Study on the environmental effects of heavy metals in coal gangue and coal combustion by ReCiPe2016 for life cycle impact assessment

2020-12-30PENGHaoWANGBaofengYANGFenglingCHENGFangqin

PENG Hao, WANG Bao-feng, YANG Feng-ling, CHENG Fang-qin

(Institute of Resources and Environmental Engineering, Engineering Research Center of CO2 Emission Reduction and Resource Utilization-Ministry of Education of the People′s Republic of China, Shanxi University, Taiyuan 030006, China)

Abstract: During coal and coal gangue combustion, many heavy metal pollutants are emitted and cause serious environmental problems.In this paper, the environmental effect values of As and Pb emission during coal gangue and coal combustion in the 330 MW pulverized coal boiler, 50 kW circulated fluidized bed boiler and laboratory were calculated by ReCiPe2016.The results show that when coal combustion in 330 MW pulverized coal boiler, the environment effect values of As for bottom slag, fly ash and flue gas are 3.28×10-6, 2.68×10-5 and 3.89×10-3 respectively; while the environment effect value of Pb for bottom slag, fly ash and flue gas are 8.57×10-6, 6.00×10-5 and 4.83×10-2, respectively.The environmental effects of As and Pb in bottom slag are lower than those in the fly ash; and the environmental effects of As and Pb on air are higher than those on soil.Moreover, when coal combustion in the 50 kW circulated fluidized boiler, the effect values of As and Pb in fly ash on environment are 3.26×10-5 and 1.28×10-4; and the effect values of As and Pb in bottom slag are 1.16×10-6 and 1.43×10-5 respectively.The results also show that when coal gangue combustion in the laboratory, the effect values of As and Pb emission increase with increasing of the temperature; and the proportions of total environmental effects of As and Pb on air are higher than those on soil.Besides that, this study also indicates that the effect of Pb emitted into environment is higher than that of As at the same conditions during coal combustion both in circulated fluidized boiler and pulverized coal boiler.The results may provide basic data for predicting the environmental effects of As and Pb during coal gangue combustion in circulating fluidized bed for life cycle impact assessment.

Key words: coal gangue; heavy metals; combustion; environmental effect

Combustion is one of the main ways to use coal gangue and coal effectively.Coal gangue and coal contain many kinds of heavy metals which can be emitted and cause serious environmental pollution during combustion.Therefore, studying environmental effects of heavy metals during coal gangue and coal combustion is extremely important.The occurrence modes of heavy metals can influence the emission of them during combustion, so it is necessary to know the occurrence modes of these heavy metals.Xie et al[1]showed that arsenic in coal from western Guizhou was mainly associated with minerals, and there was an obvious positive correlation between the content of arsenic and pyrite sulfur in coal.Feng et al[2]showed that arsenic in raw coal from northeast of China was mainly in residual form and arsenic in fire coal was mainly in ion exchange state.For mercury, Kolker et al[3]showed that mercury in bituminous coal was found mainly within Fe-sulfides, whereas lower rank coal tended to have a higher proportion of organic-bound mercury.Feng et al[2]found that the forms of mercury in raw coal and fire coal were mainly in residual form.Cao et al[4]showed that the occurrence mode of mercury in coal gangue was similar to the occurrence mode of arsenic in coal gangue which was mainly in sulfide-bound form, and mercury and arsenic in this form accounted about 67.66% to 72.68% and 56.71% to 79.36% of total mercury and arsenic respectively.Zhou et al[5]showed that As in coal gangue was in the occurrence modes of Fe-Mn oxide binding state, residual binding state and carbonate binding state.

