degradation of organic compounds or the inactivation of microorganisms (Laroussi and Leipold, 2004; Surowsky et al, 2015). Due to high reactivity, ROS and RNS can react with all cell components by breaking chemical bonds and cell membrane lesions. As a result, most reactive species contribute to etching and ultimately disperse macromolecules inside cells (Abd El-Aziz et al, 2014; Park et al, 2015; Yang et al, 2016). ROS and RNS may be used to provide important macronutrients to the targeted rice grain, resulting in the inactivation and decontamination of pathogenic fungi, thereby stopping the development of mycotoxins (Khamsen et al, 2016).

Cold plasma as microbial decontamination medium

Microbial decontamination in rice grain postharvest management should be seriously considered due to the presence of various foodborne pathogens, such as,and(Lee et al, 2016, 2018), mycotoxins produced by,and(Ten Bosch et al, 2017) as well as seedborne rice seedling bacterial diseases, for instance,and(Ochi et al, 2017). The presence of foodborne pathogens cannot be neglected as the pathogens are easily discovered in raw and cooked rice; thus, a person can be highly exposed to foodborne diseases (Ha et al, 2012). Besides, the existence of mycotoxins deteriorates crops, affecting human health (Placinta et al, 1999; Pestka, 2010). The failure to control seedborne rice seedling bacterial diseases results in yield loss (Webster, 1992).

The initial microbial count ofwas set at 5.79 and 5.80 log CFU/g for cooked brown and white rice, respectively. Using the cold plasma source generated from a dielectric barrier discharge (DBD) with the input power of 250 W, the rice samples are exposed for 5, 10 and 20 min. The longest treatment duration contributes to the highest reduction ofcount, with the final count of 2.01 and 2.03 log CFU/g for cooked brown and white rice, respectively. Similar experimental procedures were applied using another foodborne pathogen,. The initial microbial count ofis reduced significantly from 5.68 and 5.67 log CFU/g to 3.39 and 0.05 log CFU/g for cooked brown and white rice, respectively, after the longest exposure of 20 min (Lee et al, 2018). Moreover, the cold plasma treatment of 250 W with the maximum exposure time of 20 min successfully reduces the microbial count offrom 4.23 to 1.29 log CFU/g for brown rice (Lee et al, 2016). The inactivation of,andis initiated by the accumulation of sufficient charged particles on pathogens’ surface, which eventually forms an electrical field and produces cavity in pathogens’ membrane (Guo et al, 2015).

The condition of paddy with 15% moisture content and relative humidity of 75% at 25 ºC attracts the growth development of,and, with their optimal growth temperature of 30ºCto 35 ºC (and) and 45 ºCto 50 ºC () (Lacey et al, 1980). With that condition, the appropriate drying and microbial inactivation techniques are required. Several previous attempts have been made for drying of high moisture paddy using mixed flow dryer (Mondal et al, 2019), microwave treatment (Smith, 2017), as well as combined impinging stream and pneumatic drying (Nimmol et al, 2012). However, several limitations have been identified such as non-uniform drying distribution and inconsistency drying (Li et al, 2011; Wang et al, 2019), as well as lower head rice yield (Nimmol et al, 2012) although high drying rates achieved, especially in both microwave treatment and pneumatic drying. Operationally, for cold plasma treatment, electrical discharge plays the main role in order to generate chemical and bioactive radicals in terms of ROS and RNS (Laroussi and Leipold, 2004), which makescold plasma the appropriate technique for microbial inactivation. However, for large scale volume of high moisture paddy, the multi-phase treatment system should be considered to improve drying and microbial decontamination effectiveness. For example, early phase of high moisture paddy drying is carried out using mixed flow dryer, before being post-treated by cold plasma system to ensure total microbial decontamination without causing any thermal damage to treated rice grains, since cold plasma treatment has advantage in terms of microbial decontamination as well as no thermal damage to treated grains (Niemira, 2012), while mixed flow dryer ensures higher head rice yield in comparison with conventional method (Mondal et al, 2019).

Cold plasma exposure on mycotoxins is demonstrated using the extracts of rice cultures from fumonisin B1, enniatin B, sterigmatocystin and zearalenone to produce,,andmycotoxins, respectively. Each mycotoxin with the initial level of 100 µg/mL was exposed to the plasma source of a DBD with an approximate power density of 4 W/cm2, discharge gap of 2 mm and air flow of 130 L/min. In general, the degradation rate for all mycotoxins decreases as the plasma exposure duration increases. From the observation, the degradation rates of fumonisin B1 and enniatin B show linear decay, requiring only about 10 s for both mycotoxins to complete the degradation process. Meanwhile, the exponential decay behaviour can be observed in the degradation rates of sterigmatocystin and zearalenone, which requiresa slightly longer duration, approximately 20 s for complete degradation (Ten Bosch et al, 2017). Significant degradation of aflatoxins B1 by 90% and 70% was reported for cold plasma treatment at 60 W for 12 min and 40 W for 15 min, respectively (Devi et al, 2017). In addition, recent report shows the 99% reduction of deoxynivalenol (DON) mycotoxin using 85 kV cold plasma treatment with treatment time of 20 min (Ott et al, 2021). Mechanism of mycotoxins degradation through cold plasma exposure is eventually related to the generation of free radicals such as O· and ·OH during treatment. Electrically generated cold plasma discharge eventually ionizes H2O molecules, O2and CO2from utilized precursors which lead to formation of reactive gas species in terms of ROS and RNS, such as ozone, hydroxyl as well as aldehyde radicals (Misra et al, 2019a). These ROS and RNS have been identified as the most active plasma components that can induce oxidation and are significantly responsible for the degradation of mycotoxins that contribute to the cleavage of molecular bonds (Hopfe and Sheel, 2007). The cold plasma treatment towards the rice grains also has no significant change in terms of antioxidant activities on rice kernel (Yodpitak et al, 2019), although the treated rice grain samples are exposed with ROS and RNS. However, evaluation of antioxidant activity level on rice grains with respect of storage duration (e.g. 1, 2 and 3 months) is suggested to be the focus in future research.

Furthermore, successful control of seedborne rice seedling bacterial diseases (e.g.,and) using cold plasma treatment might become the game-changer in rice grain postharvest management. The rice seed samples are inoculated withandbefore being immersed in sterile distilled water for 10 min at 50 ºC and are subsequently exposed to a cold plasma source for 10 min. A customised setup of a cylindrical DBD with the applied voltage of 20 kV and air flowrate of 16 L/min is used to generate plasma discharge. Two indicators are evaluated for assessing the efficiency of cold plasma treatment: the percentage of plants with symptoms and the disease severity index (DSI). Bakanae disease initiated byis successfully reduced by 7.8% and 18.1% for the percentage of plants with symptoms and DSI, respectively. Additionally,DSI for bacterial seedling blight initiated byis significantly decreased by 38.6% and 40.1% in vacuum-inoculated seeds and infected seeds harvested from spray-inoculated rice plant heads, respectively (Ochi et al, 2017). The production of ROS during cold plasma exposure might become the major factor in reducing the percentage of plants with symptoms and DSI, especially through the accumulation of H2O2and the possible activation of plant immune systems (Torres et al, 2006; Hayashi et al, 2014).

