拱棚自动插架装置设计与试验

2020-04-09王春颖秦洪政侯加林

刘 平,王春颖,秦洪政,侯加林

拱棚自动插架装置设计与试验

刘 平,王春颖,秦洪政,侯加林※

(山东农业大学机械与电子工程学院山东省园艺机械与装备重点实验室,智能化农业机械与装备实验室,泰安 271018)

目前建造拱棚主要以手工为主,为了提高其机械化、自动化水平以及建造拱棚的效率,该文设计与研制了拱棚智能插架覆膜机的拱棚自动插架装置。基于拱棚搭建的入土深度、棚架宽度、棚架高度等技术要求和曲柄存在的条件,对其关键部件曲柄滑块机构和弯折手臂进行结构设计与优化。当曲柄的长度为230 mm,连杆的长度为220 mm,偏心距为220 mm时,达到最好的传力效果和运动效率;同时对曲柄滑块机构进行运动分析,确定插架作业时曲柄的初始角度和最大位置角度分别为132°和30°;设计弯折手臂使棚杆变弯,确保棚杆垂直入土;然后基于ANSYS分析拱棚抗风性能,当棚度架宽与棚杆长度的比值在0.60~0.66之间时,拱棚抗风性最强;最后通过田间试验测量分析棚架平均宽度、棚杆平均入土深度和棚架平均高度分别为93.85、15.23和56.19 cm,获得棚架高度、棚架宽度的稳定系数均为99%。装置插架效果满足农艺需求,进一步验证了装置设计的正确性和方案的可行性。研究结果可为实现拱棚的自动插架覆膜机研制提供理论基础。

农业机械;优化;建造拱棚;插架装置;抗风性能

0 引 言

现代农业生产中,拱棚在蔬菜栽培、育苗等方面的应用越来越广泛[1]。利用竹木、钢材等材料作为棚杆,并覆盖塑料薄膜,建成拱形棚,可提早或延迟蔬菜供应,提高蔬菜供应量、新鲜度以及品质,增加经济效益[2-8],是保护地蔬菜栽培的重要类型,发展潜力巨大。

小拱棚成本较低,加盖草后,增温的效果并不比大型的温室大棚差,棚架宽度多为80~150 cm,棚架高度约为40~100 cm,常用于园艺作物的育苗、提早定植或矮小植株的作物栽培。但小拱棚的棚架仍是人工搭建[7],手动弯杆插入土中,劳动强度大,棚架直线度低,影响拱棚的牢固性和抗风性。

随着农业装备智能化的发展,实现拱棚建造的机械化、自动化和智能化是必然的趋势。国外拱棚机的研究较为成熟,日本藤木农机制作所研制了棚杆打孔掩埋机,但需要人工参与作业,例如重复进行行走启动和液压复位控制。美国ANDROS公司的拱棚机和Dubois Agrinovation公司研制的Machanical Transplanter Tunnel Layer Model 95可以通过人工弯杆,由拖拉机牵引实现自动插架。Mark William 研制的拱棚机通过拖拉机牵引,可完成人工放杆,拱棚机自动弯杆、覆膜。Tunnelmatic、LesAgrisudvennde公司研制的拱棚机,基于拖拉机牵引实现插架覆膜一体化搭建拱棚。目前国内相关研究多为地膜覆膜机[9-12],戴飞等[13]设计了横腰带覆土式全膜双垄沟覆膜联合作业机器实现起垄、覆膜、覆土等作业。国外的拱棚机多为拖拉机牵引,并不能满足国内蔬菜种植农户以及地形的要求。总结国外拱棚机的研究现状可知,拱棚插架装置是拱棚机实现自动化的主要装置。因此,针对国内现有地膜覆膜机不能实现自动弯杆、插架的问题,设计与优化拱棚自动插架装置,提高拱棚建造的效率,降低劳动强度,确保棚杆的入土深度,保证拱棚的牢固性和抗风性,实现机械化、自动化建造拱棚。

目前对于拱棚的抗风性分析多集中于大拱棚和温室,如Rackwoo等[14]、Briassoulis等[15]和丁敏等[16]考虑风向、风雪天气、跨度数等因素,分析了温室的结构失效问题。并且丁敏等[17-18]模拟了单片薄膜受风,研究薄膜厚度、尺寸(长度×宽度)、预张力和外荷载对单膜承载力的影响。吴昆等[19]进一步研究了拱形塑料群棚模型在不同风向角、不同棚间距下的表面风压特性。小拱棚骨架柔长细薄,结构外侧覆盖着柔性的塑料薄膜,对风荷载较为敏感[20],因此保证拱棚的抗风性尤其重要。拱棚的抗风性不仅与拱棚插架装置的机械性能有关,而且与棚杆材料及其长度选择有关。本试验采用玻璃纤维的棚杆作为试验材料,为提高小拱棚的抗风性,针对不同栽培方法需求的棚架宽度,通过ANSYS仿真分析,获得抗风性最强的棚架宽度与棚杆长度的比值。

该文设计的拱棚智能插架覆膜机的拱棚自动插架装置在液压系统带动下,通过关键部件弯折手臂和扦插机构实现棚杆的弯折与扦插,其扦插效果决定拱棚的稳定性进而决定拱棚插架装置的拱棚建造质量。首先分析拱棚自动插架装置的工作原理及工作过程;其次对该插架机构关键部件曲柄滑块进行设计与优化,以达到最好的传力效果;并设计弯折手臂的结构,选择合适的弯折压板位置和长度,在相同作用力的仿真情况下,棚杆产生的形变最大。通过田间试验对机械结构进行验证,分析装置的作业数据和效果,对各关键部件的参数进一步优化和确定。该文设计的拱棚自动插架装置能够实现直棚杆的有序弯折扦插,可为拱棚智能插架覆膜机的设计提供借鉴,提高国内拱棚建造作业的机械化、自动化水平。