There are also many studies about emission characteristics of heavy metals.Zhou et al[6]showed that Ni, Cu, Zn, Cd, Sn, Pb and As were vaporized at intermediate temperature and had high volatilize ratio, while V, Cr, and Co were relatively non-volatile.Lu et al[7]showed that the release fraction of Zn was the largest, followed by Pb and Cd, and the release fraction of Cu, Ni and Cr were the least at the same co-incineration condition.Zhang et al[8]showed that Hg, As, Be and Cd in coal gangue were highly volatilized during combustion.Liu et al[9]showed that with increasing of the temperature, the volatilize rate of As in coal during oxy-fuel combustion was also increasing.Besides that, Spörl et al[10]showed that the Hg2+/Hgtotratios in the flue gas were higher during oxy-fuel combustion compared to air-firing.Chen et al[11]showed that wet flue gas desulfurization had good removal efficiency on Hg2+, which was exhausted to plaster and wastewater, and the proportion was 0.15∶1.Wang et al[12]showed that during coal gangue combustion, V2O5was tested as the sorbent and was found to effectively oxide elemental mercury(Hg0).Ultrafine V2O5particles were formed during coal gangue combustion process and resulted in a high surface area aerosol which could effectively catalyze the oxidation of Hg0.Hoffart et al[13]showed that Hg removal rates of 50%-70% were realized for the bituminous coal by pre-treating the coal prior to a wash with hot concentrated HCl.Marczak et al[14]showed that the efficiency of As removal for subbituminous coal ranged from 21.86% to 90.80% depending on the sorbent used.Duan et al[15]showed that before combustion high uranium coal, Se, Hg and U could not be fully removed through stepped release flotation.

Furthermore, Tian et al[16]showed that there were serious ecological environmental risks of heavy metals pollution in soil around coal gangue mountain in Liuzhi mining area.Finkelman[17]showed that selenium, arsenic, lead, tin, bismuth, fluorine and other elements condensed when the hot gaseous emissions came in contact with ambient air and formed mats of concentrated efflorescent minerals on the surface of the ground.Liu et al[18]showed that Se and As in coal were more likely to be released into water in combustion, whereas Hg and Be were less likely to be released into water.Furthermore, Kong et al[19]showed that heavy metals pollution of soil and vegetation in waste incineration plants increased.Heavy metals contents in soil and vegetation are much higher than those in the background value.Zhang et al[20]used two calculation methods to calculate capacity of heavy metals in the Beijing Rivers in Pearl River Valley and obtained natural environment capacity of Cd as 24.8-26.3 kg/d for about 202 km long river section.

Moreover, there are many studies about the environmental effect by using ReCiPe2016.Literatures showed that ReCiPe2016 including eighteen midpoint indicators and eight endpoint indicators were used to generate a full-fledged cradle-to-farm gate life cycle assessment of greenhouse tomatoes in a typical Albanian farm, while spatial differentiation and indicators were not covered by contemporary life cycle assessments.ReCiPe2016[21]also was used to estimate impacts hydropower plants in alpine and non-alpine areas of Europe by a systematic life cycle assessment approach.Huijbregts et al[22]implemented human health, ecosystem quality and resource scarcity as three areas of protection and determined three environmental indicators including human health, ecosystem and resources of horticultural crops by ReCiPe2016.

From previous literatures we could know that ReCiPe2016 is applicable to calculate the environmental impact factors to assessment environmental effects of heavy metals for life cycle assessment.With the widespread concern of environmental effects of heavy metals in the whole world, it is necessary to understand the environmental effect of heavy metals emission during coal combustion.This paper mainly studies the environmental effects of As and Pb during pulverized coal combustion in pulverized coal boiler and lignite in circulated fluidized bed boiler by using the software of ReCiPe2016.Besides that, the environmental effects of As and Pb during coal gangue combustion in laboratory also is studied by using the software of ReCiPe2016.The aim of this paper is to clarify the environmental effect of As and Pb in coal and coal gangue during combustion at different sized reactors, and provide basic data for predicting the environmental effects of As and Pb during coal gangue combustion in circulating fluidized bed for life cycle impact assessment.

1 Methodology and variable description

Life cycle impact assessment translates emissions and resource extractions into a limited number of environmental impact scores by means of so-called characteristic factors.ReCiPe2016 is a kind of life cycle impact assessment software.According to the previous literatures, it can be used to calculate the environmental impact factors[23]and the scope of life cycle assessment by ReCiPe2016 also includes environmental effects of heavy metals on soil and air during coal combustion.

