Effect of Calcium Carbonate Whisker on Impact Toughness of Precast Concrete

2021-06-14LinnWANGYisaHEYongjiaWANGFazhouHUShuguang

LÜ Linnü, WANG Yisa, HE Yongjia, WANG Fazhou, HU Shuguang

(1. School of Science, Wuhan University of Technology, Wuhan 430070, China; 2. State Key Laboratory of Silicate Materials for Architectures (Wuhan University of Technology), Wuhan 430070, China; 3. School of Materials Science and Engineering, Wuhan University of Technology, Wuhan 430070, China)

Abstract: The impact toughness and compressive strength of concrete added with calcium carbonate whisker are studied. It is found that calcium carbonate whisker can significantly improve the impact energy consumption at failure of 55 ℃ steam cured concrete, but has limited impact on 90 ℃ steam cured concrete.At the same time, SEM, XRD and LF-NMR were used to study the micro morphology, hydration product components and pore structure of the concrete, and the mechanism of the influence of calcium carbonate whisker on the impact toughness and compressive strength of concrete was analyzed.

Key words: calcium carbonate whisker; concrete products; impact toughness; compressive strength

1 Introduction

Cement concrete is the most widely used artificial material, and plays an important role in the development of human society. Concrete has many advantages,such as easy to obtain raw materials, low cost, strong adaptability and long service life, but there are also some shortcomings, such as low tensile strength and greater brittleness. Especially, the steam cured or autoclaved precast concrete products are more likely to brittle damage under impact load, and the breakage and cracking are easy to occur during the production,transportation, construction and service of these precast concrete products, which affect the quality, performances and service life. The reason for the brittleness of the concrete experienced hydrothermal curing is that the crystallinity of the hydration products produced at high hydration temperature becomes higher and the grains becomes coarser; Furthermore, the temperature gradient and the steam transmission pressure gradient cause uneven stress distribution, which causes the micro structure damage of the concrete, and forms more micro cracks and defects.

Under impact load, the micro cracks expand rapidly, which results in brittle failure of concrete. C Famyet alFound that the higher curing temperature changed the microstructure and morphology of C-S-H hydration products[1,2]. H H Patelet alfound that under the higher steam curing temperature (85 ℃), the micro cracks of cement paste were more than that at low temperature(46 ℃)[3]. Y Xiet alfound that under continuous autoclave curing, the pore structure of slag cement paste coarsened with the prolongation of curing time[4]. Guo Liet alfound that autoclave curing increased the porosity and average pore size of concrete, which resulted in the increase of chloride diffusion coefficient and carbonation depth[5]. The change of pore structure in high strength pre-stressed pile concrete with steam curing and autoclave curing was studied by Zhiyong Liuet al.It was found that the pore structure deteriorated obviously with the increase of curing temperature[6].W G Wonget alfound that the impact toughness of cement-based materials under dynamic load is related to its curing system[7]. Youjun Xieet alfound that the micro cracks caused by thermal damage during steam curing at high temperature (80 ℃) reduced the impact resistance of concrete specimens[8].

In order to reduce the micro structure deterioration and damage of concrete products caused by heat curing, and improve the impact resistance and durability, many technical means have been adopted by researchers, including using fiber reinforcement, optimization of curing scheme, incorporation of organic polymers or mineral admixtures,etc. For example, Y Xiet alfound that adding silica fume can mitigate the pore structure deterioration caused by hydrothermal curing[4]. W G Wonget alproposed the use of polymer to improve the impact toughness of cementitious materials[7]. Youjun Xie and others regarded that in order to reduce the thermal damage during steam curing, the curing temperature should not exceed 60 ℃[8].Saif K Mezzalet alfound that adding fiber can greatly improve the fracture toughness and impact resistance of concrete[9]. In this paper, the effect of micron sized calcium carbonate whiskers on the impact toughness of concrete products is studied, and its micro mechanism is discussed.