1 机构组成和工作原理

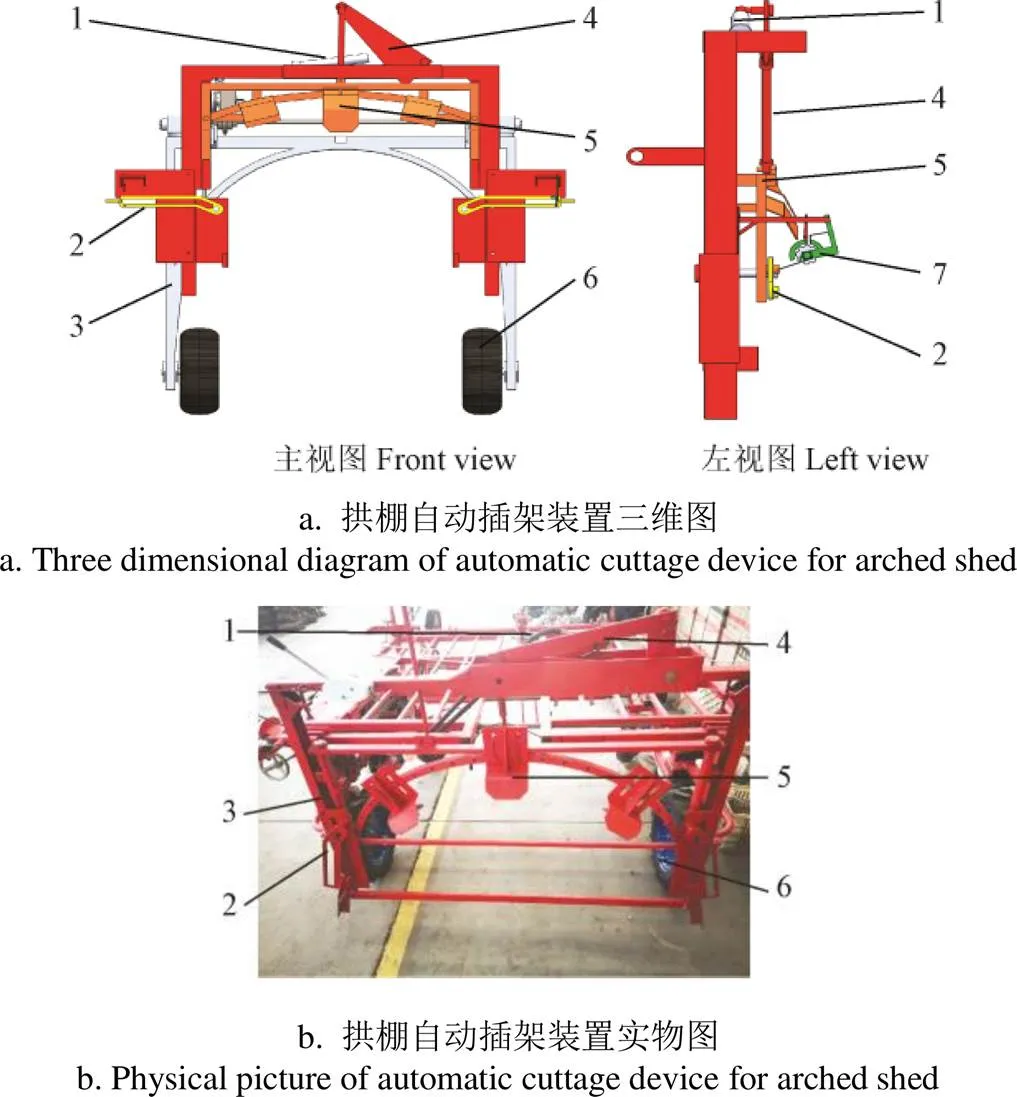

1.1 结构组成

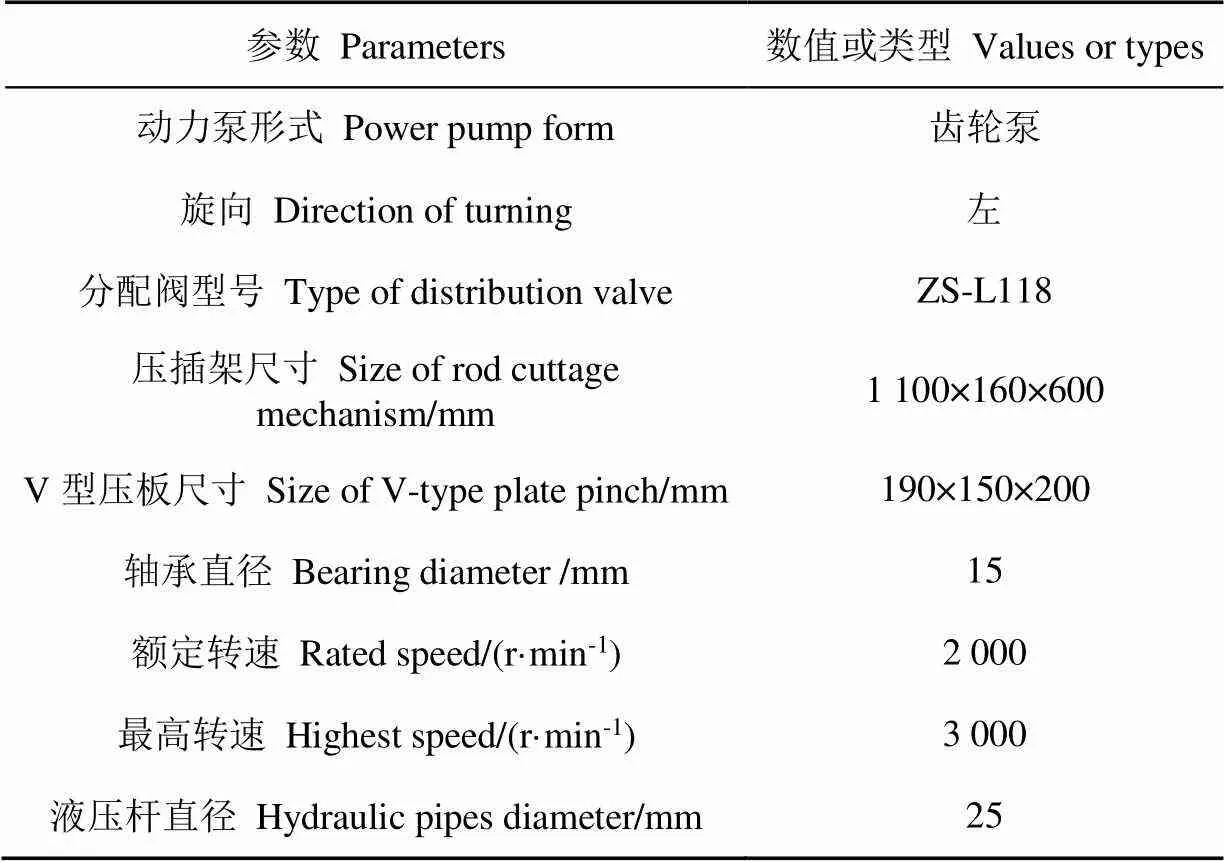

针对目前国内小拱棚农艺需求,棚架宽度多为80~150 cm,棚架高度约为40~100 cm,该文设计的拱棚自动插架装置主要由液压传动系统、曲柄滑块机构、棚杆扦插机构、弯折手臂机构等组成,具体如图1,其中液压参数如表1。