Cold plasma as insect pest mortality medium

Insect pest infestation contributes to 5% of global rice grain loss (Xu et al, 2017). Thus, the study of optimal conditions for insect life cycle characteristics is crucial to reduce rice grain loss. In general, the optimal conditions for the insect life cycle depend on the conditions of rice storage facilities, especially the temperature and humidity of rice grain storage (Atungulu et al, 2019). Insects that deteriorate rice grain can be classified into primary and secondary insects (Wakil et al, 2010). Primary insect pests, including rice weevil, angoumois grain moth and lesser grain borer, are considered more destructive due to their penetration ability and larvae feed inside the rice grain. Secondary insects, including saw-toothed grain beetle, rust red flour beetles, cadelle, flat grain beetle, Indian meal moth, almond moth, rice moth, corn sap beetle and psocids, only eat the rice grain surface but still lead to rice grain loss in terms of quality and quantity (Atungulu et al, 2019).

The optimal conditions for the insect life cycle depend on the temperature and humidity of rice grain storage. The maximum development rate of the stored pests happens at temperature between 25 ºCto 33 ºC. Storage temperature below 25 ºC eventually slows the rate of development, and the development might cease at 17 ºC, while the increment of storage temperature between 45 ºCto 50 ºC will kill those pests within several hours. Further increment of storage temperature within 50 ºCto 60 ºC will definitely lead to pest’s mortality within several minutes. In terms of storage humidity, the relative humidity of 70% with moisture content from 9% to 14% is the optimal condition for their survival. Secondary insects favour the temperature range of rice grain storage from 25 ºC to 35 ºC with a relative humidity of 75%, which are within the range of favoured temperature and humidity conditions for primary insects (Atungulu et al, 2019). Therefore, data collection of favoured temperature and humidity conditions of the insect life cycle is necessary and required to help researchers to design an appropriate rice grain storage system to reduce and, if possible, achieve zero percent rice loss. Recent work might become a benchmark especially in data collection involving equilibrium moisture content (EMC) and equilibrium relative humidity (ERH) from selected milled rice, which eventually leads to useful mathematical model for evaluation of isotherms properties as well as allowable storage maximum moisture content, in order to become the guideline for the safe storage of rice (Chen et al, 2019).

Several studies have been conducted to demonstrate the efficiency of cold plasma on insect pest mortality. However, most studies lack important details, such as the type of grain used, initial storage temperature and initial storage moisture content. Besides, cold plasma treatment has been significantly proven as an insect pest mortality medium. Mortality of100% forandwas successfully achieved after plasma treatment for 20 s (Mohammadi et al, 2015), and 53% of pupal and 86% of larval mortality led to the low emergence of adult(i.e., 46%) after the exposure to pulsed plasma (Abd El-Aziz et al, 2014). In the early 2000s, the combination of vacuum plasma and high-frequency electromagnetic field treatment achieved 100% mortality ofwith the treatment duration of 10 s.mortality is influenced by the treatment duration, and a longer treatment duration increasesits mortality (Mishenko et al, 2000). Recent studies on insect pest control using cold plasma exposure show the possibility of 100% mortality of red flour beetles(Herbst) in all development stages from egg, larvae to adult phases, with optimized operational plasma of 2.5 kV for 15 min exposure (Ramanan et al, 2018). Besides, more comprehensive study has been developed in evaluation of mortality of,,first instar larvae andadult,andusing atmospheric pressure plasma jet. Long plasma exposure up to 21 min leads to 100% mortality ofand, with only 6.3 and 9.6 min required for 50% mortality in both insects, respectively. However, no mortality is recorded for the rest of insects, as it might be due to different characteristics of intrinsic physiological systems (Kwon et al, 2019).

Enhancement of rice seed growth and yield quantity through cold plasma technology

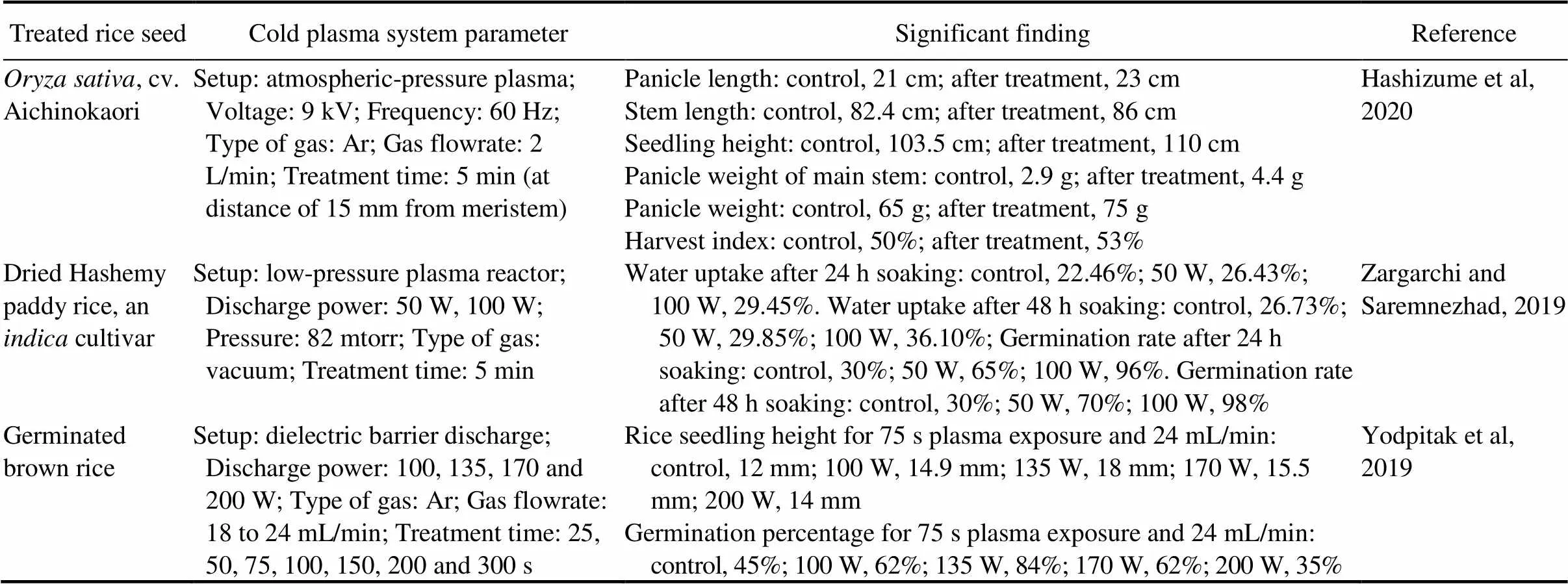

Recently, cold plasma has been utilised to improve the growth and yield quantity of rice plant seeds in a paddy field (Yodpitak et al, 2019; Zargarchi and Saremnezhad, 2019; Hashizume et al, 2020). Table 1 shows the recent compilation of field data on the effect of cold plasma exposure on rice seed germination and production. The effect of cold plasma exposure on rice seed leads to significant increase of panicle length, stem length, seedlings height, panicle weight of main stem, panicle weight, as well as harvest index. Plasma source with 60 Hz and 9 kV is set with the assistance of argon gas at the flowrate of 2 L/min. The cold plasma treatment was performed for 30 s in the open air and 5 min at a distance of 15 mm from the meristem (Hashizume et al, 2020). Significant rice paddy germination rate was also recorded, with the influence of plasma discharge power (Zargarchi and Saremnezhad, 2019). Besides, optimized treatment parameters which lead to significant increases of rice seedling height and germination percentage, such as treatment time, plasma discharge power and gas flowrate,are identified (Yodpitak et al, 2019). Nevertheless, the results of significant growth of cold plasma-treated rice plants have been explored and verified earlier in a pilot or laboratory scale (Khamsen et al, 2016; Amnuaysin et al, 2018). The significant growth of cold plasma-treated rice plants compared to untreated rice plants can be related to the mechanism of plasma etching towards rice seedlings. The etching forms microcavity in rice seedlings, which eventually increases the rate of water imbibition and enhances the growth rate of rice plants (Khamsen et al, 2016).