2 Experimental

2.1 Raw materials

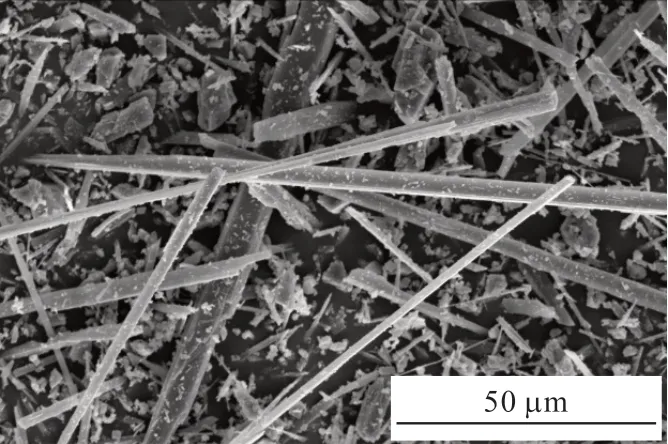

Fig.1 Micro morphology of calcium carbonate whiskers

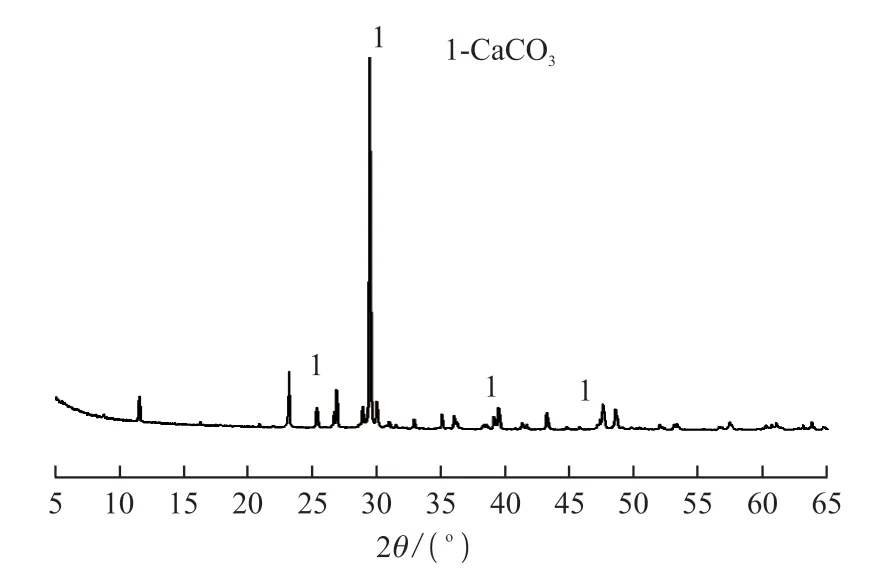

Fig.2 XRD pattern of calcium carbonate whiskers

The cement used is P·O 52.5 cement according to Chinese national standard GB175-2007, and the chemical compositions and the basic properties of the cement are shown in Table 1and Table 2 respectively.The coarse aggregate is 5-25 mm continuous graded limestone gravel; the fine aggregate is river sand with fineness modulus of 2.7. The superplasticizer is polycarboxylate type and the solid content is 12.8%. The mixing water is tap water. The commercially available calcium carbonate whisker (CW) is used as the micro fiber in the experiment. The relative density of CW is 2.8 ± 0.2 g/cm3, the diameter is 1-5 μm, and the fiber length is 20-100 μm. The micro morphology of CW is shown in Fig.1, and the X-ray diffraction (XRD) pattern is shown in Fig.2.

Table 1 Chemical composition of cement/wt%

2.2 Specimen preparation and curing

The mixture of concrete is shown in Table 3.First, polycarboxylate superplasticizer was added into the mixing water to mix evenly, and then CWs were added and stirred for 5 min. In the stirring, ultrasonic wave was used to strengthen the dispersion of CWs.The dry materials were poured into the concrete mixer and mixed for 30 s, then the water with CWs and superplasticizer was added and keeping mixing for 3 min.Meanwhile, for comparison, the control concrete specimen without CW was prepared.

