Effect of New Hardening Accelerator on the Strength of Segment Concrete

2021-06-14DENGZuiliangWANGWeishanLUGuiminFULefengZHENGBaicun

DENG Zuiliang, WANG Weishan, LU Guimin, FU Lefeng, ZHENG Baicun

(1. School of Resources and Environmental Engineering, East China University of Science and Technology, Shanghai 200237, China; 2.Technical Center, Shanghai Engineering Research Center of Construction Admixtures, Shanghai 200231, China; 3. Technical Center, Shanghai Sunrise Polymer Material Co., Ltd., Shanghai 200231, China)

Abstract: A novel crystal nucleus-based cement-hardening accelerator was evaluated using various mortar and segment concrete experiments. The mechanism of hardening acceleration was investigated via hydration temperature variation analysis, hydration degree analysis, X-ray diffraction (XRD) and scanning electron microscopy (SEM). In the presence of accelerator, the fluidity loss of mortar was increased after 30 minuites, and a coagulation was also observed. Moreover, based on the image of SEM, the formation of C-S-H gels was enhanced in the early hydration. As a result, the hardening accelerator could significantly boost the early strength of concrete, especially within one day of pouring, and shorten steam curing time to meet the demolding strength.

Key words: crystal nucleus; hardening accelerator; C-S-H; hydration; strength

1 Introduction

Increasing demands of precast concrete components have been witnessed with the development of infrastructure during the last few years. An improvement in strength development rate is favorable as it would increase the mold turnover and productivity.Autoclave curing and chemical accelerator are always used to speed up the mold turnover[1,2]. Generally,autoclave curing is energy intensive; therefore, suitable chemical accelerators with good cost performance become the preferred technical solution.

Inorganic and organic accelerators have been commonly used in the fabrication of concrete for years, however, resulting defects are unavoidable.For example, the optimal dosage of triethanolamine is difficult to ascertain, and over-dosage will easily cause over-retardation and too fast setting[3]. Chlorine accelerator will cause rebar corrosion[4]. Sulfate-based accelerators result in the introduction of large bubbles,and will cause a reduction in the impermeability and corrosion resistance of the concrete[5,6]. To increase the early strength of cement-based material, C-S-H is synthesized[7]. However, a huge number of variations in structure and composition exist for synthetic C-S-H,caused by variations in the initial Ca/Si ratio of the different preparation methods[8-10]. A new crystal nucleus-based accelerator structured inorganic micro crystal/polymer hybrid particle therein can induce cement hydration into the formation of C-S-H gel,which can be used to reduce the activation energy of cement hydration reaction[11-16]. A crystal nucleus named C-S-H-300 used for concrete hardening acceleration was selected as the accelerator in this experiment in which nano-scaled calcium silicate particles were the main component. The effect of crystal nucleusbased accelerator on the workability and strength of mortar and segment concrete was investigated,and the variation in the cement hydration process and morphology of hardened paste were analyzed to elucidate the mechanism and its performance in subway segment concrete.

2 Experimental

2.1 Materials

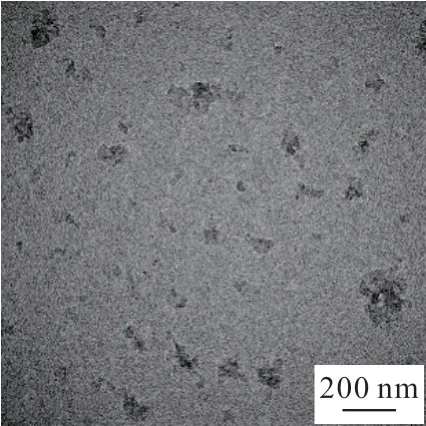

Cement (P.O 42.5) was produced by South Cement Co., Ltd. Grade-F-fly ash in accordance with the requirements of Chinese standard GB/T 1596-2005 was used. River sand with fineness module of 2.3 was used. The size of coarse aggregate was 5-25 mm.Water reducer PC-E (acrylic/trimethyl-tributylethanol polyvinyl alcohol ether copolymer) and crystal nucleus C-S-H-300 for concrete hardening acceleration were both supplied by Shanghai Sunrise Polymer Material Co., Ltd. C-S-H-300 was synthesized by precipitation method using calcium nitrate and sodium silicate. The solid content of C-S-H-300 suspension was 20.0%, and the average particle size was 200 nm. The morphology of the C-S-H sol particles by transmission electron microscopy were showed in Fig.1.