The environmental effects of As and Pb emission during coal combustion in 330 MW pulverized coal boiler, 50 kW circulated fluidized bed boiler and in the tube furnace in laboratory was studied as follows:

Firstly, according to the previous works[24-30], the contents of As and Pb in lignite and pulverized coal during combustion in the 330 MW pulverized coal boiler and 50 kW circulated fluidized bed boiler were listed.Then the releasing contents of As and Pb during combustion in the two boilers were calculated respectively.Finally the environmental effects of As and Pb for 1 kg fuel during combustion were looked through according to ReCiPe2016, and the environmental effects of As and Pb emission during combustion in the 330 MW pulverized coal boiler, 50 kW circulated fluidized bed boiler and coal gangue combustion in laboratory were calculated respectively.

The effect value of As and Pb emitted into the environment during coal combustion in the 50 kW circulated fluidized bed boiler and 330 MW pulverized coal boiler can be calculated according to formula(1), and the effect value of As and Pb emitted into environment during coal gangue combustion in the laboratory was calculated according to formula(2):

E1=bf×c×RP×be×10-5

(1)

E2=bf×c×r×be×10-5

(2)

whereE1is effect values of As and Pb emitted into environment during coal combustion in the 330 MW pulverized coal boiler and 50 kW circulated fluidized bed boiler;E2is effect values of As and Pb emitted into environment during coal gangue combustion in the laboratory, 1,4-DCB eq.(1,4-DCB eq.is effect values of 1 kg As and Pb emitted into soil and air.The effect value of As emitted into soil and air is 8.88 and 3380259, respectively.The effect value of Pb emitted into soil and air is 9.77 and 707927 respectively);bfis fuel baseline, kg;cis the contents of As and Pb in coal and coal gangue, g/kg;RPis mass proportion of As and Pb from bottom slag, fly ash and flue gas in circulated fluidized bed and pulverized coal boiler, %;ris the volatilization rate of As and Pb during coal gangue combustion in the laboratory, %;beis environmental effect baseline, 1,4-DCB eq.

By using ReCiPe2016, the environmental effects of As and Pb emission during coal gangue and coal combustion in different scales of reactors can be calculated, while the differences of the environmental effects of As and Pb emission during coal gangue and coal combustion at different operation conditions and different sized reactors cannot be determined.

2 Result and discussion

2.1 Emission characteristics of As and Pb during coal combustion in the 330 MW pulverized coal boiler

2.1.1ContentandrelativemassdistributionofAsandPbfromthe330MWpulverizedcoalboiler

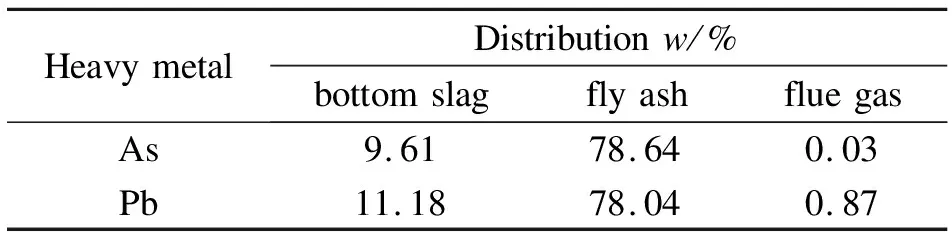

According to the literature, for the 330 MW pulverized coal boiler, the content of As and Pb in the pulverized coal is 3.84 and 7.85 mg/kg respectively[24].Table 1 is the relative mass distribution of As and Pb from the 330 MW pulverized coal boiler, which is obtained from the previous literature[24].According to these basic data, the migration path of comparison of As and Pb and environmental effects of As and Pb emission during combustion coal gangue in the 330 MW pulverized coal boiler was calculated.