Table 1. Field data of cold plasma exposure on rice seed treatment.

The utilisation of cold plasma significantly improvesrice cooking properties in terms of cooking duration and textural properties (Chen et al, 2012; Thirumdas et al, 2015). Cold plasma treatment successfully reduces the brown rice cooking duration from 24.8 min for a regular cooking duration to 17.2, 18.2 and 18.8 min for cold plasma treatment of 1, 2 and 3 kV, respectively. The shorter rice cooking duration is contributed by the etching effect of cold plasma treatment that changes the rice grain morphological structure from compact bran surface into wide and shallow bran surface. The treatment eventually forms microcavity on the rice grain surface, allowing enhanced water absorption during cooking (Chen et al, 2012). Other than cooking duration, there is a significant change of basmati rice textural properties (e.g., hardness, stickiness and adhesiveness) when applying cold plasma. The hardness and stickiness decreases, but its adhesiveness increases slightly (Thirumdas et al, 2015). Solid leaching from basmati rice grains has been identified as the primary contributor to reduced hardness and increased adhesiveness (Leelayuthsoontorn and Thipayarat, 2006), whereas the leaching of starch components determines stickiness in terms of amylopectin and amylose proportions (Ong and Blanshard, 1995). Compiled literature has witnessed significant ability of cold plasma treatment in improvement of rice cooking properties especially in terms of cooking duration as well as rice textural properties. However, it is suggested that for future research, rice cooking properties should be investigated to consider the effect of rice storage duration (e.g., 1, 2 and 3 months), which enable experts to evaluate the level of rice safety and shelf-life after certain storage period.

In the perspective of nutritional and enzymatic properties, significant changes in γ-aminobutyric acid (GABA) and α-amylase have been verified for cold plasma-treated brown rice (Chen et al, 2016; Lee et al, 2016). The importance of GABA cannot be ignored as the compound is crucial for the function in the human brain, blood pressure and heart rate regulation, pain and anxiety alleviation, as well as it acts as a powerful secretagogue of insulin from the pancreas (Adeghate and Ponery, 2002). A previous study demonstrates a significant increase of GABA content from approximately 19 to 28 mg (in 3 kV cold plasma-treated brown rice) for 100 g brown rice (Chen et al, 2016). In addition,α-amylase is considered a crucial industrial enzyme that hydrolyses polysaccharides, starch and glycogen by randomly cleaving internal α-1,4-glucosidic linkages to convert sugars from starch degradation (Lee et al, 2014). A significant increment of α-amylase activity is recorded from 3.49 to 4.21, 3.99 and 3.90 U/g for 5, 10 and 20 min of cold plasma treatment, respectively (Lee et al, 2016). However, the mechanism of the increment of GABA content and α-amylase activity after cold plasma treatment is not yet understood.

Cold plasma potential in rice grain postharvest management

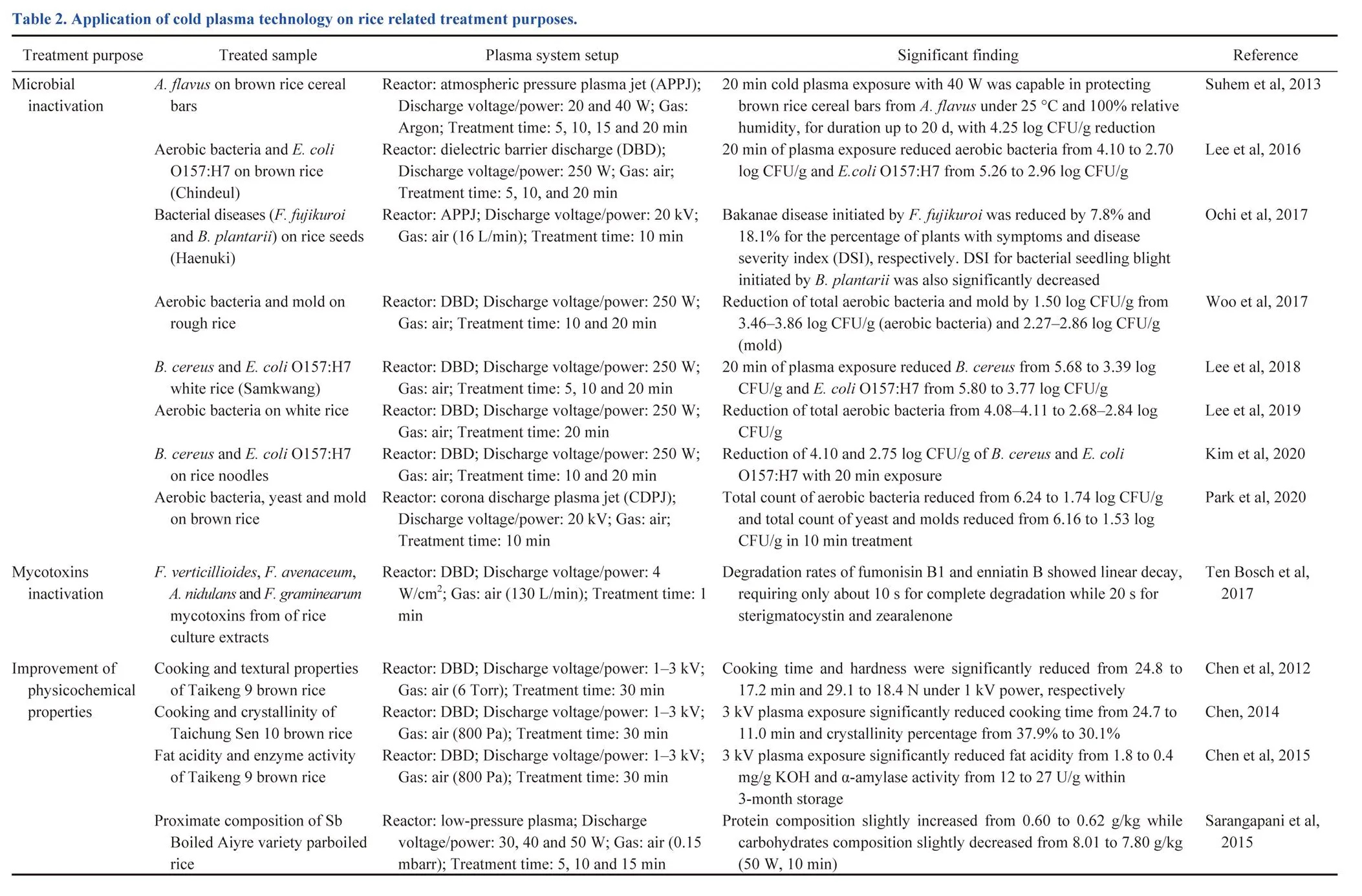

Application of cold plasma technology may lead us to more efficient postharvest management in terms of microbial and mycotoxins inactivation, improvement of physicochemical properties, as well as enhancement of seed germination. Table 2 summarizes the application of cold plasma technology on rice related treatment purposes.