Fig.1 TEM micrograph of C-S-H-300

2.2 Equipment

Automatic thermostatic cement hydration heat meter (SHR-650D) was produced by Wuxi Jianyi Instrument & Machinery Co., Ltd.

2.3 Methods

2.3.1 Test methods

Test of mortar fluidity was referred to Chinese standard GB/T 2419-2016. Setting time of mortar was tested according to EN 196-2005. Hydration temperature of cement was recorded according to GB/T 12959-2008. Mortar strength was tested according to GB 17671-1999. Concrete strength was tested according to GB 50081-2002.

2.3.2 Test mixes

Cement: Sand: Water= 1: 2.55: 0.36, Cement: Fly ash: Sand: Gravel: Water= 358: 63: 700: 1 192: 127.6.The dosage of admixture was by weight of cement and changed to control the slump at 80 mm in concrete mix.After the preparation, concrete samples were cured in the >90% R.H. and 20±1℃ chamber for 2 h, then one set of blocks were cured in standard condition to specific age, and another set of blocks were exposed to steam curing at 50 ℃ for 5 or 3 h, before cooling in the>90% R.H. and 20±1 ℃ chamber for 1 h, and then the compressive strength of concrete was tested.2.3.3 Hydration degree

The hydration degree was analyzed by testing immobilized water. The cement sample (w/c=0.5)was cured to scheduled age with absolute ethanol to terminate the hydration. Then the sample was dried and grinded to particle size of 0.075 mm and still was dried at 60℃ to constant weight to remove the unbound water. Afterwards, the sample was calcined at 960 ℃for 30 min to remove the immobilized water.

2.3.4 Hydration temperature

The hydration temperature of cement was tested by a modified solute heat meter, and a set of automatic temperature-length measuring system was used to record the hydration temperature in time. Cement paste(w/c=0.35) was mixed and moved to container in 5 min for hydration temperature test.

2.3.5 Characterization methods

The variation of crystal structure of sample was tested by X-ray radiation (XRD). To observe the morphology of hardened paste, an SEM (JEOL; JSM-6360LV model) was used.

3 Results and discussion

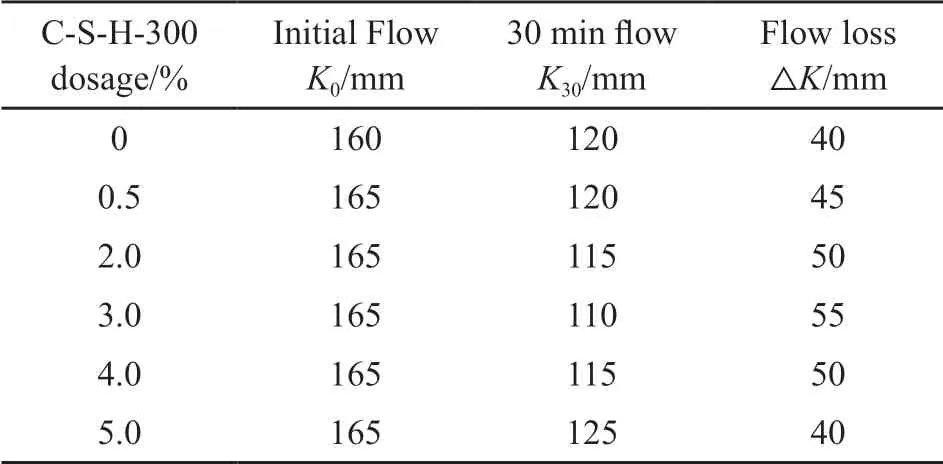

3.1 Effect of crystal nucleus accelerator on mortar fluidity loss

The fluidity test results with crystal nucleus accelerator and PC-E are listed in Table 1. The 30 min flow result shows slight increment with increasing the dosage of accelerator. As shown from Table 1, there are no further fluidty loss after the accerlator dosage of 3.0% since the flow loss from the dosage of 5.0% does not go above 55 mm. The accelerator can enhance the hydration of cement and speed up the structure building of paste with lowering the plasticity of paste.