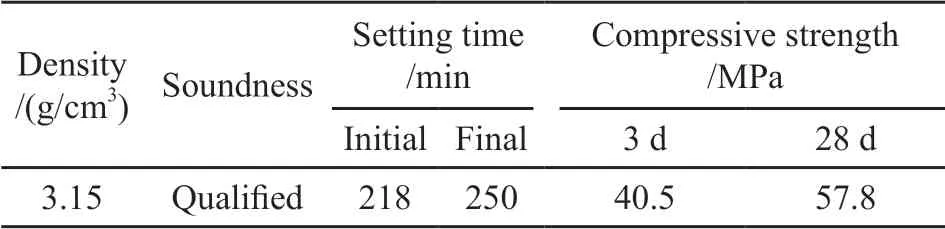

Table 2 Basic properties of cement

Table 3 Mixture of concrete/(kg/m³)

The fresh concrete was poured into φ152 mm×63.5 mm cylindrical molds and 150 mm×150 mm×150 mm cubic molds respectively, and vibrated for 30 s to prepare the specimens for impact toughness test and the compressive strength test. For standard curing,the specimens was cured at room temperature for 24 h, then demolded and put into 20±2 ℃,RH=95%±5%condition for standard curing to 28 d. For 55 ℃ steam curing, the specimens was cured at room temperature for 4 h, then put into steam curing box, steam cured at 55 ℃ for 8 h, and then standard curing to 28 d. For 90℃ steam curing, the specimens was cured at room temperature for 4 h, then put into steam curing box, steam cured at 90 ℃ for 8 h, and then standard curing to 28 d.In steam curing, the heating rate and the cooling rate are both 15 ℃/h.

Fig.3 Schematic diagram (a) and physical picture (b) of the impact device

2.3 Testing methods

The test of impact toughness was referred to the drop hammer impact test method described in ACI-544-2R, and the schematic diagram and physical picture of the device are shown in Fig.3(a) and 3(b). Each five identical specimens were a group. The impact energy consumption was calculated according to the weight and falling height of the hammer, and the falling times when the specimen was failure. Compressive strength test was according to the method described in GB/T-50081-2002.

Quanta FEG 450 scanning electron microscope(SEM) was used to observe the micro morphology of concrete samples, and the secondary electron image mode was used in the test. The samples for SEM observation were prepared by taking the core part of the concrete specimen out with sharp tool, dried at 45 ℃for 8 h and then coated with Pt under vacuum. MesoMR12-060H-1 low field nuclear magnetic resonance(LF-NMR) spectrometer was used to characterize the pore structure of the samples. Before the test, the samples need to be saturated with water in vacuum for 12 h. The echo number, repeated sampling interval and cumulative sampling times were 2 000, 3 000 and 128,respectively. The Bruker D8 advance X-ray diffractometer was used for X-ray diffraction (XRD) analysis, and the 2θtest angle was between 5 ° and 60 °.

3 Results

3.1 Impact toughness

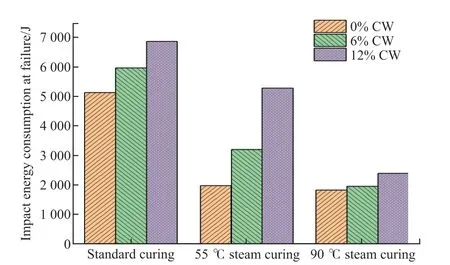

Fig.4 shows the impact toughness test results of the concrete specimens with different compositions under the conditions of standard curing, 55 and 90 ℃steam curing.

Fig.4 Energy consumption of impact failure of the concrete specimens

It can be seen from the figure that, compared with the standard curing conditions, the impact failure energy consumption of concrete specimen under standard curing is significantly higher than that of specimens steam cured at 55 and 90 ℃. The energy consumption of impact failure of the standard cured control group without CW added is 5 123 J, while that of the 55 ℃steam cured control specimen is only 1 956 J. When the steam curing temperature is increased to 90 ℃, the impact failure energy consumption of the control specimen is 1 815 J, which is close to that of the 55 ℃ steam cured specimen. The impact failure energy consumption of concrete can be increased by adding micro scale CW,and the increase range is related to the amount of CW.For the concrete specimens of standard curing, when the content of CW is 6% and 12%, the impact failure energy consumption is 16.14% and 33.86% higher than that of the control group respectively, which are 5 950 and 6 858 J respectively. For the 55 ℃ steam cured concrete specimen, the effect of CW on the energy consumption of impact failure is more obvious. When the content of CW is 6% and 12%, the impact failure energy consumption is 62.89% and 169.07% higher than that of the control group respectively. It can be seen that when the content of CW reaches 12%, the impact failure energy consumption of 55 ℃ steam cured specimen is higher than that of standard cured control group. However,when the steam curing temperature is increased to 90℃, the toughening effect of CW is weakened. When the content of the whiskers is 6% and 12%, the impact failure energy consumption is 6.67% and 31.11% higher than that of the control group respectively.