1.液压传动系统 2.弯折手臂机构 3.机架 4.曲柄滑块机构 5.棚杆扦插机构 6.车轮 7.进杆装置

表1 拱棚自动插架装置技术参数表

1.2 工作过程

拱棚插架覆膜机的工作过程如图2,包括取杆、放杆、弯杆和压杆。而拱棚自动插架装置实现其中的2步作业,具体过程如下:

1)棚杆扦插机构下压。通过自动进杆装置自动取杆后,棚杆由弯折手臂的挡板支撑。此时液压传动系统工作,液压泵在发动机带动下转动,通过液压动作带动曲柄滑块机构运动,作为曲柄滑块部分中的滑块(棚杆扦插机构)向下作业,其中弯折手臂的导轨轴承固定在棚杆扦插机构上,进而弯折手臂从水平位置旋转到竖直位置,使棚杆变弯,棚杆扦插机构继续向下作业,将弯棚杆压入土。

2)棚杆扦插机构复位。棚杆入土后,弯折手臂的挡板回弹,与棚杆分离,进而液压动作带动棚杆扦插机构复位,完成一次插架作业。

图2 拱棚插架覆膜机的工作过程

拱棚自动插架装置实现自动弯杆、扦插作业,提高了效率,为拱棚插架覆膜机机械化、自动化作业提供了保障。

2 关键部件设计与优化

2.1 偏心曲柄滑块机构结构设计与优化

为实现拱棚自动插架装置扦插功能,该文利用偏心曲柄滑块机构和滚轮滑槽,带动棚杆扦插机构在竖直方向运动。如图3a,偏心曲柄滑块机构由连杆、曲柄和滑块组成。

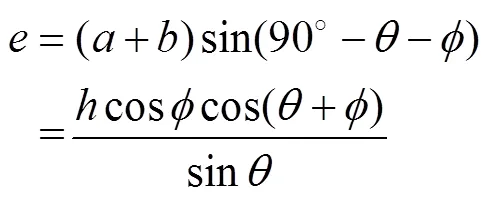

注:AC2为滑块行程最大处位置;AB1C1为滑块行程最小处位置;AB3C3为曲柄与滑块运动方向垂直位置处;C1C2为滑块运动行程h,mm;e为偏心距离,mm;a为曲柄AB长度,mm;b为连杆BC长度,mm;γ为传动角,(°);θ为极位角,(°);为辅助角,(°)。

设计偏心曲柄滑块机构如图3b,以点为固定铰链点,包括偏心曲柄滑块机构的3种形态:1)连杆与滑块运动方向相同(11);2)曲柄与滑块运动方向垂直(33);3)曲柄与连杆在同一直线上(2),此时机构形成死点。

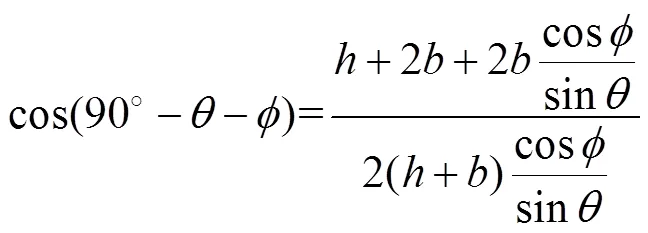

式中为行程速度比系数。

偏心曲柄滑块机构的几何结构关系为

其中

基于MATLAB仿真软件进行优化仿真,得到最小传动角γmin与K、的关系示意图(图4)。分析可知:当曲柄滑块的行程速度比系数K=1.25,=0.6981 rad= 40.01°时得到最大的最小传动角γmin=1.5 rad=85.98°。此时,压力角最小,a=226.5 mm,b= 221.5 mm,e=223.9 mm,达到最好的传力效果和运动效率[23-27],行程速度比系数K小于2,插架机构产生的冲击惯性较小,插架装置进行扦插时运行稳定。因此,通过对上述数据取整,曲柄滑块的具体设计尺寸:曲柄AB的长度为230 mm,连杆BC的长度为220 mm,偏心距为220 mm。