Table 1 Relative mass distribution of As and Pb from the 330 MW pulverized coal boiler

From Table 1, it can be seen that the relative proportions of As and Pb in fly ash are the highest and those in the flue gas are the lowest, which imply that most of As and Pb are emitted into the fly ash during combustion.

2.1.2EnvironmentaleffectsofAsandPbemissionduringcoalcombustioninthe330MWpulverizedcoalboiler

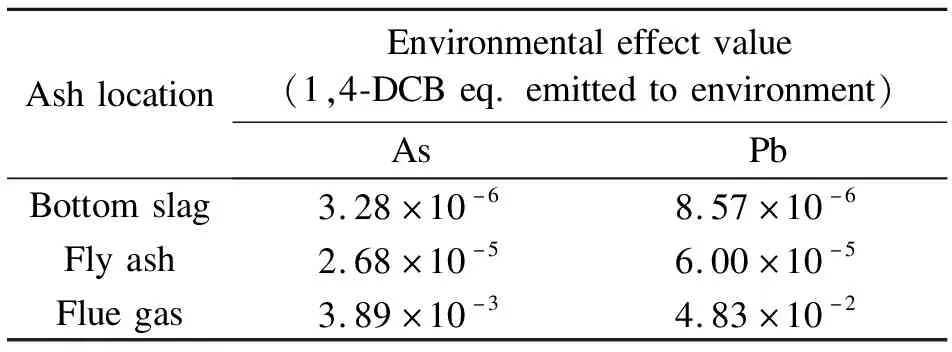

Table 2 shows environmental effects of As and Pb emission from various parts of the 330 MW pulverized coal boiler[24].The environmental effects of As and Pb from bottom slag and fly ash on soil are only considered, and the environmental effects of As and Pb from flue gas on air are considered.The environmental effect values are obtained according to the literature data by Hua et al[24].

Table 2 Environmental effects of As and Pb emission during coal combustion in the 330 MW pulverized coal boiler

Table 2 shows that in 330 MW pulverized coal boiler the effect values for 1 kg coal emitting As into environment from bottom slag, fly ash and flue gas are 3.28×10-6, 2.68×10-5and 3.89×10-3respectively, and those for Pb from bottom slag, fly ash and flue gas are 8.57×10-6, 6.00×10-5and 4.83×10-2respectively.

From the results it can be seen that the environment effect values of As and Pb from flue gas are the highest and those from bottom slag are the lowest.

2.1.3MigrationpathcomparisonofAsandPbduringcoalcombustioninthe330MWpulverizedcoalboiler

Figure 1 is relative proportion of environmental impacts of As and Pb emission from various parts of 330 MW pulverized coal boiler equipped with an electrostatic precipitator combustion[24].

Figure 1 Relative proportion of environmental effects of As and Pb emission from various parts of 330 MW pulverized coal combustion

Figure 1 shows that in 330 MW pulverized coal boiler, the relative proportion of environmental effects of As from bottom slag, fly ash and flue gas are 0.08%, 0.68% and 99.24% respectively, and the relative proportion of environmental effects of Pb from bottom slag, fly ash and flue gas are 0.02%, 0.13% and 99.85% respectively.As is more enriched in fly ash and less enriched in bottom slag, which is coinciding with the literature[25], and with the decreasing of the particle size of fly ash, the concentration of As in fly ash is getting higher[26].The results also indicate that the most serious environmental effect of As and Pb emission is caused by flue gas, and As and Pb in bottom ash cause less serious effect on environment.The reason maybe is that the occurrence mode of As in fly ash is different from that in bottom slag.As literatures report, As in fly ash is mainly in residue state[27], while the occurrence mode of As in bottom slag is mainly in iron closed state[28].Therefore, when combustion in 330 MW coal pulverized boiler, the effect value of As in fly ash emitting into environment is higher than that in the bottom slag.Besides, the occurrence mode of Pb in fly ash also is different from that in bottom slag.The occurrence mode of Pb in fly ash is also mainly in residue state[29], while Pb in bottom slag is mainly in exchange state[29].Therefore, the effect value of Pb in fly ash emitting into environment is higher than that in bottom slag.