Table 1 Effect of accelerator on mortar fluidity

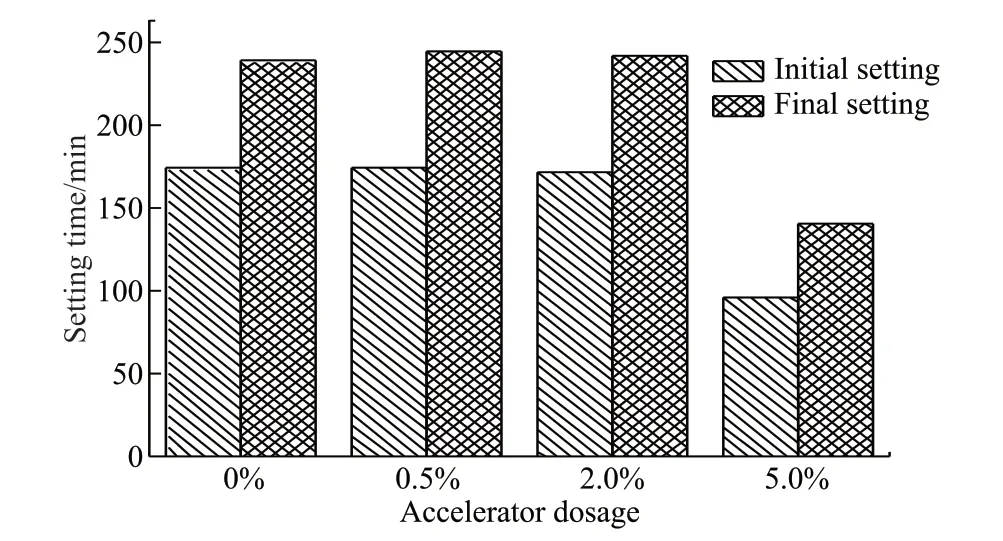

3.2 Effect of accelerator on the setting time of mortar

The effect of crystal nucleus accelerator on the setting time mortar is shown in Fig.2. The setting time of mortar shows no obvious variation when the dosage of accelerator is less than 2.0%. When the dosage of accelerator is increased to 5.0%, the initial and final setting times decrease significantly.

Fig.2 Effect of crystal nucleus accelerator on setting time of mortar

3.3 Effect of accelerator on the strength development of mortar

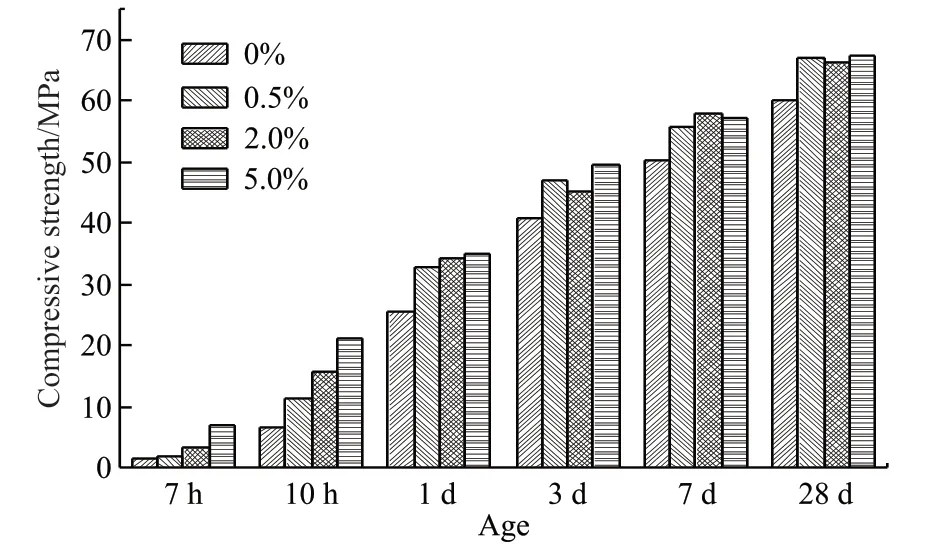

The strength development of mortar with crystal nucleus accelerator under natural curing conditions is displayed in Fig.3. The strength of mortar shows a robust enhancement with increasing dosage of crystal nucleus accelerator within the age of 1-day: for example, the sample containing 5.0% of accelerator exhibited compressive strengths of 7.1 MPa and 21.3 MPa at 7 and 10 h respectively, however, the data of the 0% sample was 1.6 and 6.7 MPa, respectively.No decreasing phenomenon is observed in the 28-day strength.