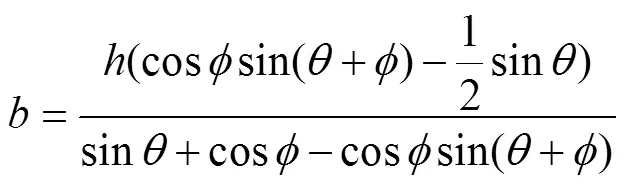

2.2 偏心曲柄滑块机构运动学分析

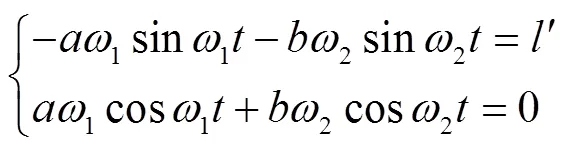

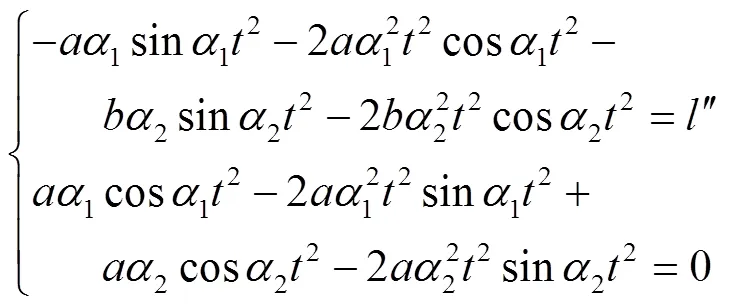

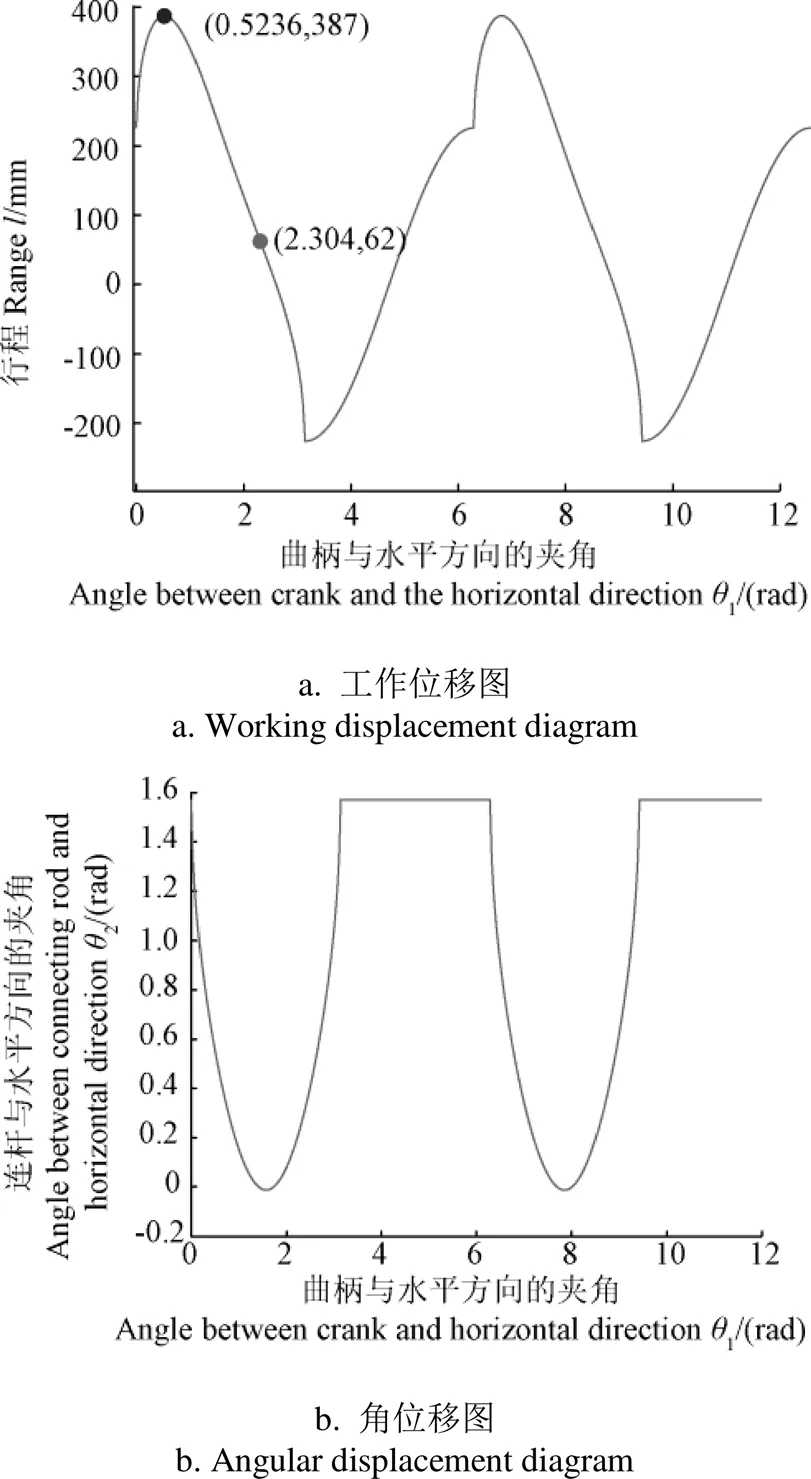

为验证曲柄滑块机构中各构件的运动是否满足要求,对其进行运动分析,模型如图5。12分别为曲柄和连杆与水平方向的夹角,(°)。1、2分别为2种曲柄滑块状态时的工作位移,且=1−2,对机构运动分析如下:

对时间进行求导,=,得到角速度关系:

进一步对时间()进行求导,=,得到角加速度关系:

注:为曲柄;为连杆;为偏心距离,mm;为曲柄长度,mm;为连杆长度,mm;1为曲柄与水平方向的夹角,(°);2为连杆与水平方向的夹角,(°);为工作位移,mm。

Note:is crank;is connecting rod;is eccentric distance, mm;is crank length, mm;is connecting rod length, mm;1is angle between crankand the horizontal direction, (°);θis angle between connecting rodand the horizontal direction, (°);is slider displacement, (°).

图5 曲柄滑块机构运动分析简图

Fig.5 Schematic diagram of motion analysis of crank slider mechanism

图6 曲柄滑块机构运动仿真结果

图6a中,max=387 mm,min=−200 mm,可知Δ大于所需工作行程,满足设计要求。因此选择=62 mm和=max=387 mm作为曲柄的初始位置和结束位置,曲柄的初始角度和最大位置角度分别为132°(2.304 rad)和30°(0.5236 rad)。从图6b可知,θ始终在一个锐角范围内变化,因此曲柄与连杆之间的夹角小于180°,满足设计要求。

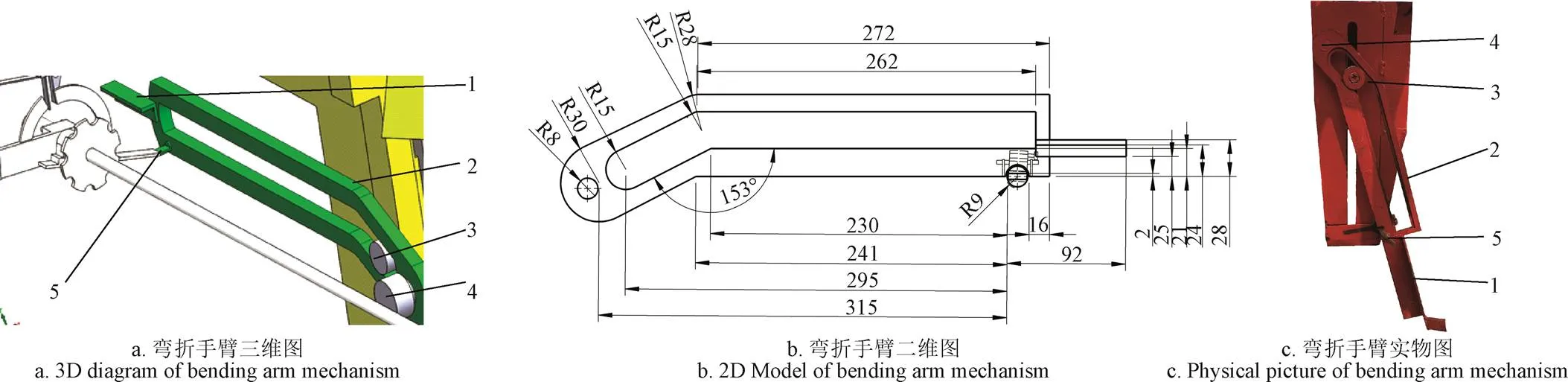

2.3 弯折手臂机构设计

弯折手臂机构如图7所示,安装在机架两侧,包括弯折压板、导轨、导轨轴承、固定端点轴和挡板,其中导轨轴承与棚杆扦插机构相连,固定端点轴固定导轨在机架上,且导轨能够绕固定端点轴旋转。