2.2 Emission characteristics of As and Pb during coal combustion in 50 kW circulated fluidized bed boiler

The results of calculation value of environmental effects of As and Pb emission during coal combustion in 330 MW pulverized coal boiler by ReCiPe2016 are consistent with the actual situation, so we can infer that ReCiPe2016 is apt at analyzing the environmental effects of As and Pb during coal combustion, and then we using it further calculate the environmental effects of As and Pb emission during lignite combustion in 50 kW circulated fluidized bed boiler.

2.2.1ContentandrelativemassdistributionofAsandPbfrom50kWcirculatedfluidizedbedboiler

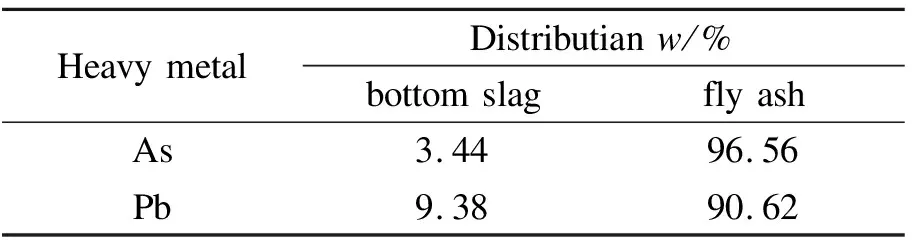

According to the literature, the lignite was burned in a 50 kW circulated fluidized bed boiler, and the contents of As and Pb in lignite are 3.80 mg/kg and 15.55 mg/kg respectively[30].Table 3 is the relative mass distribution of As and Pd in 50 kW circulated fluidized bed boiler obtained from the literature by Zhao et al[26].The data are the basic data for comparison of As and Pb migration path and emission environmental effect during combustion.

Table 3 Relative mass distribution rate of As and Pb from 50 kW circulated fluidized bed boiler

From Table 3, we can see that the relative proportions of As and Pb in fly ash are higher than those in bottom slag.

2.2.2EnvironmentaleffectsofAsandPbemissionduringlignitecombustioninthe50kWcirculatedfluidizedbedboiler

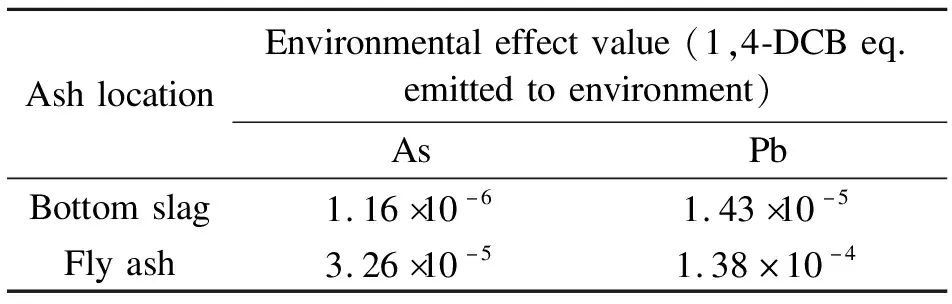

Table 4 is the environmental effects of As and Pb emission in bottom slag and fly ash on soil in 50 kW circulated fluidized bed boiler[30], and the environmental effects value are calculated according to the data in literature[30].

Table 4 Environmental effects of As and Pb emission during coal combustion in 50 kW circulated fluidized bed boiler

Table 4 shows that when combustion 1 kg coal in 50 kW circulated fluidized bed boiler, the environmental effect values of As from bottom slag and fly ash are 1.16×10-6and 3.26×10-5respectively, and the effect values of Pb from bottom slag and fly ash emitting into environment are 1.43×10-5and 1.38×10-4respectively.The environment effect values of As and Pb in fly ash are much higher than those in bottom slag.The reason also maybe that the occurrence modes of As and Pb in bottom slag and fly ash are different.