Influenced treatment parameters

Designing a cold plasma reactor is part of the decontamination or inactivation of microbes in rice grain storage facilities. Several parameters should be carefully considered to ensure a high possibility of a working plasma treatment system. In this section, three influenced treatment parameters (voltage and current, gas type and treatment time) are thoroughly described.

Voltage and power

An electrical field has a significant role in dissociating oxygen molecules to form ozone through vigorous electron and ion bombardment (Pankaj et al, 2015). This eventually results in the massive production of ozone from the chemical reaction of oxygen free radicals with diatomic oxygen that contributes to etching, which ultimately disperses the cell membrane of microbes and causes possible changes in physico- chemical and cooking properties (Thirumdas et al, 2015; Muhammad et al, 2018). However, the breakdown of O–O bond requires high energy to exceed the respective breakdown voltage; thus, the use of a high-voltage power source is required (Morgan, 2009). According to the literature, the level of intensity of voltage or power input depends on a particular application. In microbial inactivation and decontamination, high intensity of input voltage or power is used. For example, high-intensity plasma treatment of 250 W is utilized to inactivate foodborne pathogens, such as,and(Lee et al, 2016, 2018). Moreover, mycotoxins produced by,andare degraded using the input voltage of 38 kV and the input power of 500 W (Ten Bosch et al, 2017). Seedborne rice seedling bacterial diseases (e.g.,and) are also treated by the cold plasma setup of 20 kV (Ochi et al, 2017).High intensity of input power of 462 W is also applied to enhance rice seed germination (Penado et al, 2018), while lower intensity of voltage or power was applied to create changes in functional, physicochemical and cooking properties of rice. A low-intensity level of the input power of 30, 40 and 50 W is applied to reduce the amylase content, endothermic enthalpies and percentage of crystallinity (Sarangapani et al, 2016), and to improve the total phenolic content and absorption intensities (Thirumdas et al, 2016). A cold plasma system with a low-intensity discharge voltage of 1–3 kV is applied to increase GABA and total phenolic content (Chen et al, 2016), to reduce fat acidity, α-amylase and lipoxygenase acidity (Chen et al, 2015), and to decrease cooking time, cooking loss and gelatinisation enthalpy (Chen, 2014). Cold plasma treatment at 120 W for 20 s significantly shortens the cooking time, and decreases the rice hardness as well as improves the elasticity and adhesiveness of milled rice.However, the intensity increment of cold plasma treatment from 120 to 520 W leads to severe rice kernel surface rupture (Liu et al, 2021). Therefore, it is interesting to study the ideal range of applied voltage and power for treatment, which can preserve the rice kernel morphology to ensure longer shelf-life for rice grain storage.

Gas type

In designing a cold plasma reactor system, the selection of carrier gas is crucial as the gas properties influence the chemical reaction produced. Most of the previous researchers tend to choose atmospheric air as the carrier gas in their customised cold plasma treatment systems, especially in the inactivation of foodborne pathogens (Lee et al, 2016, 2018), treatment of seedborne rice seedling bacterial diseases (Ochi et al, 2017), rice seed germination (Penado et al, 2018)and improvement of functional, physicochemical and cooking properties of rice (Chen, 2014; Chen et al, 2015, 2016; Sarangapani et al, 2015, 2016; Thirumdas et al, 2017). Atmospheric air contains ozone, oxygen and reactive species produced during cold plasma generation. The presence of oxygen is very important to generate ROS with strong binding energy (e.g., peroxides and ozone), resulting in effective microbial inactivation (Shi et al, 2017). The binding energy from these reactive species contributes to the deterioration of cell membrane in terms of cell apoptosis, cell leakage, mycelial tips deformation, degradation of cellular protein, loss of permeability, and also fragmentation and DNA release (Liao et al, 2017; Misra et al, 2019a). However, the major challenge in utilising atmospheric air is its low ionisation potential, which requires a higher voltage to dissociate diatomic molecules; thus, the use of a voltage power source with high intensity for plasma generation is justified (Morgan, 2009). As an alternative to air, gases which are much easier to ionise is chosen, such as argon (Khamsen et al, 2016; Yodpitak et al, 2019). However, the use of argon might incur higher operational costs as argon is more expensive (Niemira, 2012; Muhammad et al, 2018).

Treatment time

Treatment time is among the most studied parameters in cold plasma treatment for rice-related research, especially for the past five years. The increase of treatment time significantly influences the cold plasma treatment effectiveness in the decontamination of foodborne pathogens (e.g.,,and) (Lee et al, 2016, 2018), degradation of mycotoxins produced by,and(Ten Bosch et al, 2017), enhancement of rice seed germination (Yodpitak et al, 2019) and improvement of physicochemical and functional properties (Sarangapani et al, 2016). Based on the existing literature, the range of treatment time can be categorised according to treatment purposes. For example, treatment time of 5 to 20 min is applied for the inactivation of foodborne pathogens (Lee et al, 2016, 2018), whereas seedborne rice seedling bacterial diseases are treated with plasma exposure for 10 min (Ochi et al, 2017). The treatment time range between 5 and 30 min is applied on the tested rice samples to improve physicochemical, functional, storage and cooking properties (Chen, 2014; Chen et al, 2015, 2016; Sarangapani et al, 2016). In rice seed germination, the treatment time applied is capped at 5 min, ranging from 25 to 300 s (Khamsen et al, 2016; Yodpitak et al, 2019). The treatment time is capped at 1 min, ranging from 5 to 60 s, to degrade mycotoxins extracted from rice cultures (Ten Bosch et al, 2017). Therefore, the selection of treatment time range depends on treatment purposes. A longer treatment time (5 to 30 min) is suitable for the inactivation or decontamination of microbes and bacteria, as well as for any treatments to improve or enhance the physicochemical, functional, storage and cooking properties,whereas a shorter treatment time (below 5 min) is preferred for seed germination purposes and any applications involving chemical degradation and decomposition.

Grain capacity

Since conducted in laboratory scale, most of treatment setupsare designed based on limited scale of grain capacity, ranging from 3 to 20 g (Misnal et al, 2021). The arising issue is to upgrade the treatment system’s ability from small scale to large scale grain capacity in order to fulfil the industrial demand. However, first things first, one should understand the nature of cold plasma discharge, as different input parameters or setup produced different discharge characteristics (Vaideki, 2016). Basically, cold plasma discharge can be categorized into glow discharge, atmospheric pressure plasma discharge, corona discharge and DBD. Glow discharge is usually initiated by radio frequency (40 kHz, 13.45 MHz), low frequency (50 Hz) and direct current. This is a low-pressure plasma technique which easily generates uniform cold plasma discharge area coverage. For atmospheric pressure plasma discharge, the setup normally consists of combination of high flow rate of inert gases (such as He and Ar) with additives (such as O2and H2O) to generate highest possible plasma density discharge.Corona discharge is generated by applied low frequency or high voltage over an electrode pair in atmospheric pressure condition. The produced discharge will be in small lightning form which is definitely non-uniform and localized plasma discharge.DBD is generated by applying high voltage over an electrode pair (at least one of electrode being insulated by dielectric material). DBD can be considered as the combined characteristics of corona discharge with glow discharge, as the produced discharge still in lightning form, but the presence of dielectric material prevents the arcing, thus improving plasma discharge uniformity and stability.