当直棚杆送至弯折手臂挡板处,通过固定在棚杆扦插机构的导轨轴承在导轨中运动,固定端点轴处对棚杆起支撑作用,弯折压板对棚杆作用向下的力,使棚杆变弯,棚杆受力如图8所示。弯折压板保持棚杆弯曲状态,并确保棚杆能两端垂直入土。对棚杆在初始状态时的受力进行分析,结果如表2,其中受力位置指的是弯折压板末端距离棚杆两端的距离,距离越近,产生的形变最大。因此预留棚杆入土深度后,设定总的弯折手臂长度为44 cm,其中7 cm为弯折压板长度。

1.弯折压板 2.导轨 3.导轨轴承 4.固定端点轴 5.挡板 1.Platen 2.Guide 3.Guide bearing 4.Fixed axis 5.Baffle

注:F为弯折压板对棚杆向下的作用力,N;N为固定端点轴对棚杆的支撑力,N。

表2 初始状态下棚杆的静力学分析

3 抗风性仿真

小拱棚对蔬菜、作物的栽培具有重要意义,抗风性是衡量小拱棚牢固性的重要指标。不同栽培方式对棚架宽度有不同的需求,从0.80~1.50 m不等,因此本文利用ANSYS分析棚杆的抗风性,以明确在棚架宽度确定条件下抗风性最好时的棚杆长度。

该文采用的拱棚材料是玻璃纤维棒,在常温(20℃)条件下,该材料的抗压强度为40.59 MPa、抗折强度为85.76 MPa、拉伸强度为83.68 MPa,剪切强度为7.53 MPa、拉伸弹性模量为1.61 GPa、硬度为52.1 N/mm2、密度为1.53 g/cm3。由于该材料轻质高强,棚杆弯折入土后,棚杆在地面上方会形成自然弧线,形成拱棚,通过SOILDWORKS建立棚杆模型。

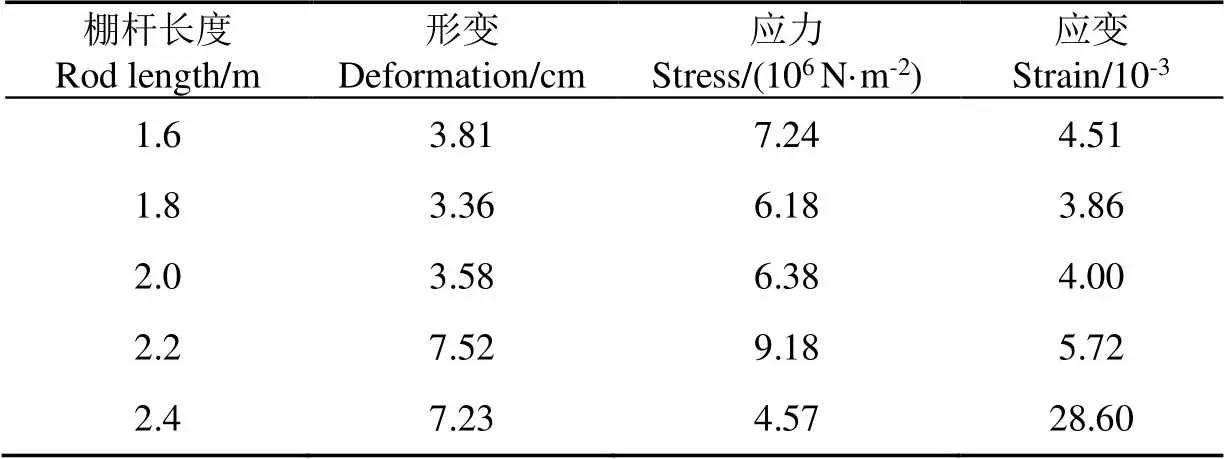

在相同风载情况下,添加棚杆两端的固定约束,模拟棚杆入土后土壤对棚杆的固定;并对不同棚杆的左侧添加风载荷,模拟10级风力下棚杆的受力情况,分析不同棚架宽度和棚杆长度的应力、应变和变形。

当棚杆长度为2 m时,不同棚架宽度的最大应力、应变和变形如表3。当棚架宽度为1.20 m时,不同棚杆长度的最大应力应变和变形如表4。

表3 棚杆长度为2 m时,不同棚架宽度下的受力仿真

注:风载为60 N·m-2。下同。

Note: Wind load is 60 N·m-2. Same below

表4 棚架宽度为1.2 m时,不同棚杆长度下的受力仿真

从表3和表4可知,棚杆长度为2 m的棚架宽度1.20 m时,形变且应力应变最小,抗风性最强,应力为6.38×106N/m2,形变为3.58 cm。棚架宽度1.20 m时,棚杆长度1.80 m的形变且应力应变最小,抗风性最强。因此,较优的棚杆选取方案为棚架宽度/杆长为0.60~0.66。

4 田间试验与结果分析

拱棚自动插架装置样机采用功率为7.35 kW的发动机,排量为30 mL/r的液压泵,液压杆的直径为25 mm。拱棚自动插架装置扦插棚杆时,压强为13 MPa。自动插架装置尺寸为:1 100 mm×600 mm,曲柄长度为230 mm,连杆长度为220 mm,偏心距为220 mm,曲柄角度1范围为132°~30°,且连杆的长度可以根据入土深度需求调节,范围为200~300 mm。选取1.60 m的棚杆搭建0.95 m的拱棚,此时,棚架宽度/杆长=0.60。测量棚架高度、棚架宽度和棚杆入土的深度等关键参数,分析是否满足拱棚扦插工艺要求,验证上述仿真的正确性和方案的可行性。