Compared the environmental effect values of Pb in Table 2 and Table 4, it can be seen that the environmental effect values of Pb during coal combustion in 330 MW pulverized coal boiler are lower than those in 50 kW circulated fluidized bed boiler.One of the reasons is maybe that Pb content in coal of 330 MW pulverized coal boiler is lower than that in the lignite burned in the 50 kW circulated fluidized bed boiler, and it also maybe is that 330 MW pulverized coal boiler has devices to control heavy metals emission, while 50 kW circulated fluidized bed boiler does not have.

2.3 Environmental effects of As and Pb emission during coal gangue combustion in laboratory

2.3.1VolatilizationratesofAsandPbduringcoalganguecombustioninthelaboratory

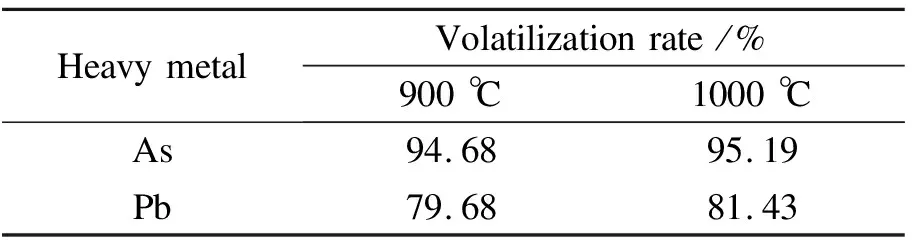

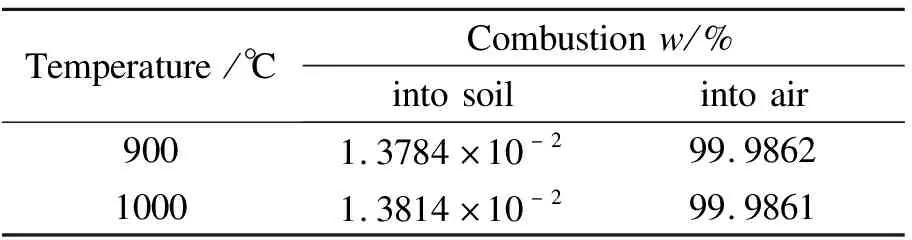

For further understanding and prediction the environmental effect of coal gangue combustion in circulated fluidized bed boiler, the environmental effects of As and Pb emission during coal gangue combustion in laboratory is also studied by ReCiPe2016.Table 5 is the volatilization rates of As and Pb during coal gangue combustion at 900 and 1000 ℃ in the laboratory, which is obtained from our previous work[31].Using these basic data, the environmental effects of As and Pb emission in the laboratory are calculated, and the migration path comparison of As and Pb during coal gangue combustion is also studied.

Table 5 Volatilization rates of As and Pb during coal gangue combustion

Table 5 shows volatilization rates of As and Pb during coal gangue combustion[31].When the combustion temperature increases from 900 to 1000 ℃, the volatilization rates of As and Pb are also increasing.

2.3.2EnvironmentaleffectsofAs,Pbemissionduringcoalganguecombustion

Figure 2 shows the result of environmental effects of As for 1 kg coal gangue emitting into environment(soil and air)during combustion in laboratory without pollution control device[31].

Figure 2 Effect value of As emitting into environment during coal gangue combustion in laboratory

Figure 2 shows that for 1 kg coal gangue combustion at 900 ℃ in the laboratory, the effect values of As emitting into ash and air are 3.60×10-2and 13729 respectively, and at 1000 ℃, the effect values of As emitting into ash and air change slightly.The proportion of total environmental effect of As emitting into air is higher than that into ash.Arsenic has high volatilization rate, and As diffuses faster in the atmosphere than in the soil.The majority of As in coal gangue emits into air as aerosol during combustion, and the environmental effect on air is higher.