3.2 Compressive strength

Fig.5 shows the experimental results of compressive strength of the specimens with different contents of CW under the conditions of standard curing, 55 and 90 ℃ steam curing.

Fig.5 Compressive strength of specimens at different ages

It can be seen from the figure that steam curing significantly improves the early compressive strength of concrete specimens. When steam cured at 55 ℃,the 1, 3 and 7 d compressive strength of concrete specimens are increased respectively 39.3%, 24.2% and 18.8% compared to the standard curing specimens. The 1 d compressive strength of concrete steam cured at 90℃ is 40.1 MPa, higher than that of standard cured and 55 ℃ steam cured specimens 53.1% and 9.9% respectively, and the 3 d compressive strength is 41.6 MPa,which is equivalent to 55 ℃ steam cured specimen and higher than standard cured specimen. The adding of 6% CW is beneficial to the compressive strength of the concrete specimens cured at all the three curing conditions, however, with the content of CW increased to 12%, the compressive strengths of the concrete specimens decrease a little, but still comparable to the specimens without CW.

3.3 Mineral compositions of hydration products

The XRD patterns of the specimens with 0%, 6%and 12% CW and prepared under different curing conditions are shown in Fig.6 (a)-(c). It can be seen from the figure that there are obvious diffraction peaks of CaCO3in all the samples added with CW, but it is not obvious in the control sample without CW. At the same time, the minor diffraction peak of calcium monocarboaluminate hydroxide and calcium hemicarboaluminate hydroxide minerals can be observed in the samples added with CW, which indicates that a small number of finer CW may participate in the hydration reaction of cement and combine with aluminum to form calcium carboaluminate hydroxide.