In the aspect of rice grain postharvest treatment management, different nature of plasma discharge may be set according to different stages of treatment. For example, DBD may be applied for rice seed germination and rice grain drying stages, especially in larger capacity since DBD possess high discharge intensity with improved uniformity and stability. Atmospheric pressure plasma discharge setup can be considered for microbial and bacterial inactivation, due to the presence of RNS and ROS, which play a significant role to deteriorate the microbial and bacterial cells. Post-treatment process may be initiated by low-pressure plasma (glow discharge) to improve appearance, grading as well as textural properties of rice grains. However, realistically speaking, the treatment process involving larger capacity of rice grains eventually requires multiple plasma sources or reactors, in order to ensure discharge uniformity in higher volumetric capacity samples.

Food safety aspects

Globally, the food treatment using cold plasma technology can be considered as under regulatory review in order to ensure human safety, long term food sustainability and food ecosafety. For example, in United States, the claim of effectiveness of DBD plasma treatment in terms of reduced spoilage requires specific experimentation, data analysis and post data analysis to be present during initial pre-paperwork regulatory meeting. Involvement of regulatory bodies such as United States Department of Agriculture, Environmental Protection Agency and Food and Drug Administration are necessary for review and approval purpose in terms of regulatory oversight, as well as evaluation of new technology effectiveness (Bourke et al, 2018). Same regulation is also applied in Canada, as cold plasma technology evaluation by Canadian Food Inspection Agency is decided based on accurate, high-quality and science-based research (Varilla et al, 2020). Recent publications started to emphasize on specific experimentation and data analysis on food safety in terms of inactivation of bacterial food borne diseases (Thomas-Popo et al, 2019), microbial decontamination (Los et al, 2020), fungal decontamination (Ott et al, 2021) and heavy metal contamination and health risk assessment (Román-Ochoa et al, 2021) in order to fulfil the future requirement of cold plasma technology approval set by the corresponding regulatory authorities.

Cold plasma technology scaling up and commercialization challenges

As most of the research and development regarding cold plasma treatment in the rice-related industry is only limited to laboratory-scale size, the demand for scaling up the system is required to fulfil industrial needs. An overview on how the cold plasma technology being translated from laboratory scale to industrial scale has been highlighted and may become the benchmark for any scaling up and commercialization attempts (Cullen et al, 2018). Several approaches should be taken into consideration: (1) The use of multiple plasma sources or reactors, in order to ensure discharge uniformity in higher volumetric capacity samples (Furmanski et al, 2011). (2) Appropriate ratio of gas mixtures and operating flow rates, without effecting the production of reactive species especially in larger scale treatment process. (3) Use of microplasma arrays, in order to ensure stable discharges at atmospheric pressure (Boettner et al, 2010). (4) Use of surface or coplanar dielectric barrier discharge concept, due to its compatibility with scale-up (Brandenburg, 2017). (5) Installation of sealed enclosure (tunnel, package or containment reactor), in order to ensure retention of reactive species (Ziuzina et al, 2016). (6) Frequency of plasma dosage or plasma intensity, in order to at least maintain the nutritional content in treated food.

Several attempts have been made to scale up the cold plasma treatment system in certain applications, such as the decontamination of cherry tomatoes by integrating cold plasma technology with in-package conveyor belt (Ziuzina et al, 2016) and in grain treatment by integrating the design of drive belt with a helical dielectric barrier and mesh ground electrode (Scally et al, 2018). The idea of grain augers has also been proposed, which are designed as an enclosed treatment reactor in form of a tube fitted with a spiral shaft (Kaur et al, 2020).

However, as most researchers are preparing for the direction of technology scale-up for industrial commercialisation, the challenges in treatment parameters should not be neglected. In an industrial scale, the use of higher voltages might be required (possible to reach 130 kV) to maintain plasma uniformity for treating higher volumes of rice grains (Cullen et al, 2018). Furthermore, when dealing with higher volumes of rice grains, the treatment time range needs to be re-evaluated to determine the highest possible treatment efficiency; thus, the systematic operational cost might be affected (Feizollahi et al, 2021). Therefore, the optimization of influenced parameters with a scaled-up system should be considered for future research direction.

Potential applications of cold plasma technology in Malaysian rice industry

In Malaysia, the challenges of rice grain postharvest management include global warming, hot and humid climate, inconsistency in the implementation of operating parameters, and the overuse of pesticides, herbicides and fertilizers. These issues eventually contributed to significant air, water and soil pollution, greenhouse gas emissions and rice grain loss in terms of quantity and quality. Cold plasma can be a microbial decontamination medium, an insect pest mortality medium and also an enhancer of functional, nutritional and cooking properties, especially in rice grains. As the application of cold plasma technology offers a huge potential for the improvement of quantity and quality of rice grain, it should be considered in the Malaysian rice industry. In future research, attention should be given on the optimization of operating parameters to determine the best possible treatment and the efficiency of treatment on rice grain storage quality, especially to overcome the presence of insect pests, and also the microbial content (e.g. total bacterial count, as well as growth of yeasts and fungi)of rice grains with respect to storage duration. Last but not least, an attempt to fabricate a pilot scale of rice grain treatment system should be taken into consideration, based on optimized plasma operating parameters.

ACKNOWLEDGEMENTS

The authors thank Universiti Teknologi Malaysia Zamalah Scholarship and Universiti Teknologi Malaysia School of Graduate Studies for the financial support.

Abd El-Aziz M F, Mahmoud E A, Elaragi G M. 2014. Non thermal plasma for control of the Indian meal moth,(Lepidoptera: Pyralidae)., 59: 215‒221.

Adeghate E, Ponery A S. 2002. GABA in the endocrine pancreas: cellular localization and function in normal and diabetic rats., 34(1): 1‒6.

Agus C, Putra P B, Kusumaningrum A P, Hasanah N A I, Cahyanti P A B. 2021. Climate change and sustainable development goals program in Indonesia.: Handbook Climat Change Management. Switzerland: Springer Nature: 1‒22.

Ahn J B, Kim Y H, Shim K M, Suh M S, Cha D H, Lee D K, Hong S Y, Min S K, Park S C, Kang H S. 2021. Climatic yield potential of-type rice in the Korean Peninsula under RCP scenarios using the ensemble of multi-GCM and multi- RCM chains., 41: E1287‒E1302.

Akasapu K, Ojah N, Gupta A K, Choudhury A J, Mishra P. 2020. An innovative approach for iron fortification of rice using cold plasma., 136: 109599.

Amnuaylojaroen T, Chanvichit P, Janta R, Surapipith V. 2021. Projection of rice and maize productions in Northern Thailand under climate change scenario RCP8.5., 11(1): 23.

Amnuaysin N, Korakotchakorn H, Chittapun S, Poolyarat N. 2018. Seed germination and seedling growth of rice in response toatmospheric air dielectric-barrier discharge plasma., 40(4): 819‒823.