Fig.3 Effect of crystal nucleus accelerator on strength development of mortar

3.4 Effect of accelerator on the strength development of concrete

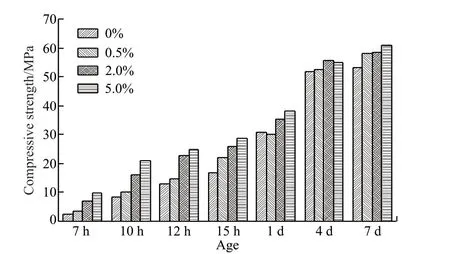

Fig.4 shows the strength development of segment concrete with crystal nucleus accelerator under standard curing condition. The early strength of concrete presents an apparent improvement with increasing crystal nucleus accelerator dosage,especially for the early strength within the age of 1-day. The 7-h compressive strength of the blank concrete specimen (0% accelerator) is only 0.4 MPa; in contrast, the 7-h compressive strength of the specimen containing 5.0% accelerator is 9.73 MPa. In addition,the 10-h compressive strength of concrete with 5.0%of accelerator is 20.8 MPa, and that of blank sample is only 8.43 MPa. Generally, the module can be released from the mold when the strength of concrete products reaches 18-20 MPa. This kind of accelerator is favorable for shortening module occupation time,improving the productivity of concrete production.

Fig.4 Effect of crystal nucleus accelerator on strength development of concrete

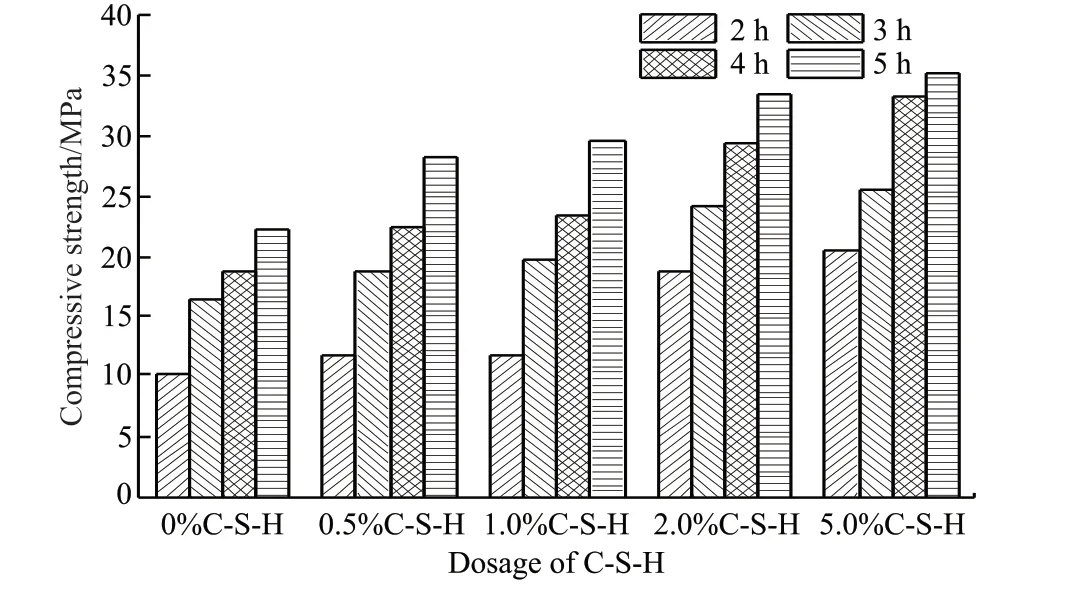

Fig.5 Effect of crystal nucleus accelerator on strength development of concrete in steam curing condition at different curing time

As is shown in Fig.5, it costs 4 hours for concrete curing at 50 ℃ without crystal nucleus accelerator to reach 18 MPa . However, adding 0.5% accelerator can reduce the curing time to 3 hours. Adding 2.0%accelerator will shorten the curing time further.