Fig 6 The XRD patterns of the specimens with 0%, 6% and 12%CW

3.4 Micromorphology

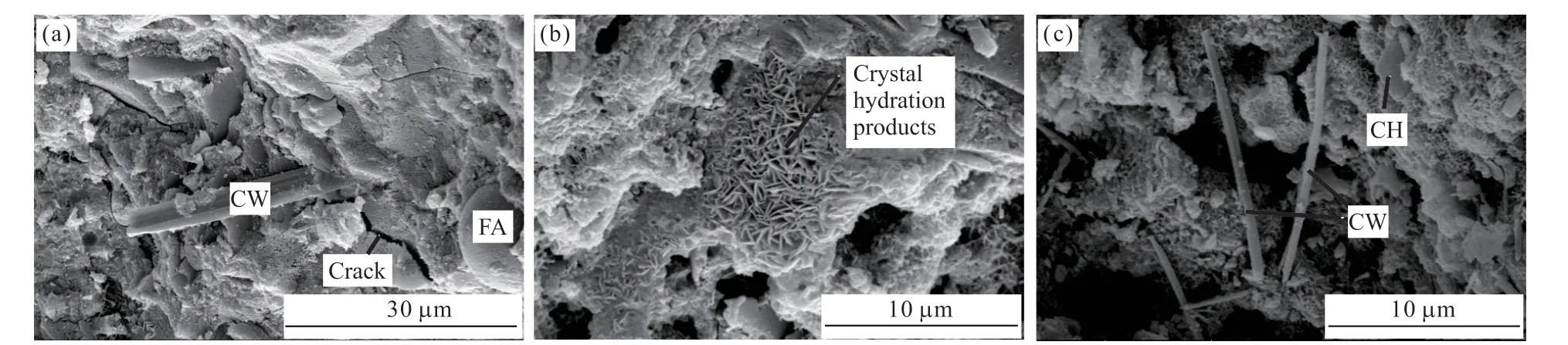

The micro morphology (SEM image) of the specimens with 0%, 6% and 12% CW and prepared under different curing conditions is shown in Fig.7 - Fig.9 respectively. Fig.7 shows the control specimen without whisker. It can be seen from the figure that the micro morphology of the specimen changes with the curing temperature. The cement hydration products of the control specimen cured at 20 ℃ is relatively dense. The surface of the fly ash particle (it is believed from the mineral admixture of cement) embedded in the matrix is smooth without obvious reaction trace, which indicates that flay ash in cement paste shows low reactivity at 20 ℃ (Fig.7(a)). Some micro cracks and crystal hydration products can be seen in the 55 ℃ steam cured specimen (Fig.7(b), Fig.8(b)), and there are some traces of reaction on the fly ash particles,e g, some very small granular hydration products (Fig.9(b)), which indicates that fly ash particle shows higher hydration reactivity at 55 ℃ than at 20 ℃. Furthermore, there are plenty of crystal hydration products and pores observed in the 90 ℃ steam cured specimen (Fig.7(c)). Compared with the specimens cured at 20 and 55 ℃, the morphology of hydrated calcium silicate in the specimens cured at 90 ℃ is more likely to be microfibril or granular with higher degree of crystallization. It is shown in Fig.9(c)that the fly ash particle in the 90 ℃ steam cured specimen has obvious reaction traces and produces coarse hydration products. In the SEM images of the specimens added with CW, it can be seen that CW embeds in the hardened cement paste (Fig.8(a), Fig.8(c)), and prevents the extension of the crack (Fig.8(a)). However, with the increase of the content of CW from 6% to 12%, the agglomeration phenomenon is observed in the cement paste (Fig.9(a)).

Fig.7 SEM images of the samples with 0% CW: (a) 20 ℃; (b) 55 ℃; (c) 90 ℃

Fig.8 SEM images of the samples with 6% CW: (a) 20 ℃; (b) 55 ℃; (c) 90 ℃

Fig.9 SEM images of the samples with 12% CW: (a) 20 ℃; (b) 55 ℃; (c) 90 ℃

3.5 Pore structure

LF-NMR was used to characterize the pore structure of the concrete specimens. The results are shown in Fig.10 - Fig.12. The LF-NMR spectrum reflect the signal of hydrogen atom. Due to the different environment of hydrogen atom, the influence of surrounding atoms on it is different, which will affect the time (relaxation time,T2) required for it to return to equilibrium. The relaxation time corresponds to the pore size of the sample saturated with water, and the larger the pore is, the longer the relaxation time of hydrogen atom in water will be. Therefore, the pore size distribution can be characterized by the distribution ofT2spectrum. It can be seen from the figures that there is a main peak in the distribution diagram ofT2, and there are two less obvious secondary peaks. With the increase of the curing temperature, the relaxation peak shifts to the right,that is,T2increases, which indicates that the pore size increases with the increase of curing temperature. This trend is obvious in the samples with 6% CW content,but in the samples with 12% CW content, there is little difference between the 20 ℃ standard cured sample and the 55 ℃ steam cured sample. It is considered that 12% CW may improve the compactness of 55 ℃ steam cured sample due to its filling effect.