Atungulu G G, Kolb R E, Karcher J, Shad Z M. 2019. Postharvest technology: Rice storage and cooling conservation.: Bao J S. Rice: Chemistry and Technology. Woodhead Publishing and AACC International Press: 517‒555.

Boettner H, Waskoenig J, O’Connell D, Kim T L, Tchertchian P A, Winter J, Schulz-von der Gathen V. 2010. Excitation dynamics of micro-structured atmospheric pressure plasma arrays., 43(12): 124010.

Bourke P, Ziuzina D, Boehm D, Cullen P J, Keener K. 2018. The potential of cold plasma for safe and sustainable food production., 36(6): 615‒626.

Brandenburg R. 2017. Dielectric barrier discharges: Progress on plasma sources and on the understanding of regimes and single filaments., 26(5): 053001.

Chen H H. 2014. Investigation of properties of long-grain brown rice treated by low-pressure plasma., 7(9): 2484‒2491.

Chen H H, Chen Y K, Chang H C. 2012. Evaluation of physicochemical properties of plasma treated brown rice., 135(1): 74‒79.

Chen H H, Hung C L, Lin S Y, Liou G J. 2015. Effect of low-pressure plasma exposure on the storage characteristics of brown rice., 8(2): 471‒477.

Chen H H, Chang H C, Chen Y K, Hung C L, Lin S Y, Chen Y S. 2016. An improved process for high nutrition of germinated brown rice production: Low-pressure plasma., 191: 120‒127.

Chen Z T, Wang R L, Li X J, Zhu J, Xu Y N, Liu J J. 2019. Sorption equilibrium moisture and isosteric heat of cold plasma treated milled rice., 55: 35‒47.

Cullen P J, Lalor J, Scally L, Boehm D, Milosavljević V, Bourke P, Keener K. 2018. Translation of plasma technology from the lab to the food industry., 15(2): 1700085.

Department of Statistics Malaysia. 2020. Current Population Estimates. Malaysia [Press release]. shorturl.at/dwBNO. July 15, 2020.

Department of Statistics Malaysia. 2020. Selected Agricultural Indicators. Malaysia [Press release]. shorturl.at/zGHPS. November27, 2020.

Devi Y, Thirumdas R, Sarangapani C, Deshmukh R R, Annapure U S. 2017. Influence of cold plasma on fungal growth and aflatoxins production on groundnuts., 77: 187‒191.

Feizollahi E, Misra N N, Roopesh M S. 2021. Factors influencing the antimicrobial efficacy of Dielectric Barrier Discharge (DBD) Atmospheric Cold Plasma (ACP) in food processing applications., 61(4): 666‒689.

Furmanski J, Kim J Y, Kim S O. 2011. Triple-coupled intense atmospheric pressure plasma jet from honeycomb structural plasma device., 39(11): 2338‒2339.

Guo J, Huang K, Wang J P. 2015. Bactericidal effect of various non-thermal plasma agents and the influence of experimental conditions in microbial inactivation: A review., 50: 482‒490.

Ha J H, Kim H J, Ha S D. 2012. Effect of combined radiation and NaOCl/ultrasonication on reduction ofspores in rice., 81(8): 1177‒1180.

Habibi E, Niknejad Y, Fallah H, Dastan S, Tari D B. 2019. Life cycle assessment of rice production systems in different paddy field size levels in north of Iran., 191(4): 202.

Harun S N, Hanafiah M M, Aziz N I H A. 2021. An LCA-based environmental performance of rice production for developing a sustainable agri-food system in Malaysia., 67: 146‒161.

Hashizume H, Kitano H, Mizuno H, Abe A, Yuasa G, Tohno S, Tanaka H, Ishikawa K, Matsumoto S, Sakakibara H, Nikawa S, Maeshima M, Mizuno M, Hori M. 2020. Improvement of yield and grain quality by periodic cold plasma treatment with rice plants in a paddy field., 18: e2000181.

Hayashi N, Yagyu Y, Yonesu A, Shiratani M. 2014. Sterilization characteristics of the surfaces of agricultural products using active oxygen species generated by atmospheric plasma and UV light., 53: 05FR03.

Hong S C, Hur S O, Choi S K, Choi D H, Jang E S. 2018. Elevated temperature treatment induced rice growth and changes of carbon content in paddy water and soil., 37(1): 15‒20.

Hopfe V, Sheel D W. 2007. Atmospheric-pressure PECVD coating and plasma chemical etching for continuous processing., 35(2): 204‒214.

Jeong S T, Kim G W, Hwang H Y, Kim P J, Kim S Y. 2018. Beneficial effect of compost utilization on reducing greenhouse gas emissions in a rice cultivation system through the overall management chain., 613/614: 115‒122.

Jittanit W, Srzednicki G, Driscoll R. 2010. Seed drying in fluidized and spouted bed dryers., 28(10): 1213‒1219.

Kaur M, Hüberli D, Bayliss K L. 2020. Cold plasma: Exploring a new option for management of postharvest fungal pathogens, mycotoxins and insect pests in Australian stored cereal grain., 71(8): 715‒724.

Khamsen N, Onwimol D, Teerakawanich N, Dechanupaprittha S, Kanokbannakorn W, Hongesombut K, Srisonphan S. 2016. Rice (L.) seed sterilization and germination enhancement via atmospheric hybrid nonthermal discharge plasma., 8(30): 19268‒19275.

Kim H J, Lee B W, Baek K H, Jo C, Kim J K, Lee J Y, Lee Y Y, Kim M Y, Kim M H, Lee B. 2020. Quality characteristics of rice noodles treated with cold plasma., 52(5): 560‒563.

Kwon D H, Kim H S, Park M R. 2019. Plasma-based organism evaluation equipment using atmospheric-pressure plasma jets: Efficacy for controlling insect pests., 22(3): 868‒873.

Lacey J, Hill S T, Edwards M A. 1980. Micro-organisms in stored grains: Their enumeration and significance., 39: 19‒33.

Laroussi M, Leipold F. 2004. Evaluation of the roles of reactive species, heat, and UV radiation in the inactivation of bacterial cells by air plasmas at atmospheric pressure., 233: 81‒86.

Lee J H, Woo K S, Jo C, Jeong H S, Lee S K, Lee B W, Lee Y Y, Lee B, Kim H J. 2019. Quality evaluation of rice treated by high hydrostatic pressure and atmospheric pressure plasma., 2019: 4253701.

Lee K H, Choi H S, Choi Y H, Park S Y. 2014. Changes in isoflavone content and quality characteristics of Cheonggukjang prepared withHJ18-3 and KACC 15935., 21(1): 121‒128.

Lee K H, Kim H J, Woo K S, Jo C, Kim J K, Kim S H, Park H Y, Oh S K, Kim W H. 2016. Evaluation of cold plasma treatments for improved microbial and physicochemical qualities of brown rice., 73: 442‒447.

Lee K H, Woo K S, Yong H I, Jo C, Lee S K, Lee B W, Oh S K, Lee Y Y, Lee B, Kim H J. 2018. Assessment of microbial safety and quality changes of brown and white cooked rice treated with atmospheric pressure plasma., 27(3): 661‒667.

Leelayuthsoontorn P, Thipayarat A. 2006. Textural and morphological changes of jasmine rice under various elevated cooking conditions., 96(4): 606‒613.