Therefore, usage of accelerator is favored since it can reduce curing temperature and shorten curing time while achieving the targeted strength[17].

3.5 Effect of accelerator on the hydration process of cement

3.5.1 Hydration temperature analysis

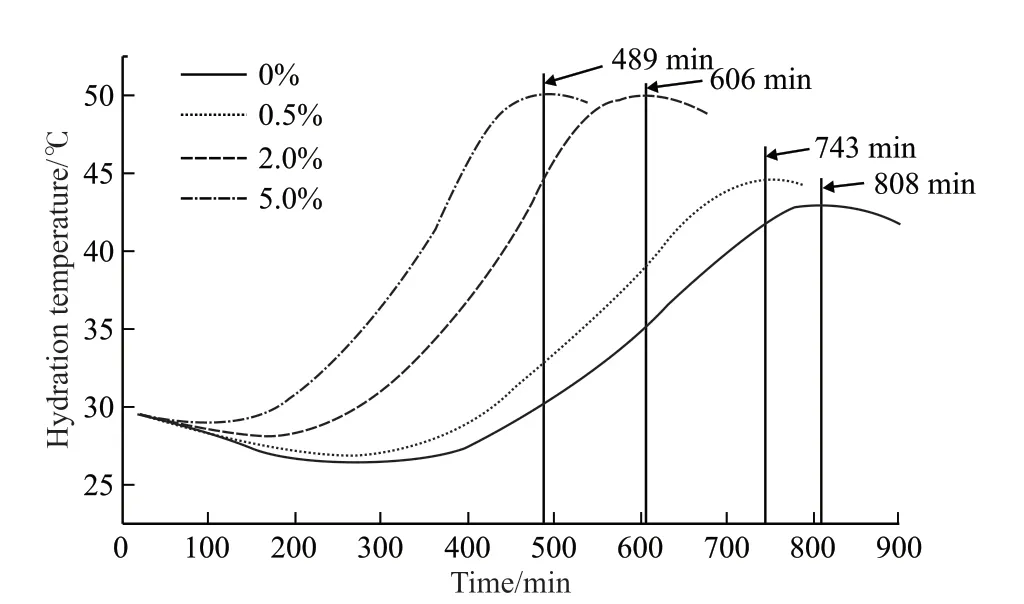

The hydration temperature curve of cement prepared with various dosage of crystal nucleus accelerator is shown in Fig.6. The time of the peak arises much earlier with higher dosage of accelerator,and the temperature at the peak is higher. The highest temperature peak (50.2 ℃) arises at 489 min with 5.0%of accelerator, 391 min earlier than that of blank sample,and the peak temperature also increases by 7.1 ℃.

Fig.6 Effect of crystal nucleus accelerator on the hydration temperature curve of cement

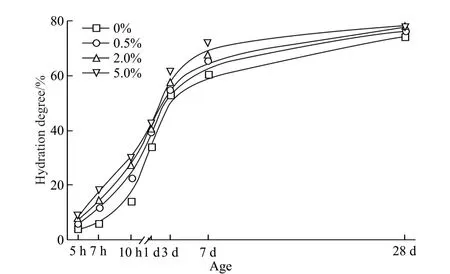

3.5.2 Hydration degree analysis

The hydration degree at different ages, ascertained by testing for chemically bound water, is shown in Fig.7. The crystal nucleus increases the hydration degree of cement, especially for the early age within 1-day. The hydration degree of the blank sample at 7-h is 6.10%, however, the hydration degree of sample with 5.0% of accelerator reaches 19.83% after the same curing time. These results show the crystal nucleus-based accelerator can promote the formation of hydration products and speed up the hydration process.