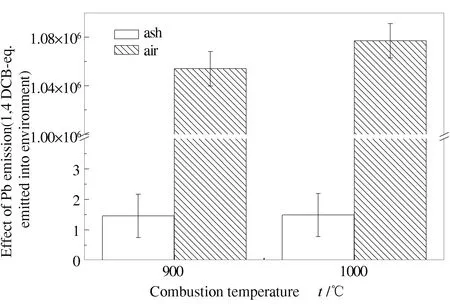

Figure 3 is the result of environmental effects of Pb for 1 kg coal gangue emitting into environment(soil and air)during combustion in laboratory[31].

Figure 3 Effect value of Pb emitting into environment during coal gangue combustion

Figure 3 shows that for 1 kg coal gangue combustion at 900 ℃ in laboratory, the effect values of Pb retaining in ash and emitting into air are 1.46×10-3and 1054, respectively.At 1000 ℃, the effect value of Pb emitting into air is higher than that at 900 ℃, and the proportion of total environmental effect of Pb emitting into air is also higher than that into ash.The reason is just the same as that of arsenic mentioned above.

2.3.3MigrationpathcomparisonofAsandPbduringcoalganguecombustioninlaboratory

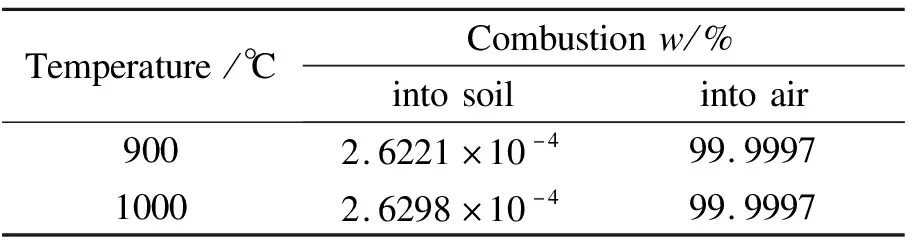

Table 6 and Table 7 are proportions of total environmental effects of As and Pb on soil and air for coal gangue combustion in laboratory respectively[31].Here we assume that As and Pb in ashes mainly have effect on soil and As and Pb in atmosphere mainly have effect on air.

Table 6 Proportion of total effect of combustion As emission in laboratory

Table 7 Proportion of total effect of combustion Pb emission in laboratory

Table 6 and Table 7 show that for coal gangue combustion at 900 and 1000 ℃ in the laboratory, proportion of total environmental effects of As and Pb emitting into air are 99.9997% and 99.9862% respectively, which implies that during coal gangue combustion in laboratory, the environmental effects of As and Pb on air are the highest and dominant, which maybe is because that there are not pollutants controlling devices in the process.

3 Conclusions

Higher contents of As and Pb lead to higher environmental effect values, and the environmental effects of As and Pb on air are much higher than those on soil.The environmental effects of As and Pb in bottom slag are lower than those in fly ash on soil both for 330 MW pulverized coal boiler and 50 kW circulated fluidized bed coal boiler.

The environmental effect values of Pb emitting into air increase with the increasing of temperature during coal gangue combustion, and the proportion of total environmental effects of As and Pb on air are higher than those on soil.

The environmental effect values of Pb are higher than those of As at the same conditions in circulated fluidized boiler and pulverized coal boiler.

Acknowledgments

The authors thank Prof.Jun Nakatani, Ryosuke Yokoi and Yuichi Moriguchi in the University of Tokyo for their help throughout the course of this work.

杂志排行

燃料化学学报的其它文章

- 复合聚并协同脱除燃煤颗粒物及颗粒态重金属的中试研究

- In-situ reaction between arsenic/selenium and minerals in fly ash at high temperature during blended coal combustion

- 典型钙/镁基吸附剂对二氧化硒吸附特性研究

- Speciation analysis of arsenic in coal and its combustion by-products in coal-fired power plants

- 燃煤烟气中As、Se、Pb的形态分布及S、Cl元素对其形态分布的影响

- 燃煤电厂砷、硒、铅的排放与控制技术研究进展