Li Z Y, Wang R F, Kudra T. 2011. Uniformity issue in microwave drying., 29(6): 652‒660.

Liao X Y, Liu D H, Xiang Q S, Ahn J, Chen S G, Ye X Q, Ding T. 2017. Inactivation mechanisms of non-thermal plasma on microbes: A review., 75: 83‒91.

Liu J J, Wang R L, Chen Z T, Li X J. 2021. Effect of cold plasma treatment on cooking, thermomechanical and surface structural properties of Chinese milled rice., 14: 866‒886.

Los A, Ziuzina D, Boehm D, Bourke P. 2020. Effects of cold plasma on wheat grain microbiome and antimicrobial efficacy against challenge pathogens and their resistance., 335: 108889.

MESTECC (Ministry of Energy, Science, Technology, Environment and Climate Change). 2018. Malaysia’s Third National Communication and Second Biennial Update Report to UNFCCC. https://unfccc.int/sites/default/files/resource/Malaysia%20NC3%20BUR2_final%20high%20res.pdf.

MetMalaysia. 2019. Annual Report 2019. https://www.met.gov.my/content/pdf/penerbitan/laporantahunan/laporantahunan2019.pdf.

Mishenko A A, Malinin O A, Rashkovan V M, Basteev A V, Bazyma L A, Mazalov Y P, Kutovoy V A. 2000. Complex high-frequency technology for protection of grain against pests., 35(3): 179‒184.

Misnal M F I, Redzuan N, Zainal M N F, Ibrahim R K R, Ahmad N, Agun L. 2021. Emerging cold plasma treatment on rice grains: A mini review., 274: 129972.

Misra N N, Yadav B, Roopesh M S, Jo C. 2019a. Cold plasma for effective fungal and mycotoxin control in foods: Mechanisms, inactivation effects, and applications., 18(1): 106‒120.

Misra N N, Yepez X, Xu L, Keener K. 2019b. In-package cold plasma technologies., 244: 21‒31.

Mohammadi S, Imani S, Dorranian D, Tirgari S, Shojaee M. 2015. The effect of non-thermal plasma to control of stored product pests and changes in some characters of wheat materials., 7(5): 150‒156.

Mondal M H T, Shiplu K S P, Sen K P, Roy J, Sarker M S H. 2019. Performance evaluation of small scale energy efficient mixed flow dryer for drying of high moisture paddy., 37(12): 1541‒1550.

Morgan N N. 2009. Atmospheric pressure dielectric barrier discharge chemical and biological applications., 4(13): 885‒892.

Muhammad A I, Xiang Q S, Liao X Y, Liu D H, Ding T. 2018. Understanding the impact of nonthermal plasma on food constituents and microstructure: A review., 11(3): 463‒486.

Niemira B A. 2012. Cold plasma decontamination of foods., 3: 125‒142.

Nimmol C, Sathapornprasath K, Devahastin S. 2012. Drying of high-moisture paddy using a combined impinging stream and pneumatic drying system., 30(16): 1854‒1862.

Nordin Ibrahim M, Sarker M S H, Ab Aziz N, Mohd Salleh P M. 2014. Drying performance and overall energy requisite of industrial inclined bed paddy drying in Malaysia., 9(3): 398‒409.

Ochi A, Konishi H, Ando S, Sato K, Yokoyama K, Tsushima S, Yoshida S, Morikawa T, Kaneko T, Takahashi H. 2017. Management of bakanae and bacterial seedling blight diseases in nurseries by irradiating rice seeds with atmospheric plasma., 66(1): 67‒76.

Omar S C, Shaharudin A, Tumin S A. 2019. The Status of the Paddy and Rice Industry in Malaysia. Kuala Lumpur: Khazanah Research Institute.

Ong M H, Blanshard J M V. 1995. Texture determinants of cooked, parboiled rice: II. Physicochemical properties and leaching behaviour of rice., 21(3): 261‒269.

Ott L C, Appleton H J, Shi H, Keener K, Mellata M. 2021. High voltage atmospheric cold plasma treatment inactivatesspores and deoxynivalenol toxin., 95: 103669.

Pankaj S K, Bueno-Ferrer C, Misra N N, O'Neill L, Tiwari B K, Bourke P, Cullen P J. 2015. Dielectric barrier discharge atmospheric air plasma treatment of high amylose corn starch films., 63(2): 1076‒1082.

Park H, Puligundla P, Mok C. 2020. Cold plasma decontamination of brown rice grains: Impact on biochemical and sensory qualities of their corresponding seedlings and aqueous tea infusions., 131: 109508.

Park J H, Kumar N, Park D H, Yusupov M, Neyts E C, Verlackt C C W, Bogaerts A, Kang M H, Uhm H S, Choi E H, Attri P. 2015. A comparative study for the inactivation of multidrug resistance bacteria using dielectric barrier discharge and nano-second pulsed plasma., 5(1): 13849.

Penado K N M, Mahinay C L S, Culaba I B. 2018. Effect of atmospheric plasma treatment on seed germination of rice (L.)., 57: 01AG08.

Peng S B, Huang J L, Sheehy J E, Laza R C, Visperas R M, Zhong X H, Centeno G S, Khush G S, Cassman K G. 2004. Rice yields decline with higher nighttemperature from global warming., 101(27): 9971‒9975.

Pestka J J. 2010. Deoxynivalenol: Mechanisms of action, human exposure, and toxicological relevance., 84(9): 663‒679.

Placinta C M, D'Mello J P F, Macdonald A M C. 1999. A review of worldwide contamination of cereal grains and animal feed with., 78: 21‒37.

Poonsawat K, Kiattinun R, Worakul P, Thonglor P, Amnuaycheewa P, Dangtip S. 2018. FTIR analysis of thermal and plasma treatments on riceberry brown rice., 1144: 012175.

Potluri S, Sangeetha K, Santhosh R, Nivas G, Mahendran R. 2018. Effect of low-pressure plasma on bamboo rice and its flour., 42(12): e13846.

Ramanan K R, Sarumathi R, Mahendran R. 2018. Influence of cold plasma on mortality rate of different life stages ofon refined wheat flour., 77: 126‒134.

Román-Ochoa Y, Delgado G T C, Tejada T R, Yucra H R, Durand A E, Hamaker B R. 2021. Heavy metal contamination and health risk assessment in grains and grain-based processed food in Arequipa region of Peru., 274: 129792.

Rukunudin I H. 2009. Enhancing food safety and security during storage of paddy in Malaysia through the use of aeration technology. Proceedings of the 4th Session of the Technical Committee of APCAEM.Chiang Rai, Thailand.

Sahari Y, Abdul Wahid R, Mhd Adnan A S, Sairi M, Hosni H, Engku Abdullah E H, Alwi S, Mohd Amin Tawakkal M H, Zainol Abidin M Z, Aris Z. 2018. Study on the drying performance and milling quality of dried paddy using inclined bed dryers in two different paddy mills located in MADA and IADA KETARA., 25(6): 2572‒2578.

Sarangapani C, Devi Y, Thirumdas R, Annapure U S, Deshmukh R R. 2015. Effect of low-pressure plasma on physico-chemical properties of parboiled rice., 63(1): 452‒460.