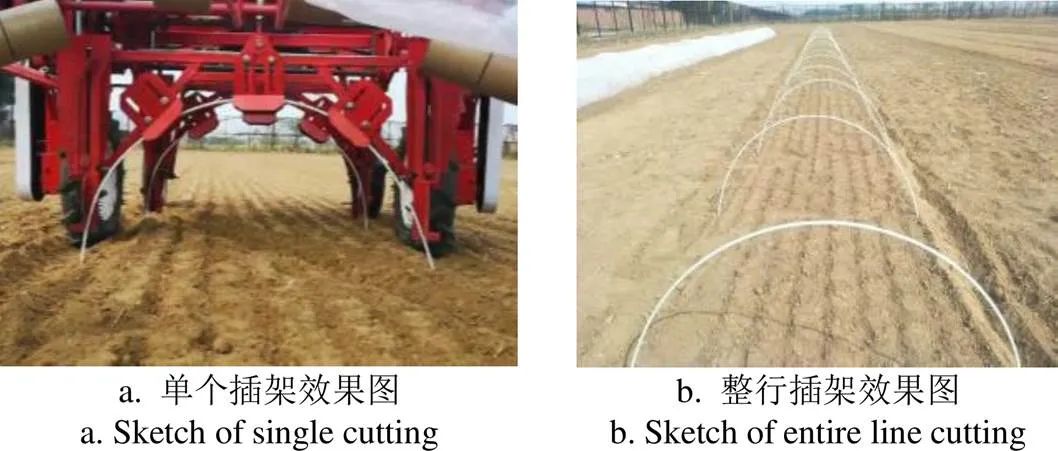

选择春季进行试验,此时土壤含水率低,土壤坚实度较大。试验用地的土壤为黄土,土壤分析知土壤含水率为20%,土壤坚实度平均值为850 kPa。试验中,拱棚自动插架装置各部件运行稳定,工作安全可靠,棚杆扦插稳定,利用卷尺、秒表和直尺进行测量,采集棚架高度、棚架宽度和棚杆的入土深度进行分析,如图9,插架效果如图10。经试验测定并对数据进行统计分析,结果如表5。棚杆入土深度对棚架高度的影响较小,但对于棚架宽度的影响较大,从图9可以看出,当左右入土深度差距较大时,棚架宽度明显高于平均值。

图9 试验结果分析

表5 试验结果参数

图10 插架效果图

总体来看,棚架高度、棚架宽度的误差在允许范围10 cm内,棚架高度、棚架宽度的平均值分别为56.19和93.85 cm,其稳定系数(稳定系数=1-变异系数,表征数据波动情况)均为99%,拱棚自动插架装置运行稳定。棚杆的入土深度稳定系数较低,左右两侧入土深度存在差异,原因是由于左右两侧的弯折手臂的挡板未能同时回弹,造成某侧并不是垂直插入土中,而是斜着硬压入土。后期将进一步对弯折手臂挡板进行改进优化。

5 结 论

1)确定拱棚自动插架装置进行插架作业时,曲柄的长度为230 mm,连杆的长度为220 mm,偏心距为220 mm,达到最好的传力效果和运动效率。进而确定曲柄的初始角度和最大位置角度分别为132°和30°。设计弯折手臂弯折压板位置使棚杆最容易变弯,并保证棚杆垂直入土。

2)对小拱棚的抗风性进行分析,通过ANSYS仿真分析得到在棚架宽度/杆长为0.6~0.66时,抗风性最好。

3)棚架平均入土深度为15.23 cm,稳定系数为97.86%;棚架高度、棚架宽度的平均值为56.19和93.85 cm,稳定系数均为99%,稳定性高,进一步验证了装置设计的正确性和方案的可行性。

针对棚杆入土深度稳定性以及左右两侧入土深度差异的问题,后续工作将研究与改进弯折手臂的挡板,保证棚杆左右两侧同时接触地面来减少棚杆左右入土深度差异,提高稳定性。

[1]王晓东. 发挥拱棚生产优势推进蔬菜产业发展[J]. 农业与技术,2018,38(10):150.

Wang Xiaodong. Give full play to the production advantages of the arch shed to promote the development of the vegetable industry[J]. Agriculture and Technology, 2018, 38(10): 150. (in Chinese with English abstract)

[2]张国森,殷学云,蒋宏,等. 西北多层覆盖大跨度拱棚蔬菜有机生态型无土栽培[J]. 中国蔬菜,2014(2):83-85.

Zhang Guoshen, Yin Xueyun, Jiang Hong, et al. Organic eco-type soilless cultivation of vegetables with multi-layer cover and large span arch shed in northwest China[J]. China Vegetables, 2014(2): 83-85. (in Chinese with English abstract)

[3]郭宗万,王春夏,高林夏. 青岛地区春胡萝卜植绳播种中拱棚无公害栽培技术[J]. 农业科技通讯,2018(7):311-312.

Guo Zongwan, Wang Chunxia, Gao Linxia. Technique of pollution-free cultivation of spring carrot in Qingdao area[J]. Agricultural Science and Technology communication, 2018(7): 311-312. (in Chinese with English abstract)

[4]谷端银,焦娟,刘中良,等. 减施化肥配施有机肥对大拱棚早春西瓜生长及品质的影响[J]. 北方园艺,2019(23):48-56.

Gu Ruiyin, Jiao Juan, Liu Zhongliang, et al. Effects of reduced application of chemical fertilizer and organic fertilizer on the growth and quality of watermelon in early spring in large arch shed[J]. Northern Horticulture, 2019(23): 48-56. (in Chinese with English abstract)

[5]陈晓东,王舜. 脱毒马铃薯—荷兰15早春小拱棚高产栽培技术[J]. 河南农业,2018(25):18.

Chen Xiaodong, Wang Shun. Detoxification potato - Dutch 15 early spring small arch shed high yield cultivation technology[J]. Henan Agricultural, 2018(25): 18. (in Chinese with English abstract)

[6]芦月琴. 塑料拱棚双膜覆盖娃娃菜、冬瓜、油白菜一年三茬高效栽培技术[J]. 农业工程技术,2018,38(13):86-89.