Fig.10 T2 distribution of the 0% CW specimens

Fig.11 T2 distribution of the 6% CW specimens

Fig.12 T2 distribution of the 12% CW specimens

4 Analysis and discussion

From the micromorphology shown in Fig.1, it can be seen that CWs are typical micro fibers, and the length of single fiber is mostly between 50-100 μm. A large number of studies have reported that fibers have good toughening and crack resistance effects on cement-based materials[10-12]. The commonly used steel fibers, polymer fibers and carbon fibers are mostly visible to the naked eye, and their length is usually above the millimeter level, even up to the centimeter level. In recent years, a large number of nano and micro scale fibers have been studied and applied in cement-based materials. It is reported that the incorporation of these fibers significantly improves the tensile strength and toughness of brittle cement-based material[13-16]. Compared with nano carbon fibers and nano carbon tubes,the preparation of calcium carbonate micro fibers is much cheaper. When the concrete is under stress,the micro cracks begin to germinate from the defects formed in the hardened cement paste and the weak interfacial transition zone (ITZ) between cement paste and the aggregate. When the stress increases, the micro cracks will extend into micro cracks. With the further increase of stress, meso cracks propagate into macro cracks, which leads to the failure of concrete. Steel fiber, polyacrylonitrile fiber and carbon fiber play an important role in preventing the propagation of macro cracks, but they have little effect on preventing the propagation of micro cracks, while micro fibers such as CWs can effectively prevent the propagation of micro cracks[17]. Mehran Khanet albelieved that CWs can act as micro fibers in hardened cement paste to bridge the micro cracks or deflect, thus consuming cracking energy and improving the crack resistance of cement paste[18]. The cracking behavior of concrete under dynamic load such as impact load is different from that caused by static load, but the fiber also plays an effective role in preventing the cracking caused by dynamic load, and its mechanism is that the bridging effect of fiber on the crack surface effectively improves the energy absorption of concrete against impact[19]. Fig.8(a)shows that CWs are embedded in the cement matrix and closely combined with it, which play a role of bridging the cracks and consuming the impact energy on the micro scale.

For the three samples of standard curing, 55 ℃steam curing and 90 ℃ steam curing, the effect of CW on the impact toughness of 55 ℃ steam curing samples is the most obvious, and the effect of 12% is better than that of 6%. However, its effect of improving the impact toughness of 90 ℃ steam curing samples is limited. It is analyzed that the main reason may be that the high temperature of 90 ℃ steam curing forms many largescale damages and defects in the concrete samples(Fig.8(c)). As a result, micro cracks expand rapidly and converge into macro cracks under impact loading, so the role of micro calcium carbonate whiskers is limited.Youjun Xieet alstudied the influence of steam curing temperature on the impact mechanical characteristics of concrete, and they found that the impact resistance decreased with the increase of curing temperature. They suggested that in order to reduce the thermal damage in the process of steam curing, the curing temperature should not exceed 60 ℃[8].

In addition, CWs also affect the hydration process and hydration products of cement to a certain extent.Mingli Cao investigated the effect of CW on the hydration and strength of cement paste, and it is found that the whiskers added into the cement play a role of “dilution”, at the same time, they play a role of crystal seed due to the size effect, which promotes the deposition and growth of hydration products on the their surface,and makes the combination between the whiskers and the cement paste closer; On the other hand, CW can also react with aluminum phase minerals in cement[20].According to the XRD pattern shown in Fig.6, CW really participated in the hydration reaction and led to the formation of calcium carboaluminate hydroxide minerals. Although the dilution effect and seed effect of CW promote the hydration of cement to a certain extent, it replaces part of cement, resulting in the reduction of cement content. When the dosage is higher (12%), it affects the development of concrete strength (Fig.5).

5 Conclusions

a) The addition of CW has a positive effect on improving the impact toughness of concrete products,especially for the 55 ℃ steam cured concrete. When the whisker content is 6% and 12%, the impact failure energy consumption is increased by 62.89% and 169.07%. The mechanism is that the micro cracks are prevented from expanding and merging into macro cracks by micro scale CWs. However, when the steam curing temperature is too high (90 ℃), the improvement effect is limited. The reason may be that the high steam curing temperature causes more and larger thermal damage defects in the concrete products.

b) Some finer CW may take part in the hydration process of cement, and it can react with the clinker minerals to produce calcium carboaluminate hydroxide minerals. When the content of CW is high, the cement content is reduced correspondingly, which has a certain influence on the compressive strength of the concrete.

杂志排行

Journal of Wuhan University of Technology(Materials Science Edition)的其它文章

- In Vitro Angiogenic Behavior of HUVECs on Biomimetic SF/SA Composite Scaffolds

- Synthesis and Performance Characterization of a Low Adsorption Clay-resistant Polycarboxylate Superplasticizer

- Strength and Microstructural Analysis of Geopolymer Prepared with Recycled Geopolymer Powder

- Preparation of Phlogopite-based Geopolymer and Its Surface Nonpolar Modification

- Properties and Structure of PEO Treated Aluminum Alloy

- Effects of Strain Rate on the Mechanic Performance of Lattice Materials