Sarangapani C, Thirumdas R, Devi Y, Trimukhe A, Deshmukh R R, Annapure U S. 2016. Effect of low-pressure plasma on physico-chemical and functional properties of parboiled rice flour., 69: 482‒489.

Scally L, Lalor J, Gulan M, Cullen P J, Milosavljević V. 2018. Spectroscopic study of excited molecular nitrogen generation due to interactions of metastable noble gas atoms., 15(9): 1800018.

Shi H, Ileleji K, Stroshine R L, Keener K, Jensen J L. 2017. Reduction of aflatoxin in corn by high voltage atmospheric cold plasma., 10(6): 1042‒1052.

Smith D L. 2017. Development of a One Pass Microwave Heating Technology for Rice Drying and Decontamination [Master thesis]. Fayetteville, USA. University of Arkansas.

Sookwong P, Yodpitak S, Doungkaew J, Jurithayo J, Boonyawan D, Mahatheeranont S. 2014. Application of oxygen-argon plasma as a potential approach of improving the nutrition value of pre-germinated brown rice., 2(12): 946‒951.

Suhem K, Matan N, Nisoa M, Matan N. 2013. Inhibition ofon agar media and brown rice cereal bars using cold atmospheric plasma treatment., 161(2): 107‒111.

Suriyasak C, Hatanaka K, Tanaka H, Okumura T, Yamashita D, Attri P, Koga K, Shiratani M, Hamaoka N, Ishibashi Y. 2021. Alterations of DNA methylation caused by cold plasma treatment restore delayed germination of heat-stressed rice (L.) seeds., 1: 5‒10.

Surowsky B, Schlüter O, Knorr D. 2015. Interactions of non-thermal atmospheric pressure plasma with solid and liquid food systems: A review., 7(2): 82‒108.

Ten Bosch L, Pfohl K, Avramidis G, Wieneke S, Viöl W, Karlovsky P. 2017. Plasma-based degradation of mycotoxins produced by,andspecies., 9(3): 97.

Thirumdas R, Deshmukh R R, Annapure U S. 2015. Effect of low temperature plasma processing on physicochemical properties and cooking quality of basmati rice., 31: 83‒90.

Thirumdas R, Saragapani C, Ajinkya M T, Deshmukh R R, Annapure U S. 2016. Influence of low pressure cold plasma on cooking and textural properties of brown rice., 37: 53‒60.

Thirumdas R, Trimukhe A, Deshmukh R R, Annapure U S. 2017. Functional and rheological properties of cold plasma treated rice starch., 157: 1723‒1731.

Thomas-Popo E, Mendonça A, Misra N N, Little A, Wan Z F, Moutiq R, Coleman S, Keener K. 2019. Inactivation of Shiga-toxin-producing,and natural microflora on tempered wheat grains by atmospheric cold plasma., 104: 231‒239.

Torres M A, Jones J D G, Dangl J L. 2006. Reactive oxygen species signaling in response to pathogens., 141(2): 373‒378.

Trinh T A, Feeny S, Posso A. 2021. The impact of natural disasters and climate change on agriculture: Findings from Vietnam.: Taha C. Economic Effects of Natural Disasters. Elsevier: 261‒280.

Vaideki K. 2016. Plasma technology for antimicrobial textiles.: Gang S. Antimicrobial Textiles. Woodhead Publishing: 73‒86.

Varilla C, Marcone M, Annor G A. 2020. Potential of cold plasma technology in ensuring the safety of foods and agriculturalproduce: A review., 9(10): 1435.

Wagner H E, Brandenburg R, Kozlov K V, Sonnenfeld A, Michel P, Behnke J F. 2003. The barrier discharge: Basic properties and applications to surface treatment., 71(3): 417‒436.

Wakil W, Ashfaq M, Ghazanfar M U, Riasat T. 2010. Susceptibility of stored-product insects to enhanced diatomaceous earth., 46(4): 248‒249.

Wang Q F, Li S, Han X, Ni Y Y, Zhao D D, Hao J X. 2019. Quality evaluation and drying kinetics of shitake mushrooms dried by hot air, infrared and intermittent microwave-assisted drying methods., 107: 236‒242.

Webster R K, Gunnell P S. 1992. Compendium of Rice Diseases.St. Paul, USA: The American Phytopathological Society.

Woo K S, Yong H I, Jo C, Lee S K, Lee B W, Lee B W, Lee Y Y, Oh S K, Kim H J. 2017. Changes in microbial and chemical properties of rough rice treated with cold plasma by storage temperatures and periods., 24(7): 908‒914.

Wu F, Wang Y H, Liu Y, Liu Y W, Zhang Y L. 2021. Simulated responses of global rice trade to variations in yield under climate change: Evidence from main rice-producing countries., 281: 124690.

Xu S, Zhou Z Y, Li K L, Jamir S M, Luo X W. 2017. Recognition of the duration and prediction of insect prevalence of stored rough rice infested by the red flour beetle (Herbst) using an electronic nose., 17(4): 688.

Yang X L, Chang X J, Tei R T, Nagatsu M. 2016. Effect of excited nitrogen atoms on inactivation of spore-forming microorganisms in low pressure N2/O2surface-wave plasma., 49(23): 235205.

Yodkhum S, Gheewala S H, Sampattagul S. 2017. Life cycle GHG evaluation of organic rice production in northern Thailand., 196: 217‒223.

Yodpitak S, Mahatheeranont S, Boonyawan D, Sookwong P, Roytrakul S, Norkaew O. 2019. Cold plasma treatment to improve germination and enhance the bioactive phytochemical content of germinated brown rice., 289: 328‒339.

Zargarchi S, Saremnezhad S. 2019. Gamma-aminobutyric acid, phenolics and antioxidant capacity of germinatedpaddy rice as affected by low-pressure plasma treatment., 102: 291‒294.

Zhao X, Pu C, Ma S T, Liu S L, Xue J F, Wang X, Wang Y Q, Li S S, Lal R, Chen F, Zhang H L. 2019. Management-induced greenhouse gases emission mitigation in global rice production., 649: 1299‒1306.

Ziuzina D, Misra N N, Cullen P J, Keener K M, Mosnier J P, Vilaró I, Gaston E, Bourke P. 2016. Demonstrating the potential of industrial scale in-package atmospheric cold plasma for decontamination of cherry tomatoes., 6: 397‒412.

6 January 2021;

17 May 2021

Mohd Fadthul Ikmal Misnal (mofim91@gmail.com); Norizah Redzuan (norizah@utm.my)

Copyright © 2022, China National Rice Research Institute. Hosting by Elsevier B V

This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/)

Peer review under responsibility of China National Rice Research Institute

http://dx.doi.org/10.1016/j.rsci.2021.12.001

(Managing Editor: Fang Hongmin)

杂志排行

Rice Science的其它文章

- Rice Drying, Storage and Processing: Effects of Post-Harvest Operations on Grain Quality

- UvWhi2 Is Required for Stress Response and Pathogenicity in Ustilaginoidea virens

- Fine Mapping of QTLs for Stigma Exsertion Rate from Oryza glaberrima by Chromosome Segment Substitution

- Simple Bioassay for PAMP-Triggered Immunity in Rice Seedlings Based on Lateral Root Growth Inhibition

- Ionomic Profiling of Rice Genotypes and Identification of Varieties with Elemental Covariation Effects

- Diversity of Sodium Transporter HKT1;5 in Genus Oryza