Lu Yueqin. Plastic arch canopy double membrane covering baby vegetables, winter gourd, oil cabbage three crops a year efficient cultivation technology[J]. Agricultural Engineering Technology, 2018, 38(13): 86-89. (in Chinese with English abstract)

[7]高秀瑞,李冰,张敬敬,等. 西瓜早春小拱棚地膜双覆盖生产技术规范[J]. 中国瓜菜,2019,32(11):94-96.

Gao Xiurui, Li Bing, Zhang Jingjing, et al. Technical specification for double mulch production of small arch shed plastic film for watermelon in early spring[J]. China Cucurbits and Vegetables, 2019, 32(11): 94-96. (in Chinese with English abstract)

[8]丁艳礼. 葡萄简易钢骨小拱棚建造方法及避雨栽培技术[J]. 现代农业科技,2013(23):122-123.

Ding Yianli. Construction method and rain-proof cultivation technique of grape simple steel frame small arch shed[J]. Modern Agricultural Science and Technology, 2013(23): 122-123. (in Chinese with English abstract)

[9]戴飞,赵武云,马明义,等. 双垄耕作施肥喷药覆膜机工作参数优化[J]. 农业机械学报,2016,47(1):83-90.

Dai Fei, Zhao Wuyun, Ma Mingyi, et al. Parameters optimization of operation machine for tillage-fertilization and spraying-filming on double ridges[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(1): 83-90. (in Chinese with English abstract)

[10]王维,贺功民,王亚妮,等. 辣椒起垄覆膜机的设计与试验研究[J]. 农机化研究,2020,42(6):57-62.

Wang Wei, He Gongmin, Wang Yani, et al. Design and experimental research of pepper ridging and laminating machine[J]. Journal of Agricultural Mechanization Research, 2020, 42(6): 57-62. (in Chinese with English abstract)

[11]史瑞杰,戴飞,赵武云,等. 全膜双垄沟起垄覆膜机横向土带堆放机构的设计与试验[J]. 中国农业大学学报,2019,24(5):140-149.

Shi Ruijie, Dai Fei, Zhao Wuyun, et al. Design and experiment of transverse soil-belt stacking mechanism for full-film double-furrow ridge mulching laminating machine[J]. Journal of China Agricultural University, 2019, 24(5): 140-149. (in Chinese with English abstract)

[12]王伯凯,胡良龙,王少康,等. 甘薯双垄旋耕起垄覆膜机的设计及试验研究[J]. 中国农业大学学报,2018,23(7):116-125.

Wang Bokai, Hu Lianglong, Wang Shaokang, et al. Design and experiment of sweet potato transplanting operation machine with rotary tillage, ridging and covering film functions[J]. Journal of China Agricultural University, 2018, 23(7): 116-125. (in Chinese with English abstract)

[13]戴飞,赵武云,史瑞杰,等. 横腰带覆土式全膜双垄沟覆膜联合作业机设计与试验[J]. 农业机械学报,2019,50(6):130-139.

Dai Fei, Zhao Wuyun, Shi Ruijie, et al. Design and experiment of operation machine for filming and girdle covering on double ridges[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(6): 130-139. (in Chinese with English abstract)

[14]Rackwoo K, Sewoon H, Inbok L, et al. Evaluation of wind pressure acting on multi-span greenhouses using CFD technique, Part 1: Development of the CFD model[J]. Biosystems Engineering, 2017, 164(11): 257-280.

[15]Briassoulis D, Dougka G, Dimakogianni D, et al. Analysis of the collapse of a greenhouse with vaulted roof[J]. Biosystems Engineering, 2016, 151(11): 495-509.

[16]丁敏,朱丹,许晶,等. 风雪荷载作用下Venlo型温室结构整体性能研究[J]. 中国农业大学学报,2017,22(1):120-128.

Ding Min, Zhu Dan, Xu Jing, et al. Space robustness of Venlo greenhouse structure under wind and snow load[J]. Journal of China Agricultural University, 2017, 22(1): 120-128. (in Chinese with English abstract)

[17]丁敏,李密密,施旭栋,等. 考虑覆盖材料蒙皮效应的温室结构稳定承载力计算[J]. 农业工程学报,2016,32(1):224-232.

Ding Min, Li Mimi, Shi Xudong, et al. Stable bearing capacity coculation of greenhouse structures considering skin effect of covering material[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(1): 224-232. (in Chinese with English abstract)

[18]丁敏,施旭栋,李密密,等. 薄膜承载力及其对日光温室结构稳定性能的影响[J]. 农业工程学报,2013,29(12):194-202.

Ding Min, Shi Xudong, Li Mimi, et al. Load-bearing capacity of films and its effect on structure stability of Chinese solar greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(12): 194-202. (in Chinese with English abstract)

[19]吴昆,王少杰,张广鹏,等. 拱形塑料大棚风致干扰效应及风压特性研究[J]. 农业工程学报,2019,35(15):165-174.

Wu Kun, Wang Shaojie, Zhang Guangpeng, et al. Wind-induced interference effects and wind pressure characteristics of arched plastic greenhouses[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(15): 165-174. (in Chinese with English abstract)

[20]姜迎春,白义奎,王永刚,等. 塑料大棚结构风振响应规律研究[J]. 华中农业大学学报,2018,37(5):123-130.

Jiang Yingchun, Bai Yikui, Wang Yonggang, et al. Study on the law of wind vibration response of plastic greenhouse structure[J]. Journal of Huazhong Agricultural University, 2018, 37(5): 123-130. (in Chinese with English abstract)

[21]鲁春发,夏德洲. 偏心曲柄滑块机构中偏心距对机构传动性能的影响[J]. 湖北汽车工业学院学报,2003(2):21-23.

Lu Chunfa, Xia Dezhou. Influence of eccentricity on transmission performance of mechanism in eccentric crank slider mechanism[J]. Journal of Hubei Automotive Industries Institute, 2003(2): 21-23. (in Chinese with English abstract)

[22]冀晓红,丁勇. 基于最佳传动性能的偏心曲柄滑块机构设计[J]. 机械研究与应用,2011,24(6):102-106.

Ji Xiaohong, Ding Yong. Design of eccentric crank slider mechanism based on the best transmission performance[J]. Mechanical Research and Application, 2011, 24(6): 102-106. (in Chinese with English abstract)

[23]韩刚,龚灯. 偏置曲柄滑块机构的运动仿真与分析[J]. 机械工程与自动化,2012(5):57-58.