Fig.7 Effect of crystal nucleus accelerator on the hydration degree of cement

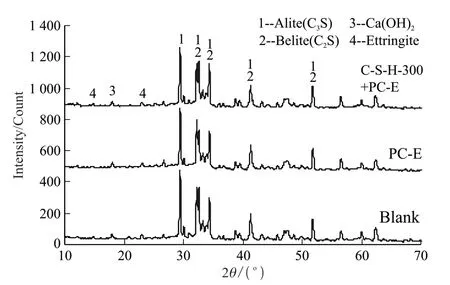

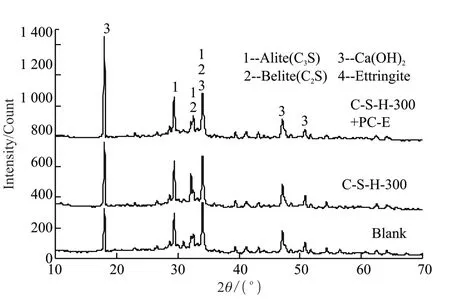

3.5.3 Hydration products analysis

The XRD analysis of hardened cement paste with varying dosage of crystal nucleus accelerator is shown in Fig.8 and Fig.9. As is shown in Fig.8, the XRD pattern of sample at 7-h shows no apparent variation in comparison to the blank sample. The peak of cement clinker (C3S, C2S) shows a slight decrease, and the intensity of ettringite peak shows no enhancement.According to the results of hydration temperature and hydration degree, after 7-h the cement has been hydrated to a large extent, however the intensity of ettringite peak shows no enhancement, indicating that the crystal nucleus accelerator promotes the hydration process by speeding up the formation of C-S-H gel.However, the XRD peak is very weak for C-S-H (not displayed in the pattern).3.5.4 Morphology analysis of hydration products

Fig.8 XRD patterns of hydration products at 7 h

Fig. 9 XRD patterns of hydration products at 3 d

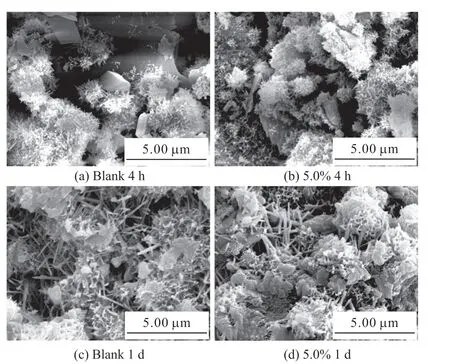

Fig.10 SEM observations of cement hydration products

The SEM images of cement hydration products are shown in Fig.10. As is shown in Fig.10(a), (b),at 4 h there are more widely distributed fiber shaped C-S-H(I) and flocculent C-S-H(II) in the sample with the accelerator than in the blank sample. In Fig.10(c),(d), the flocculent structure of 1 d samples with accelerator is denser than in the blank sample. There arises irregular flat C-S-H(III) with similar size, and C-S-H gel linked with other hydration products such as ettringite, calcium hydroxide,etc. However, loosely distributed acicular ettringite and flocculent C-S-H(II)are observed in blank sample[15].

4 Conclusions

The fluidity loss of mortar increases slightly with the addition of crystal nucleus accelerator. The setting time of mortar slightly decreases with increasing the dosage of accelerator. The early strength of mortar and segment concrete, especially the early strength within 1 day, are significantly improved with increasing dosage of crystal nucleus accelerator, without any noticeable decrease in long-term strength. Under steam curing conditions the time taken to get to the demolding strength of segment concrete was shortened by the addition of the accelerator. The cement hydration rate and hardening strength are both increased by the introduction of new crystal nucleus.

杂志排行

Journal of Wuhan University of Technology(Materials Science Edition)的其它文章

- In Vitro Angiogenic Behavior of HUVECs on Biomimetic SF/SA Composite Scaffolds

- Synthesis and Performance Characterization of a Low Adsorption Clay-resistant Polycarboxylate Superplasticizer

- Strength and Microstructural Analysis of Geopolymer Prepared with Recycled Geopolymer Powder

- Preparation of Phlogopite-based Geopolymer and Its Surface Nonpolar Modification

- Properties and Structure of PEO Treated Aluminum Alloy

- Effects of Strain Rate on the Mechanic Performance of Lattice Materials