Han Gang, Gong Deng. Motion simulation and analysis of offset crank slider mechanism[J]. Mechanical Engineering and Automation, 2012(5): 57-58. (in Chinese with English abstract)

[24]朱苛娄,闫广超,李禹生. 曲柄滑块机构优化设计和运动仿真分析[J]. 电气制造,2014(9):60-64.

Zhu Goulou, Yan Guangchao, Li Yusheng. Optimization design and motion simulation analysis of crank slider mechanism[J]. Electrical Manufacturing, 2014(9): 60-64. (in Chinese with English abstract)

[25]高国华,马帅. 曲柄滑块滚轮滑槽用于蔬菜封膜装置设计与试验[J]. 农业工程学报,2015,31(5):9-16.

Gao Guohua, Ma Shuai. Simulation and test of film sealing device for tray packaged vegetables preservation based on crank-slider mechanism and roller chute mechanism [J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(5): 9-16. (in Chinese with English abstract)

[26]汲文峰,吴启明,黄海东,等. 基于振动机理的藜蒿扦插机分苗机构设计与试验[J]. 农业工程学报,2015,31(增刊1):21-27.

Ji Wenfeng, Wu Qiming, Huang Haidong, et al. Design and experiment of seedling seperation device of Artemisia arborescens transplanter based on vibration mechanism[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(Supp.1): 21-27. (in Chinese with English abstract)

[27]雷昌毅,陈建能,李鹏鹏,等. 非圆齿轮—曲柄滑块压捆机构反求设计[J]. 农业工程学报,2012,28(13):22-27.

Lei Changyi, Chen Jianneng, Li Pengpeng, et al. Reverse design of non-circular gear-crank slider hay baler mechanism[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(13): 22-27. (in Chinese with English abstract)

[28]闫俊月,周磊,周长吉,等. 塑料大棚设计中基本风压取值方法[J]. 农业工程学报,2014,30(12):171-176.

Yan Junyue, Zhou Lei, Zhou Changji, et al. Method for calculating basic wind pressure of plastic greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(12): 171-176. (in Chinese with English abstract)

[29]姜迎春,白义奎,王永刚,等. 考虑脉动风速的平面刚架日光温室结构动力响应规律[J]. 中国农业大学学报,2019,24(4):136-147.

Jiang Yingchun, Bai Yikui, Wang Yonggang, et al. Dyanmic response anslyses of plane frame solar greenhouse considering fluctuating wind speed[J]. Journal of China Agricultural University, 2019, 24(4): 136-147. (in Chinese with English abstract)

[30]郭韦佟,朱丹,宓林,等. 拱形屋面温室纵向抗风分析中的曲梁刚度矩阵模型[J]. 中国农业大学学报,2017,22(10):113-119.

Guo Weitong, Zhu Dan, Mi Lin, et al. Curved beam stiffness matrix model for the longitudinal wind resistance analysis of arch roof green house[J]. Journal of China Agricultural University, 2017, 22(10): 113-119. (in Chinese with English abstract)

Design and test of automatic cuttage device for arched shed

Liu Ping, Wang Chunying, Qin Hongzheng, Hou Jialin※

(,,,271018,)

In modern agricultural production, the arched shed is more and more widely used in vegetable cultivation and seedling breeding. The arched shed is mainly built by manual. At present, the agricultural demand of arched shed width is about 0.8-1.5 m, and the height of arched shed is about 0.4-1 m. In order to improve the mechanization and automation level and the efficiency in the process of building arched shed, automatic cuttage device of arched shed was designed in this paper. Automatic cuttage device of arched shed was mainly composed of hydraulic transmission system, arm bending, crank slide mechanism, and tent pole cuttage mechanism. The hydraulic transmission system was the power source of the device. According to the technical requirements of building the arched shed and the conditions for the existence of crank, the structural optimization design of the crank slider mechanism was carried out, which was the critical component of automatic cuttage device of arched shed. When the length of the crank was 230 mm, the length of the connecting rod was 220 mm, and the eccentricity was 220 mm, the best force transmission effect and the movement efficiency were achieved. In addition,, the motion analysis of the crank slider mechanism was carried out. The initial angle and the maximum position angle of the crank were determined as 132° and 30°, respectively. The bending arm was designed to bend the shed rod, and at the same time to ensure that the shed rod vertical into the soil. The stress analysis of the rod in the initial state was simulated with different place of application of force, which is the different distance between the end of the bending platen and both ends of the rod. The closer this distance is, the greater the deformation will be. Therefore, the total bending arm length was set to be 44 cm, of which the length of bending platen was 7 cm. The thin and soft skeleton of the arched shed was covered with a flexible plastic film on the outside of the structure, which is more sensitive to the wind load. It is particularly important to ensure the wind resistance of the arch canopy. The wind resistance of small arch shed was analyzed by ANSYS, and it was found that the wind resistance of arched shed was the best when the ratio of frame width to frame length was between 0.60-0.66. The key parameters such as the height of the roof from the top of the shed, the width of arbor and the depth of shed insert soil were measured. The average buried depth was 15.23 cm, and the stability coefficient was 97.86%. The average height and width of the tunnel were 56.19 cm and 93.85 cm respectively, the stability coefficient of them were 99%. Combined with the agricultural demand, the errors were within the allowable range. The correctness of the optimized design, the feasibility of the solution and the stability of the machine operation are further verified.

agricultural machinery; optimization; arched shed; cuttage device; wind resistant

刘 平,王春颖,秦洪政,侯加林. 拱棚自动插架装置设计与试验[J]. 农业工程学报,2020,36(3):21-29.doi:10.11975/j.issn.1002-6819.2020.03.003 http://www.tcsae.org

Liu Ping, Wang Chunying, Qin Hongzheng, Hou Jialin. Design and test of automatic cuttage device for arched shed[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(3): 21-29. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2020.03.003 http://www.tcsae.org

2019-09-26

2020-01-30

国家自然科学基金(31700644);山东省农机装备研发创新计划项目(2018YF004);山东省重点研发计划(2017CXGC0926)

刘 平,教授,博士生导师,主要从事农业装备智能控制技术、机器人控制与导航等方面的教学与科研工作。Email:liupingsdau@126.com

侯加林,教授,博士生导师,主要从事智能农业装备和机械自动化等方面的教学与科研工作。Email:jlhou@sdau.edu.cn

10.11975/j.issn.1002-6819.2020.03.003

S224

A

1002-6819(2020)-03-0021-09